Page 1

OPERATING INSTRUCTIONS

Modular Coldroom

Page 2

WILLIAMS MODULAR COLDROOM

Contents:

1. Old Coldrooms.......................................................................................................................……………………Page 3

2. Unpacking..............................................................................................................................……………………Page 3

3. Installation..............................................................................................................................……………………Page 3

4. Mains Connection..................................................................................................................……………………Page 3

5. Locking Facility......................................................................................................................……………………Page 3

6. Door Release Mechanism .....................................................................................................……………………Page 3

7. Ventilation..............................................................................................................................……………………Page 3

8. Thermometer.........................................................................................................................……………………Page 4

9. Controller...............................................................................................................................……………………Page 4

10. General Produce Models.......................................................................................................……………………Page 4

11. Fresh Meat Models with Electric Defrost...............................................................................……………………Page 4

12. Frozen Food Storage Models................................................................................................……………… ……Page 4

13. Defrost Operation ..................................................................................................................……………………Page 5

14. Hi-Lo Alarm............................................................................................................................……………………Page 5

15. Probe Fail Safe Feature ........................................................................................................……………………Page 5

16. Cleaning.................................................................................................................................……………………Page 5

17. Routine Maintenance.............................................................................................................……………………Page 5

18. Condensor Cleaning..............................................................................................................……………………Page 5

19. Cleaning / Replacing the Gasket...........................................................................................……………… ……Page 6

20. Panel Joints...........................................................................................................................……………………Page 6

21. Breakdown.............................................................................................................................……………………Page 6

22. Warranty Policy......................................................................................................................……………………Page 7

2

Page 3

WILLIAMS MODULAR COLDROOM

Operating Instructions

Please read these Operating Instructions before using your Coldroom.

1. Old Coldrooms

Please ensure any old/redundant refrigeration is disposed of safely and legally. We would recommend that doors are

removed prior to disposal to ensure safety.

2. Unpacking

This is to be carried out by the installer, who will remove all interior and exterior packaging and accessories.

3. Installation

The intended site for the coldroom should be level to facilitate accurate erection and to ensure correct operation of selfclosing doors and proper drainage of condensate from the evaporator. If a freezer room is to be installed the provision

needs to be made for a 90mm floor.

An appropriate assessment should be undertaken by the user to avoid risk of slips, trips and other potential Health &

Safety risks. Consideration should be given to non-slip floor coverings or mats. These can be provided by Williams

Refrigeration.

4. Mains Connection

Your modular ‘made-to-measure’ coldroom will have been properly connected to the mains electrical supply during

assembly and installation. All necessary electrical components will be supplied. If you ever decide to relocate the

coldroom, consults a qualified electrician.

5. Locking Facility

On models with locking facility it is recommended that the key be removed from the lock during normal working use and

stored in a safe place. It is possible for the key to be damaged or knocked if left in the lock. This could result in having a

new lock fitted.

Removing the key from the lock will also prevent the possibility of accidental locking while the door is open. This will

prevent the door closing properly and cause the interior temperature to rise, this may results in loss of food if left in that

condition.

6. Door Release Mechanism

All users should familiarise themselves with how to use the internal door release before operating the room. Try the

release whilst the door is in the open position.

Regular checks and maintenance of the release is essential to ensure it is working co rrectly and prevent accidents.

Before entering the room, ensure that someone knows you are in there and how long you plan to be in there.

If you become trapped inside:

DO NOT PANIC an emergency internal release device is fitted to this Williams room.

Located on the door, at handle level, positioned to the left of the right hand side. (opposite the door hinge).

Push the round (luminous) handle firmly in and the door will open, even if locked.

IF THE DOOR FAILS TO OPEN, then there may be an obstruction to the release. Twist and rotate the release handle

and then push it very firmly in to the door. Repeat as necessary. Use the full weight of your body to aid you.

Be cautious of items, which may have fallen and obstructed the door opening outside of the room.

In the unlikely event that you are still unable to exit the room, activate the internal person trapped alarm switch, if

fitted.

7. Ventilation

It is essential to ensure that the room in which the equipment is installed is adequately ventilated. The condensing unit

and fans generate considerable amounts of heat and if operated in unventilated spaces, especially in warm weather, will

quickly cause the ambient temperature to rise to excessive temperatures. This can cause motor and compressor

overheating and possible damage to windings. At the very least such installation will cause the coldroom to use an

excessive amount of electricity and have an impact on its performance.

3

Page 4

WILLIAMS MODULAR COLDROOM

Operating Instructions

8. Thermometer

The controller measures in either Centigrade or Fahrenheit for the thermometer display. The thermometer should be

checked daily to ensure that the equipment is maintaining the correct temperature.

9. Controller

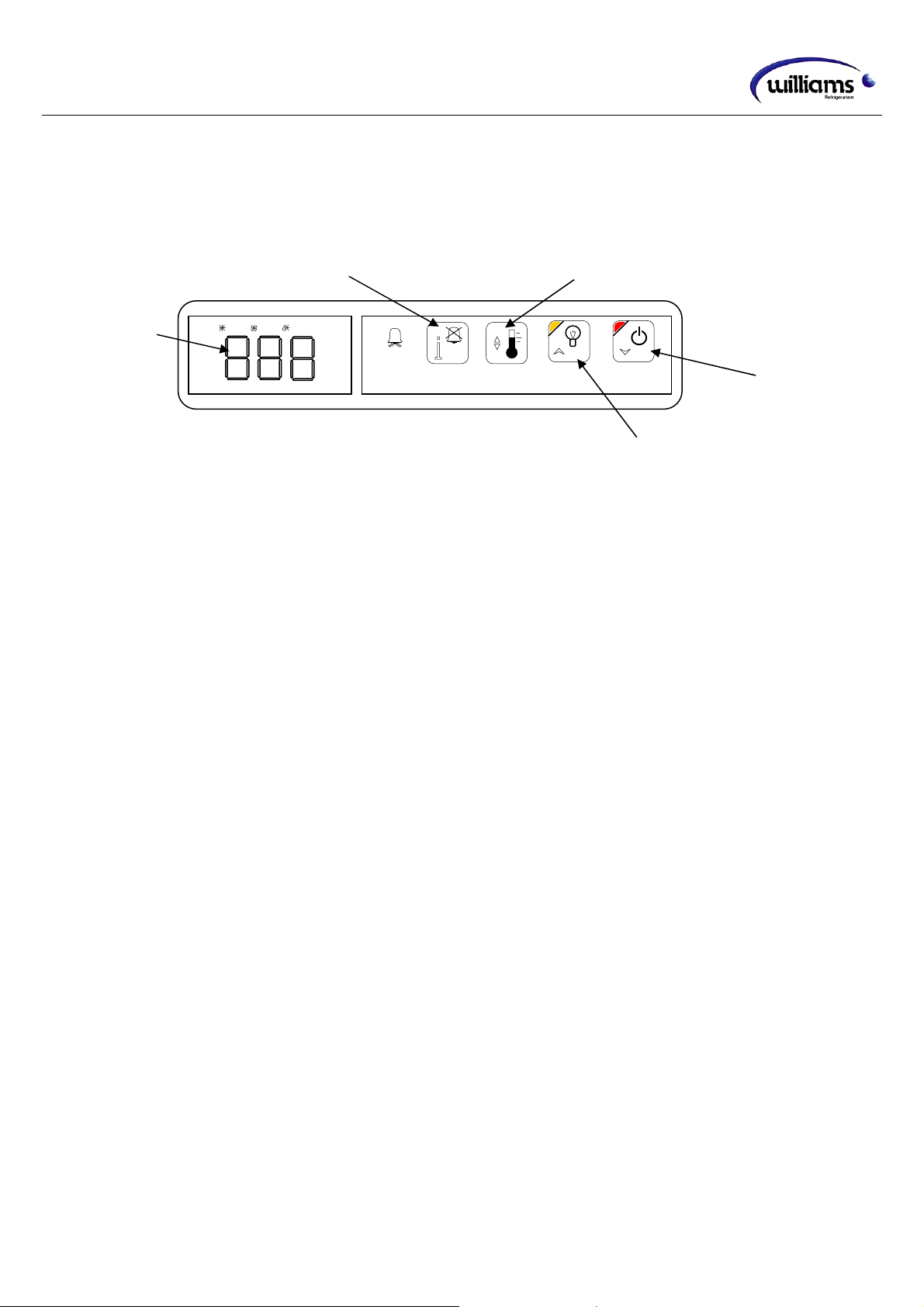

LED

Display

After you switch the room on the controller will diplay [---]. This is the self test phase.

A permanent indication on display OFF indicates the room is on standby. The only buttons that can be operated in this

state is the light switch ([UP] button) and the standby switch, which turns the room on/off standby ([DOWN] button).

During normal operation the display shows the room temperature or, if the controller is performing defrost the controller

will display DEF, the indication will remain until the defrost has finished.

An anomaly is reported on the display through the flashing of an abbreviation indicating its cause:

HI / LO, High or low alarm temperature in the room.

DO, Door open alarm.

CHI, High condenser temperature.

CLN, Periodic condenser cleaning.

E1, Failure of probe T1.

E2, Failure of probe T2.

By pressing button [INFO] you enter the information menu. In this menu you can start a manual defrost by scrolling to

[DF] holding the [INFO] button whilst pressing the [UP] arrow button. Also you can display the T1, T2, T3 temperature

probes just by scrolling through the options.

To exit this menu, press the [SET] button or after 30 seconds of no button activation the controller will automatically exit.

To operate the light switch, press the [UP] button.

10. General Produce Models

These models are designed to operate at +1°C/+4°C (34°F/39°F). Defrost is automatic. The temperature can be adjusted

via the electronic controller.

11. Fresh Meat Models with Electric Defrost

These models are designed to operate at –2°C/+2°C (28°F/36°F). The temperature can be adjusted if necessary by

setting the electronic controller.

12. Frozen Food Storage Models

These models are designed to operate at -18°C/-22°C (0°F/-8°F). The temperature can be adjusted by setting the

thermostat via electronic controller.

All equipment is factory set, condition on site will be different to the test conditions and it may be necessary to

perform certain adjustments to the parameters to obtain a perfect temperature cycle.

INFO

Button

SET

Button

DOWN

Button

UP

Button

4

Page 5

WILLIAMS MODULAR COLDROOM

Operating Instructions

13. Defrost Operation

When defrost is in progress, the defrost indicator on the control panel will become illuminated.

On fresh meat and freezer coldrooms, every 6 hours the machine will go through an automatic defrost cycle, which lasts

for a maximum of 20 minutes. The refrigeration system is turned off whilst the electric defrost system is switched on. This

defrosts the evaporator coil. This operation raises the temperature of the coldroom slightly for a short period but does not

affect the stored product.

On GP coldrooms, when the machine goes into defrost the refrigeration system is turned of and the coldroom is allowed

to naturally defrost (off-cycle defrost).

14. Hi-Lo Alarm

The modular coldroom controller features a built in audio/visual Hi-Lo alarm. If the temperature within the room exceeds

the factory set alarm temperature for 45 minutes or more the control will emit an alarm signal through the display and the

buzzer. The alarm can be cancelled by pressing the [INFO] button.

15. Probe Fail Safe Feature

The Coldroom controllers feature a special fail-safe condition. In the event of a temperature probe failure the compressor

will not continue in normal sequence.

Instead the compressor will switch to a five minute cycle, which it cycles on for five minutes then off for five minutes . The

normal compressor cycle will be restored upon the repair of the probe fault. This feature is designed to avoid the

compressor overheating and preserve the temperature of the food within the cabinet.

16. Cleaning

For health safety and hygiene, as well as keeping the equipment in good condition, described below are some guidelines

on how to maintain your Williams Modular product.

Exterior: Normal day-to-day cleaning should be carried out with a soft cloth and soapy water. Never use abrasive

materials or cleaners.

Interior: Clean up all spillages immediately. Where prolonged door openings arise, ensure condensation is wiped off the

door and strip curtains are fitted. Clean interior and any shelving regularly in accordance with your cleaning schedule.

Always use a ‘food safe’ cleaning solution.

Check that the inner door release operates properly. This should be undertaken in the door open position. Gently rotate

side to side the release handle to ensure there are no obstructions. Person Trapped Alarms and lights should be regularly

checked for proper operation.

For efficient operation, do not overload the compartment or restrict airflow. Do not block air chute with shelving or product.

Ensure shelves are loaded safely. Do not obstruct the doorway or switches. Do not attempt to undertake maintenance on

the internal evaporator, fan unit or remote guards. This work should only taken by a qualified engineer.

17. Routine Maintenance

A competent, qualified person should carry out all maintenance. We recommend that you undertake regular preventative

maintenance using a qualified service provider in order to get the best from your equipment. The door inner release

should be checked for operation and lubricated as necessary.

18. Condenser Cleaning

Disconnect the coldroom from the electrical supply by unplugging.

The controller has a condenser clean alarm that is factory set, this alarm will sound every time the condenser needs

cleaning. The condenser, which is part of the refrigeration unit, is sited on the roof of the modular coldroom and requires

cleaning approximately four times per year. On rooms that are supplied with remote condenser units, the coil is located in

the condensing unit box. If your room has been supplied with refrigeration equipment by someone other than Williams,

the location may be different an you should consult your installation contractor and confirm its location. To clean the

5

Page 6

WILLIAMS MODULAR COLDROOM

Operating Instructions

condenser, disconnect the mains supply, brush the fins vertically with a stiff brush, taking care not to damage the fins or

push dirt further and vacuum away. Remember to reconnect mains supply once finished.

Warning: Condenser blocking is the most common cause of equipment overload and failure – make sure that the

condenser coil is kept free of dust and dirt and regularly checked.

If there are further grease deposits remaining on the condenser call your Service Provider to carry out a full service.

NOTE: Non-compliance may invalidate your Warranty.

19. Cleaning / Replacing the Gasket

Door gaskets should be checked and cleaned regularly and replaced if damaged. To clean the gasket, wipe with warm

soapy water and a soft cloth, ensuring it is completely dry before closing the door. DO NOT use a sharp knife to clean or

scrape the gasket. Damaged gaskets do not seal correctly and can increase the amount of electricity consumed,

seriously affecting the efficiency and performance of the coldroom.

Damaged gaskets are easily replaced. To fit a new gasket – simply pull out the old gasket and

push the new gasket into the channel (gasket retainer) at the centre and work along the gasket

pushing the channel, continue in the same way on the other three sides, pushing the corners in

last.

20. Panel Joints

Inspect the panel joints when cleaning for any loss of mastic sealer or gaps appearing. Use warm soapy water to clean

along the panel joints with a soft cloth. Do not use stiff brushes as they may cause damage to the sealant. Replace any

missing sealant with silicon sealer (available from kitchen suppliers and DIY stores).

23. Breakdown

A competent qualified engineer must carry out breakdown repair.

In the event of a breakdown, please check the thermostat setting and fuse before calling the service engineer.

If the light on the coldroom is not working isolate the supply and change the bulb, if this does not cure the problem

change the fuse located on the exterior at the bottom of the control panel. If problem consists call an engineer.

When calling the engineer, please advise him of the model and serial number of the machine. These details are on the

identification plate inside the coldroom and should also be noted on the back cover of this booklet. Please ensure all

redundant parts are disposed of safely and legally.

6

Page 7

WILLIAMS MODULAR COLDROOM

Operating Instructions

WARRANTY POLICY – Effective from 1

Warranty applies to equipment manufactured by Williams Refrigeration Warranty applies to equipment manufactured by

Williams Refrigeration and equipment bearing the Williams nameplate and serial number identification tag.

We undertake, in conjunction with the supplying agent, distributor or representative, to repair free of charge any such

piece of equipment or part thereof used which is found to be faulty in either materials or workmanship.

Products Covered

A 24 months Warranty from the original date of purchase is given to the following Williams equipment:

• Garnet / Sapphire / Zircon / Jade / Amber (stainless) / Mobile Heated / Mobile Refrigerated.

• Reach-in Blast Chillers / Reach-in Blast Chiller Freezers.

• Opal / Emerald / Onyx / Aztra / Salad Counters.

• Crystal Bakery Cabinets and Counters.

A 12 months Warranty from the original date of purchase is given to all other Williams equipment including:

• All Modular Products (including coldrooms).

• Remote Systems (including glycol).

• Bottle Coolers.

• Multidecks.

• GEM product range.

• Bottle Well / Meat Freezer Well.

• Thermowell.

• White Goods.

• Non standard products.

Warranty Terms

The equipment has been installed correctly and has not been subject to misuse or abuse but is functioning incorrectly.

The equipment was purchased by the authorised supplying distributor direct from Williams Refrigeration and not through

a wholesaler or other supplier whose warranty may be different.

The Warranty Policy shall be non-transferable.

Replacement of defective equipment can only be made with the approval of Williams Refrigeration.

Any repair under warranty will only be carried out in its position of operation or in a suitable location on the customer’s

premises. If the product has to be removed for security or any other reason, this will be subject to additional charge (may

include hydrocarbon charged equipment).

Warranty work will be covered by Williams Refrigeration or by one of its appointed agents between the hours of 8.00am

and 5.30pm Monday to Friday.

Exceptions to Standard Warranties

• Second hand equipment.

• The Standard warranty is for Mainland GB only (does not cover Marine equipment).

• Any third party item(s) connected to the equipment that may affect performance.

• Components including gaskets, doors / drawers, handles, shelves, trayslides, all internal fixings, plug and lead,

connectors, the outer shell, castors / legs, food probes, refrigerant and blockages as well as consumable items

such as (but not limited to) batteries, fuses, light bulbs, printer cartridges, keys, glass and paper roll.

• Any fault not reported within 10 working days of being discovered.

• No claim shall exceed the original selling price.

st

March 2010

7

Page 8

WILLIAMS MODULAR COLDROOM

Operating Instructions

• Where equipment is manufactured to the customers’ own design, Williams Refrigeration will not be liable for any

non performance or operation of the equipment as a result of a design fault.

• The customer permits persons other than those authorised by Williams Refrigeration to perform or effect repairs

or adjustments to the equipment.

• Repairs are made using spare parts or replacements not of the same make as those supplied originally as

components of the equipment unless authorised by Williams Refrigeration.

• If authorised representatives of Williams Refrigeration are denied full and free rights of access to the equipment

for inspection during normal business hours as previously stated.

• The customer has not properly maintained the equipment or carried out annual servicing, including cleaning of

the condenser, in accordance with instructions, literature or directions issued by Williams Refrigeration.

(Operating Instructions are supplied with all equipment but also available at www.williams-refrigeration.com

• The customer fails to observe commonly accepted operating practices.

• The customer uses or installs the equipment in such a way that it exceeds its design envelope.

• Call out and repair costs if no fault found or access denied.

• The initial supply date shall apply to a replacement.

• Equipment fails through misuse, abuse, accidental damage, power surges or spikes, fire, flooding or acts of God.

• Food and / or contents of the product (including pharmaceutical).

Claim Procedure

If a customer wishes to make a claim under the terms of this warranty, the following procedure should be observed:

• Contact the supplying agent, representative or distributor.

• Quote the model, date of installation and serial number of the cabinet. The serial number is located on the cabinet

identification plate inside the cabinet. It should also be recorded on the operating instruction booklet supplied with

the cabinet.

• Note: contents risk and insurance responsibility remains at all times with the customer.

A current list of main distributors is available on request.

Extended Warranty

Extended Warranty offers the opportunity to protect your equipment (subject to conditions outlined) for an additional

period of up to 5 years inclusive of original warranty periods.

Should you require Extended Warranty, state on your order or notify the Dealer or Williams Sales Manager at the time of

purchase and they will be able to arrange it for you.

To ensure your Extended Warranty Policy remains valid, at least one maintenance / service visit per year must take place

in years 2, 3, 4 and 5.

All – inclusive Parts & Labour Warranty

An all inclusive 2 year Parts & Labour Warranty, subject to the Warrant Policy terms, is available from your Williams

Dealer. Contact your dealer for further details.

).

8

Page 9

WILLIAMS MODULAR COLDROOM

Operating Instructions

9

Page 10

WILLIAMS MODULAR COLDROOM

Operating Instructions

10

Page 11

WILLIAMS MODULAR COLDROOM

Operating Instructions

11

Page 12

WILLIAMS MODULAR COLDROOM

Operating Instructions

Sales Tel: +44 1553 817000 Fax: +44 1553 817111

Spares Tel: +44 1553 817017 Fax: +44 1553 817020

WILLIAMS REFRIGERATION

Bryggen Road,

North Lynn Industrial Estate

King’s Lynn, Norfolk PE30 2HZ

Email: info@williams-refrigeration.co.uk

Website: www.williams-refrigeration.com

WILLIAMS SILVER FROST

30 Route d’Ahun

23150 Lavaveix Les Mines

France

Tel: +33 5 55 52 27 88 Fax: +33 5 55 62 10 61

Email: cmalabre@williams-silverfrost.com

Website: www.williams-silverfrost.com

WILLIAMS REFRIGERATION AUSTRALIA

38-42 Gaine Road

Dandenong South, Victoria 3175

Australia

Tel: +61 3 8787 4747 Fax: +61 3 8787 4787

Email: sales@williamsref.com.au

Website: www.williamsref.com.au

WILLIAMS HONG KONG

4A Harrington Building

36-50 Wang Wo Tsai Street, Tsuen Wan,

North Territories, Hong Kong

Tel: +852 2407 5422 Fax: +852 2407 3767

Email: mfco@williams-hongkong.com

Website: www.williams-hongkong.com

12

Coldroom O&M

Rev 4

June 2010

Loading...

Loading...