Page 1

IND OUT MORE

F

FIND OUT MORE

ON

THE WEB.

ON

THE WEB.

WILBURCURTIS.COM

WILBURCURTIS.COM

Models Included

TP2S

WARNING HOT LIQUID,

Scalding may occur.

Avoid splashing.

WILBUR CURTIS COMPANY, INC.

Service Manual – ThermoPro Single Head Brewer

Important Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance should be performed by an

authorized Wilbur Curtis service center.

• Do NOT immerse the unit in water or any other liquid

• To reduce the risk of fire or electric shock, do NOT open top or side panels. No user serviceable parts inside. Repair

should be done only by authorized service personnel.

• Keep hands and other items away from hot parts of unit during operation.

• Never clean with scouring powders, bleach or harsh implements.

Conventions

CAUTION: Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions can result in injury or

the voiding of the warranty.

IMPORTANT:

Equipment to be

installed to comply with

applicable federal, state, or local

plumbing/electrical codes having

jurisdiction.

CAUTION: DO NOT

connect this brewer to

hot water. The inlet valve

is not rated for hot water.

WARNING TO AVOID

SCALDING, Do not

remove brewcone while

brew light is flashing.

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

This Curtis Generation 3 Unit is Factory Pre-Set and Ready to Go… Right from the Carton.

Following are the Factory Settings for your G3 Coffee Brewing Systems:

• Brew Temperature = 200°F • Water Bypass = On for LARGE (35%) MEDIUM (10%) SMALL (0%)

• Brew Volume = Set to Vessel Requirement. • Sleep Mode = Off

System Requirements:

• Water Source 20 – 90 PSI (Minimum Flow Rate of 1 GPM)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.com for your model.

SETUP STEPS

The unit should be level (left to right and front to back), located on a solid counter top. Connect a water line from the water filter

to the brewer. NOTE: Some type of water filtration device must be used to maintain a trouble-free operation. (In areas with

extremely hard water, we suggest that a sedimentary and taste & odor filter be installed.) This will prolong the life of your brewing

system and enhance coffee quality.

The National Sanitation Foundation requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) so that the machine can be moved

for cleaning underneath.

2. In some areas an approved backflow prevention device may be required between the brewer and the water supply.

1. A 3/8” NPT x 3/8” Flare elbow has been supplied for water line connection. Use tubing sized sufficiently to provide a

minimum of 1.0 GPM.

2. To hookup the InterLock grinder, Locate the jack labeled “Class 2 Wiring Only” on brewer and grinder. Connect the two with

the cable plug.

3. Connect the unit to an appropriate electrical power circuit.

4. Turn on the toggle (STANDBY/ON) switch behind the unit. The heating tank will start to fill. When the water level in the

tank rises to the correct volume, the heating elements will energize automatically. With ADS Systems there is no danger

of element burnout caused by an empty tank.

5. The heating tank will require 20 to 30 minutes to reach operating temperature (200°F) as indicated by the READY-TOBREW indicator.

6. Prior to brewing, dispense 12 ounces of hot water through the hot water faucet.

7. Brew a cycle of at least 12 ounces, to purge the water lines of any air that may be trapped after filling.

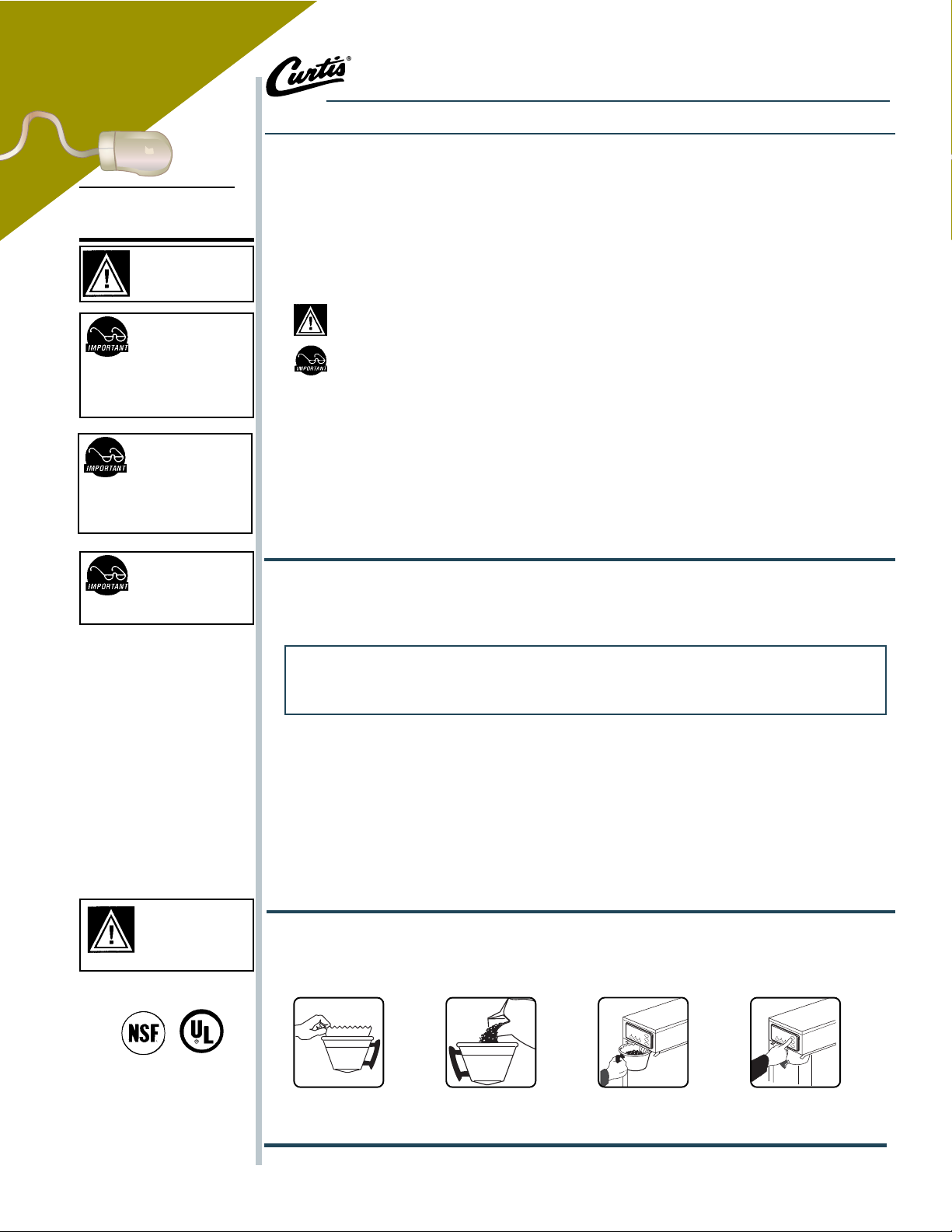

BREWING INSTRUCTIONS

1. Brewer should be ON (Confirm at rear toggle switch, then press the ON/OFF button). Ready-to-Brew should be ON. If

connected to an InterLock grinder, grinder should be on. If Interlocked, grind coffee at this time.

2. Place an empty ThermoPro server under the brewcone.

ISO 9001 REGISTERED

WILBUR CURTIS COMPANY

Montebello, CA 90640

3. Place a clean filter

into the brewcone.

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO

4. Fill brewcone with

ground coffee.

W W W.WILBU RC URTIS.COM

5. Transfer filled

brewcone to

brewer.

6. Press Brew button.

Brewing will begin

immediately.

1

Page 2

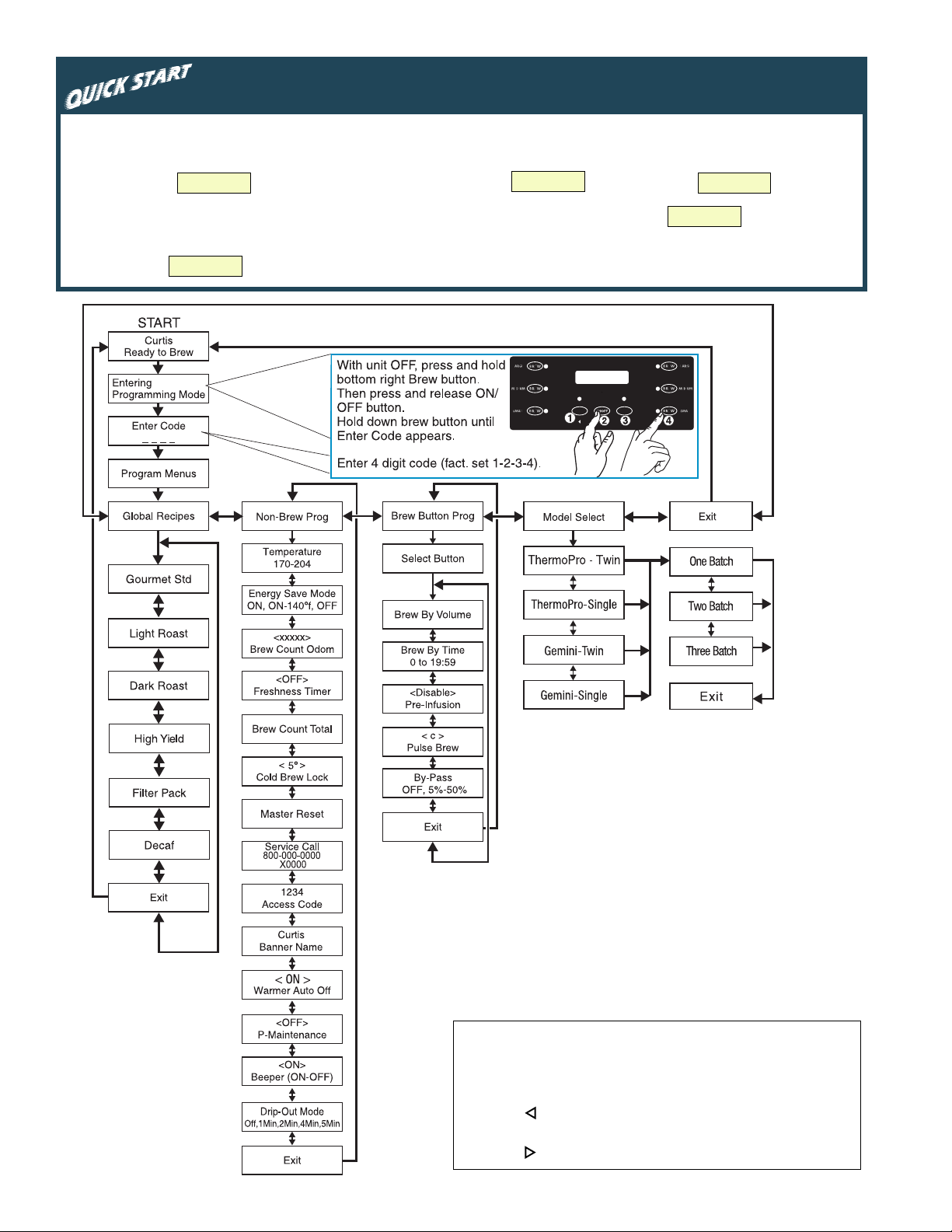

ThermoPro

Your Curtis ADS System is Factory Pre-Set for Optimum Performance.

After connection to water and power; the rear toggle switch must be on. You will hear a beep sound, indicating power is available to the controller.

The control displays . Press ON/OFF button and the screen will display . After three seconds, is displayed.

CURTIS

T-PRO 1

CURTIS

Water will fill the tank (approximately 2-3 minutes depending on water flow rate). When the proper level is reached will appear on the

screen. It takes approximately 20 minutes to reach setpoint temperature of 200°F.

Control will display when temperature reaches the setpoint (200°F). Unit is now ready to brew.

CURTIS

READY TO BREW

CURTIS

HEATING . . .

CURTIS

FILLING . . .

IMPORT ANT NOTE:

All programming selections are performed with the three center buttons.

The symbols below the buttons are:

Scroll LEFT

SELECTION or ENTER to save new parameter

2

Scroll RIGHT

Page 3

Illustrated Parts List

Nº Part Nº Description

1

WC-61509

GEM-6-01

2

GEM-6

2A

3

WC--3765L*

WC- 844-101*

4

WC-39444

2

6

D

E

F

5

5A

WC-39417

WC-39416

5B

WC-3354

6

6A

WC-3357

WC-29050*

7

WC-58037-101

8

9

WC- 847*

WC-1501

10

WC-37122*

11

12

WC-37132*

WC-1825

13

WC-8559*

14

14A

WC-8556-101

WC-8591*

15

WC-3526

16

17

WC-5350*

WC-5851

18

WC-5502*

19

20

WC-4382

WC-5310*

21

WC- 904-04

22

22A

WC- 906-04*

WC- 522*

23

WC-61500

24

24A

WC-61505

WC- 102*

25

WC-5231*

26

27

WC-1438-101*

WC-37176

28

WC-43055

29

COVER, TOP WRAP

FILTERS, 12½” X 4” 500/PKG (FOR WC-3354)

FILTERS, 500/PKG (USE WITH WC-3357)

KIT, VALVE REPAIR USE ON WC-825 & WC-826

VAL VE, ADJ BY-PASS

LABEL, UCM OVERLAY TP2S 3-BATCH CURTIS

LABEL, UCM OVERLAY TP2S 1-BATCH CURTIS

LABEL, UCM OVERLAY TP2S 2-BATCH CURTIS

BREWCONE ASSY, GOURMET LARGE CAP

BREWCONE ASSY W/BASKET (NOT SHOWN)

SPRAYHEAD ASSY, ADVANCED FLOW

COVER, CENTER WRAP

VALVE, WATER INLET 2GPM 120V 10W

FUSE HOLDER W/5A FUSE

KIT, DUMP VALVE BREW RIGHT

KIT, DUMP VALVE WC-820WC-821,WC-844

FAUCET ASSY, HOT WATER TP2S/2T

RELAY, SOLID STATE 40A W/HEAT SINK

HEATSINK, ASSY W/OPTICAL BD (OLDER UNITS)

CAPACITOR, X2

LEG, ADJUSTABLE 4 IN ASSY

TUBE, ½ ID x 1/8W SILICONE

COVER, TANK W/KNOTCHES

PROBE, WATER LEVEL

GUARD, SHOCK HEATING ELEMENTS

TUBE, 5/16” I.D. X 1/8” SILICONE (NOT SHOWN)

ELEMENT, HEATING 1.6KW 120V W/JAM NUTS

ELEMENT, HEATING 2KW 220V W/JAM NUTS

THERMOSTA T, RESET

TANK ASSY, COMPLETE 120V 3.2KW

TANK ASSY, COMPLETE 220V 4.0KW

SWITCH, TOGGLE

COMPOUND, SILICONE

SENSOR, HEATING TANK

KIT, UCM & LABEL INSTRUCTIONS

GUARD, SHOCK RESET THERMOSTAT

* Recommended Parts to Stock

28

3

D

11

12

E

C

26

27

C

3

Page 4

Electrical Diagram

ThermoPro Single – 220 Volt

4

Page 5

ThermoPro Single – 220 Volt

SEE ECN-7023 FOR RESIVIONS

7023

A

SJ

5

Page 6

Product Warranty Information

The Wilbur Curtis Company certifies that its products are free from defects in material and workmanship under normal use. The following limited warranties

and conditions apply:

3 Y ears, Parts and Labor , from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, fittings and tubing.

1 Y ear , Labor , from Original Date of Purchase on all electrical components, fittings and tubing.

Additionally, the W ilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds of coffee, whichever

comes first. Stainless Steel components are warranted for two (2) years from date of purchase against leaking or pitting and replacement parts are

warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty period of the equipment in which the component is

installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-0417. Effective date

of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company , Inc., assumes no responsibility for substitute replacement

parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty does not

cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating water flow rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation in

equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner . Charges incurred by delays,

waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner of the

equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per in-warranty

service call.

RETURN MERCHANDISE AUTHORIZA TION: All claims under this warranty must be submitted to the Wilbur Curtis Company Technical Support

Department prior to performing any repair work or return of this equipment to the factory . All returned equipment must be rep ackaged properly in

the original carton. No units will be accepted if they are damaged in transit due to improper packaging. NO UNITS OR PARTS WILL BE AC-

CEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CART ON OR

SHIPPING LABEL. All in-warranty service calls must be performed by an authorized service agent. Call the Wilbur Curtis T echnical Support

Department to find an agent near you.

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

6

Web Site: www.wilburcurtis.com

Printed in U.S.A. 9/06 F-3316-S Rev C

Loading...

Loading...