Wilbur Curtis TXSG0101S00 Service Manual

Wilbur Curtis Company, inC.

Service Manual – TXSG Server

Models Included:

TXSG0101S600 TXSG1501S600 TXSG0101S00 TXSG0101S600

WARNING – Thermopro servers may be heavy when lled.

Care must be taken when transporting to avoid dropping or spilling.

Use only coffee or water in the insulated dispenser. Do not use the ThermoPro server to dispense any

other beverage. Preheating is recommended.

1. Place a clean and empty server centered under one of the brewcones of your coffee brewer.

2. Make sure the screen reads READY TO BREW.

3. Fill brewcone with the correct measure of ground coffee for the intended volume of brewed coffee.

4. Select the brew button that matches the brew volume and press to brew into the coffee dispenser.

5. Allow coffee in the brewcone to drip completely before removing the insulated dispenser.

SERVICING THE THERMOPRO SERVER

1. Completely drain the unit of any coffee.

2. Allow server to cool.

3. Unscrew and remove the lid and tube assembly.

REPLACING THE GAUGE GLASS

The gauge glass can be removed for maintenance and cleaning. Refer to the illustration on page three [3] for assembly sequence.

1. Unscrew the vented cap plug from the top of the gauge glass shield.

2. Carefully lift out the gauge glass tube from the shield and scrub inside the glass with a tube cleaning brush and mild

detergent solution. Inspect the glass tube for cracks or chips. If broken, carefully remove all traces of glass and then insert

a new gauge glass tube.

3. Check the top and bottom washers that make the tube water tight. Clean the washers. Make sure they are not leaking.

Replace if necessary.

4. With the sight glass seated in the gauge glass shield, thread the cap plug onto the top of the shield. Do not overtighten.

REMOVING THE BASE & BOTTOM COVER

To replace the silicone elbow tting for repair or cleaning:

1. Remove the base assembly. Press down on the slide tab on the back side of the stand and lift off the

server section.

2. Turn the server upside down and take off the plastic bottom cover. This will reveal the silicone elbow

tting.

3. Remove the wire hose clamps by squeezing the wire ears together. While holding the clamp open,

loosen the soft silicone elbow from the liner drain pipe and the faucet shank and pull out elbow.

4. Check for leaks and replace with a new part if necessary.

5. Reverse these steps to assemble.

REMOVING THE FAUCET

The faucet will require periodic cleaning and maintenance.

1. Remove the faucet from the body of the server. Unscrew the large nut holding the faucet to the shank to

take off faucet.

2. Disassemble the faucet. Unscrew the bonnet from the body of the faucet.

3. Remove the faucet handle by pressing inward on the seat cup (see photo at right) then unhooking the

handle from the center shaft.

4. The seat cup, center shaft and spring will now separate from the bonnet. Clean these parts with a mild

detergent solution.

5. While you have these parts disassembled for cleaning, check the seat cup for tearing of splitting. Make sure

the faucet spring is free of corrosion. Replace these parts with repair kit if necessary (item 15, page 3).

ASSEMBLY

Assemble the unit by reversing the steps for disassembly. Finger tighten wing nut onto faucet. Make sure clamps are fastened prop-

erly and silicone ttings are in good condition. Once assembled, check for leaks around the tting and faucet.

1

Cleaning Instructions

CAUTION

Do not immerse in water.

Do not place in dishwasher.

Do not use harsh powders or cleansers containing chlorine.

These cleaning and sanitizing instructions are only a guide line to be used for the cleaning and sanitizing of the TLXS dispenser.

Your current in-house cleaning and sanitizing methods may be just as effective.

1. Daily – Rinse the unit between brews.

a. Rinse unit with hot water and empty completely.

b. Dry outside surfaces with a cleaning rag.

c. To preheat, ll the insulated server with hot water and allow it to heat before emptying hot water. The empty server is

` now ready for brewing.

2. Cleaning the lid assembly.

a. Unscrew the top lid from the insulated server and wash it in cleaning solution.

b. Using the supplied brush, clean inside the lling tube.

c. Rinse with clean water.

3. Cleaning and sanitizing body assembly.

a. Partially ll the insulated server with cleaning solution. Use a sponge brush to thoroughly clean inside liner.

b. Rinse the unit using a fresh water rinse.

c. Pour sanitizing solution into the insulated server. Allow to sit for 5 minutes then drain through the faucet.

d. Rinse by pouring water inside the unit, allowing rinse water to ow into a sink until water runs clear.

e. Wipe outside of unit with clean cloth moistened with a mild cleaning solution.

f. Place body assembly upside down on rack to thoroughly air dry.

4. Cleaning the faucet parts.

a. Remove faucet (see Removing the Faucet on page 1) and gauge glass from unit and brush out with cleaning solution.

b. Place in cleaning solution to soak for 5 minutes,

c. With the faucet removed, use the tube brush soaked in cleaning solution to insert through the faucet shank.

d. Rinse parts and dry.

5. Assemble parts that were removed.

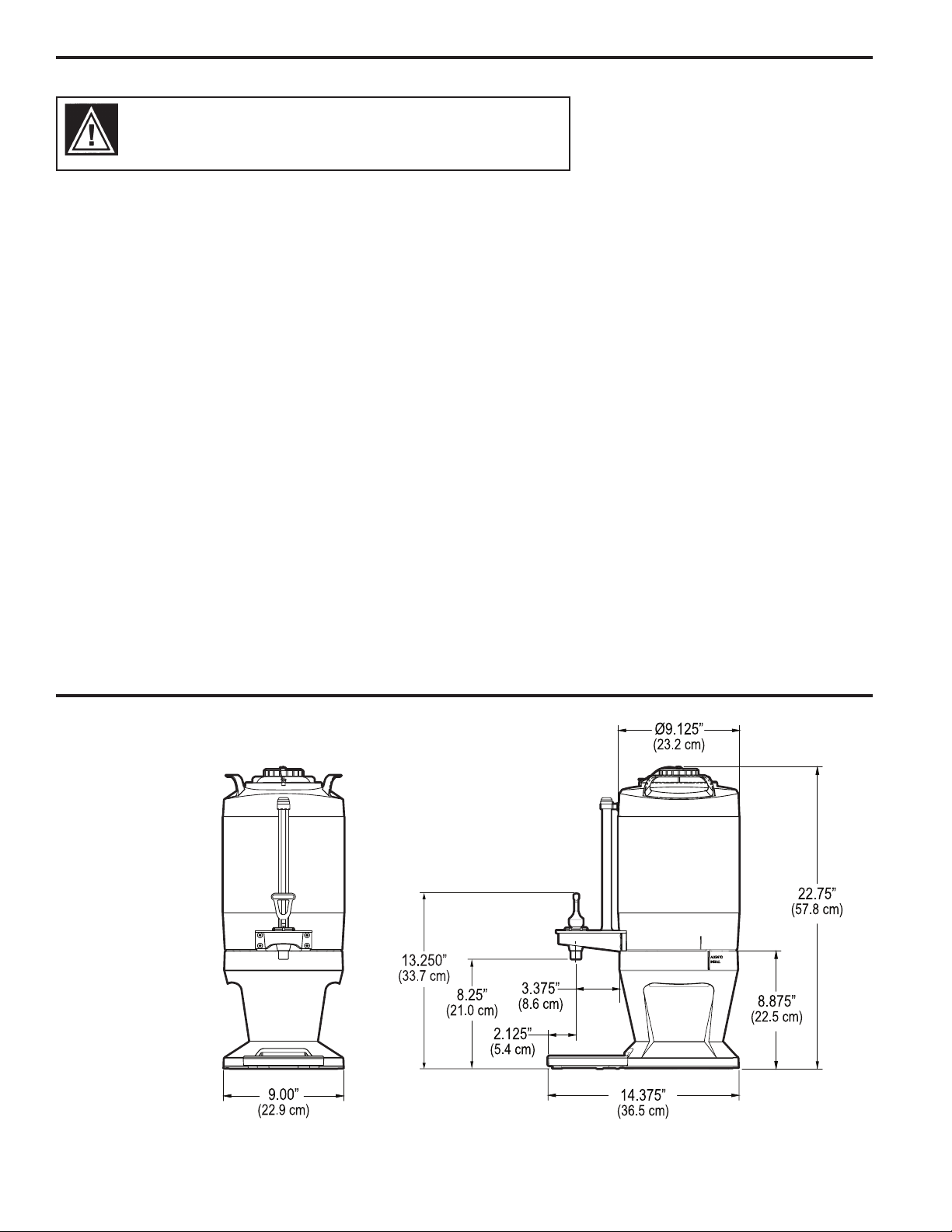

Rough-In Drawing

2

Loading...

Loading...