Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

EN

DE

FR

ES

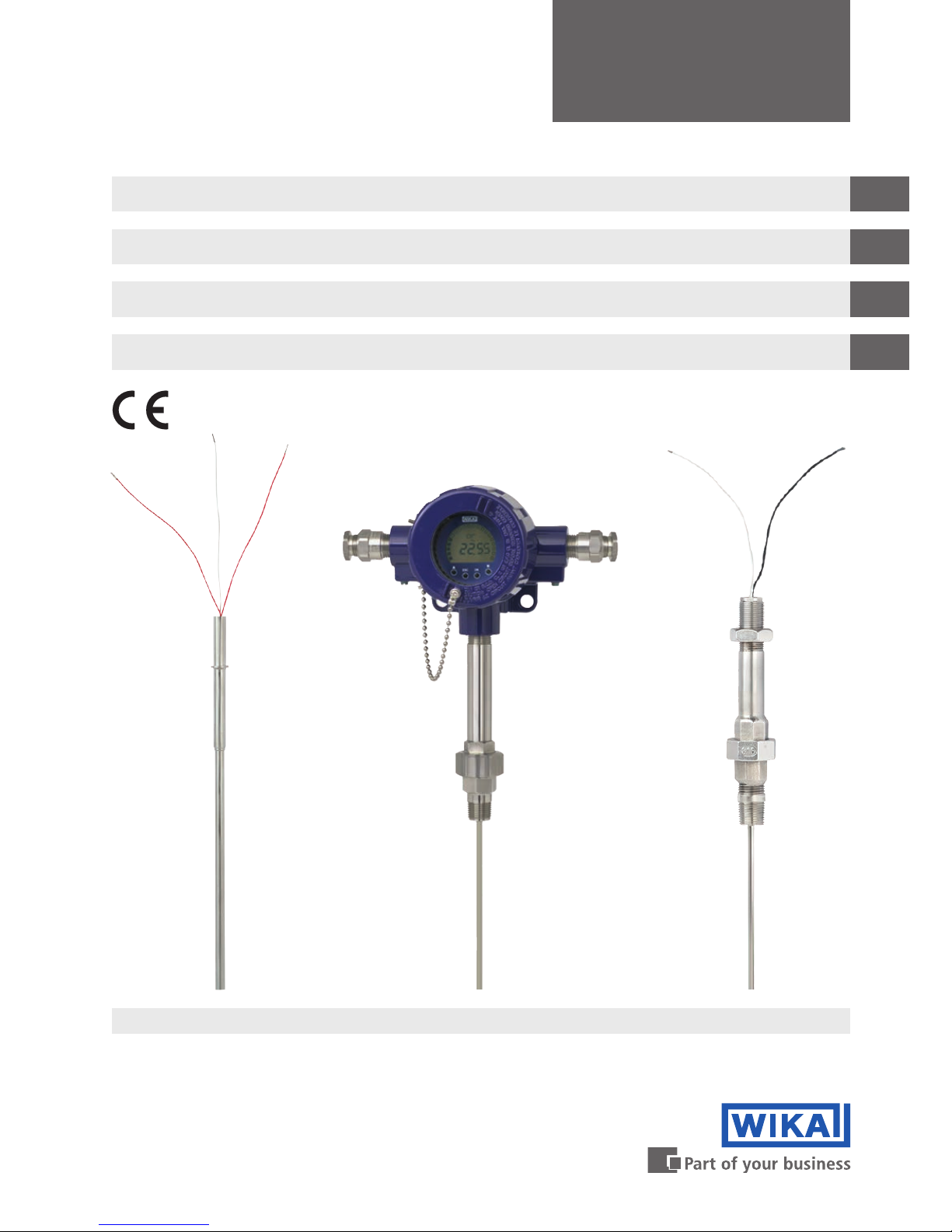

Models TR12-B, TC12-B Models TR12-M, TC12-MModels TR12-A, TC12-A

Resistance thermometer TR12 and thermocouple TC12

Widerstandsthermometer TR12 und Thermoelement TC12

Sonde à résistance TR12 et thermocouple TC12

Termorresistencia TR12 y termopar TC12

Page 2

EN

DE

FR

ES

2

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

Operating instructions models TR12 and TC12

Page

3 - 28

Betriebsanleitung Typen TR12 und TC12

Seite

29 - 54

Mode d'emploi types TR12 et TC12

Page

55 - 80

Manual de instrucciones modelos TR12 y TC12

Página

81 - 105

© 08/2013 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA

®

is a registered trademark in various countries.

WIKA

®

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Page 3

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

3

Contents

Contents

1. General information 4

2. Design and function 4

3. Safety 8

4. Transport, packaging and storage 11

5. Commissioning, operation 12

6. Faults 17

7. Maintenance, cleaning and calibration 19

8. Dismounting, return and disposal 20

9. Specifications 21

10. Accessories 27

Page 4

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

4

1. General information

■

The thermometers described in the operating instructions have been manufactured

using state-of-the-art technology.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument’s range of use.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

Subject to technical modifications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TE 60.16 (TR12-A)

TE 60.17 (TR12-B, TR12-M)

TE 65.16 (TC12-A)

TE 65.17 (TC12-B, TC12-M)

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

Abbreviations

RTD “Resistance temperature detector”; resistance thermometer

TC Thermocouple

2. Design and function

2.1 Description

The model TR12-B (resistance thermometer) and model TC12-B (thermocouple) electrical

thermometers consist of a module (TR12-M, TC12-M) which is built into a case. The

module is made up of a spring-loaded measuring insert (TR12-A, TC12-A) built into a neck

tube. The measuring insert (TR12-A, TC12-A) is replaceable.

The active measuring component of the measuring insert is manufactured from a welded

tube or from mineral-insulated cable, optionally in combination with ceramic-insulated

thermocouple wires. The sensor is embedded in ceramic powder, heat-resistant potting

compound, cement compound or thermally conductive paste.

1. General information / 2. Design and function

Page 5

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

5

If the temperature sensor is designed as a grounded thermocouple, the thermocouple

is joined directly to the sheath. Versions with a diameter smaller than 3 mm and with

grounded thermocouples should be considered as galvanically connected with earth

potential.

The connection side of the measuring insert consists of a transition sleeve with connected

bare wires.

This document describes standard versions of instruments. For applications in hazardous

areas special instrument designs are required.

For further information for operation in hazardous areas, see the additional information for

the corresponding ignition protection type (separate document).

CAUTION!

Damage to the instrument

To avoid damage to the instrument, thermometers of this model range must

be installed with a thermowell.

▶

Select a suitable thermowell (any type of thermowell can be selected) and

take the operational process data (temperature, pressure, density and

flow velocity) into account.

▶

The use of special designs without thermowell is possible, but is the

responsibility of the operator.

Possible sensor measuring ranges:

Model TR12: -200 ... +600 °C

Model TC12: -40 ... +1,200 °C

The following mounting and operating information has been compiled with care. However, it

is not possible to consider all potential usage cases.

2. Design and function

Page 6

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

6

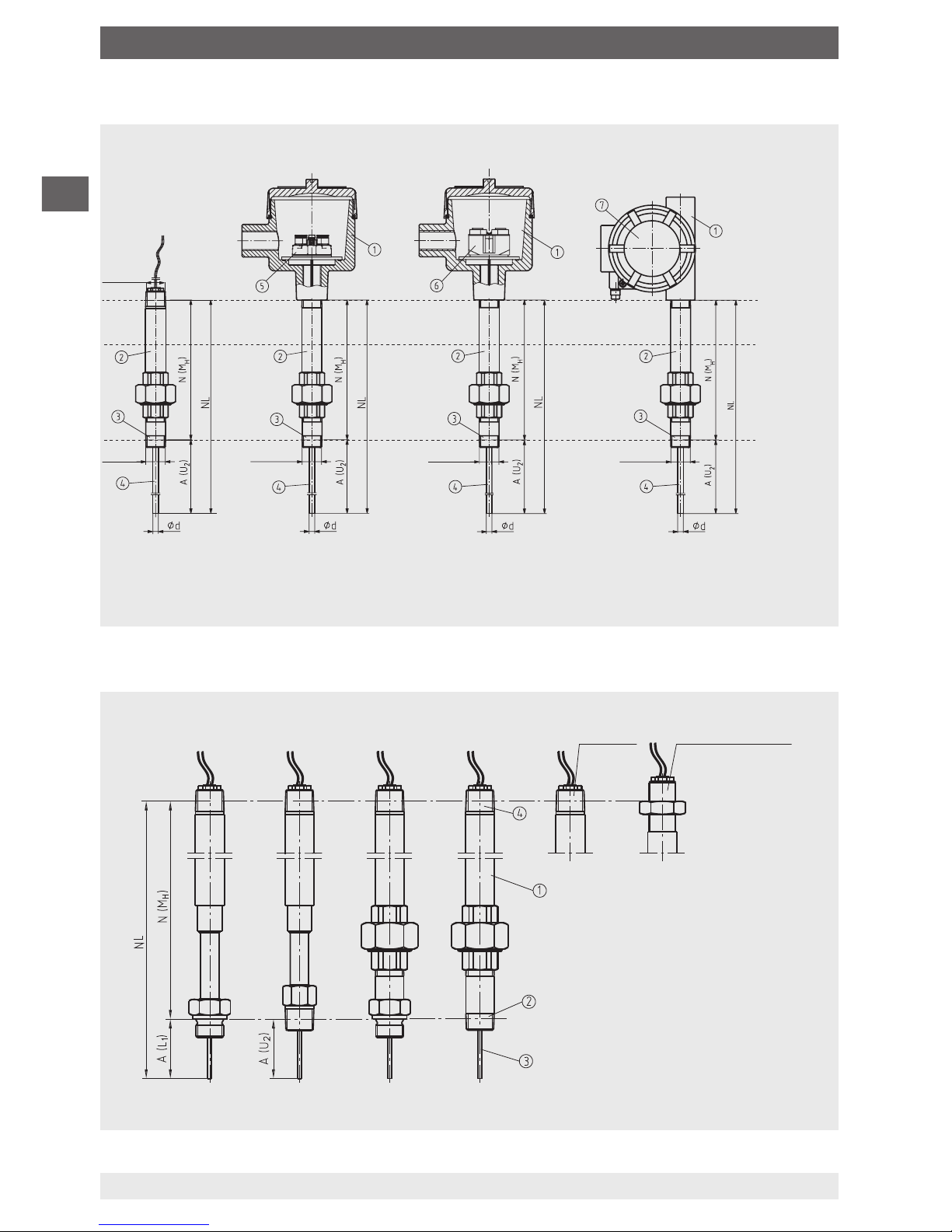

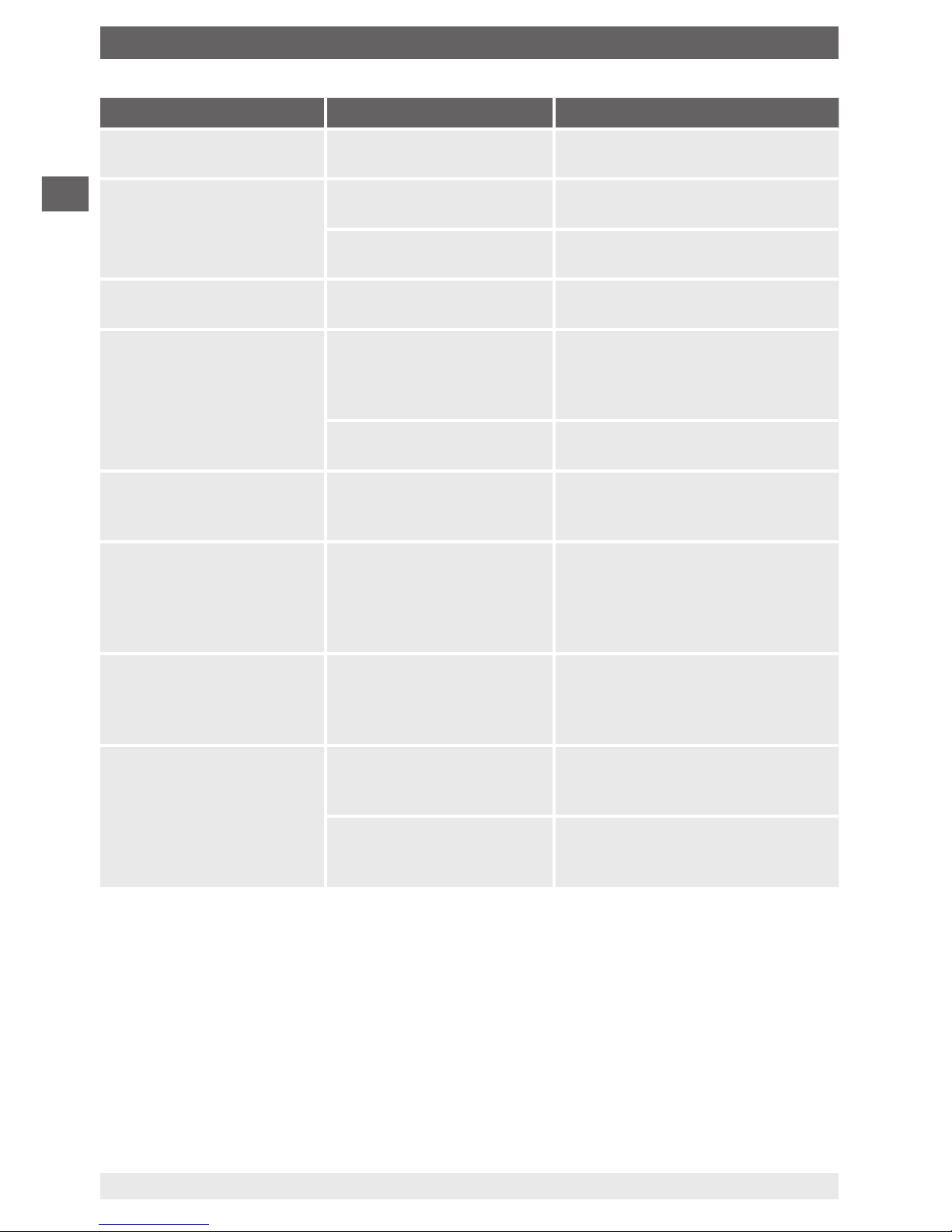

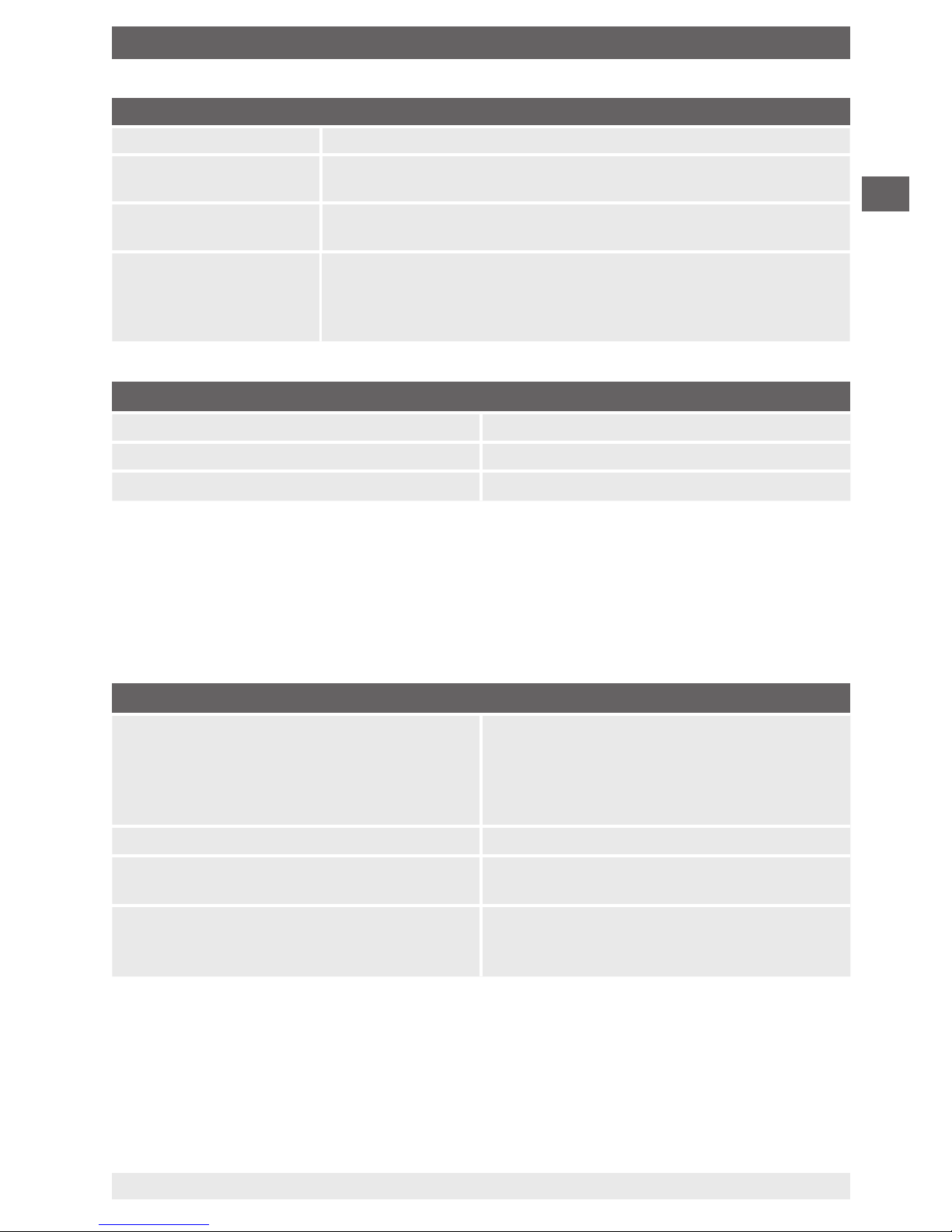

2.2 Technical description of the three variants

Legend:

Neck tube

Thread to the thermowell

Measuring insert

Thread to the connection head

A(U

2

) Insertion length

(tapered thread)

A(L

1

) Insertion length

(parallel thread)

NL Nominal length

N(M

H

) Neck length

tapered

thread

parallel

thread

14013854.02

parallel

thread

tapered

thread

fabricated neck tube

(neck tube welded)

“nipple-union-nipple”

neck tube

tapered thread

parallel thread with

counter nut

TR12-B, TC12-B

Variant 1

TR12-B, TC12-B

Variant 2

TR12-B, TC12-B

Variant 3

Thread

TR12-M, TC12-M

Module

Thread

Thread Thread Thread

Legend:

Connection head

Neck tube

Connection to thermowell

Measuring insert

Terminal block

Transmitter (option)

Field transmitter

14039769.01

T

max

= +80 °C

T

max

= +150 °C

T

max

= +300 °C

T

max

= undefined

2.3 Neck tube versions

2. Design and function

Page 7

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

7

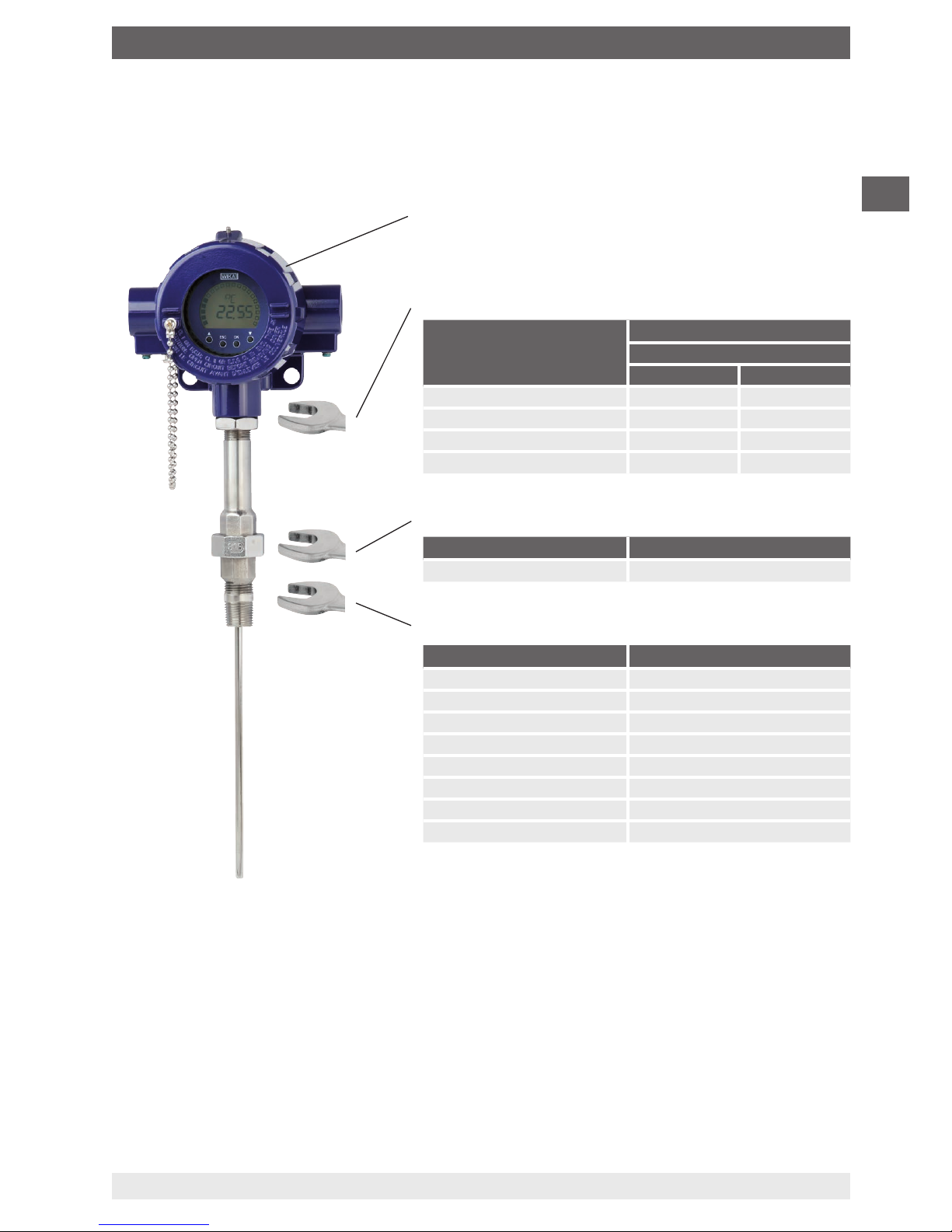

2.4 Case- and connection heads

The dimensions of the case- and connection heads are given in the respective data sheet.

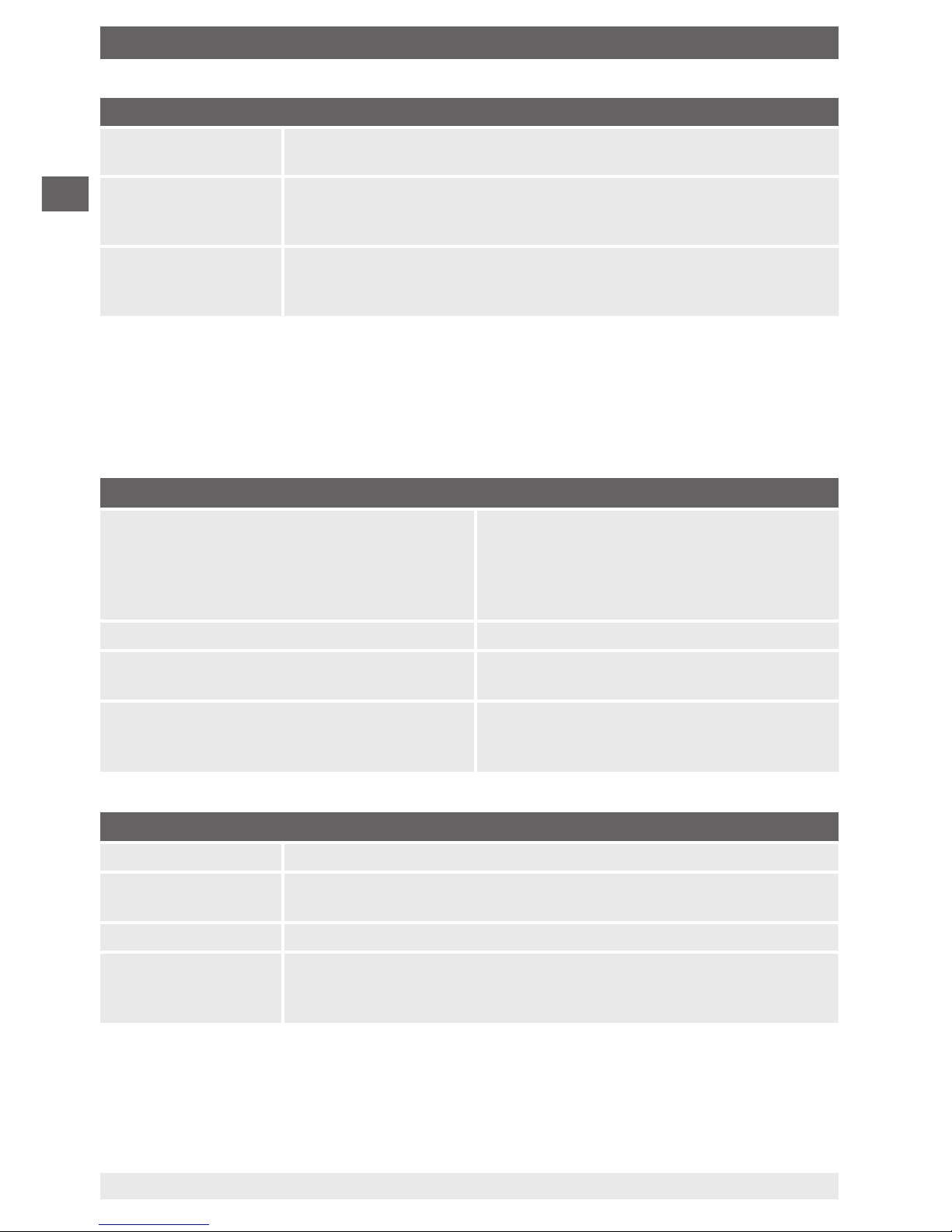

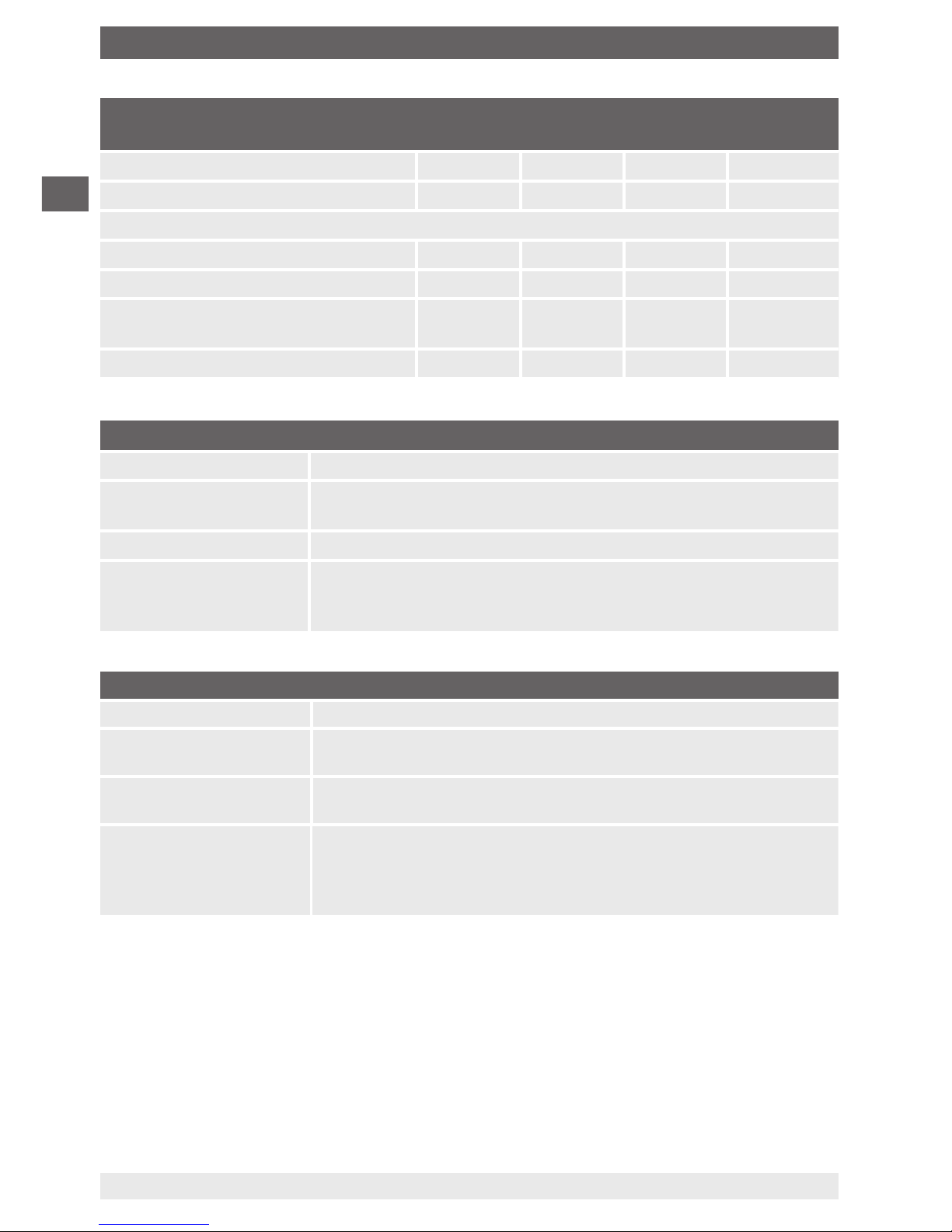

2.5 Tightening torques

Connection head, selectable (example)

Thread Tightening torques in Nm

Connection head material

Aluminium Stainless steel

1/2 NPT 32 35

3/4 NPT 36 40

M20 x 1.5, with counter nut

1)

23 25

M24 x 1.5, with counter nut

1)

27 30

Tightening torques between connection head and neck tube

Tightening torques for connection to thermowell

Tightening torques for connection to neck tube

1) only for versions with fabricated neck tube

Thread Tightening torques in Nm

R 1/2

1)

50 ... 60

Thread Tightening torques in Nm

1/2 NPT 35

3/4 NPT 40

G 1/2 B 35

G 3/4 B 40

M14 x 1.5 25 ... 30

M18 x 1.5 35

M20 x 1.5 35 ... 40

M27 x 2 40 ... 45

■

Only ever screw in, or unscrew, the instrument via the spanner flats and to the

prescribed torque using an appropriate tool.

■

The correct torque depends on the dimensions of the connection thread and the sealing

used (form/material).

■

When screwing in or unscrewing the instrument, do not use the connection head as

contact surface.

■

When screwing in the instrument, please observe that the threads are not skewed.

2.6 Scope of delivery

Cross-check scope of delivery with delivery note.

2. Design and function

Page 8

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

8

3. Safety

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to property or the environment, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused

by hot surfaces or liquids, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

3.2 Intended use

These resistance thermometers and thermocouples are used for temperature

measurement in industrial applications. They can be combined with a variety of thermowell

designs, but the operational process data (temperature, pressure, density and flow

velocity) must be taken into account. Operation without thermowell is only recommended

in certain applications. The replaceable, centrically spring-loaded measuring insert and

its extended spring travel enable combination with the widest range of connection head

designs.

Neither repairs nor structural modifications are permitted, and any would void the

guarantee and the respective certification. The manufacturer shall not be responsible for

constructional modifications after delivery of the instruments.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

3. Safety

Page 9

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

9

3.3 Responsibility of the operator

The system operator is responsible for selecting the thermometer or thermowell, and for

the selection of their materials, so as to guarantee their safe operation within the plant or

machine. When preparing a quote, WIKA can only give recommendations which are based

on our experience in similar applications.

The safety instructions within these operating instructions, as well as the safety, accident

prevention and environmental protection regulations for the application area must be

maintained.

The operator is obliged to maintain the product label in a legible condition.

3.4 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to

equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled electrical personnel who have the qualifications

described below.

Skilled electrical personnel

Skilled electrical personnel are understood to be personnel who, based on their technical

training, know-how and experience as well as their knowledge of country-specific

regulations, current standards and directives, are capable of carrying out work on

electrical systems and independently recognising and avoiding potential hazards. The

skilled electrical personnel have been specifically trained for the work environment they

are working in and know the relevant standards and regulations. The skilled electrical

personnel must comply with current legal accident prevention regulations.

Operating personnel

The personnel trained by the operator are understood to be personnel who, based on their

education, knowledge and experience, are capable of carrying out the work described and

independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

3. Safety

Page 10

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

10

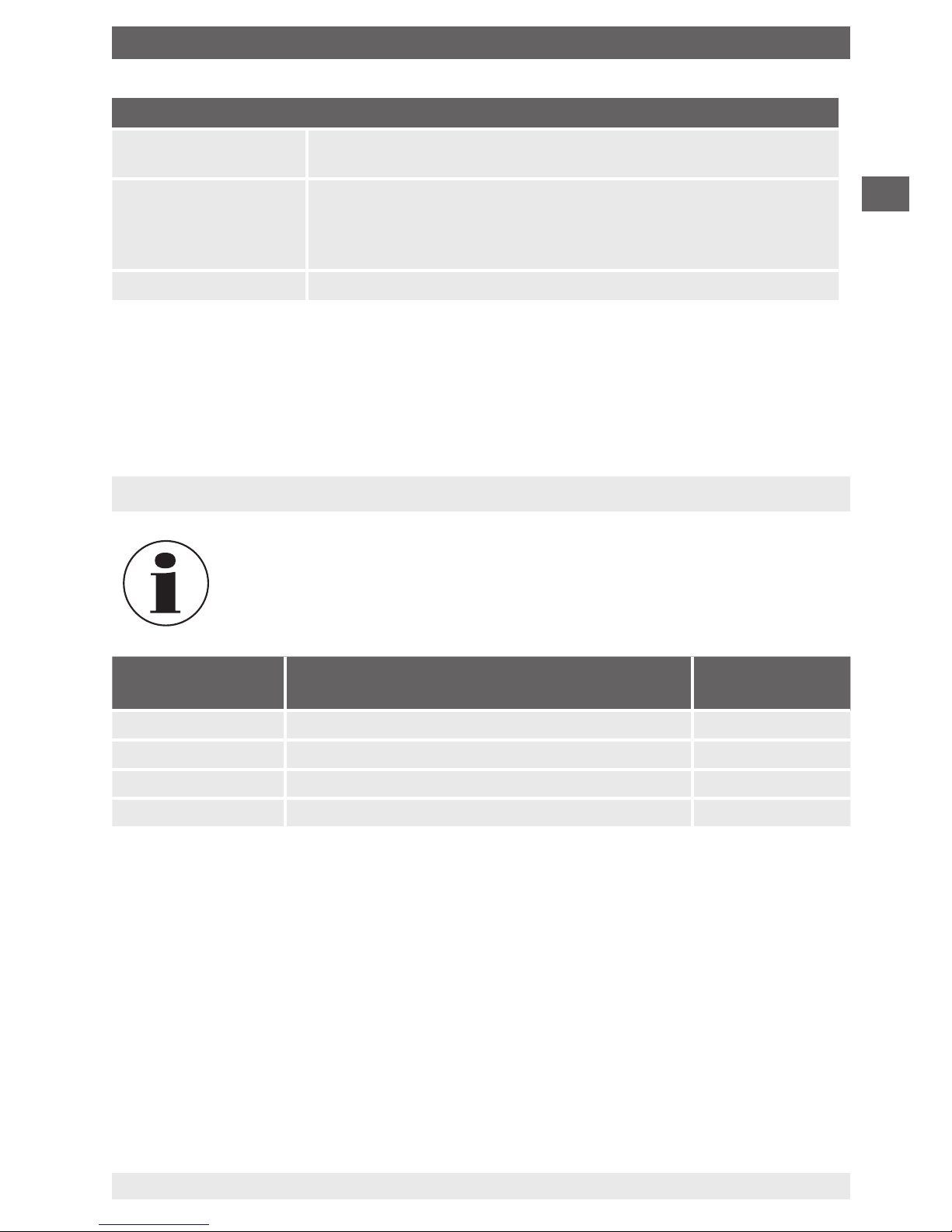

3.5 Labelling, safety marks

Product label (example)

Model

A = measuring insert

B = process thermometer

M = basic module

Serial number

Approval-related data

Year of manufacture

■

Information on version (measuring element, measuring range...)

Sensor in accordance with standard (resistance thermometer)

- F =

Thin-film measuring resistor

- W = Wire-wound measuring resistor

Sensor in accordance with standard (thermocouple)

- ungrounded = ungrounded welded

- grounded = welded to the sheath (grounded)

- quasi grounded = The thermometer is, due to its low insulation clearances between

resistance sensor and sheath, to be considered as grounded.

■

Transmitter model (only for design with transmitter)

Before mounting and commissioning the instrument, ensure you

read the operating instructions!

TR12-M-IDBZ

1 x Pt100 / A / 3 (F) -50 ... +500 °C

Um = DC 30 V / Pm = 2 W

BVS 07 ATEX E 071 X

IECEx BVS 11.0042X

II 2 G Ex db IIC T* Gb

EN 60751

0158

WIKA Alexander Wiegand SE & Co.KG, D-63911 Klingenberg

Made in Germany 2013

WARNING: DO NOT OPEN WHILE ENERGIZED!

11012345

3. Safety

Page 11

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

11

4. Transport, packaging and storage

4.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal

transport, proceed carefully and observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter 4.2 “Packaging

and storage”.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Permissible conditions at the place of storage:

■

Storage temperature:

Instruments without built-in transmitter: -40 ... +80 °C

Instruments with built-in transmitter: see operating instructions of the transmitter in

question

■

Humidity: 35 ... 85 % relative humidity (non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the instrument in its original packaging in a location that fulfils the conditions listed

above. If the original packaging is not available, pack and store the instrument as described

below:

1. Place the instrument, along with shock-absorbent material, in the packaging.

2. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

4. Transport, packaging and storage

Page 12

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

12

5. Commissioning, operation

WARNING!

Damage to the measuring instrument by operation outside the upper

or lower limits of the operating temperature

Failure to observe the permissible operating temperature, also taking

into account convection and radiation, can even cause damage to the

thermometer during mounting.

▶

The upper and lower limits of the specified operating temperature range

must not be exceeded.

During installation, take care to

■

Avoid distorting the cable sheath when tightening the pressure screw.

■

Avoid cutting too deep into the cable sheath.

■

Use suitable cable.

■

Be careful of the clamping area of the cable gland.

■

Thermometers must be earthed if dangerous voltages could be expected at the

connection wires (caused, for example, by mechanical damage, electrostatic charge or

induction)!

■

The protection class is not valid with armoured cables (stainless steel sheathed).

■

Seals should be checked for signs of brittleness and, if necessary, replaced.

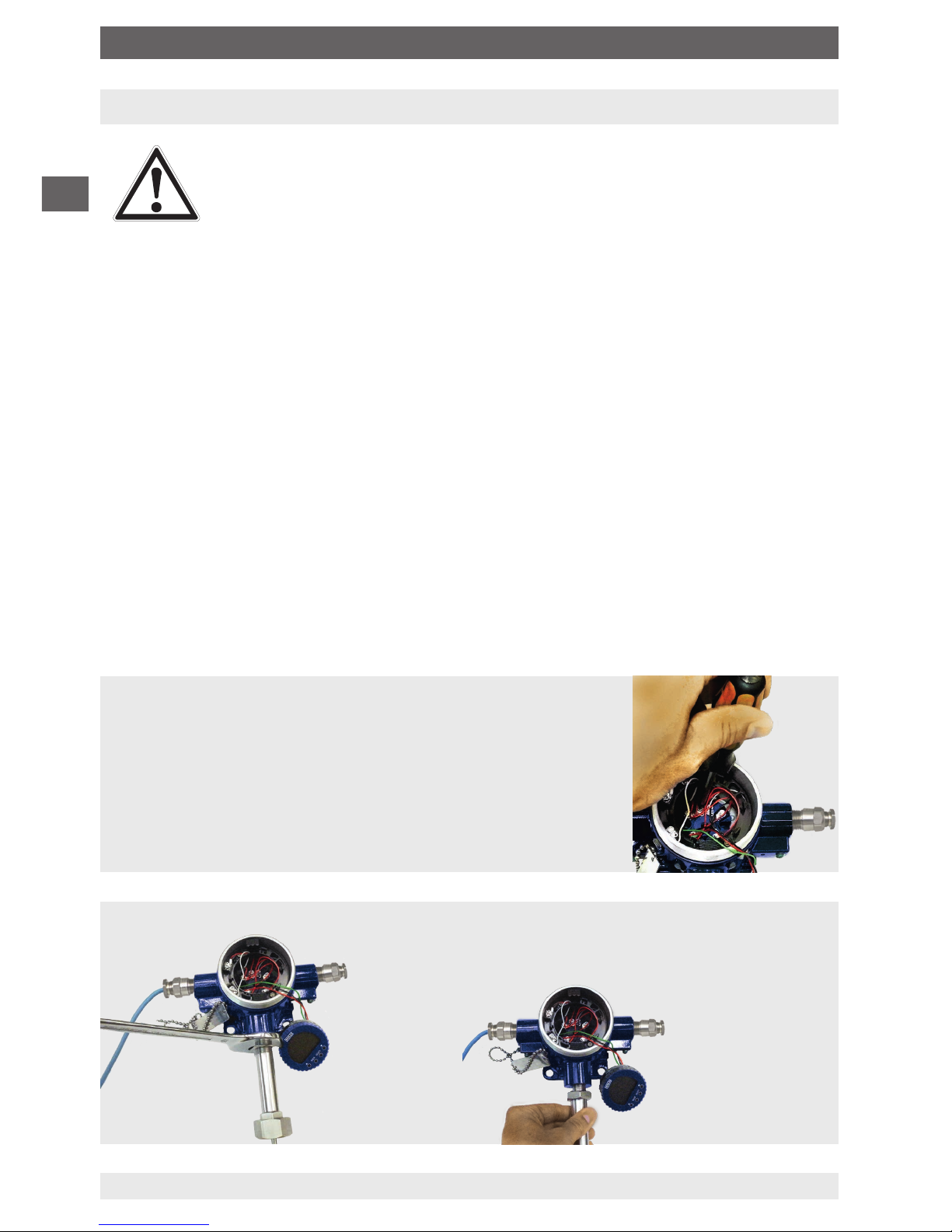

5.1 Removal and installation of the measuring insert

The bare wires have a cross-section of approx. 0.22 mm², are 150 mm long and are colourcoded dependent upon the sensor type. The measuring insert is secured against twisting.

Before removing the measuring insert, fully disconnect the

electrical connections to the terminal block or transmitter.

After that, the neck tube can be loosened and unscrewed from the head.

5. Commissioning, operation

Page 13

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

13

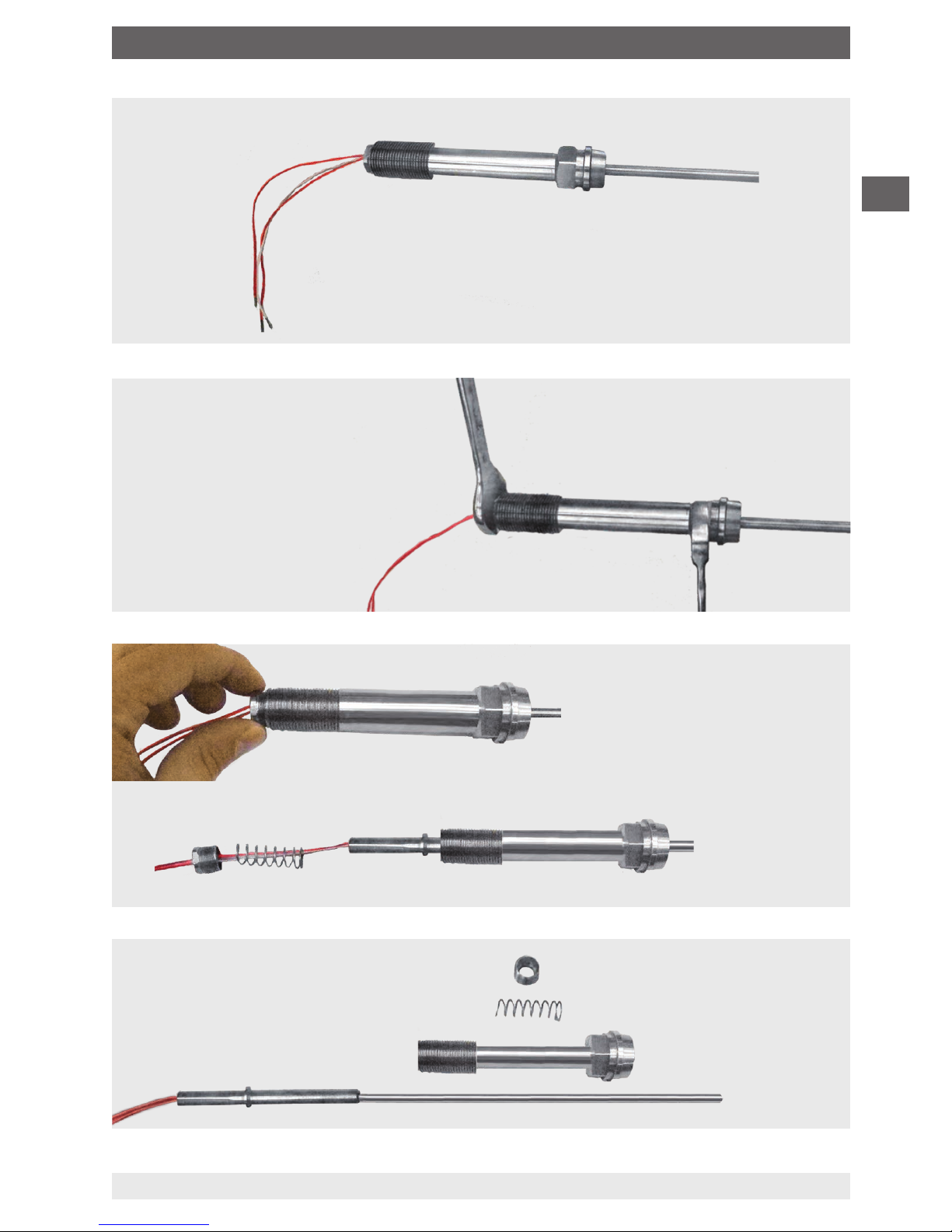

Removed measuring insert with neck tube:

To disconnect the measuring insert

from the neck tube, loosen the M16

bolt at the top end of the neck tube

and unscrew it.

5. Commissioning, operation

Page 14

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

14

The installation of the measuring insert is carried out in

the reverse order (clean the measuring insert prior to

installation).

The hexagonal crimped tip of the measuring insert is

guided by the screw-in of the hexagonal socket screw.

Tightening torque of the screw: 12 ... 14 Nm

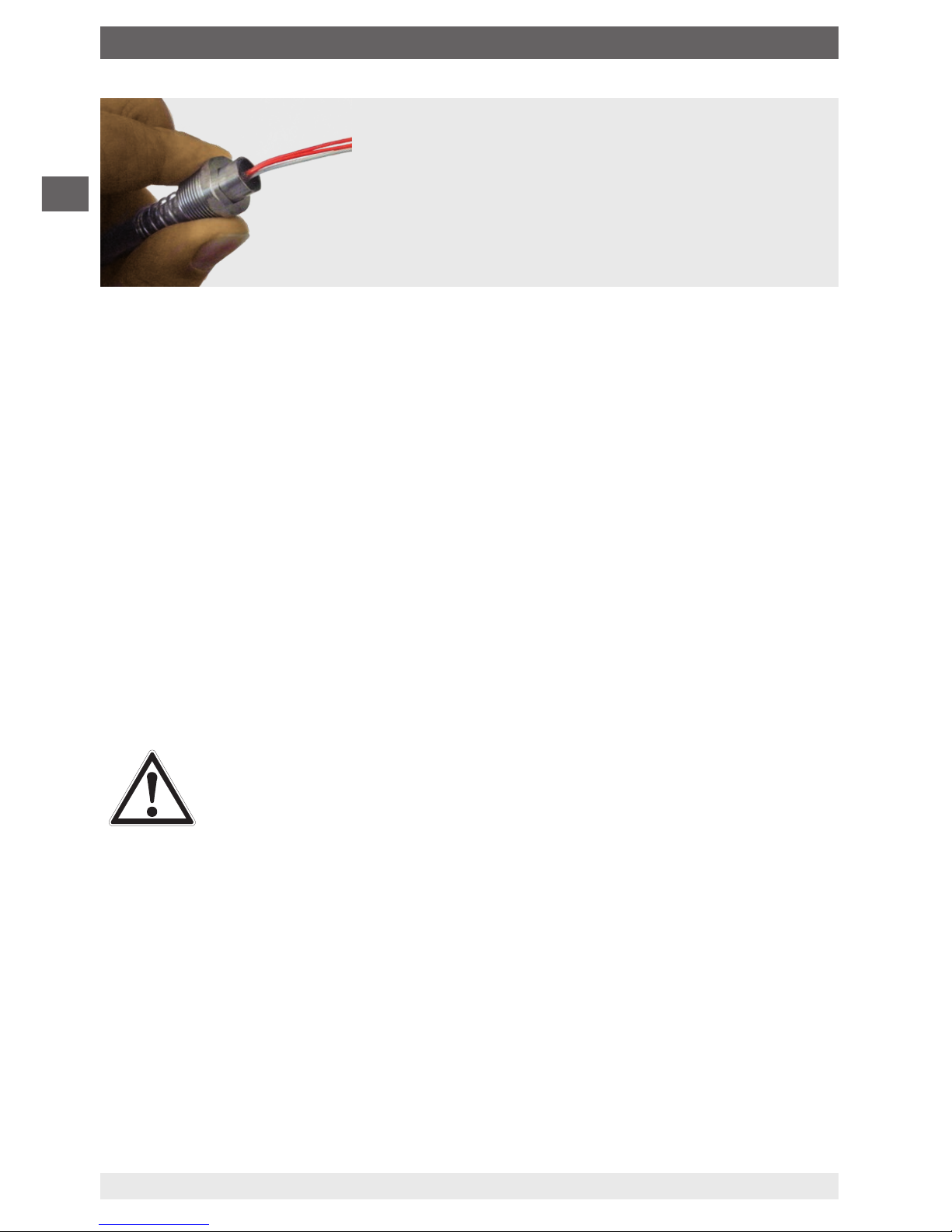

5.2 Electrical mounting

Cable glands

Requirements for meeting ingress protection:

■

Only use cable glands within their indicated clamping area (cable diameter suitable for

the cable gland).

■

Do not use the lower clamping area with very soft cable types.

■

Only use round cables (if necessary, slightly oval in cross-section).

■

Do not twist the cable.

■

Repeated opening/closing is possible; however only if necessary, as it might have a

detrimental effect on the ingress protection

■

For cables with a pronounced cold-flow behaviour the screw connection must be fully

tightened.

5.3 Electrical connection

CAUTION!

Danger of short circuit

Damage to cables, wires and connection points can lead to malfunction of

the instrument.

▶

Avoid damaging the cables and wires.

▶

Fine-stranded leads with bare ends must be finished with end splices

(cable preparation).

▶

Both the internal effective capacitance and inductance must be

considered.

The electrical connection is to be made according to the following sensor connections/

pin assignments.

5. Commissioning, operation

Page 15

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

15

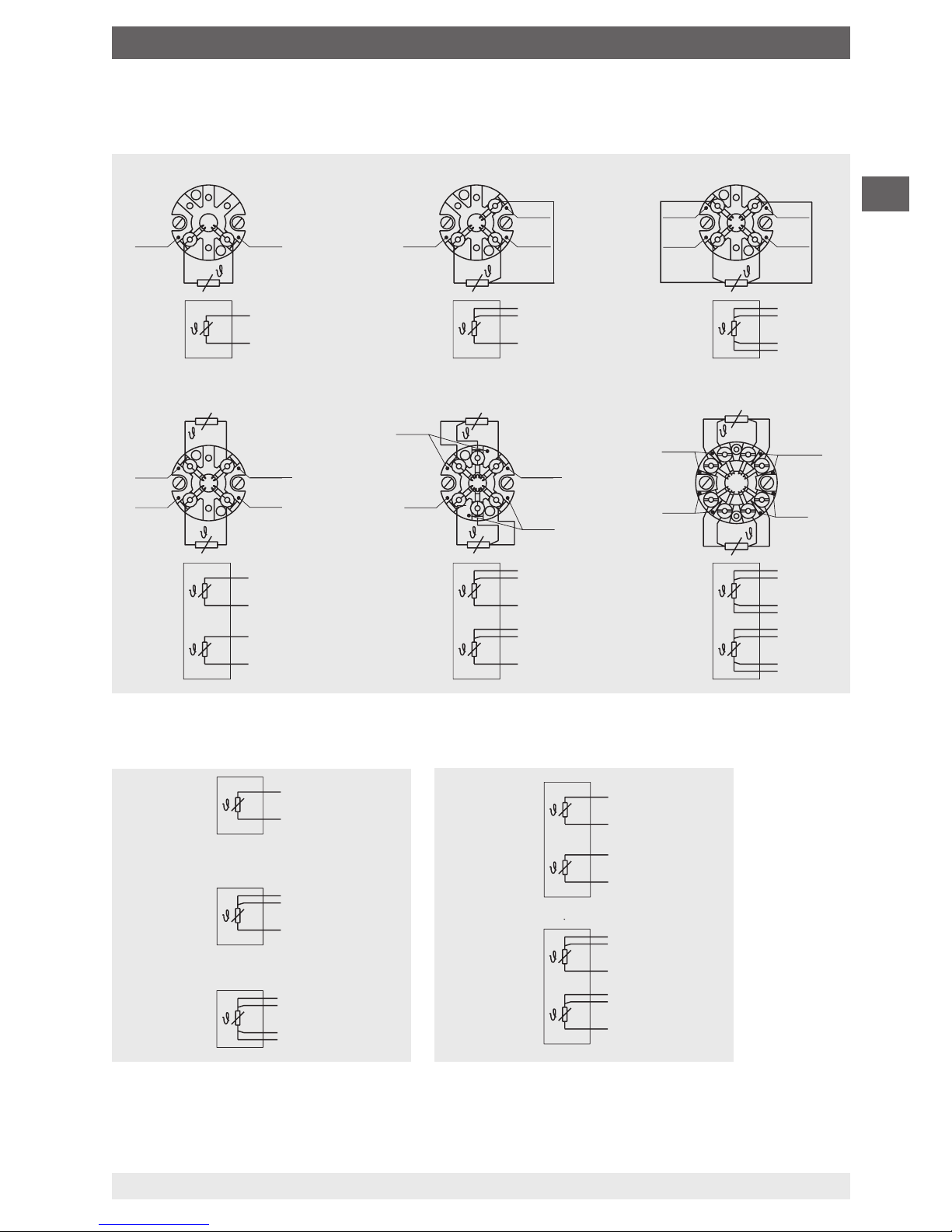

5.3.1 Resistance thermometer

■

With terminal block

■

With connection cable

3160629.06

red

1 x Pt100, 2-wire 1 x Pt100, 3-wire 1 x Pt100, 4-wire

white white

red

red

red

red

white

white

white

white

white

white

red

red

red

red

red

2 x Pt100, 2-wire

2 x Pt100, 3-wire

2 x Pt100, 4-wire

red

white

white

red

red

white

black

yellow

yellow

yellow

black

black

white

white

red

red

red

red

black

black

black

black

yellow

yellow

yellow

red

white

black

yellow

white

1 x Pt100

2-wire

1 x Pt100

3-wire

1 x Pt100

4-wire

2 x Pt100

2-wire

2 x Pt100

3-wire

red

red

red

red

red

red

red

red

white

white

white

white

white

white

black

black

black

yellow

yellow

3160629.06

5. Commissioning, operation

Page 16

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

16

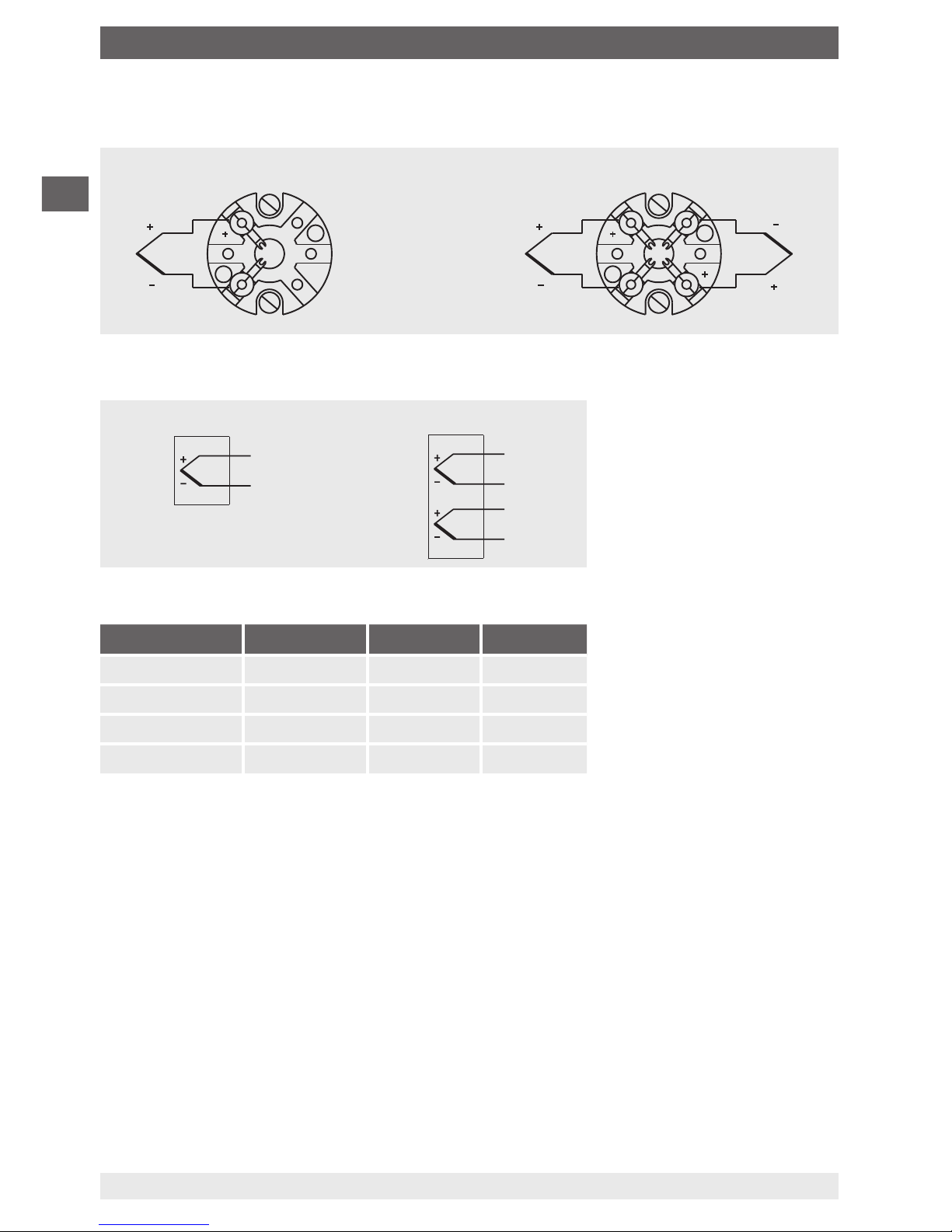

5.3.2 Thermocouples

■

With terminal block

■

With connection cable

Colour coding of cable strands

Sensor type Standard Positive Negative

K IEC 60584 Green White

J IEC 60584 Black White

E IEC 60584 Violet White

N IEC 60584 Pink White

Variant 1

For the electrical specifications (e.g. connection diagrams, tolerance values, etc.), see

chapter 6.1 “Electrical connection” or the data sheets TE 60.17 (for TR12) and TE 65.17

(for TC12).

Variant 2

For the electrical specifications (e.g. connection diagrams, tolerance values, etc.) please

refer to the relevant operating instructions and/or data sheet for the built-in head-mounted

transmitter.

Variant 3

For the electrical specifications (e.g. connection diagrams, tolerance values, etc.) please

refer to the relevant operating instructions and/or the relevant data sheet for the built-in field

transmitter.

Single thermocouple Dual thermocouple

The colour coding

at the positive poles

of the instrument

decides the

correlation of polarity

and terminal.

3166822.03

Single thermocouple Dual thermocouple

5. Commissioning, operation

Page 17

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

17

Variant 1 and 2

■

Junction between cable gland and connection head

M20 x 1.5 thread: Tightening torques 12 Nm

½ NPT thread: Tightening torques 30 Nm

■

Junction between cable and cable gland

Screw the pressure screw tightly into the adapter (use appropriate tools!)

6. Faults

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the instrument

must be taken out of operation immediately.

▶

Ensure that there is no longer any signal present and protect against being

put into operation accidentally.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 8.2

“Return”.

WARNING!

Physical injuries and damage to property and the environment caused

by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature

and under high pressure or vacuum may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate

existing codes or regulations must also be followed.

▶

Wear the required protective equipment (depending on the application; the

thermometer itself is basically not dangerous).

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

5. Commissioning, operation / 6. Faults

Page 18

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

18

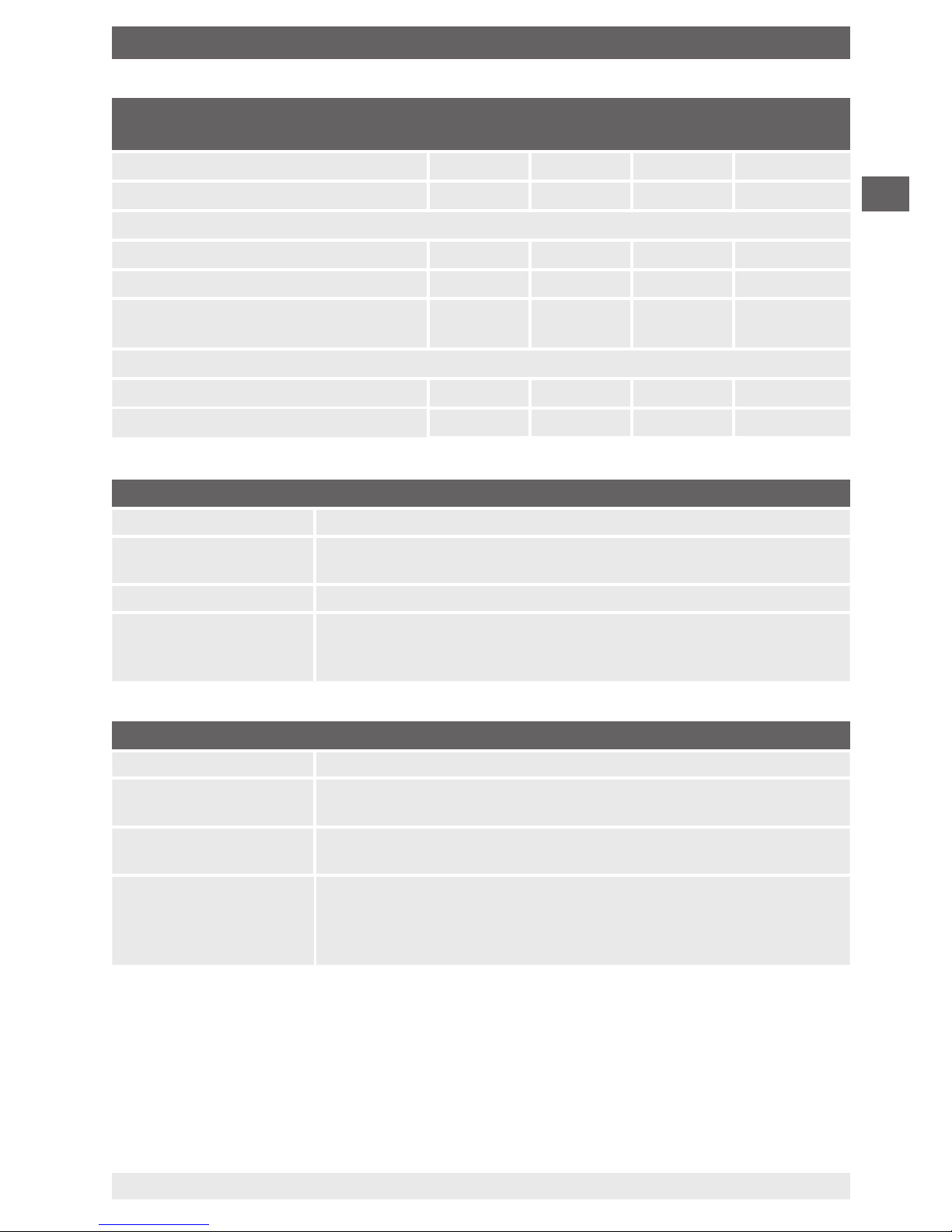

Faults Causes Measures

No signal/cable break Mechanical load too high or

overtemperature

Replace probe or measuring insert

with one of a suitable design

Erroneous measured

values

Sensor drift caused by

overtemperature

Replace probe or measuring insert

with one of a suitable design

Sensor drift caused by

chemical attack

Use a suitable thermowell.

Erroneous measured

values (too low)

Entry of moisture into cable

or measuring insert

Replace probe or measuring insert

with one of a suitable design

Erroneous measured

values and response

times too long

Wrong mounting geometry,

for example mounting depth

too deep or heat dissipation

too high

The temperature-sensitive area

of the sensor must be inside the

medium, and surface measurements

must be ungrounded

Deposits on the sensor or

thermowell

Remove deposits

Erroneous measured

values (of thermocouples)

Parasitic voltages (thermal

voltages, galvanic voltage) or

wrong equalisation line

Use suitable compensating cable

Temporary or sporadic

interruptions of the

measured value signal

Cable break in connection

cable or loose contact

caused by mechanical

overload

Replace probe or measuring insert

with a suitable design, for example

equipped with a bend protection

spring or a thicker conductor crosssection

Corrosion Composition of the medium

not as expected or modified

or wrong thermowell material

selected

Analyse medium and then select a

more suitable material or replace

thermowell regularly

Signal interference Stray currents caused by

electric fields or earth circuits

Use shielded connection leads, and

increase the distance to motors and

power cables

Earth circuits Eliminate potential differences by

using galvanically isolated barriers

or transmitters

6. Faults

Page 19

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

19

7. Maintenance, cleaning and calibration

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

7.1 Maintenance

The thermometers described here are maintenance-free.

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

Physical injuries and damage to property and the environment

Improper cleaning may lead to physical injuries and damage to property and

the environment. Residual media in the dismounted instrument can result in a

risk to persons, the environment and equipment.

▶

Carry out the cleaning process as described below.

1. Prior to cleaning, disconnect the electrical connections properly.

2. Use the required protective equipment (depending on the application; the thermometer

itself is basically not dangerous).

3. Clean the instrument with a moist cloth.

This applies in particular to thermometers with a case made of plastic to ensure that any

risk of electrostatic charge is avoided.

Electrical connections must not come into contact with moisture!

CAUTION!

Damage to the instrument

Improper cleaning may lead to damage to the instrument!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects for cleaning.

4. Wash or clean the dismounted instrument, in order to protect persons and the

environment from exposure to residual media.

7.3 Calibration, recalibration

It is recommended that the measuring insert is recalibrated at regular intervals (resistance

thermometers: approx. 24 months, thermocouples: approx. 12 months). This period can

reduce, depending on the particular application. The calibration can be carried out by the

manufacturer, as well as on site by qualified skilled personnel with calibration instruments.

7. Maintenance, cleaning and calibration

Page 20

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

20

8. Dismounting, return and disposal

8.1 Dismounting

WARNING!

Physical injuries and damage to property and the environment

through residual media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

▶

Before storage of the dismounted instrument (following use) wash or

clean it, in order to protect persons and the environment from exposure to

residual media.

▶

Use the required protective equipment (depending on the application; the

thermometer itself is basically not dangerous).

▶

Observe the information in the material safety data sheet for the

corresponding medium.

Only disconnect the thermometer once the system has been depressurised.

WARNING!

Risk of burns

During dismounting there is a risk of dangerously hot media escaping.

▶

Let the instrument cool down sufficiently before dismounting it!

8.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media in the dismounted instrument can result in a risk to persons,

the environment and equipment.

▶

With hazardous substances, include the material safety data sheet for the

corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

When returning the instrument, use the original packaging or a suitable transport packaging.

To avoid damage:

1. Place the instrument, along with shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

2. If possible, place a bag containing a desiccant inside the packaging.

3. Label the shipment as carriage of a highly sensitive measuring instrument.

8. Dismounting, return and disposal

Page 21

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

21

Information on returns can be found under the heading “Service” on our local

website.

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

Do not dispose of with household waste. Ensure a proper disposal in

accordance with national regulations.

9. Specifications

9.1 Models TR12-A, TR12-M

Output signal Pt100

Temperature range Measuring range -200 ... +600 °C

Measuring element

(measuring current: 0.1 ... 1.0 mA)

1)

Pt100 measuring resistor

Connection method 1 x 2-wire, 1 x 3-wire, 1 x 4-wire, 2 x 2-wire, 2 x 3-wire,

2 x 4-wire

2)

Tolerance value of the measuring

element per EN 60751 Class B

Class A

Class AA

Wire-wound Thin film

-200 ... +600 °C

-100 ... +450 °C

-50 ... +250 °C

-50 ... +500 °C

-30 ... +300 °C

0 ... 150 °C

Measuring insert (replaceable)

Material Stainless steel 1.4571, 316/316L

Diameter Standard: 3 mm

3)

, 6 mm, 8 mm (with sleeve)

Option (on request): 1/8" 3) (3.17 mm), 1/4" (6.35 mm), 3/8" (9.53 mm)

Spring travel approx. 20 mm

Response time (in

water, per EN 60751)

t

50

< 10 s t90 < 20 s (measuring insert diameter 6 mm: The thermowell

required for operation increases the response time dependent upon the

actual parameters for the thermowell and the process.)

Use resistance thermometers with shielded cable, and, if the lines are longer than 30 m or leave the building, ground the

shield on at least one end of the lead. For a correct determination of the overall measuring deviation, both sensor and

transmitter measuring deviations have to be considered.

1) For detailed specifications for Pt100 sensors, see Technical information IN 00.17 at www.wika.com.

2) Not for 3 mm diameter

3) Not for 2 x 4-wire connection method

8. Dismounting, return and disposal / 9. Specifications

Page 22

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

22

Neck tube (only model TR12-M)

Material Stainless steel 1.4571, 316/316L

Connection thread to the

thermowell

G 1/2 B, G 3/4 B, 1/2 NPT, 3/4 NPT, M14 x 1.5, M18 x 1.5,

M20 x 1.5, M27 x 2

Connection thread to the head

■

M20 x 1.5 with counter nut

■

M24 x 1.5 with counter nut

■

1/2 NPT

■

3/4 NPT

Neck length

■

min. 150 mm, standard neck length

■

200 mm

■

250 mm

other neck lengths on request

Ambient conditions

Ambient and storage

temperature

-60

4)

/ -40 ... +80 °C

Ingress protection IP00 per IEC/EN 60529

Vibration resistance

■

6 g peak-to-peak, wire-wound measuring resistor or thin film (standard)

■

20 g peak-to-peak, thin-film measuring resistor (option)

■

50 g peak-to-peak, thin-film measuring resistor (option)

5)

4) Special version on request (only available with selected approvals), other ambient and storage temperature on request

For further specifications see WIKA data sheets TE 60.16, TE 60.17 and the order

documentation.

9.2 Model TR12-B

Output signal Pt100

Temperature range Measuring range -200 ... +600 °C

Measuring element

(measuring current: 0.1 ... 1.0 mA)

6)

Pt100 measuring resistor

Connection method 1 x 2-wire, 1 x 3-wire, 1 x 4-wire, 2 x 2-wire, 2 x 3-wire,

2 x 4-wire

Tolerance value of the measuring

element per EN 60751 Class B

Class A

Class AA

Wire-wound Thin film

-200 ... +600 °C

-100 ... +450 °C

-50 ... +250 °C

-50 ... +500 °C

-30 ... +300 °C

0 ... 150 °C

Use resistance thermometers with shielded cable, and, if the lines are longer than 30 m or leave the building, ground

the shield on at least one end of the lead. For a correct determination of the overall measuring deviation, both sensor

and transmitter measuring deviations have to be considered.

5) For measuring insert diameter < 8 mm

6) For detailed specifications for Pt100 sensors, see Technical information IN 00.17 at www.wika.com.

9. Specifications

Page 23

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

23

Output signal 4 ... 20 mA, HART® protocol, FOUNDATION™ Fieldbus and

PROFIBUS

®

PA

7)

Transmitter model (selectable versions) T15 T32 T53 TIF50, TIF52

Data sheet TE 15.01 TE 32.04 TE 53.01 TE 62.01

Output

■

4 ... 20 mA x x x

■

HART® protocol x x

■

FOUNDATION™ Fieldbus and

PROFIBUS® PA

x

Connection method

1 x 2-wire, 3-wire or 4-wire x x x x

Measuring current < 0.2 mA < 0.3 mA < 0.2 mA < 0.3 mA

Measuring insert (replaceable)

Material Stainless steel 1.4571, 316/316L

Diameter Standard: 3 mm

8)

, 6 mm, 8 mm (with sleeve)

Option (on request): 1/8" 8) (3.17 mm), 1/4" (6.35 mm), 3/8" (9.53 mm)

Spring travel approx. 20 mm

Response time (in

water, per EN 60751)

t

50

< 10 s t90 < 20 s (measuring insert diameter 6 mm: The thermowell

required for operation increases the response time dependent upon the

actual parameters for the thermowell and the process.)

Neck tube

Material Stainless steel 1.4571, 316/316L

Connection thread to

the thermowell

G 1/2 B, G 3/4 B, 1/2 NPT, 3/4 NPT, M14 x 1.5, M18 x 1.5, M20 x 1.5,

M27 x 2

Connection thread to

the head

■

M20 x 1.5 with counter nut

■

M24 x 1.5 with counter nut

■

1/2 NPT

■

3/4 NPT

Neck length

■

min. 150 mm, standard neck length

■

200 mm

■

250 mm

other neck lengths on request

7) Protect the temperature transmitter from temperatures > 85 °C.

8) Not for 2 x 4-wire connection method

9. Specifications

Page 24

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

24

Ambient conditions

Ambient and storage

temperature

-60

9)

/ -40 ... +80 °C

Ingress protection IP66 per IEC/EN 60529

The specified ingress protection only applies with corresponding thermowell,

connection head, cable gland and appropriate cable dimensions

Vibration resistance

■

6 g peak-to-peak, wire-wound measuring resistor or thin film (standard)

■

20 g peak-to-peak, thin-film measuring resistor (option)

■

50 g peak-to-peak, thin-film measuring resistor (option)

10)

9) Special version on request (only available with selected approvals), other ambient and storage temperature on request

10) For measuring insert diameter < 8 mm

For further specifications see WIKA data sheet TE 60.17 and the order documentation.

9.3 Models TC12-A, TC12-M

Output signal thermocouple

Recommended max. operating temperature

■

Type K

■

Type J

■

Type E

■

Type N

1,200 °C

800 °C

800 °C

1,200 °C

Thermocouple per DIN EN 60584-1

11)

Types K, J, E, N

Measuring point

■

Ungrounded welded (ungrounded)

■

Grounded

Tolerance value of the measuring element

■

per EN 60584-1

■

per ASTM E230 (only for types K and J)

Class 1 and 2

Standard and special

Measuring insert (replaceable)

Material Inconel 600, others on request

Diameter Standard: 3 mm, 4.5 mm, 6 mm, 8 mm

Option (on request): 1/8" (3.17 mm), 1/4" (6.35 mm), 3/8" (9.53 mm)

Spring travel approx. 20 mm

Response time (in

water, per EN 60751)

t

50

< 5 s t90 < 10 s (measuring insert diameter 6 mm: The thermowell

required for operation increases the response time dependent upon the

actual parameters for the thermowell and the process.)

11) For detailed specifications for thermocouples, see Technical information IN 00.23 at www.wika.com.

9. Specifications

Page 25

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

25

Neck tube (only model TC12-M)

Material Stainless steel 1.4571, 316/316L

Connection thread to

the thermowell

G 1/2 B, G 3/4 B, 1/2 NPT, 3/4 NPT, M14 x 1.5, M18 x 1.5, M20 x 1.5,

M27 x 2

Connection thread to

the head

■

M20 x 1.5 with counter nut

■

M24 x 1.5 with counter nut

■

1/2 NPT

■

3/4 NPT

Neck length

■

min. 150 mm, standard neck length

■

200 mm

■

250 mm

other neck lengths on request

Ambient conditions

Ambient and storage temperature -60

12)

/ -40 ... +80 °C

Ingress protection IP00 per IEC/EN 60529

Vibration resistance 50 g, peak-to-peak

12) Special version on request (only available with selected approvals), other ambient and storage temperature on request

For further specifications see WIKA data sheets TE 65.16, TE 65.17 and the order

documentation.

9.4 Model TC12-B

Output signal thermocouple

Recommended max. operating temperature

■

Type K

■

Type J

■

Type E

■

Type N

1,200 °C

800 °C

800 °C

1,200 °C

Thermocouple per DIN EN 60584-1

13)

Types K, J, E, N

Measuring point

■

Ungrounded welded (ungrounded)

■

Grounded

Tolerance value of the measuring element

■

per EN 60584-1

■

per ASTM E230 (only for types K and J)

Class 1 and 2

Standard and special

13) For detailed specifications for thermocouples, see Technical information IN 00.23 at www.wika.com.

9. Specifications

Page 26

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

26

Output signal 4 ... 20 mA, HART® protocol, FOUNDATION™ Fieldbus and

PROFIBUS

®

PA

14)

Transmitter model (selectable versions) T16 T32 T53 TIF50, TIF52

Data sheet TE 16.01 TE 32.04 TE 53.01 TE 62.01

Output

■

4 ... 20 mA x x x

■

HART® protocol x x

■

FOUNDATION™ Fieldbus and

PROFIBUS® PA

x

Galvanic isolation x x x x

Measuring insert (replaceable)

Material Ni alloy 2.4816 (Inconel 600), others on request

Diameter Standard: 3 mm, 4.5 mm, 6 mm, 8 mm

Option (on request): 1/8" (3.17 mm), 1/4" (6.35 mm), 3/8" (9.53 mm)

Spring travel approx. 20 mm

Response time (in

water, per EN 60751)

t

50

< 5 s t90 < 10 s (measuring insert diameter 6 mm: The thermowell

required for operation increases the response time dependent upon

the actual parameters for the thermowell and the process.)

Neck tube

Material Stainless steel 1.4571, 316/316L

Connection thread to

the thermowell

G 1/2 B, G 3/4 B, 1/2 NPT, 3/4 NPT, M14 x 1.5, M18 x 1.5, M20 x 1.5,

M27 x 2

Connection thread to

the head

■

M20 x 1.5 with counter nut

■

M24 x 1.5 with counter nut

■

1/2 NPT

■

3/4 NPT

Neck length

■

min. 150 mm, standard neck length

■

200 mm

■

250 mm

other neck lengths on request

14) Protect the temperature transmitter from temperatures > 85 °C.

9. Specifications

Page 27

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

27

Ambient conditions

Ambient and storage

temperature

-60

15)

/ -40 ... +80 °C

Ingress protection IP66 per IEC/EN 60529

The specified ingress protection only applies with corresponding

thermowell, connection head, cable gland and appropriate cable

dimensions

Vibration resistance 50 g, peak-to-peak

15) Special version on request (only available with selected approvals), other ambient and storage temperature on request

For further specifications see WIKA data sheet TE 65.17 and the order documentation.

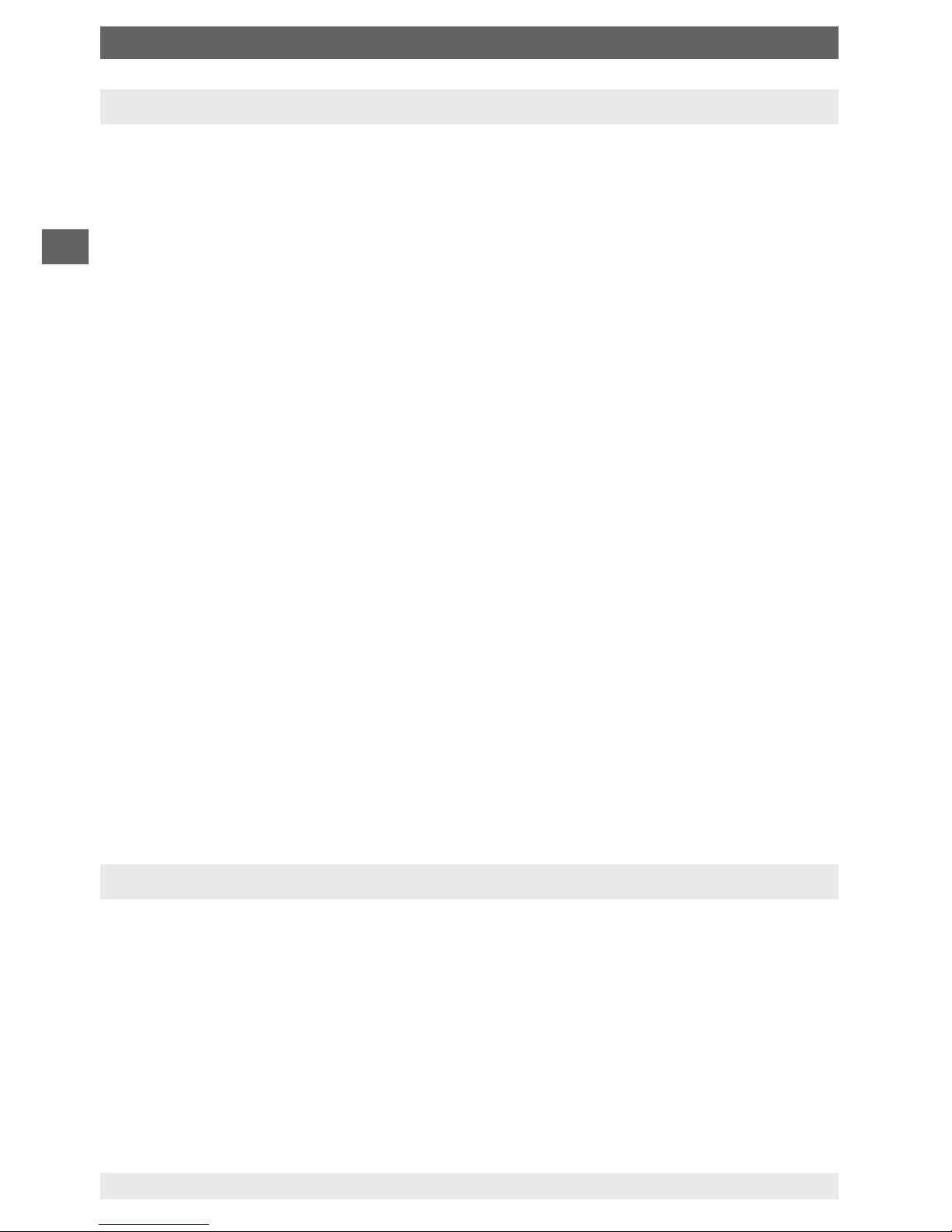

10. Accessories

The seals can be ordered from WIKA, indicating the WIKA order number and/

or the designation (see table).

WIKA order

number

Designation Suitable for

threads

11349981 per DIN 7603 form C 14 x 18 x 2 -CuFA G ¼, M14 x 1.5

11349990 per DIN 7603 form C 18 x 22 x 2 -CuFA G ⅜, M18 x 1.5

11350008 per DIN 7603 form C 21 x 26 x 2 -CuFA G ½, M20 x 1.5

11350016 per DIN 7603 form C 27 x 32 x 2.5 -CuFA G ¾, M27 x 2

Legend:

CuFA = Copper, max. 45HB

a

; filled with asbestos-free sealing material

9. Specifications / 10. Accessories

Page 28

EN

14064370.02 08/2018 EN/DE/FR/ES

WIKA operating instructions models TR12, TC12

28

Page 29

DE

WIKA Betriebsanleitung Typen TR12, TC12

29

14064370.02 08/2018 EN/DE/FR/ES

Inhalt

Inhalt

1. Allgemeines 30

2. Aufbau und Funktion 30

3. Sicherheit 34

4. Transport, Verpackung und Lagerung 37

5. Inbetriebnahme, Betrieb 38

6. Störungen 43

7. Wartung, Reinigung und Kalibrierung 45

8. Demontage, Rücksendung und Entsorgung 46

9. Technische Daten 47

10. Zubehör 53

Page 30

DE

WIKA Betriebsanleitung Typen TR12, TC12

30

14064370.02 08/2018 EN/DE/FR/ES

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Thermometer werden nach dem aktuellen

Stand der Technik gefertigt.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TE 60.16 (TR12-A)

TE 60.17 (TR12-B, TR12-M)

TE 65.16 (TC12-A)

TE 65.17 (TC12-B, TC12-M)

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Abkürzungen

RTD englisch: „Resistance temperature detector“; Widerstandsthermometer

TC englisch: „Thermocouple“; Thermoelement

2. Aufbau und Funktion

2.1 Beschreibung

Die elektrischen Thermometer Typ TR12-B (Widerstandsthermometer) bzw. Typ TC12-B

(Thermoelement) bestehen aus einem Modul (TR12-M, TC12-M) welches an ein Gehäuse

angebaut ist. Das Modul besteht aus einem federnd gelagertem Messeinsatz (TR12-A,

TC12-A) eingebaut in ein Halsrohr. Der Messeinsatz (TR12-A, TC12-A) ist auswechselbar.

Der messaktive Teil des Messeinsatzes ist hergestellt aus einem angeschweißten

Röhrchen oder aus mineralisolierter Leitung, optional in Kombination mit keramikisolierten

Thermodrähten. Der Sensor ist eingebettet in Keramikpulver, hitzebeständiger Vergussmasse, Zementkitt oder Wärmeleitpaste.

1. Allgemeines / 2. Aufbau und Funktion

Page 31

DE

WIKA Betriebsanleitung Typen TR12, TC12

31

14064370.02 08/2018 EN/DE/FR/ES

Wenn der Temperatursensor als geerdetes Thermoelement ausgeführt ist, ist das Thermopaar direkt mit dem Mantel verbunden. Ausführungen mit Durchmesser kleiner 3 mm und

geerdete Thermoelemente sind als galvanisch mit Erdpotential verbunden zu betrachten.

Die Anschlussseite des Messeinsatzes besteht aus einer Übergangshülse mit verbundenen Anschlusslitzen.

Dieses Dokument beschreibt Geräte in Standardausführung. Für Anwendungen in explosionsgefährdeten Bereichen sind spezielle Geräteausführungen erforderlich.

Weitere Informationen für den Einsatz im explosionsgefährdeten Bereich siehe Zusatzinformation für die entsprechende Zündschutzart (separates Dokument).

VORSICHT!

Beschädigung des Gerätes

Um Beschädigungen am Gerät zu vermeiden müssen Thermometer dieser

Typenreihen mit einem Schutzrohr verbaut werden.

▶

Geeignetes Schutzrohr auswählen (Schutzrohrbauform beliebig wählbar)

und die operativen Prozessdaten (Temperatur, Druck, Dichte und

Strömungsgeschwindigkeit) berücksichtigen.

▶

Der Einsatz von Sonderbauformen ohne Schutzrohr ist möglich, unterliegt

aber der Verantwortung des Betreibers.

Mögliche Sensormessbereiche:

Typ TR12: -200 ... +600 °C

Typ TC12: -40 ... +1.200 °C

Die nachfolgenden Einbau- und Betriebshinweise haben wir mit Sorgfalt zusammengestellt. Es ist jedoch nicht möglich, alle erdenklichen Anwendungsfälle zu berücksichtigen.

2. Aufbau und Funktion

Page 32

DE

WIKA Betriebsanleitung Typen TR12, TC12

32

14064370.02 08/2018 EN/DE/FR/ES

2.2 Technische Beschreibung der drei Varianten

Legende:

Halsrohr

Gewinde zum Schutzrohr

Messeinsatz

Gewinde zum Anschlusskopf

A(U

2

) Einbaulänge

(kegeliges Gewinde)

A(L

1

) Einbaulänge

(zylindrisches Gewinde)

NL Nennlänge

N(M

H

) Halslänge

kegeliges

Gewinde

zylindrisches

Gewinde

14013854.02

zylindrisches

Gewinde

kegeliges

Gewinde

nicht-teilbares Halsrohr

(Halsrohr verschweißt)

teilbares Halsrohr

(Nipple-Union-Nipple)

kegeliges

Gewinde

zylindrisches Gewinde

mit Kontermutter

TR12-B, TC12-B

Variante 1

TR12-B, TC12-B

Variante 2

TR12-B, TC12-B

Variante 3

Gewinde

TR12-M, TC12-M

Modul

Gewinde

Gewinde Gewinde Gewinde

Legende:

Anschlusskopf

Halsrohr

Anschluss zum Schutzrohr

Messeinsatz

Klemmsockel

Transmitter (Option)

Feldtransmitter

14039769.01

T

max

= +80 °C

T

max

= +150 °C

T

max

= +300 °C

T

max

= undefiniert

2.3 Halsrohrausführungen

2. Aufbau und Funktion

Page 33

DE

WIKA Betriebsanleitung Typen TR12, TC12

33

14064370.02 08/2018 EN/DE/FR/ES

2.4 Gehäuse- und Anschlussköpfe

Die Abmessungen der Gehäuse- bzw. Anschlussköpfe dem jeweiligen Datenblatt entnehmen.

2.5 Anzugsdrehmomente

Anschlusskopf, wählbar (Beispiel)

Gewinde Anzugsdrehmomente in Nm

Werkstoff Anschlusskopf

Aluminium CrNi-Stahl

1/2 NPT 32 35

3/4 NPT 36 40

M20 x 1,5 mit Kontermutter

1)

23 25

M24 x 1,5 mit Kontermutter

1)

27 30

Anzugsdrehmomente zwischen Anschlusskopf und Halsrohr

Anzugsdrehmomente für Anschluss zum Schutzrohr

Anzugsdrehmomente für Anschluss zum Halsrohr

1) nur bei Ausführungen mit nicht teilbarem Halsrohr

Gewinde Anzugsdrehmomente in Nm

R 1/2

1)

50 ... 60

Gewinde Anzugsdrehmomente in Nm

1/2 NPT 35

3/4 NPT 40

G 1/2 B 35

G 3/4 B 40

M14 x 1,5 25 ... 30

M18 x 1,5 35

M20 x 1,5 35 ... 40

M27 x 2 40 ... 45

■

Das Gerät nur über die Schlüsselflächen mit einem geeigneten Werkzeug und dem

vorgeschriebenen Drehmoment ein- bzw. ausschrauben.

■

Das richtige Drehmoment ist abhängig von der Dimension des Anschlussgewindes

sowie der verwendeten Dichtung (Form/Werkstoff).

■

Zum Ein- bzw. Ausschrauben nicht den Anschlusskopf als Angriffsfläche verwenden.

■

Beim Einschrauben beachten, dass die Gewindegänge nicht verkantet werden.

2.6 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

2. Aufbau und Funktion

Page 34

DE

WIKA Betriebsanleitung Typen TR12, TC12

34

14064370.02 08/2018 EN/DE/FR/ES

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann,

wenn sie nicht gemieden wird.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberflächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie

nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

3.2 Bestimmungsgemäße Verwendung

Diese Widerstandsthermometer und Thermoelemente dienen zur Temperaturmessung

in industriellen Anwendungen. Sie können mit einer Vielzahl von Schutzrohrbauformen

kombiniert werden, jedoch müssen die operativen Prozessdaten (Temperatur, Druck,

Dichte und Strömungsgeschwindigkeit) berücksichtigt werden. Ein Betrieb ohne Schutzrohr ist nur in speziellen Fällen zweckmäßig. Der auswechselbare, zentrisch gefederte Messeinsatz und sein erweiterter Federweg ermöglichen die Kombination mit den

verschiedensten Anschlusskopfvarianten.

Reparaturen sowie bauliche Veränderungen sind nicht zulässig und führen zur Erlöschung

der Garantie und der jeweiligen Zulassung. Bauliche Veränderungen nach Auslieferung der

Geräte obliegen nicht in der Verantwortung des Herstellers.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

3. Sicherheit

Page 35

DE

WIKA Betriebsanleitung Typen TR12, TC12

35

14064370.02 08/2018 EN/DE/FR/ES

3.3 Verantwortung des Betreibers

Die Verantwortung für die Auswahl des Thermometers bzw. Schutzrohres, sowie für

deren Werkstoffauswahl zur Gewährleistung einer sicheren Funktion in der Anlage bzw.

Maschine obliegt dem Betreiber. WIKA kann während der Angebotserstellung lediglich

Empfehlungen aussprechen, die sich an unseren Erfahrungen in ähnlichen Applikationen

orientieren.

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den Einsatzbereich des

Gerätes gültigen Sicherheits-, Unfallverhütungs- und Umweltschutzvorschriften einhalten.

Der Betreiber ist verpflichtet das Typenschild lesbar zu halten.

3.4 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Elektrofachpersonal nachfolgend beschriebener Qualifikation durchführen

lassen.

Elektrofachpersonal

Das Elektrofachpersonal ist aufgrund seiner fachlichen Ausbildung, Kenntnisse und Erfahrungen sowie Kenntnis der landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der Lage, Arbeiten an elektrischen Anlagen auszuführen und mögliche Gefahren

selbstständig zu erkennen und zu vermeiden. Das Elektrofachpersonal ist speziell für

das Arbeitsumfeld, in dem es tätig ist, ausgebildet und kennt die relevanten Normen und

Bestimmungen. Das Elektrofachpersonal muss die Bestimmungen der geltenden gesetzlichen Vorschriften zur Unfallverhütung erfüllen.

Bedienpersonal

Das vom Betreiber geschulte Personal ist aufgrund seiner Bildung, Kenntnisse und

Erfahrungen in der Lage, die beschriebenen Arbeiten auszuführen und mögliche Gefahren

selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

3. Sicherheit

Page 36

DE

WIKA Betriebsanleitung Typen TR12, TC12

36

14064370.02 08/2018 EN/DE/FR/ES

3.5 Beschilderung, Sicherheitskennzeichnungen

Typenschild (Beispiel)

Typ

A = Messeinsatz

B = Prozess-Thermometer

M = Basismodul

Seriennummer

Zulassungsrelevante Daten

Herstellungsjahr

■

Angaben zur Ausführung (Messelement, Messbereich...)

Sensor gemäß Norm (Widerstandsthermometer)

- F =

Dünnfilm-Messwiderstand

- W = Drahtgewickelter Messwiderstand

Sensor gemäß Norm (Thermoelement)

- ungrounded = isoliert verschweißt

- grounded = mit dem Mantel verschweißt (geerdet)

- quasi geerdet = Das Thermometer ist, aufgrund geringer Isolationsabstände zwischen

Widerstandssensor und Mantel, als geerdet zu betrachten.

■

Transmittertyp (nur bei Ausführung mit Transmitter)

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

TR12-M-IDBZ

1 x Pt100 / A / 3 (F) -50 ... +500 °C

Um = DC 30 V / Pm = 2 W

BVS 07 ATEX E 071 X

IECEx BVS 11.0042X

II 2 G Ex db IIC T* Gb

EN 60751

0158

WIKA Alexander Wiegand SE & Co.KG, D-63911 Klingenberg

Made in Germany 2013

WARNING: DO NOT OPEN WHILE ENERGIZED!

11012345

3. Sicherheit

Page 37

DE

WIKA Betriebsanleitung Typen TR12, TC12

37

14064370.02 08/2018 EN/DE/FR/ES

4. Transport, Verpackung und Lagerung

4.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Beschädigungen durch unsachgemäßen Transport

Bei unsachgemäßem Transport können Sachschäden in erheblicher Höhe

entstehen.

▶

Beim Abladen der Packstücke bei Anlieferung sowie innerbetrieblichem

Transport vorsichtig vorgehen und die Symbole auf der Verpackung beachten.

▶

Bei innerbetrieblichem Transport die Hinweise unter Kapitel 4.2 „Verpackung und Lagerung“ beachten.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur:

Geräte ohne eingebauten Transmitter: -40 ... +80 °C

Geräte mit eingebautem Transmitter: siehe Betriebsanleitung des entsprechenden

Transmitters

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (nicht kondensierend)

Folgende Einflüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort lagern, der die oben gelisteten Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät wie folgt

verpacken und lagern:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

2. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

4. Transport, Verpackung und Lagerung

Page 38

DE

WIKA Betriebsanleitung Typen TR12, TC12

38

14064370.02 08/2018 EN/DE/FR/ES

5. Inbetriebnahme, Betrieb

WARNUNG!

Beschädigung des Messgeräts durch Unter- oder Überschreiten der

zulässigen Betriebstemperatur

Bei Missachtung der zulässigen Betriebstemperatur, auch unter Berücksichtigung von Konvektion und Wärmestrahlung, kann das Thermometer bereits

während der Montage beschädigt werden.

▶

Spezifizierter Betriebstemperaturbereich nicht unter- oder überschreiten.

Bei der Montage beachten

■

Wegfließen des Kabelmantels bei fest angezogener Druckschraube vermeiden.

■

Übermäßig tiefe Einschneidungen im Kabelmantel vermeiden.

■

Geeignete Kabel verwenden.

■

Klemmbereich der Kabelverschraubung beachten.

■

Thermometer müssen geerdet sein, wenn an den Anschlussdrähten mit gefährlichen

Spannungen zu rechnen ist (hervorgerufen durch z. B. mechanische Beschädigung,

elektrostatische Aufladung oder Induktion)!

■

Schutzart ist bei armierten Kabel (VA-Geflecht) nicht gegeben.

■

Dichtungen auf Versprödungen überprüfen und ggf. ersetzen.

5.1 Aus- und Einbau des Messeinsatzes

Die Anschlusslitzen haben einen Querschnitt von ca. 0,22 mm², sind 150 mm lang und

sind je nach Sensortyp farblich gekennzeichnet. Der Messeinsatz ist gegen Verdrehen

gesichert.

Vor dem Ausbau des Messeinsatzes die elektrischen

Verbindungen zum Anschlusssockel oder Transmitter

vollständig lösen.

Danach kann das Halsrohr vom Kopf gelöst und herausgeschraubt werden.

5. Inbetriebnahme, Betrieb

Page 39

DE

WIKA Betriebsanleitung Typen TR12, TC12

39

14064370.02 08/2018 EN/DE/FR/ES

Ausgebauter Messeinsatz mit Halsrohr:

Zum Ausbau des Messeinsatzes

aus dem Halsrohr die M16-Schraube am oberen Ende des Halsrohres

lösen und herausschrauben.

5. Inbetriebnahme, Betrieb

Page 40

DE

WIKA Betriebsanleitung Typen TR12, TC12

40

14064370.02 08/2018 EN/DE/FR/ES

Der Einbau des Messeinsatzes wird in umgekehrter

Reihenfolge vorgenommen (Messeinsatz vor der

Montage reinigen).

Das sechseckig gecrimpte Ende des Messeinsatzes

wird beim Einschrauben der Innensechskantschraube

geführt.

Anzugsdrehmoment der Schraube: 12 ... 14 Nm

5.2 Elektrische Montage

Kabelverschraubungen

Voraussetzungen zur Erreichung der Schutzart:

■

Kabelverschraubung nur im angegebenen Klemmbereich (Kabeldurchmesser passend

zur Kabelverschraubung) verwenden.

■

Bei Verwendung sehr weicher Kabeltypen nicht den unteren Klemmbereich verwenden.

■

Nur Rundkabel verwenden (ggf. leicht ovaler Querschnitt).

■

Kabel nicht verdrillen.

■

Mehrmaliges Öffnen/Schließen möglich; hat ggf. jedoch negative Auswirkung auf die

Schutzart

■

Bei Kabeln mit ausgeprägtem Kaltfließverhalten Verschraubung nachziehen.

5.3 Elektrischer Anschluss

VORSICHT!

Kurzschlussgefahr

Beschädigung an Kabeln und Leitungen, sowie Verbindungsstellen können

zu Fehlfunktion des Geräts führen.

▶

Beschädigungen an Kabeln und Leitungen vermeiden.

▶

Feindrähtige Leiterenden mit Aderendhülsen versehen (Kabelkonfektionierung).

▶

Innere wirksame Kapazität und Induktivität beachten.

Elektrischen Anschluss gemäß nachfolgend aufgezeigter Sensoranschlüsse/Klemmenbelegungen durchführen.

5. Inbetriebnahme, Betrieb

Page 41

DE

WIKA Betriebsanleitung Typen TR12, TC12

41

14064370.02 08/2018 EN/DE/FR/ES

5.3.1 Widerstandsthermometer

■

Mit Anschlusssockel

■

Mit Anschlusskabel

3160629.06

rot

1 x Pt100, 2-Leiter 1 x Pt100, 3-Leiter 1 x Pt100, 4-Leiter

weiß weiß

rot

rot

rot

rot

weiß

weiß

weiß

weiß

weiß

weiß

rot

rot

rot

rot

rot

2 x Pt100, 2-Leiter

2 x Pt100, 3-Leiter

2 x Pt100, 4-Leiter

rot

weiß

weiß

rot

rot

weiß

schwarz

gelb

gelb

gelb

schwarz

schwarz

weiß

weiß

rot

rot

rot

rot

schwarz

schwarz

schwarz

schwarz

gelb

gelb

gelb

rot

weiß

schwarz

gelb

weiß

1 x Pt100

2-Leiter

1 x Pt100

3-Leiter

1 x Pt100

4-Leiter

2 x Pt100

2-Leiter

2 x Pt100

3-Leiter

rot

rot

rot

rot

rot

rot

rot

rot

weiß

weiß

weiß

weiß

weiß

weiß

schwarz

schwarz

schwarz

gelb

gelb

3160629.06

5. Inbetriebnahme, Betrieb

Page 42

DE

WIKA Betriebsanleitung Typen TR12, TC12

42

14064370.02 08/2018 EN/DE/FR/ES

5.3.2 Thermoelemente

■

Mit Anschlusssockel

■

Mit Anschlusskabel

Farbkennzeichnung der Kabellitzen

Sensortyp Norm Plus-Pol Minus-Pol

K IEC 60584 Grün Weiß

J IEC 60584 Schwarz Weiß

E IEC 60584 Violett Weiß

N IEC 60584 Rosa Weiß

Variante 1

Die elektrischen Daten (z. B. Anschlussschaltbilder, Grenzabweichungen etc.) siehe

Kapitel 6.1 „Elektrischer Anschluss“ bzw. Datenblatt TE 60.17 (für TR12) und TE 65.17 (für

TC12).

Variante 2

Die elektrischen Daten (z. B. Anschlussschaltbilder, Grenzabweichungen etc.) der jeweiligen Betriebsanleitung bzw. dem jeweiligen Datenblatt des eingebauten Kopftransmitters

entnehmen.

Variante 3

Die elektrischen Daten (z. B. Anschlussschaltbilder, Grenzabweichungen etc.) der jeweiligen Betriebsanleitung bzw. dem jeweiligen Datenblatt des angebauten Feldtransmitters

entnehmen.

Einfach-Thermoelement Doppel-Thermoelement

Für die Zuordnung

Polarität - Klemme

gilt die farbliche

Kennzeichnung der

Plus-Pole am Gerät

3166822.03

3171966.01

Einfach-Thermoelement Doppel-Thermoelement

5. Inbetriebnahme, Betrieb

Page 43

DE

WIKA Betriebsanleitung Typen TR12, TC12

43

14064370.02 08/2018 EN/DE/FR/ES

Variante 1 und 2

■

Verbindung zwischen Kabelverschraubung und Anschlusskopf

Gewinde M20 x 1,5: Anzugsdrehmomente 12 Nm

Gewinde ½ NPT: Anzugsdrehmomente 30 Nm

■

Verbindung zwischen Kabel und Kabelverschraubung

Die Druckschraube fest in das Zwischenstück einschrauben (geeignete Werkzeuge

verwenden!)

6. Störungen

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Können Störungen mit Hilfe der aufgeführten Maßnahmen nicht beseitigt

werden, Gerät unverzüglich außer Betrieb setzen.

▶

Sicherstellen, dass kein Signal mehr anliegt und gegen versehentliche

Inbetriebnahme schützen.

▶

Kontakt mit dem Hersteller aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel 8.2 „Rücksendung“ beachten.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

Messstoffe

Bei Kontakt mit gefährlichen Messstoffen (z. B. Sauerstoff, Acetylen, brennbaren oder giftigen Stoffen), gesundheitsgefährdenden Messstoffen (z. B. ätzend,

giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen, Kompressoren

besteht die Gefahr von Körperverletzungen, Sach- und Umweltschäden.

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur

und unter hohem Druck oder Vakuum anliegen.

▶

Bei diesen Messstoffen müssen über die gesamten allgemeinen Regeln

hinaus die einschlägigen Vorschriften beachtet werden.

▶

Notwendige Schutzausrüstung tragen (abhängig von der jeweiligen Applikation; Das Thermometer selbst ist prinzipiell ungefährlich.).

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der Betriebsanleitung.

5. Inbetriebnahme, Betrieb / 6. Störungen

Page 44

DE

WIKA Betriebsanleitung Typen TR12, TC12

44

14064370.02 08/2018 EN/DE/FR/ES

Störungen Ursachen Maßnahmen

Kein Signal/

Leitungsbruch

Zu hohe mechanische Belastung

oder Übertemperatur

Fühler oder Messeinsatz durch eine

geeignete Ausführung ersetzen

Fehlerhafte

Messwerte

Sensordrift durch Übertemperatur Fühler oder Messeinsatz durch eine

geeignete Ausführung ersetzen

Sensordrift durch chemischen

Angriff

Geeignetes Schutzrohr verwenden

Fehlerhafte

Messwerte (zu gering)

Feuchtigkeitseintritt an Kabel

oder Messeinsatz

Fühler oder Messeinsatz durch eine

geeignete Ausführung ersetzen

Fehlerhafte

Messwerte und zu

lange Ansprechzeiten

Falsche Einbaugeometrie, z. B.

zu geringe Einbautiefe oder zu

hohe Wärmeableitung

Der temperaturempfindliche Bereich

des Sensors muss innerhalb des

Mediums liegen, Oberflächenmessungen müssen isoliert sein

Ablagerungen auf dem Sensor

oder Schutzrohr

Ablagerungen entfernen

Fehlerhafte

Messwerte (bei

Thermoelementen)

Parasitäre Spannungen

(Thermospannungen, galvanische Spannung) oder falsche

Ausgleichsleitung

Geeignete Ausgleichsleitung

verwenden

Zeitweise oder sporadische Unterbrechungen des Messwertsignals

Leitungsbruch im Anschlusskabel oder Wackelkontakt durch

mechanische Überbelastung

Fühler oder Messeinsatz durch eine

geeignete Ausführung ersetzen z. B.

mit Knickschutzfeder oder dickerem

Leitungsquerschnitt

Korrosion Zusammensetzung des Mediums

nicht wie angenommen oder

geändert oder falsches Schutzrohrmaterial gewählt

Medium analysieren und danach

besser geeignetes Material wählen

oder Schutzrohr regelmäßig

erneuern

Signal gestört Einstreuung durch elektrische

Felder oder Erdschleifen

Geschirmte Anschlussleitungen

verwenden, Abstand zu Motoren

und leistungsführenden Leitungen

erhöhen

Erdschleifen Potentiale beseitigen, galvanisch

getrennte Trennbarrieren oder Transmitter verwenden

6. Störungen

Page 45

DE

WIKA Betriebsanleitung Typen TR12, TC12

45

14064370.02 08/2018 EN/DE/FR/ES

7. Wartung, Reinigung und Kalibrierung

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der

Betriebsanleitung.

7.1 Wartung

Die hier beschriebenen Thermometer sind wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

7.2 Reinigung

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Eine unsachgemäße Reinigung führt zu Körperverletzungen, Sach- und

Umweltschäden. Messstoffreste im ausgebauten Gerät können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Reinigungsvorgang wie folgt beschrieben durchführen.

1. Vor der Reinigung die elektrischen Verbindungen ordnungsgemäß trennen.

2. Notwendige Schutzausrüstung verwenden (abhängig von der jeweiligen Applikation; Das

Thermometer selbst ist prinzipiell ungefährlich).

3. Das Gerät mit einem feuchten Tuch reinigen.

Dies gilt insbesondere für Thermometer mit Gehäusen aus Kunststoff um die Gefahr von

elektrostatischen Aufladungen zu vermeiden.

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen!

VORSICHT!

Beschädigung des Gerätes

Eine unsachgemäße Reinigung führt zur Beschädigung des Gerätes!

▶

Keine aggressiven Reinigungmittel verwenden.

▶

Keine harten und spitzen Gegenstände zur Reinigung verwenden.

4. Ausgebautes Gerät spülen bzw. säubern, um Personen und Umwelt vor Gefährdung

durch anhaftende Messstoffreste zu schützen.

7.3 Kalibrierung, Rekalibrierung

Es wird empfohlen, den Messeinsatz in regelmäßigen Zeitabständen zu rekalibrieren

(Widerstandsthermometer: ca. 24 Monate, Thermoelemente: ca. 12 Monate). Dieser

Zeitraum verringert sich abhängig vom Einsatzfall. Die Kalibrierung kann durch den

Hersteller sowie mit Kalibriergeräten vor Ort durch qualifiziertes Fachpersonal erfolgen.

7. Wartung, Reinigung und Kalibrierung

Page 46

DE

WIKA Betriebsanleitung Typen TR12, TC12

46

14064370.02 08/2018 EN/DE/FR/ES

8. Demontage, Rücksendung und Entsorgung

8.1 Demontage

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch Messstoffreste

Bei Kontakt mit gefährlichen Messstoffen (z. B. Sauerstoff, Acetylen, brennbaren oder giftigen Stoffen), gesundheitsgefährdenden Messstoffen (z. B. ätzend,

giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen, Kompressoren

besteht die Gefahr von Körperverletzungen, Sach- und Umweltschäden.

▶

Vor der Einlagerung das ausgebaute Gerät (nach Betrieb) spülen bzw.

säubern, um Personen und Umwelt vor Gefährdung durch anhaftende

Messstoffreste zu schützen.

▶

Notwendige Schutzausrüstung verwenden (abhängig von der jeweiligen

Applikation; Das Thermometer selbst ist prinzipiell ungefährlich.).

▶

Angaben im Sicherheitsdatenblatt für den entsprechenden Messstoff

beachten.

Thermometer nur im drucklosen Zustand demontieren.

WARNUNG!

Verbrennungsgefahr

Beim Ausbau besteht Gefahr durch austretende, gefährlich heiße Messstoffe.

▶

Vor dem Ausbau das Gerät ausreichend abkühlen lassen!

8.2 Rücksendung

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoffen (Säuren, Laugen, Lösungen, etc.) sein und sind daher vor der Rücksendung zu reinigen.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch Messstoffreste

Messstoffreste im ausgebauten Gerät können zur Gefährdung von Personen,

Umwelt und Einrichtung führen.

▶

Bei Gefahrenstoffen das Sicherheitsdatenblatt für den entsprechenden

Messstoff beilegen.

▶

Gerät reinigen, siehe Kapitel 7.2 „Reinigung“.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

2. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

3. Sendung als Transport eines hochempfindlichen Messgerätes kennzeichnen.

8. Demontage, Rücksendung und Entsorgung

Page 47

DE

WIKA Betriebsanleitung Typen TR12, TC12

47

14064370.02 08/2018 EN/DE/FR/ES

Hinweise zur Rücksendung befinden sich in der Rubrik „Service“ auf unserer

lokalen Internetseite.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezifischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

Nicht mit dem Hausmüll entsorgen. Für eine geordnete Entsorgung gemäß

nationaler Vorgaben sorgen.

9. Technische Daten

9.1 Typen TR12-A, TR12-M

Ausgangssignal Pt100

Temperaturbereich Messbereich -200 ... +600 °C

Messelement

(Messstrom: 0,1 ... 1,0 mA)

1)

Pt100-Messwiderstand

Schaltungsart 1 x 2-Leiter, 1 x 3-Leiter, 1 x 4-Leiter, 2 x 2-Leiter, 2 x 3-Leiter,

2 x 4-Leiter

2)

Grenzabweichung des

Messelementes nach

EN 60751

Klasse B

Klasse A

Klasse AA

Drahtgewickelt Dünnfilm

-200 ... +600 °C

-100 ... +450 °C

-50 ... +250 °C

-50 ... +500 °C

-30 ... +300 °C

0 ... 150 °C

Messeinsatz (auswechselbar)

Werkstoff CrNi-Stahl 1.4571, 316/316L

Durchmesser Standard: 3 mm

3)

, 6 mm, 8 mm (mit Hülse)

Option (auf Anfrage): 1/8" 3) (3,17 mm), 1/4" (6,35 mm), 3/8" (9,53 mm)

Federweg ca. 20 mm

Ansprechzeit (in Wasser,

nach EN 60751)

t

50

< 10 s t90 < 20 s (Messeinsatzdurchmesser 6 mm: Das zum

Betrieb notwendige Schutzrohr erhöht die Ansprechzeit abhängig von

den tatsächlichen Schutzrohr- und Prozessparametern.)

Widerstandsthermometer mit geschirmter Leitung betreiben und den Schirm auf mindestens einer Leitungsseite erden,

wenn die Leitungen länger als 30 m sind oder das Gebäude verlassen. Bei der Ermittlung der Gesamtmessabweichung

sowohl die Sensor- als auch die Transmittermessabweichung berücksichtigen.

1) Detaillierte Angaben zu Pt100-Sensoren siehe Technische Information IN 00.17 unter www.wika.de.

2) Nicht bei Durchmesser 3 mm

3) Nicht bei Schaltungsart 2 x 4-Leiter

8. Demontage, Rücksendung ... / 9. Technische Daten

Page 48

DE

WIKA Betriebsanleitung Typen TR12, TC12

48

14064370.02 08/2018 EN/DE/FR/ES

Halsrohr (nur Typ TR12-M)

Werkstoff CrNi-Stahl 1.4571, 316/316L

Anschlussgewinde zum

Schutzrohr

G 1/2 B, G 3/4 B, 1/2 NPT, 3/4 NPT, M14 x 1,5, M18 x 1,5, M20 x 1,5,

M27 x 2

Anschlussgewinde zum

Kopf

■

M20 x 1,5 mit Kontermutter

■

M24 x 1,5 mit Kontermutter

■

1/2 NPT

■

3/4 NPT

Halslänge

■

min. 150 mm, Standardhalslänge

■

200 mm

■

250 mm

andere Halslängen auf Anfrage

Umgebungsbedingungen

Umgebungs- und

Lagertemperatur

-60

4)

/ -40 ... +80 °C

Schutzart IP00 nach IEC/EN 60529

Vibrationsfestigkeit

■

6 g Spitze-Spitze, Messwiderstand drahtgewickelt oder Dünnfilm (Standard)

■

20 g Spitze-Spitze, Messwiderstand Dünnfilm (Option)

■

50 g Spitze-Spitze, Messwiderstand Dünnfilm (Option)

5)

4) Sonderausführung auf Anfrage (nur mit ausgewählten Zulassungen verfügbar), andere Umgebungs- und Lagertemperatur

auf Anfrage