Wilkerson Instrument DM7010 Operating Manual

DM7010

FREQUENCY INPUT

FIELD RANGEABLE

ISOLATED TRANSMITTER

The DM7010 provides an isolated output

voltage or current proportional to the

frequency of the input AC voltage. The wide

input voltage range allows the module to be

used with low level magnetic pick-ups, for

flow or speed applications, for digital signals,

or for direct power line monitoring.

A selectable pull-up resistor allows input

drive from switch closure or open collector

transistor. Also, CMOS or TTL inputs are

accepted.

The output is fully isolated from input, line

power, and ground. The unit is useful for

eliminating ground loops and for isolating

from common mode voltages. The DM7010

utilizes a feedback voltage controlled

oscillator to develop a digital signal with a

duty cycle proportional to the input signal

amplitude. This signal is coupled through an

isolating pulse transformer to the output

circuitry, where the duty cycle data is

converted to a proportional output signal

level.

The module includes filtering and conditioning

to reduce susceptibility to transients and

noisy environments.

Input and output ranges are fully usersettable. With handy gold plated jumper

connections, the user selects and sets input frequency span, filter capacitor, voltage/

current output, output range, and normal/

reverse acting output. Input span and zero

adjustments provide full range adjustability.

All adjustments, settings, and input and

output connections are easily accessed

from under a pull off/push on cover panel. A

write-on label is supplied on the front panel

for the user’s convenience.

The DIN Rail package snaps onto the rail and

is easily removed from the front side by using

a screwdriver to release the spring loaded

snap.

OPTIONS

(User specified)

AC Power 24, 115 or 230 VAC

DC Power 12 or 24 VDC

U All circuit boards conformal coated for

protection against moisture.

INSTALLATION

DM7010 mounts on standard DIN Rail. Install

it by hooking the top of the module’s latch

onto the top of the rail, then use a downward

rotating motion to snap the module onto the

rail. To remove the module, insert a

screwdriver into the slot on the spring loaded

snap which is located on the lower backside

of the unit. Apply a downward pressure on

the release and rotate the module up and off

of the rail.

1. Remove the front panel by spanning the

top and bottom edges between the thumb

and index finger. Use a rocking motion to

pull the front panel away from the module.

2. Input, Output and Power connections are

shown on the terminal block labels.

CAUTION: BEFORE PROCEEDING,

REMOVE ALL POWER TO THE WIRES

AND MODULE TO AVOID THE DANGER

OF SHOCK AND/OR DAMAGE TO THE

UNIT.

To access input and output terminals, the

connecting wires are inserted into the top

of the top terminal block, and into the

bottom of the bottom terminal block. The

terminal blocks unplug. Wiring can be

completed before the product is installed.

Recommended wire sizes are 22-14 AWG

Cu, with a strip length of 0.25 inches.

3. Replace the front panel by inserting the pins

into the slotted holes located on the bezel

and pushing it into position.

4. The front panel label provides space for the

user to make application notes.

CALIBRATION

The DM7010 is factory calibrated to the input

and output noted on the side label.

The DM7010 allows the user to calibrate the

module to operate as required for a specific

application.

Field adjustments can be made by using the

following recommended procedure.

CAUTION: BE SURE ALL RANGE

SELECT JUMPERS ARE SET TO THEIR

PROPER POSITIONS BEFORE

APPLYING INPUT OR POWER.

1. Remove the front panel and disconnect the

power.

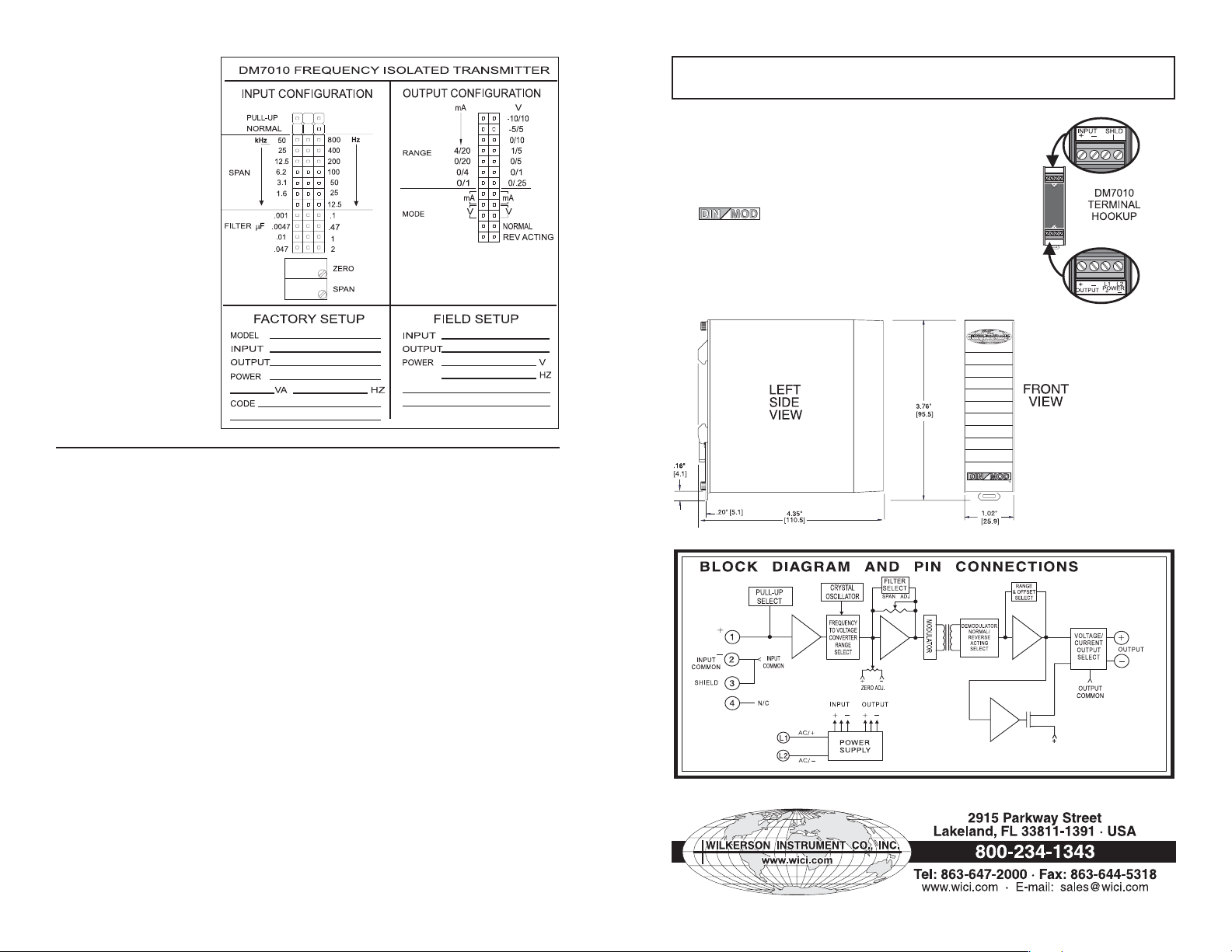

2. Using the label on the side of the module

(Figure 1) as a guide, position the jumper

blocks for the desired operation of the

following functions:

span -

Choose the frequency span which

includes the maximum inputfrequency.

pull-up/normal -

ohm to +5 Volts load to the input terminal.

filter capacitor -

chart to obtain the desired filter and response

time.

output range -

range to obtain the desired output.

output mode -

this selection must be made in conjunction

with the output range selection. There are

two jumper positions for this selection, both

must be selected.

normal or reverse acting output -

for the output to increase as the input

increases, select reverse for the output to

decrease with increasing input.

3. Connect calibrated frequency source to the

input; and meters to the input and output

terminals. Apply power to the module.

4. Set the input frequency to represent the zero

level, the lowest value of the input span.

5. Observe the output meter. Use the ZERO

adjustment to raise or lower the output to the

desired zero level.

Choose pull-up to add a 4700

Use the filter capacitor selection

Select the voltage or current

Select either voltage or current,

Select normal

6. Set the input frequency to represent the

upper limit of the SPAN, the highest value

of the input span.

7. Observe the output monitor. Use the SPAN

adjustment to raise or lower the output to

the desired maximum level.

8. Repeat steps 4 to 7 to fine tune the output.

Usually 3 repetitions will give the desired

results.

9. Remove power, disconnect test equipment

and install the module for operation.

Replace the front panel.

Example for Frequency and Filter

Selection:

Input Frequency: 100 Hz to 1000 Hz

Maximum Ripple: .1%

Output: +5/-5 Volts

Actual Span: 900 Hz

(must include maximum input frequency)

Select Span Jumper for 1600 Hz

Select Filter Capacitor Jumper for 0.1µF

(from the Chart)

Select Output Mode Jumpers for Volts

(two positions)

Select Output Mode Jumper for

REV ACTING

Select Output Range Jumper for -5/+5

Set input frequency to 100 Hz

Adjust Zero for +5 Volt output

Set Input frequency to 1000 Hz

Adjust Span for -5 Volt output

Repeat adjustments for accurate

calibration

FILTER CAPACITOR SELECTION CHART

FREQUENCY

SPAN

SETTING

HERTZ

12500 0.01 0.5 0.0047 0.24

25000 0.01 0.5 0.0047 0.24

50000 0.0047 0.24 0.001 0.05

MINIMUM CAPACITOR*

SETTING FOR LESS THAN

0.1% RIPPLE PEAK-PEAK

.

CAPACITOR

RESPONSE

(uF)

TO 99%

12 2.2 110 1.0 50

25 2.2 110 1.0 50

50 1.0 50 0.47 24

100 1.0 50 0.47 24

200 0.47 24 0.47 24

400 0.47 24 1.0 5

800 0.47 24 0.047 2.4

1600 0.1 5 0.047 2. 4

3200 0.047 2.4 0.047 2. 4

6400 0.047 2.4 0.01 0.5

(*SEC) **

MINIMUM CAPACITOR*

SETTING FOR LESS THAN

0.5% RIPPLE PEAK-PEAK

CAPACITOR

RESPONSE

(uF)

TO 99%

(*SEC) **

1 2

* The minimum capacitor

value is based on full span

where the minimum frequency is 0.1% of the frequency setting. When the

minimum frequency to be

measured is greater than

0.1% of the frequency setting, the capacitor value may

be decreased to improve

the response time.

** The minimum frequency

which will meet the ripple

specifications is 0.5 Hertz.

Figure 1

SPECIFICATIONS

INPUT

Frequency Range

10 Hz to 50 kHz

Impedance

100,000 ohms

Coupling AC

Voltage range

50 mV to 700 V p-

p

Span Select

(User settable)

12, 25, 50, 100,

200, 400, 800,

1600, 3200, 6400,

12500, 25000 and

50000 Hz

Span adjustment

+5%, -55% of

selected span

Zero adjustment

±30% of selected

span

Offsets

(User settable)

None

Pull-Up Resistor

4.7 kilohm (+5 VDC)

OUTPUT

Modes

Normal/

Reverse Acting

Range

(User settable)

0/.25, 0/1, 0/5,

0/10, -5/5,

& -10/10 VDC

0/1, 0/4, 0/20,

& 4/20 mAdc

Accuracy

0.1% of span

Step response time

see FILTER

CAPACITOR

SELECTION CHART

Ripple

(peak-to- peak)

see FILTER

CAPACITOR

SELECTION CHART

Input to Output

Linearity

±0.01% of span

COMMON MODE

REJECTION

120 dB DC

to 60 Hz

ISOLATION,

OUTPUT/INPUT

>500 megohms

BREAKDOWN,

OUTPUT TO INPUT

>1000 volts

RMS sinewave

BREAKDOWN,

POWER CIRCUITRY

>1500 volts

RMS sinewave

OPERATING

TEMPERATURE

-13° to 140°F

(-25° to 60°C)

TEMPERATURE

STABILITY

±(0.01% of span)/°C

POWER

Wattage

2.5 W max

AC Options

115 VAC

±10%,

50/60 Hz

230 VAC

±10%,

50/60 Hz

24 VAC

±10%,

50/60 Hz

DC Options

12 VDC nominal

(10 to 15 VDC)

24 VDC nominal

(21 to 28 VDC)

CAUTION: THE DIN/RAIL SHOULD BE EARTH GROUNDED (GREEN WIRE) TO

ENSURE SAFEST OPERATION AND TO PROVIDE OPTIMUM PERFORMANCE.

MOUNTING

The DIN Rail package is installed by snapping it onto

the rail and it is removed from the front side by using

a screwdriver to release the spring loaded snap

(located on the lower backside of the unit).

WARRANTY

The Series of products carry a limited

permanent warranty. In the event of a failure due to

defective material or workmanship, the unit will be

repaired or replaced at no charge. Relays are not

covered by the warranty.

CASE DIMENSIONS INCHES [mm]

Specifications Are Subject To Change Without Notice. © 2007 Wilkerson Instrument Co., Inc. DWG#W102762D 3/07

3 4

Loading...

Loading...