Page 1

WILBUR CURTIS COMPANY, INC.

TPS1S 1 Gallon Brewer Instructions

Models Included

• TPS1S

WARNING HOT

LIQUID, Scalding

may occur. Avoid

splashing.

CAUTION: Please use

this setup procedure

before attempting

to use this brewer. Failure to

follow the instructions can result

in injury or the voiding of the

warranty.

CAUTION: DO NOT

connect this brewer

to hot water. The inlet

valve is not rated for hot water.

Important Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance

should be performed by an authorized Wilbur Curtis service center.

•

• To reduce the risk of fire or electric shock, do NOT open top or front panel. There are no

user serviceable parts inside. Repair should be performed only by authorized service per-

sonnel.

•

•

Curtis GT Units are Factory Pre-Set and Ready to Go… Right out of the Carton.

Following are the Factory Settings for your TPS1S Coffee Brewing System:

• Brew Temperature = 200°F

• Brew Volume = Set to dispensing vessel requirements (1.0 gallon and .5 gallon)

Generally, factory settings will provide trouble-free operation. However, should you need to make

slight adjustments to meet your brewing needs, programming instructions are provided later in this

manual.

System Requirements:

• Water Source 20 – 90 PSI (Minimum Flow Rate of 1 GPM)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.com for

your model.

Equipment to be installed to comply with applicable federal, state, or local plumbing/electrical codes

having jurisdiction.

SETUP STEPS

The unit should be level (left to right and front to back), located on a solid counter top. Connect a

water line from the water filter to the brewer. NOTE: Some type of water filtration device must be

used to maintain a trouble-free operation. In areas with extremely hard water, we suggest that a

sedimentary and taste & odor filter be installed (such as Curtis filter CSC10AC00 or CSC15AC00).

This will prolong the life of your brewing system and enhance coffee quality.

Do NOT immerse the unit in water or any other liquid

Keep hands and other items away from hot parts of unit during operation.

Never clean with scouring powders, bleach, harsh chemicals or sharp implements.

Conventions:

WARNINGS – To help avoid personal injury Important Notes/Cautions

Sanitation Requirements

ISO 9001 REGISTERED

WILBUR CURTIS COMPANY

Montebello, CA 90640

The National Sanitation Foundation requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) so that

the machine can be moved for cleaning underneath.

2. In some areas an approved backflow prevention device may be required between the

brewer and water supply.

1. A 3/8” NPT compression elbow has been supplied for water line connection. Use tubing sized

sufficiently to provide a minimum of 1.0 GPM.

2. Connect the unit to an appropriate electrical power circuit.

3. Turn on the toggle (STANDBY/ON) switch behind the unit. The heating tank will start to fill.

When the water level in the tank rises to the correct volume, the heating elements will energize

automatically. With G3 brewers, element burnout caused by an empty tank is no longer a

problem.

4. The heating tank will require 20 to 30 minutes to reach operating temperature (200°F). This will

be indicated when the screen reads READY TO BREW .

5. Prior to brewing, dispense 12 ounces of hot water through the hot water faucet.

6. Run a brewcycle of at least 12 ounces to purge the water lines of any air that may be trapped

after filling.

1

Page 2

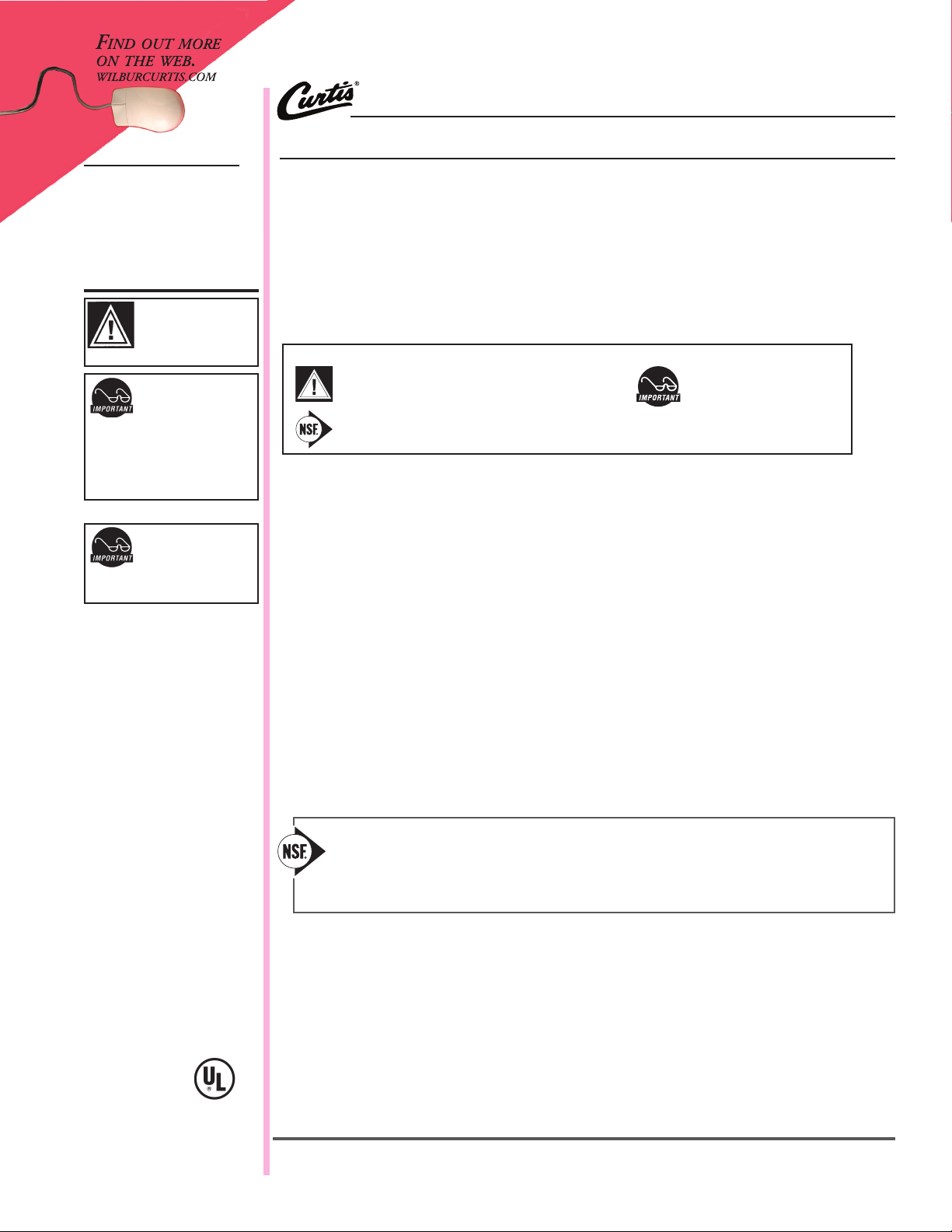

T-Pro Short

Twin

T-Pro Short

Singl

e

IMPORTANT NOTE:

All programming selections are performed with the three center buttons.

The symbols below the buttons are:

Scroll LEFT

SELECTION or ENTER to save new parameter

Scroll RIGH

T

2

Page 3

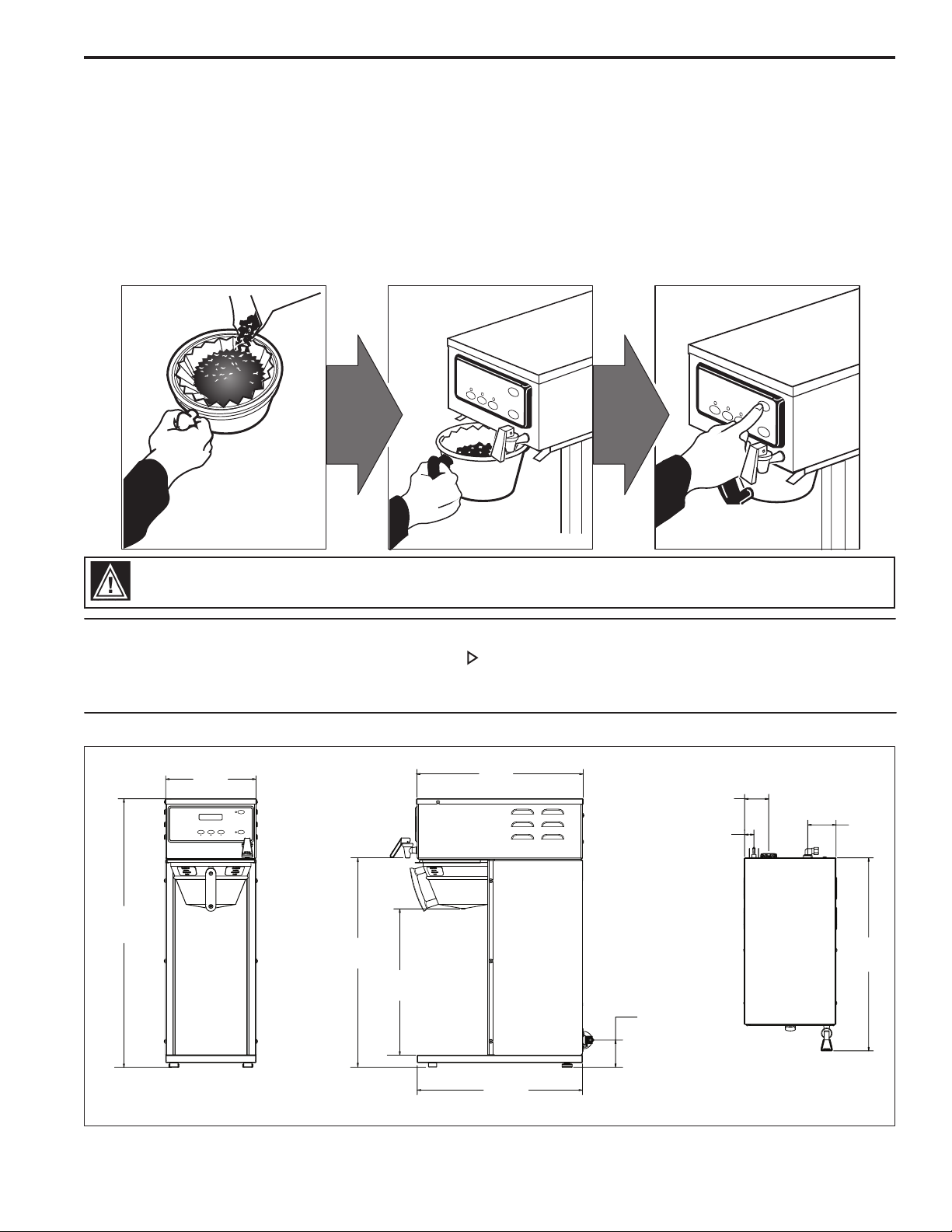

26.75"

(67.9 cm)

2.875"

(7.3 cm)

.875”

(2.2 cm)

2.375"

(6.0 cm)

19.25"

(48.9 cm)

20.875"

(53.0 cm)

2.75"

(7.0 cm)

16.625"

(42.2 cm)

16.5"

(41.3 cm)

14.625"

(37.1 cm)

9”

(47.2 cm)

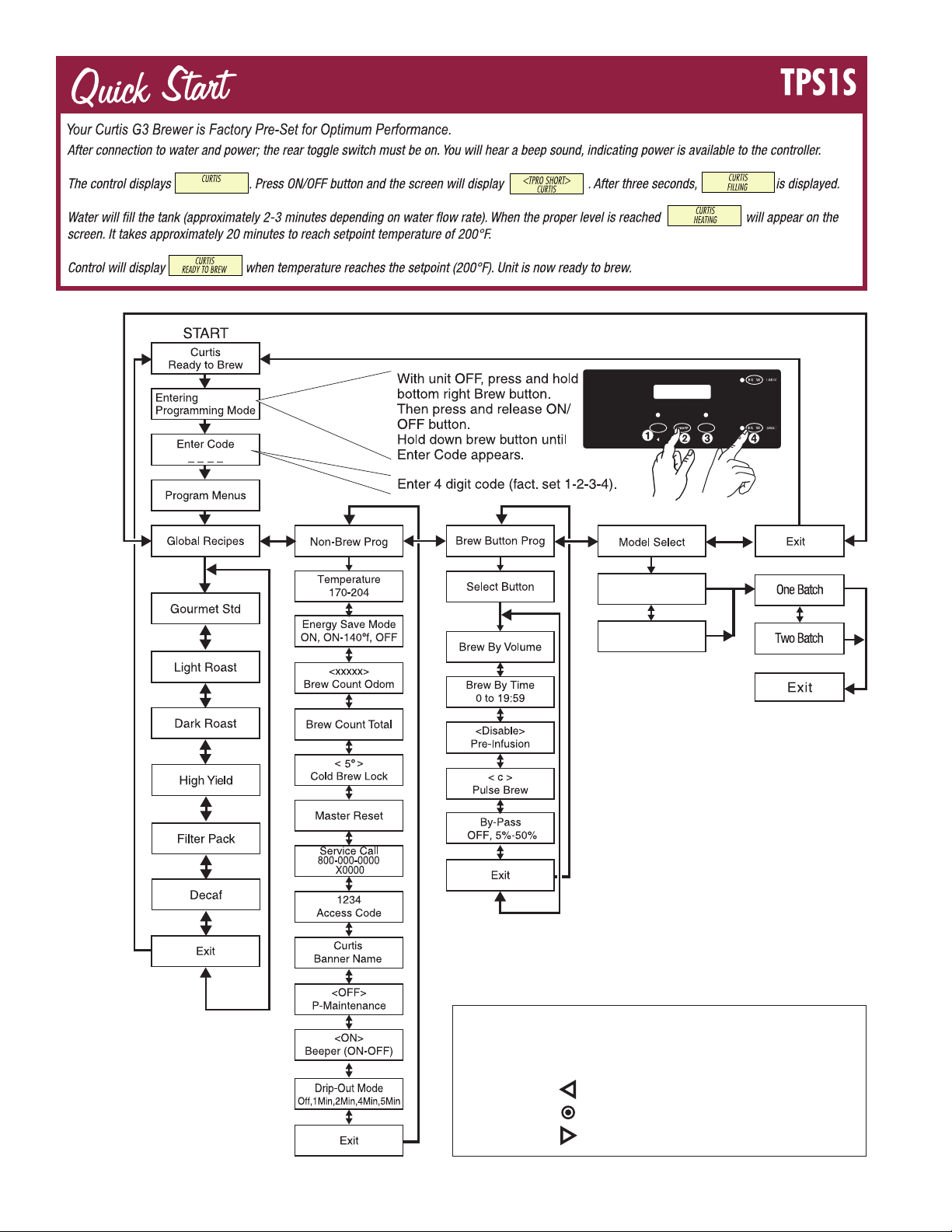

BREWING INSTRUCTIONS

Use only coffee or water in the ThermoPro dispenser. Do not use the server to dispense any other beverage. Preheating the server

with hot water is recommended.

1. Place a clean and empty server on the deck. Server should be centered below the brewcone of the brewer.

2. Make sure the brewer is up to temperature and the screen reads READY TO BREW.

3. Place a filter in the brewcone and pour in the correct measure of ground coffee for the brew volume.

4. Slide the brewcone into the brew rails.

5. Select and press desired brew button.

6. Allow coffee in the brewcone to out drip completely before removing the insulated server.

INSERT BREW

CONE INTO

RAILS

POUR COFFEE

INTO BASKET

PRESS BREW

BUTTON

WARNING – THERMOPRO SERVERS MAY BE HEAVY WHEN FILLED.

CARE MUST BE TAKEN WHEN TRANSPORTING TO AVOID DROPPING OR SPILLING

.

Tank Temperature Check

When brewer is on and Ready to Brew is displayed, press and hold button (see illustration, page two) for 5 seconds. The water temperature

inside the tank will be displayed.

ROUGH-IN DRAWING

3

Page 4

PARTS DIAGRAMS

TPS1S

32

17

1

2

3

4

5

6

7

8

9

10

11

34

12

13

33

14

15

29

30

31

18

19

20

21

22

23

24

16

25

26

27

28

4

Page 5

PARTS LIST TPS1S

PHASE:

WIRES:

AMPERAGE:

WATTAGE:

HERTZ:

VOLTAGE:

REVISION:

PART NUMBER

:

TITLE:

1 PHASE

3W + G

SEE TABLE

50/60 HZ

SEE TABLE

120 / 220V (DV)

A

LADDER DIAGRAM

LD-TPS1S-SSR-63

4 USE THIS DIAGRAM FOR ALL OTHER MODELS WITH ADDED PREFIX

1. NOTE REMOVE

D

2. INST

ALL GROUND LUG OVER THE SENSOR ON TANK SENSOR STUD.

3. LOCATE MATED CONNECTORS AWAY FROM HEAT

.

LETTERS AND/OR SUFFIX NUMBERS ON THEIR PART NUMBERS HAVING

THE SAME ELECTRICAL RATINGS.

NOTES: UNLESS OTHERWISE SPECIFIED

Ex.: SCTPS1S63.

5 12GA WHT WIRE IS ONLY USED WHEN UNIT IS TO BE USED IN THE 120V

AC

CONFIGURATION

.

20 = BREW VALVE LEFT

LEGEND

SSR PIN ASSIGNMENTS

-

3

1

+

4

2

2 = COMMON - SOLID STAT

E

11 = SENSOR WARMER RIGHT

8 = WARMER LEFT

18 = 120VAC HOT

17 = 120VAC RETURN

15 = GROUND CHASSIS

16 = WATER LEVEL PROB

E

9 = WARMER RIGHT

10 = BYPASS VA

LVE LEFT

14 = SENSOR COMMON

13 = SENSOR TANK

12 = SENSOR WARMER LEFT

19 = BREW VALVE RIGHT

7 = BYPASS VALVE RIGHT

PIN ASSIGNMENT (20 PIN

)

6 = INLET

VALVE

4 = SOLENOID LOCK RIGHT

5 = SOLENOID LOCK LEFT

RELAY & GRINDE

R

1 = GRINDER

UNIVERSAL CONTROL MODUL

E

3 = +5 VDC

AC OUTPUT

DC INPUT

USE .187

TERMINAL LU

G

ELEMENTS

HEATING

TPS1S

(W

ATTS)

TOTA

L

POWER

CURRENT

(AMPERES)

TOTA

L

-63 120/220

1650/2700

13.8/12.3

1x 1.6KW/2x 1.6KW

(H1,H2)

ELECTRICAL RATING TABLE

3

1

4

2

11

15

9

13

7

19

6

G

L1

N

L2

16

14

18

17

4

3

2

1

H2

H1

UNIVERSAL CONTROL MODULE

HEATING

T°

SENSOR

SENSOR STUD

TANK GROUND

(WHT)

TA

NK

TA

NK

1

STP VIO

VIO

YEL

GRN

STP YEL

5W/120V

.5 GPM 12W/120V

.5 GPM 12W/120V

2.0 GPM 10W/120V

220°F

THERMOSTAT

MAN. RESET

DPST

40A/277V

(WHT)

PROBE

BLK

2

COMMON STUD

CHASSIS GROUND

25A/125-250V

TOGGLE SW.

SPST

GRN/12GA

BLK

C

POWER BLOCK

57-65A/300-450V

RED/12GA

BLK/12GA

.47MF

C1

275VAC

WHT/12GA

WHT

STP GR

Y

GRY

STP YEL

ORG

WHT/12GA

BLU/12GA BLK/12GA

RED/12GA

BYPASS

VALV

E

BREW

VALV

E

INLET

VALV

E

WHT

WHT

WH

T

5

WHT

40A/600V

SOLID STATE RELAY

314

2

GRY

STP GR

Y

+-

Item Nº Part Nº

1

WC-58117

2

WC-29047

3

WC-5502

4

WC-29048

5

WC-4394

6

WC-43055

7

WC-1438-101

8

WC-61556

9

WC-43068

10

WC-62037

WC-2959-101

11

12

WC- 904-04

13

WC- 522*

14

WC- 844-01

15

WC-37122

16

WC-2977-101

17

WC-8559

18

WC- 723-101

Description

COVER, TOP

ELBOW, OVERFLOW PLASTIC

PROBE, WATER LEVEL

FITTING, STRAIGHT PLASTIC

GUARD, SHOCK HEATING ELEMENT

GUARD, SHOCK RESET THERMOSTAT

SENSOR, HEATING TANK

COVER, TANK

GASKET, TANK LID

TANK COMPLETE TPS1S

FITTING, STRAIGHT PLASTIC 12MM

ELEMENT, HEATING 1.6KW 120V W/JAM NUT

THERMOSTAT, HI LIMIT

VALVE, BY-PASS, NON-ADJUSTABLE W/RSTRCTR

KIT, DUMP VALVE RIGHT

FITTING, SPRAYHEAD ULTEM

RELAY, SOLID STATE 40A W/HEAT SINK

CONTROL MODULE, 120V TPS1S

HTR DPST 277V 40A

Item Nº Part Nº

WC-39580

19

WC-39585

19A

WC-38439

20

WC-1809

21

WC- 102*

22

WC-8591*

23

WC- 847*

24

WC-29050

25

WC-2805

26

WC-3518

27

WC-3503

28

WC-61551

29

WC-3357

30

WC-3765L*

31

WC-37132*

32

WC-5231*

33

WC-5310*

34

Description

LABEL, UCM OVERLAY 2-BATCH

LABEL, UCM OVERLAY 1-BATCH

LABEL, FRONT HOT WATER

FAUCET, HOT WATER W/JAMNUT

SWITCH, TOGGLE 125/250 VAC RESISTIVE

CAPACITOR, X2

VALVE, INLET 2GPM

SPRAYHEAD, AMBER ADVANCED FLOW

ELBOW, COMPRESSION 3/8 NPT X 3/8 O.D.

LEG, GLIDE 3/8-16 STUD SCREW

LEG, 3/8-16 STUD SCREW (NON-GLIDE)

COVER, FRONT SS TPS1S

BREWCONE W/HANDLE (STD CAPACITY)

KIT, VALVE REPAIR USE ON WC-847

KIT, VALVE REPAIR USE ON WC-844WDR

COMPOUND, SILICONE 5 OZ TUBE

TUBING, SILICONE, 5/16” I.D. ( 1 FT.)

ELECTRICAL SCHEMATIC

5

Page 6

CLEANING

Regular cleaning of your TPS1T coffee brewer will maintain the highest quality coffee your equipment is capable of producing.

Proper cleaning is essential to maintain that fresh, appealing look to your coffee service.

1. First turn off the brewer using the ON/OFF button on the front control panel.

2. Wipe all exterior surfaces with a damp cloth, removing spills and debris.

3. Slide the brewcone out and clean it. Thoroughly wipe sprayhead area with a damp cloth.

4. Wash the brewcone and wire brew basket, if applicable. Use a soft bristled brush for hard to clean areas. Wash both parts with a

detergent

CAUTION

Do not use harsh powders or cleansers containing chlorine.

solution or put these parts through a dishwasher.

Cleaning and Sanitizing Instructions for TLXG01 Server

CAUTION

Do not immerse server in water.

Do not place in server dishwasher.

Do not use harsh powders or cleansers containing chlorine.

Do not use a wire brush or pot scourer to clean inside liner.

These cleaning and sanitizing instructions are only a guide line to be used for the cleaning and sanitizing

of the TLXG01. Your current in-house cleaning and sanitizing methods may be just as effective.

For cleaning and sanitizing of the TLXG01, the three sink method is recommended. This method consists

of a sink of water filled with a detergent and water solution, a fresh water rinse, and a sink filled with an

aqueous sanitizing solution. Immerse parts in commercial BarTabs/Sani-Tabs sanitizing solution. The solu

tion must be warm (75°F.) Let the parts soak at least one minute.

-

1. Daily, Rinse the unit after use.

a. Rinse unit with hot water and empty completely.

b. Fill unit with hot water.

c. Open unit and empty contents completely.

2. Clean and sanitize the lid assembly.

a. Remove lid from unit and submerse it in cleaning solution, cleaning thoroughly.

b. Using the supplied brush, clean inside the filling tube.

c. Rinse with clean water.

d. Submerse in sanitizing solution for 5 minutes then air dry completely.

3. Cleaning and sanitizing body assembly.

a. Completely fill the unit with cleaning solution. With a sponge brush, thoroughly clean inside liner.

b. Rinse the unit using a fresh water rinse.

c. Fully fill unit with sanitizing solution. Allow to sit for 5 minutes then drain through the faucet.

d. Remove faucet and gauge glass from unit and brush out with cleaning solution.

e. With the faucet removed, clean the silicone elbow fitting (Tank to Faucet Tube). Use the tube brush soaked in cleaning

solution, inserted

sink until water runs clear.

f. Wipe outside of unit with clean cloth moistened with cleaning solution.

g. Place body assembly upside down on rack to thoroughly air dry.

4. Cleaning the faucet parts.

a. Unscrew the bonnet/handle assembly from the faucet and disassembly removing spring, seat cup and shaft.

b. Clean and rinse parts. Place in sanitizing solution for 5 minutes, remove and air dry,

5. When all pieces are completely dry reassemble for use.

through the faucet shank. Rinse by pouring water from inside the unit, allowing rinse water to flow into a

6

Page 7

7

Page 8

Product Warranty Information

The Wilbur Curtis Company certifies that its products are free from defects in material and workmanship under normal

use. The following limited warranties and conditions apply:

3 Years, Parts and Labor, from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, fittings and tubing.

1 Year, Labor, from Original Date of Purchase on all electrical components, fittings and tubing.

Additionally, the Wilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds

of coffee, whichever comes first. Stainless Steel components are warranted for two (2) years from date of purchase against leaking

or pitting and replacement parts are warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty

period of the equipment in which the component is installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-

0417. Effective date of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for

substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The

warranty does not cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all

local electrical, mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating

water flow rate.

5) Adjustments and cleaning:

The resetting of safety thermostats and circuit breakers, programming and temperature

adjustments are the responsibility of the equipment owner. The owner is responsible for proper cleaning and regular

maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be

made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for

variation in equipment operation due to excessive lime or local water conditions. The equipment must be maintained accord ing to the manufacturer’s recommendations.

8) Replacement of items subject to normal use and wear:

rings, gaskets, silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and

whipper propellers.

9) Repairs and/or Replacements

are subject to our decision that the workmanship or parts were faulty and the defects showed

up under normal use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of

the owner. Charges incurred by delays, waiting time, or operating restrictions that hinder the service technician’s ability to

perform service is the responsibility of the owner of the equipment. This includes institutional and correctional facilities.

The Wilbur Curtis Company will allow up to 100 miles, round trip, per in-warranty service call.

to view the full product warranty information.

This shall include, but is not limited to, light bulbs, shear disks, “0”

RETURN MERCHANDISE AUTHORIZATION:

All claims under this warranty must be submitted to the Wilbur Curtis Company

Technical Support Department prior to performing any repair work or return of this equipment to the factory. All returned equipment must be repackaged properly in the original carton. No units will be accepted if they are damaged in transit due to improper

packaging. NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA

NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL. All in-warranty service calls must be performed by an

authorized service agent. Call the Wilbur Curtis Technical Support Department to find an agent near you.

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

8

3/29/7 . 8.1 . edr 5027

Printed in U.S.A. 3/07 F-3554 Rev NC

Loading...

Loading...