WIKA TXA2CL, TXS2CL, TXA4CL, TXS4CL, TXA2QL Instruction Manual

...

INSTRUCTION MANUAL

TEMPERATURE SWITCHES SERIE TXS, TXA

NI-492WE

Rev. 4 05/18

WEATHERPROOF AND INTRINSICALLY SAFE:MODELS TXS; FLAMEPROOF: MODELS TXA

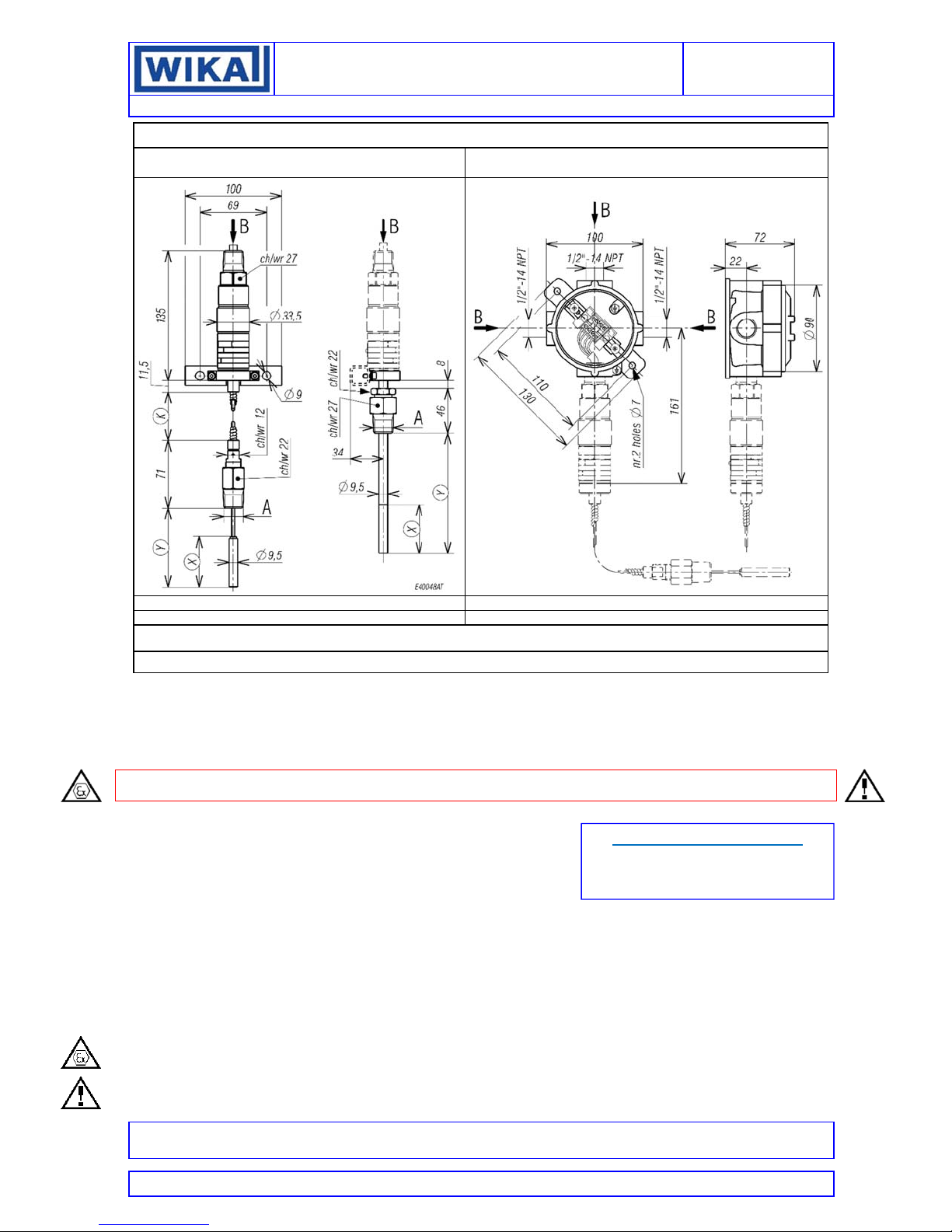

CORD CABLE INSTRUMENT INSTRUMENT WITH JUNCTION BOX

Stem Type C-Q-R Stem Type B

WEIGHT 0,4kg Dimension in mm WEIGHT 1kg Dimension in mm

Stem Type B: Y = 125mm ; X = 50mm

Stem Type C: K = 2m ; Y max. = 350mm Stem Type R: K = 10m ; Y max. = 1800mm

For surface mounting use two screws M6 (not supplied with the instrument)

NOTE: dimensions and weights are not binding unless released on certified drawings.

CAUTION

Before installing, using or carrying out maintenance on the instrument it is necessary to read and understand the indications given

in the attached Instruction Manual.

The instrument must only be installed and maintained by qualified personnel in relation to working with instruments for hazardous

areas.

INSTALLATION IS TO BE CARRIED OUT ONLY AFTER CHECKING THAT INSTRUMENT CHARACTERISTICS ARE

CONSISTENT WITH PROCESS AND PLANT REQUIREMENTS.

The functional features of the instrument and its degree of protection are shown on the identification plate fixed to the case.

CONTENTS:

GENERAL

1 2 -OPERATING PRINCIPLE

3 -MODEL CODE

4 -NAMEPLATE AND MARKINGS

5 -SPECIAL CONDITIONS FOR SAFE USE (X)

6 -SET POINT ADJUSTMENT

7 -SET POINT CALIBRATION

8 -INSTRUMENT PLUMBING

9 -MOUNTING AND CONNECTIONS

10 -PUTTING INTO OPERATION

11 -VISUAL INSPECTION

12 -FUNCTIONAL VERIFICATION

13 -STOPPING AND DISMOUNTING

14 -DISPOSAL

15 -TROUBLE SHOOTING

SAFETY INSTRUCTIONS FOR USE IN EXPLOSIVE ATMOSPHERES

RECOMMENDATIONS FOR THE SAFE USE OF THE INSTRUMENT

Stem Type Q: K = 5m ; Y max. = 900mm

DOCUMENT CORRELATED

to document authenticated with certificates

N° IECEx PRE 16.0073X

N° IECEx PRE 16.0074X

All data, statements and recommendations supplied with this manual are based on information believed by us to be reliable. As the conditions of effective

use are beyond our control, our products are sold under the condition that the user himself evaluates such conditions before following our recommendations

for the purpose or use foreseen by him.

This document is the property of ALEXANDER WIEGAND SE &Co and may not be reproduced in any form, nor used for any purpose other than for which

it is supplied.

INSTRUCTION MANUAL

range

Max working

temperature

(T max.)

Shall not exceed the

maximum

temperature specified

on the nameplate

(see fig.1 item 5).

Max electrical rating

(resistive load)

5A@24V d.c.; 5A@250V a.c.

See nameplate of the instrument

(electrical rating)

Max electrical

rating

(resistive load)

5A@24V d.c.;

5A@250V a.c.

See nameplate of

the instrument

(electrical rating)

1 - GENERAL

1.1 FOREWORD

The wrong choice of a models or a version, as well as the

incorrect installation, lead to malfunction and reduce instrument

life. Failure to follow the indications given in this manual can

cause damage to the instrument, the environment and persons.

1.2 ALLOWED OVERRANGES

Temperature exceeding the working range can be allowed only

for testing proposal up to the proof temperature. Continuous

temperature exceeding the (adjustable) “RANGE* (see fig 1) can

be applied to the instrument, provided they are clearly stated in

the instrument features (see fig.1, “MAX TEMPERATURE”).

The current and voltage values stated in the technical

specifications and data plate must not be exceeded: transitory

overranges can have a destructive effect on the switch.

1.3 TEMPERATURES

The temperature of the instrument is influenced by the

environmental and process temperature. Special attention must

be taken to avoid the exceeding of the limits specified in table 1

and 2.

For the instrument version TX**B* (stem for direct mounting) the

following table is applicable

Table 1 – Temperature conditions

Temp.

Classification

T6

T5

T4

T3

T2

T1

Ambient

temperature

range (Tamb)

-50 … +60 °C

-50 … +85 °C

For the instrument versions TX**C*, TX**Q*, TX**R* (stem for

remote mounting) and TX**S* (helical bulb for ambient

temperature) the following table is applicable

Table 2 – Temperature conditions

Temperature

Classification

T6

T5

T4

T3

T2

T1

Ambient

temperature

(Tamb)

-50..+60 °C

-50..+85 °C

2 - OPERATING PRINCIPLE

The operating principle is based on a pressure measuring

element, connected via a capillary tube to a bulb. This system is

partially filled with a volatile liquid, the residual free volume being

filled by its saturated vapour. In this system a pressure is

generated which is a non-linear function of bulb temperature; this

pressure acts on a stainless steel diaphragm which applies a

force to a stiff disc; this force is directly proportional to the

temperature value to which the bulb is submitted and is

contrasted by an compression spring charged by a suitable bush.

When the force balance point is exceeded, the stiff disc shifts

and, by means of a rigid rod, activates one or two

simultaneous release electric microswitches. The

microswitches are of the rapid release type with automatic rearm.

When the temperature moves away from the set values,

returning towards the normal values, the switch is rearmed.

3 - MODEL CODE

See Annex 1

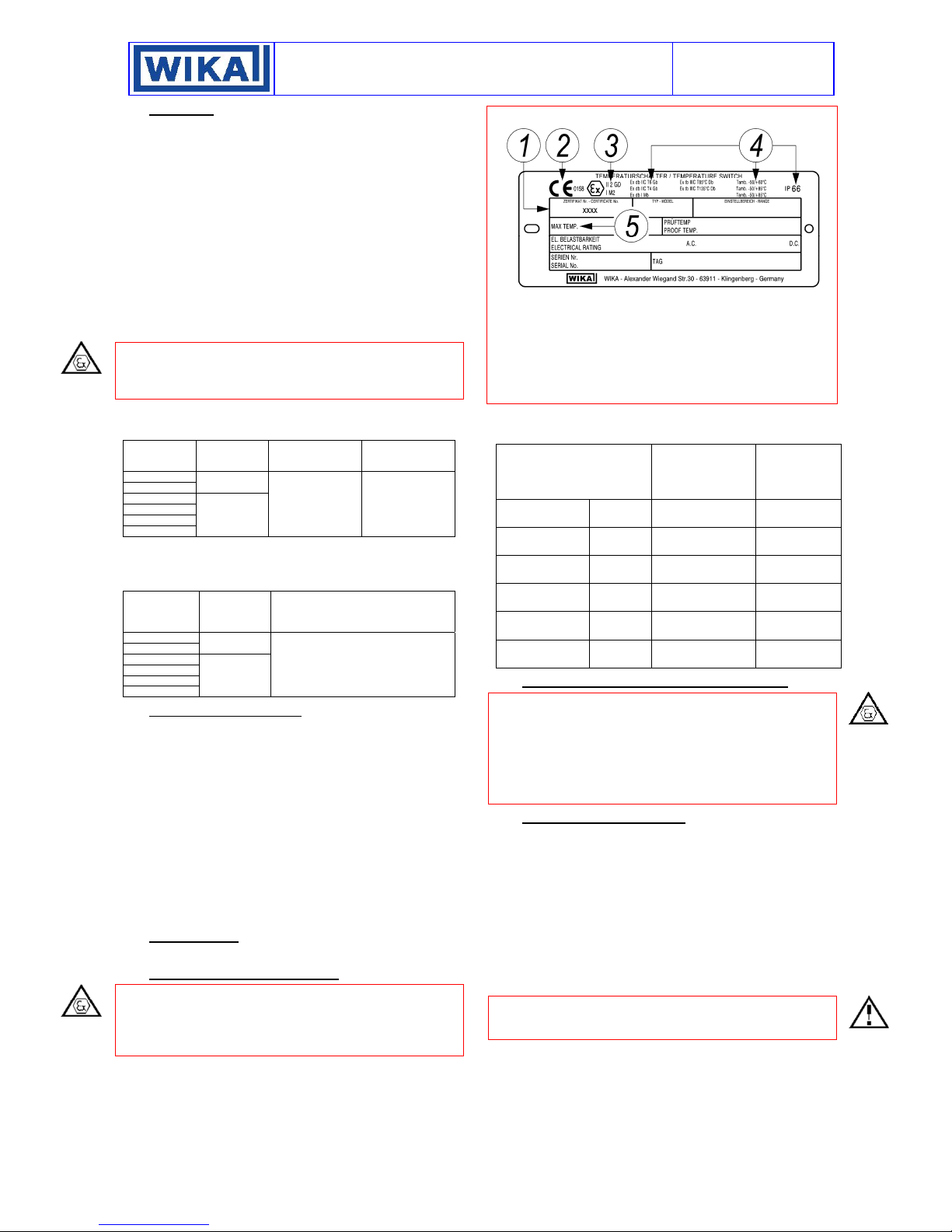

4 - NAMEPLATE AND MARKINGS

The i nstru ment is f itted wit h a metal plate beari ng al l its functional

characteristics and in case of flameproof or intrinsic safety

execution, also the markings prescribed by standard IEC/EN

60079-0. Fig.1 shows the plate mounted on flameproof

instruments.

NI-492WE

Rev.4 05/18

Fig. 1 - Flameproof instruments plate

1 Notified body that issued the type certificate and number of said

certificate.

2 CE marking and identification number of the notified body

responsible for production surveillance.

3 Apparatus classification according to ATEX 2014/34/EU

directive.

4 Type of protection and ambient temperature limits of operation.

5 Max working temperature

The following table gives the relationship between hazardous

areas, ATEX Categories and Equipment Protection Level (EPL)

listed on the flameproof instrument nameplate.

Hazardous area

Gas, vapours,

fog

Gas, vapours,

fog

Gas, vapours,

fog

Zone 0 1G Ga

Zone 1 2G or 1G Gb or Ga

Zone 2 3G, 2G or 1G Gc, Gb or Ga

Dust Zone 20 1D Da

Dust Zone 21 2D or 1D Db or Da

Dust Zone 22 3D, 2D or 1D Dc, Db or Da

5 - SPECIAL CONDITIONS FOR SAFE USE (X)

The instrument cannot be repaired (see also throubleshooting).

Should the instrument be installed without a junction box require

an electric connection suitable for the mode of protection chosen

at the free end of the cable.

Should the instrument be installed in mines (Group I) the elettrical

connection has require to be protected by chemical agents.

Therefore a mounting with cable protected by tubing is

mandatory.

6 - SET POINT ADJUSTMENT

The compression of the spring can be regulated by means of the

bush (for adjustment) in such a way that the switch is released

when the temperature reaches (either increasing or decreasing)

the desired value (set point). The instrument is usually supplied

with the switches set at 0°C or at the lowest setting range value

if this is higher than 0°C (factory calibration).

The instrument is supplied with an adhesive label showing the

set point calibration value. With factory calibration the values

are not indicated on the label as these are temporary and will be

modified with the definitive values. Prior to installation the

instrument must be calibrated and the definitive calibration

values written on the label.

If the instrument has been ordered with a specific calibration, it

is a good rule to check the calibration values marked on the

relevant adhesive label, prior to installation.

Categories

according to

2014/34/EU

Directive (ATEX)

EPL

2 of 7

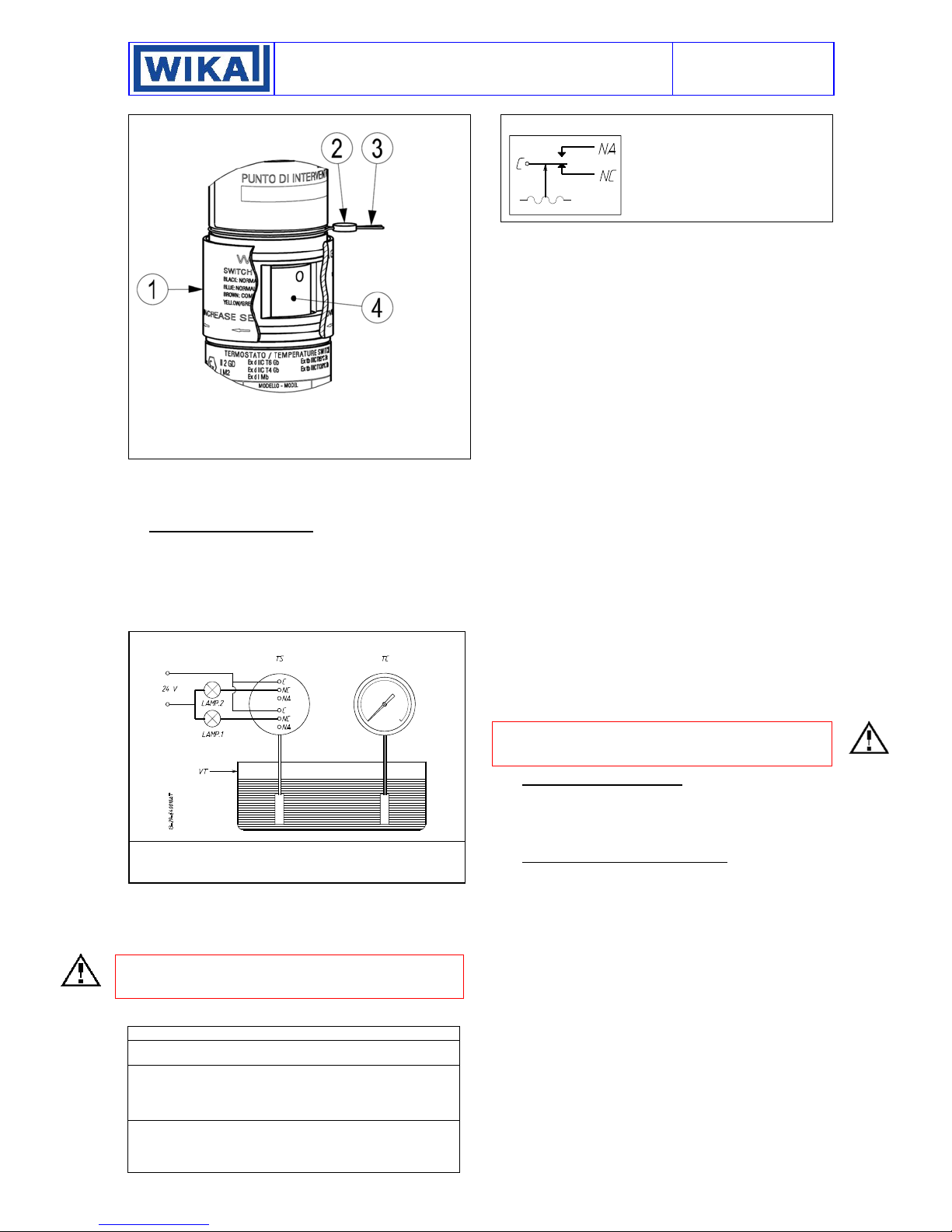

The position of the adjusting bush is given in Fig. 2.

Fig. 2 - Adjusting bush and plumbing

Adjustment slot cover

Sealing lead

Stainless steel wire

Adjusting bush

The effect of the sense of rotation of the adjusting bush is shown

on the slot cover. Rotate the bush by inserting a 3mm dia. rod or

drill into the holes on the bush itself (It recommends using a drill

bit on the side of the shank).

7 - SET POINT CALIBRATION

In order to proceed with the calibration and the periodical

functional verification of the instrument a suitable calibration

circuit (Fig. 3) and of an adequate source of heat are required.

The test instrument should have a measurement range

approximately equal to or slightly wider than the pressure switch

range and should have an accuracy consistent with the accuracy

required to calibrate the set point.

Fig. 3 – Calibration circuit

TS - Temperature switch

TT - Test thermometer

TB - Thermostatic bath

7.1 PRELIMINARY OPERATIONS

Slide up the adjustment cover (Fig. 2 item 1).

7.2 CALIBRATION CIRCUIT AND OPERATIONS

Prepare the control circuit as indicated in Fig.3

If the instrument is equipped with two contacts, remember that

they are released simultaneously but within the specification

tolerance.

The warning lamps should be connected to the terminals NA or

NC according to the required contact action.

Fig. 4 – Color of wires and function

GDN-Internal grounding connection: color jellow/green

C-Common: color brown

NO-Normally open: color blue

NC-Normally closed: color black

C-Common: color gray

NO-Normally open: color red

NC-Normally closed: color white

.

INSTRUCTION MANUAL

NI-492WE

Rev.4 05/18

Contacts status at atmospheric pressure.

C - Common

NA - Normally open

NC - Normally closed

Connection between C and NA

• If the circuit is open at the workin temperature, the instrument

closes the circuit when the set point is reached with temperature

on rise (closure on rise).

• If the circuit is closed at the working temperature, the instrument

opens the circuit when the set point is reached with temperature

on fall (opening on fall).

Connection between C and NC

• If the circuit is closed at the working temperature, the instrument

opens the circuit when the set point is reached with temperature

on rise (opening on rise).

• If the circuit is open at the working temperature, the instrument

closes the circuit when the set point is reached with temperature

on fall (closure on fall).

The temperature switch must be kept in the normal installation

position, i.e. with the temperature connection downwards.

Modify the temperature in the circuit up to the desired

microswitch set point value.

Using a 3mm dia. rod drill into the holes on the bush (It

recommends using a drill bit on the side of the shank).

Adjust its position until the relative lamp turns on (or turns off);

then turn it in the opposite direction until the lamp turns off (or

on). Slowly turn the bush again until the lamp turns on (or off)

7.3 SET POINT VERIFICATION

Increase the temperature up to the normal working temperature

(Tw), wait the stabilization of the temperature. Modify, slowly the

temperature up to the set value (Ti) and record the set point

value. Write the set point value on the adhesive label.

Note: the verification of the repeatability have to be tested

checking the set point (Ti) three times approaching the set point

from the same starting point (Tw). The temperature cycles have

to be performed slowly.

7.4 FINAL OPERATIONS

Disconnect the instrument from the calibration circuit.

Close the adjustment slot by sliding down the slot cover (Fig. 2,

1), then seal with lead the instrument.

Mount on pressure connection the protecting cap supplied with

the instrument. It should be definitively removed only during the

connection steps.

8 - INSTRUMENT PLUMBING

The plumbing (see Fig. 2), aimed as a guarantee against

possible tampering of the calibration, can be carried out using a

flexible steel wire (2), 1 mm

case in the groove purposely provided.

9 - MOUNTING AND CONNECTIONS

9.1 MOUNTING

Mount instruments with capillary either on pipe or surface by

means of the proper bracket (see Fig. 9 and 10) or direct on plant.

Select a location where possible shocks and temperature

variations remain within tolerable limits.

For the instrument with capillary the difference in height between

bulb and case have not exceeding two meters (fig 11 and 12

distance h).

9.2 INSTALLATION OF TEMPERATURE SWITCH

WITH DIFFERENCE IN HEIGHT BETWEEN BULB

AND INSTRUMENT ENCLOSURE GREATER THAN 2

METERS

Micro 1

9.2.1 TEMPERATURE SWITCHES CLASS SAMA II A

Difference in height between bulb and instrument enclosure

causes a systematic error of set point calibrated value (“bulb

elevation error”). This error can be corrected during calibration

using the table attached to our technical instruction IS-TC.401E,

available on request.

Micro 2

2

in section, wound up around the

3 of 7

Loading...

Loading...