Page 1

Blast Chillers & Freezers

Making Food Safety as Easy as

Reach-in Blast Chillers

Reach-in Blast Chiller Freezers

Reach-in Bakery Blast Chiller Freezer

Modular Blast Chillers

Modular Blast Chiller Freezers

Modular Blast Freezers

Page 2

For over 25 years Williams Refrigeration has continued to be one of the world’s leading manufacturers

and suppliers of commercial refrigeration solutions. With thousands of Blast Chillers, Chiller

Freezers and Freezers installed around the world, Williams has built a global reputation for quality,

performance, durability and ease of use.

Whilst Cook Chill is commonly associated with institutional and airline

catering, no catering operation is too small to adopt a Cook Chill system.

From the smallest caterer to the largest production unit, whether on land or

at sea, Williams offers the innovation and flexibility to answer your needs

with powerful, compact yet sophisticated equipment designed to be cost

effective and simple to use.

Williams customers include many leading in-flight/airline catering companies,

hotel and restaurant chains, hospitals, universities, armed forces, naval and

government facilities such as prisons as well as conference and banqueting

facilities for major sports events and stadia.

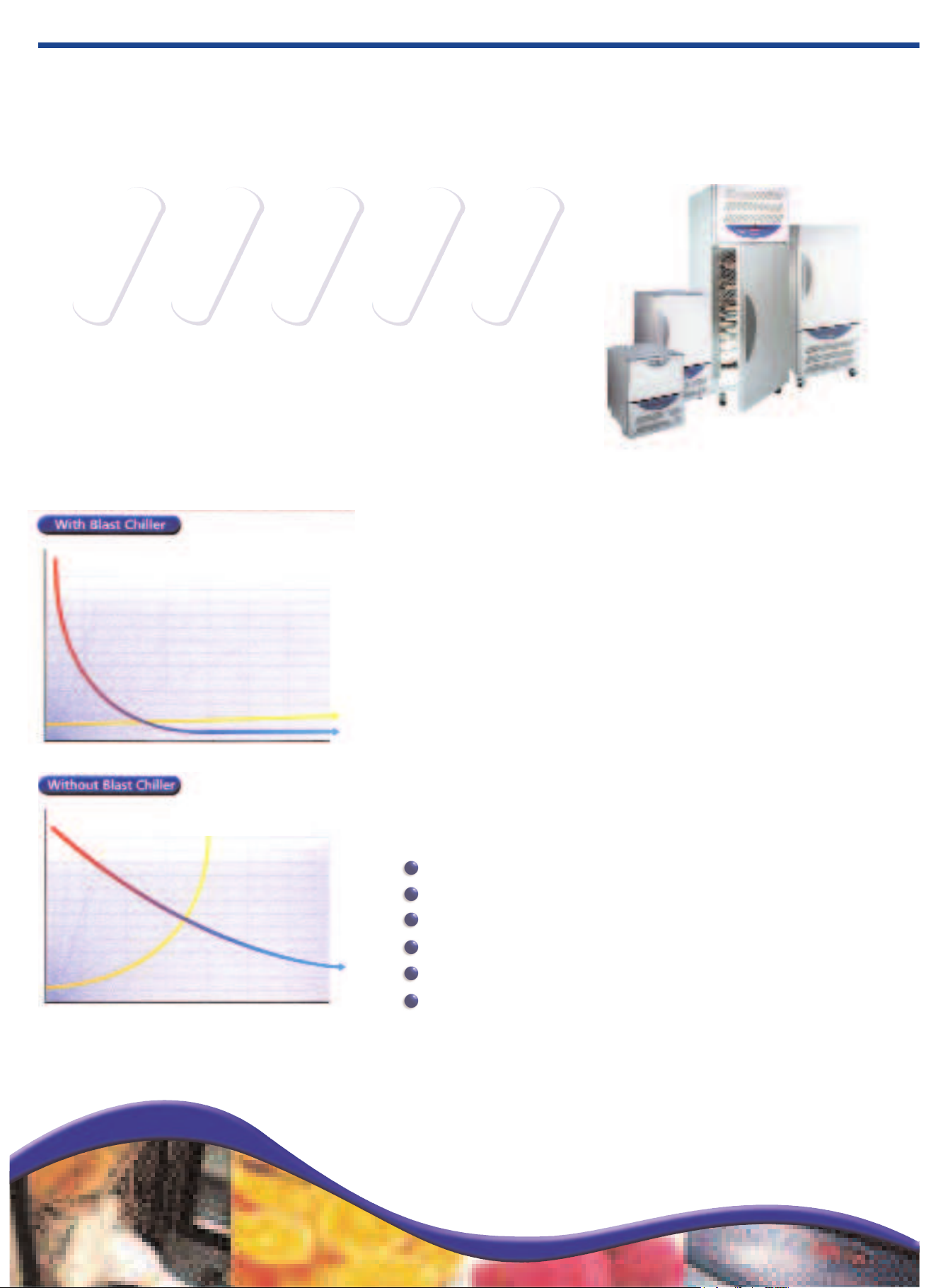

Why use a Blast Chiller or Freezer

The principle feature of Blast Chillers, Blast Freezers or Chiller Freezers

is that they are capable of rapidly reducing the temperature of hot foods

from +90°C to low, safe temperatures of +3°C or -18°C. This eliminates

the risk of slow cooling where food can stay at between +60°C and

+10°C for long periods of time. The powerful Williams range is

designed to blast chill and freeze from +90°C enabling you to

exceed the latest Food Safety / HACCP legislation.

Blast Chiller and Freezer Summary:

Is simple to operate.

Reduces food wastage.

Improves time management, efficiency and productivity.

Enables easy menu expansion.

Increases profitability by up to 30%.

Preserves quality, appearance, texture, taste and

nutritional value.

90°

75°

40°

20°

3°

0°

90°

75°

40°

20°

3°

0°

cooling time

cooling time

Bacteriological Growth

Bacteriological Growth

For more information on Cook-Chill Systems and how they can benefit your business refer to the Aga Foodservice Equipment Guide to Cook Chill.

Page 3

Williams Easy Blast 1-2-3 Controller

The unique Williams Easy Blast (WEB) 1-2-3 controller has been designed to make our equipment easy to

operate with clear easy to read digital display and just 3 simple steps to initiate a blast chill or freeze cycle.

Select soft chill or hard chill

(or freeze cycle on blast chiller freezer)

Select timed cycle of 90 (chill) or 240 (freeze)

or food temperature probe controlled cycle

Start cycle

Blast Chillers & Freezers

Built-in high quality thermal printer:

standard on modular products - blast cycle

activity print-out - meets HACCP requirements

3 simple steps...

Time Display

Displays the time elapsed during a blast cycle offering more flexibility enabling the

cycle to be stopped for half loads or delicate products.

Temperature Display

Shows the food probe temperature during a probe driven blast cycle

The WEB controller offers many user and engineering benefits:

simple to repeat last programme.

equipment can be customised locally when commissioned via the

control panel parameters to suit product type or site requirements

– for enhanced user flexibility.

controller diagnostics enables quick fault finding for ease of service

and maintenance.

Page 4

Reach-in Blast Chillers and Chiller Freezers

Offering the flexibility to suit any catering operation, large or small. The Williams

extensive range of powerful Reach-in Blast Chillers and Chiller Freezers are

designed to accommodate capacities from 10kg to 50kg.

Construction:

Marine specification: positive latch handles,

bulkhead fixings and flanged legs.

US specification models.

Adjustable legs in place of castors.

Dedicated bakery blast chiller freezer for

60x40 (Euronorm) bakery trays.

Refrigeration:

Options:

Easy to clean, durable 304 or 430 stainless steel exterior and 304 interior.

Accommodate 1/1GN pans or shelves.

75mm environmentally friendly ODP zero foam insulation for excellent thermal

efficiency and performance in 43°C environments.

Self closing doors fitted with easy to clean and replace magnetic balloon gaskets.

Radius corners for enhanced airflow together with fully removable trayslides and

racking for easy cleaning and hygiene.

Heavy duty swivel and brake castors for easy positioning.

Easy to access integral refrigeration system and enhanced control panel technology simplifies servicing

and maintenance.

Advanced AirSmart airflow design for even product chilling/freezing eliminates product dehydration and

damage to food.

A short defrost cycle is automatically initiated on completion of every cycle and every 6 hours to ensure

continuous effective and efficient operation.

An audible alarm sounds at the end of every blast chill or freeze cycle to alert staff the cycle is complete.

All models automatically switch to storage mode at the end of each blast chill or freeze cycle, holding

product at the correct temperature until the operator is ready to transfer it to the correct storage cabinet

or room.

*NB: WBC50/WBCF50 is 3-phase and requires connection to a main drain

WBC30/40 and WBCF30/40 require hardwire connection to 16 amp supply

Page 5

Blast Chillers & Freezers

Roll-in Blast Chillers and Chiller Freezers

Offering flexibility for larger catering operations, the Williams extensive range of Modular Blast Chillers,

Chiller Freezers and Freezers have been designed to offer improved performance and efficiency as well as

ease of use, installation and servicing.

Thaw Cabinets

Ideal for use with gastronorm freezers and blast freezers for the safe and effective thawing of frozen

product under controlled conditions. The Thaw cabinets feature forced air heating and cooling circuits

which cycle alternately keeping food in the range from 0°C to 3°C.

Additional frozen products can be placed into the cabinet with no detrimental effect on

products already inside enabling continual supply of thawed food.

1 and 2-door models with tough, hygienic stainless steel interior

and exterior complete with 7 nylon coated shelves per door section.

75mm environmentally friendly ODP zero foam insulation offers excellent

thermal efficiency and performance in 43°C ambient environments.

Digital control panel with clear display to ensure easy temperature

monitoring and ease of use even in the busiest environments.

Designed to accommodate 2/1GN or Combi Trolleys the range offers

capacities from 90kg to 320kg upwards including two dedicated Blast

Freezers for 100 or 200kg.

Choice of finishes available to suit all budget and environmental

conditions including high quality, durable stainless steel or white PVC

coated galvanised steel.

90mm environmentally friendly ODP zero foam insulation for excellent

thermal efficiency and performance.

Large surface evaporator for more powerful performance and

efficiency in 43°C environments.

Large diameter energy efficient, high velocity 4-pole fans offer

advanced airflow for uniform chilling and freezing across all product

preventing cell damage and dehydration ensuring excellent product

quality every time.

Designed to make servicing and maintenance simple with

easy to access and removal of fans for inspection,

repair or replacement.

Page 6

Commissioning is made simpler with easy access to the

expansion valve for superheat adjustment during installation.

New design incorporates additional and more powerful defrost

heaters to reduce defrost cycle time increasing operational

efficiency and increased product turnaround time.

Additionally, the WEB 1-2-3 controller offers simple operation

and user friendliness with a clear audible alarm at the end of

each blast chill or freeze cycle to alert staff product is ready to

be transferred to suitable storage.

Range of options include:

Insulated floors for Blast Freezer models.

High performance UV disinfection.

Internal light.

Pass through models - can improve production enabling quick transfer into cold storage.

To ensure continuous effective and efficient operation auto defrost is initiated on completion

of every cycle and every 6 hours. All models automatically switch to storage mode at the end of each

cycle holding product at the correct temperature until you are ready to transfer it to the correct storage

cabinet or coldroom, maximising efficient working practices.

The Williams unique POD system offers an excellent energy efficient solution should the Blast Chillers,

Chiller Freezers and Freezers be used for supplementary or overnight storage and reduces the wear and

tear on the Blast Chiller system, extending its life.

Williams offers one of the most comprehensive UV disinfection systems on the blast

chillers/chiller freezers and freezers. Complementing standard hygiene

practices it can be initiated with a single button at the start or end of the day.

Utensils, racking, shelves and containers can also be placed inside the chamber

to be disinfected. The failsafe design ensures that the UV programme automatically

switches off once the door is opened or at the end of the 10 minute cycle.

Page 7

Blast Chillers & Freezers

Soft Blast Chill

Designed to gently chill delicate products from +90°C to +3°C in 90 minutes with the air temperature remaining

above 0°C making it ideal for such products as fish, fruit and vegetables ensuring the texture, taste, aroma,

appearance and nutritional value are maintained.

Hard Blast Chill

This chill cycle is more suitable for denser products with a higher fat content such as meat joints and casseroles,

mashed potatoes and vacuum packed products. Chilling from +90°C to +3°C in 90 minutes with the air

temperature dropping below freezing point during the cycle - whilst ensuring the product stays in prime quality.

Blast Freeze

Rapid freezing of cooked foods to -18°C preventing cell damage to the product, preserving texture, appearance,

taste, aroma and quality as well as nutritional value by converting the water in the product into micro-crystals –

the air temperature of the cabinet reaches -35°C.

Monitoring and Recording

Printer

The high quality thermal IP65 rated printer with a protective cover, features longer lasting

print quality and clear recording of all blast cycle and storage information with space for the

user to show specific product detail. Designed to store up to 7-days worth of data, so

should the printer run out of paper, the data is safely stored.

Tab Software

Williams also offers the unique TAB software designed for temperature and blast chill or freeze cycle monitoring.

Available in place of the printer this can be used to monitor up to 25 units. The hardwire network link is designed

to work with Windows 2000/XP and remote printers with an automatic blast cycle print out at the end of each cycle

in text or graph format. It enables continual monitoring and permanent data storage of each cycle as well as

temperature monitoring and alarm management.

Softwire application also available enabling monitoring system to operate remotely across radio frequency.

Page 8

WBC10

WBC20

WBC30

WBC40

WBC50

temperatures

& capacities

dimensions (wxdxh) mm

pairs of shelf slides

capacity (kgs)

Reach-in Blast Chillers & Freezers

10kg

20kg

30kg

40kg

50kg

707x804x885

707x804x1290 707x804x1735

707x804x1735

707x804x1905

6

13

10

10

3

separate datasheets available on both the Bakery and Jade Blast Chiller models - call for more information

standard

optional

options

& features

FINISH

DOORS

REFRIGERATION

ELECTRICS

OPTIONS

HACCP

WBC20

WBC10

WBCF10

WBCF20

WBC30

WBCF30

WBCF40

WBC40

WBC50

Bakery

& Jade

BBC1-400

BBCF1-400

J1BC

*

*

*

*

WBCF50

**

accommodates 40 x 60 Euronorm bakery trays on trayslides

note: WBC/F30 & WBC/F40

require 16 amp connection

* **

****

UV Disinfection system

430 Stainless Exterior & 304 Interior

304 Stainless Steel Interior & Exterior

Left hand hung door

+90°C / +3°C in 90 minutes

+90°C / -18°C in 240 minutes

R404a Refrigerant

Automatic switch to storage facility

Single Phase

Three Phase

220-240v supply

380-420v supply

Adjustable legs

Marine Specification

1/1 GN Pans

1/1 GN Shelving

TAB monitoring system

Printer

Williams reserve the right to modify the design, materials and finish in accordance with its progressive development policy.

Page 9

Roll-in Blast Chillers & Freezers

temperatures

& capacities

WMBC120 WMBC160 WMBC240 WMBC320

WMBC90

standard

optional

90kg

120kg

160kg

240kg

320kg

+90°/+3°C in 90mins

+90°/-18°C in 240mins

Trolley capacity (GN)

1 x 2/1

1 x 2/1

1 x 2/1

2 x 2/1

2 x 2/1

WMBC120

WMBC90

WMBCF90

WMBCF120

WMBC160

WMBCF160

WMBCF240

WMBC240

WMBCF320

WMBC320

304 Stainless Steel Interior & Exterior

Left hand hung doors

POD style refrigeration system

Automatic switch to storage mode

TAB monitoring system

UV disinfection system

90mm insulated floor / external ramp

Roll-Through

2/1 trolleys supplied with Blast Chiller

White PVC coated exterior / stainless

steel interior

Internal Light

Heated probes for Blast Freezers

Door mullion heaters

415 volt / 50 cycle 3-phase unit

Internal protective bumper bars

options

& features

WMBF100

WMBCF200

WMBF200

WMBC200

FINISH & CONSTRUCTION

REFRIGERATION

ELECTRIC

HACCP

Printer

404A refrigeratnt

WMBC200

200kg

2 x 2/1

Williams reserve the right to modify the design, materials and finish in accordance with its progressive development policy.

Page 10

Technical Specification

WMBC/F

120C

WMBC/F

160C

WMBC/F

240C

WMBC/F

320C

WMBC90C

standard

optional

90kg

120kg

160kg

240kg

320kg

+90°/+3°C in 90 mins

+90°/-18°C in 240mins

Trolley capacity (Combi)

1 x 2/1

1 x 2/1

1 x 2/1

2 x 2/1

2 x 2/1

WMBCF120

WMBCF160

WMBCF200

WMBC240

Roll-in Blast Chillers & Freezers - Combi

1. It is recommended to use 50mm GN pans to achieve effective rapid cooling within the timescales

given. For quicker results or to increase the product load reduce depth of product to 25mm

2. The water and fat content, plus density of food will all have an affect on time it takes to reach the

desired temperature - always take this into consideration when selecting a cycle

WMBC

200C

200kg

2 x 2/1

304 Stainless Steel Interior & Exterior

Left hand hung doors

POD style refrigeration system

Automatic switch to storage mode

TAB monitoring system

UV disinfection system

90mm insulated floor/External Ramp

Roll-Through

2/1 trolleys supplied with Blast Chiller

White PVC coated exterior / stainless

steel interior

Internal Light

Heated probes for Blast freezers

Door mullion heaters

415 volt / 50 cycle 3-phase unit

Internal protective bumper bars

FINISH & CONSTRUCTION

REFRIGERATION

ELECTRIC

HACCP

Printer

404A refrigeratnt

options

& features

WMBC120C

WMBC90C

WMBCF90C

WMBCF120C

WMBC160C

WMBCF160C

WMBCF240C

WMBC240C

WMBCF320C

WMBC320C

WMBF100C

WMBCF200C

WMBF200C

WMBC200C

* Modular Blast Chiller with Freeze option must have an insulated floor - external height increases by 90mm.

**

Modular Blast Chillers and Freezers require condensing unit not included - trolleys not included. Refrigeration system is designed

as a pump down system - therefore there is no requirement for electrical connections between blast chiller and condensing unit.

Williams reserve the right to modify the design, materials and finish in accordance with its progressive development policy.

Page 11

Williams Unique AirSmart Advanced

Airflow System

Ensures your food products stay in perfect con-

dition throughout the blast chilling or freezing

cycle.

Powerful, energy efficient fans and the

equalised air pressure chamber design ensure

that air flows evenly over all food products.

Ensures uniform rapid chilling or freezing

whether product is at the top or bottom of the

blast chiller.

Ensures product stays in perfect condition

eliminating any risk of dehydration, skinning

or damage.

Blast Chilling or Freezing with Williams AirSmart

technology ensures products not only stay in

perfect condition but maintain their taste, texture,

aroma, appearance and nutritional value.

When Blast Chilling or Freezing a less than full load

reduce food thickness by distributing over more pans

/shelves to speed up chilling times.

Soft Chill - even the most delicate of products stays

in prime condition.

Hard Chill - even the most dense products are

evenly chilled to ensure food quality and safety.

Blast Freezing with AirSmart technology

ensures that microcrystals form eliminating the

risk of cell damage to the product as well as

maintaining the colour of the product.

Save time with reduced loads by distributing

the product being chilled over more pans /

shelves. Thinner product loads blast

chill/freeze quicker.

warm air on to heat exchanger

cold air off the heat exchanger

EASY AS 1-2-3

AirSmart Advanced Airflow System

Save Time - Ensure Product Quality

Airflow from above ...

Page 12

Bryggen Road, North Lynn Industrial Estate, King’s Lynn, Norfolk. PE30 2HZ

Tel: +44 (0) 1553 817000 Fax: +44 (0) 1553 817111

Email: sales@williams-refrigeration.co.uk Website: www.williams-refrigeration.com

Williams Refrigeration

MK/LIT/WMBCF/0307 MAR 07

FOODSERVICE EQUIPMENT

Dealer Stamp

Williams reserve the right to modify the design, materials and finish in

accordance with its progressive development policy

www.blastchill.com

Loading...

Loading...