Wildcat Territory E15609900A User Manual

W

ILDCAT

Scale

Technical Manual

E15609900A

12/00.01

© Mettler-Toledo, Inc. 2000

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written permission

of Mettler-Toledo, Inc.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

CUSTOMER FEEDBACK

Your feedback is important to us! If you have a problem with this product, or just a suggestion on how we can serve you better,

please fill out this form and send it to us. If you are in the United States, you can mail this postpaid form to the address on the

reverse, or fax it to (614) 438-4355. If you are outside the United States, please apply the appropriate amount of postage before

mailing. You can also send your feedback via email to: quality_feedback.mtwt@mt.com

Your Name: Date:

Organization Name: METTLER TOLEDO Order Number

Address: Part / Product Name:

Part / Model Number:

Serial Number:

Phone Number: ( ) Fax Number: ( ) Company Name for Installation:

E-mail Address: Contact Name:

Phone Number:

How well did this product meet your

Comments:

expectations in its intended use?

Met and exceeded my needs

Met all needs

Met most needs

Met some needs

Did not meet my needs

COMMENTS/QUESTIONS:

DO NOT WRITE IN SPACE BELOW; FOR METTLER TOLEDO USE ONLY

Retail Light Industrial Heavy Industrial Systems

RESPONSE: Include Root Cause Analysis and Corrective Action Taken.

.

E

FOLD THIS FLAP FIRST

NO POSTAGE

NECESSARY IF

MAILED IN THE

UNITED STATES

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 414 COLUMBUS, OH

POSTAGE WILL BE PAID BY ADDRESSE

Mettler-Toledo, Inc.

Quality Manager - MTWI

1150 Dearborn Drive

Worthington, Ohio 43085

USA

Please seal with tape.

INTRODUCTION

Information regarding METTLER TOLEDO Technical Training may be obtained by contacting:

METTLER TOLEDO

1900 Polaris Parkway

Columbus, Ohio 43240

(US and Canada) 614- 438-4511

(All Others) 614-438-4888

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the

Canadian Department of Communications. Operation is subject to the following conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his or her own expense.

This manual correctly describes the operation and functionality of the WILDCAT scale containing software

version 125362 Sr 2.00. The software version is displayed during the power-up sequence.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR

CHANGES WITHOUT NOTICE.

PRECAUTIONS

SAFETY NOTICE

Product safety is a fundamental concern at METTLER TOLEDO. Use common sense and follow the simple

precautions listed below to ensure your safety and optimize the use and performance of this product.

• Read this manual before operating or servicing this product. Save this manual for future reference.

• Observe safety warnings located throughout this manual.

• Use caution when lifting or moving heavy equipment.

• Engage wheel brakes before operating WW (mobile / wheeled) products.

• Do not use this product in washdown environments. Never immerse electronic products in liquids.

• This product should be serviced by qualified personnel. Exercise care when moving, testing, or adjusting this product.

• Disconnect all power to this product before installing, servicing, or cleaning.

• Use only METTLER TOLEDO parts for repair.

• Observe electrostatic handling precautions for electronic components. Allow at least 30 seconds after power disconnection to

allow charges to dissipate before servicing any electronic components.

• Allow the product to stabilize at ambient room temperature before applying power.

FAILURE TO FOLLOW THESE PRECAUTIONS COULD RESULT IN DAMAGE TO EQUIPMENT OR

BODILY HARM.

CONTENTS

1 Introduction...................................................................................................1-1

Specifications..................................................................................................................... 1-1

2 Assembly Procedures..................................................................................... 2-1

Assembly Instructions......................................................................................................... 2-1

Load Cell Wiring................................................................................................................. 2-3

Serial Port Connections ...................................................................................................... 2-3

3 Programming and Calibration......................................................................... 3-1

Key Functions..................................................................................................................... 3-2

Entering the Programming Mode ......................................................................................... 3-2

Entering and Configuring Program Blocks............................................................................. 3-3

Exiting the Programming Mode ........................................................................................... 3-3

Sealing the Enclosure (Legal for Trade) ............................................................................... 3-3

Factory Default Settings ...................................................................................................... 3-4

F1 Scale Block.................................................................................................................... 3-5

F2 Application Block ........................................................................................................... 3-7

F3 Interface Block............................................................................................................... 3-8

Exit Sub-Block.................................................................................................................... 3-9

Calibration....................................................................................................................... 3-10

Gravity Adjustment ........................................................................................................... 3-10

4 Maintenance and Troubleshooting................................................................... 4-1

Cleaning ............................................................................................................................ 4-1

Troubleshooting.................................................................................................................. 4-1

Error Codes........................................................................................................................ 4-1

Voltage Checks................................................................................................................... 4-2

AC Power Test ......................................................................................................... 4-2

Controller PCB Input Voltage Test................................................................................ 4-2

Check Battery Voltage(Battery-powered units)........................................................... 4-2

RS232 Serial Output Test .......................................................................................... 4-2

Parts Replacement and Adjustments .................................................................................... 4-3

Battery Replacement ............................................................................................................ 4-3

Keyboard Replacement......................................................................................................... 4-4

Controller PCB Replacement.................................................................................................. 4-4

Load Cell Replacement......................................................................................................... 4-5

Overload Stop Adjustment..................................................................................................... 4-6

Shift Test ............................................................................................................................ 4-7

Power-Up Sequence............................................................................................................ 4-8

5 Parts List ...................................................................................................... 5-1

Column and Base (WS30, WS60, WS150)........................................................................... 5-2

Column and Base (WW250 and WW500) ............................................................................ 5-3

6 Appendices ................................................................................................... 6-1

Appendix 1: Demand Mode Output....................................................................................... 6-1

Weight Field Format.............................................................................................................6-1

Appendix 2: Continuous Mode Output .................................................................................. 6-4

Status Byte Definition............................................................................................................ 6-5

Appendix 3: ASCII Input Commands .................................................................................... 6-6

Appendix 4: GEO Codes ...................................................................................................... 6-7

1 Introduction

The WILDCAT bench and portable scale is designed to meet the real world requirements

of manufacturing, agricultural, packaging, and general weighing applications, and is

ready to use right out of the box. This manual provides important information for

installing and servicing the scale. For information on operating the scale, refer to the

Operator’s Card provided with the unit.

The WILDCAT scale is intended for use in general purpose industrial and commercial

environments. For the best performance, it should not be used in environments requiring

washdown, immersion in liquids, or exposure to corrosive chemicals.

Specifications

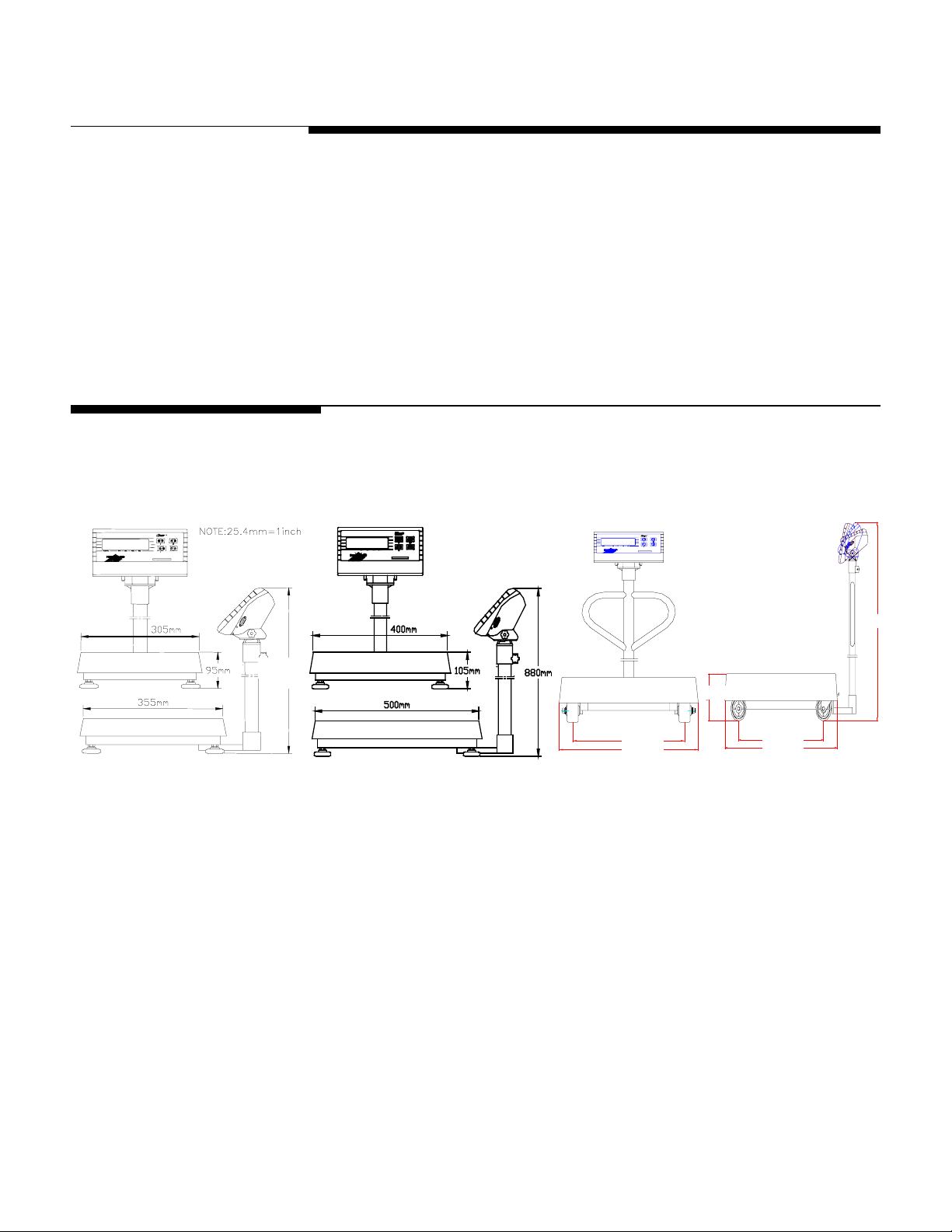

The WILDCAT scale is available in three base sizes. Specifications for the models below

are listed on the next page.

Chapter 1: Introduction

Specifications

540 mm

540 mm

Figure 1-1: WS30R, WS60R Figure 1-2: WS60LR, WS150R

190 mm

418 mm

520 mm

544 mm

720 mm

Figure 1-3: WW250, WW500

1250 mm

(12/00) 1-1

METTLER TOLEDO WILDCAT Scale Technical Manual

WS30R/WS30VR WS60R/WS60VR WS60LR/WS60LVR WS150R/WS150VR WW250VR WW500VR

Displayed

Resolution

Maximum Capacity

Minimum Division

Size

Trade -Approved

Build

Maximum Back

weight

Safe Overload 45 kg (90 lb) 90 kg (225 lb) 225 kg (450 lb) 300 kg (660 lb) 600 kg (1320 lb)

Corner Loading

Base Dimensions

W x D x H

Scale Dimensions

W x D x H

Actual Weight 11 kg (24 lb) 22 kg (49 lb) 50 kg (110 lb)

Shipping Weight

Load Cell (2mV/V) 100 kg (220 lb) 250 kg (550 lb) 500 kg 1000 kg

30 kg (60 lb)

0.01 kg

(0.02 lb)

30 kg (60 lb) 10 kg (4 lb) 30 kg (95 lb)

305 x 355 x

(95 – 110)** mm

12 x 14 x

(3.8 – 4.3**) in

305 x 500 x (540 – 555)** mm 400 x 650 x (885 – 990)** mm 510 x 850 x 1320 mm

12 x 19.7 x (21.3 – 21.8)** in 15.7 x 25.6 x (34.8 – 35.3)** in 20 x 33.5 x 52 in

14 kg (31 lb)

60 kg (150 lb)

0.01kg

(0.05 lb)

60 kg (150 lb)

0.02 kg

(0.05 lb)

400 x 500 x (105 – 120)** mm 510 x 710 x 200 mm

30 kg (66 lb)

Up to 10,000d

100% of full capacity.

15.7 x 19.7 x (4.1 – 4.6)** in 20 x 28 x 7.8 in

150 kg (300 lb)

0.05 kg

(0.1 lb)

250 kg (500 lb)

0.1 kg

(0.2 lb)

90 kg (200 lb) 180kg (400 lb)

51 kg (112 lb)

500 kg (1000 lb)

0.2 kg

(0.5 lb)

Construction

Column

Construction

Environment General purpose, dry. Load cell is moisture- and dust-resistant.

Display Six-digit, 25 mm (1 in) tall, high contrast, LCD

Keypad 4 color-coded, tactile-feel keys

Approvals UL Listed

Power 10.2 VDC / 0.15 A (AC transformer included) or six “D” cells

Battery Life Up to 500 hrs with six ‘D Cell’ batteries

Operating Temp.

Storage

Temperature

Data Output ASCII via RS-232 standard

Weighing Units pounds, kilograms and grams

*NTEP and Industry Canada approvals pending on WW models

** The height will vary depending on the height of the leveling feet.

***Information not available at this time.

350 mm (14 in) stainless steel 700 mm (28 in) stainless steel 1118 mm (44 in) stainless steel

Platter: Fabricated 304 Stainless Steel

Base Support Frame: Formed and Welded Carbon Steel Polyurethane Painted Navy Blue

Display Enclosure: ABS Charcoal Gray Plastic

ZERO, TARE, FUNCTION, and PRINT

Industry Canada AM-5319*

NTEP Class III #99-053*

-10°C to 40°C with 10 to 95% relative humidity, non-condensing

-20°C to 60°C with 10 to 95% relative humidity, non-condensing

Table 1-1

(12/00) 1-2

“”

Enchufa o utilice seis

baterías tipo “”D

Herramientas adicionales

que pudiese necesitar

Additional tools

you may need

Plug in or use

6 “D ” size batteries

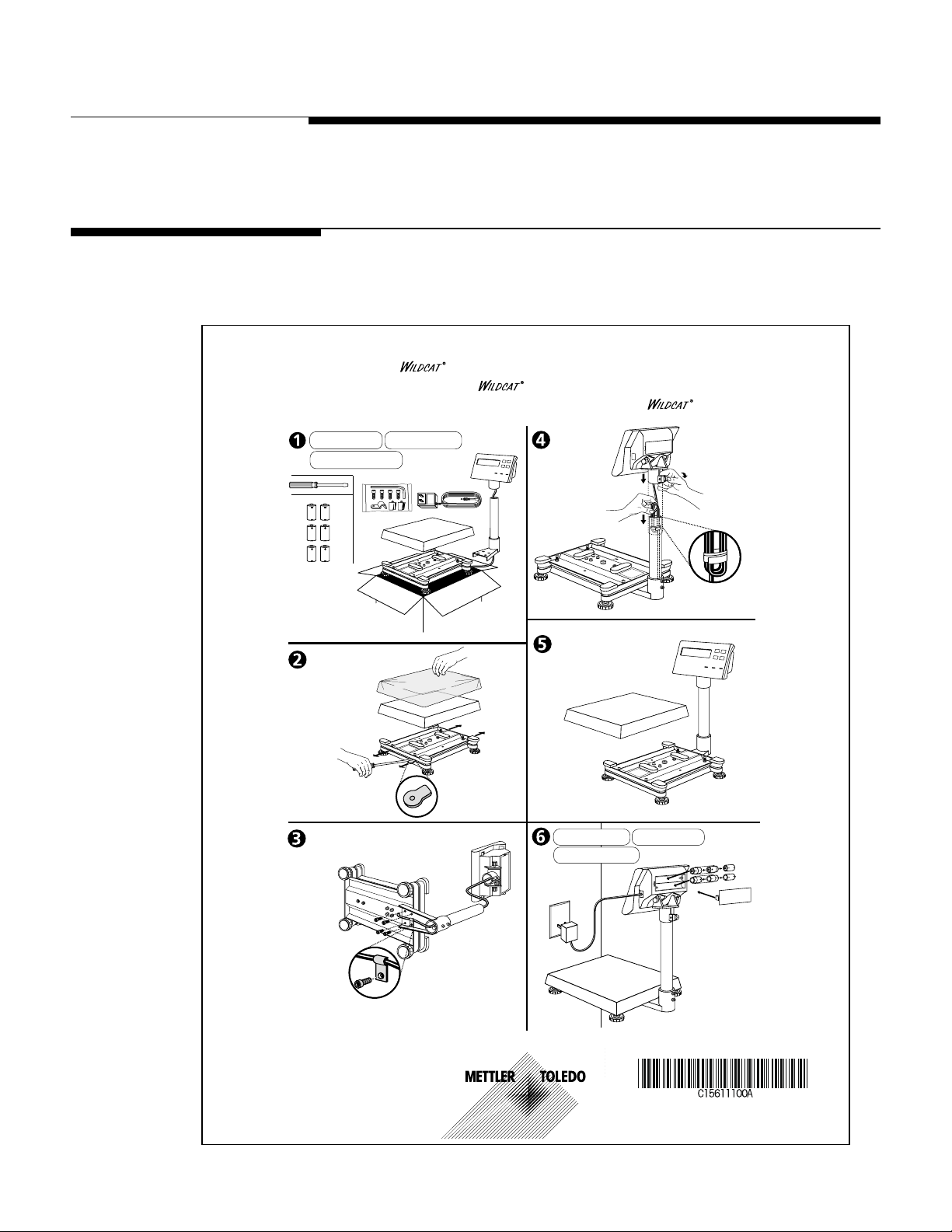

2 Assembly Procedures

Assembly Instructions

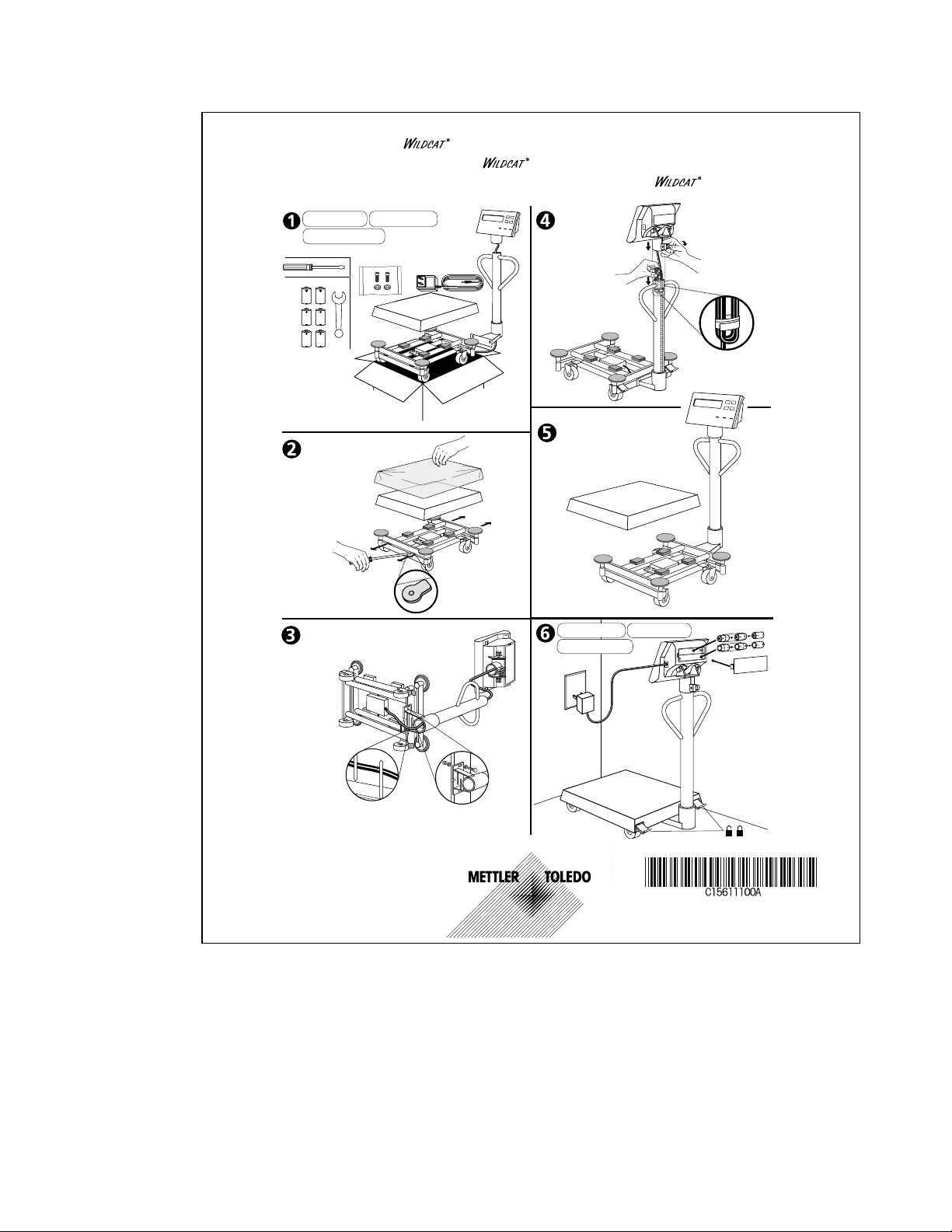

Assembly instructions for the WILDCAT scale are provided with the unit. A copy of these

instructions appears below and on the next page.

Báscula Portátil de Mesa Instrucciones Para Ensamblaje

Instructions D‘assemblage de la Bascule

Outils supplémentaires dont

vous pourriez avoir besoin

Wi

Scale Assembly Instructions

Chapter 2: Assembly Procedures

Assembly Instructions

Branchez le courant ou

utilisez 6 piles de taille D

© 2000 Mettler-Toledo, Inc.

Figure 2-1: Assembly instructions for Models WS30, WS60, and WS150

(12/00) 2-1

METTLER TOLEDO WILDCAT Scale Technical Manual

Outils supplémentaires dont

vous pourriez avoir besoin

Branchez le courant ou

utilisez 6 piles de taille D

“”

Enchufa o utilice seis

baterías tipo

“”D

Herramientas adicionales

que pudiese necesitar

Additional tools

you may need

Plug in or use

6 “D ” size batteries

Báscula Portátil de Mesa Instrucciones Para Ensamblaje

Instructions D‘assemblage de la Bascule

Scale Assembly Instructions

© 2000 Mettler-Toledo, Inc.

Figure 2-2: Assembly instructions for Models WW250 and WW500

(12/00) 2-2

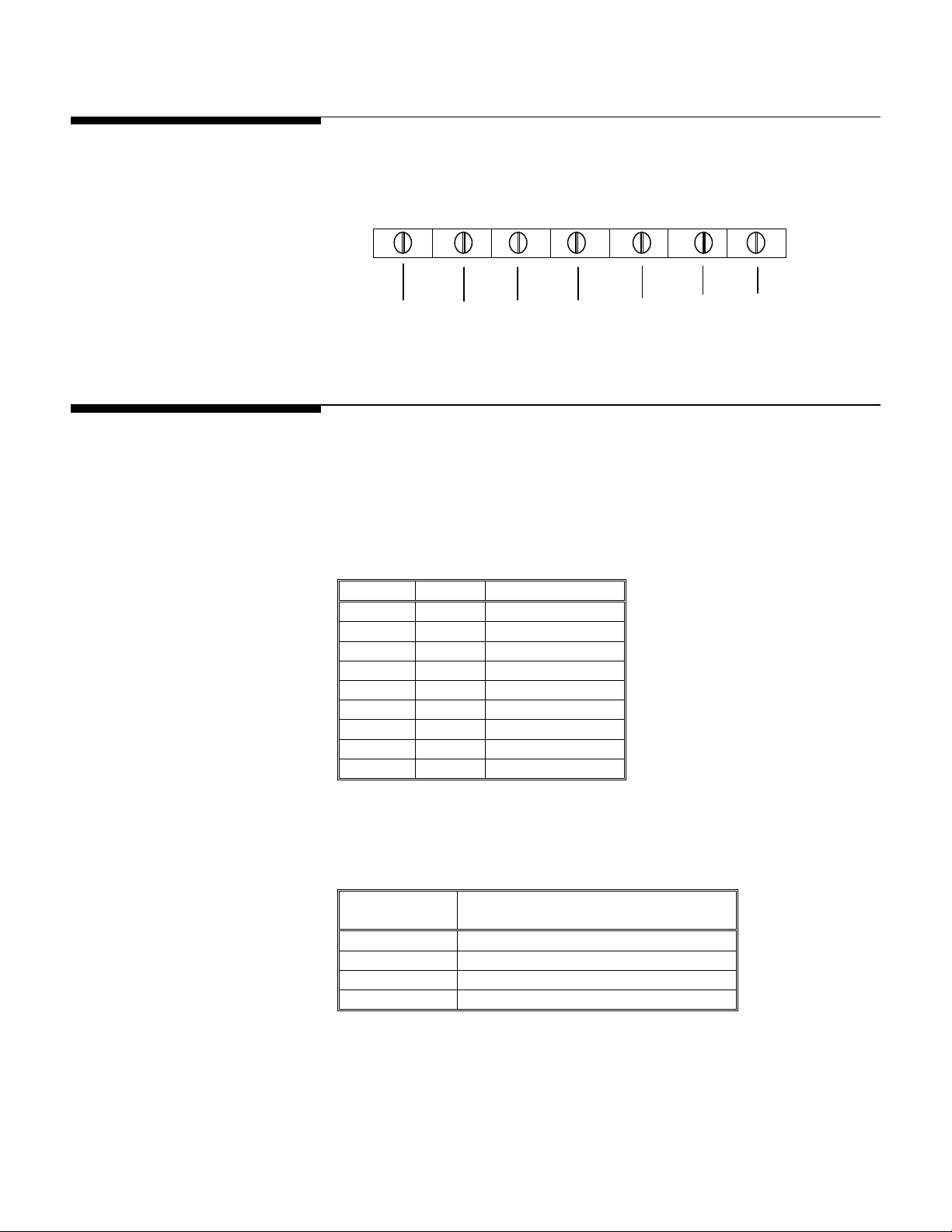

Load Cell Wiring

Figure 2-3 shows the load cell terminal strip wiring for the WILDCAT scale.

Serial Port Connections

The WILDCAT scale provides a bi-directional RS-232 port to be used to send data to or

receive commands from a computer, printer, or other serial device. The following chart

(Table 2-1) describes the pin configuration of the 9-pin D-Sub female connector on the

side of the terminal (indicator) of the WILDCAT scale. The maximum recommended

cable length for RS-232 is 50 feet (15 meters).

NOTE: Bi-directional capability

was added in version 2.0

software. Previous versions did

not provide ASCII input

commands.

Table 2-2 shows the ASCII commands that may be used to communicate with the

WILDCAT scale via the serial port. A more complete explanation is given in Appendix 3.

Chapter 2: Assembly Procedures

+EXC +SEN +SIG Shield -SIG -SEN -EXC

Green Blue Red Orange White Brown Black

Figure 2-3

Pin Signal Description

1 Not Connected

2 RxD Receive Data

3 TxD Transmit Data

4 Not Connected

5 Gnd Logic Ground

6 Not Connected

7 Not Connected

8 Not Connected

9 Not Connected

Table 2-1

ASCII

Function Performed in the WILDCAT Scale

Command

C Clear Tare

T Tare

P Print

Z Zero

Table 2-2

Load Cell Wiring

(12/00) 2-3

METTLER TOLEDO WILDCAT Scale Technical Manual

NOTES

(12/00) 2-4

Loading...

Loading...