Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Resistance thermometers with digital display

Model TR75, battery powered

Widerstandsthermometer mit digitaler Anzeige

Typ TR75, Batteriebetrieb

Sondes à résistance avec achage numérique

Type TR75, fonctionnement sur pile

Termorresistencia con indicación digital

Modelo TR75, alimentación por batería

DiwiTherm

GB

D

F

E

®

DiwiTherm® model TR75

Page 2

Operating instructions model TR75 Page 3 - 24

GB

D

Betriebsanleitung Typ TR75 Seite 25 - 46

F

Mode d'emploi type TR75 Page 47 - 68

E

Manual de instrucciones modelo TR75 Página 69 - 89

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

4. Design and function 9

5. Transport, packaging and storage 16

6. Commissioning, operation 17

7. Maintenance and cleaning 20

8. Faults 21

9. Dismounting, return and disposal 22

GB

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 3

Page 4

1. General information

1. General information

■

The instrument described in the operating instructions has been designed and

GB

manufactured using state-of-the-art technology. All components are subject to stringent

quality and environmental criteria during production. Our management systems are

certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations

for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TE 60.75

- Application consultant:

Tel.: +49 9372 132-0

Fax +49 9372 132-406

info@wika.com

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or

death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to equipment or the environment, if not avoided.

4 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 5

1. General information / 2. Safety

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

thermometer has been selected in terms of measuring range, design and

specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

Further important safety instructions can be found in the individual chapters of

these operating instructions.

2.1 Intended use

The DiwiTherm

temperatures.

®

thermometer is used mainly in the process industry to monitor process

GB

The instrument has been designed and built solely for the intended use described here, and

may only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation, wait

for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 5

Page 6

2. Safety

2.2 Personnel qualication

WARNING!

GB

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge

of country-specic regulations, current standards and directives, are capable of carrying out

the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Special hazards

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in this operating instruction may only be carried out

by skilled personnel who have the qualications described below.

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases or

liquids, and refrigeration plants, compressors, etc., in addition to all standard

regulations, the appropriate existing codes or regulations must also be followed.

WARNING!

To ensure safe working on the instrument, the operating company must ensure

■

that suitable rst-aid equipment is available and aid is provided whenever

required.

■

that the operating personnel are regularly instructed in all topics regarding

work safety, rst aid and environmental protection and know the operating

instructions and, in particular, the safety instructions contained therein.

6 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 7

2. Safety

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment. Take sucient precautionary measures.

Do not use this instrument in safety or emergency stop devices. Incorrect use of

the instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature and

under high pressure or vacuum may be present at the instrument.

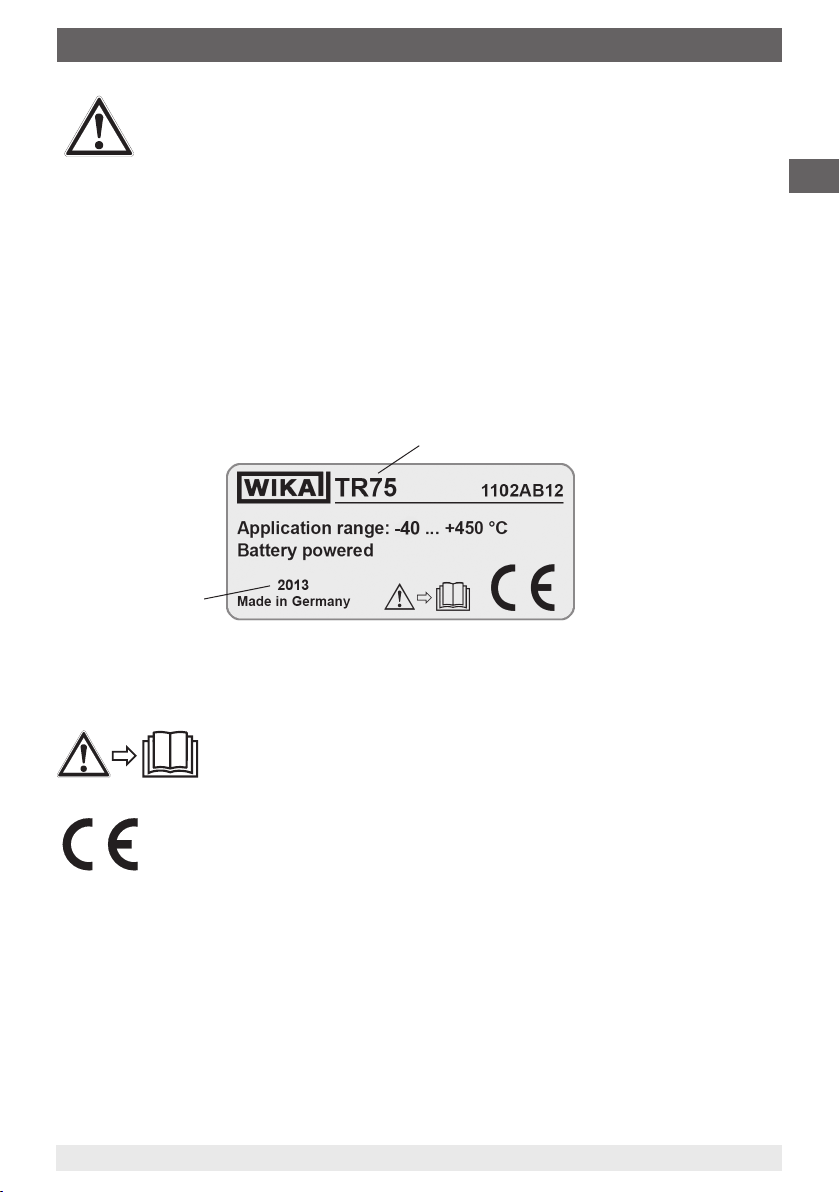

2.4 Labelling, safety marks

Product label

Year of manufacture

GB

Model

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 7

Page 8

3. Specications

3. Specications

Specications

GB

Measuring range

Model TR75

Display in °C

Range 1

Range 2

-40.0 ... +199.9 °C

200 ... 450 °C with automatic measuring range changeover

(Autorange)

Display

Principle 3 ½- digit LCD, 7-segment display, 21 mm high

Resolution 0.1 K up to 199.9 °C; 1 K from 200 °C

Accuracy

0.5 % of the respective full-range value ±1 digit

Instrument versions

■

DiwiTherm® with sensor for insertion

Design Sensor with connection cable

■

Max. working temperature 200 °C

■

Housing for panel mounting, with panel mounting ange

■

DiwiTherm® for mounting in a thermowell

Design Spring-loaded sensor

Threaded connection to thermowell

■

Housing with neck tube

■

Option

Adjustable stem and dial (rotatable through 360° and tiltable

through 90°)

■

DiwiTherm® for mounting on a pipe surface

Design Contact bulb for xing with tightening strap

■

Max. working temperature 200 °C

■

Housing with neck tube

■

Option

Adjustable stem and dial (rotatable through 360° and tiltable

through 90°)

■

Housing for panel mounting, with connecting cable and panel

mounting ange

Case

Nominal size 100

Material Stainless steel

Ingress protection IP 65 per EN 60529 / IEC 60529

Bezel ring Bayonet ring

Window Instrument glass

Power supply U

B

DC 3.6 V from 3.6 V lithium battery, AA size (Mignon), included in

1)

delivery

Operating time min. 10 years

Special features If the battery drops below 2.7 V, the display switches into “LO” mode

Electromagnetic compatibility (EMC)

CE conformity per EN 61326

Miscellaneous

Sensor Pt1000

Ambient/storage temperature -20 ... +60 °C

1) Not replaceable by the customer.

8 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 9

3. Specications / 4. Design and function

Vibration (at sensor) 10 ... 500 Hz 5 g EN 60068-2-6 / IEC 60068-2-6

Shock (at sensor) EN 60068-2-7 / IEC 60068-2-7

Weight approx. 1 kg (actual weight depends on design and possibly

For further specications see WIKA data sheet TE 60.75 and the order documentation.

4. Design and function

4.1 Description

The DiwiTherm

thermometer. This compact thermometer can be used in a wide range of applications and

works without an external power supply.

A wide variety of possibilities for the combination of insertion length, neck length, connection

to thermowell etc. are available for the thermometers, suitable for any thermowell and any

application.

®

model TR75 is the ideal combination of a digital display and a resistance

mounted thermowell)

GB

Operation without thermowell is only recommended in certain applications.

Optionally, the DiwiTherm

®

model TR75 can be manufactured with a process connection for

measuring the temperature on a pipe's surface.

®

4.1.1 DiwiTherm

with sensor for insertion

Sensor

Material: stainless steel

Sensor length A ≤ 150 mm: Rigid sensor tube

The tubular design features a rigid construction to the metal sensor tip; therefore tubular

designs must not be bent. Internally, the measuring resistor is connected directly to an

insulated lead. Therefore tubular-design resistance thermometers can only be used up to the

temperatures specied for the lead (see operating temperatures).

Sensor length above 150 mm: Sheathed measuring cable (MI cable)

The junction between the metal part of the sensor and the connecting cable, when using MI

cable, is either crimped, rolled or potted, depending on the design. This area should not be

immersed within the process and must not be bent.

Compression ttings should not be attached to the transition. The type and dimensions of

the transition depend largely on the combination between input leads and metal sensor and

the sealing requirements.

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 9

Page 10

4. Design and function

The sensor diameter should be approx. 1 mm smaller than the bore diameter of the

thermowell or the blind bore, respectively.

Gaps of more than 0.5 mm between thermowell and the sensor will have a negative eect on

GB

the heat transfer, and they will result in unfavourable response behaviour of the thermometer.

Sensor lengths

Sensor Ø in mm

6 50 100 150

8 - 100 150

Special lengths are possible.

Process connection

A compression tting enables simple, on-site adjustment to the required insertion length.

Compression tting

Material: stainless steel

G ¼ B male thread (not with Ø 8 mm sensors) or G ½ B

Delivery also possible without process connection.

Cable

Silicone, shielded, application range -40 ... +200 °C with EMC cable gland

Cable length to customer specication.

The sensor sleeve and case are connected by the cable shielding. Earthing on both ends

can lead to potential losses and indication inaccuracy.

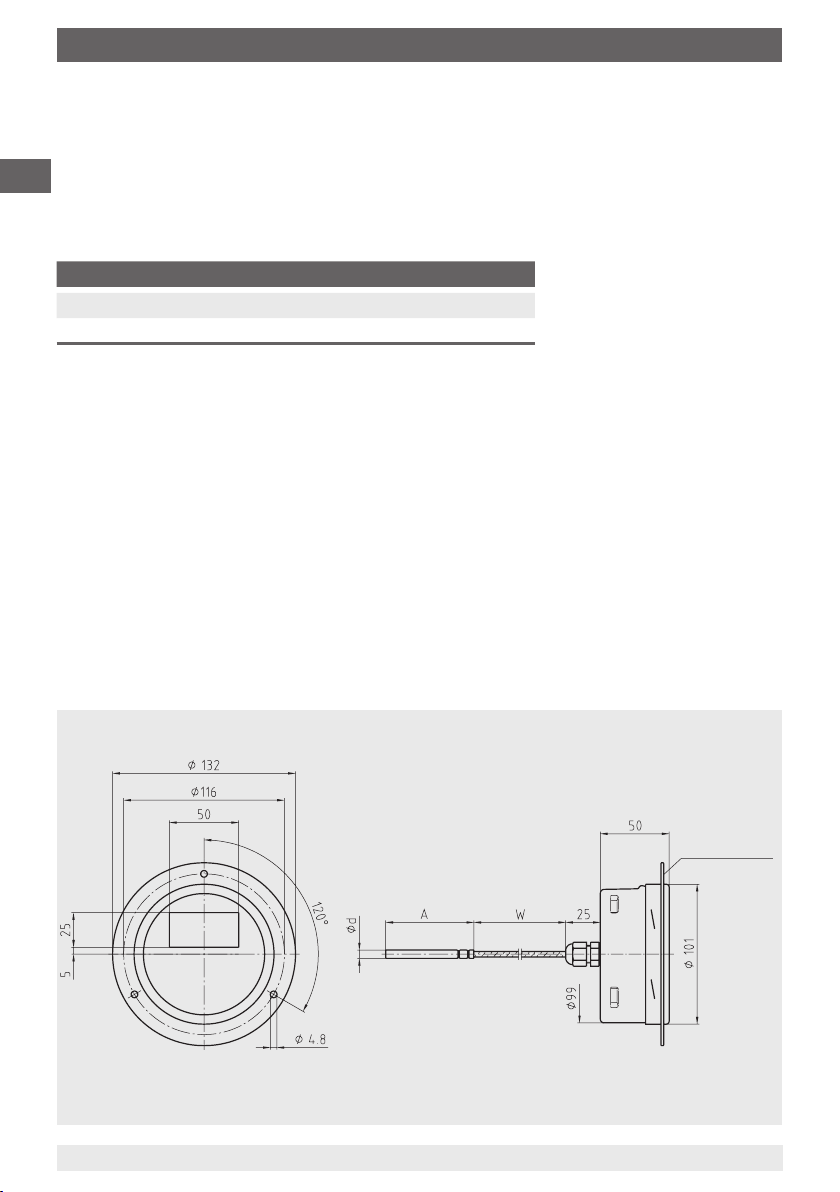

Standard sensor lengths A (l1) in mm

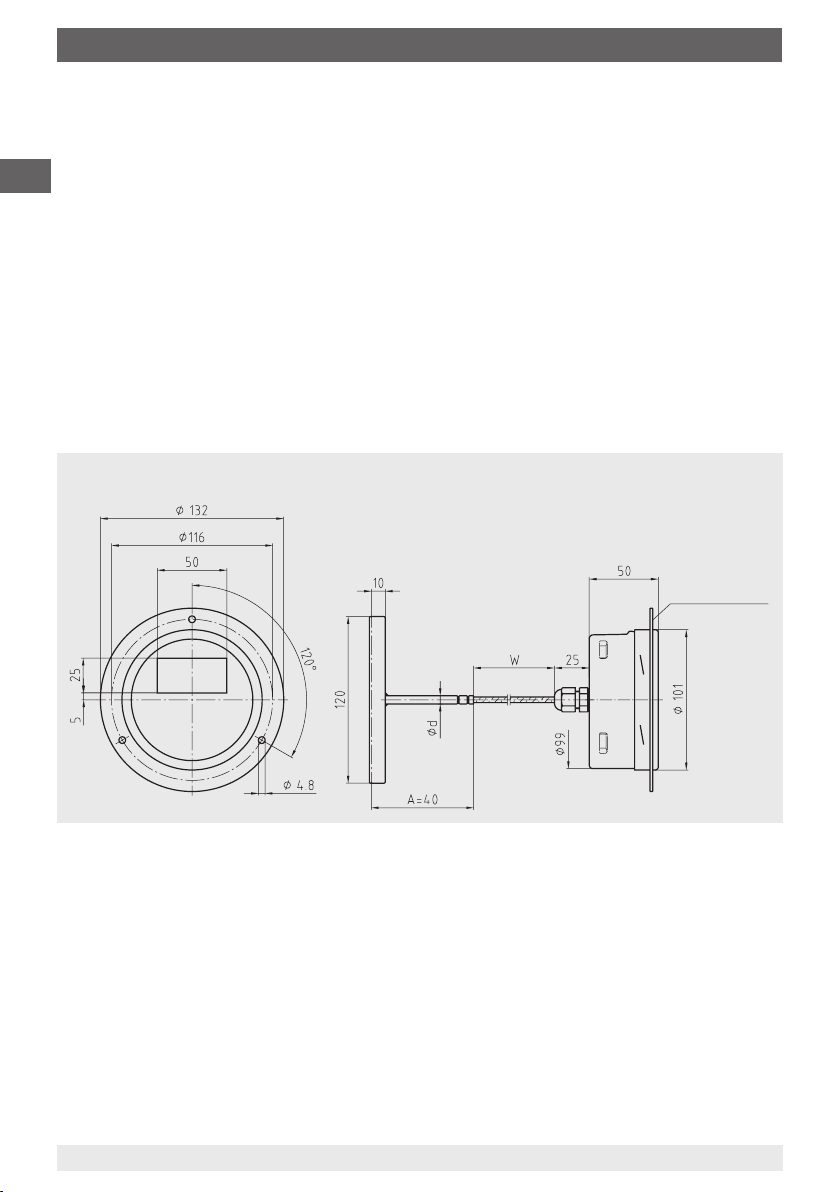

DiwiTherm® battery operation, model TR75 with sensor for insertion, rear cable entry, with

panel mounting ange

Panel mounting

ange

Legend:

Ø d Sensor diameter

A Insertion length

W Cable length

10 WIKA operating instructions DiwiTherm®, model TR75

3165575.05

11325232.04 01/2014 GB/D/F/E

Page 11

4. Design and function

4.1.2 DiwiTherm® for mounting in a thermowell

Sensor

Material: stainless steel

The sensor is made from vibration-resistant, sheathed cable (MI cable).

The sensor diameter should be approx. 1 mm smaller than the bore diameter of the

thermowell. Gaps of more than 0.5 mm between thermowell and the sensor will have a

negative eect on the heat transfer, and they will result in unfavourable response behaviour

of the thermometer.

When tting the measuring insert into a thermowell, it is very important to determine the

correct insertion length (= thermowell length for bottom thicknesses of ≤ 5.5 mm). In order to

ensure that the sensor is rmly pressed down onto the bottom of the thermowell, the sensor

must be spring-loaded (spring travel: max 10 mm).

Process connection (standard process connection)

Material: stainless steel

Threaded connection: G ½ B

M14 x 1.5

M18 x 1.5

½ NPT

Union nut: G ½ B

Male nut: G ½ B

GB

Neck tube

Material: stainless steel

Neck tube diameter: 12 mm

Standard neck length: 150 mm

others on request

(minimum neck length: 30 mm)

Sensor lengths

Sensor Ø in mm Standard insertion lengths A (l1) in mm

3 110 140 145 170 200 205 230 245 260 294 305 345 350 395 410 445 545

6 - - - 170 200 205 230 245 260 295 305 345 350 395 410 445 545

8 - - - - 200 205 230 245 260 295 305 345 350 395 410 445 545

Special lengths are possible.

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 11

Page 12

4. Design and function

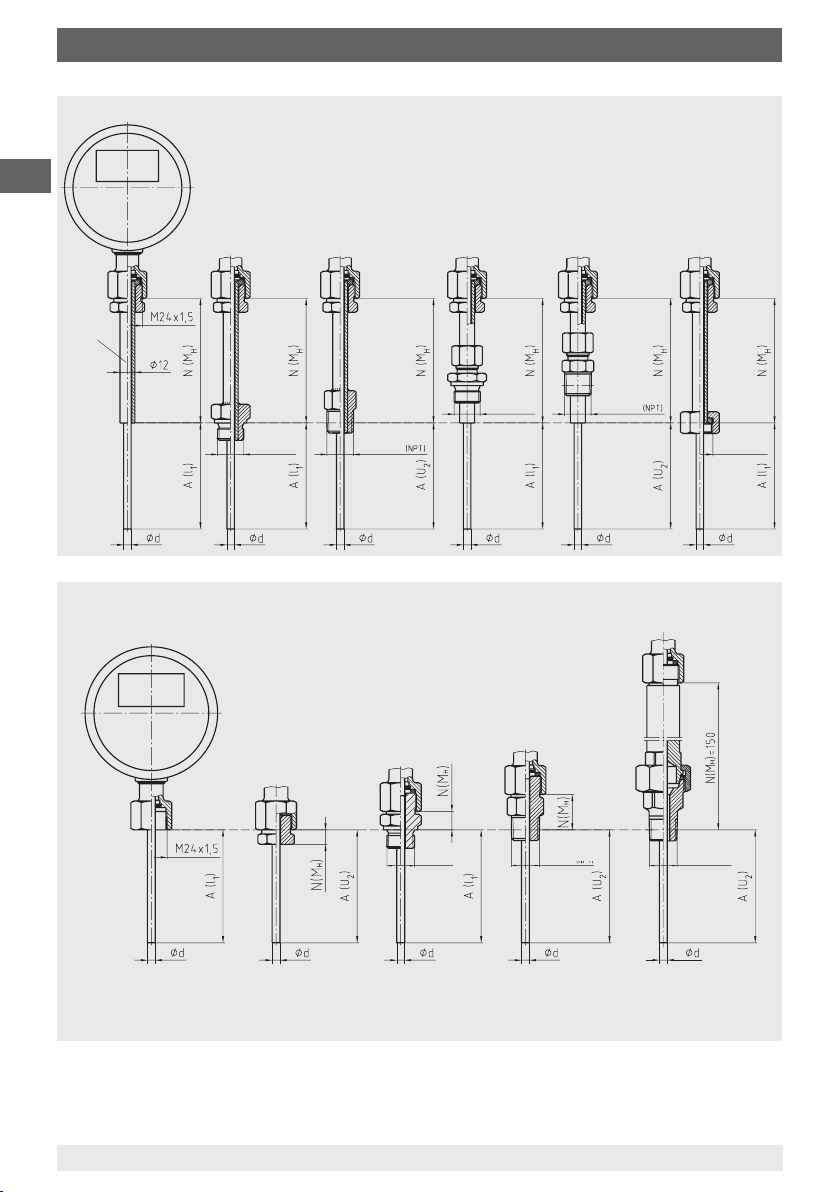

Connection to thermowell (with neck tube)

GB

Neck tube

smooth

Connection to thermowell

Fixed threaded

connections / threads

Thread

Male nut for

sealing case

Compression tting

(xing to neck tube)

Thread

Double nipple version

Thread

3172503.07

Thread

Thread

“nipple-union-nipple”

neck tube

11363533.03

Female thread

M24 x 1.5

Thread Thread

Legend:

Ø d Sensor diameter

A (l

) Insertion length

1

Thread

(NPT)

A (U

N(M

) Insertion length

2

(for tapered threads)

) Neck length

H

(NPT)

12 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 13

4. Design and function

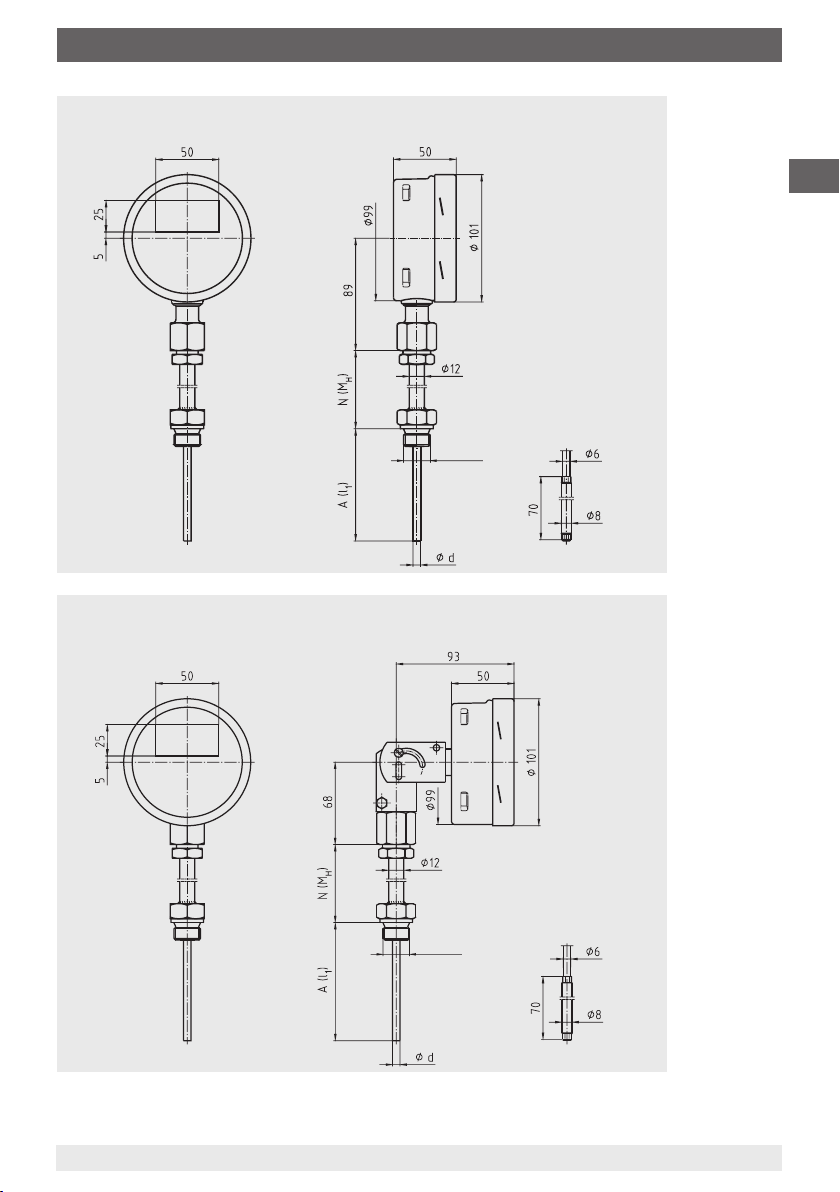

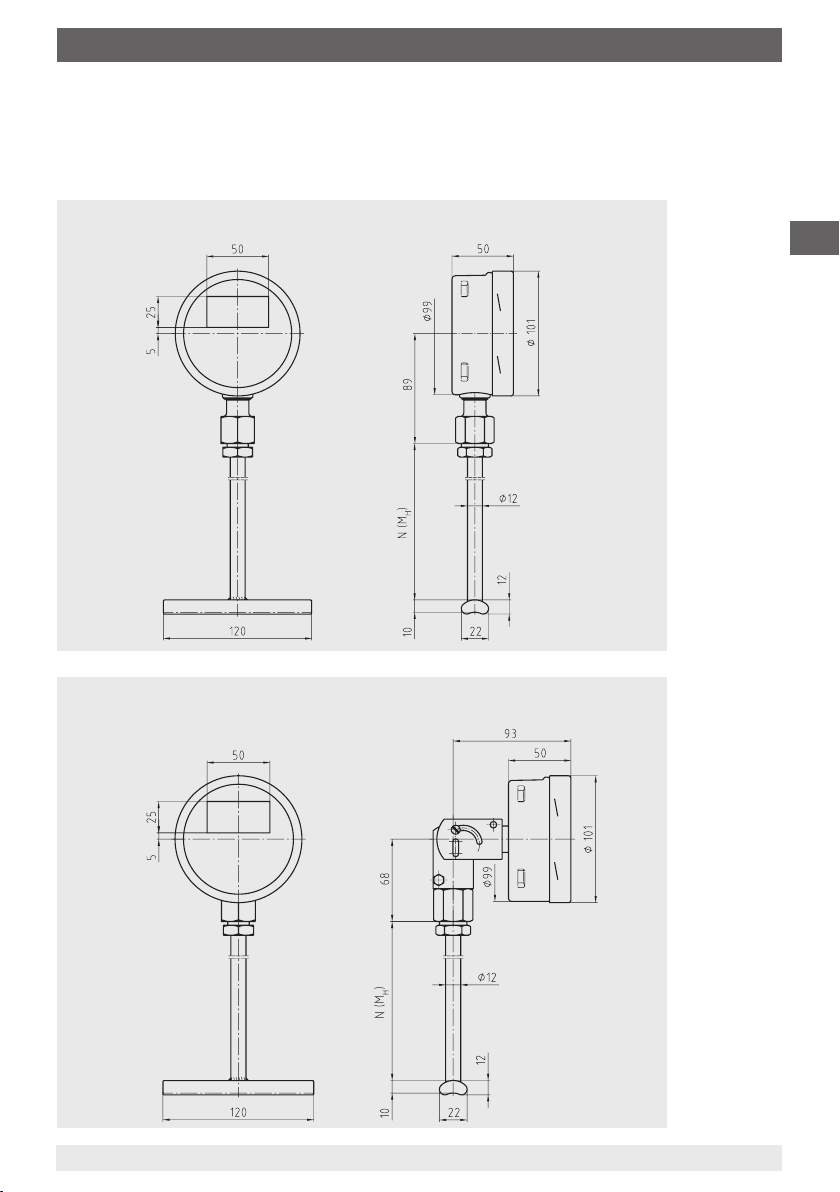

DiwiTherm® model TR75 for mounting in a thermowell, with neck tube

Connection from housing to neck tube: xed, lower mount

Ø 8 mm variant

Thread

DiwiTherm® model TR75 for mounting in a thermowell, with neck tube

Connection from housing to neck tube: adjustable stem and dial,

rear mount, centric

GB

3161218.06 3161374.06

Ø 8 mm variant

Thread

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 13

Page 14

4. Design and function

4.1.3 DiwiTherm® for mounting on a pipe surface

Contact bulb

Material: stainless steel

GB

Mounting tube: 120 mm

Fixing with a tightening strap (not included in delivery)

Cable

Silicone, shielded, application range -50 ... +200 °C

Cable length to user specications

The sensor sleeve and case are connected by the cable shielding. Earthing on both ends

can lead to potential losses and indication inaccuracy.

The specied accuracy can only be guaranteed up to a maximum cable length of 15 m. With

longer cable lengths, the accuracy can deviate sharply.

DiwiTherm® model TR75 for mounting on a pipe surface, rear cable output,

with panel mounting ange

Panel mounting

3157559.05

ange

14 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 15

4. Design and function

Neck tube

Material: stainless steel

Neck tube diameter: 12 mm

Standard neck length: 150 mm, others on request (minimum neck length: 100 mm)

DiwiTherm® model TR75 for mounting on a pipe surface, with neck tube

Connection from housing to neck tube: xed, lower mount

3157541.04

GB

DiwiTherm® model TR75 for mounting on a pipe surface, with neck tube

Connection from housing to neck tube: adjustable stem and dial,

rear mount, centric

11144807.04

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 15

Page 16

4. Design and function / 5. Transport, packaging and storage

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

GB

5. Transport, packaging and storage

5.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

Examine the packaging material carefully so that no accessories that might be packed within

it are lost.

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +60 °C

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the instrument in its original packaging in a location that fulls the conditions listed

above. If the original packaging is not available, pack and store the instrument as described

below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument along with shock-absorbent material in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual media.

This is of particular importance if the medium is hazardous to health, e.g. caustic,

toxic, carcinogenic, radioactive, etc.

16 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 17

6. Commissioning, operation

6. Commissioning, operation

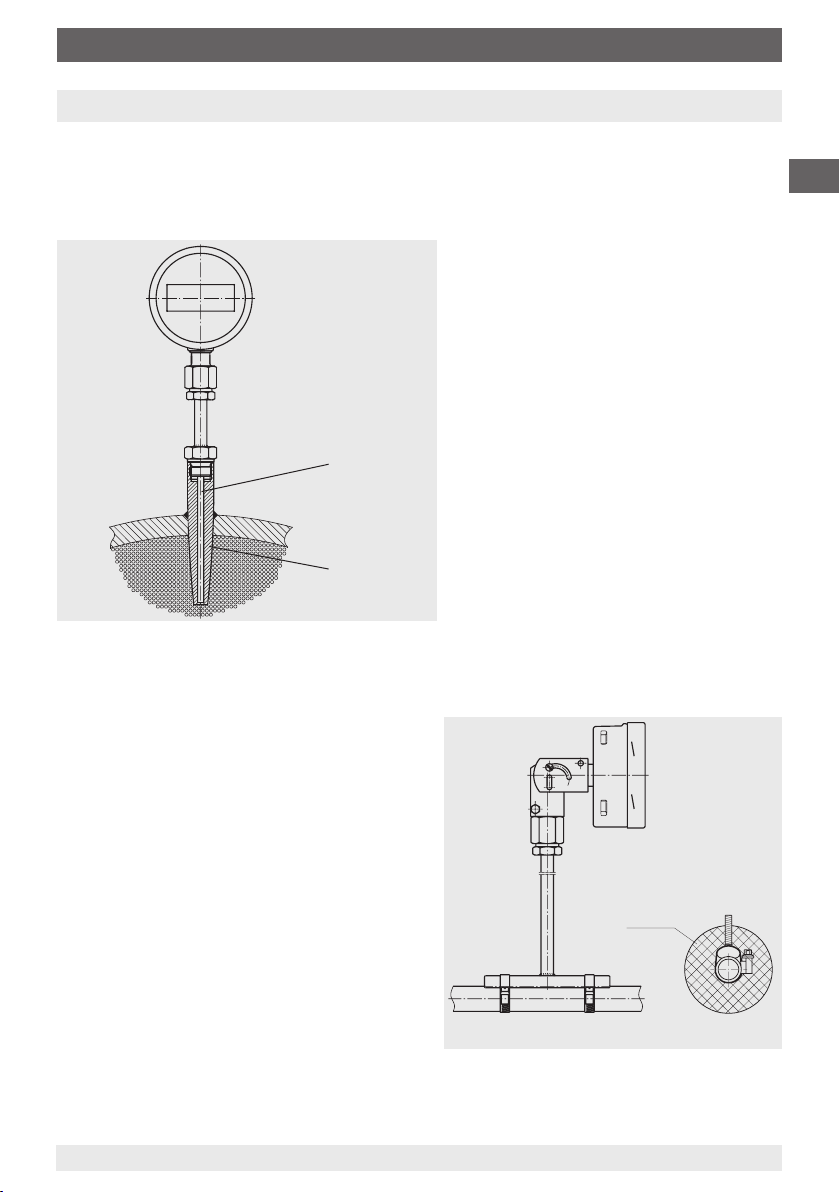

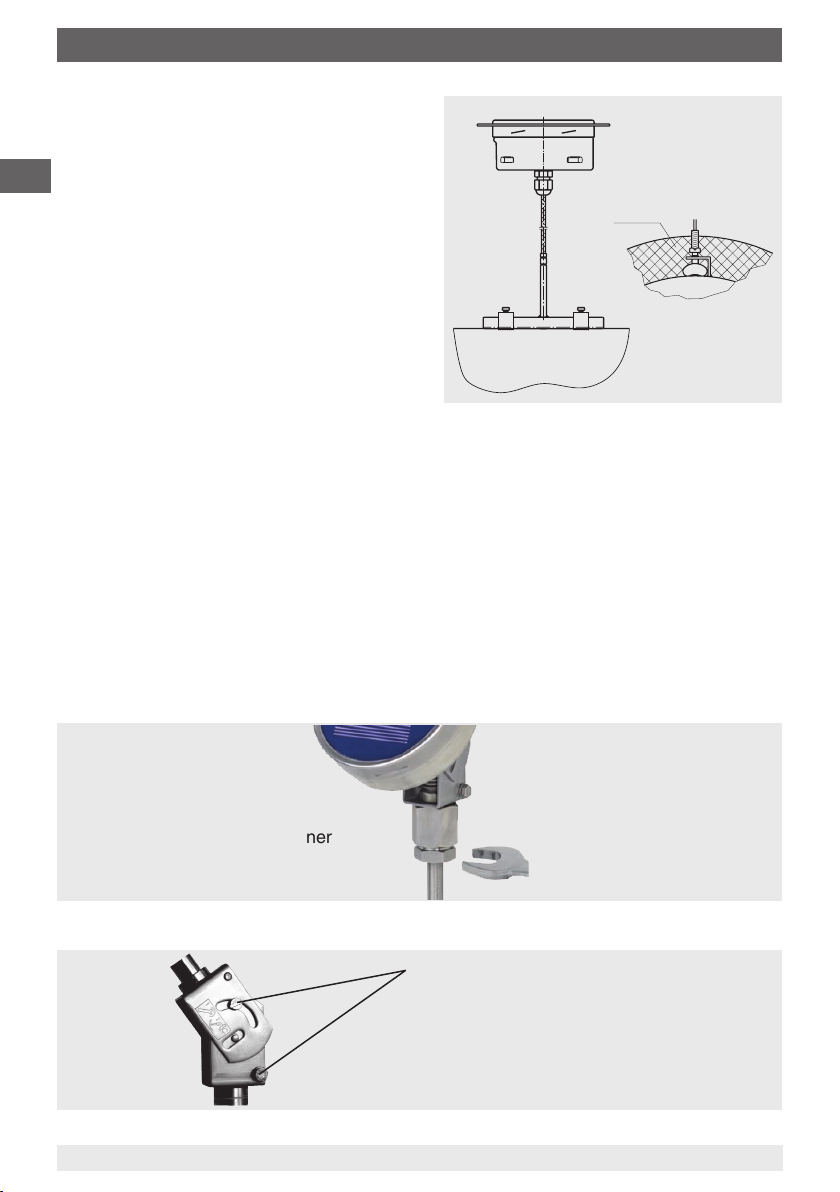

DiwiTherms® must only be operated with an additional thermowell.

Exception: Axial cable outlet (for panel mounting) or version with contact bulb.

Typical mounting situation with thermowell

Measuring

insert

Thermowell

GB

Typical mounting situation with contact bulb

■

Mounting on pipes

The geometry of the contact bulb has been

designed for pipes with external diameters

between 20 and 160 mm. For xing the

contact bulb to the pipe, pipe clamps are

sucient. The contact bulb should have

direct metallic contact with the measuring

point and have rm contact with the surface

of the pipe. Where temperatures under

200 °C are expected, a heat conductive

Pipe clamp mounting

Lagging *

paste can be used to optimise the heat

transmission between contact bulb and pipe.

Insulation must be applied at the mounting

point to avoid error due to heat loss. This

insulation must have sucient temperature

* Lagging mandatory!

resistance and is not included in the scope of delivery.

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 17

Page 18

6. Commissioning, operation

■

Mounting on tanks

The geometry of the contact bulb has been

designed for vessels with an external radius

GB

up to 160 mm. If the mounting point of the

skin mounting contact bulb on the tank has

an external radius greater than 160 mm,

we recommend the use of an intermediate

piece designed for the respective tank

diameter, made of a material with good

thermal conductivity. The contact bulb can

be fastened to the tank by means of an angle

bracket with clamping screws, or any similar

method. The contact bulb should have direct

metallic contact with the measuring point

and have rm contact with the surface of the tank.

A heat conductive paste can be used to optimise the heat transmission between contact

bulb and vessel, if temperatures under 200 °C are expected. Insulation must be applied

at the mounting point to avoid error due to heat loss. This insulation must have sucient

temperature resistance and is not included in the scope of delivery.

Angle bracket mounting

Lagging *

* Lagging mandatory!

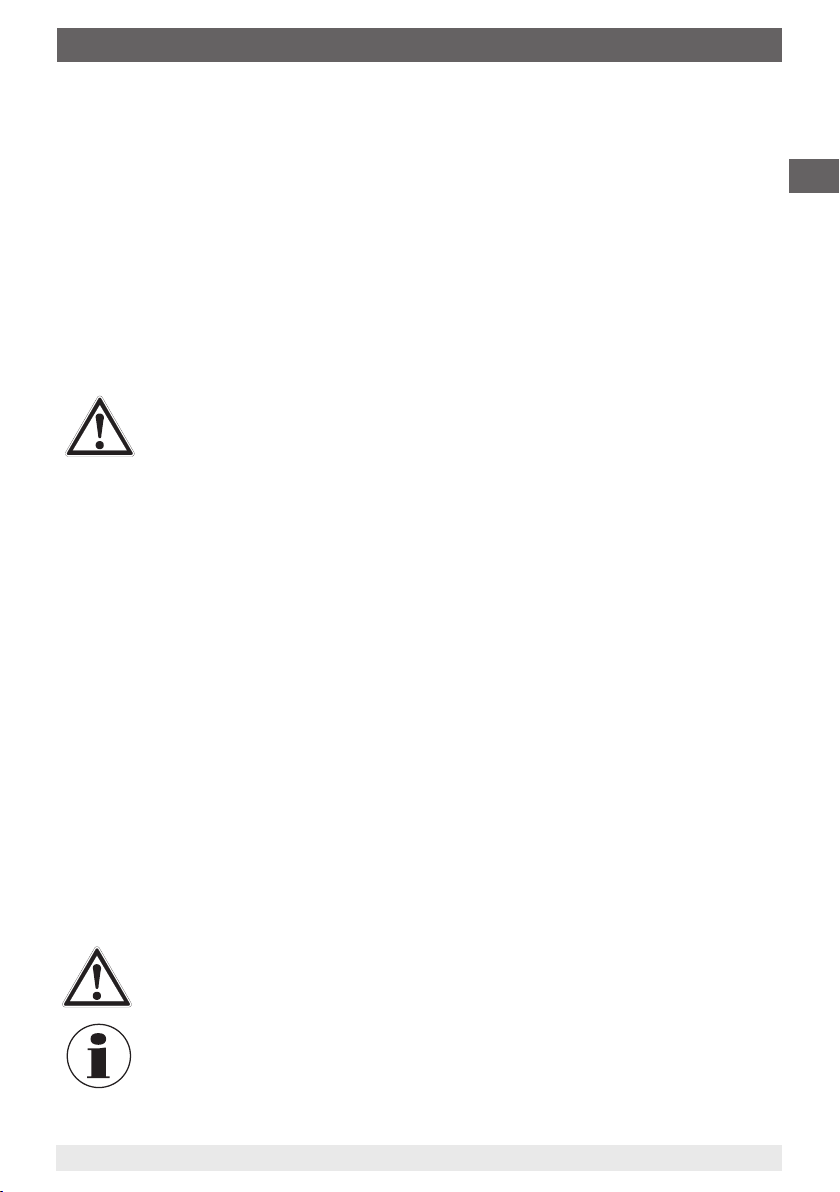

When mounting a rotatable and inclinable DiwiTherm

®

thermometer, the specic

instructions must be followed. In order to set the indicator to the desired position, the

following steps must be taken:

1. The lock nut or union nut must be loosened at the process connection.

Installation with

open-ended spanner

2. The hexagon bolts and slotted screws at the swivel joint must be loosened.

loosening

Make sure to loosen the screws on

the opposite side as well!

18 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 19

6. Commissioning, operation

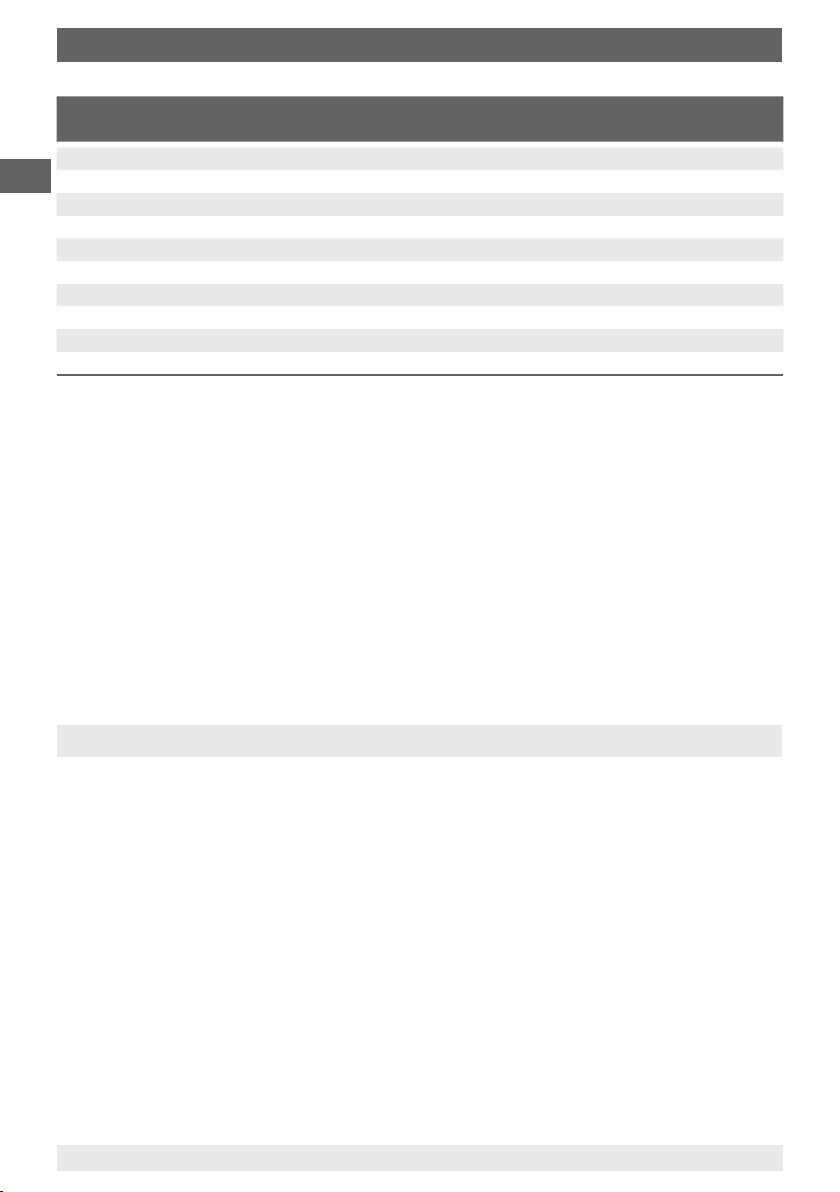

3. Position the indicator as required, tighten the hexagon bolts and slotted screws, and nally

tighten the lock nut or union nut rmly.

Observe the following points during sensor installation:

■

If possible, the entire length of the sensor should be exposed to the temperature being

measured.

■

In pipelines or at other measuring points, the temperature sensor should be directed as

far towards the ow as possible.

■

When using thermowells, ll a thermal contact medium in order to reduce the heat

transfer resistance between the outer wall of the sensor and the inner wall of the

thermowell if possible. The working temperature of the heat conductive paste is

-40 ... +200 °C.

WARNING!

Do not use any heat transfer oil!

6.1 Parallel threads

If the thermometer connecting head, neck tube, thermowell or process connection are

connected with parallel threads (e.g. G ½, M20 x 1.5 ...), these threads must be secured

using seals which prevent liquids from penetrating into the thermometer.

As standard, WIKA uses copper prole seals for the connection between the neck tube

and the thermowell, and at paper seals for the connection of the connection head and the

extension neck or thermowell.

If the thermometer and the thermowell are already connected, the seals will already be

mounted. The plant operator must check whether the seals are suitable for the operating

conditions and must replace them, if necessary, with suitable seals.

GB

For thermometers without a thermowell, and/or where these are delivered separately, the

seals are not included and must be ordered separately.

Tighten the threads by hand when carrying out the nal assembly on the plant. This will

correspond to the delivery status of the premounted components. The nal tightening torque

should be applied using a spanner (half rotation).

The seals must be replaced after dismantling!

The seals can be ordered from WIKA, indicating the WIKA order number and/or

the designation (see table).

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 19

Page 20

6. Commissioning, operation / 7. Maintenance and cleaning

WIKA

Designation Suitable for threads

Order no.

11349981 per DIN 7603 Form C 14 x 18 x 2 -CuFA G ¼, M14 x 1.5

GB

11349990 per DIN 7603 Form C 18 x 22 x 2 -CuFA M18 x 1.5, G ⅜

11350008 per DIN 7603 Form C 21 x 26 x 2 -CuFA G ½, M20 x 1.5

11350016 per DIN 7603 Form C 27 x 32 x 2.5 -CuFA G ¾, M27 x 2

11367416 per DIN 7603 Form C 20 x 24 x 2 -CuFA M20 x 1.5

1248278 per DIN 7603 D21.2 x D25.9 x 1.5 -Al G ½, M20 x 1.5

3153134

3361485

11355352 D15 x D21 x 3 -NP-Univ M24 x 1.5

1605933 D15 x D21 x 1 -NP-Univ M24 x 1.5

Legend:

CuFA= Copper, max. 45 HB

Al = Aluminium Al99; F11, 32 to 45 HB

StFA = Soft iron, 80 to 95 HBa; lled with asbestos-free sealing material

per DIN 7603 Form C D14.2 x D17.9 x 2 -StFA

per DIN 7603 Form C D33.3 x D38.9 x 2.5 -StFA

a

; lled with asbestos-free sealing material

b

G ¼, M14 x 1.5

G 1

6.2 Tapered threads (NPT)

It should be checked whether it may be necessary to seal them additionally with PTFE tape

or hemp. The threads must be lubricated with a suitable lubricant before tting.

Tighten the threads by hand when carrying out the nal assembly on the plant. This will

correspond to the delivery status of the premounted components. The nal tightening and

sealing must be made with a spanner (1.5 to 3 rotations).

7. Maintenance and cleaning

7.1 Maintenance

The DiwiTherm

The indicator should be checked once or twice every year.

To do this, the instrument must be disconnected from the process and checked using a

temperature calibrator.

DiwiTherm

The battery is not replaceable!

Repairs must only be carried out by the manufacturer.

20 WIKA operating instructions DiwiTherm®, model TR75

®

thermometer is maintenance-free.

®

model TR75: battery powered (at least 10 years service life)

11325232.04 01/2014 GB/D/F/E

Page 21

7. Maintenance and cleaning / 8. Faults

7.2 Cleaning

CAUTION!

■

Before cleaning, correctly disconnect the instrument from the pressure supply,

switch it o and disconnect it from the mains.

■

Clean the instrument with a moist cloth (soap water).

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to

protect personnel and the environment from exposure to residual media.

■

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment.

Take sucient precautionary measures.

For information on returning the instrument see chapter 9.2 “Return”.

8. Faults

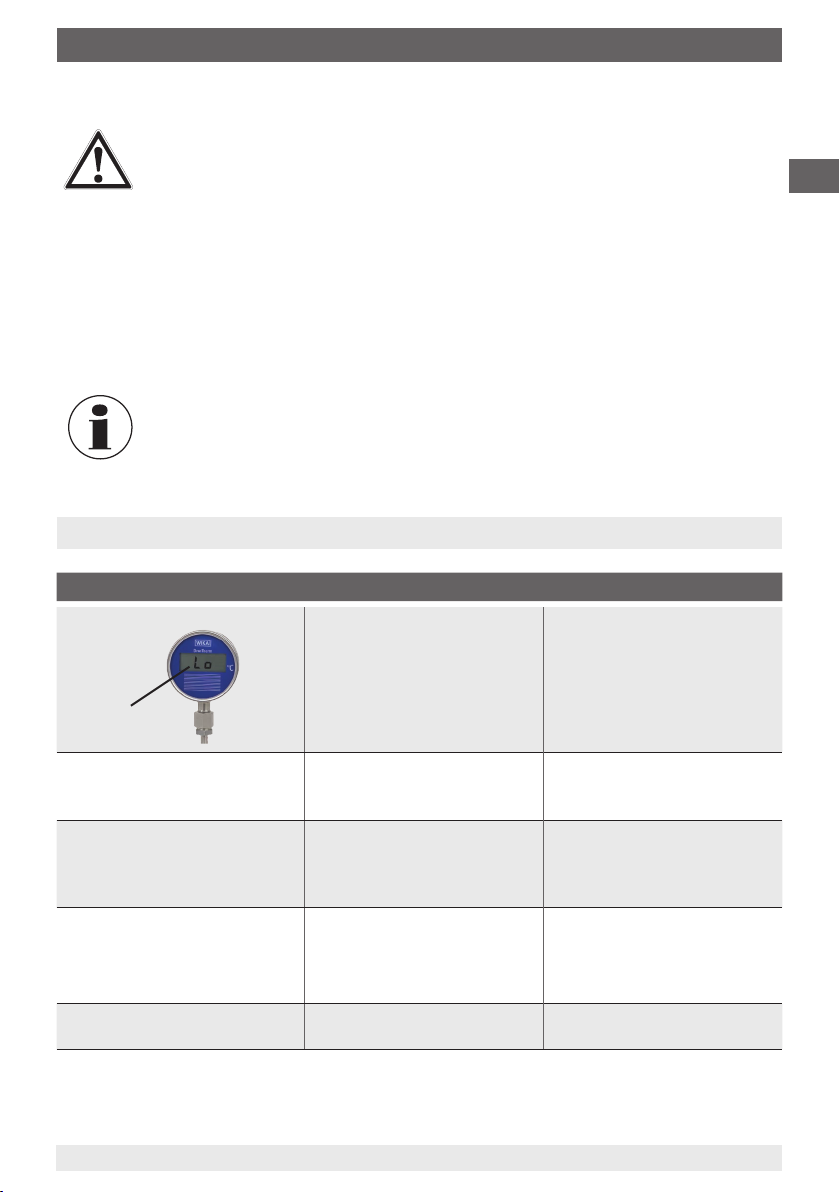

Faults Causes Measures

The battery has less than 2.7 V

The battery has less than 2.7 V Contact the manufacturer

GB

Error message

No signal/ line break Mechanical load too high or

Display of measured value jumps Cable break in connecting

Erroneous measured values and

response times too long

Erroneous measured values and

response times too long

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 21

overtemperature

cable or loose contact caused

by mechanical overload

Wrong mounting geometry, e.g.

mounting depth too deep or

heat dissipation too high

Deposits on the sensor or

thermowell

Replacement of the sensor

or the measuring insert with a

suitable version

Replacement of the sensor or

measuring insert with a suitable

design, for example a thicker

conductor cross-section

The temperature-sensitive area

of the sensor must be inside

the medium, and surfaces

measurements must be

ungrounded

Remove deposits

Page 22

8. Faults / 9. Dismounting, return and disposal

Corrosion Composition of the medium

GB

Moisture or media uid in the

housing

not as expected or modied

or wrong thermowell material

selected

No thermowell used (the cable

version is not suitable). No or

faulty sealing used between

neck tube and thermowell.

Too high humidity and strong

temperature changes.

CAUTION!

If faults cannot be eliminated by means of the measures listed above, shut

down the instrument immediately, and ensure that pressure and/or signal are no

longer present, and secure the instrument from being put back into operation

inadvertently.

In this case, contact the manufacturer.

If a return is needed, follow the instructions given in chapter 9.2 “Return”.

9. Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment.

Sucient precautionary measures must be taken.

Analyse medium and then

select a more-suitable material

or replace thermowell regularly

Contact manufacturer, send

the instrument back (For

information on returning, see

chapter 9.2 “Return”).

Check ambient conditions.

9.1 Disassembly

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting it!

During dismounting there is a risk of dangerously hot pressure media escaping.

Only disconnect the thermometer once the system has been depressurised!

22 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 23

9. Dismounting, return and disposal

9.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our local

website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

GB

11325232.04 01/2014 GB/D/F/E

WIKA operating instructions DiwiTherm®, model TR75 23

Page 24

GB

24 WIKA operating instructions DiwiTherm®, model TR75

11325232.04 01/2014 GB/D/F/E

Page 25

Inhalt

Inhalt

1. Allgemeines 26

2. Sicherheit 27

3. Technische Daten 30

4. Aufbau und Funktion 31

5. Transport, Verpackung und Lagerung 38

6. Inbetriebnahme, Betrieb 39

7. Wartung und Reinigung 42

8. Störungen 43

9. Demontage, Rücksendung und Entsorgung 44

D

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 25

Page 26

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach dem aktuellen Stand der

Technik konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach

ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und

Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften

und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes

für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TE 60.75

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen

oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn

sie nicht gemieden wird.

26 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 27

1. Allgemeines / 2. Sicherheit

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten und störungsfreien Betrieb hervor.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

Thermometer hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden

auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln

dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Das DiwiTherm

die Temperatur des Prozesses zu überwachen.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezi-

kationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten WIKAServicemitarbeiter erforderlich.

®

-Thermometer wird hauptsächlich in der Prozessindustrie eingesetzt, um

D

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind ausgeschlossen.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 27

Page 28

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

■

D

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess-

und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über agressive Medien.

2.3 Besondere Gefahren

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen lassen.

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder

giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die

gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet

werden.

WARNUNG!

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei

Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen von

Arbeitssicherheit, Erste-Hilfe und Umweltschutz unterwiesen wird, sowie

die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

28 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 29

2. Sicherheit

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen.

Fehlerhafte Anwendungen des Gerätes können zu Verletzungen führen.

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur und

unter hohem Druck oder Vakuum anliegen.

2.4 Beschilderung, Sicherheitskennzeichnungen

Typenschild

Typ

Herstellungsjahr

D

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden europäischen Richtlinien.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 29

Page 30

3. Technische Daten

3. Technische Daten

Technische Daten

Typ TR75

Messbereich

Anzeige in °C

Bereich 1

D

Bereich 2

-40,0 ... +199,9 °C

200 ... 450 °C mit autom. Messbereichsumschaltung (Autorange)

Anzeige

Prinzip 3 ½-stellig LCD, 7-Segment-Anzeige, 21 mm hoch

Auösung 0,1 K bis 199,9 °C; 1 K ab 200 °C

Genauigkeit

0,5 % vom jeweiligen Bereichsendwert ±1 Digit

Gerätevarianten

■

DiwiTherm® mit Fühler zum Einstecken

Aufbau Fühler mit Anschlusskabel

■

Einsatztemperatur max. 200 °C

■

Gehäuse für Schalttafeleinbau, mit Befestigungsrand vorn

■

DiwiTherm® zum Einbau in ein Schutzrohr

Aufbau Fühler gefedert

Einschraubzapfen zum Schutzrohr

■

Gehäuse mit Halsrohr

■

Option

Gehäuse dreh- und schwenkbar (um 360° drehbar und um 90°

schwenkbar)

■

DiwiTherm® zur Montage an einer Rohroberäche

Aufbau Anliegefühler zur Befestigung mittels Spannband

■

Einsatztemperatur max. 200 °C

■

Gehäuse mit Halsrohr

■

Option

Gehäuse dreh- und schwenkbar (um 360° drehbar und um 90°

schwenkbar)

■

Gehäuse für Schalttafeleinbau, mit Anschlusskabel und

Befestigungsrand vorn

Gehäuse

Nenngröße 100

Material CrNi-Stahl

Schutzart IP 65 nach EN 60529 / IEC 60529

Ring Bajonettring

Sichtscheibe Instrumentenachglas

Hilfsenergie U

B

DC 3,6 V aus Lithium-Batterie 3,6 V, Größe AA (Mignon), gehört zum

Lieferumfang

1)

Betriebsdauer min. 10 Jahre

Besonderheiten Wenn die Batterie 2,7 V unterschreitet schaltet die Anzeige in „LO“

Betrieb

Elektromagnetische Verträglichkeit (EMV)

CE-Konformität nach EN 61326

Sonstiges

Sensor Pt1000

Umgebungs-/Lagertemperatur -20 ... +60 °C

1) Nicht durch den Kunden austauschbar.

30 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 31

3. Technische Daten / 4. Aufbau und Funktion

Vibration (am Fühler) 10 ... 500 Hz 5 g EN 60068-2-6 / IEC 60068-2-6

Schock (am Fühler) EN 60068-2-7 / IEC 60068-2-7

Gewicht ca. 1 kg (tatsächliches Gewicht abhängig von Bauform und evtl.

Weitere technische Daten siehe WIKA-Datenblatt TE 60.75 und Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Das DiwiTherm

Widerstandsthermometer. Dieses kompakte Thermometer kann vielseitig eingesetzt werden

und arbeitet ohne externe Hilfsenergie.

Vielfältige Kombinationsmöglichkeiten von Einbaulänge, Halslänge, Anschluss zum Schutzrohr etc. führen zu Thermometern, passend für jede Schutzrohrdimension und jede Anwendung.

®

Typ TR75 ist die ideale Kombination aus einer Digitalanzeige und einem

montiertem Schutzrohr)

D

Ein Betrieb ohne Schutzrohr ist nur in speziellen Fällen zweckmäßig.

Optional kann das DiwiTherm

®

Typ TR75 mit einem Prozessanschluss zur Messung der

Temperatur an einer Rohroberäche gefertigt werden.

®

4.1.1 DiwiTherm

mit Fühler zum Einstecken

Fühler

Werksto: CrNi-Stahl

Fühlerlänge A ≤ 150 mm: Starres Fühlerrohr

Der Rohraufbau zeichnet sich durch einen starren Aufbau der metallischen Sensorspitze

aus, daher dürfen Rohraufbauten nicht gebogen werden. Im Inneren ist der Messwiderstand

direkt an eine isolierte Zuleitung kontaktiert. Daher können Widerstandsthermometer im

Rohraufbau nur bis zu Temperaturen eingesetzt werden, für welche die Zuleitung speziziert

ist (siehe Einsatztemperaturen).

Fühlerlänge ab 150 mm: Mantelmessleitung (MI-Leitung)

Der Übergang zwischen metallischem Teil des Fühlers und Anschlussleitung ist bei der

Verwendung von MI-Leitung je nach Ausführung gecrimpt, gerollt oder vergossen. Dieser

Bereich sollte nicht in den Prozess eingetaucht werden und darf nicht geknickt werden.

Auf dieser Übergangshülse sollte keine Klemmverschraubung befestigt werden. Ausführung

und Dimension der Übergangsstelle hängen stark von der Kombination zwischen Zuleitung

und metallischen Sensor und den Anforderungen an die Dichtigkeit ab.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 31

Page 32

4. Aufbau und Funktion

Der Fühlerdurchmesser soll ca. 1 mm kleiner sein als der Bohrungsdurchmesser des

Schutzrohres bzw. der Sacklochbohrung.

Spaltbreiten größer als 0,5 mm zwischen Schutzrohr und Fühler wirken sich negativ auf den

Wärmeübergang aus und haben ein ungünstiges Ansprechverhalten des Thermometers zur

Folge.

D

Fühlerlängen

Fühler-Ø in mm

6 50 100 150

8 - 100 150

Sonderlängen sind möglich.

Prozessanschluss

Eine Klemmverschraubung erlaubt an der Montagestelle das einfache Anpassen auf die

gewünschte Einbaulänge.

Klemmverschraubung

Werksto: CrNi-Stahl

Außengewinde G ¼ B (nicht bei Fühler-Ø 8 mm) oder G ½ B

Lieferung auch ohne Prozessanschluss möglich.

Kabel

Silikon, geschirmt, Anwendungsbereich -40 ... +200 °C mit EMV-Kabelverschraubung

Kabellänge nach Kundenspezikation.

Sensorhülse und Gehäuse sind durch die Schirmung des Kabels verbunden. Beidseitige

Erdung kann zu Potentialverschleppung und Anzeigeungenauigkeit führen.

DiwiTherm® Batteriebetrieb, Typ TR75 mit Fühler zum Einstecken, rückseitiger Kabelabgang,

mit Befestigungsrand vorn für Schalttafeleinbau

Standard-Fühlerlängen A (l1) in mm

Befestigungsrand

Legende:

Ø d Fühlerdurchmesser

A Einbaulänge

W Kabellänge

32 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

vorn

3165575.05

11325232.04 01/2014 GB/D/F/E

Page 33

4. Aufbau und Funktion

4.1.2 DiwiTherm® zum Einbau in ein Schutzrohr

Fühler

Werksto: CrNi-Stahl

Der Fühler ist aus vibrationsunempndlicher Mantelleitung (MI-Leitung) gefertigt.

Der Fühlerdurchmesser soll ca. 1 mm kleiner sein als der Bohrungsdurchmesser des

Schutzrohres. Spaltbreiten größer als 0,5 mm zwischen Schutzrohr und Fühler wirken sich

negativ auf den Wärmeübergang aus und haben ein ungünstiges Ansprechverhalten des

Thermometers zur Folge.

Wichtig beim Einbau in ein Schutzrohr ist die Ermittlung der korrekten Einbaulänge

(= Schutzrohrlänge bei Bodenstärken ≤ 5,5 mm). Zu beachten ist dabei, dass der Fühler

gefedert ist (Federweg: max. 10 mm), um eine Anpressung auf den Schutzrohrboden zu

gewährleisten.

Prozessanschluss (Standardprozessanschluss)

Werksto: CrNi-Stahl

Einschraubzapfen: G ½ B

M14 x 1,5

M18 x 1,5

½ NPT

Überwurfmutter: G ½ B

Druckschraube: G ½ B

Halsrohr

Werksto: CrNi-Stahl

Halsrohrdurchmesser: 12 mm

Standard Halslänge: 150 mm

andere auf Anfrage

(minimale Halslänge: 30 mm)

D

Fühlerlängen

Fühler-Ø in mm Standard-Einbaulängen A (l1) in mm

3 110 140 145 170 200 205 230 245 260 294 305 345 350 395 410 445 545

6 - - - 170 200 205 230 245 260 295 305 345 350 395 410 445 545

8 - - - - 200 205 230 245 260 295 305 345 350 395 410 445 545

Sonderlängen sind möglich.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 33

Page 34

4. Aufbau und Funktion

Anschluss zum Schutzrohr (mit Halsrohr)

3172503.07

D

Halsrohr

glatt

Anschluss zum Schutzrohr

Innengewinde

M24 x 1,5

Feste Verschraubung /

Gewinde

Gewinde

Druckschraube

zur Abdichtung

zum Gehäuse

Gewinde

Klemmverschraubung

(Befestigung auf Halsrohr)

Gewinde

Doppelnippel

Gewinde

Gewinde

teilbares Halsrohr

11363533.03

Gewinde Gewinde

Legende:

Ø d Fühlerdurchmesser

A (l

) Einbaulänge

1

Gewinde

(NPT)

) Einbaulänge

A (U

2

(bei kegeligen Gewinden)

N(M

) Halslänge

H

(NPT)

34 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 35

4. Aufbau und Funktion

DiwiTherm® Typ TR75 zum Einbau in ein Schutzrohr, mit Halsrohr

Anschluss vom Gehäuse zum Halsrohr: fest, radial unten

Variante Ø 8 mm

Gewinde

DiwiTherm® Typ TR75 zum Einbau in ein Schutzrohr, mit Halsrohr

Anschluss vom Gehäuse zum Halsrohr: dreh- und schwenkbar, rückseitig

zentrisch

D

3161218.06 3161374.06

Variante Ø 8 mm

Gewinde

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 35

Page 36

4. Aufbau und Funktion

4.1.3 DiwiTherm® zur Montage an einer Rohroberäche

Anliegefühler

Werksto: CrNi-Stahl

Befestigungsrohr: 120 mm

Befestigung mittels Spannband (nicht im Lieferumfang)

D

Kabel

Silikon, geschirmt, Anwendungsbereich -50 ... +200 °C

Kabellänge nach Kundenspezikation

Sensorhülse und Gehäuse sind durch die Schirmung des Kabels verbunden. Beidseitige

Erdung kann zu Potentialverschleppung und Anzeigeungenauigkeit führen.

Die angegebene Genauigkeit kann nur bis zu einer maximale Kabellänge von 15 m gewährleistet werden. Bei längeren Kabellängen kann die Genauigkeit stark abweichen.

DiwiTherm® Typ TR75 zur Montage an einer Rohroberäche, rückseitiger Kabelabgang,

mit Befestigungsrand vorn für Schalttafeleinbau

3157559.05

Befestigungsrand

vorn

36 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 37

4. Aufbau und Funktion

Halsrohr

Werksto: CrNi-Stahl

Halsrohrdurchmesser: 12 mm

Standard-Halslänge: 150 mm, andere auf Anfrage (minimale Halslänge: 100 mm)

DiwiTherm® Typ TR75 zur Montage an einer Rohroberäche, mit Halsrohr

Anschluss vom Gehäuse zum Halsrohr: fest, radial unten

3157541.04

D

DiwiTherm® Typ TR75 zur Montage an einer Rohroberäche, mit Halsrohr

Anschluss vom Gehäuse zum Halsrohr: dreh- und schwenkbar, rückseitig

zentrisch

11144807.04

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 37

Page 38

5. Transport, Verpackung und Lagerung

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

D

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

Das Verpackungsmaterial genau durchsehen, damit keine evtl. beigepackten Zubehörteile

verloren gehen.

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -20 ... +60 °C

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort, der die oben gelisteten Bedingungen

erfüllt, lagern. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät wie folgt

verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der Verpa-

ckung beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden Messstoreste

entfernen. Dies ist besonders wichtig, wenn der Messsto gesundheitsgefähr-

dend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

38 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 39

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

DiwiTherms® dürfen nur mit einem zusätzlichen Schutzrohr betrieben werden.

Ausnahme: Axialer Kabelausgang (für Schalttafeleinbau) oder Ausführungen mit Anliegefühler.

Typische Einbausituation mit Schutzrohr

Messeinsatz

Schutzrohr

Typische Einbausituation mit Anliegefühler

■

Montage an Rohren

Die Geometrie des Anliegefühlers ist

abgestimmt auf Rohre mit einem Außendurchmesser zwischen 20 und 160 mm.

Zum Befestigen des Anliegefühlers am

Rohr genügen Rohrschellen. Der Anliegefühler sollte direkten metallischen Kontakt

zur Messstelle aufweisen und fest auf der

Oberäche des Rohres auiegen. Sofern

die zu erwartenden Temperaturen unter

Rohrschellenmontage

Isolierung *

200 °C liegen, kann zur Optimierung des

Wärmeüberganges zwischen Anliegefühler

und Rohr eine Wärmeleitpaste eingesetzt

werden. Eine lsolierung muss an der Montagestelle angebracht werden, um Wärme-

* Isolierung zwingend notwendig!

ableitfehler zu vermeiden. Diese lsolierung muss ausreichend temperaturbeständig sein

und gehört nicht zum Lieferumfang.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 39

D

Page 40

6. Inbetriebnahme, Betrieb

■

Montage an Behältern

Die Geometrie des Anliegefühlers ist

abgestimmt auf Behälteraußendurchmesser

bis 160 mm. Beträgt an der Montagestelle

des Anliegefühlers der Behälteraußendurchmesser mehr als 160 mm, empfehlen wir das

D

Verwenden eines auf den jeweiligen Behälterdurchmesser abgestimmten Zwischenteiles aus einem Material mit guter thermischer

Leitfähigkeit. Zum Befestigen des Anliegefühlers am Behälter kann z. B. eine Halterung aus Winkeleisen mit Anpressschrauben

eingesetzt werden. Der Anliegefühler sollte

direkten metallischen Kontakt zur Messstelle

aufweisen und fest auf der Oberäche des Behälters auiegen.

Zur Optimierung des Wärmeüberganges zwischen Anliegefühler und Behälter kann eine

Wärmeleitpaste eingesetzt werden, wenn die zu erwartenden Temperaturen unter 200 °C

liegen. Eine lsolierung muss an der Montagestelle angebracht werden, um Wärmeableitfehler zu vermeiden. Diese lsolierung muss ausreichend temperaturbeständig sein und

gehört nicht zum Lieferumfang.

Winkeleisenhalterung

Isolierung *

* Isolierung zwingend

notwendig!

Bei der Montage eines dreh- und schwenkbaren DiwiTherms

®

sind besondere

Vorschriften zu beachten. Um die Anzeige in die gewünschte Position zu bringen, müssen

folgende Schritte eingehalten werden:

1. Die Konter- oder Überwurfmutter muss am Prozessanschluss gelöst sein.

Montage mit

Gabelschlüssel

2. Sechskant- und Schlitzschrauben müssen am Schwenkgelenk gelöst sein.

lösen

Unbedingt auch die auf der gegenüberliegenden Seite liegenden

Schrauben lösen!

40 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 41

6. Inbetriebnahme, Betrieb

3. Anzeige positionieren, Sechskant- und Schlitzschrauben anziehen und schließlich die

Konter- oder Überwurfmutter fest anziehen.

Beim Fühlereinbau sind folgende Gesichtspunkte zu beachten:

■

Der Fühler soll möglichst mit seiner ganzen Länge der zu messenden Temperatur ausgesetzt sein.

■

Der Temperaturfühler sollte in Rohrleitungen oder sonstigen Messstellen der Strömungsrichtung möglichst schräg entgegen gerichtet stehen.

■

Bei Verwendung von Schutzrohren ist nach Möglichkeit durch Einfüllen eines Wärmekontaktmittels der Wärmeübertragungswiderstand zwischen Fühleraußenwand und Schutzrohrinnenwand zu reduzieren.

Die Arbeitstemperatur der Wärmeleitpaste beträgt -40 ... +200 °C.

WARNUNG!

Keine Wärmeträgeröle verwenden!

6.1 Zylindrische Gewinde

Wenn Thermometeranschlusskopf, Halsrohr, Schutzrohr oder Prozessanschluss mit zylindrischen Gewinden (z. B. G ½, M20 x 1,5 ...) verbunden werden, müssen diese Gewinde mit

Dichtungen gegen den Eintritt von Flüssigkeiten in das Thermometer gesichert werden.

WIKA verwendet standardmäßig eine Kupfer-Proldichtung für die Verbindung Halsrohr zum

Schutzrohr und eine Papier-Flachdichtung für die Verbindung Anschlusskopf zum Halsrohr

oder Schutzrohr.

D

Bei Zusammenbauten von Thermometer und Schutzrohr sind diese Dichtungen bereits

vormontiert. Es obliegt dem Betreiber der Anlage, die Eignung dieser Dichtung im Hinblick

auf die Einsatzbedingungen zu überprüfen und ggfs. durch eine geeignete Dichtung zu

ersetzen.

Bei Thermometern ohne Schutzrohr bzw. getrennter Lieferung liegen Dichtungen nicht bei

und müssen vom Anwender getrennt bestellt werden.

Bei der Endmontage in die Anlage sind die Gewinde zunächst handfest anzuziehen. Das

entspricht auch dem Auslieferungszustand bei vormontierten Zusammenbauten. Die

Endfestigkeit muss mit einer halben Schraubenschlüssel-Umdrehung hergestellt werden.

Dichtungen sind nach einer Demontage zu ersetzen!

Dichtungen können unter Angabe der Gewinde mit WIKA-Bestell-Nr. und/oder

Bezeichnung (siehe Tabelle) bei WIKA bezogen werden.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 41

Page 42

6. Inbetriebnahme, Betrieb / 7. Wartung und Reinigung

WIKA

Bezeichnung Geeignet für Gewinde

Bestell-Nr.

11349981 nach DIN 7603 Form C 14 x 18 x 2 -CuFA G ¼, M14 x 1,5

11349990 nach DIN 7603 Form C 18 x 22 x 2 -CuFA M18 x 1,5, G ⅜

11350008 nach DIN 7603 Form C 21 x 26 x 2 -CuFA G ½, M20 x 1,5

11350016 nach DIN 7603 Form C 27 x 32 x 2,5 -CuFA G ¾, M27 x 2

D

11367416 nach DIN 7603 Form C 20 x 24 x 2 -CuFA M20 x 1,5

1248278 nach DIN 7603 D21,2 x D25,9 x 1,5 -Al G ½, M20 x 1,5

3153134

3361485

11355352 D15 x D21 x 3 -NP-Univ M24 x 1,5

1605933 D15 x D21 x 1 -NP-Univ M24 x 1,5

Legende:

CuFA= Kupfer, max. 45 HB

Al = Aluminium Al99; F11, 32 bis 45 HB

StFA = Weicheisen, 80 bis 95 HBa; mit einer Füllung aus asbestfreiem Dichtungsmaterial

nach DIN 7603 Form C D14,2 x D17,9 x 2 -StFA

nach DIN 7603 Form C D33,3 x D38,9 x 2,5 -StFA

a

; mit einer Füllung aus asbestfreiem Dichtungsmaterial

b

G ¼, M14 x 1,5

G 1

6.2 Kegelige Gewinde (NPT)

Die Notwendigkeit einer zusätzlichen Dichtung mittels PTFE-Band oder Hanf prüfen. Die

Gewinde sollten vor der Montage mit einem geeigneten Mittel geschmiert werden.

Bei der Endmontage in die Anlage sind die Gewinde zunächst handfest anzuziehen. Das

entspricht auch dem Auslieferungszustand bei vormontierten Zusammenbauten. Die

Endfestigkeit und Dichtheit muss mit einer 1,5 bis 3-fachen Schraubenschlüssel-Umdrehung

hergestellt werden.

7. Wartung und Reinigung

7.1 Wartung

Das DiwiTherm

Eine Überprüfung der Anzeige sollte etwa 1 bis 2 mal pro Jahr erfolgen.

Dazu ist das Gerät vom Prozess zu trennen und mit einem Temperaturkalibrator zu kontrollieren.

DiwiTherm

Die Batterie ist nicht auswechselbar!

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

42 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

®

-Thermometer ist wartungsfrei.

®

Typ TR75: Batteriebetrieben (min. 10 Jahre Lebensdauer)

11325232.04 01/2014 GB/D/F/E

Page 43

7. Wartung und Reinigung / 8. Störungen

7.2 Reinigung

VORSICHT!

■

Vor der Reinigung das Gerät ordnungsgemäß von der Druckversorgung

trennen, ausschalten und vom Netz trennen.

■

Das Gerät mit einem feuchten Tuch (Seifenlauge) reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

■

Ausgebautes Gerät vor der Rücksendung spülen bzw. säubern, um Mitarbeiter

und Umwelt vor Gefährdung durch anhaftende Messstoreste zu schützen.

■

Messstoreste in ausgebauten Geräten können zur Gefährdung von Perso-

nen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 9.2 „Rücksendung“.

8. Störungen

Störungen Ursachen Maßnahmen

Unterschreitung von 2,7 V der

Batterie

Unterschreitung von 2,7 V der

Batterie

Hersteller kontaktieren

D

Fehlermeldung

Kein Signal/Leitungsbruch Zu hohe mechanische Belas

Anzeige des Messwertes

springt

Fehlerhafte Messwerte und zu

lange Ansprechzeiten

Fehlerhafte Messwerte und zu

lange Ansprechzeiten

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 43

tung oder Übertemperatur

Leitungsbruch im Anschlusska

bel oder Wackelkontakt durch

mechanische Überbelastung

Falsche Einbaugeometrie, z. B.

zu geringe Einbautiefe oder zu

hohe Wärmeableitung

Ablagerungen auf dem Sensor

oder Schutzrohr

Ersatz des Fühlers oder Mes

seinsatzes durch eine geeignete

Ausführung

-

Ersatz des Fühlers oder Mes

seinsatzes durch eine geeignete Ausführung z. B. dickerer

Leitungsquerschnitt

Der temperaturempndliche

Bereich des Sensors muss

innerhalb des Mediums liegen,

Oberächenmessungen müs

sen isoliert sein

Ablagerungen entfernen

-

-

-

Page 44

8. Störungen / 9. Demontage, Rücksendung und Entsorgung

Korrosion Zusammensetzung des Me

Feuchtigkeit oder Mediums

üssigkeit im Gehäuse

D

diums nicht wie angenommen

oder geändert oder falsches

Schutzrohrmaterial gewählt

Kein Schutzrohr verwendet

-

(betrit nicht die Kabelversion).

Keine oder fehlerhafte Dichtung

zwischen Halsrohr und Schutz

rohr verwendet

Zu hohe Luftfeuchte und starke

Temperaturwechsel.

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht beseitigt

werden, ist das Gerät unverzüglich außer Betrieb zu setzen, sicherzustellen,

dass kein Druck bzw. Signal mehr anliegt und gegen versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel 9.2 „Rücksendung“

beachten.

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von Personen,

Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

-

Medium analysieren und da

nach besser geeignetes Material auswählen oder Schutzrohr

regelmäßig erneuern

Hersteller kontaktieren, Gerät

einschicken (Hinweise zur

Rücksendung siehe Kapitel

-

9.2 „Rücksendung“)

Umgebungsbedingungen

überprüfen.

-

9.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen!

Beim Ausbau besteht Gefahr durch austretende, gefährlich heiße Messstoe.

Das Thermometer nur im drucklosen Zustand demontieren!

44 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 45

9. Demontage, Rücksendung und Entsorgung

9.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren, Laugen,

Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf unserer

lokalen Internetseite.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

D

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

11325232.04 01/2014 GB/D/F/E

WIKA Betriebsanleitung DiwiTherm®, Typ TR75 45

Page 46

D

46 WIKA Betriebsanleitung DiwiTherm®, Typ TR75

11325232.04 01/2014 GB/D/F/E

Page 47

Sommaire

Sommaire

1. Généralités 48

2. Sécurité 49

3. Spécications 52

4. Conception et fonction 53

5. Transport, emballage et stockage 60

6. Mise en service, utilisation 61

7. Entretien et nettoyage 64

8. Dysfonctionnements 65

9. Démontage, retour et mise au rebut 66

F

11325232.04 01/2014 GB/D/F/E

WIKA mode d'emploi DiwiTherm®, type TR75

47

Page 48

1. Généralités

1. Généralités

■

L'instrument décrit dans le mode d'emploi est conçu et fabriqué selon les dernières

technologies en vigueur. Tous les composants sont soumis à des critères de qualité et

d'environnement stricts durant la fabrication. Nos systèmes de gestion sont certiés selon

ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de

l'instrument. Il est possible de travailler en toute sécurité avec ce produit en respectant

F

toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les prescriptions

générales de sécurité en vigueur pour le domaine d'application de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité immédiate

de l'instrument et accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement

et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par

une utilisation non conforme à l'usage prévu, de non respect de ce mode d'emploi,

d'utilisation de personnel peu qualié de même qu'en cas de modications de

l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : TE 60.75

- Conseiller applications :

Tel. : +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la

mort ou des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de provoquer

de légères blessures ou des dommages matériels et pour l'environnement si elle

n'est pas évitée.

48 WIKA mode d'emploi DiwiTherm®, type TR75

11325232.04 01/2014 GB/D/F/E

Page 49

1. Généralités / 2. Sécurité

Information

... met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que le

thermomètre a été choisi de façon adéquate, en ce qui concerne l'étendue de

mesure, la version et les conditions de mesure spéciques.

Un non respect de cette consigne peut entraîner des blessures corporelles

graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections individuelles du

présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Le thermomètre DiwiTherm

®

est principalement utilisé dans l'industrie du process pour

surveiller la température du process.

L'instrument est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respectées.

En cas d'utilisation inadéquate ou de fonctionnement de l'instrument en dehors des

spécications techniques, un arrêt et contrôle doivent être immédiatement eectués par un

collaborateur autorisé du service de WIKA.

Si l'instrument est transporté d'un environnement froid dans un environnement chaud,

la formation de condensation peut provoquer un dysfonctionnement fonctionnel de

l'instrument. Il est nécessaire d'attendre que la température de l'instrument se soit adaptée à

la température ambiante avant une nouvelle mise en service.

F

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage

prévu.

11325232.04 01/2014 GB/D/F/E

WIKA mode d'emploi DiwiTherm®, type TR75

49

Page 50

2. Sécurité

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages corporels et

matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées

que par un personnel ayant la qualication décrite ci-dessous.

F

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances dans

le domaine de la technique de mesure et de régulation et de ses expériences de même

que de sa connaissance des prescriptions nationales, des normes et directives en vigueur,

en mesure d'eectuer les travaux décrits et de reconnaître automatiquement les dangers

potentiels.

Les conditions d'utilisation spéciales exigent également une connaissance adéquate par

exemple des liquides agressifs.

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l'oxygène,

l'acétylène, les substances combustibles ou toxiques, ainsi que dans le cas

d'installations de réfrigération, de compresseurs etc., les directives appropriées

existantes doivent être observées en plus de l'ensemble des règles générales.

AVERTISSEMENT !

An de travailler en toute sécurité sur l'instrument, la société exploitante doit

s'assurer

■

qu'un équipement de premier secours adapté est disponible et que les

premiers soins peuvent être dispensés sur place à tout moment en cas de

besoin.

■

que le personnel de service reçoit à intervalles réguliers des instructions

relatives à toutes les questions pertinentes concernant la sécurité du travail,

les premiers secours et la protection de l'environnement et qu'il connaît le

mode d'emploi et particulièrement les consignes de sécurité contenues dans

celui-ci.

50 WIKA mode d'emploi DiwiTherm®, type TR75

11325232.04 01/2014 GB/D/F/E

Page 51

2. Sécurité

AVERTISSEMENT !

Les restes de uides se trouvant dans des appareils démontés peuvent mettre

en danger les personnes, l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

Ne pas utiliser cet instrument dans des dispositifs de sécurité ou d'arrêt

d'urgence. Une utilisation incorrecte de l'instrument peut occasionner des

blessures.

En cas d'erreur, des uides agressifs peuvent être présents à une température

extrême et sous une pression élevée ou sous vide au niveau de l'instrument.

2.4 Etiquetage, marquages de sécurité

Plaque signalétique

F

Type

Année de fabrication

Explication des symboles

Lire impérativement le mode d'emploi avant le montage et la mise en

service de l'instrument !

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux directives européennes

pertinentes.

11325232.04 01/2014 GB/D/F/E

WIKA mode d'emploi DiwiTherm®, type TR75

51

Page 52

3. Spécications

3. Spécications

Spécications

Type TR75

Etendue de mesure

Achage en °C

Etendue 1

Etendue 2

-40,0 ... +199,9 °C

200 ... 450 °C avec changement de l'étendue de mesure

automatique (Autorange)

Achage

F

Principe Achage LCD 3 ½, 7 segments d'achage, 21 mm de hauteur

Résolution 0,1 K jusqu'à 199,9 °C ; puis 1 K à partir de 200 °C

Incertitude

0,5 % de la valeur respective totale ±1 chiffre

Versions de l'instrument

■

DiwiTherm® avec capteur pour l'insertion

Design Capteur avec câble de raccordement

■

Température maximale de fonctionnement 200 °C

■

Boîtier pour l'installation de panneau, avec collerette avant pour

montage panneau

■

DiwiTherm® pour l'installation dans un doigt de gant

Design Capteur monté sur ressort

Raccord leté côté doigt de gant

■

Boîtier avec extension

■

Option

■

DiwiTherm® pour l'installation sur une surface de tuyau

Tige et cadran orientables (pivotant à 360° et basculant à 90°)

Design Bulbe de contact pour xation avec collier de serrage

■

Température maximale de fonctionnement 200 °C

■

Boîtier avec extension

Option

■

Tige et cadran orientables (pivotant à 360° et basculant à 90°)

■

Boîtier pour l'installation de panneau, avec câble de

raccordement et bride de montage panneau

Boîtier

Diamètre 100

Matériau Acier inox

Indice de protection IP 65 selon EN 60529 / CEI 60529

Lunette Lunette baïonnette

Voyant Verre d'instrumentation

Alimentation U

B

3,6 VDC jusqu'à 3,6 V batterie au lithium, taille AA (Mignon), inclus

dans la livraison

1)

Autonomie min. 10 ans

Particularités Si la batterie dépasse les 2,7 V, l'achage commute en mode “LO”

Compatibilité électromagnétique (CEM)

Conformité CE selon EN 61326

Divers

Capteur Pt1000

Température ambiante/stockage -20 ... +60 °C

Vibration (au niveau du capteur) 10 ... 500 Hz 5 g EN 60068-2-6 / CEI 60068-2-6

1) Non remplaçable par le client.

52 WIKA mode d'emploi DiwiTherm®, type TR75

11325232.04 01/2014 GB/D/F/E

Page 53

3. Spécications / 4. Conception et fonction

Choc (au niveau du capteur) EN 60068-2-7 / CEI 60068-2-7

Poids environ 1 kg (le poids réel dépend de l'exécution et du doigt de gant

Pour de plus amples spécications, voir la che technique WIKA TE 60.75 et la

documentation de commande.

qui aura peut-être été installé)

4. Conception et fonction

4.1 Description

Le DiwiTherm

une sonde à résistance. Ce thermomètre compact peut être utilisé dans un grand nombre

d'applications et fonctionne sans alimentation électrique externe.

Une large gamme de longueurs utiles, longueurs d'extension, de raccordements aux doigts

de gant, etc., est disponible pour ces instruments de façon à ce qu'ils soient adaptés à

toutes les applications ainsi qu'à toutes les congurations de doigts de gant et à toute

application.

L'utilisation sans doigt de gant n'est recommandée que dans certaines applications.

Le DiwiTherm

pour la mesure de température sur une surface de tuyauterie.

4.1.1 DiwiTherm

Capteur

Matériau: acier inox

Longueur du capteur A ≤ 150 mm : tube de capteur rigide

L'exécution tubulaire présente une construction rigide vers l'extrémité en métal du capteur ;

donc les exécutions tubulaires ne doivent pas être courbées. Un résistance de mesure

est branchée en interne directement sur un l isolé. Les sondes à résistance tubulaires ne

peuvent donc être utilisées que jusqu'à la température spéciée pour le l (voir températures

de fonctionnement).

®

type TR75 représente l'association idéale entre un achage numérique et

®

type TR75 peut également être fabriqué en option avec un raccord process

®

avec capteur pour l'insertion

F

Longueur de capteur supérieure à 150 mm : câble de mesure gainé (câble chemisé)

La jonction entre la partie métallique du capteur et le câble de connexion, en utilisant le

câble chemisé, est soit serti, enroulé ou enrobé, suivant l'exécution. Cette partie ne doit pas

être immergée dans le process et ne doit pas être courbée.

Les raccords coulissants ne doivent pas être attachés à la transition. Le type et les

dimensions de la transition dépendent largement de la combinaison entre les liaisons

d'entrée et le capteur métallique et les exigences d'étanchéité.

11325232.04 01/2014 GB/D/F/E

WIKA mode d'emploi DiwiTherm®, type TR75

53

Page 54

4. Conception et fonction

Le diamètre du capteur devra être d'environ 1 mm plus petit que le diamètre intérieur du

doigt de gant.

Des espaces supérieurs à 0,5 mm entre le doigt de gant et le capteur auront une inuence

négative sur les échanges thermiques ; il en résultera un temps de réponse défavorable de

la sonde.

Longueurs de capteur

Capteur Ø en mm

F