Page 1

FIND OUT MORE

ON

THE WEB.

WILBURCURTIS.COM

W

ILBUR CURTIS COMPANY, INC.

SERVICE MANUAL – MODEL TLXG0201S000

USING THE THERMOPRO SERVER

WARNING – THERMOPRO SERVERS MAY BE HEAVY WHEN FILLED. CARE MUST BE TAKEN

WHEN TRANSPORTING TO AVOID DROPPING OR SPILLING.

Use only coffee or water in the insulated dispenser. Do not use the airpot to dispense any other beverage.

Preheating the airpot is recommended.

1. Place a clean and empty server centered under one of the brewcones of the ThermoPro brewer.

2. Make sure the READY TO BREW indicator is lit.

3. Fill brewcone with the correct measure of ground coffee.

4. Press the desired brew button on the side of the brewer with the empty airpot. The ThermoPro airpot

employs the Curtis Brew-Thru lid and it is not necessary to remove the top lid before brewing.

5. Allow the brewcone to completely drip before removing airpot for remote service.

SERVICING AIRPOT/THERMOPRO SERVER

Completely clear the unit of any coffee by opening the faucet to drain over a sink. Unscrew and remove the lid

and tube assembly.

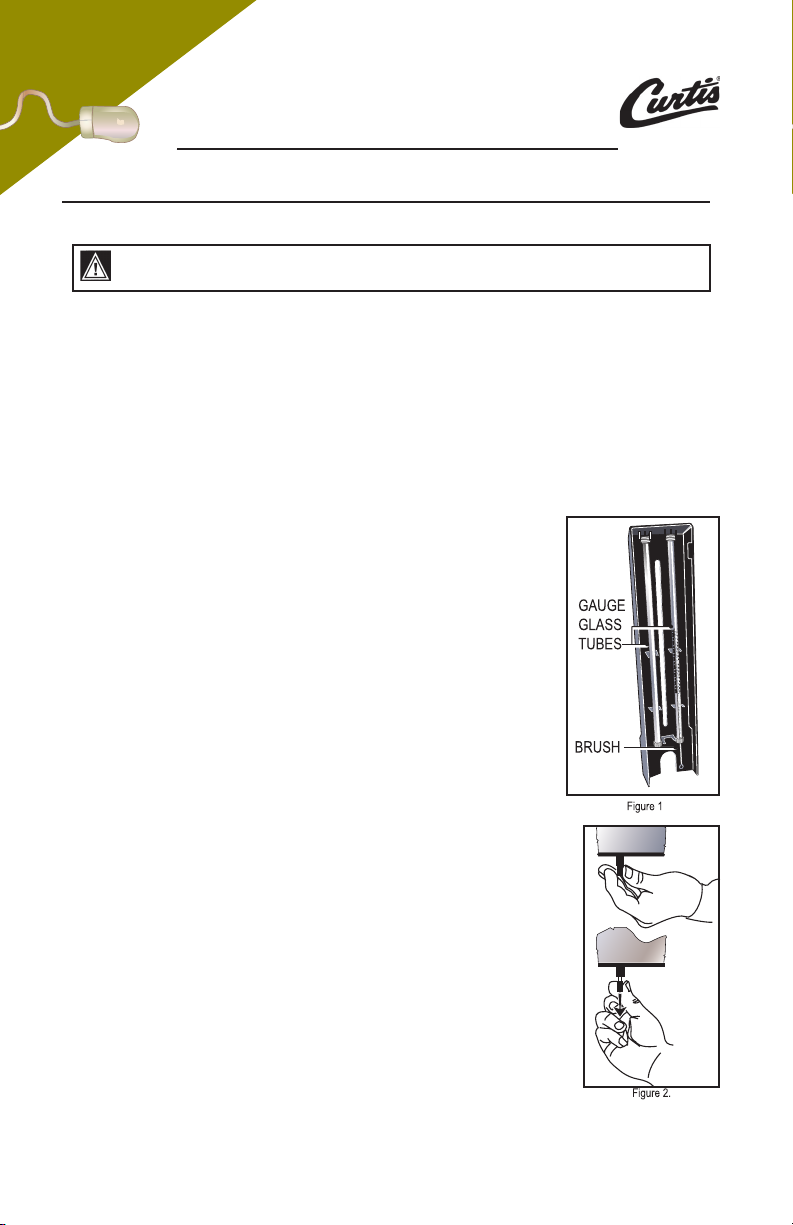

1. REPLACING THE GAUGE GLASS

The gauge glass can be removed for maintenance or to replace if broken.

1. Carefully take hold of the gauge glass guard and lift away the guard from the

front of the unit.

2. The sight glass guard contains two extra glass tubes for replacing a broken

gauge glass. These are held in slots designed into the guard that run the

length of the guard (see fig. 1).

3. Once the gauge glass guard is removed, you will observe that the gauge

glass is held by the black plastic elbow at the top. Pull back on the gauge

glass tube while slightly lifting at the elbow (flexible silicone fitting at the elbow

will allow you to tilt the gauge glass tube). Lift the gauge glass out from the

top of the faucet.

4. The glass tube will come out with a small silicone seal attached, one on each

end. You can pull these off for cleaning (take care to replace the silicone seal

as it was removed, with the large opening sliding over the glass tube).

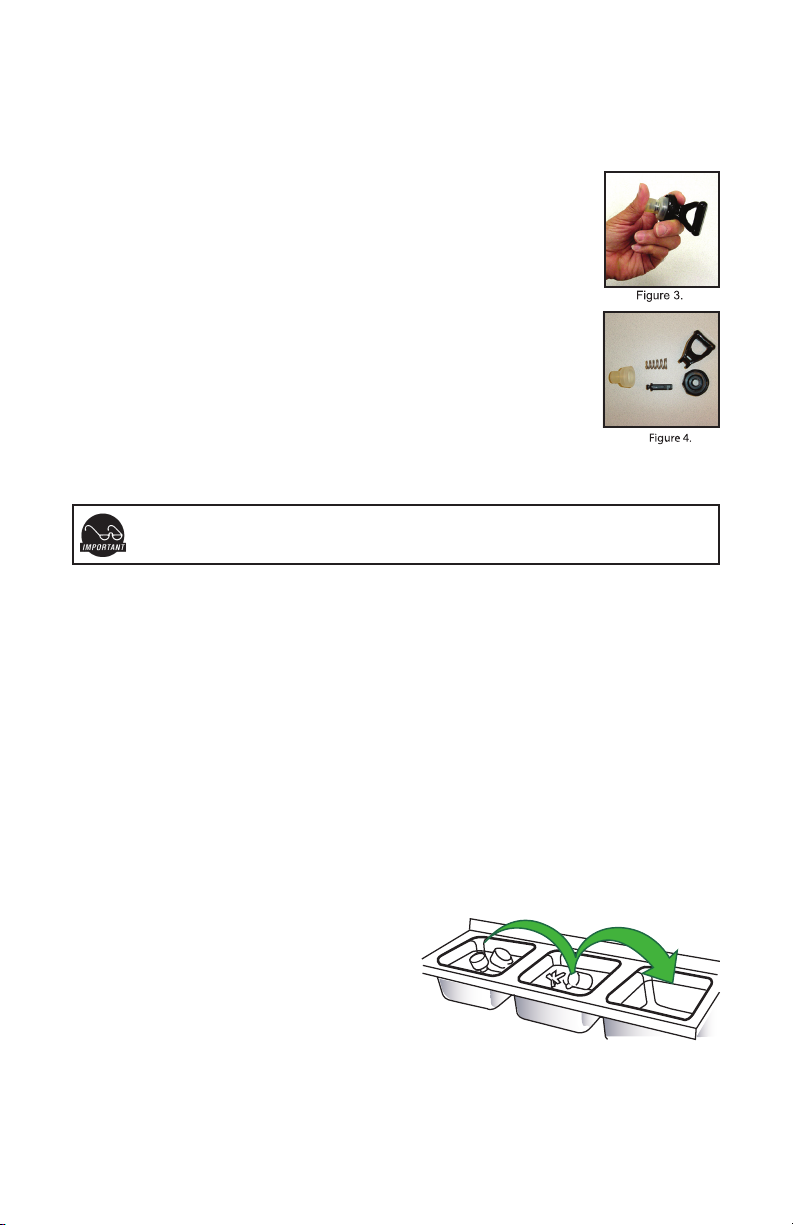

2. REMOVING THE BASE ASSEMBLY

Remove the base assembly for faucet repair or to move the body of the unit

for placement on a remote serving stand.

1. Remove the wing nut at the centerline of the ThermoPro.

2. Pull tab, left side (fig. 2.).

3. Hold the handle and Twist ¼ turn to lift off of base. Before lifting off the unit,

please notice the mark on the bottom right edge of the airpot marked, “ALIGN

TO INSTALL”. This will assist in the assembly of the base and body of the unit.

3. REMOVING THE FAUCET

To replace the faucet or the silicone elbow fitting for repair or cleaning:

1. Remove the base assembly as described above.

2. Remove the Liner Mounting Retainer at the bottom of the liner (held in place by

a black plastic nut). There is a key slot in the stainless body of the unit that aligns

with a pin on the liner retainer for assembly.

Page 2

3. The silicone fitting is held by two wire clamps. Squeeze the wire ears of the clamps to loosen and slide

one from the faucet and the other off of the liner drain port.

4. Remove the faucet, unscrew the wing nut and pull out from the front of the unit.

5. To remove the faucet guard, unscrew the four phillips screws holding it to the body of the unit.

4. SERVICING THE FAUCET

The faucet will require periodic cleaning and maintenance.

1. To disassemble the faucet unscrew the bonnet from the body of the faucet.

2. Remove the top handle by pressing inward on the seat cup (fig. 3.) and unhooking

the handle from the center shaft.

3. The seat cup/center shaft and spring will now separate from the bonnet.

4. You may now clean or replace the parts of the faucet (fig. 4). Check the seat cup

for tearing of splitting. Make sure that the faucet spring is free of corrosion.

Replace these items if necessary (items 12 & 13, page 3).

ASSEMBLY

Assemble the unit by reversing the steps for disassembly. Do not overtighten the plastic

nuts holding the base and the liner retainer. Finger tighten only. Make sure clamps are on

properly and all silicone fittings are in good condition. Once assembled, check for leaks

around fittings or faucet.

CLEANING INSTRUCTIONS

CAUTION: When washing, do not submerge the entire airpot.

When cleaning the stainless steel surface of the ThermoPro server, DO NOT use powders, liquids,

cleansers, or any substance containing chlorine.

CLEANING OF LINER

1. Rinse out the liner with hot water to remove coffee from the server.

2 Fill the liner with a mild detergent solution and let it stand for 10 to 15 minutes.

3 After about 15 minutes take a sponge and scrub out the stainless steel liner.

4 Completely drain out the soapy solution from the liner.

5 Fill the airpot with clean water to rinse out any detergent left inside the unit. Repeat this rinsing

several times until the water runs clear and free of all traces of detergent solution.

CLEANING OF PARTS

This insulated server is designed to be easily disassembled for maintenance (see page one for recommended

disassembly).

Use three sinks to clean and sterilize airpot parts. Fill one sink with tepid water containing detergent. In the

another sink mix a solution with chloride type of sterilization liquid diluted with water to a density of 200 ppm. Fill

the last sink with clean water for rinsing.

1. In the sink filled with the detergent solution, clean the removed parts. A small, soft bristled brush will

clean hard to reach areas.

2. Pay special attention to the small gauge glass liquid level hole on the body of the faucet. You can brush

this out with a small pipe cleaner.

3. Rinse the parts in clear water.

4. Place the parts into the sterilization sink and immerse them for five minutes.

5. Rinse the sterilization solution from the parts.

6. Allow all cleaned parts to completely air dry.

7. Assemble the dried parts onto the airpot.

2

Page 3

ThermoPro – 2 Gal Server

TLXG0201S000 ILLUSTRATED PARTS LIST

ITEMNºPART

Nº

1 WC-5673 Lid & Filling Tube Assy TLXG020

2 WC-3116 Valve, Check W/Ball t O’ Ring

3 WC-3269 Handle, Carrying Black Plastic

4 WC-2425 Fitting, Gauge Glass/Elbow Silicone

5 WC-2423 Elbow, Gauge Glass Black Plastic

6 WC-5677 Cover, Top Black Plastic

7 WC-43072 Seal, Gauge Glass Silicone TLXG020

8 WC-2057 Gauge Glass, .36 OD x 11.25 L

9 WC-3692 Brush, Gauge Glass

10 WC-2055 Shield, Gauge Glass TLXG020

11 WC-1858 Faucet Assy, for 2 Gal Server TLXG020

12 WC-1805 Seat Cup, S’ Faucet

13 WC-3402 Return Spring, S’ Series Faucet

14 WC-2424 Fitting, Faucet Elbow Silicone

15 WC-5674 Retainer, Liner Mounting TLXG020

16 WC-42002 Nut, Black Plastic Faucet

17 WC-5675 Base Assembly Stand

18 WC-42003 Nut Wing Base Hold-down Black Plastic

19 WC-5680 Drip Tray ThermoPro Server

20 WC-3707 Kit, Faucet SPB Series Non-Lock

20A WC-3705D Kit, Faucet SPB Series Decaf Non-Lock

DESCRIPTION

TLXG020

TLXG020

TLXG020

TLXG020

TLXG020

3

Page 4

WARRANTY We hereby certify that the products manufactured by the Wilbur Curtis Company, Inc., are, to the best of

The following warranties and conditions are applicable:

• 2 Year Parts and Labor from Date of Purchase from factory: This warranty covers all fittings and

•

All in-warranty service calls must have prior authorization from the manufacturer. For an RMA (Return

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc.,

1) Improper operation of equipment. The equipment must be used for its designed and intended purpose

2) Improper installation of equipment. This equipment must be installed by a professional, certified techni

3) Wilbur Curtis Company will not be responsible for the operation of equipment at other than the stated

4) Abuse or neglect (including failure to periodically clean or remove lime accumulations). Manufacturer is

5) Replacement of items subject to normal use and wear. This shall include, but is not limited to, light

6) Any faults resulting from inadequate water supply. This includes, but is not limited to, excessive or low

7) All repairs and/or replacements are subject to our decision that the workmanship or parts were faulty

8) All labor shall be performed during regular working hours. Overtime charges are the responsibility of

9) Charges incurred by delays, waiting time, or operating restrictions that hinder the service technician’s

10) All claims under this warranty must be submitted to the Wilbur Curtis Company Technical Service

11) All equipment returned to us must be repackaged properly in the original carton. No units will be

12) Damaged in transit.

13) The resetting of safety thermostats and circuit breakers, programming and temperature adjustments

NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION

All in-warranty service calls must be performed by an authorized service center, where service is avail-

our knowledge, free from all defects and faulty workmanship.

tubing.

90 Days from Date of Purchase: On replacement parts that have been installed on out of warranty

equipment

Merchandise Authorization) number, call Technical Support at 1-800-995-0417. The Wilbur Curtis Com

pany will allow up to 100 miles, round trip, per in-warranty service call.

assumes no responsibility for substitute replacement parts installed on Curtis equipment that have not

been purchased from the Wilbur Curtis Company. Inc. The Wilbur Curtis Company will not accept any

responsibility if the following conditions are not met. The warranty does not cover and is void under these

circumstances:

and function.

cian and must comply with all local electrical, mechanical and plumbing codes.

voltages on the serial plate.

not responsible for variation in equipment operation due to excessive lime or local water conditions.

bulbs, shear disks, “0” rings, gaskets, canister assemblies, whipper chambers and plates, mixing bowls,

agitation assemblies and whipper propellers.

water pressure, and inadequate or fluctuating water flow rate.

and the defects showed up under normal use.

the owner.

ability to perform service is the responsibility of the owner of the equipment. This includes institutional and

correctional facilities.

Department before return of the unit to the factory.

accepted if they are damaged in transit due to improper packaging.

are the responsibility of the equipment owner.

(RMA). RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL.

able. Call the factory for location near you.

-

-

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

4

10/07 F-3251-S Rev E

Loading...

Loading...