Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Thermowell for sanitary applications, model TW61

Schutzrohr für die sterile Verfahrenstechnik, Typ TW61

Doigt de gant pour applications sanitaires, type TW61

Vaina para procesos estériles, modelo TW61

GB

D

F

E

Thermowells model TW61

Page 2

GB

Operating instructions model TW61

D

Betriebsanleitung Typ TW61

F

Mode d'emploi type TW61

E

Manual de instrucciones modelo TW61

Page 3 - 18

Seite 19 - 34

Page 35 - 50

Página 51 - 65

© 2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions thermowell, model TW61

11593963.03 03/2014 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 7

4. Design and function 7

5. Transport, packaging and storage 12

6. Commissioning, operation 12

GB

Maintenance and cleaning

7.

8. Faults 14

9. Dismounting, return and disposal 15

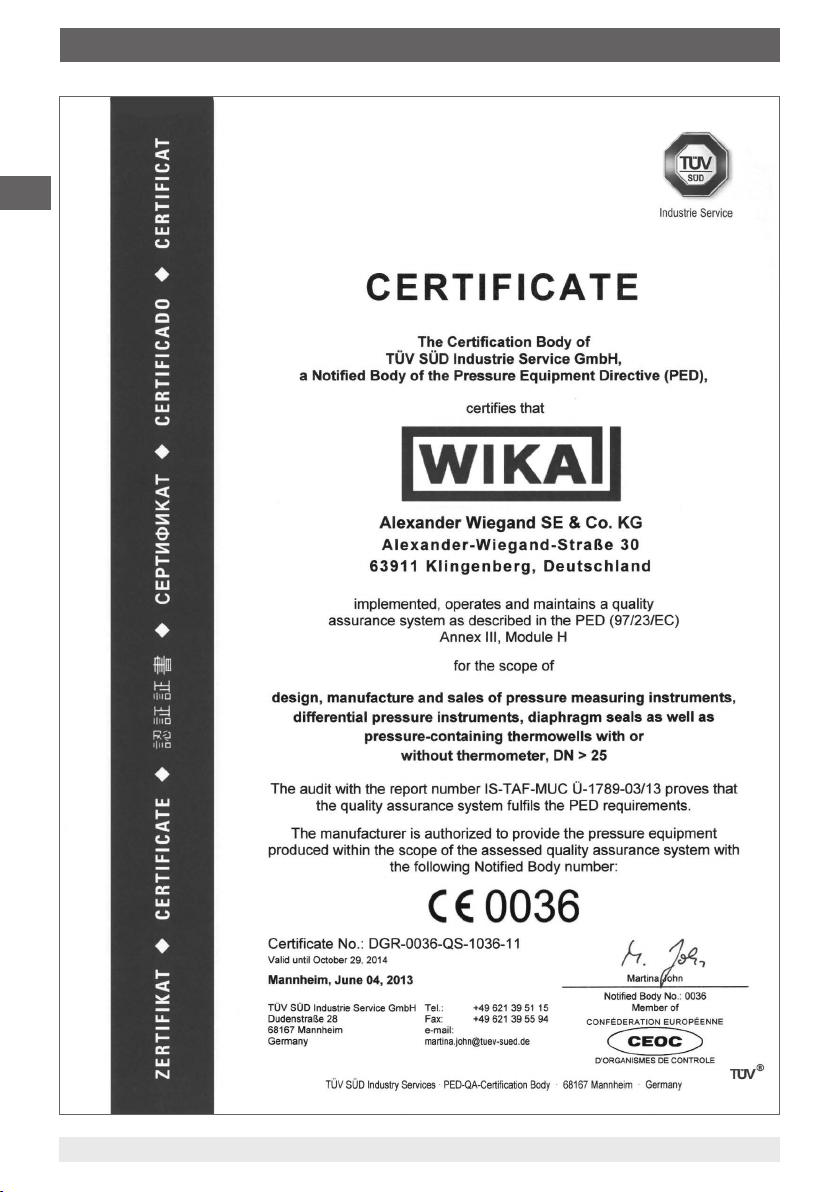

Appendix 1: TÜV certicate 16

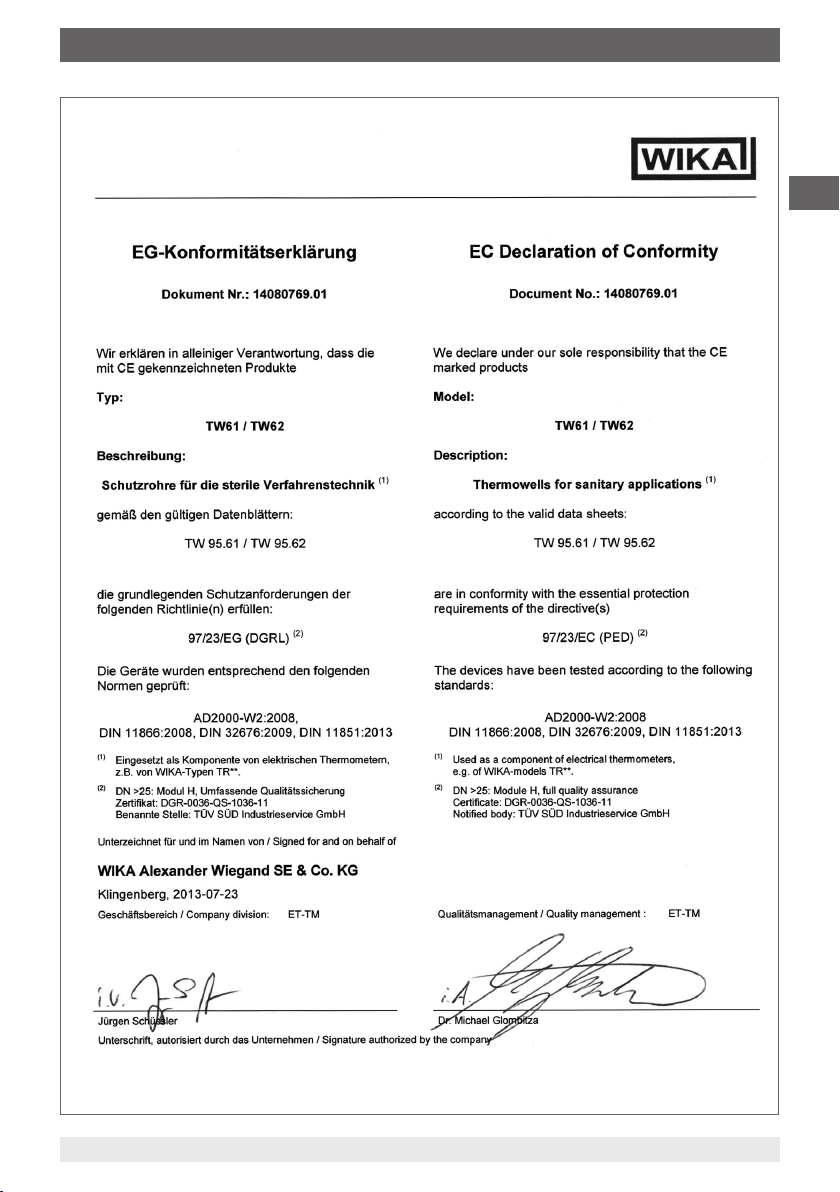

Appendix 2: EC declaration of conformity 18

Declarations of conformity can be found online at www.wika.com.

13

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

3

Page 4

1. General information

1. General information

■

The thermowells described in these operating instructions have been designed and

manufactured using state-of-the-art technology. All components are subject to stringent

GB

quality and environmental criteria during production. Our management systems are certied to

ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the thermowell.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for

the thermowell‘s range of use.

■

The operating instructions are part of the product and must be kept in the immediate vicinity of

the thermowell and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions prior to

beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instructions, assignment of

insuciently qualied skilled personnel or unauthorised modications to the thermowell.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet:

- Application consultant:

TW 95.61

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death,

if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage

to equipment or the environment, if not avoided.

Information

… points out useful tips, recommendations and information for ecient and trouble-

free operation.

4

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

Page 5

1. General information / 2. Safety

DANGER!

... identies hazards due to electrical power. Should the safety instructions not be

observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused by hot

surfaces or liquids, if not avoided.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

thermowell has been selected in terms of design and specic measuring conditions.

Before installation, commissioning and operation, ensure that the thermowell material

used is chemically resistant/neutral to the medium being measured and that it

withstands the mechanical stresses from the process.

Non-observance can result in serious injury and/or damage to the equipment.

Further important safety instructions can be found in the individual chapters of these

operating instructions.

2.1 Intended use

Thermowells are used to protect temperature sensors from the process conditions. Furthermore,

thermowells enable the removal of the temperature sensor without having to shut down the

process; and they guard against damage to either the environment or to personnel, which might

be caused by escaping process media. The model TW61 thermowell has been specically

developed for use in sanitary applications.

GB

The thermowell has been designed and built solely for the intended use described here and may

only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications requires

the instrument to be taken out of service immediately and inspected by an authorised WIKA

service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

5

Page 6

2. Safety

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

GB

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specic regulations, current standards and directives, are capable of carrying out the

work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

2.3 Special hazards

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in these operating instructions may only be carried out by

skilled personnel who have the qualications described below.

■

Keep unqualied personnel away from hazardous areas.

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases or liquids,

and refrigeration plants, compressors, etc., in addition to all standard regulations, the

appropriate existing codes or regulations must also be followed.

DANGER!

Make sure that the thermowell is suciently earthed.

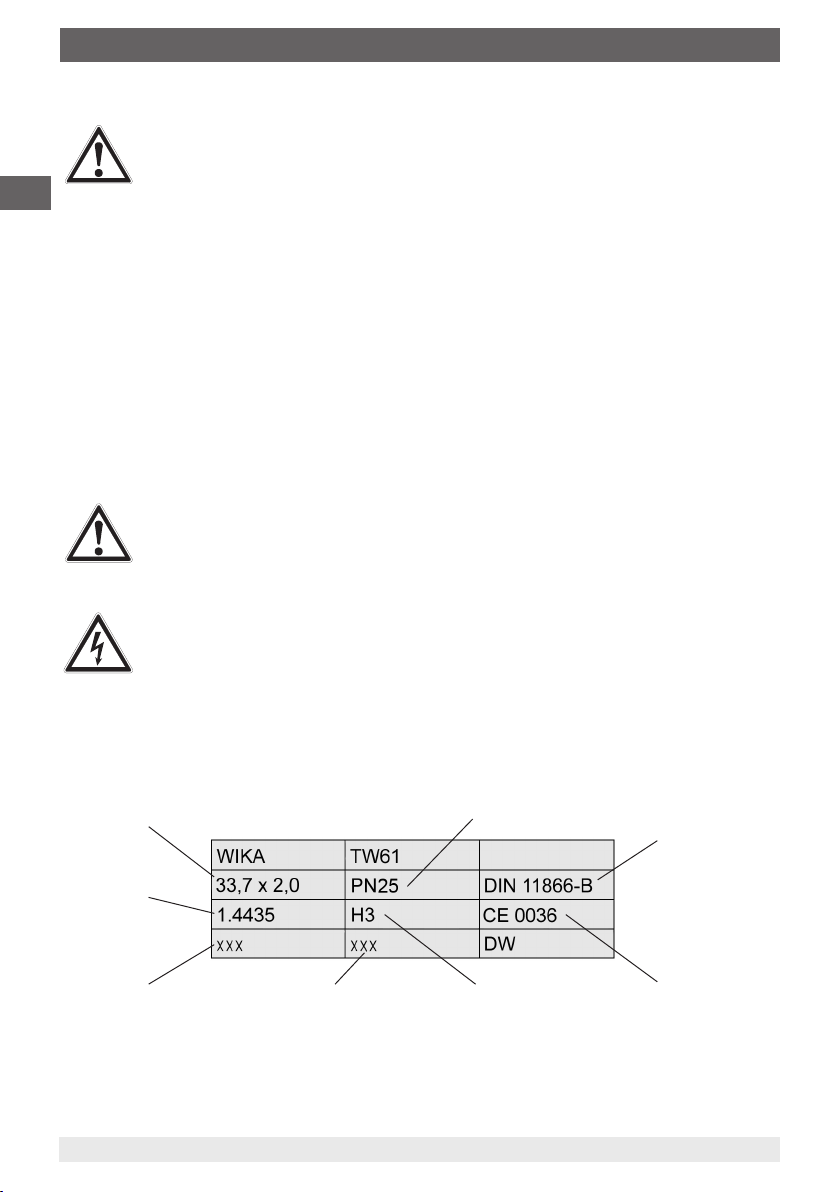

2.4 Labelling, safety marking

Outer diameter x wall thickness

Tubular body

material

Material code

(complete assembly)

6

Identication of the qualied

inspector (for stamping)

max. nominal pressure

Pipe standard

Hygiene class

WIKA operating instructions thermowell, model TW61

CE marking (required

for DN > 25 mm)

11593963.03 03/2014 GB/D/F/E

Page 7

3. Specications / 4. Design and function

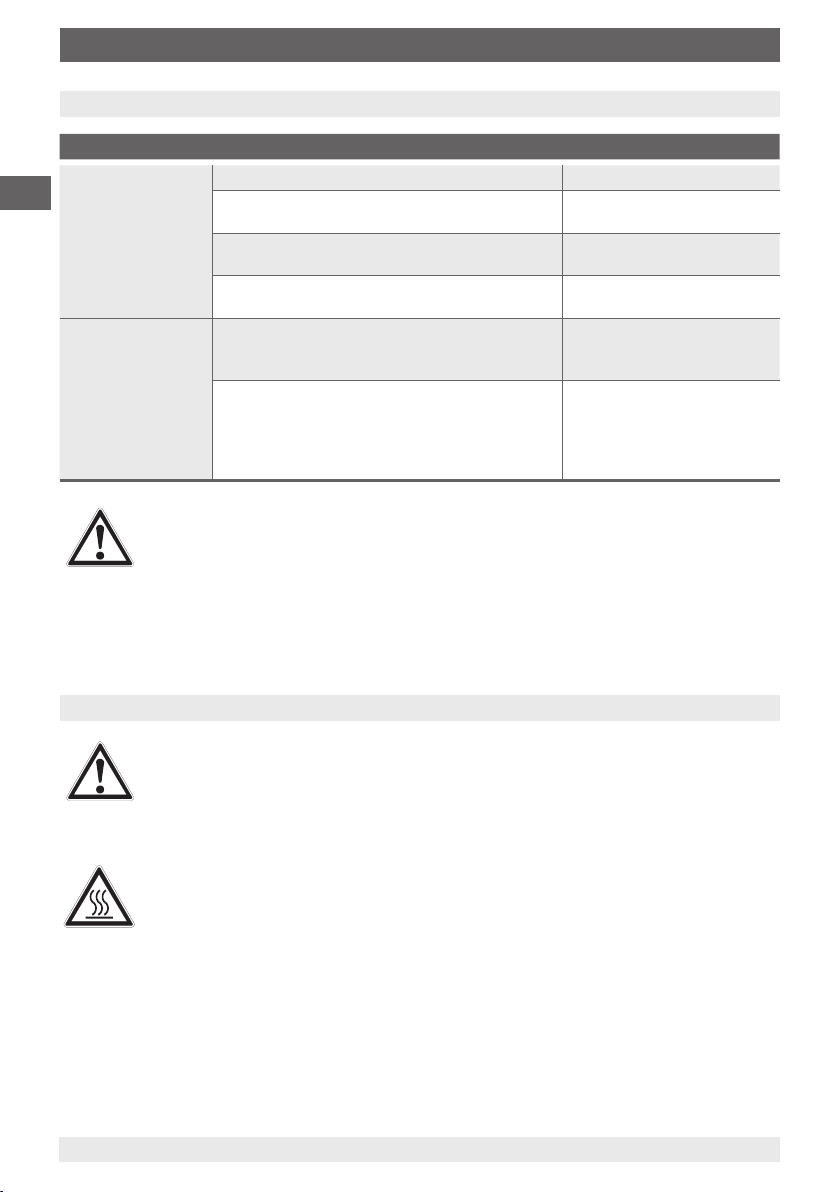

3. Specications

Specications Model TW61

Designs of connection Flow-through housing or angular housing

Nominal width of tube Pipe classes per DIN, ISO and ASME BPE

see table of dimensions, chapter 4.2 “Dimensions and

Permissible temperature ranges

■

Ambient

■

Medium to be measured

Materials (wetted parts)

■

Pipes to DIN 11866 series A (metric) and

series B (ISO)

■

Pipes to DIN 11866 series C (ASME BPE)

Connection to the thermometer Model TR21-B: G 3/8 male

For further specications see WIKA data sheet TW 95.61 and the order documentation.

4. Design and function

4.1 Description

The model TW61 thermowell is used to adapt thermometers and measuring inserts to the

process and protects the sensor against harsh process conditions. Furthermore, it enables the

removal of the temperature sensor without having to open the process.

pressure ratings”

-40 ... +85 °C

-50 ... +250 °C

Stainless steel 1.4435

Stainless steel 316L

Model TR22-B: M24 x 1.5 rotatable male nut

GB

To integrate it into the process, the thermowell is directly orbitally-welded into a pipeline. The

connection ends are smooth and prepared for orbital welding.

In combination with a resistance thermometer, the rotatable threaded connection of the

connection head or the display can be loosened and turned to the desired orientation. The

measuring insert can be withdrawn together with the connection head. In this way, it is possible to

calibrate the entire measuring chain (sensor, transmitter if applicable, connection cable) on site,

without having to disconnect the electrical connection. In addition this avoids having to open the

process, and thus the risk of contamination is minimised.

The thermowell is not piggable.

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

7

Page 8

4. Design and function

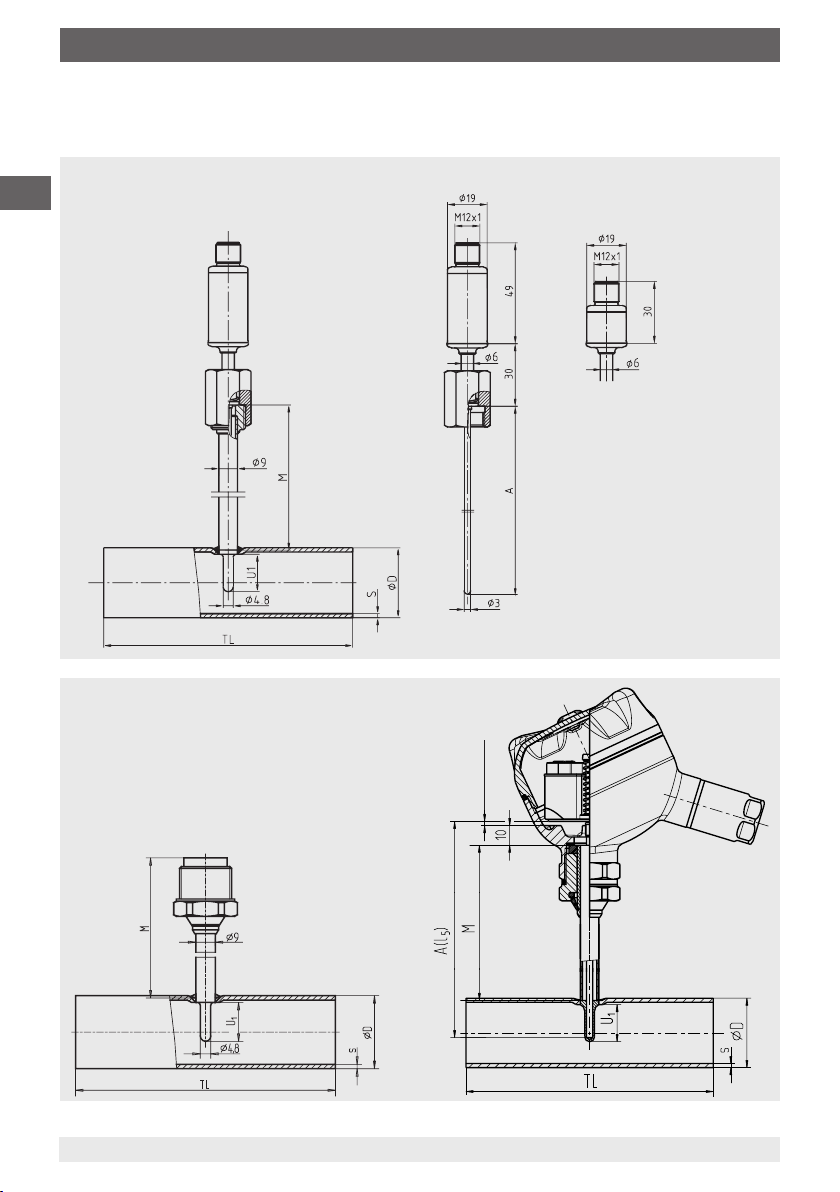

4.2 Dimensions in mm

■

Flow-through housing

For model TR21-B miniature resistance thermometer

GB

Output signal

4 ... 20 mA

1)

Output signal

Pt100

1) In the event of replacement,

calculate sensor length, A,

as follows:

A

= U1 + M + 3 mm

TR21-B

11610565.01

For model TR22-B resistance thermometer

1) In the event of replacement, select a resistance thermometer

measuring insert model TR22-B.

The corresponding sensor length, A(l5), is calculated as follows:

Insertion length U1+ neck tube length M + 5 mm pre-load +

10 mm head dimension

11528266.01

8

pre-load

1)

WIKA operating instructions thermowell, model TW61

14006093.02

11593963.03 03/2014 GB/D/F/E

Page 9

4. Design and function

Metric or DIN 11866 series A

Nominal

width of

tube

OD PN

10 25 13 1.5 70 6 51 129

15 25 19 1.5 70 9 48 126

20 25 23 1.5 80 11 46 124

25 25 29 1.5 100 18 39 117

32 25 35 1.5 110 18 39 117

40 25 41 1.5 120 18 39 117

50 25 53 1.5 160 30 27 105

65 16 70 2.0 210 30 27 105

80 16 85 2.0 260 45 12 90

100 12.5 104 2.0 310 45 12 90

Nominal

pressure

in bar

1) 2)

Outer

diameter

Tube wall

thickness

Tube

length

of pipe

Ø D s TL U

Thermowell

insertion

length

1

ISO tubes or DIN 11866 series B

Nominal

width of

tube

OD PN

13.5 25 13.5 1.6 64 6 51 129

17.2 25 17.2 1.6 68 9 48 126

21.3 25 21.3 1.6 72 11 46 124

26.9 25 26.9 1.6 110 11 46 124

33.7 25 33.7 2.0 120 18 39 117

42.4 25 42.4 2.0 130 18 39 117

48.3 25 48.3 2.0 130 18 39 117

60.3 25 60.3 2.0 180 30 27 105

76.1 16 76.1 2.0 220 30 27 105

88.9 16 88.9 2.3 260 45 12 90

Nominal

pressure

in bar

1) 2)

Outer

diameter

Tube wall

thickness

Tube

length

of pipe

Ø D s TL U

Thermowell

insertion

length

1

Neck tube length

TR21-B TR22-B

M M

Neck tube length

TR21-B TR22-B

M M

GB

ASME BPE or DIN 11866 series C

Nominal

width of

tube

OD PN

½" 13.8 12.7 1.65 95.2 6 51 129

¾" 13.8 19.05 1.65 101.6 9 48 126

1" 13.8 25.4 1.65 108.0 11 46 124

1 ½" 13.8 38.1 1.65 120.6 18 39 117

2" 13.8 50.8 1.65 146.0 18 39 117

2 ½" 13.8 63.5 1.65 158.8 30 27 105

3" 13.8 76.2 1.65 171.4 30 27 105

4" 13.8 101.6 2.11 209.6 45 12 90

1) Maximum operating temperature 150 °C

2) All thermowells of this model series which are exposed to internal pressure and have a nominal diameter (DN) of > 25 mm are

manufactured and tested in accordance with module H of the pressure equipment directive 97/23/EC.

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

Nominal

pressure

in bar

1) 2)

Outer

diameter

Tube wall

thickness

Tube

length

of pipe

Ø D s TL U

Thermowell

insertion

length

1

Neck tube length

TR21-B TR22-B

M M

9

Page 10

4. Design and function

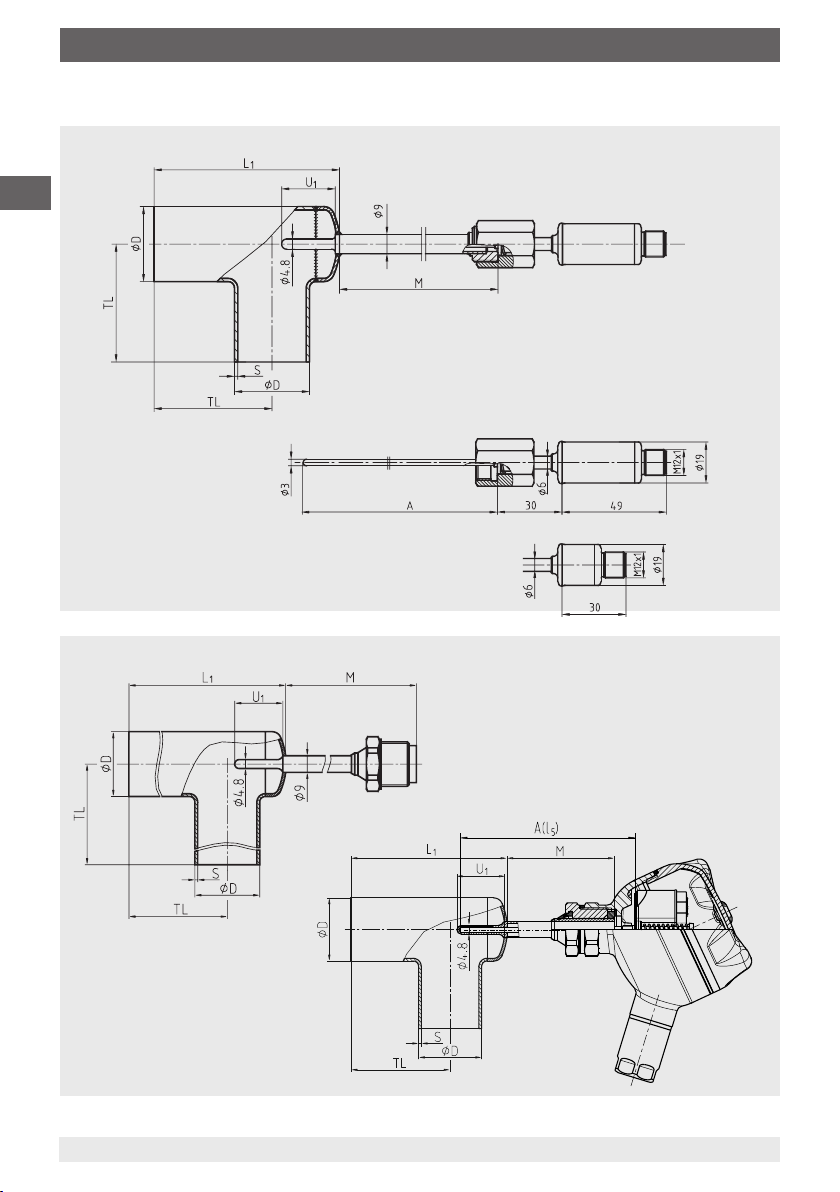

■

Angular housing (recommended mounting position, see chapter 6 “Commissioning, operation”)

For model TR21-B miniature resistance thermometer

GB

Output signal

4 ... 20 mA

11610565.01

1)

1) In the event of replacement, calculate

sensor length, A, as follows:

A

= U1 + M + 3 mm

TR21-B

For model TR22-B resistance thermometer

10

Output signal

Pt100

1) In the event of replacement, select a resistance

thermometer measuring insert model TR22-B.

The corresponding sensor length, A(l5), is

calculated as follows:

11528452.01

Insertion length U1+ neck tube length M +

5 mm pre-load + 10 mm head dimension

WIKA operating instructions thermowell, model TW61

11575795.02

11593963.03 03/2014 GB/D/F/E

Page 11

4. Design and function

Metric or DIN 11866 series A

Nominal

width of

tube

OD PN

10 25 13 1.5 35 55 14 43 121

15 25 19 1.5 35 55 18 39 117

20 25 23 1.5 40 63 18 39 117

25 25 29 1.5 50 77 30 27 105

32 25 35 1.5 55 87 30 27 105

40 25 41 1.5 60 97 30 27 105

50 25 53 1.5 80 126 30 27 105

65 16 70 2.0 105 165 45 12 90

80 16 85 2.0 130 201 45 12 90

100 12.5 104 2.0 155 241 45 12 90

Nominal

pressure

in bar

1) 2)

Outer

diameter

Tube wall

thickness

Tube

length

of pipe

Ø D s TL L

Thermowell

insertion

length

U

1

1

ISO tubes or DIN 11866 series B

Nominal

width of

tube

OD PN

13.5 25 13.5 1.6 32 55 14 43 121

17.2 25 17.2 1.6 34 55 16 41 119

21.3 25 21.3 1.6 36 58 18 39 117

26.9 25 26.9 1.6 55 81 30 27 105

33.7 25 33.7 2.0 60 91 30 27 105

42.4 25 42.4 2.0 65 102 30 27 105

48.3 25 48.3 2.0 65 108 30 27 105

60.3 25 60.3 2.0 90 145 45 12 90

76.1 16 76.1 2.0 110 173 45 12 90

88.9 16 88.9 2.3 130 203 45 12 90

Nominal

pressure

in bar

1) 2)

Outer

diameter

Tube wall

thickness

Tube

length

of pipe

Ø D s TL L

Thermowell

insertion

length

U

1

1

Neck tube length

TR21-B TR22-B

M M

Neck tube length

TR21-B TR22-B

M M

GB

ASME BPE or DIN 11866 series C

Nominal

width of

tube

OD PN

½" 13.8 12.7 1.65 47.6 71 14 43 121

¾" 13.8 19.05 1.65 50.8 71 18 39 117

1" 13.8 25.4 1.65 54.0 79 18 39 117

1 ½" 13.8 38.1 1.65 60.3 94 30 27 105

2" 13.8 50.8 1.65 73.0 118 30 27 105

2 ½" 13.8 63.5 1.65 79.4 134 45 12 90

3" 13.8 76.2 1.65 85.7 150 45 12 90

4" 13.8 101.6 2.11 104.8 190 45 12 90

1) Maximum operating temperature 150 °C

2) All thermowells of this model series which are exposed to internal pressure and have a nominal diameter (DN) of > 25 mm are

manufactured and tested in accordance with module H of the pressure equipment directive 97/23/EC.

Nominal

pressure

in bar

1) 2)

Outer

diameter

Tube wall

thickness

Tube

length

of pipe

Ø D s TL L

Thermowell

insertion

length

U

1

1

Neck tube length

TR21-B TR22-B

M M

4.3 Scope of delivery

Cross-check the scope of delivery with the delivery note.

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

11

Page 12

5. Transport, packaging and storage / 6. Commissioning, ...

5. Transport, packaging and storage

5.1 Transport

Check the thermowell for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

GB

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: 0 ... 70 °C

■

Humidity: 35 ... 85 % relative humidity (no condensation)

WARNING!

Before storing the thermowell (following operation), remove any residual media. This

is of particular importance if the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

6. Commissioning, operation

CAUTION!

Before commissioning the thermowell, clean the plant in accordance with the

cleaning specications.

The thermowell must not be bent or altered in order to mount it. The tting should be carried

out such that there can be no damage to the thermowell as a result of the plant operation or the

operator. If necessary, one of the thermowell/pipeline mountings mentioned below (e.g. using a

pipe clamp) will be required. In particular, the neck should be secured by appropriate methods

against bending.

Version for orbital welding

In the orbital welding version, the TW61 is directly welded into the pipeline. Weld the thermowell

centered, without axial oset (without irregularities), orbitally in the pipeline.The weld joint should

therefore be made with appropriate care and in line with the applicable and accredited welding

procedures and tested. Likewise, the requirements of the 97/23/EC pressure equipment directive

should be followed.

For general information on the design of a hygienic weld, we recommend the following

documents (among others):

■

EHEDG guideline 35 - Welding of stainless steel tubing in the food industry

■

EHEDG guideline 9 - Welding stainless steel to meet hygienic requirements

■

EHEDG guideline 8 - Hygienic equipment design criteria, 7.5

■

3-A® sanitary standard for sensors and sensor ttings, number 74-06, D 6.1.4

12

WIKA operating instructions thermowell, model TW61

11593963.03 03/2014 GB/D/F/E

Page 13

6. Commissioning, operation / 7. Maintenance and cleaning

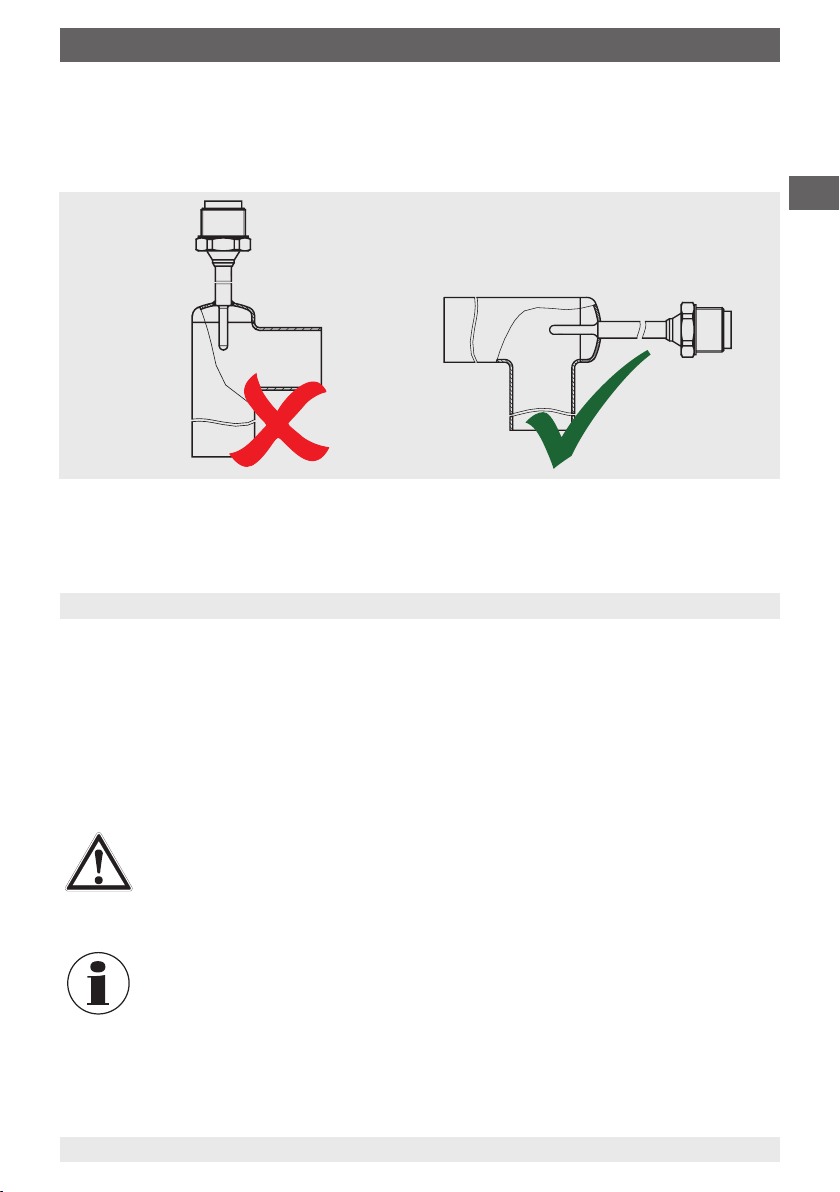

Recommended installation for the angular housing design

Concerning the angular housing design it is recommended, to install the sensor horizontally and

not vertically in the pipeline. Consequently the formation of an air pocket during sterilization in the

cupola is avoided.

7. Maintenance and cleaning

GB

7.1 Maintenance

In general, thermowells are maintenance-free.

We recommend a visual check of the thermowell for leaks and damages at regular intervals.

Make sure that the seal is in perfect condition!

Repairs should only be carried out by the manufacturer or, following prior consultation, by

correspondingly qualied skilled personnel.

7.2 Cleaning

CAUTION!

■

Wash or clean the dismounted instrument before returning it, in order to protect

personnel and the environment from exposure to residual media.

■

Residual media in the dismounted thermowell can result in a risk to persons, the

environment and equipment. Sucient precautionary measures must be taken.

For information on returning the instrument see chapter 9.2 “Return”.

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

13

Page 14

8. Faults / 9. Dismounting, return and disposal

8. Faults

Faults Causes Measures

Not possible

GB

to insert the

temperature sensor

into the thermowell

Escape of process

medium

CAUTION!

If faults cannot be eliminated by means of the measures listed above, shut down the

instrument immediately, and ensure that pressure and/or signal are no longer present,

and secure the instrument from being put back into operation inadvertently.

In this case, contact the manufacturer.

If a return is needed, follow the instructions given in chapter 9.2 “Return”.

Foreign bodies in the thermowell Remove foreign bodies

Damaged or contaminated fastening thread on

thermowell or temperature sensor

Damaged fastening thread on thermowell or

temperature sensor

Thermowell or sensor has been bent or

damaged during installation

Where there is an escape of process medium

at the process connection, errors in mounting or

faulty seals can be the cause.

Should process media escape at the interface

between the thermowell and the temperature

sensor or at the temperature sensor itself,

safe operation of the plant can no longer be

guaranteed

Clean the threads

Return the thermowell

(see chapter 9.2 “Returns”)

Return for repair

Check the seal and also

check the tightening torques

Remove the thermowell from

operation and contact WIKA

9. Dismounting, return and disposal

WARNING!

Residual media in the dismounted thermowell can result in a risk to persons, the

environment and equipment. Sucient precautionary measures must be taken.

9.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting! During dismounting

there is a risk of dangerously hot pressure media escaping.

Only disconnect thermowells once the system has been depressurised!

14

WIKA operating instructions thermowell, model TW61

11593963.03 03/2014 GB/D/F/E

Page 15

9. Dismounting, return and disposal

9.2 Return

WARNING!

Absolutely observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, leachate, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the shipping box.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading „Service“ on our local

website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible

way and in accordance with the country-specic waste disposal regulations.

GB

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

15

Page 16

Appendix 1: TÜV certicate

GB

16

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

Page 17

Appendix 2: EC declaration of conformity

GB

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

17

Page 18

GB

18

11593963.03 03/2014 GB/D/F/E

WIKA operating instructions thermowell, model TW61

Page 19

Inhalt

Inhalt

1. Allgemeines 20

2. Sicherheit 21

3. Technische Daten 23

4. Aufbau und Funktion 23

5. Transport, Verpackung und Lagerung 28

6. Inbetriebnahme, Betrieb 28

Wartung und Reinigung

7.

8. Störungen 30

9. Demontage, Rücksendung und Entsorgung 30

Anlage 1: TÜV-Zertikat 32

Anlage 2: EG-Konformitätserklärung 34

Konformitätserklärungen nden Sie online unter www.wika.de.

29

D

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

19

Page 20

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Schutzrohre werden nach dem aktuellen Stand

der Technik gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Schutzrohr.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Schutzrohres geltenden örtlichen Unfallverhütungsvorschriften

und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Schutzrohres für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung,

Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten Fachpersonals

sowie eigenmächtiger Veränderung am Schutzrohr.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt:

- Anwendungsberater:

TW 95.61

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder

leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten

und störungsfreien Betrieb hervor.

20

WIKA Betriebsanleitung Schutzrohr, Typ TW61

11593963.03 03/2014 GB/D/F/E

Page 21

1. Allgemeines / 2. Sicherheit

GEFAHR!

… kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der

Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie nicht

gemieden wird.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Schutzrohr

hinsichtlich Ausführung und spezischen Messbedingungen ausgewählt wurde.

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der verwendete

Schutzrohrwerksto gegenüber dem Messmedium chemisch beständig/neutral ist,

sowie den prozessseitigen mechanischen Belastungen stand hält.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden

auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln dieser

Betriebsanleitung.

D

2.1 Bestimmungsgemäße Verwendung

Schutzrohre dienen zum Schutz des Temperaturfühlers gegenüber den Prozessbedingungen.

Des Weiteren ermöglichen Schutzrohre den Ausbau des Temperaturfühlers ohne den Prozess

stillzulegen und verhindern Umwelt- oder Personenschäden durch den Austritt von Prozessmedium. Das Schutzrohr Typ TW61 wurde speziell für den Einsatz in der sterilen Verfahrenstechnik entwickelt.

Das Schutzrohr ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezikationen

macht die sofortige Stilllegung und Überprüfung durch einen autorisierten WIKA-Servicemitarbeiter erforderlich.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

21

Page 22

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal

nachfolgend beschriebener Qualikation durchführen lassen.

■

D

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess- und

Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften,

geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen und

mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über agressive

Medien.

2.3 Besondere Gefahren

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen

Stoen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die gesamten

allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

GEFAHR!

Auf ausreichende Erdung des Schutzrohres achten.

2.4 Beschilderung, Sicherheitskennzeichnungen

Außendurchmesser x Wandstärke

Material

Rohrkörper

Materialcode

(Baugruppe komplett)

22

Kurzzeichen des

Umstempelberechtigten Prüfers

max. Nenndruck

Rohrnorm

Hygieneklasse

WIKA Betriebsanleitung Schutzrohr, Typ TW61

CE-Kennzeichen

(erforderlich DN > 25 mm)

11593963.03 03/2014 GB/D/F/E

Page 23

3. Technische Daten / 4. Aufbau und Funktion

3. Technische Daten

Technische Daten Typ TW61

Bauformen Durchgangsgehäuse oder Eckgehäuse

Rohr-Nennweite Rohrklassen nach DIN, ISO und ASME BPE

Zulässige Temperaturbereiche

■

Umgebung

■

Messmedium

Werkstoe (messstofberührte

Bauteile)

■

Rohre nach DIN 11866 Reihe A

(metrisch) und Reihe B (ISO)

■

Rohre nach DIN 11866 Reihe C

(ASME BPE)

Anschluss zum Thermometer Typ TR21-B: G 3/8 Außengewinde

Weitere technische Daten siehe WIKA-Datenblatt TW 95.61 und Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Das Schutzrohr Typ TW61 dient zur Prozessadaption eines Thermometers bzw. Messeinsatzes

und schützt den Sensor vor rauen Prozessbedingungen. Des Weiteren ermöglicht es den

Ausbau des Temperaturfühlers ohne den Prozess önen zu müssen.

siehe Maßtabellen Kapitel 4.2 „Abmessungen und Druckstufen“

-40 ... +85 °C

-50 ... +250 °C

CrNi-Stahl 1.4435

CrNi-Stahl 316L

Typ TR22-B: Druckschraube M24 x 1,5 drehbar

D

Für die Einbindung in den Prozess wird das Schutzrohr direkt orbital in eine Rohrleitung eingeschweißt. Die Anschlussenden sind glatt und zum Orbitalschweißen vorbereitet.

Bei einer Kombination mit einem Widerstandsthermometer lassen sich durch die drehbare

Verschraubung der Anschlusskopf oder die Anzeige lösen und in die gewünschte Richtung

drehen. Der Messeinsatz ist zusammen mit Anschlusskopf herausziehbar. Dadurch ist es

möglich, die gesamte Messkette (Sensor, ggf. Transmitter, Anschlusskabel) vor Ort zu kalibrieren, ohne Abklemmen der elektrischen Anschlüsse. Zudem wird es vermieden, den Prozess zu

önen und damit ein Hygienerisiko minimiert.

Das Schutzrohr ist nicht molchbar.

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

23

Page 24

4. Aufbau und Funktion

4.2 Abmessungen in mm

■

Durchgangsgehäuse

Für Miniatur-Widerstandsthermometer Typ TR21-B

D

11610565.01

Ausgangssignal

Pt100

1)

Für Widerstandsthermometer Typ TR22-B

1) Im Ersatzfall ist ein Widerstandsthermometer-Messeinsatz

Typ TR22-B zu wählen.

Die entsprechende Sensorlänge A(l5) errechnet sich wie folgt:

Einbaulänge U1+ Halsrohrlänge M + 5 mm Vorspannung +

10 mm Kopfmaß

24

Ausgangssignal

4 ... 20 mA

Vorspannung

11528266.01

1)

1) Im Ersatzfall errechnet sich

die Sensorlänge A wie folgt:

A

TR21-B

WIKA Betriebsanleitung Schutzrohr, Typ TW61

= U1 + M + 3 mm

14006093.02

11593963.03 03/2014 GB/D/F/E

Page 25

4. Aufbau und Funktion

Metrisch bzw. DIN 11866 Reihe A

RohrNennweite

OD PN

10 25 13 1,5 70 6 51 129

15 25 19 1,5 70 9 48 126

20 25 23 1,5 80 11 46 124

25 25 29 1,5 100 18 39 117

32 25 35 1,5 110 18 39 117

40 25 41 1,5 120 18 39 117

50 25 53 1,5 160 30 27 105

65 16 70 2,0 210 30 27 105

80 16 85 2,0 260 45 12 90

100 12,5 104 2,0 310 45 12 90

Nenndruck

in bar

1) 2)

Rohraußen-Ø

Ø D s TL U

Rohrwandstärke

Rohrlänge

Schutzrohreinbaulänge

1

ISO-Rohre bzw. DIN 11866 Reihe B

RohrNennweite

OD PN

13,5 25 13,5 1,6 64 6 51 129

17,2 25 17,2 1,6 68 9 48 126

21,3 25 21,3 1,6 72 11 46 124

26,9 25 26,9 1,6 110 11 46 124

33,7 25 33,7 2,0 120 18 39 117

42,4 25 42,4 2,0 130 18 39 117

48,3 25 48,3 2,0 130 18 39 117

60,3 25 60,3 2,0 180 30 27 105

76,1 16 76,1 2,0 220 30 27 105

88,9 16 88,9 2,3 260 45 12 90

Nenndruck

in bar

1) 2)

Rohraußen-Ø

Ø D s TL U

Rohrwandstärke

Rohrlänge

Schutzrohreinbaulänge

1

Halsrohrlänge

TR21-B TR22-B

M M

Halsrohrlänge

TR21-B TR22-B

M M

D

ASME BPE bzw. DIN 11866 Reihe C

RohrNennweite

OD PN

½" 13,8 12,7 1,65 95,2 6 51 129

¾" 13,8 19,05 1,65 101,6 9 48 126

1" 13,8 25,4 1,65 108,0 11 46 124

1 ½" 13,8 38,1 1,65 120,6 18 39 117

2" 13,8 50,8 1,65 146,0 18 39 117

2 ½" 13,8 63,5 1,65 158,8 30 27 105

3" 13,8 76,2 1,65 171,4 30 27 105

4" 13,8 101,6 2,11 209,6 45 12 90

1) Maximale Betriebstemperatur 150 °C

2) Alle innendruckbeaufschlagte Schutzrohre dieser Typenreihe mit einem Nenndurchmesser (DN) > 25 mm werden nach Modul H der

Druckgeräterichtlinie 97/23/EG gefertigt und geprüft.

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

Nenndruck

in bar

1) 2)

Rohraußen-Ø

Ø D s TL U

Rohrwandstärke

Rohrlänge

Schutzrohreinbaulänge

1

Halsrohrlänge

TR21-B TR22-B

M M

25

Page 26

4. Aufbau und Funktion

■

Eckgehäuse (empfohlene Einbaulage, siehe Kapitel 6 „Inbetriebnahme, Betrieb“)

Für Miniatur-Widerstandsthermometer Typ TR21-B

D

Ausgangssignal

4 ... 20 mA

1) Im Ersatzfall errechnet sich die

Sensorlänge A wie folgt:

A

= U1 + M + 3 mm

TR21-B

Für Widerstandsthermometer Typ TR22-B

1)

Ausgangssignal

Pt100

11528452.01

1) Im Ersatzfall ist ein WiderstandsthermometerMesseinsatz Typ TR22-B zu wählen.

Die entsprechende Sensorlänge A(l5) errechnet

sich wie folgt:

Einbaulänge U1+ Halsrohrlänge M + 5 mm

Vorspannung + 10 mm Kopfmaß

11610565.01

26

11575795.02

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

Page 27

4. Aufbau und Funktion

Metrisch bzw. DIN 11866 Reihe A

RohrNennweite

OD PN

10 25 13 1,5 35 55 14 43 121

15 25 19 1,5 35 55 18 39 117

20 25 23 1,5 40 63 18 39 117

25 25 29 1,5 50 77 30 27 105

32 25 35 1,5 55 87 30 27 105

40 25 41 1,5 60 97 30 27 105

50 25 53 1,5 80 126 30 27 105

65 16 70 2,0 105 165 45 12 90

80 16 85 2,0 130 201 45 12 90

100 12,5 104 2,0 155 241 45 12 90

Nenndruck

in bar

1) 2)

Rohraußen-Ø

Ø D s TL L1U

Rohrwandstärke

Rohrlänge Schutzrohr-

einbaulänge

1

ISO-Rohre bzw. DIN 11866 Reihe B

RohrNennweite

OD PN

13,5 25 13,5 1,6 32 55 14 43 121

17,2 25 17,2 1,6 34 55 16 41 119

21,3 25 21,3 1,6 36 58 18 39 117

26,9 25 26,9 1,6 55 81 30 27 105

33,7 25 33,7 2,0 60 91 30 27 105

42,4 25 42,4 2,0 65 102 30 27 105

48,3 25 48,3 2,0 65 108 30 27 105

60,3 25 60,3 2,0 90 145 45 12 90

76,1 16 76,1 2,0 110 173 45 12 90

88,9 16 88,9 2,3 130 203 45 12 90

Nenndruck

in bar

1) 2)

Rohraußen-Ø

Ø D s TL L1U

Rohrwandstärke

Rohrlänge Schutzrohr-

einbaulänge

1

Halsrohrlänge

TR21-B TR22-B

M M

Halsrohrlänge

TR21-B TR22-B

M M

D

ASME BPE bzw. DIN 11866 Reihe C

RohrNennweite

OD PN

½" 13,8 12,7 1,65 47,6 71 14 43 121

¾" 13,8 19,05 1,65 50,8 71 18 39 117

1" 13,8 25,4 1,65 54,0 79 18 39 117

1 ½" 13,8 38,1 1,65 60,3 94 30 27 105

2" 13,8 50,8 1,65 73,0 118 30 27 105

2 ½" 13,8 63,5 1,65 79,4 134 45 12 90

3" 13,8 76,2 1,65 85,7 150 45 12 90

4" 13,8 101,6 2,11 104,8 190 45 12 90

1) Maximale Betriebstemperatur 150 °C

2) Alle innendruckbeaufschlagte Schutzrohre dieser Typenreihe mit einem Nenndurchmesser (DN) > 25 mm werden nach Modul H der

Druckgeräterichtlinie 97/23/EG gefertigt und geprüft.

Nenndruck

in bar

1) 2)

Rohraußen-Ø

Ø D s TL L1U

Rohrwandstärke

Rohrlänge Schutzrohr-

einbaulänge

1

Halsrohrlänge

TR21-B TR22-B

M M

4.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

27

Page 28

5. Transport, Verpackung, Lagerung / 6. Inbetriebnahme, ...

5. Transport, Verpackung und Lagerung

5.1 Transport

Das Schutzrohr auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

D

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen Schutz

(z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: 0 ... 70 °C

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

WARNUNG!

Vor der Einlagerung des Schutzrohres (nach Betrieb) alle anhaftenden Messstoreste entfernen. Dies ist besonders wichtig, wenn der Messsto gesundheitsgefähr-

dend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

6. Inbetriebnahme, Betrieb

VORSICHT!

Vor Inbetriebnahme das Schutzrohr entsprechend den Reinigungsvorschriften der

Anlage reinigen.

Ein Verbiegen oder Anpassen des Schutzrohres zur Montage ist nicht zulässig. Der Einbau hat

so zu erfolgen, dass Beschädigungen des Schutzrohres durch den Anlagenbetrieb oder den

Anwender ausgeschlossen werden. Gegebenenfalls ist dafür eine über die unten beschriebene hinausgehende Befestigung des Schutzrohres/der Rohrleitung (z. B. mittels Rohrschellen)

notwendig. Insbesondere der Hals ist durch geeignete Maßnahmen vor Abknicken zu schützen.

Ausführung zum orbitalen Einschweißen

In der Ausführung zum orbitalen Einschweißen ist das TW61 direkt in die Rohrleitung einzuschweißen. Das Schutzrohr zentrisch ohne Achsversatz (stufenfrei) in die Rohrleitung orbital

einschweißen. Die Schweißverbindung ist dabei mit der erforderlichen Sorgfalt und unter Beachtung der gültigen und anerkannten Schweißverfahren herzustellen und zu prüfen. Ebenso sind

die Vorgaben der Druckgeräterichtlinie 97/23/EG zu beachten.

Für generelle Hinweise zur Ausführung einer hygienegerechten Schweißverbindung empfehlen

sich u.a. folgende Dokumente:

■

EHEDG Guideline 35 - Welding of stainless steel tubing in the food industry

■

EHEDG Guideline 9 - Welding stainless steel to meet hygienic requirements

■

EHEDG Guideline 8 - Hygienic equipment design criteria, 7.5

■

3-A® sanitary standard for sensors and sensor ttings, number 74-06, D 6.1.4

28

WIKA Betriebsanleitung Schutzrohr, Typ TW61

11593963.03 03/2014 GB/D/F/E

Page 29

6. Inbetriebnahme, Betrieb / 7. Wartung und Reinigung

Einbauempfehlung für die Ausführung mit Eckgehäuse

Bei der Ausführung mit Eckgehäuse wird empfohlen, den Fühler waagerecht und nicht

senkrecht in die Rohrleitung einzubauen. Somit wird die Bildung eines Luftpolsters während der

Sterilisation im Dom vermieden.

7. Wartung und Reinigung

7.1 Wartung

Schutzrohre sind im Allgemeinen wartungsfrei.

Empfohlen wird eine Sichtüberprüfung des Schutzrohres auf Leckagen oder Beschädigungen in

regelmäßigen Intervallen. Insbesondere auf einwandfreie Funktion der Dichtung achten!

D

Reparaturen sind ausschließlich vom Hersteller oder nach Absprache durch entsprechend

qualiziertes Fachpersonal durchzuführen.

7.2 Reinigung

VORSICHT!

■

Ausgebautes Gerät vor der Rücksendung spülen bzw. säubern, um Mitarbeiter

und Umwelt vor Gefährdung durch anhaftende Messstoreste zu schützen.

■

Messstoreste an ausgebauten Schutzrohren können zur Gefährdung von

Personen, Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen

sind zu ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 9.2 „Rücksendung“.

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

29

Page 30

8. Störungen / 9. Demontage, Rücksendung und Entsorgung

8. Störungen

Störungen Ursachen Maßnahmen

Temperaturfühler

lässt sich nicht in

das Schutzrohr

einführen

D

Austritt von Prozessmedium

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht beseitigt werden,

ist das Gerät unverzüglich außer Betrieb zu setzen, sicherzustellen, dass kein Druck

bzw. Signal mehr anliegt und gegen versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise siehe Kapitel 9.2 „Rücksendung“

beachten.

Fremdkörper im Schutzrohr Fremdkörper entfernen

Verschmutzte Befestigungsgewinde von

Schutzrohr oder Temperaturfühler

Beschädigte Befestigungsgewinde von

Schutzrohr oder Temperaturfühler

Schutzrohr oder Fühler wurde bei Montage

verbogen oder beschädigt

Bei Austritt von Prozessmedium am

Prozessanschluss können Fehler bei der

Montage oder fehlerhafte Dichtungen die

Ursache sein.

Tritt Prozessmedium an der Schnittstelle des

Schutzrohres zu Temperaturfühler oder am

Temperaturfühler selbst aus ist ein sicherer

Betrieb der Anlage nicht mehr gewährleistet

Gewinde reinigen

Schutzrohr zurücksenden

(siehe Kapitel 9.2 „Rücksendung“)

Zur Reparatur zurück senden

Dichtung überprüfen sowie die

Anzugsmomente kontrollieren

Schutzrohr außer Betrieb setzen

und Kontakt mit WIKA aufnehmen

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste an ausgebauten Schutzrohren können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen sind zu

ergreifen.

9.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen! Beim Ausbau besteht

Gefahr durch austretende, gefährlich heiße Messstoe.

Schutzrohre nur im drucklosen Zustand demontieren!

30

WIKA Betriebsanleitung Schutzrohr, Typ TW61

11593963.03 03/2014 GB/D/F/E

Page 31

9. Demontage, Rücksendung und Entsorgung

9.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren, Laugen,

Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung

verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf unserer lokalen

Internetseite.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

D

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

31

Page 32

Anlage 1: TÜV-Zertikat

D

32

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

Page 33

Anlage 2: EG-Konformitätserklärung

D

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

33

Page 34

D

34

11593963.03 03/2014 GB/D/F/E

WIKA Betriebsanleitung Schutzrohr, Typ TW61

Page 35

Sommaire

Sommaire

1. Généralités 36

2. Sécurité 37

3. Spécications 39

4. Conception et fonction 39

5. Transport, emballage et stockage 44

6. Mise en service, exploitation 44

Entretien et nettoyage

7.

8. Dysfonctionnements 46

9. Démontage, retour et mise au rebut 46

Annexe 1 : Certicat du TÜV (contrôle technique allemand) 48

Annexe 2 : Déclaration de conformité CE 49

Déclarations de conformité se trouve sur www.wika.fr.

45

F

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

35

Page 36

1. Généralités

1. Généralités

■

Les doigts de gant décrits dans ce mode d'emploi sont conçus et fabriqués selon les

dernières technologies en vigueur. Tous les composants sont soumis à des critères de qualité

et d'environnement stricts durant la fabrication. Nos systèmes de gestion sont certiés selon

ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation du doigt de

gant. Il est possible de travailler en toute sécurité avec ce produit en respectant toutes les

F

consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les prescriptions

générales de sécurité en vigueur pour le domaine d'application du doigt de gant.

■

Le mode d'emploi fait partie du produit et doit être conservé à proximité immédiate du doigt de

gant et être accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement et

compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par une

utilisation non conforme à l'usage prévu, de non respect de ce mode d'emploi, d'utilisation de

personnel peu qualié de même qu'en cas de modications du doigt de gant eectuées par

l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d‘autres informations:

- Consulter notre site internet : www.wika.fr

- Fiche technique correspondante :

- Conseiller applications :

TW 95.61

Tel. : +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou

des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de provoquer de

légères blessures ou des dommages matériels et pour l'environnement si elle n'est

pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

36

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

Page 37

1. Généralités / 2. Sécurité

DANGER !

… indique les dangers liés au courant électrique. Danger de blessures graves ou

mortelles en cas de non respect des consignes de sécurité.

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer des

brûlures dues à des surfaces ou liquides chauds si elle n'est pas évitée.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que la gaine

a été choisie de façon adéquate, en ce qui concerne la version et les conditions de

mesure spéciques.

Avant l'installation, la mise en service et l'utilisation, assurez-vous que le matériau

utilisé pour le doigt de gant est chimiquement résistant/neutre au uide qui est

mesuré et qu'il résiste aux contraintes mécaniques venant du processus.

Un non-respect de cette consigne peut entraîner des blessures corporelles graves et/

ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections individuelles du

présent mode d'emploi.

F

2.1 Utilisation conforme à l'usage prévu

Les doigts de gant sont utilisés pour protéger les capteurs de température des conditions de

process. Les doigts de gant permettent en outre le retrait du capteur de température sans avoir

à arrêter le process; ils permettent également d'éviter tout dommage pour l'environnement ou le

personnel pouvant résulter d'un écoulement de uide de process. Le doigt de gant type TW61 a

été spécialement conçu pour être utilisé dans des applications sanitaires.

Le doigt de gant est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respectées. En

cas d'utilisation inadéquate ou de fonctionnement de l'instrument en dehors des spécications

techniques, un arrêt et contrôle doivent être immédiatement eectués par un collaborateur

autorisé du service de WIKA.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage prévu.

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

37

Page 38

2. Sécurité

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages corporels et

matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées que par

un personnel ayant la qualication décrite ci-après.

■

Tenir le personnel non qualié à lécart des zones dangereuses.

F

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances dans le

domaine de la technique de mesure et de régulation et de ses expériences de même que de

sa connaissance des prescriptions nationales, des normes et directives en vigueur, en mesure

d'eectuer les travaux décrits et de reconnaître automatiquement les dangers potentiels.

Les conditions d'utilisation spéciales exigent également une connaissance adéquate par

exemple des liquides agressifs.

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l'oxygène,

l'acétylène, les substances combustibles ou toxiques, ainsi que dans le cas

d'installations de réfrigération, de compresseurs etc., les directives appropriées

existantes doivent être observées en plus de l'ensemble des règles générales.

DANGER !

Assurez-vous que le doigt de gant est susamment mis à la terre.

2.4 Étiquetage, marquages de sécurité

Diamètre extérieur x épaisseur

Matériau du

corps tubulaire

Code du matériau

(assemblage complet)

38

Identication de l'inspecteur

qualié (pour l'homologation)

Pression nominale max.

Tuyauterie

standard

Classe hygiénique

WIKA mode d'emploi doigt de gant, type TW61

Marquage CE (requis

pour DN > 25 mm)

11593963.03 03/2014 GB/D/F/E

Page 39

3. Spécications / 4. Conception et fonction

3. Spécications

Spécications Type TW61

Formes du raccord Montage en ligne ou montage coudé

Taille nominale du tube Classes de tube selon DIN, ISO et ASME BPE

voir tableau des dimensions, chapitre 4.2 “Dimensions et

Plages de température admissibles

■

Ambiante

■

Fluide à mesurer

Matériaux (parties en contact avec le

uide)

■

Tuyauteries pour DIN 11866 série A

(métrique) et série B (ISO)

■

Tuyauteries pour DIN 11866 série C

(ASME BPE)

Raccord au thermomètre Type TR21-B : G 3/8 mâle

Pour de plus amples spécications, voir la che technique WIKA TW 95.61 et la documentation

de commande.

4. Conception et fonction

indications de pression”

-40 ... +85 °C

-50 ... +250 °C

Acier inox 1.4435

Acier inox 316L

Type TR22-B : raccord tournant M24 x 1,5

F

4.1 Description

Le doigt de gant type TW61 est utilisé pour adapter des thermomètres et des inserts de mesure

au process et pour protéger le capteur des conditions de process diciles. Il permet en outre le

retrait du capteur de température sans avoir à interrompre le process.

Pour l'intégration dans le process, le doigt de gant est soudé directement de manière orbitale

dans une conduite. Les extrémités de raccordement sont lisses et préparées pour la soudure

orbitale.

En combinaison avec une sonde à résistance, le raccordement leté tournant de la tête de

raccordement ou l'achage peuvent être desserrés et tournés dans l'orientation voulue. L'insert

de mesure peut être retiré avec la tête de raccordement. Ainsi, il est possible de calibrer la

totalité de la chaîne de mesure (capteur, transmetteur s'il est applicable, câble de connexion) sur

place, sans avoir à débrancher le raccordement électrique. En outre, ceci évite d'avoir à ouvrir le

process, et ainsi le risque de contamination est minimisé.

Le doigt de gant ne peut pas être raclé.

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

39

Page 40

4. Conception et fonction

4.2 Dimensions en mm

■

Montage en ligne

Pour sonde à résistance miniature type TR21-B

F

Pour sonde à résistance miniature type TR22-B

1) Dans le cas d’un remplacement, choisir un insert de mesure pour la

sonde à résistance de type TR22-B.

La longueur correspondante du capteur, A(l5), est calculée comme suit :

Longueur d’insertion U1+ longueur totale extension M + 5 mm pré-charge

+ 10 mm dimension de la tête

Signal de sortie

4 ... 20 mA

pré-charge

1)

Signal de sortie

Pt100

1) En cas de remplacement,

calculer la longueur du

capteur, A, comme suit :

A

= U1 + M + 3 mm

TR21-B

11610565.01

14006093.02

40

11528266.01

1)

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

Page 41

4. Conception et fonction

Métrique ou DIN 11866 série A

Taille

nominale

du tube

OD PN

10 25 13 1,5 70 6 51 129

15 25 19 1,5 70 9 48 126

20 25 23 1,5 80 11 46 124

25 25 29 1,5 100 18 39 117

32 25 35 1,5 110 18 39 117

40 25 41 1,5 120 18 39 117

50 25 53 1,5 160 30 27 105

65 16 70 2,0 210 30 27 105

80 16 85 2,0 260 45 12 90

100 12,5 104 2,0 310 45 12 90

Pression

nominale

en bar

1) 2)

Diamètre

extérieur de

la tuyauterie

Ø D s TL U

Epaisseur

de paroi de

la tuyauterie

Longueur

de tube

Longueur

d'insertion du

doigt de gant

1

Tuyauteries ISO ou DIN 11866 série B

Taille

nominale

du tube

OD PN

13,5 25 13,5 1,6 64 6 51 129

17,2 25 17,2 1,6 68 9 48 126

21,3 25 21,3 1,6 72 11 46 124

26,9 25 26,9 1,6 110 11 46 124

33,7 25 33,7 2,0 120 18 39 117

42,4 25 42,4 2,0 130 18 39 117

48,3 25 48,3 2,0 130 18 39 117

60,3 25 60,3 2,0 180 30 27 105

76,1 16 76,1 2,0 220 30 27 105

88,9 16 88,9 2,3 260 45 12 90

Pression

nominale

en bar

1) 2)

Diamètre

extérieur de

la tuyauterie

Ø D s TL U

Epaisseur

de paroi de

la tuyauterie

Longueur

de tube

Longueur

d'insertion du

doigt de gant

1

Longueur totale

extension

TR21-B TR22-B

M M

Longueur totale

extension

TR21-B TR22-B

M M

F

ASME BPE ou DIN 11866 série C

Taille

nominale

du tube

OD PN

½" 13,8 12,7 1,65 95,2 6 51 129

¾" 13,8 19,05 1,65 101,6 9 48 126

1" 13,8 25,4 1,65 108,0 11 46 124

1 ½" 13,8 38,1 1,65 120,6 18 39 117

2" 13,8 50,8 1,65 146,0 18 39 117

2 ½" 13,8 63,5 1,65 158,8 30 27 105

3" 13,8 76,2 1,65 171,4 30 27 105

4" 13,8 101,6 2,11 209,6 45 12 90

1) Température maximale d’exploitation 150 °C

2) Tous les doigts de gant de cette série qui sont exposés à la pression interne et ont un diamètre nominal (DN) de > 25 mm sont

fabriqués et testés en conformité avec le module H de la directive sur les équipements sous pression 97/23/CE.

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

Pression

nominale

en bar

1) 2)

Diamètre

extérieur de

la tuyauterie

Ø D s TL U

Epaisseur

de paroi de

la tuyauterie

Longueur

de tube

Longueur

d'insertion du

doigt de gant

1

Longueur totale

extension

TR21-B TR22-B

M M

41

Page 42

4. Conception et fonction

■

Montage angulaire (position de montage recommandée, voir chapitre 6 “Mise en service,

exploitation”)

Pour sonde à résistance miniature type TR21-B

F

Signal de sortie

4 ... 20 mA

1) En cas de remplacement, calculer la

longueur du capteur, A, comme suit :

A

= U1 + M + 3 mm

TR21-B

1)

Signal de sortie

Pt100

11610565.01

Pour sonde à résistance miniature type TR22-B

42

1) Dans le cas d’un remplacement, choisir un insert de

mesure pour la sonde à résistance de type TR22-B.

La longueur correspondante du capteur, A(l5), est

calculée comme suit :

Longueur d’insertion U1+ longueur totale extension

M + 5 mm pré-charge + 10 mm dimension de la tête

11528452.01

WIKA mode d'emploi doigt de gant, type TW61

11575795.02

11593963.03 03/2014 GB/D/F/E

Page 43

4. Conception et fonction

Métrique ou DIN 11866 série A

Taille

nominale

du tube

OD PN

10 25 13 1,5 35 55 14 43 121

15 25 19 1,5 35 55 18 39 117

20 25 23 1,5 40 63 18 39 117

25 25 29 1,5 50 77 30 27 105

32 25 35 1,5 55 87 30 27 105

40 25 41 1,5 60 97 30 27 105

50 25 53 1,5 80 126 30 27 105

65 16 70 2,0 105 165 45 12 90

80 16 85 2,0 130 201 45 12 90

100 12,5 104 2,0 155 241 45 12 90

Pression

nominale

en bar

1) 2)

Diamètre

extérieur de

la tuyauterie

Ø D s TL L1U

Epaisseur

de paroi de

la tuyauterie

Longueur

de tube

Longueur

d'insertion du

doigt de gant

1

Tuyauteries ISO ou DIN 11866 série B

Taille

nominale

du tube

OD PN

13,5 25 13,5 1,6 32 55 14 43 121

17,2 25 17,2 1,6 34 55 16 41 119

21,3 25 21,3 1,6 36 58 18 39 117

26,9 25 26,9 1,6 55 81 30 27 105

33,7 25 33,7 2,0 60 91 30 27 105

42,4 25 42,4 2,0 65 102 30 27 105

48,3 25 48,3 2,0 65 108 30 27 105

60,3 25 60,3 2,0 90 145 45 12 90

76,1 16 76,1 2,0 110 173 45 12 90

88,9 16 88,9 2,3 130 203 45 12 90

Pression

nominale

en bar

1) 2)

Diamètre

extérieur de

la tuyauterie

Ø D s TL L1U

Epaisseur

de paroi de

la tuyauterie

Longueur

de tube

Longueur

d'insertion du

doigt de gant

1

Longueur totale

extension

TR21-B TR22-B

M M

Longueur totale

extension

TR21-B TR22-B

M M

F

ASME BPE ou DIN 11866 série C

Taille

nominale

du tube

OD PN

½

" 13,8 12,7 1,65 47,6 71 14 43 121

¾

" 13,8 19,05 1,65 50,8 71 18 39 117

1" 13,8 25,4 1,65 54,0 79 18 39 117

½

1

2" 13,8 50,8 1,65 73,0 118 30 27 105

½

2

3" 13,8 76,2 1,65 85,7 150 45 12 90

4" 13,8 101,6 2,11 104,8 190 45 12 90

1) Température maximale d’exploitation 150 °C

2) Tous les doigts de gant de cette série qui sont exposés à la pression interne et ont un diamètre nominal (DN) de > 25 mm sont

fabriqués et testés en conformité avec le module H de la directive sur les équipements sous pression 97/23/CE.

Pression

nominale

en bar

" 13,8 38,1 1,65 60,3 94 30 27 105

" 13,8 63,5 1,65 79,4 134 45 12 90

Diamètre

extérieur de

la tuyauterie

1) 2)

Ø D s TL L1U

Epaisseur

de paroi de

la tuyauterie

Longueur

de tube

Longueur

d'insertion du

doigt de gant

1

Longueur totale

extension

TR21-B TR22-B

M M

4.3 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

43

Page 44

5. Transport, emballage et stockage / 6. Mise en service, ...

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le doigt de gant liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale (par ex.

F

changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

■

Température de stockage : 0 ... 70 °C

■

Humidité : 35 ... 85 % d‘humidité relative (sans condensation)

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant l'entreposage du doigt de gant

(après le fonctionnement). Ceci est particulièrement important lorsque le uide

représente un danger pour la santé, comme par exemple des substances corrosives,

toxiques, cancérogènes, radioactives etc.

6. Mise en service, exploitation

ATTENTION !

Avant de mettre en service le doigt de gant, nettoyer les installations dans le respect

des consignes de nettoyage.

Le doigt de gant ne doit pas être plié ou modié pour le montage. L'installation doit être

eectuée de sorte qu'il n'y ait aucun dommage causé au doigt de gant par le fonctionnement

de l'installation ou par l'opérateur. Si nécessaire, il faudra avoir une des installations de doigts

de gant/de conduites mentionnées plus bas (par exemple en utilisant un collier de serrage). En

particulier, le col sera protégé par des méthodes appropriées contre toute courbure.

Exécution pour soudure orbitale

Dans l'exécution pour soudure orbitale, le TW61 est soudé directement dans la conduite. Souder

le doigt de gant de manière centrée et sans décalage de l‘axe (sans étages) dans la conduite par

soudage orbital. La jointure de soudure devra donc être eectuée avec le soin requis et être en ligne

avec les procédures applicables et accréditées et ensuite testée. De manière similaire, les exigences

de la directive 97/23/CE concernant les équipements de pression doivent être respectées.

Pour obtenir des informations générales concernant la conception d'une liaison soudée

hygiénique, nous recommandons les documents suivants (entre autres) :

■

EHEDG Guideline 35 - Welding of stainless steel tubing in the food industry

■

EHEDG Guideline 9 - Welding stainless steel to meet hygienic requirements

■

EHEDG Guideline 8 - Hygienic equipment design criteria, 7.5

■

3-A® sanitary standard for sensors and sensor ttings, number 74-06, D 6.1.4

44

WIKA mode d'emploi doigt de gant, type TW61

11593963.03 03/2014 GB/D/F/E

Page 45

6. Mise en service, exploitation / 7. Entretien et nettoyage

Installation recommandée pour la version pour montage angulaire

Concernant la version pour montage angulaire, il est recommandé d'installer le capteur à

l'horizontale et non verticalement dans la tuyauterie. De cette façon, on évite la formation d'une

poche d'air dans la coupole pendant la stérilisation.

7. Entretien et nettoyage

F

7.1 Entretien

En général, les doigts de gant ne nécessitent aucune maintenance.

Nous recommandons de procéder à un contrôle visuel des doigts de gant à la recherche de

fuites et de détériorations à intervalles réguliers. Assurez-vous que les joints sont en parfait état !

Toute réparation doit être conée exclusivement au fabricant ou, après consultation préalable de

WIKA, à un personnel qualié.

7.2 Nettoyage

ATTENTION !

■

Laver ou nettoyer l'instrument démonté avant de le retourner an de protéger le

personnel et l'environnement contre le danger lié aux restes de uides adhérents.

■

Les restes de uides se trouvant dans les doigts de gant démontés peuvent mettre

en danger les personnes, l'environnement ainsi que l'installation. Des mesures de

sécurité susantes doivent être prises.

Indications concernant le retour de l'instrument, voir chapitre 9.2 “Retour”.

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

45

Page 46

8. Dysfonctionnements / 9. Démontage, retour, mise au rebut

8. Dysfonctionnements

Dysfonctionnements

Impossible d'insérer

le capteur de

température dans le

doigt de gant

F

En fuite du uide de

process

Raisons Mesures

Présence de corps étrangers dans le doigt de gant Retirer les corps étrangers

Filetage de xation du doigt de gant ou du capteur

de température endommagé ou contaminé

Filetage de xation du doigt de gant ou du capteur

de température endommagé

Le doigt de gant ou le capteur a été tordu ou

endommagé pendant l'installation

Lorsque le uide de process fuit au niveau du

raccord process, la raison peut en être des erreurs

de montage ou des joint d'étanchéité défectueux

Si des uides de process s'échappent à l'interface

entre le doigt de gant et le capteur de température

ou au niveau du capteur de température lui-même,

un fonctionnement en toute sécurité de l'installation

ne peut plus être garanti

Nettoyer les letages

Renvoyer le doigt de gant

(voir chapitre 9.2 “Retour”)

Retour pour réparation

Vérier le joint et

également contrôler les

couples de serrage

Déconnecter le doigt de

gant et contacter WIKA

ATTENTION !

Si des dysfonctionnements ne peuvent pas être éliminées à l'aide des mesures

indiquées ci-dessus, arrêter immédiatement l'instrument et s'assurer de l'absence de

pression et/ou de signal. Puis, sécuriser l'instrument an d'empêcher toute remise en

service involontaire. Contacter dans ce cas le fabricant.

S'il est nécessaire de renvoyer l'instrument au fabricant, suivre les indications

mentionnées au chapitre 9.2 “Retour”.

9. Démontage, retour et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans les doigts de gant démontés peuvent mettre

en danger les personnes, l'environnement ainsi que l'installation. Des mesures de

sécurité susantes doivent être prises.

9.1 Démontage

AVERTISSEMENT !

Danger de brûlure !

Avant le démontage, laisser refroidir susamment l'instrument ! Danger de brûlure lié

à la sortie de uides dangereux chauds.

Déconnecter les doigts de gant uniquement une fois que le système a été mis hors pression !

46

WIKA mode d'emploi doigt de gant, type TW61

11593963.03 03/2014 GB/D/F/E

Page 47

9. Démontage, retour et mise au rebut

9.2 Retour

AVERTISSEMENT !

Il faut absolument observer les consignes suivantes lors de l'expédition de

l'instrument :

Tous les instruments envoyés à WIKA doivent être exempts de toute substance

dangereuse (acides, lixiviats, solutions, etc.).

Pour retourner l'instrument, utiliser l'emballage original ou un emballage adapté pour le transport.

Pour éviter des dommages :

1. Emballer l'instrument dans une feuille de plastique antistatique.

2. Placer l'instrument avec le matériau isolant dans l'emballage.

Isoler de manière uniforme tous les côtés de l'emballage de transport.

3. Mettre si possible un sachet absorbeur d'humidité dans l'emballage.

4. Indiquer lors de l'envoi qu'il s'agit d'un instrument de mesure très sensible à transporter.

Des informations relatives à la procédure de retour de produit(s) défectueux sont

disponibles sur notre site internet au chapitre “Services”.

9.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage conformément aux

prescriptions nationales pour le traitement et l'élimination des déchets et aux lois de protection

de l'environnement en vigueur.

F

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

47

Page 48

Annexe 1 : Certicat du TÜV (contrôle technique allemand)

F

48

11593963.03 03/2014 GB/D/F/E

WIKA mode d'emploi doigt de gant, type TW61

Page 49

Annexe 2 : Déclaration de conformité CE

E

11593963.03 03/2014 GB/D/F/E

WIKA manual de instrucciones vaina, modelo TW61

49

Page 50

E

50

11593963.03 03/2014 GB/D/F/E

WIKA manual de instrucciones vaina, modelo TW61

Page 51

Contenido

Contenido

1. Información general 52

2. Seguridad 53

3. Datos técnicos 55

4. Diseño y función 55

5. Transporte, embalaje y almacenamiento 60

6. Puesta en servicio, funcionamiento 60

Mantenimiento y limpieza

7.

8. Fallos 62

9. Desmontaje, devolución y eliminación 62

Anexo 1: Certicado TÜV (Inspección Técnica) 64

Anexo 2: Declaración de conformidad CE 65

Declaraciones de conformidad puede encontrar en www.wika.es.

61

E

11593963.03 03/2014 GB/D/F/E

WIKA manual de instrucciones vaina, modelo TW61

51

Page 52

1. Información general

1. Información general

■

Las vainas descritas en el manual de instrucciones están fabricadas según el estado actual

de la técnica. Todos los componentes están sujetos a rigurosos criterios de calidad y medio

ambiente durante la producción. Nuestros sistemas de gestión están certicados según

ISO 9001 e ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes acerca del manejo de

la vaina. Para un trabajo seguro, es imprescindible cumplir con todas las instrucciones de

seguridad y manejo indicadas.

■

Cumplir siempre las normativas sobre la prevención de accidentes y las normas de seguridad

E

en vigor en el lugar de utilización de la vaina.

■

El manual de instrucciones es una parte integrante del producto y debe guardarse en las

proximidades de la vaina, para que el personal especializado pueda consultarlo en cualquier

momento.

■

El personal especializado debe haber leído detenidamente y entendido el manual de

instrucciones antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso de daños causados

por un uso no conforme a la nalidad prevista, la inobservancia del presente manual

de instrucciones, un manejo por personal insucientemente cualicado así como una

modicación no autorizada de la vaina.

■

Se aplican las condiciones generales de venta incluidas en la documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente:

- Servicio técnico:

TW 95.61

Tel.: +34 933 938-630

Fax: +34 933 938-666

info@wika.es

Explicación de símbolos

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda causar la muerte o

lesiones graves si no se evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que pueda causar lesiones leves o

medianas o daños materiales y medioambientales si no se evita.

Información

... marca consejos y recomendaciones útiles así como informaciones para una

utilización ecaz y libre de fallos.

52

11593963.03 03/2014 GB/D/F/E

WIKA manual de instrucciones vaina, modelo TW61

Page 53

1. Información general / 2. Seguridad

¡PELIGRO!

... indica riesgos causados por corriente eléctrica. Existe riesgo de lesiones graves o

mortales si no se observan estas indicaciones de seguridad.

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda causar quemaduras

debido a supercies o líquidos calientes si no se evita.

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta en servicio y el funcionamiento asegurarse de que

se haya seleccionada la vaina adecuada con respecto a versión y condiciones de

medición especícas.

Antes del montaje, la puesta en servicio y el funcionamiento asegurarse de que

el material de la vaina sea químicamente resistente/neutral al medio de medir y

resistente a las cargas mecánicas durante el proceso.

Riesgo de lesiones graves y/o daños materiales en caso de inobservancia.

Los distintos capítulos de este manual de instrucciones contienen otras importantes

indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Las vainas protegen el sensor de temperatura frente a condiciones de proceso adversas.

Además, posibilitan el desmontaje del sensor de temperatura sin tener que parar el proceso y

evitan daños al medio ambiente o a personas a causa de escape del medio de proceso. La vaina

modelo TW61 fue especialmente desarrollada para el uso en de procesos estériles.

La vaina ha sido diseñado y construido únicamente para la nalidad aquí descrita y debe

utilizarse en conformidad a la misma.

Deben observarse las especicaciones técnicas indicadas en este manual de instrucciones.