Page 1

Wilbur Curtis Company, inC.

Service Manual – G4 ThermoPro 1 Gallon Twin

Important Safeguards/Symbols

This equipment is designed for commercial use. Any servicing other than cleaning and routine maintenance

should be performed by an authorized Wilbur Curtis Company Service Technician.

• DO NOT immerse the unit in water or any other liquid

• To reduce the risk of re or electric shock, DO NOT open service panels. There

are no user serviceable parts inside.

• Keep hands and other items away from hot areas of the unit during operation.

• Never clean with scouring powders or harsh chemicals.

Symbols:

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Model

G4TP1T

CAUTION: Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions can result in injury or the

voiding of the warranty.

IMPORTANT: Equipment

to be installed to comply

with applicable governmental plumbing/electrical codes

having jurisdiction.

CAUTION: DO NOT

connect this brewer to hot

water. The inlet valve is

not rated for hot water.

Sanitation Requirements

This Curtis Generation 4 Unit is Factory Pre-Set and Ready to Go Right from the Box.

Following are the Factory Settings for your G4 Coffee Brewing System:

• Brew Temperature = 200°F • Water Bypass = LARGE & MEDIUM Brew Only

• Brew Volume = Set to Vessel Requirement.

System Requirements:

• Water Source 20 – 90 PSI (Minimum Flow Rate of 1 GPM)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.

com for your model.

SETUP STEPS

1. The unit should be level (left to right - front to back), on a secure surface.

2. Connect the water line to the water inlet tting on the rear of the unit. Water volume ow to the machine

should be consistent. Use tubing sized sufciently to provide a minimum ow rate of one gallon per minute.

NOTE: A water ltration system must be used to help maintain trouble-free operation. In areas with

extremely hard water, we highly recommend the use of a Curtis approved water lter. For our full line

of lters, please log on to www.wilburcurtis.com. A water ltration system will greatly prolong the life

of the unit and enhance the quality and taste of the product.

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) is required so

that the unit can be moved for cleaning.

2. This unit must be installed with adequate backow protection to comply with applicable federal,

state and local codes.

3. Water pipe connections and xtures directly connected to a portable water supply shall be sized,

installed and maintained in accordance with federal, state, and local codes.

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 West Acco Street

Montebello, CA 90640-5403

For the latest information go to

www.wilburcurtis.com

Tel: 800-421-6150

Fax: 323-837-2410

3. Connect the unit to electrical outlet with appropriate amperage rating (see serial tag on machine).

4. Once power has been supplied to the unit, ip the toggle switch to the ‘ON’ position (located on the rear of

the unit), the water tank will begin to ll. When the water level in the tank reaches the probe, the heating

element(s) will turn on.

5. Water in the heating tank will require approximately a half hour before reaching operating temperature

(factory setting of 200°F). Where applicable, turn on the Universal Control Module (UCM). When the unit

reaches operating temperature, it will display “READY TO BREW”.

For the latest specications and information go to www.wilburcurtis.com

1

Page 2

Your Curtis G4/Gold Cup Series is Factory Pre-Set for Optimum Performance.

After connection to water and power; turn on the brewer at the rear toggle switch. You will hear a beep and the status lights will come on for a moment.

The screen will display . Next is displayed. Water will ll the tank (2-3 minutes depending on water ow rate).

MODEL NUMBER

CONTROL BD NUMBER

FILLING

When the proper level is reached will appear on the screen. It takes approximately 30 minutes to reach the set point temperature.

Control will display when temperature reaches the set point. The unit is now ready to brew.

READY TO BREW

HEATING

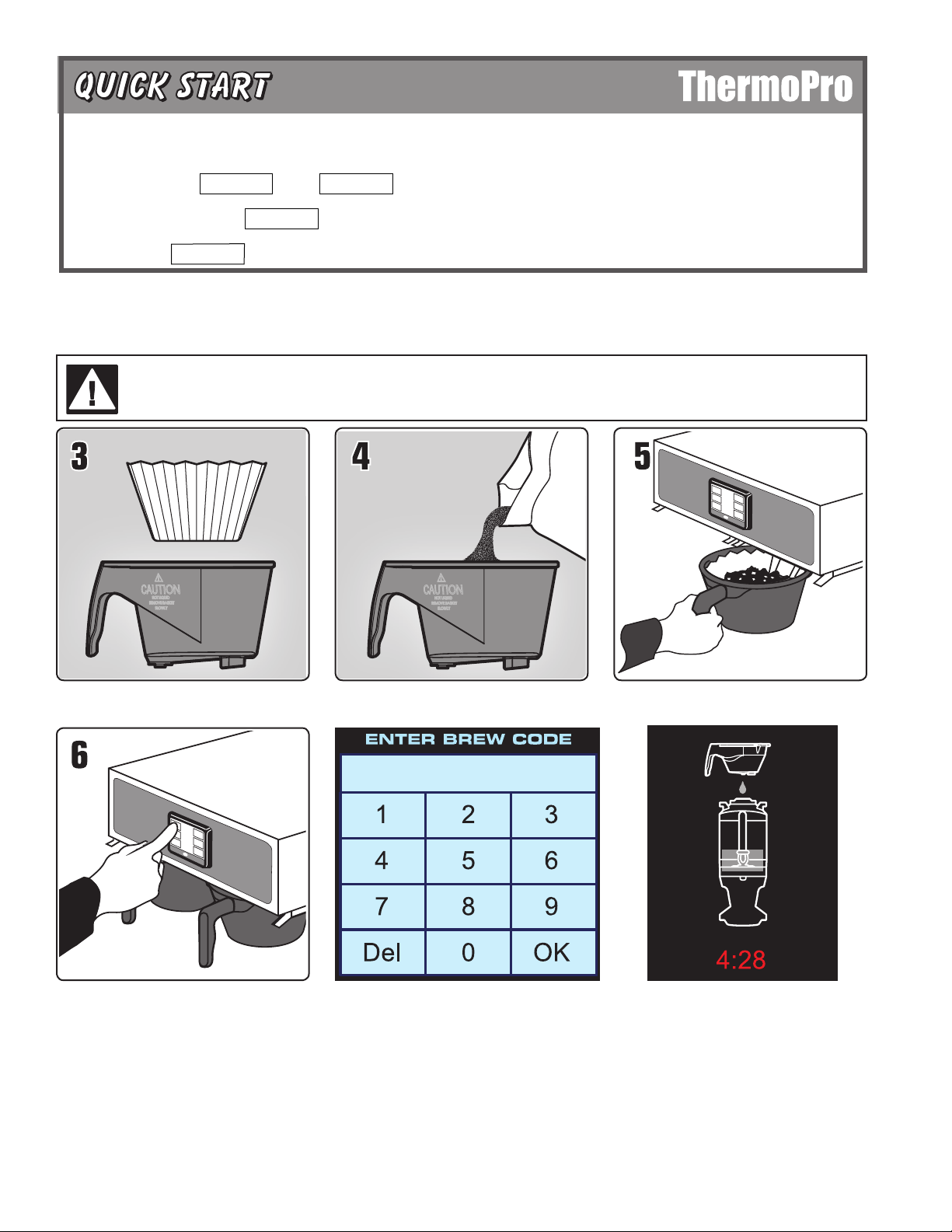

COFFEE BREWING INSTRUCTIONS

1. Brewer should be ON. Conrm this at the toggle switch on the back of the brewer. The touch screen should read Ready to Brew.

2. Place an empty coffee container centered beneath the brew cone.

WARNING – AVOID SCALDING: USE BOTH HANDLES FOR BETTER CONTROL. The brew cone may be lled with hot coffee

grounds and is difcult to manage with one hand.

The coffee vessel is heavy when full. Take precautions to avoid dropping while moving.

3. Place a new paper lter into the brew

cone.

6. Start the brew cycle by hold your nger

on the desired brew icon. As soon as

you hear the click of the brew valve, the

brew cycle has started and you can lift

your nger.

Brew Code: You may nd that when a brew

button is pressed, a key pad appears on the

screen. This is a brew lock-out feature that

4. Fill the brew cone with the proper

amount of ground coffee.

requires a code to be entered before a brew

will start. The default is OFF.

CAUTION: When enabled, as soon as you

enter the brew code a brew cycle starts.

Refer to page 8 for more information about the

Brew Code.

5. Transfer the lled brew cone to the

brewer.

During the brew cycle, an animated 1½

gallon server icon will appear on the screen

and a brew timer will count down the time

remaining on the brew cycle.

2

Page 3

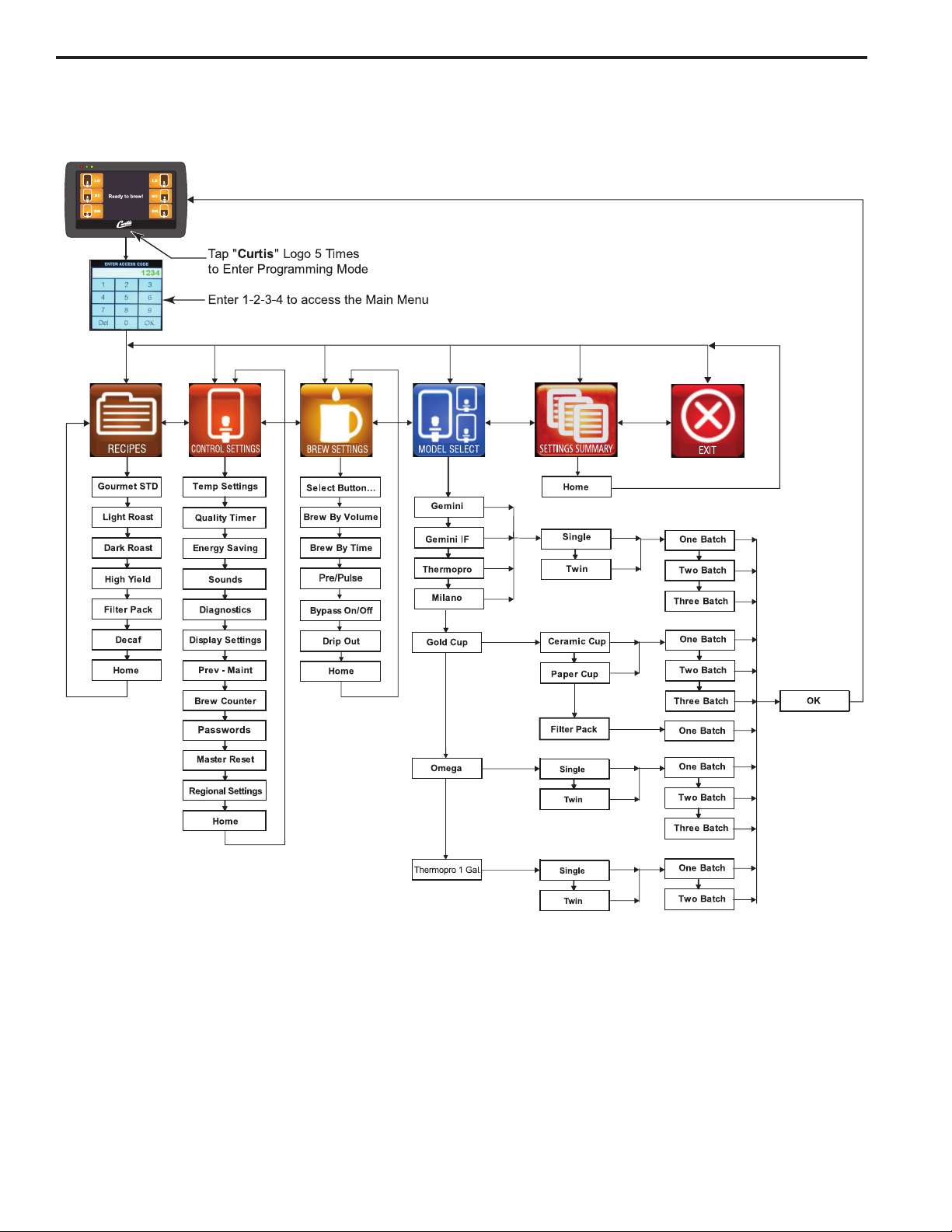

Touch Screen Control Module

The touch screen turns on when power is available to the controller. The screen will contain standard control feature such as symbols and buttons. Press-

ing these elements with your nger tip will activate the programming functions. The default screen, as well as some added control buttons are shown in the

illustration below.

STATUS LIGHTS

BREW BUTTONS

CURTIS LOGO

TO ENTER PROGRAMMING

Tap Curtis logo 5 times to bring

up the ACCESS CODE screen.

CONTROL SYMBOLS

All of these symbols may not

be visible at one time.

RETURN TO HOME SCROLL RETURN TO PREVIOUS

PROGRAMMING

ACCESS CODE screen. Default is 1 2 3 4.

Once the code is entered, press OK. The

Main Menu screen will appear.

The access code can be reset in Control

Settings, PASSWORDS.

UNDO

MAIN MENU screen contains six control icons:

RECIPES, CONTROL SETTINGS, BREW SETTINGS,

MODEL SELECT, SETTINGS SUMMARY and EXIT.

PROGRAMMING Continued . . .

3

Page 4

Menu Tree

This chart explains how to enter the program mode and menu selections available from the MAIN MENU.

4

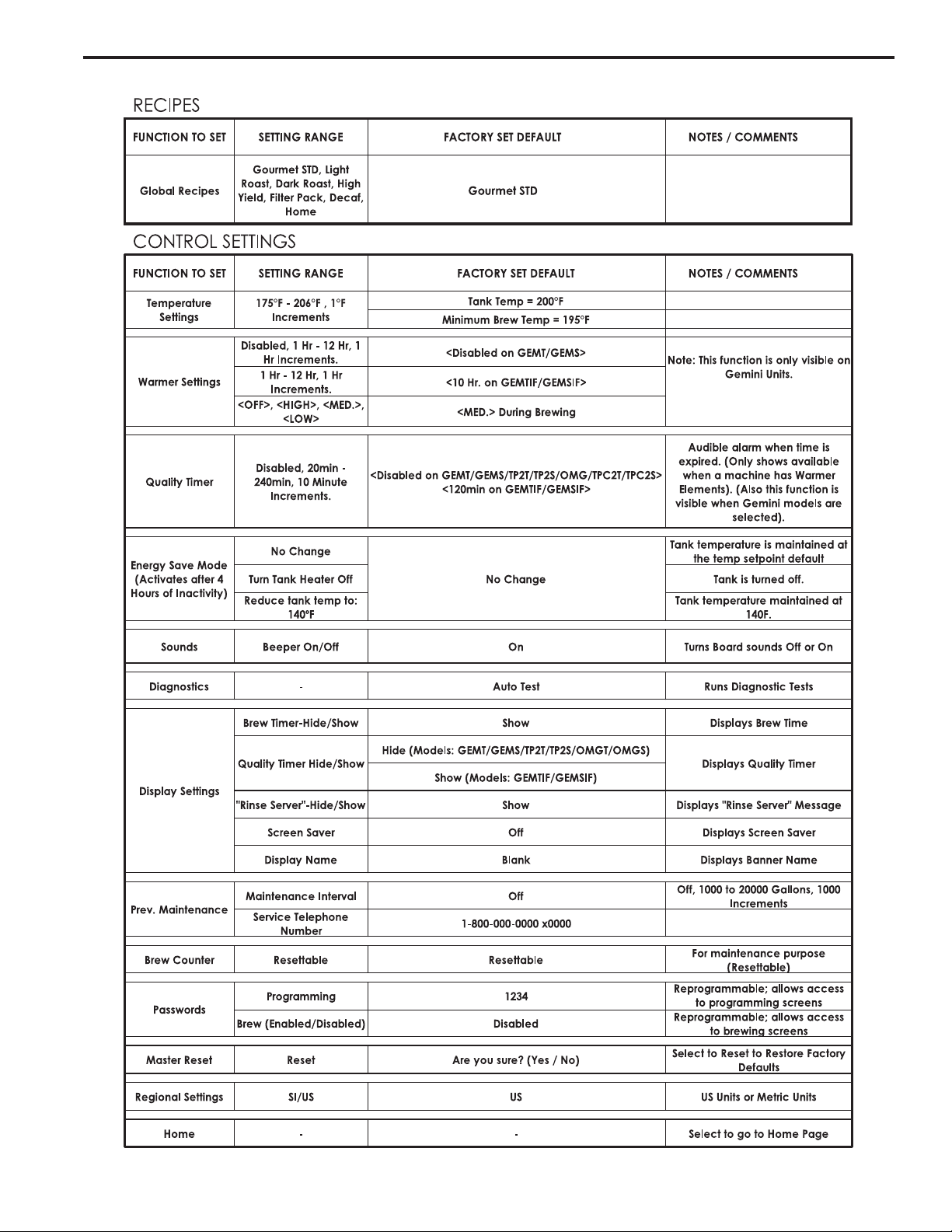

Page 5

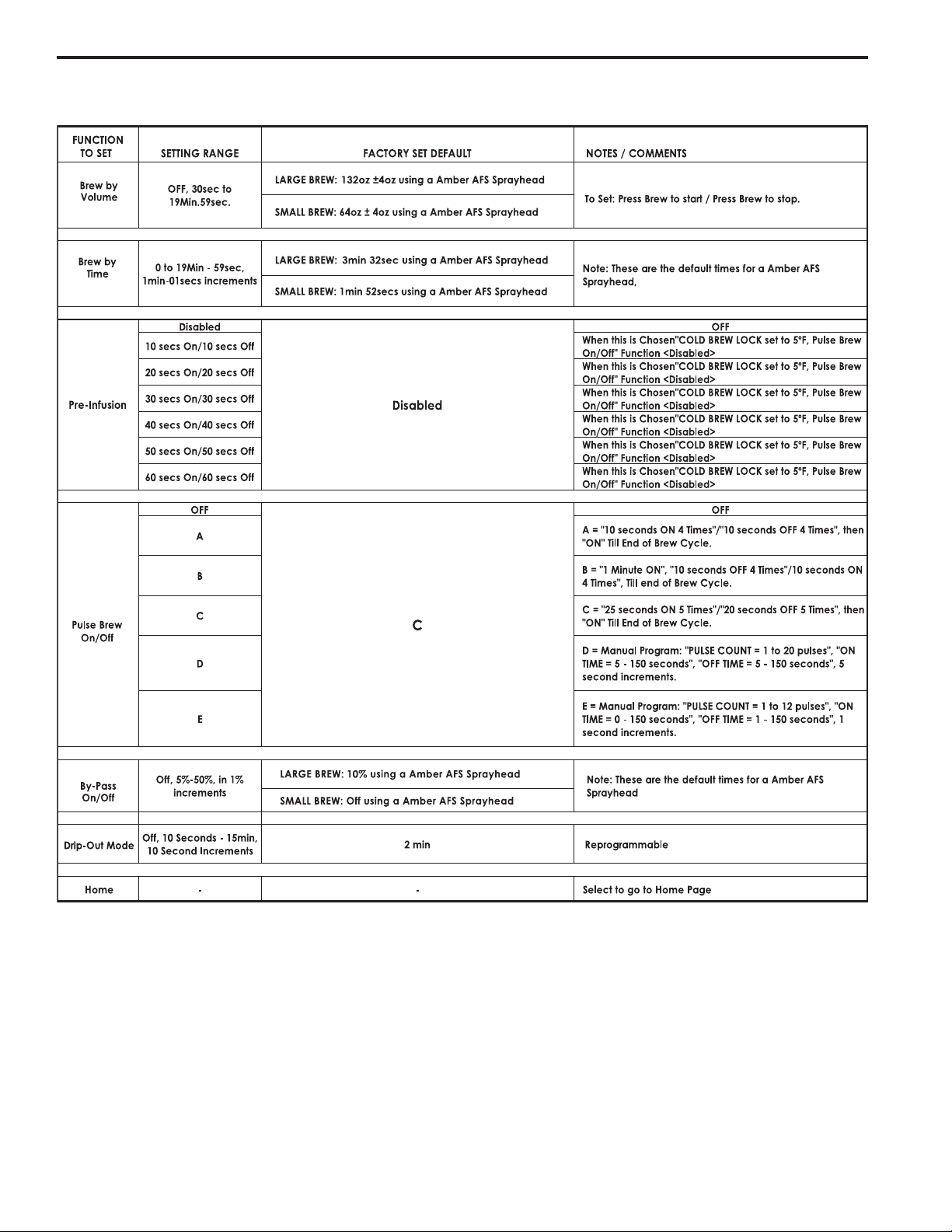

Menu Features

5

Page 6

Menu Features

Brew Settings

6

Page 7

System Fault Messages

7

Page 8

Brew Access Code

8

Page 9

USB – Easy Programming

There are two methods that can be used to change the default settings on G4 brewers. They can be programmed at the brewer by

the touch screen universal control module (UCM) or the settings can be changed using the USB (Universal Serial Bus) data port

on the side of the brewer. Using the USB connection and a ash memory data storage device will easily reprogram the settings

simply by copying data.

The ash drive can upload or download the entire setting from one G4 brewer, into another G4

brewer. This eliminates the need to walk through the usual steps in reprogramming that would

be required when you use the touch screen to make a change. This is an advantage for a

service technician when standardizing the program settings on multiple G4 brewers.

Use a USB drive with USB 2.0 support and a type-A USB connection. Storage capacity should

be 2 GB minimum (reference the illustration on page 2).

IMPORTANT: The ash drive must be completely blank. Before starting, please erase any les that may be in the USB drive.

SOFTWARE INFORMATION TRANSFER

UPLOAD TO USB

1. Make sure the brewer is on. Determine that the G4 brewer you wish to copy is properly programmed for your desired settings.

2. Connect an empty ash drive into the USB port on the brewer. The UCM on the brewer will upload all of the particular setup

data onto the ash drive. The yellow LED on top of the touch screen will light indicating that data is transferring. This will only

take a second to complete.

DOWNLOAD TO BREWER

1. Select the brewer you wish to make the program changes on. The brewer should be on.

2. Plug the loaded ash drive into the USB port on the brewer. The data copied from the rst G4 brewer will automatically download, overwriting all the settings that were on the second brewer.

3. The red LED on the UCM will indicate that the download is in process. This will only take a second.

4. Once the download is complete, the UCM will reboot in order for the changes to take effect.

5. Remove the ash drive. The download is complete. The data on the ash drive can be downloaded into as many G4 brewers

as needed.

9

Page 10

USB – File Transfer

This screen will be presented whenever the USB ash is inserted, as long as UCM is showing main brew screen and is not currently brewing.

The default action is ‘No action’.

The UCM will always create a backup on the USB ash drive before downloading settings/recipes or screen saver.

If a rmware update le is present on the USB ash, the rmware update procedure will be started BEFORE this screen is shown.

Case 1: Settings/recipes le

present, screen saver not pres-

ent. User has selected ‘Download from USB’ for settings/

recipes le.

Case 2: As above, but user has

selected ‘Upload to USB’ for settings/recipes le.

With this action, the overwrite

warning appears.

10

Page 11

Illustrated Parts

Main View

1

2

3

11

12

13

4

14

5

6

7

8

10

9

ITEM NO. PART NO. DESCRIPTION

1 WC-5459 COVER, TOP WRAP

2 WC-37121* KIT, DUMP VALVE LEFT

3 WC- 844-101* VALVE, BYPASS 120V-14W NON ADJUSTABLE w/RESTRICTOR (WC-2945)

4 WC-3417 BREW CONE,ASSY W/SPLASH POCKET BRWN STYLIZED HOT COFFEE

5 WC-1825 FAUCET ASSY, HOT WATER

6 WC-14045-101* CURRENT SENSOR ASSY G4

7 WC-8559 RELAY, SOLID STATE 40A w/INTEGRATED HEAT SINK

8 WC-3503 * LEG, 3/8”-16 STUD SCREW BUMPBER

9 WC-3518 * LEG, GLIDE 3/8”-16 STUD SCREW

10 WC-58037-102 COVER, CENTER WRAP

11 WC-5983-101 PANEL, TOP WRAP BACK

12 WC- 847 * VALVE, INLET 2GPM 120V-10W

13 WC-1501 FUSE, HOLDER ASSY w/5A FUSE

14 WC- 102 * SWITCH, TOGGLE NON-LIT SPST 15A 125/250VAC RESISTIVE

11

Page 12

Illustrated Parts

Top Wrap

15

16

17

18

19

20

21

22

23

24

ITEM NO. PART NO. DESCRIPTION

15 WC-2977-101K* KIT, SPRAYHEAD FITTING PLASTIC

16 WC-43089* GASKET, 1.00”OD x .625” I.D. x .030” THK RED SILICONE 40 SHORE

17 WC- 442 * SOLENOID, LOCK BREW CONE RIGHT 120VAC

18 WC-37122* KIT, DUMP VALVE RIGHT

19 WC- 589-101 TRANSFORMER, 120VAC-24VAC 4.8VA W/TERMINALS

20 WC-13450 HARNESS ASSY, COMPLETE G4TP2T/G4GEMT/G4GEMTIF

21 WC-10000 CONTROL MODULE, TOUCH SCREEN G4

22 WC-4212-02* NUT, 5/8-18 JAM PLASTIC-ULTEM

23 WC-29050* SPRAYHEAD ASSY, AFS-AMBER

24 WC-10008 UNIVERSAL HOST ADAPTER (USB)

* RECOMMENDED PARTS TO STOCK

12

Page 13

Illustrated Parts

Heating Tank

25

26

27

28

29

30

31

32

33

34

35

36

ITEM NO. PART NO. DESCRIPTION

25 WC-37008* KIT, TANK LID ROUND

26 WC-43067* O-RING, 4-1/2 I.D. x Ø.285 C.S. SILICONE

27 WC-37266* KIT, FITTING TANK OVERFLOW (8MM)

28 WC-5502-01* KIT, PROBE, ASSY WATER LEVEL W/HEX FITTING, O-RING & NUT

29 WC-37317* KIT, STRAIGHT FITTING & BUSHNG (8MM)

30 WC-37357* KIT, STRAIGHT PLASTIC FITTING KIT, STRAIGHT PLASTIC FITTING

31 WC-62033 TANK, COMPLETE GEMTS W/ULTEM FITTINGS

32 WC- 934-04* KIT,ELEMENT HEATING 2.5KW 220V W/ JAM NUT & SILICONE WASHERS

33 WC-1438-101* SENSOR, TEMPERATURE TANK

34 WC- 522 * THERMOSTAT, HI LIMIT HEATER DPST 277V-40A

35 WC-4382* GUARD, SHOCK (HEATING ELEMENT

36 WC-43055* GUARD, SHOCK RESET THERMOSTAT

* RECOMMENDED PARTS TO STOCK

13

Page 14

Illustrated Parts

38

39

37

40

ITEM NO. PART NO. DESCRIPTION

37 WC-10001* UNIVERSAL POWER MODULE - G4

38 GEM-6 * FILTER, 500PK GEM-12/230A

39 WC-5310* TUBE, 5/16 ID x 1/8W SILICONE

40 WC-5350* TUBE, SILICONE Ø1/2” ID x Ø3/4” OD x 1/8” WALL

Rough-In Drawing

* RECOMMENDED PARTS TO STOCK

14

Page 15

Electrical Schematic

ThermoPro 1 Gallon Twin G4TP1T-10

15

Page 16

Cleaning the ThermoPro

Regular cleaning and preventive maintenance is essential in keeping your coffee brewer looking and working like new.

To clean the coffee brewer and components, prepare a mild solution of dish washing detergent and warm water.

CAUTION – Do not use cleansers, bleach liquids, powders or any other substance containing chlorine. These products promote corrosion and will pit the stainless steel. USE OF THESE PRODUCTS WILL VOID THE WARRANTY.

DAILY CLEANING

1. Wipe exterior surfaces with a damp cloth, removing spills and debris.

2. Slide the brewcone out and clean it. Wipe the sprayhead area with a cloth soaked in a mild detergent solution.

3. Rinse with a cloth soaked with clean water. Dry the brewcone and sprayhead area.

4. Drain drip trays of coffee. Water rinse.

5. Dry the tray.

WEEKLY CLEANING

1. Reach behind the brewer and turn off the power at the toggle switch. Allow the brewer to cool.

2. Clean the sprayhead and dome plate area.

a. Remove the sprayhead, unscrewing counterclockwise from the dome plate.

b. Thoroughly clean and rinse the dome plate area.

c. Clean the brewcone rails with a brush soaked with a mild detergent solution. Rinse the area with a cloth

soaked with clean water, removing any residual detergent.

d. Dry the area.

c. Attach the sprayhead.

Liquid Level Probe

Cleaning intervals for the probe are to be determined by the user or the service

tech, based on water conditions. The use of water lters, or the type of water lter

that is being used can impact the service interval. Intervals can be from one month

to several years, however, replacing rather than cleaning the probe is preferable.

WARNING: Disconnect electrical power before removing access panels!

This procedure involves working with hot water and hot surfaces!

1. Unplug the power cord and shut off the water line.

2. Remove the top cover of the unit. Locate the top of the tank and remove the

cover.

3. Drain the tank to a level about 3” below the tip of the probe.

4. Allow some time for the probe to cool before working on the

brewer.

5. Clean the tip of the probe using a Scotch-BriteTM scuff pad.

6. If a residual white layer is still visible on the probe, remove the

probe and soak it in vinegar or a scale removing chemical. Repeat this step until the white layer is removed.

7. When assembling the probe back onto the tank, make sure the

tip of the probe is pointing downward as illustrated.

LIQUID LEVEL PROBEHEATING TANK

16

Page 17

Cleaning the Thermoserver

1. Drain coffee from the server.

2. Fill the liner with a mild detergent solution and let it stand for 10 to 15 minutes.

3. After about 15 minutes take a sponge brush and scrub out the stainless steel liner.

4. When clean, drain out the soapy solution from the server.

5. Fill the server with clean water to rinse detergent from inside the unit. Repeat this rinsing until the water runs clear.

CLEANING OF THERMOSERVER FAUCET

1. Remove the faucet handle assembly. Take hold of the bonnet and turn counterclockwise to unscrew it from the

faucet.

2. Clean the handle assembly with a mild detergent solution. When clean, rinse the handle with water. Inspect for

cracks or tears in the seat cup. Replace if damaged.

3. Clean the coffee level gauge glass.

a. Remove the sight glass cover by pulling up and off from the front of the server.

b. Using the narrow brush provided for this purpose, brush out the inside of the glass with a

detergent solution. Rinse the sight glass tube of all detergent residue.

c. Pay special attention to the small gauge glass liquid level hole on the body of the faucet. You

can brush this out with a small pipe cleaner.

d. Replace the sight glass. Make sure the top and bottom silicone seals are seated.

17

Page 18

Product Warranty Information

The Wilbur Curtis Company certies that its products are free from defects in material and workmanship under normal use. The following limited

warranties and conditions apply:

3 Years, Parts and Labor, from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, ttings and tubing.

1 Year, Labor, from Original Date of Purchase on all electrical components, ttings and tubing.

Additionally, the Wilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds of coffee,

whichever comes rst. Stainless Steel components are warranted for two (2) years from date of purchase against leaking or pitting and replacement parts are warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty period of the equipment in which

the component is installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-0417. Effective

date of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty

does not cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or uctuating water ow

rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation

in equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by

delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner

of the equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per

in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION: All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Support Department prior to performing any repair work or return of this equipment to the factory. All returned equipment must be repackaged

properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging. NO UNITS OR PARTS WILL

BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON

OR SHIPPING LABEL. All in-warranty service calls must be performed by an authorized service agent. Call the Wilbur Curtis Technical Sup-

port Department to nd an agent near you.

10/16/13 . EDR 8920 . rev NC

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

10/2013 . F-3964 rev NC

Loading...

Loading...