Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

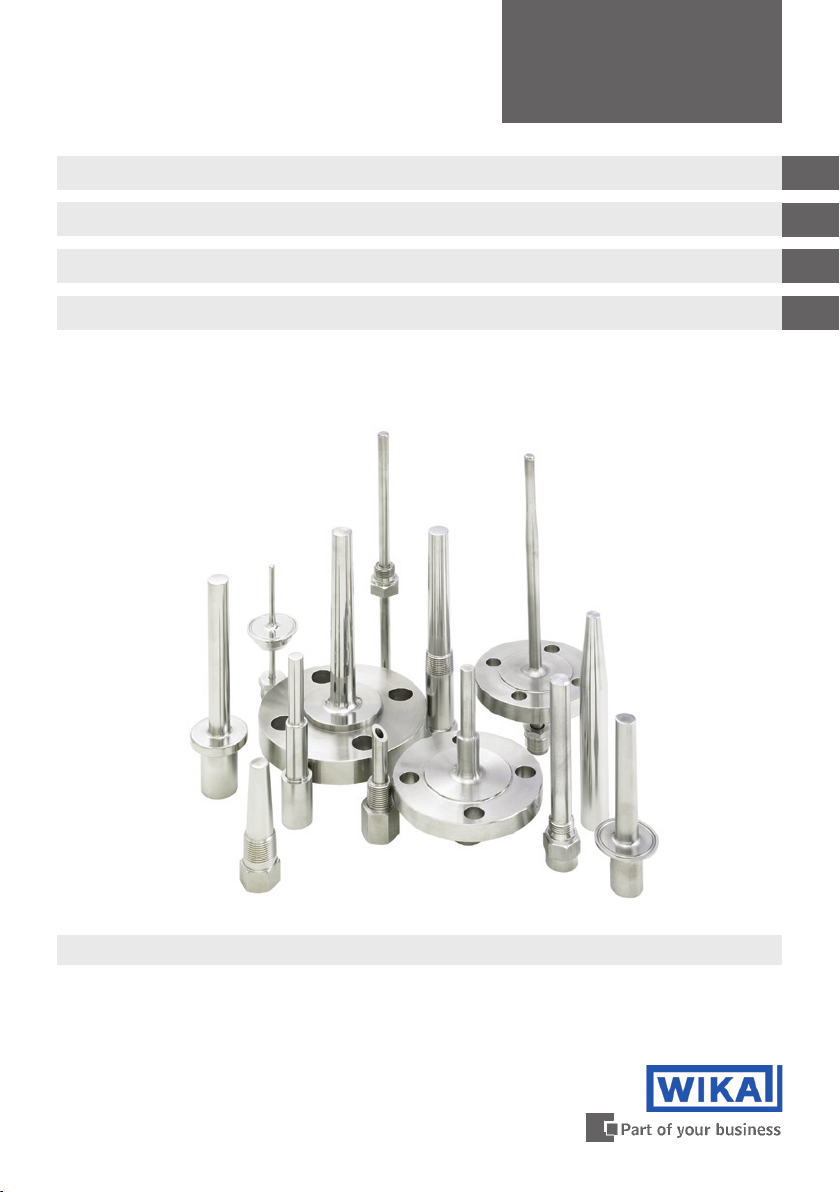

Thermowells

Schutzrohre

Doigts de gant

Vainas

GB

D

F

E

Examples/Beispiele/Exemples/Ejemplos

Page 2

Operating instructions thermowells

GB

Page 3 - 12

Betriebsanleitung Schutzrohre

D

F

Mode d'emploi doigts de gant

E

Manual de instrucciones vainas

Seite 13 - 22

Page 23 - 32

Página 33 - 41

© WIKA Alexander Wiegand SE & Co. KG 2010

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta posterior!

2

WIKA operating instructions thermowells

11405821.06 09/2010 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 6

4. Design and function 6

5. Transport, packaging and storage 6

6. Commissioning, operation 7

GB

Maintenance and cleaning

7.

8. Faults 10

9. Dismounting, return and disposal 10

9

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

3

Page 4

1. General Information

1. General Information

■

The thermowell described in the operating instructions has been manufactured using state-ofthe-art technology. All components are subject to stringent quality and environmental criteria

GB

during production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the thermowell. Working

safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the

thermowell's range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity of

the thermowell and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions, prior to

beginning any work.

■

The manufacturer‘s liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instructions, assignment of

insuciently qualied skilled personnel or unauthorised modications to the thermowell.

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address:

- Application consultant:

www.wika.de / www.wika.com

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation, which can result in serious injury or

death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can result in light injuries or

damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and troublefree operation.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused by hot

surfaces or liquids, if not avoided.

4

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

Page 5

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate thermowell has been selected in terms of measuring range, design and specic measuring

conditions.

Before installation, commissioning and operation, ensure that the thermowell material used is chemically resistant/neutral to the medium being measured and that it

withstands the mechanical stresses from the process.

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual chapters of these

operating instructions.

2.1 Intended use

Thermowells are used to protect temperature sensors from the process conditions. Furthermore, thermowells enable the removal of the temperature sensor without having to shut down the

process; and they guard against damage to either the environment or to personnel, which might

be caused by escaping process media.

The thermowell has been designed and built solely for the intended use described here, and may

only be used accordingly.

The technical specications contained in these operating instructions must be observed. Should

the thermowell be improperly handled or operated outside of its technical specications, it has to

be inspected immediately.

GB

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried out by

skilled personnel who have the qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specic regulations, current standards and directives, are capable of carrying out the

work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive or toxic

media.

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

5

Page 6

2. Safety / 3. Specications / 4. Design, function / 5. Transport, packaging ...

2.3 Special hazards

WARNING!

GB

For hazardous media such as oxygen, acetylene, ammable or toxic gases or liquids,

and refrigeration plants, compressors, etc., in addition to all standard regulations, the

appropriate existing codes or regulations must also be followed.

Make sure that the thermowell is suciently earthed.

WARNING!

Residual media on dismounted thermowells can result in a risk to persons, the

environment and the equipment. Take sucient precautionary measures.

3. Specications

For specications see the appropriate WIKA data sheets for current thermowell versions and the

order documentation.

4. Design and function

4.1 Description

Metal thermowells can be manufactured as solid-machined or fabricated versions. Thermowells

can be connected to the process by screw-, weld- or ange-tting. The temperature sensor is

directly fastened to the thermowell using a female or male thread or by means of an neck tube.

If thermowells made of metallic materials do not show a sucient temperature or corrosion resistance during continuous operation at temperatures above 1200 °C, ceramic thermowells should

be used.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check thermowell for any damage that may have been caused by transport. Obvious damage

must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for repair).

6

WIKA operating instructions thermowells

11405821.06 09/2010 GB/D/F/E

Page 7

5. Transport, packaging and storage / 6. Commissioning, operation

5.3 Storage

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects (for thermowells with plastic coating)

■

Mechanical vibration, mechanical shock (putting it down hard)

WARNING!

Before storing the thermowell (following operation), remove any residual media. This

is of particular importance if the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

6. Commissioning, operation

6.1 Mounting

During mounting (especially with ceramic thermowells) the thermowells should not be subjected

to thermal shocks or mechanical impacts.

Insert the thermowell into the process adapter without forcing or damaging it. The thermowell must

not be bent or altered in order to mount it.

The exception is the retrospective machining of the support ring in order that the thermowell is

supported free of play within the nozzle ("interference t"). The retrospective adjustment of a

support ring with a loose t is not permissible. In general, thermowells with a support ring are not

recommended within ASME PTC 19.3 TW 2010 and are outside of the scope of the standard.

GB

It is recommended to mount the temperature measuring instrument into the thermowell using a

suitable sealing material to avoid, for example, humidity ingress.

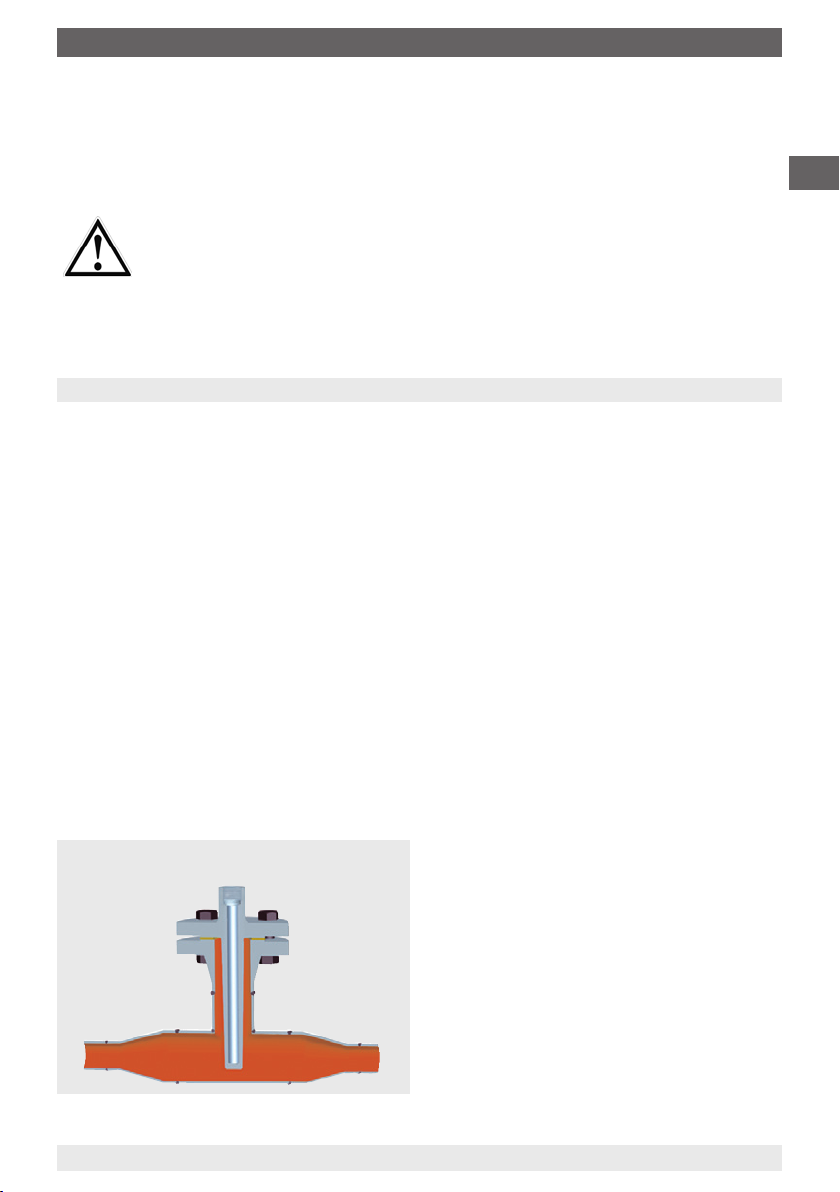

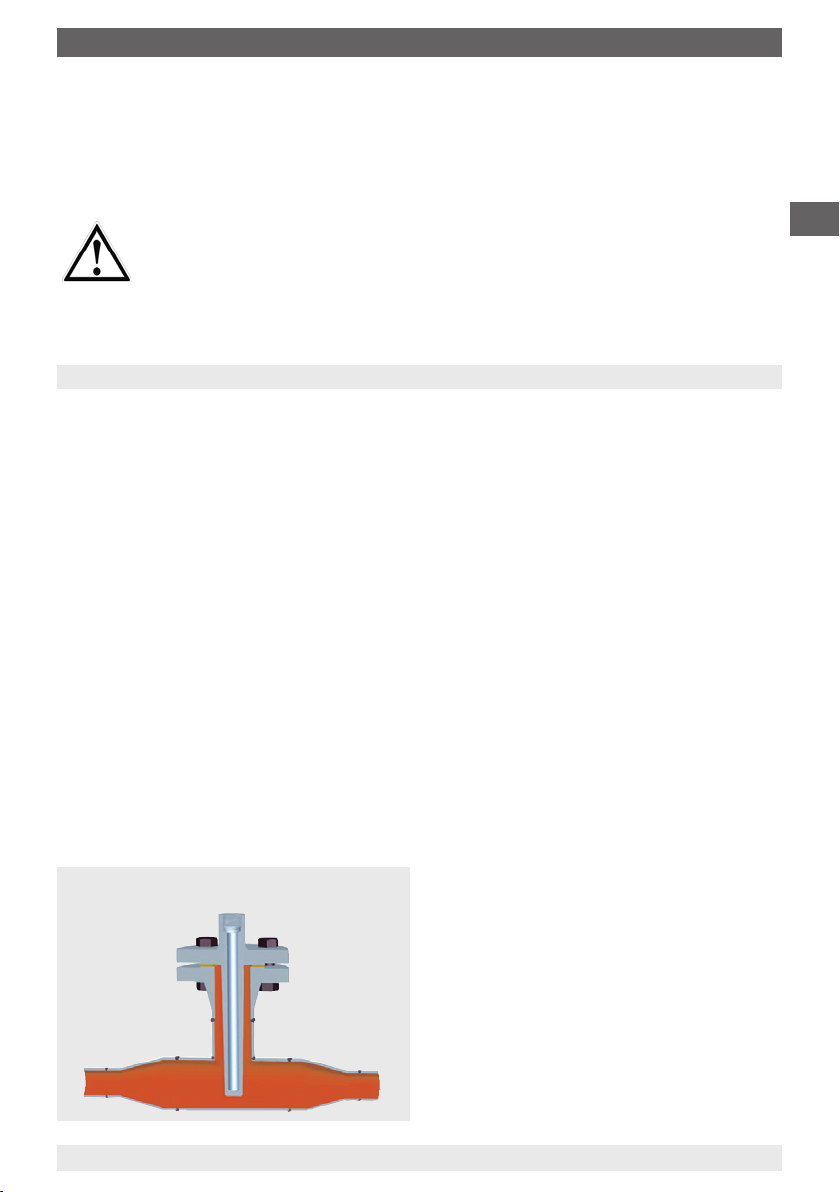

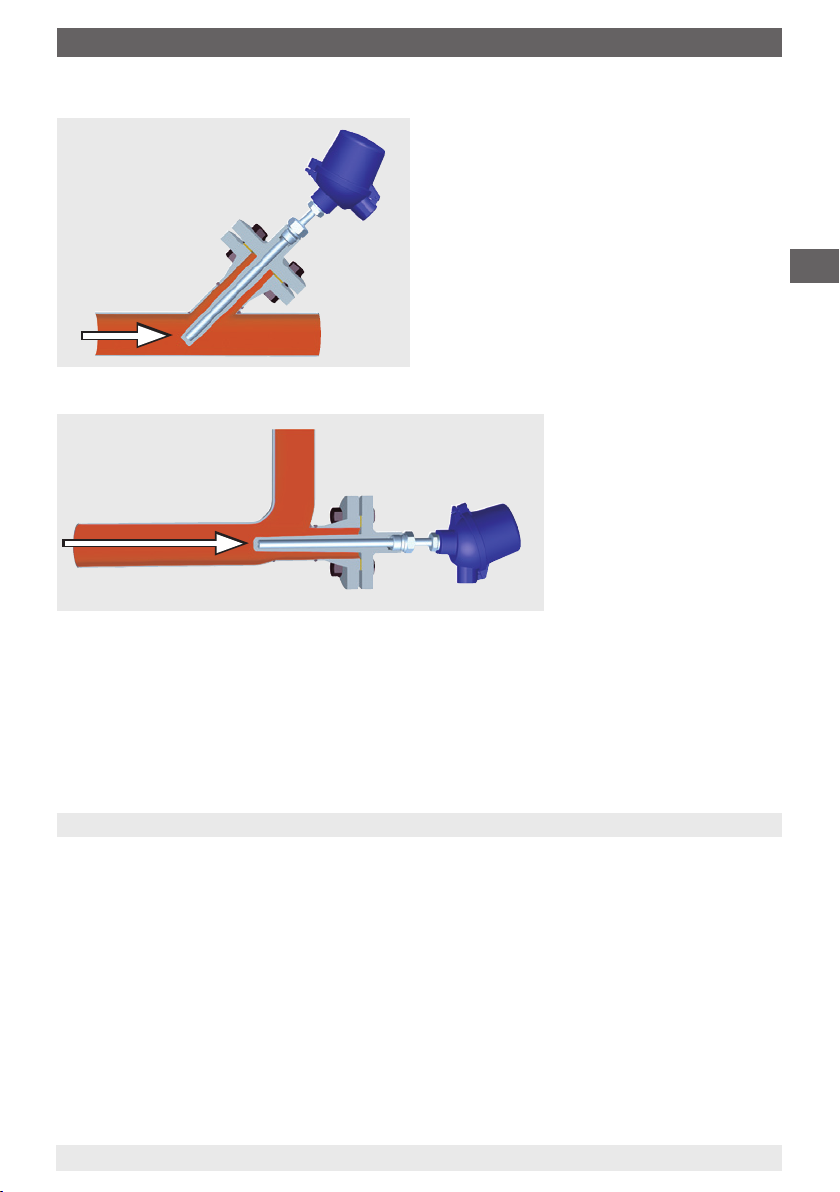

In general, the tip of the thermowell should be placed in the middle third of the pipe, though

the position may dier in special cases. It must be ensured that the measuring element (Pt100,

thermocouple, bimetal, etc.) is completely exposed to the medium and is not shielded by the

ange stubs. If, as a result of a small pipe diameter, this cannot be ensured, a pipe expansion can

be inserted around the measuring point.

Expansion of the pipe diameter

from DN 40 to DN 80

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

7

Page 8

6. Commissioning, operation

Screw-tting thermowells

When using parallel threads, a suitable seal should be used when mounting. Tapered threads

can be sealed by suitable seals or an additional welded seam. The correct tightening torques and

suitable tools (e.g. spanner) should be used.

GB

Weld-tting thermowells

Weld-in thermowells can be mounted into the process directly (pipe or vessel wall) or by using

a welding socket. Make sure that the weld seam is clean and that suitable equipment is used. If

necessary, heat-treat the weld seams.

Thermowells with ange connection

The ange dimensions of the thermowell must match those of the mating ange on the process

side. The seals used must be suitable for the process and the ange geometries (consult the

delivery note). The correct tightening torques and suitable tools (e.g. spanner) should be used

for installation. For thermowells with a collar, make sure that it matches the inner diameter of the

coupling and is supported by it. In the case of an interference collar, they should be adapted to the

inner diameter of the coupling.

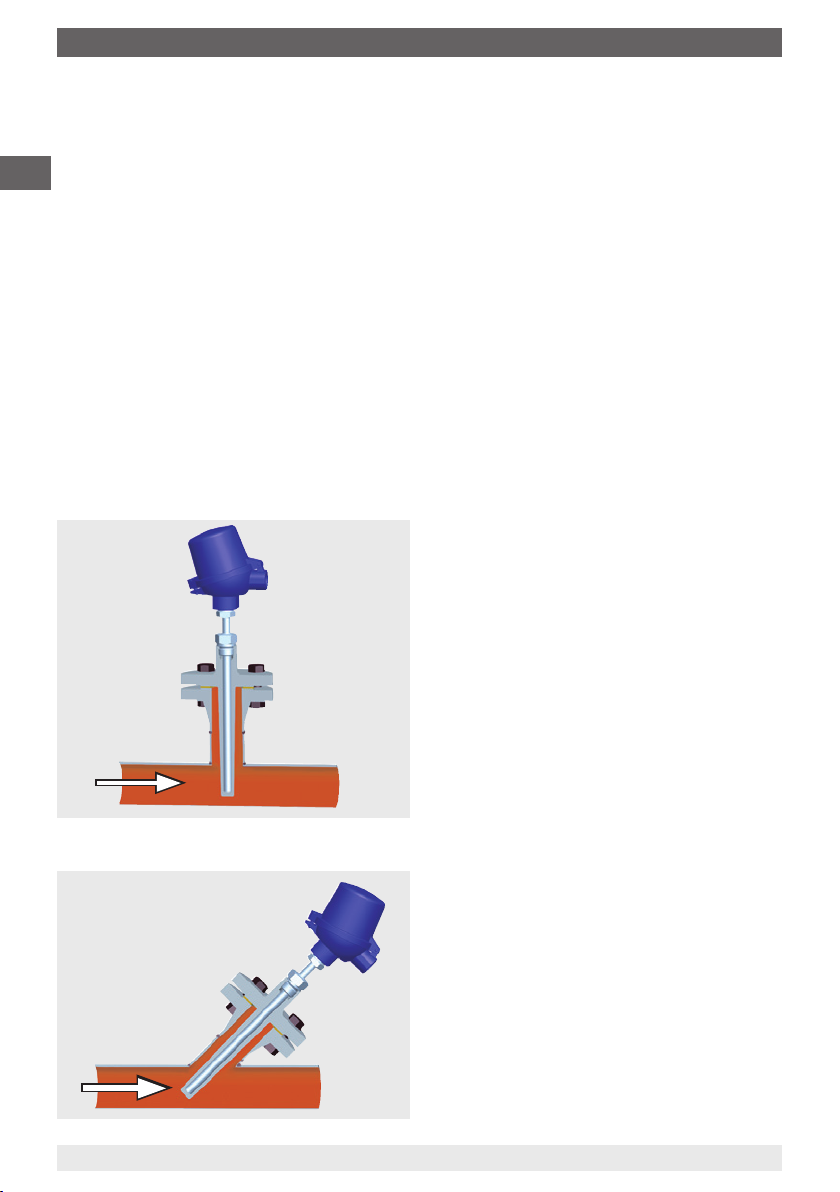

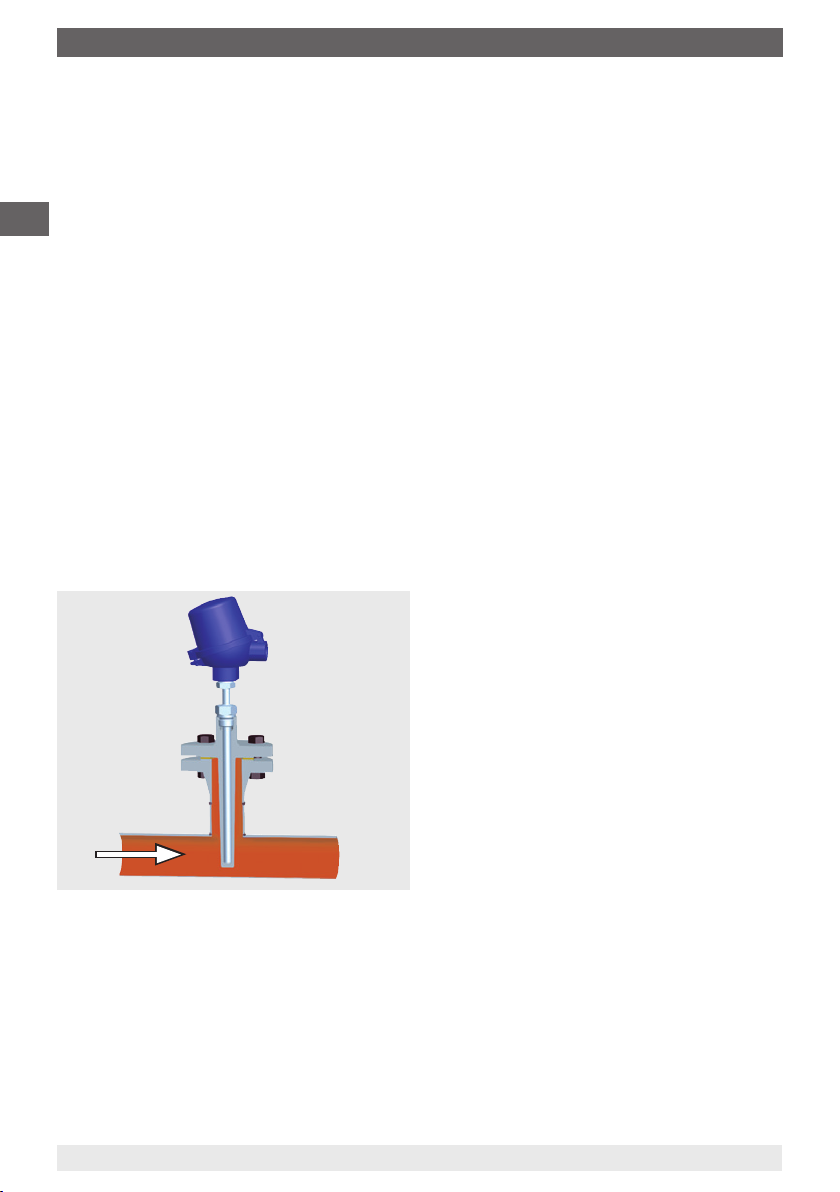

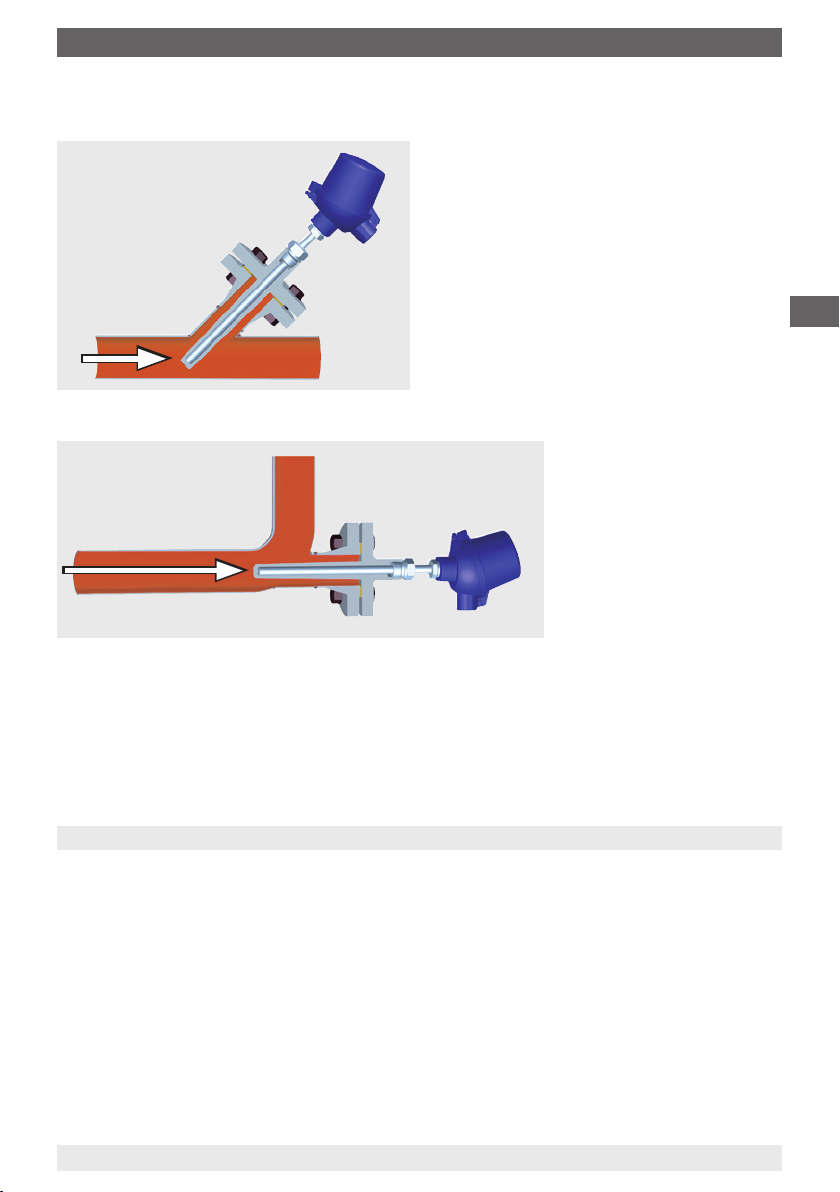

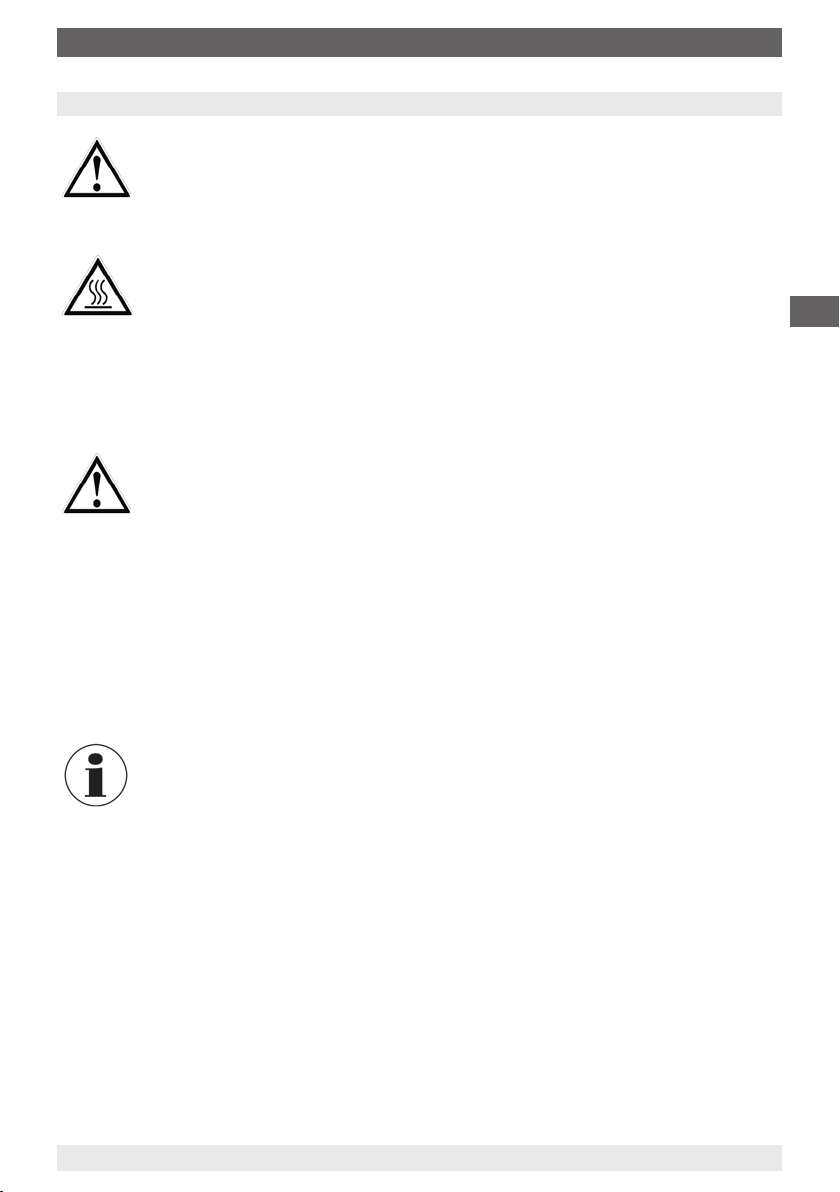

Irrespective of the process connection, 3 mounting positions of thermowells in pipes are possible:

■

Right-angled position with respect to the ow (most unfavourable position)

■

Tilted position with respect to the ow (tip inclined towards the ow direction is preferred)

8

WIKA operating instructions thermowells

11405821.06 09/2010 GB/D/F/E

Page 9

6. Commissioning, operation / 7. Maintenance and cleaning

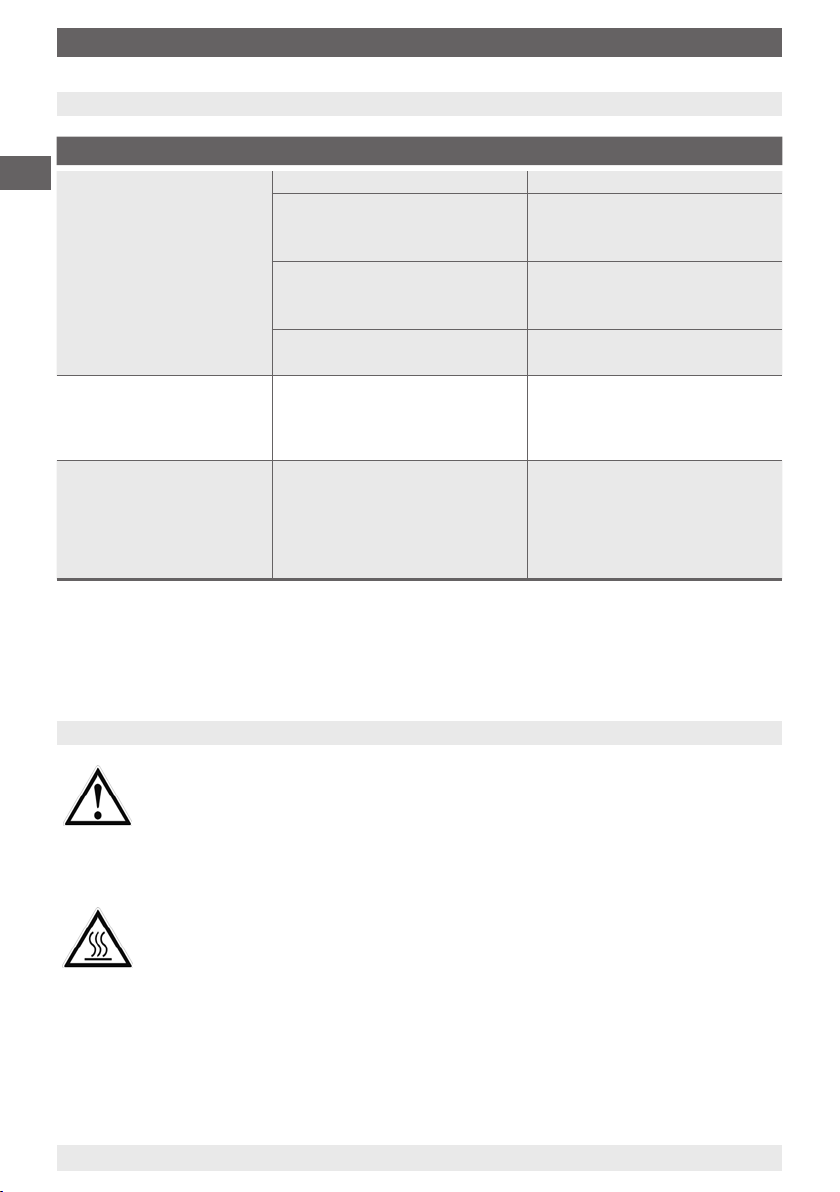

■

Flow towards the tip in an elbow (most favourable position)

The insertion length and the diameter of the thermowell are dependent on the process conditions,

especially on the ow rate of the measured medium.

The regulations in accordance with VDI/VDE 3511-5, DIN 43772 Appendix 1/2 and the AD Codes

must be observed.

7. Maintenance and cleaning

7.1 Maintenance

In general, thermowells are maintenance-free.

We recommend a visual check of the thermowell for leaks and damages at regular intervals.

Make sure that the seal is in perfect condition!

GB

Repairs should only be carried out by the manufacturer or, following prior consultation, by correspondingly qualied skilled personnel.

7.2 Cleaning

CAUTION!

Wash or clean the dismounted instrument before returning it, in order to protect sta

and the environment from exposure to residual media.

For information on returning the thermowell see chapter "9.2 Return".

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

9

Page 10

8. Faults / 9. Dismounting, return and disposal

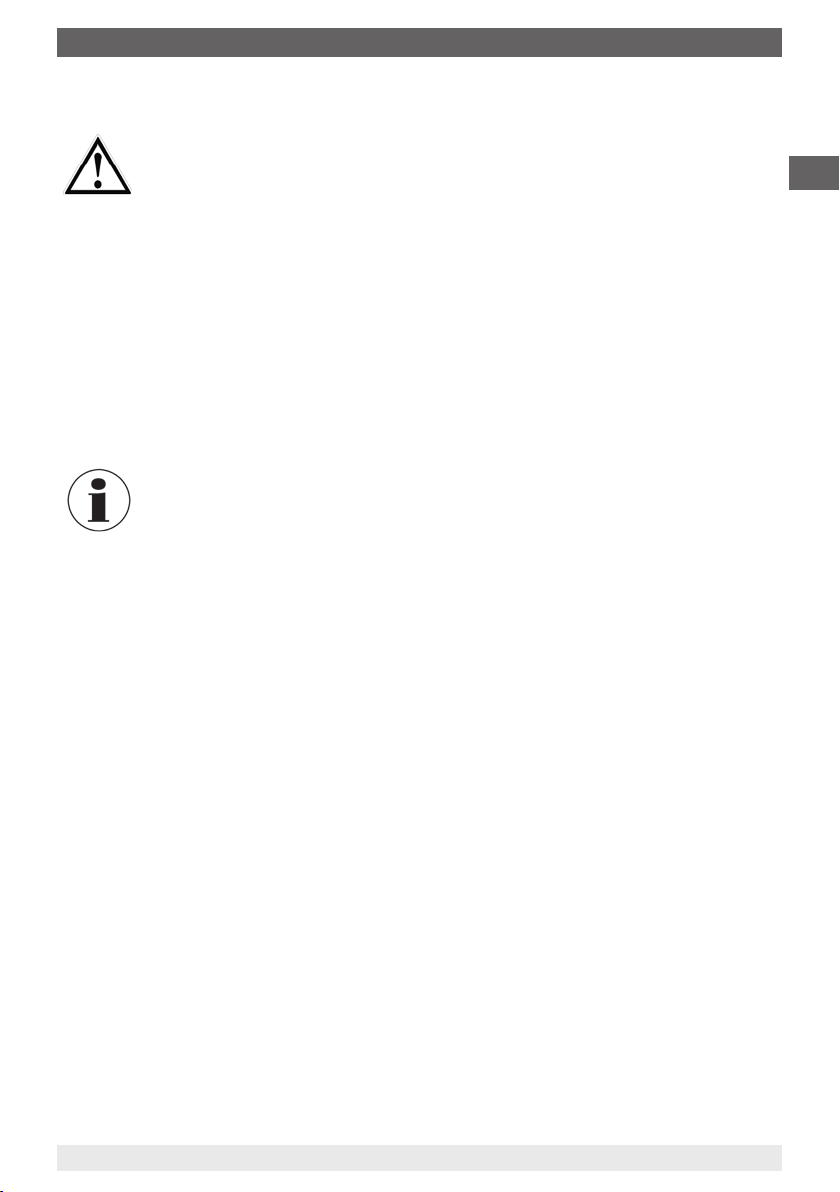

8. Faults

Faults Causes Measures

GB

Not possible to insert the

temperature sensor into the

thermowell

Leakage of process media

■

at the connection between

the process and the

thermowell

■

from the interface between

the thermowell and the

sensor

In the case of critical installations, we recommend calculating the harmonic frequency of the

thermowell according to ASME PTC 19.3 or Dittrich/Klotter. This engineering service is oered by

WIKA.

Foreign bodies in the thermowell Remove foreign bodies

Damaged or contaminated

thermowell or temperature sensor

fastening thread

Sensor dimension and those of the

inner diameter of the thermowell do

not match

Thermowell or sensor has been

bent or damaged during installation

Error during installation or defective

seals

Damage, e.g. caused by operating

the thermowell under a resonant

vibration load

Clean or recut the thread

Check order documentation

Return for repair

Check the seal, check the

tightening torques

Safe operation of the plant can no

longer be guaranteed

(in the worst case, this might

result in a complete rupture of the

thermowell)

9. Dismounting, return and disposal

WARNING!

Residual media on dismounted thermowells can result in a risk to persons, the

environment and equipment. Take sucient precautionary measures.

9.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting it!

When dismounting it, there is a risk that dangerously hot pressure media may escape.

Only disconnect thermowells once the system has been depressurised!

10

WIKA operating instructions thermowells

11405821.06 09/2010 GB/D/F/E

Page 11

9. Dismounting, return and disposal

9.2 Return

WARNING!

Strictly observe when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

Enclose the completed return form with the instrument.

The return form is available on the internet:

www.wika.de / Service / Return

9.3 Disposal

Incorrect disposal can put the environment at risk.

GB

Dispose of instrument components and packaging materials in an environmentally compatible

way and in accordance with the country-specic waste disposal regulations.

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

11

Page 12

GB

12

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

Page 13

Inhalt

Inhalt

1. Allgemeines 14

2. Sicherheit 15

3. Technische Daten 16

4. Aufbau und Funktion 16

5. Transport, Verpackung und Lagerung 16

6. Inbetriebnahme, Betrieb 17

Wartung und Reinigung

7.

8. Störungen 20

9. Demontage, Rücksendung und Entsorgung 21

19

D

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

13

Page 14

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Schutzrohre werden nach den neuesten Erkenntnissen gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien.

Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Schutzrohr. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und

Handlungsanweisungen.

■

Die für den Einsatzbereich des Schutzrohres geltenden örtlichen Unfallverhütungsvorschriften

und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Schutzrohres

für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung,

Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten Fach-personals

sowie eigenmächtiger Veränderung am Schutzrohr.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Anwendungsberater:

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder

leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten

und störungsfreien Betrieb hervor.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die durch heiße Oberächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie nicht gemieden

wird.

14

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

Page 15

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Schutzrohr

hinsichtlich Ausführung und spezischen Messbedingungen ausgewählt wurde.

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der verwendete Schutzrohrwerksto gegenüber dem Messmedium chemisch beständig/neutral ist, sowie

den prozessseitigen mechanischen Belastungen stand hält.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden

auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln dieser

Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Schutzrohre dienen zum Schutz des Temperaturfühlers gegenüber den Prozessbedingungen.

Des weiteren ermöglichen Schutzrohre den Ausbau des Temperaturfühlers ohne den Prozess

stillzulegen und verhindern Umwelt- oder Personenschäden durch den Austritt von Prozessmedium.

Das Schutzrohr ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben des Schutzrohres außerhalb der technischen Spezikationen

macht die sofortige Überprüfung erforderlich.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal

nachfolgend beschriebener Qualikation durchführen lassen.

D

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess- und

Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften,

geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen und

mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über aggressive

oder toxische Medien.

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

15

Page 16

2. Sicherheit / 3. Technische Daten / 4. Aufbau, Funktion / 5. Transport, ...

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen

Stoen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die gesamten allge-

D

meinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

Gegebenenfalls ist auf ausreichende Erdung des Schutzrohres zu achten.

WARNUNG!

Messstoreste an ausgebauten Schutzrohren können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

3. Technische Daten

Technische Daten siehe aktuelle WIKA Datenblätter der entsprechenden Schutzrohrtypen und

Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Metall-Schutzrohre können als einteilige Ausführung aus Vollmaterial oder durch mehrteiligen

Rohraufbau hergestellt werden. Schutzrohre können am Prozess durch Einschrauben, Einschweißen oder mittels Flansch befestigt werden. Die Befestigung des Temperaturfühlers an das Schutzrohr erfolgt direkt über ein Innen- oder Außengewinde oder mittels eines Halsrohres.

Falls im Dauereinsatz bei Temperaturen >1200 °C Schutzrohre aus metallischen Werkstoen

keine ausreichende Temperatur oder Korrosionsbeständigkeit aufweisen, kommen keramische

Schutzrohrwerkstoe zum Einsatz.

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Schutzrohr auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen Schutz

(z. B. wechselnder Einbauort, Reparatursendung).

16

WIKA Betriebsanleitung Schutzrohre

11405821.06 09/2010 GB/D/F/E

Page 17

5. Transport, Verpackung und Lagerung / 6. Inbetriebnahme, Betrieb

5.3 Lagerung

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen (bei Schutzrohren mit Kunststobeschichtung)

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

WARNUNG!

Vor der Einlagerung des Schutzrohres (nach Betrieb) alle anhaftenden Messstoreste

entfernen. Dies ist besonders wichtig, wenn der Messsto gesundheitsgefährdend ist,

wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

6. Inbetriebnahme, Betrieb

6.1 Montage

Bei der Montage (insbesondere bei keramischen Schutzrohren) die Schutzrohre weder Temperaturschocks noch mechanischen Stoßbelastungen aussetzen.

Das Schutzrohr ohne Kraftanwendung oder Beschädigung in die prozessseitige Aufnahme

einführen. Ein Verbiegen oder Anpassen des Schutzrohres zur Montage ist nicht zulässig.

Ausnahme hiervon ist die nachträgliche Anpassung eines Ankers zwecks spielfreier Abstützung des Schutzrohes im Flanschstutzen („interference t“). Die nachträgliche Anpassung

eines Ankers mit Spielpassung ist nicht zulässig. Im Allgemeinen sind Ankerabstützungen eines

Schutzrohres gemäß ASME PTC 19.3 TW2010 nicht empfohlen und liegen außerhalb dieses

Standards.

D

Empfohlen wird bei der Montage des Temperaturmessgerätes in das Schutzrohr den Einsatz

eines geeigneten Dichtungsmittels, um z. B. das Eindringen von Feuchtigkeit zu vermeiden.

Generell sollte sich die Schutzrohrspitze im mittleren Drittel der Rohrleitung benden, wobei

Sonderfälle hiervon abweichen können. Es muss sichergestellt sein, dass das Messelement

(Pt100, Thermoelement, Bimetall, etc.) komplett angeströmt und nicht durch den Flanschstutzen

abgeschirmt wird. Falls dies auf Grund eines zu kleinen Rohrleitungsdurchmessers nicht gewährleistet werden kann, können Rohrerweiterungen im Bereich der Temperaturmessstelle eingesetzt

werden.

Rohrerweiterung

von DN 40 auf DN 80

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

17

Page 18

6. Inbetriebnahme, Betrieb

Schutzrohre zum Einschrauben

Bei zylindrischen Gewinden ist eine geeignete Dichtung zur Montage zu verwenden. Konische

Gewinde können durch geeignete Dichtungsmittel oder eine zusätzliche Schweißnaht abgedichtet werden. Die entsprechenden Anzugsmomente und Werkzeuge (z. B. Gabelschlüssel) sind zu

verwenden.

D

Schutzrohre zum Einschweißen

Einschweiß-Schutzrohre können direkt in den Prozess eingeschweißt (Rohr- oder Behälterwand)

oder über einen Schweißstutzen befestigt werden. Es ist auf Sauberkeit, geeignete Betriebsmittel

und eine gegebenenfalls notwendige Wärmenachbehandlung der Schweißnähte zu achten.

Schutzrohre mit Flanschanschluss

Die Flanschabmessungen des Schutzrohres müssen mit denen des prozessseitigen Gegenansches übereinstimmen. Die verwendenden Dichtungen müssen für den Prozess und die Flanschgeometrien (aus dem Lieferschein ersichtlich) geeignet sein. Zur Montage sind die entsprechenden Anzugsmomente und Werkzeuge (z. B. Gabelschlüssel) zu verwenden.

Bei Schutzrohren mit Anker ist darauf zu achten, dass dieser zu dem Innendurchmesser des

Stutzens passt und in diesem abgestützt wird. Bei Ankern mit Übermaß sind diese auf den Innendurchmesser des Stutzens entsprechend anzupassen.

Unabhängig von Prozessanschluss, kommen 3 Einbaupositionen von Schutzrohren in Rohrleitungen zur Anwendung:

■

Rechtwinklige Anströmung (ungünstigster Belastungsfall)

18

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

Page 19

6. Inbetriebnahme, Betrieb / 7. Wartung und Reinigung

■

Schräge Anströmung (zu bevorzugen, Spitze gegen Strömungsrichtung geneigt)

■

Anströmung zur Spitze in Rohrbogen (günstigster Belastungsfall)

D

Die Einbaulänge und Durchmesser des Schutzrohres sind abhängig von den Prozessdaten,

insbesondere der Strömungsgeschwindigkeit des zu messenden Mediums.

Die Vorgaben der VDI/VDE 3511-5, der DIN 43772 Beiblatt 1/2 und des AD-Regelwerkes sind zu

beachten

7. Wartung und Reinigung

7.1 Wartung

Schutzrohre sind im Allgemeinen wartungsfrei.

Empfohlen wird eine Sichtüberprüfung des Schutzrohres auf Leckagen oder Beschädigungen in

regelmäßigen Intervallen. Insbesondere auf einwandfreie Funktion der Dichtung achten!

Reparaturen sind ausschließlich vom Hersteller oder nach Absprache durch entsprechend qualiziertes Fachpersonal durchzuführen.

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

19

Page 20

7. Wartung und Reinigung / 8. Störungen

7.2 Reinigung

VORSICHT!

Ausgebautes Gerät vor der Rücksendung spülen bzw. säubern, um Mitarbeiter und

Umwelt vor Gefährdung durch anhaftende Messstoreste zu schützen.

D

Hinweise zur Rücksendung des Schutzrohres siehe Kapitel „9.2 Rücksendung“.

8. Störungen

Störungen Ursachen Maßnahmen

Temperaturfühler lässt sich

nicht in das Schutzrohr

einführen

Austritt von Prozessmedium

■

ab der Befestigungsebene

Prozess zu Schutzrohr

■

an der Schnittstelle

des Schutzrohres zu

Temperaturfühler oder am

Temperaturfühler selbst

Fremdkörper im Schutzrohr Fremdkörper entfernen

Beschädigte oder verschmutzte

Befestigungsgewinde von Schutzrohr oder Temperaturfühler

Fühlerabmessung passt nicht zum

Innendurchmesser des Schutzrohes

Schutzrohr oder Fühler wurde bei

Montage verbogen oder beschädigt

Fehler bei der Montage oder fehlerhafte Dichtungen

Defekte, z. B. durch Betrieb des

Schutzrohres im Resonanzfall

Gewinde reinigen oder

nachschneiden

Bestellunterlagen kontrollieren

Zur Reparatur zurück senden

Dichtung überprüfen, Anzugsmomente kontrollieren

Sicherer Betrieb der Anlage nicht

mehr gewährleistet

(führt im schlimmsten Fall zu einem

kompletten Abriss des Schutzrohres)

Empfohlen wird bei kritischen Anlagen eine Festigkeitsberechnung des Schutzrohres als ingenieurstechnische Dienstleistung nach ASME PTC 19.3 oder Dittrich/Klotter.

20

WIKA Betriebsanleitung Schutzrohre

11405821.06 09/2010 GB/D/F/E

Page 21

9. Demontage, Rücksendung und Entsorgung

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste an ausgebauten Schutzrohren können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Schutzrohr ausreichend abkühlen lassen! Beim Ausbau besteht

Gefahr durch austretende, gefährlich heiße Messstoe.

Schutzrohre nur im drucklosen Zustand demontieren!

9.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren, Laugen,

Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung

verwenden.

D

Um Schäden zu vermeiden:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

2. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

3. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Dem Gerät das Rücksendeformular ausgefüllt beifügen.

Das Rücksendeformular steht im Internet zur Verfügung:

www.wika.de / Service / Rücksendung

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

21

Page 22

D

22

11405821.06 09/2010 GB/D/F/E

WIKA Betriebsanleitung Schutzrohre

Page 23

Sommaire

Sommaire

1. Généralités 24

2. Sécurité 25

3. Caractéristiques techniques 26

4. Conception et fonction 26

5. Transport, emballage et stockage 27

6. Mise en service, exploitation 27

F

Entretien et nettoyage

8.

9. Dysfonctionnements 30

10. Démontage, retour et mise au rebut 31

29

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

23

Page 24

1. Généralités

1. Généralités

■

Les doigts de gant décrit dans le présent mode d'emploi est fabriqué selon les dernières

technologies en vigueur et tous les composants sont soumis à des critères de qualité et

d'environnement stricts durant la fabrication. Nos systèmes de gestion sont certiés selon

ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation du doigt de gant.

Il est possible de travailler en toute sécurité avec ce produit en respectant toutes les consignes

F

de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les prescriptions

générales de sécurité en vigueur pour le domaine d'application du doigt de gant.

■

Le mode d'emploi fait partie de l'appareil et doit être conservé à proximité immédiate du doigt

de gant et accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement et

compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par une

utilisation non conforme à l'usage prévu, de non respect de ce mode d'emploi, d'utilisation de

personnel peu qualié de même qu'en cas de modications du doigt de gant eectuées par

l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente sappliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d’autres informations:

- Consulter notre site internet :

- Conseiller applications :

www.wika.de / www.wika.com

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou

des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de provoquer de

légères blessures ou des dommages matériels et pour l'environnement si elle n'est

pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

24

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

Page 25

2. Sécurité

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer des

brûlures dues à des surfaces ou liquides chauds si elle n’est pas évitée

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que le doigt de

gant a été choisi de façon adéquate, en ce qui concerne la plage de mesure, la version et les conditions de mesure spéciques.

Avant le montage, la mise en service et le fonctionnement, s'assurer que le matériau du doigt de gant utilisé est chimiquement résistant/neutre par rapport au uide à

mesurer et résiste aux contraintes mécaniques du processus.

Un non respect de cette consigne peut entraîner des blessures corporelles graves et/

ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections individuelles du

présent mode d'emploi.

2.1 Utilisation conforme à l'emploi prévu

Les doigts de gant servent à protéger un capteur de température des conditions du process.

Les doigts de gant permettent également de démonter le capteur de température sans arrêter

le process et empêchent des blessures corporelles et/ou des détériorations de l'environnement

pouvant être provoquées par la sortie du uide process.

Le doigt de gant est conçu et construit exclusivement pour une utilisation conforme à lusage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respectées. En

cas d'utilisation inadéquate ou de fonctionnement du doigt de gant en dehors des spécications

techniques, un contrôle doit être immédiatement eectué.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage prévu.

F

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages corporels et

matériels.

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées que par un

personnel ayant la qualication décrite ci-après.

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

25

Page 26

2. Sécurité / 3. Caractéristiques techniques / 4. Conception et fonction

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances dans le

domaine de la technique de mesure et de régulation et de ses expériences de même que de

sa connaissance des prescriptions nationales, des normes et directives en vigueur, en mesure

d'eectuer les travaux décrits et de reconnaître automatiquement les dangers potentiels.

Les conditions d'utilisation spéciales exigent également une connaissance adéquate par exemple

des liquides agressifs ou toxiques.

F

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l'oxygène,

l'acétylène, des substances combustibles ou toxiques, ainsi que dans le cas

d'installations de réfrigération, de compresseurs etc., les directives appropriées

existantes doivent être observées en plus de l'ensemble des règles générales. Si

nécessaire, veiller à ce que le doigt de gant soit mis à la terre.

AVERTISSEMENT !

Les restes de uides se trouvant dans des doigts de gant démontés peuvent mettre en

danger les personnes, l'environnement ainsi que l'installation. Prendre des mesures

de sécurité susantes.

3. Caractéristiques techniques

Pour les caractéristiques techniques, voir les che techniques des types de doigts de gant correspondants et les documents de commande.

4. Conception et fonction

4.1 Description

Les doigts de gant métalliques peuvent être fabriqués à partir d'une pièce (massifs) ou d'un

assemblage de plusieurs pièces (mécanosoudé). Les doigts de gant peuvent être montés sur le

process en les vissant, en les soudant ou au moyen d'une bride. Le thermomètre est monté dans

le doigt de gant par un letage ou taraudage ou au moyen d'une extension.

Lorsque les doigts de gant en métal utilisés en permanence à des températures supérieures à

1200 °C ne présentent pas la résistance souhaitée aux températures élevées et à la corrosion,

des doigts de gant céramiques doivent être utilisés.

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

26

WIKA mode d'emploi doigts de gant

11405821.06 09/2010 GB/D/F/E

Page 27

5. Transport, emballage et stockage / 6. Mise en service, exploitation

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le doigt de gant liés au transport. Communiquer immédiatement

les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale (par ex. changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Eviter les inuences suivantes:

■

Lumière solaire directe ou proximité d'objets chauds (pour doigts de gant avec revêtement en

plastique)

■

Vibrations mécaniques, chocs mécaniques (mouvements brusques en le posant)

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant l'entreposage du doigt de gant

(après fonctionnement). Ceci est particulièrement important lorsque le uide représente un danger pour la santé comme p. ex. des substances corrosives, toxiques,

carcinogènes, radioactives etc.

F

6. Mise en service, exploitation

6.1 Montage

Lors du montage (surtout des doigts de gant céramiques), ne pas exposer les doigts de gant à

des fortes variations de température ou à des chocs mécaniques.

Le doigt de gant doit être introduit sans force et sans l'endommager dans son logement. Il n'est

pas permis de tordre ou d'adapter le doigt de gant pour pouvoir le monter.

L'adaptation ultérieure d'un boulon d'ancrage dans le but d'adapter sans jeu le doigt de gant

dans le raccord à bride ("interference t") en est l'exception. L'adaptation ultérieure d'un boulon

d'ancrage avec jeu n'est pas admissible. En général, les adaptations de boulon d'ancrage d'un

doigt de gant conformément à ASME PTC 19.3 TW2010 ne sont pas recommandées et sont en

dehors de ce standard.

Nous recommandons lors du montage du thermomètre dans le doigt de gant d'utiliser un joint

d'étanchéité adapté an d'éviter par exemple la pénétration d'humidité.

En général, l'extrémité du doigt de gant doit se trouver dans le tiers du milieu de la conduite

mais, dans des cas particuliers, la position peut diérer. Il faut s'assurer que l'élément de mesure

(Pt100, thermocouple, bimétal, etc.) est exposé complètement au uide process mesure et n'est

pas protégé par le piquage. Lorsque cela ne peut pas être garanti en raison d'un diamètre trop

petit, des pièces d'extension avec un diamètre plus élevé peuvent être montées au niveau du

point de mesure.

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

27

Page 28

6. Mise en service, exploitation

Augmentation du diamètre du tuyau

de DN 40 à DN 80

F

Doigts de gant à visser

Pour les letages cylindriques, un joint d'étanchéité adapté doit être utilisé. Les letages coniques

peuvent être étanchés grâce à un produit d'étanchéité ou un cordon de soudure. Les couples de

serrage correspondants et les outils adaptés (par ex. clé à fourche) doivent être utilisés.

Doigts de gant à souder

Les doigts de gant à souder peuvent être xés directement dans le process (paroi du tuyau ou du

réservoir) ou au moyen d'un raccord à souder. Il faut veiller à la propreté, à l'utilisation du matériel

approprié et, si nécessaire, au traitement thermique nécessaire du cordon de soudure.

Doigts de gant avec bride

Les dimensions de la bride du doigt de gant doivent correspondre à celles des contre-brides se

trouvant du coté du process. Les joints d'étanchéité utilisés doivent être adaptés pour le process

et les géométries de bride (indiquées dans le bordereau de livraison). Les couples de serrage

correspondants et les outils adaptés (par ex. clé à fourche) doivent être utilisés pour le montage.

Pour les doigts de gant dotés d'un collier, veiller à ce que celui-ci corresponde au diamètre

intérieur du puit process et soit adapté à celui-ci. Pour les colliers ayant une dimension plus

grande, ils doivent être adaptés au diamètre intérieur du puit process.

Indépendamment du raccordement au processus, trois positions de montage dans un tuyau

peuvent être sélectionnées :

■

Perpendiculairement au sens du ux (position défavorable)

28

WIKA mode d'emploi doigts de gant

11405821.06 09/2010 GB/D/F/E

Page 29

6. Mise en service, exploitation / 7. Entretien et nettoyage

■

Position inclinée (à préférer, pointe inclinée en direction du sens du ux)

■

Pointe montée dans une courbure de tuyauterie (position favorable)

F

La longueur de montage et le diamètre du doigt de gant dépendent des données process, surtout

de la vitesse d'écoulement du médium à mesurer.

Les prescriptions des normes VDI/VDE 3511-5, DIN 43772 annexe 1/2 et AD Regelwerk

(réglementations allemandes concernant les équipements sous pression) doivent être

respectées.

7. Entretien et nettoyage

7.1 Entretien

Les doigts de gant ne nécessitent en général pas d'entretien.

Il est recommander d'eectuer à des intervalles réguliers un contrôle visuel du doigt de gant an

de déceler les fuites ou les dommages. Veiller surtout à un fonctionnement parfait du joint!

Les réparations ne doivent être eectuées que par le fabricant ou après accord, par du personnel

qualié.

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

29

Page 30

7. Entretien et nettoyage / 8. Dysfonctionnements

7.2 Nettoyage

ATTENTION !

Laver ou nettoyer l'appareil démonté avant de le retourner an de protéger les

collaborateurs et l'environnement contre le danger lié aux restes de uides adhérents.

Indications concernant le retour du doigt de gant, voir chapitre "9.2 Retour".

F

8. Dysfonctionnements

Dysfonctionnements Causes Mesures pour remédier aux

dysfonctionnements

La sonde de température ne

peut pas être introduite dans

le doigt de gant

Fuite de uide de process

■

au niveau de la xation du

process au doigt de gant

■

au point de jonction du

doigt de gant et de la

sonde de température ou

au niveau de la sonde de

température

Un corps étranger se trouve dans

le doigt de gant

Le letage de xation du doigt de

gant ou de l'instrument de mesure

est endommagé ou encrassé

La dimension de la sonde ne

correspond pas au diamètre

intérieur du doigt de gant

Le doigt de gant ou la sonde a été

déformé ou endommagé lors du

montage

Erreurs lors du montage ou des

joints d‘étanchéité défectueux

En cas de défauts liés par exemple

au fonctionnement du doigt de gant

en cas de résonance,

Enlever le corps étranger

Nettoyer ou couper le letage

Vérier les documents de

commande

L'envoyer en réparation

Vérier les joints d'étanchéité, les

couples de serrage

Un fonctionnement able de

l'installation n'est plus garanti

(ces défauts provoquent dans le

pire des cas une rupture complète

du doigt de gant)

Nous recommandons pour les applications critiques des calculs de stress pour le doigt de gant

comme prestation de service technique selon ASME PTC 19.3 ou Dittrich/Klotter.

30

WIKA mode d'emploi doigts de gant

11405821.06 09/2010 GB/D/F/E

Page 31

9. Démontage, retour et mise au rebut

9. Démontage, retour et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant aux doigts de gant démontés peuvent mettre en

danger les personnes, l'environnement ainsi que l'installation. Prendre des mesures

de sécurité susantes.

9.1 Démontage

AVERTISSEMENT !

Danger de brûlure !

Avant le démontage du thermomètre, laisser refroidir susamment le doigt de gant !

Danger de brûlure lié à la sortie de uides dangereux chauds.

Démonter les doigts de gant uniquement en état exempt de pression !

9.2 Retour

AVERTISSEMENT !

En cas d'envoi de l'appareil, il faut respecter impérativement ceci :

Tous les appareils livrés à WIKA doivent être exempts de toutes substances dangereuses (acides, solutions alcalines, solutions, etc.).

Pour retourner l'appareil, utiliser l'emballage original ou un emballage adapté pour le transport.

Pour éviter des dommages :

1. Placer l'appareil avec le matériau isolant dans l'emballage.

Isoler de manière uniforme tous les côtés de l'emballage de transport.

2. Mettre si possible un sachet absorbeur d'humidité dans l'emballage.

3. Indiquer lors de l'envoi qu'il s'agit d'un appareil de mesure très sensible à transporter.

Joindre le formulaire de retour rempli à l'appareil.

Le formulaire de retour est disponible sur internet :

www.wika.de / Service / Retour

F

9.3 Élimination des déchets

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Éliminer les composants des appareils et les matériaux d'emballage conformément aux prescriptions nationales pour le traitement et l'élimination des déchets et aux lois de protection de

l'environnement en vigueur.

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

31

Page 32

F

32

11405821.06 09/2010 GB/D/F/E

WIKA mode d'emploi doigts de gant

Page 33

Contenido

Contenido

1. Información general 34

2. Seguridad 35

3. Datos técnicos 36

4. Estructura y función 36

5. Transporte, embalaje y almacenamiento 37

6. Puesta en servicio, funcionamiento 37

Mantenimiento y limpieza

8.

9. Fallos 40

10. Desmontaje, devolución y eliminación de residuos 41

39

E

11405821.06 09/2010 GB/D/F/E

WIKA manual de instrucciones vainas

33

Page 34

1. Información general

1. Información general

■

Las vainas descrita en el manual de instrucciones está construida y fabricada según los

conocimientos actuales. Todos los componentes están sujetos a criterios de calidad rígidos

durante la producción. Nuestros sistemas de gestión están certicados según ISO 9001 y

ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes acerca del manejo de la

vaina. Para un trabajo seguro es imprescindible cumplir con todas las instrucciones de seguridad y manejo indicadas.

E

■

Cumplir siempre las normativas sobre la prevención de accidentes y las normas de seguridad

en vigor en el lugar de utilización de la vaina.

■

El manual de instrucciones es una parte integrante del instrumento y debe guardarse en la

proximidad del mismo para que el personal especializado pueda consultarlo en cualquier

momento.

■

El personal especializado debe haber leído y entendido el manual de instrucciones antes de

comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso de daños causados por un

uso no conforme a la nalidad prevista, la incumplimiento del presente manual de instrucciones, un manejo por personal insucientemente cualicado así como una modicación no

autorizada de la vaina.

■

Se aplican las condiciones generales de venta incluidas en la documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.de / www.wika.com

- Servicio técnico: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Explicación de símbolos

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda causar la muerte o

lesiones graves si no se evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que pueda causar lesiones leves o

medianas o daños materiales y medioambientales si no se evita.

Información

... marca consejos y recomendaciones útiles así como informaciones para una

utilización ecaz y libre de fallos.

34

11405821.06 09/2010 GB/D/F/E

WIKA manual de instrucciones vainas

Page 35

2. Seguridad

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda causar quemaduras

debido a supercies o líquidos calientes si no se evita.

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta en servicio y el funcionamiento asegurarse de que

se haya seleccionado la vaina adecuado con respecto a versión y condiciones de

medición especícas.

Antes del montaje, la puesta en servicio y el funcionamiento asegurarse de que el

material de la vaina sea químicamente resistente/neutral al medio a medir y resistente

a las cargas mecánicas durante el proceso.

Riesgo de lesiones graves y/o daños materiales en caso de incumplimiento.

Los distintos capítulos de este manual de instrucciones contienen otras importantes

indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Las vainas de protección protegen el sensor de temperatura frente a condiciones de proceso

adversas. Además posibilitan el desmontaje del sensor de temperatura sin tener que parar el

proceso y evitan daños al medio ambiente o a personas a causa de escape del medio de proceso.

E

La vaina ha sido diseñado y construido únicamente para la nalidad aquí descrita y debe utilizarse en conformidad a la misma.

Cumplir las especicaciones técnicas de este manual de instrucciones. Un manejo no apropiado

o una utilización de la vaina no conforme a las especicaciones técnicas requiere la inmediata

comprobación.

No se admite ninguna reclamación debido a un manejo no adecuado.

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente cualicación!

Un manejo no adecuado puede causar considerables daños personales y materiales.

Las actividades descritas en este manual de instrucciones deben realizarse únicamente por personal especializado con la consiguiente cualicación.

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica de regulación y medición

así como a su experiencia y su conocimiento de las normativas, normas y directivas vigentes

en el país de utilización el personal especializado es capaz de ejecutar los trabajos descritos y

reconocer posibles peligros por sí solo.

11405821.06 09/2010 GB/D/F/E

WIKA manual de instrucciones vainas

35

Page 36

1. Información general / 3. Datos técnicos / 4. Estructura y función

Algunas condiciones de uso especícas requieren conocimientos adicionales, p. ej. acerca de

medios agresivos y tóxicos.

2.3 Riesgos especícos

¡ADVERTENCIA!

En el caso de sustancias peligrosas a medir, como p. ej. oxígeno, acetileno,

sustancias inamables o tóxicas, así como en instalaciones de refrigeración,

compresores, etc., deben observarse en cada caso, además de todas las reglas

E

generales, las disposiciones pertinentes. Prestar atención a que la vaina de

protección esté debidamente puesta a tierra.

¡ADVERTENCIA!

Restos de medios en vainas desmontadas pueden crear riesgos para personas,

medio ambiente e instalación. Tomar adecuadas medidas de precaución.

3. Datos técnicos

Para datos técnicos véase las hojas técnicas de WIKA de las versiones actuales de modelos de

vainas correspondientes y la documentación de pedido.

4. Estructura y función

4.1 Descripción

Las vainas de metal de protección existen en dos versiónes: versión sólida de una pieza o versión

modular de tubo. Las vainas de protección pueden roscarse, soldarse o jarse mediante brida. El

sensor de temperatura se ja en la vaina de protección directamente mediante una rosca hembra

o macho o mediante un tubo de cuello de tubo.

Si las vainas de protección metálicas no son lo sucientemente resistentes a la temperatura

o corrosión en uso permanente a temperaturas más altas de 1200 ºC, se utilizarán materiales

cerámicas para las vainas.

4.2 Volumen de suministro

Comparar mediante el albarán si se han entregado todas las piezas.

36

WIKA manual de instrucciones vainas

11405821.06 09/2010 GB/D/F/E

Page 37

5. Transporte, embalaje, almacenamiento / 6. Puesta en servicio, ...

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si la vaina presenta eventuales daños causados en el transporte. Noticar daños

obvios de forma inmediata.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje porque es la protección ideal durante el transporte (por ejemplo si el lugar

de instalación cambia o si se envía el instrumento para posibles reparaciones).

5.3 Almacenamiento

Evitar lo siguiente:

■

Luz solar directa o proximidad a objetos calientes (en vainas con recubrimiento de plástico)

■

Vibración mecánica, impacto mecánico (colocación brusca)

¡ADVERTENCIA!

Antes de almacenar la vaina (después del funcionamiento), eliminar todos los restos

de medios adherentes. Esto es especialmente importante cuando el medio es nocivo

para la salud, como p. ej. cáustico, tóxico, cancerígeno, radioactivo, etc.

6. Puesta en servicio, funcionamiento

E

6.1 Montaje

No exponer las vainas a choques térmicos ni golpes mecánicos durante el montaje (en particular

en caso de vainas cerámicas).

Insertar la vaina de protección en el alojamiento del proceso sin tener que aplicar fuerza o sin

causar daños. No está permitido doblar o adaptar la vaina de protección para el montaje.

Una excepción sería la adaptación posterior de un anclaje para un apoyo libre de juego de la

vaina en la tubuladura con brida ("interference t"). Una adaptación posterior de un anclaje con

juego no está permitida. Según ASME PTC 19.3 TW2010, generalmente no se recomienda el

apoyo de una vaina mediante anclaje por lo cual no está incluido en esta normativa.

Recomendamos utilizar una junta adecuada para el montaje del termómetro en la vaina de

protección para evitar, por ejemplo, la penetración de humedad.

Generalmente, la punta de la vaina debería estar insertada una longitud igual a 2/3 del diámetro

del tubo, excepto en casos especiales. Debe garantizarse que el caudal completo llegue al instrumento de medición (Pt100, termopar, elemento bimetálico, etc.) y que no esté bloqueado por la

tubuladura con brida. Si esto no puede garantizarse a causa de un diámetro muy pequeño del

tubo, es posible utilizar ampliaciones del tubo en la zona donde se mide la temperatura.

11405821.06 09/2010 GB/D/F/E

WIKA manual de instrucciones vainas

37

Page 38

6. Puesta en servicio, funcionamiento

Ampliación del tubo

de DN 40 a DN 80

E

Vainas para enroscar

Utilizar una junta adecuada para el montaje de roscas cilíndricas. Roscas cónicas pueden sellarse mediante juntas adecuadas o un cordón de soldadura adicional. Aplicar los pares de apriete

correctos y utilizar herramienta adecuada (p. ej. llave de boca).

Vainas para soldar

Las vainas de protección soldadas pueden jarse directamente en el proceso (pared del tubo

o contenedor) o mediante un racor para soldar. Mantener la zona de soldadura limpia y utilizar

equipamiento adecuado aplicando un acabado térmico a los cordones de soldadura en caso de

necesidad.

Vainas con brida

Las medidas de la brida de la vaina de protección y las de la brida del proceso deben coincidir.

Las juntas utilizadas deben ser las adecuadas para el proceso y las geometrías de las bridas

(consultar el albarán). Aplicar los pares de apriete correctos y utilizar herramienta adecuada (p.

ej. llave ja) para el montaje. Si se utilizan vainas de protección con anclaje, cerciorarse de que

tenga las mismas dimensiones que el diámetro interior del manguito y de que se apoye en éste.

En caso de anclajes de grandes dimensiones adaptarlos al diámetro interior del manguito.

Independiente de la conexión al proceso se utilizan tres diferentes posiciones de montaje de las

vainas en tubos:

■

Posición rectangular con respecto al ujo (posición desfavorable)

38

WIKA manual de instrucciones vainas

11405821.06 09/2010 GB/D/F/E

Page 39

6. Puesta en servicio, funcionamiento / 7. Mantenimiento y limpieza

■

Posición inclinada con respecto al ujo (recomendable, inclinar la punta con respecto a la

dirección de ujo)

■

Flujo alrededor de la punta en el codo de tubo (posición ideal)

E

La longitud de montaje y el diámetro de la vaina de protección dependen de los datos del proceso, en particular de la velocidad de ujo del medio a medir.

Observar las normas VDI/VDE 3511-5 y DIN 43772 hoja adjunta 1/2 así como las reglas de la

comisión alemana para recipientes a presión (AD-Regelwerk).

7. Mantenimiento y limpieza

7.1 Mantenimiento

Normalmente las vainas de protección no requieren mantenimiento.

Recomendamos inspeccionar visualmente las vainas de protección a intervalos regulares por si

presentan fugas o daños.

¡Es particularmente importante que la obturación esté intacta!

Todas las reparaciones solamente las debe efectuar el fabricante o, a convenir, personal debidamente instruido y calicado.

11405821.06 09/2010 GB/D/F/E

WIKA manual de instrucciones vainas

39

Page 40

7. Mantenimiento y limpieza / 8. Fallos

7.2 Limpieza

¡CUIDADO!

Lavar o limpiar el instrumento desmontado antes de devolverlo para proteger a los

empleados y el medio ambiente de los peligros causados por restos de medios.

Véase el capítulo "9.2 Devolución" para obtener más información acerca de la

devolución de la vaina.

E

8. Fallos

Fallos Causas Medidas

El sensor de temperatura

no se puede introducir en la

vaina.

El medio de proceso escapa

■

en el punto de jación del

proceso a la vaina

■

en el punto de contacto

entre la vaina y el sensor

de temperatura o en el

sensor mismo

Hay cuerpos extraños en la vaina Eliminar los cuerpos extraños

La rosca de jación de la vaina o

del sensor de temperatura está

dañada o sucia

Las dimensiones del sensor y el

diámetro interior de la vaina no

coinciden

La vaina o el sensor fue doblada o

dañada durante el montaje

Montaje incorrecto o juntas

defectuosas

Defectos, p. ej. por la utilización de

la vaina en el caso de resonancia

Limpiar o lubricar la rosca

Controlar la documentación de

pedido

Enviar la vaina para que se repare

Controlar la junta, controlar el par

de apriete

El funcionamiento seguro de la

instalación ya no está garantizado

(en el peor de los casos puede causar la ruptura completa de la vaina)

En caso de instalaciones críticas recomendamos un análisis de la resistencia mecánica de la

vaina de protección según ASME PTC 19.3 ó Dittrich/Klotter. WIKA les ofrece este servicio.

40

WIKA manual de instrucciones vainas

11405821.06 09/2010 GB/D/F/E

Page 41

9. Desmontaje, devolución y eliminación de residuos

9. Desmontaje, devolución y eliminación de residuos

¡ADVERTENCIA!

Restos de medios a vainas desmontadas pueden crear riesgos para personas, medio

ambiente e instalación. Tomar medidas adecuadas de precaución.

9.1 Desmontaje

¡ADVERTENCIA!

¡Riesgo de quemaduras!

¡Dejar enfriar la vaina lo suciente antes de desmontarlo! Peligro debido a medios

muy calientes que se escapan durante el desmontaje.

¡Desmontar la vaina sólo si no está bajo tensión!

9.2 Devolución

¡ADVERTENCIA!

Es imprescindible observar lo siguiente para el envío del instrumento:

Todos los instrumentos enviados a WIKA deben estar libres de sustancias peligrosas

(ácidos, lejías, soluciones, etc.).

Utilizar el embalaje original o un embalaje adecuado para la devolución del instrumento.

Para evitar daños:

1. Colocar el instrumento junto con el material aislante en el embalaje.

Aislar uniformemente todos los lados de la caja de transporte.

2. Si es posible, adjuntar una bolsa con secante.

3. Colocar aviso de mercancia fragil.

E

Rellenar el formulario de devolución y adjuntarlo al instrumento.

El formulario de devolución está disponible en internet:

www.wika.com / Service / Devolución

9.3 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio ambiente.

Eliminar los componentes de los instrumentos y los materiales de embalaje conforme a los reglamentos relativos al tratamiento de residuos y eliminación vigentes en el país de utilización.

11405821.06 09/2010 GB/D/F/E

WIKA manual de instrucciones vainas

41

Page 42

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-Mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-Mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. "Al. Stamboliiski" 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-Mail: info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-Mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-Mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-Mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-Mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-Mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-Mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763722

Fax: (+381) 11 753674

E-Mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Tel. (+34) 902 902577

Fax: (+34) 933 938666

E-Mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-Mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 21

34775 Yukari Dudullu - Istanbul

Tel. (+90) 216 41590-66

Fax: (+90) 216 41590-97

E-Mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Tel. (+38) 062 34534-16

Fax: (+38) 062 34534-17

E-Mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. (+44) 1737 644-008

Fax: (+44) 1737 644-403

E-Mail: info@wika.co.uk

www.wika.co.uk

42 WIKA operating instructions thermowells

11405821.06 09/2010 GB/D/F/E

Page 43

WIKA global

North America

Canada

WIKA Instruments Ltd.

Head Oce

Edmonton, Alberta, T6N 1C8

Tel. (+1) 780 46370-35

Fax: (+1) 780 46200-17

E-Mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.

01210 Mexico D.F.

Tel. (+52) 55 55466329

E-Mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Tel. (+1) 770 5138200

Fax: (+1) 770 3385118

E-Mail: info@wika.com

www.wika.com

WIKA Instrument Corporation

Houston Facility

950 Hall Court

Deer Park, TX 77536

Tel. (+1) 713-475 0022

Fax (+1) 713-475 0011

E-mail: info@wikahouston.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. (+1) 512 3964200-15

Fax (+1) 512 3961820

E-Mail: sales@mensor.com

www.mensor.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Tel. (+54) 11 47301800

Fax: (+54) 11 47610050

E-Mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Tel. (+55) 15 34599700

Fax: (+55) 15 32661650

E-Mail: marketing@wika.com.br

www.wika.com.br

Chile

WIKA Chile S.P.A.

Av. Coronel Pereira, 101

Ocina 101

Las Condes

Santiago de Chile

Tel. (+56) 9 66084258

Fax (+56) 2 3346219

E-Mail: info@wika.cl

www.wika.cl

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Tel. (+86) 21 538525-72

Fax: (+86) 21 538525-75

E-Mail: info@wika.com.cn

www. wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Tel. (+91) 20 66293-200

Fax: (+91) 20 66293-325

E-Mail: sales@wika.co.in

www.wika.co.in

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Tel. (+7) 32 72330848

Fax: (+7) 32 72789905

E-Mail: info@wika.kz

www.wika.kz

Korea

WIKA Korea Ltd.

#569-21 Gasan-dong

Seoul 153-771 Korea

Tel. (+82) 2 869 05 05

Fax (+82) 2 869 05 25

E-Mail: info@wika.co.kr

www.wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn. Bhd.

47100 Puchong, Selangor

Tel. (+60) 3 80 63 10 80

Fax: (+60) 3 80 63 10 70

E-Mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Tel. (+65) 68 44 55 06

Fax: (+65) 68 44 55 07

E-Mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Tel. (+886) 3 420 6052

Fax: (+886) 3 490 0080

E-Mail: info@wika.com.tw

www.wika.com.tw

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

Japan

WIKA Japan K. K.

Tokyo 105-0023

Tel. (+81) 3 543966-73

Fax: (+81) 3 543966-74

E-Mail: info@wika.co.jp

43

Page 44

WIKA global

Africa / Middle East

Egypt

WIKA Near East Ltd.

El-Serag City Towers

-Tower#2 - Oce#67-

Nasr City Cairo

Tel. (+20) 2 22733140

Fax: (+20) 2 22703815

E-Mail: wika.repcairo@wika.de

www.wika.com.eg

Namibia

WIKA Instruments Namibia (Pty)

Ltd.

P.O. Box 31263

Pionierspark

Windhoek

Tel. (+26) 4 6123 8811

Fax (+26) 4 6123 3403

E-Mail: info@wika.com.na

www.wika.com.na

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview, Johannesburg 2047

Tel. (+27) 11 62100-00

Fax: (+27) 11 62100-59

E-Mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Tel. (+971) 4 8839-090

Fax: (+971) 4 8839-198

E-Mail: wikame@emirates.net.ae

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Tel. (+61) 2 88455222

Fax: (+61) 2 96844767

E-Mail: sales@wika.com.au

www.wika.com.au

New Zealand

WIKA Instruments Limited

Unit 7 / 49 Sainsbury Road

St Lukes - Auckland 1025

Tel. (+64) 9 8479020

Fax: (+64) 9 8465964

E-Mail: info@wika.co.nz

www.wika.co.nz

WIKA Niederlassungen weltweit nden Sie online unter www.wika.de.

WIKA subsidiaries worldwide can be found online at www.wika.de.

La liste des liales WIKA dans le monde se trouve sur www.wika.de

Sucursales WIKA en todo el mundo puede encontrar en www.wika.de.

44

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

11405821.06 09/2010 GB/D/F/E

WIKA operating instructions thermowells

Loading...

Loading...