Williams Ref PC900 Installation Manual

OPERATING MANUAL

GEM SANDWICH CHILLER SC900 & 1200

GEM PASTRY CHILLER PC900

To achieve the optimum performance and reliability of your Chiller please read and

follow these installation, operating, cleaning and maintenance instructions. Failure to

do so may affect the warranty of your equipment.

Temperature parameters are set as:

Sandwich Chiller +2°C (36°F) / +5°C (41°F)

Pastry Chiller +5°C (41°F) / +8°C (47°F)

Declaration of Conformity References:

Low Voltage Directive 2006/95/EC

Machinery Directive 2006/42/EC

Electromagnetic Compatibility Directive 2004/108/EC

Pressure Equipment Directive 97/23/EC

Waste Electrical and Electronic Equipment Directive (WEEE) 2002/96/EC

Restriction on Use of Certain Hazardous Substances Directive (RoHS) 2002/95/EC

Refrigerant Designation Global Warming Potential

HFC - R134a 1300

HFC - R404a 3260

We declare that all products manufactured by Williams Refrigeration comply with the above

directives where applicable and as such are declared to be in conformity with the provisions

of the above legislation.

Model No.:

Serial No.:

CFC Free Refrigerant

INSTALLATION

Removal of Redundant Cabinets

Please ensure that old or redundant refrigeration

cabinets and equipment are disposed of safely and

legally.

It is recommended that doors are removed prior to

disposal in order to ensure safety.

Unpacking

Remove all external and interior packing and

accessories. Ensure all such material is disposed of

safely.

Ventilation

It is essential to ensure that the room in which the

unit is to be installed has adequate ventilation.

Refrigerators generate a considerable amount of heat

and, if operated in a small unventilated room in warm

weather, these will quickly cause the room temperature to

become excessive. This could cause the motor to

overheat and possibly damage the windings. At the very

least such an installation will cause the unit to use an

excessive amount of electricity. The SC1200 Sandwich

Chiller generates 2850W of heat, the SC900 2450W and

the PC900 Pastry Chiller 715W.

In addition to ventilation in a room, please ensure that

the Chillers have 200mm clearance between the back of

the Chiller and the wall to ensure efficient and effective

performance. Do not block vents by stacking boxes on

top or in front of the unit as this could affect performance.

Castors

The Chiller should stand level to ensure correct

operation and proper drainage of condensate from the

evaporator.

Mains Connection

The cabinet comes fitted with a 13 Amp fused plug and

must be earthed. If the plug or cable should fail please

contact the Williams Spares Department on +44 (0)1553

817017 for a replacement.

If the cabinet has been laid on its back or tipped,

DO NOT switch on immediately. Leave in an upright

position for at least one hour before switching on.

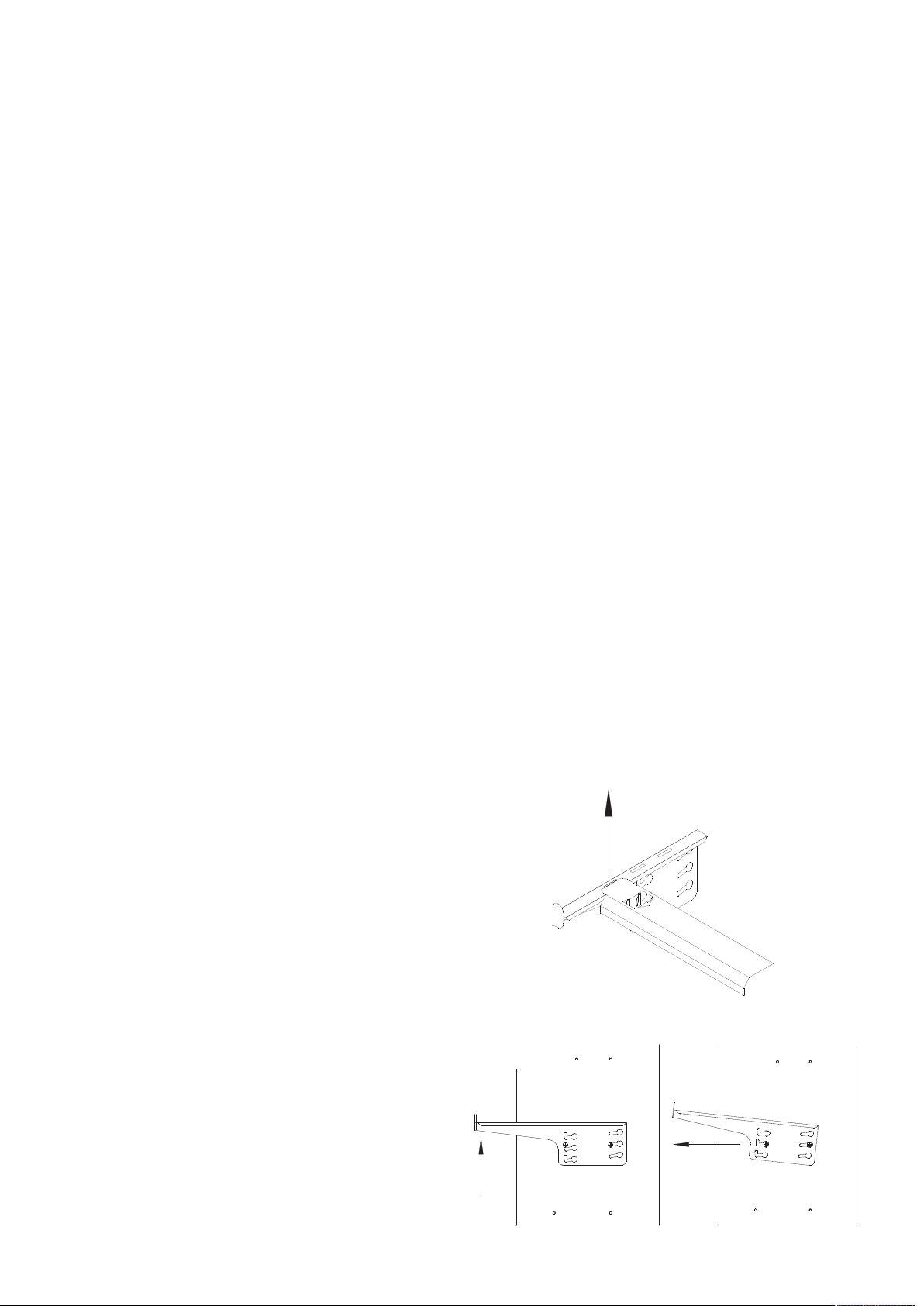

Shelf Fixing and Adjustment

Shelving is fitted in the central position as standard with

25mm adjustment up or down in a horizontal position.

To adjust:

● Isolate power supply before commencing with shelf

removal.

● Remove glass shelves before shelf adjustment begins.

● Place glass shelves carefully on a suitable surface to

avoid damage.

● Unplug power lead from the three shelf lights.

● Lift the glass supports and remove from the Chiller

(Fig. 1).

● To remove the shelving brackets loosen the retaining

screws. Lift the front of the bracket (Fig. 2) and pull

gently towards the front of the cabinet (Fig. 3). The

bracket should now detach freely.

● Repeat this process in reverse to refit the shelves.

● Brackets must be set at equal heights for each side of

the shelf.

● Light supports can be placed in any of the three slots

depending on where you require the light.

Fig. 1

It Is important that Display Chillers are positioned on a

level platform / floor. When in position ensure the brakes

have been activated by pressing the metal bar down.

Remember to release brakes before trying to move the

chiller.

Loading with Food

Sandwich and Pastry Display Chillers are not designed to

cool food from ambient temperature. It is essential that

all products placed in the display chiller have been chilled

to +2/+5°C (for the Sandwich Chiller) and +5/+8°C (for

the Pastry Chiller) before being placed inside. The unit

should be allowed 30 minutes with the night blind pulled

down to pull down to temperature before loading

(Sandwich Chillers only).

2

Fig. 2

Fig. 3

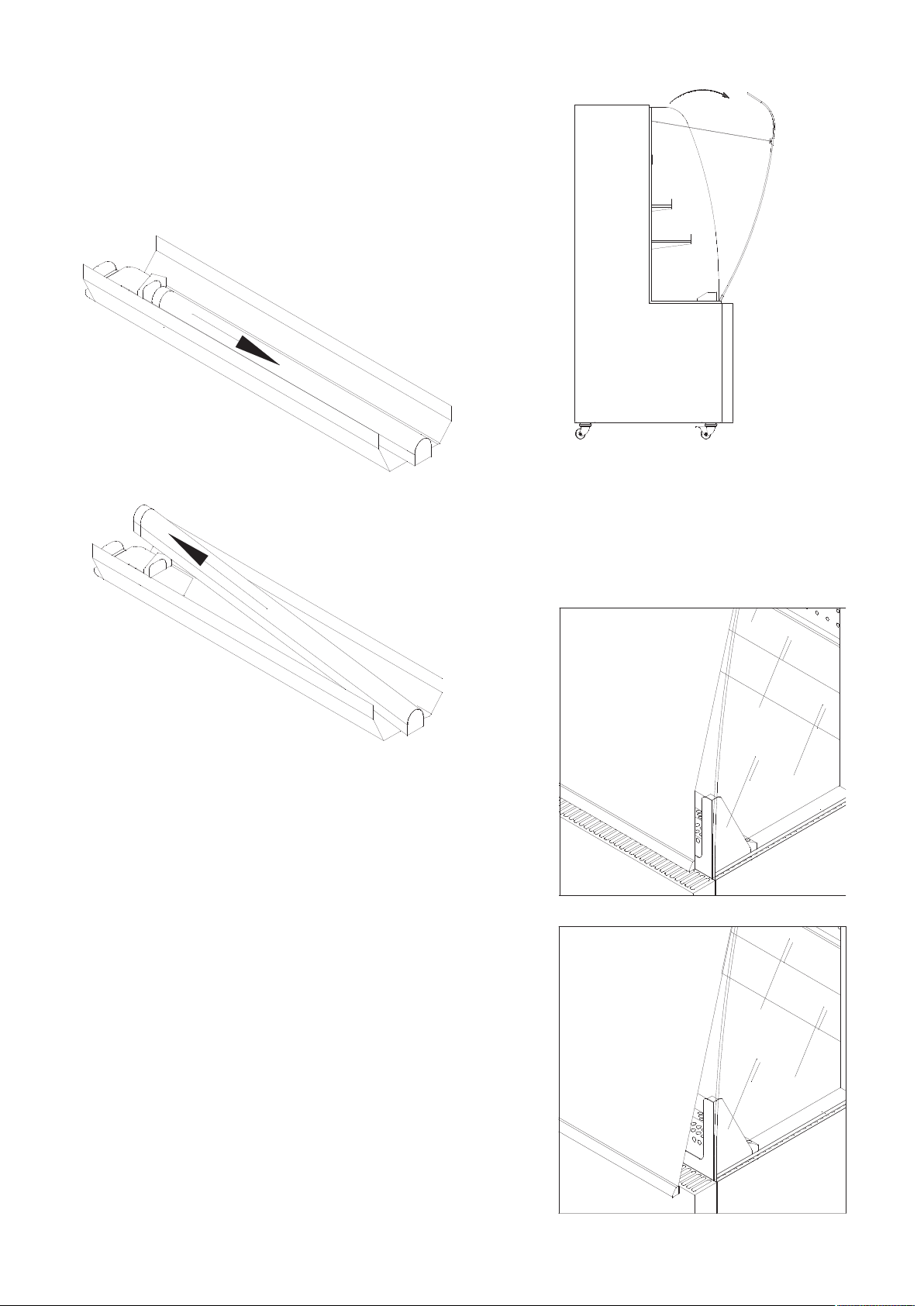

Lighting Removal

● Slide the light fitting back until it is clear of the first

mount (Fig. 4).

● Slide it back out over the mount and continue until light

fitting is removed (Fig. 5).

● Reverse process to refit.

Fig. 6

Fig. 4

Fig. 5

Carefully tilt glass back

until safety cord is taut.

OVERNIGHT OPERATION

Night blind must be closed overnight with the magnet

in the blind attached to the surround of the sneeze

screen (Fig. 7) and NOT to the front of the condenser

cover (Fig. 8), as this will cover the vent and impair

performance.

Fig. 7

Correct fitting of

magnetic night blind,

allowing air to be drawn

into the condenser.

Curved Glass Screen (Pastry Chiller Only)

The curved glass front of the Pastry Chiller should be

opened for cleaning. To do so stand in front of the unit

and slowly pull towards you until the safety chains

become taut. (Fig. 6).

Do not leave the chiller unattended with the screen in

the open position. If the glass is required to be opened

for an increased period of time then it should be removed

for safety reasons.

Removal of curved glass front:

● Two people are required.

● One person should ensure the glass is held in place

while the other removes the screws attaching the

cables to the Chiller.

● Standing with one person each side of the glass, open

fully and lift straight up to remove from the securing

angle at the base of the glass.

● Place glass shelves carefully on a suitable surface to

avoid damage.

Fig. 8

Incorrect fitting of

magnetic night blind,

restricting airflow and

performance.

3

Loading...

Loading...