Page 1

MODELS INCLUDED

• WB-10-12

• WB-10-60

Wilbur Curtis Company, inC.

Service Manual – WB-10 Water Boiler

Important Safeguards/Symbols

This equipment is designed for commercial use. Any servicing other

than cleaning and routine maintenance should be performed by an

authorized Wilbur Curtis Company service technician.

• DO NOT immerse the unit in water or any other liquid

• To reduce the risk of re or electric shock, DO NOT open service

panels. There are no user serviceable parts inside.

• Keep hands and other items away from hot areas of the unit dur-

ing operation.

• Never clean with scouring powders or harsh chemicals.

Symbols:

CAUTION: Please

use this setup

procedure before

attempting to use this

appliance. Failure to follow

the instructions can result in

injury or the voiding of the

warranty.

CAUTION: DO NOT

connect this unit

to hot water. The

inlet valve is not rated for hot

water.

WARNING: DO NOT

place this water

boiler closer than

six [6] inches from

wall. Unit must have adequate

cross-ventilation.

WARNING HOT

LIQUID, Scalding

may occur. Avoid

splashing.

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

INSTALLATION

This Curtis unit is pre-set and ready to go from the factory.

System Requirements:

• Water Supply 20 – 90 PSI (MINIMUM FLOW RATE of 2 GPM)*

• Electrical: See electrical schematic.

Factory Settings:

• Water Temperature 200ºF • Volume 10 Gallons

NSF requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) is required

so that the unit can be moved for cleaning.

2. This unit must be installed with adequate backow protection to comply with applicable

federal, state and local codes.

3. Water pipe connections and xtures directly connected to a portable water supply shall be

sized, installed and maintained in accordance with federal, state, and local codes.

SETUP STEPS

C

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO.

6913 Acco Street,

Montebello, CA 90640-5403

For the latest information go to

www.wilburcurtis.com

Tel: 800/421-6150

Fax: 323/837-2410

1. The unit should be level (left to right - front to back), on a secure surface.

2. Install the supplied water faucet on the faucet shank in front of the unit.

NOTE: A water ltration system must be used to help maintain trouble-free operation. In areas

with extremely hard water, we highly recommend the use of a Curtis approved water lter. (For

our full line of lters, please log on to www.wilburcurtis.com) A water ltration system will greatly

prolong the life of the unit and enhance the quality and taste of the product.

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO WWW.WILBURCURTIS.COM

Page 2

Setup Steps Continued

3. Connect the water line to the water inlet tting on the rear of the unit. Water volume going to the machine should be consistent.

Use tubing sized sufciently to provide a minimum ow rate of two gallons per minute.

4. Connect the unit to electrical outlet with appropriate amperage rating (refer to schematic for power requirements).

5. Turn on the circuit running power to unit. The water inlet valve will open, lling the unit. When the boiler has lled, turn on

boiler at the thermostat, twisting the knob clockwise.

6. Heating tank will require 50 to 60 minutes to attain operating temperature. Thermostat indicator will light at this time.

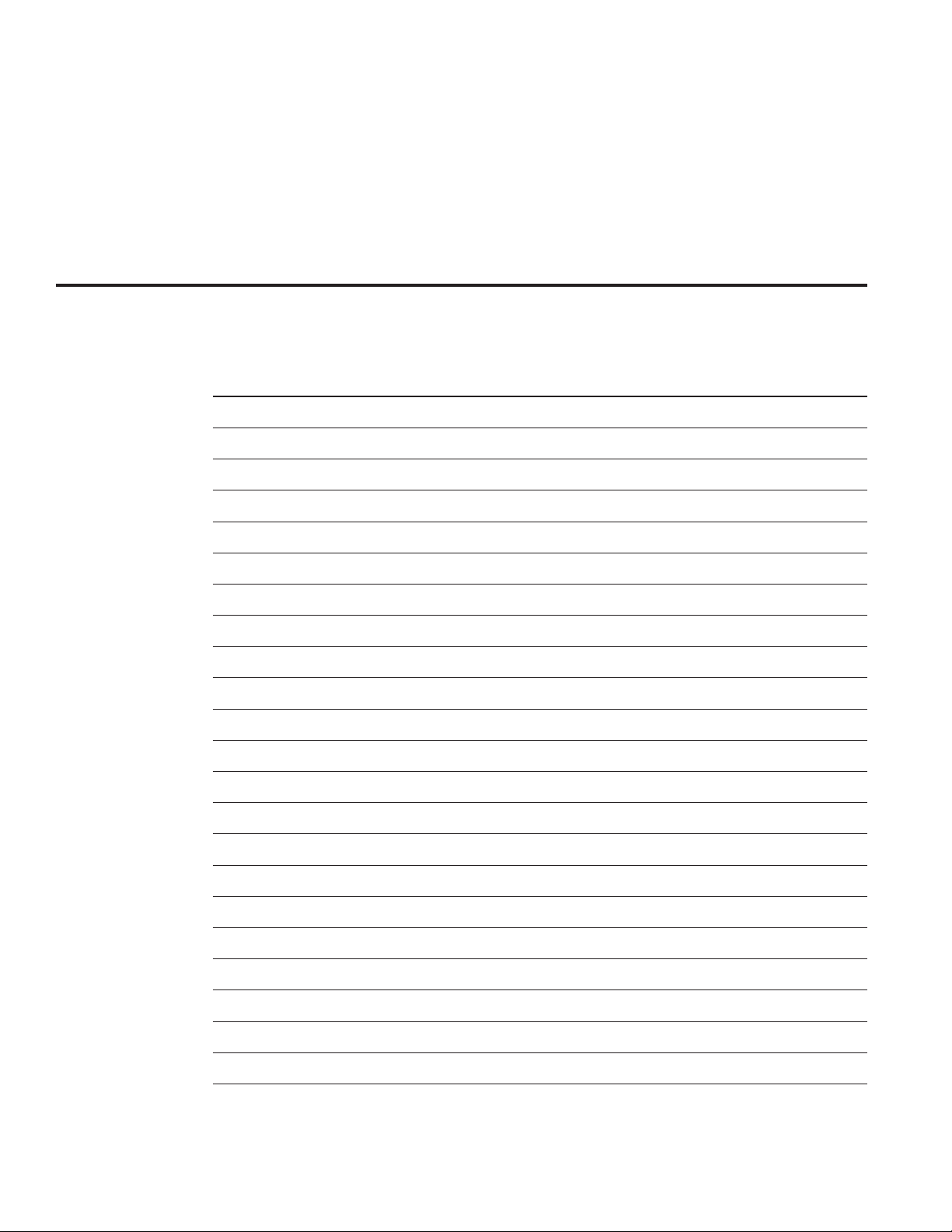

Parts List

INDEX №

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PART №

WC-5602

WC-1800HW

WC-3705HW

WC-1902

WC-1903

WC-1906

WC- 511

WC-5502-01

WC-3914

WC-2966

WC-5386

WC- 922-04

WC- 501

WC-3220

DESCRIPTION

LID WITH KNOB

FAUCET, “S” SERIES HOT WATER 1-1/32-14 UNS

KIT, FAUCET S SERIES HOT WATER

SHANK, FAUCET PLAIN W/NUTS

NUT, UNION SHANK WB-10

“C” RING .917 X .760 X .090

THERMOMETER, DIAL RU’S

KIT, PROBE, WATER LEVEL W/HEX FITTING, O-RING, NUT

LABEL, “HOT WATER” (WB-10)

FITTING, WATER INLET WB-10

TUBING ASSEMBLY, WATER INLET

ELEMENT, HEATING 3.5KW 220V W/NUTS & WASHERS

THERMOSTAT, CAPILLARY DPST 277V 30A RU/WB

BEZEL, THERMOSTAT ELECTRIC

15

16

17

18

19

19A

20

21

WC-3217

WC- 608-101

WC-5611

WC-2401

WC- 801

WC- 858

WC-3700

WC- 813

KNOB, ELECTRIC THERMOSTAT

CONTROL BOARD, LIQUID LEVEL 120/240VAC

COVER, BOTTOM WB-10

ELBOW, 3/8 NPT X 1/4 FLARE PLATED

VALVE, INLET BRASS .50 GPM 120V 10W WB-10-12

VALVE, INLET BRASS .50 GPM 220V 10W WB-10-60

KIT, INLET VALVE REPAIR

FLOW WASHER, .5 GPM .5” S45

2

Page 3

Illustrated Parts List

1

8

7

3

2

4

5

6

9

10

11

12

13

14

15

16

17

21

20

19

18

3

Page 4

TROUBLE SHOOTING

PROBLEM: WATER WILL NOT REFILL

POSSIBLE CAUSE

1. Water line closed or

clogged lter

Check the water system at your facility to make sure the line is open. Replace the water lter.

SOLUTION

2. Valve coil burned out

3. Grounded probe

4. Defective water level

control board

PROBLEM: WATER OVERFLOWING.

POSSIBLE CAUSE

1. Defective water inlet

valve

2. Liquid level probe

limed up

Turn machine off. Disconnect wires from water inlet coil terminals and connect a power cord to

the terminals. Plug cord into a 120V outlet and verify if water ows when plugged in and stops

when power is disconnected. If valve fails this test, replace valve.

When the water level gets below the probe tip, water should automatically rell the unit. If not, pull

wire off the probe terminal. Water should now start owing into the water boiler.

Disconnect wire from probe terminal. With a voltmeter, check voltage at the water inlet coil terminals. This should read 110-120 volts. If no voltage is present, check liquid level control (L.L.C.)

board. Make sure the L.L.C. board is supplied by 120V across terminals NEU and L1 120V. The

L.L.C. board is grounded to the body of the machine by contacting the board to the mounting

bracket. Make sure board is grounded here. Check for loose connections at terminals. Replace

the L.L.C. board.

Turn power off and observe water level. If water continues to ow into the heating tank, clean or

replace leaky valve.

Disconnect wire from probe terminal. Touch the body of the heating tank with the terminal at the end

of this wire. If the ow of water stops, there is and issue with the probe. Clean the probe and reconnect the wire. If water continues to ow, replace the liquid level probe.

SOLUTION

3. Non-grounded or loose

terminal connections

at liquid level control

board

PROBLEM: WATER DOES NOT REACH PROPER TEMPERATURE

POSSIBLE CAUSE

1. Thermostat is turned

OFF (or set too low)

PROBLEM: WATER OVERHEATS, ELEMENTS DO NOT SHUT OFF

POSSIBLE CAUSE

1. Defective thermostat

Liquid level control board must be securely grounded through the back of the board and the mounting bracket. Check for loose connections at the terminals. Check for voltage across the inlet valve

terminals. If there is 110 to 120 volts present at the inlet valve terminals when water level is touching

the probe tip, replace the L.L.C. board.

Check the thermostat adjustment to make sure the knob is rotated clockwise to the desired tem-

perature setting.

Replace the thermostat. You can sometimes operate temporarily by turning the thermostat knob

to off until the boiling stops.

SOLUTION

SOLUTION

4

Page 5

TROUBLE SHOOTING CONTINUED:

PROBLEM: WATER DOES NOT REACH PROPER TEMPERATURE

POSSIBLE CAUSE

2. Defective thermostat

3. Heating element burned

out.

Electric Thermostat

Adjustment

SOLUTION

Replace thermostat if contacts are open when knob is fully clockwise and water temperature

is less than 190º F. You will measure 120 volts (approximately) to ground from both thermostat

terminals when it is ON and from only one terminal when it is OFF.

In this water boiler there are two elements in parallel. Failure of either will cause very slow heating. Perform the following tests:

a. Clamp-on ammeter test: If both elements are good, you will measure about 21 amps at 240

volts, 24 amps at 208 volts or 29 amps at 120 volts. If you measure only 10 to 12 amps,

check the current to each element to identify the defective part.

b. Ohmmeter or continuity test: Disconnect all power by unplugging unit. Disconnect one

terminal to measure each element. They should each have continuity or measure about 20

ohms.

ELECTRIC THERMOSTAT ADJUSTMENT

On electric water boilers, thermostats are set at the factory to cut off at 200ºF. We do not

recommend changing this. If necessary, adjustment is as follows:

1. Rotate the thermostat knob to the right to the BOIL position. Pull off the knob.

2. Locate the tiny adjustment screw, inside the stem (see gure 1). Using a small screwdriver, adjust the temperature up or down:

a. By turning the screw ¼ turn to the left will increase the temperature about 20°F.

b. Turning ¼ to the right will decrease the temperature by 20°F.

c. To set the thermostat precisely at 200°F, insert a thermometer probe into the

water jacket through the steam hole (just under the sprayhead). Turn the screw ½

turn to the left.

d. When the thermometer reaches 200°F, slowly turn the adjustment screw to the

right until the pilot light turns off.

CLEANING

Regular cleaning and preventive maintenance is essential in keeping your water boiler looking and working like new. To clean the

water boiler, prepare a mild solution of dish detergent and warm water. Turn the thermostat dial to OFF and allow the unit to cool.

CAUTION – Do not use cleansers, bleach liquids, powders or any other substance containing chlorine. These products promote corrosion and will pit the stainless steel. USE OF THESE PRODUCTS WILL VOID THE WARRANTY.

DAILY CLEANING

1. Wipe exterior surfaces with a damp cloth, removing spills and debris.

2. Remove the lid and clean it with a cloth soaked in a mild detergent solution.

3. Rinse and dry the lid.

4. Wipe off any traces of the cleaning solution with a cloth dampened with water.

5. Dry the cabinet surfaces.

6. Rub a stainless steel polish on the outside surfaces to protect the cabinet.

5

Page 6

ELECTRICAL SCHEMATIC DUAL VOLTAGE 120V/220V

6

Page 7

ELECTRICAL SCHEMATIC 220V

7

Page 8

Product Warranty Information

The Wilbur Curtis Company certies that its products are free from defects in material and workmanship under normal use. The following limited

warranties and conditions apply:

3 Years, Parts and Labor, from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, ttings and tubing.

1 Year, Labor, from Original Date of Purchase on all electrical components, ttings and tubing.

Additionally, the Wilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds of coffee,

whichever comes rst. Stainless Steel components are warranted for two (2) years from date of purchase against leaking or pitting and replacement parts are warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty period of the equipment in which

the component is installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-0417. Effective

date of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty

does not cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or uctuating water ow rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation

in equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by

delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner

of the equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per

in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION: All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Support Department prior to performing any repair work or return of this equipment to the factory. All returned equipment must be repackaged

properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging. NO UNITS OR PARTS WILL

BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON

OR SHIPPING LABEL. All in-warranty service calls must be performed by an authorized service agent. Call the Wilbur Curtis Technical Sup-

port Department to nd an agent near you.

ECN 11526 . 7/26/13@9.0 . revF

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

8

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Printed in U.S.A. 7/2013 F-1984 Rev F

Loading...

Loading...