Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Resistance thermometers and thermocouples

Widerstandsthermometer und Thermoelemente

Sondes à résistance et thermocouples

Termorresistencias y termopares

GB

D

F

E

Examples/Beispiele/Exemples/Ejemplos

Page 2

Operating Instructions models TR and TC

GB

D

Betriebsanleitung Typen TR und TC

F

Mode d'emploi types TR et TC

E

Manual de Instrucciones modelos TR y TC

Page 3 - 18

Seite 19 - 34

Page 35 - 50

Página 51 - 66

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions resistance thermometers, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

4. Design and function 10

5. Transport, packaging and storage 11

6. Commissioning, operation 11

GB

Maintenance and cleaning

7.

8. Faults 17

9. Dismounting, return and disposal 18

16

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

3

Page 4

1. General information

1. General Information

■

The instrument described in the operating instructions has been manufactured using state-ofthe-art technology. All components are subject to stringent quality and environmental criteria

GB

during production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working

safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for

the instrument's range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity

of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions, prior to

beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instructions, assignment of

insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address:

- Application consultant:

www.wika.de / www.wika.com

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation, which can result in serious injury or

death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can result in light injuries or

damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and trouble-

free operation.

DANGER!

...identies hazards caused by electric power. Should the safety instructions not be

observed, there is a risk of serious or fatal injury.

4

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

Page 5

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

thermometer has been selected in terms of measuring range, design and specic

measuring conditions.

Choose the thermowell with regard to the maximum pressure and temperature (e.g.

table of contact ratings in DIN 43772).

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual chapters of these

operating instructions.

2.1 Intended use

These resistance thermometers and thermocouples are used for temperature measurement in

industrial applications.

The instrument has been designed and built solely for the intended use described here, and may

only be used accordingly.

The technical specications contained in these operating instructions must be observed. Improper

handling or operation of the instrument outside of its technical specications requires the

instrument to be shut down immediately and inspected by an authorised WIKA service engineer.

GB

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in the instrument malfunctioning. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in these operating instructions may only be carried out by

skilled personnel who have the qualications described below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specic regulations, current standards and directives, are capable of carrying out the

work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

5

Page 6

2. Safety

2.3 Special hazards

GB

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases or liquids,

and refrigeration plants, compressors, etc., in addition to all standard regulations, the

appropriate existing codes or regulations must also be followed.

WARNING!

Protection from electrostatic discharge (ESD) required. The proper use of grounded

work surfaces and personal wrist straps is required when working with exposed

circuitry (printed circuit boards), in order to to prevent static discharge from damaging

sensitive electronic components.

To ensure safe working on the instrument, the operating company must ensure

■

that suitable rst-aid equipment is available and aid is provided whenever required.

■

that the operating personnel are regularly instructed in all topics regarding work

safety, rst aid and environmental protection and knows the operating instructions

and, in particular, the safety instructions contained therein.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

■

Electrical instruments may only be installed and mounted by skilled electrical

personnel.

■

Operation using a defective power supply unit (e.g. short circuit from the mains

voltage to the output voltage) may result in life-threatening voltages at the

instrument!

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the environ-

ment and equipment. Take sucient precautionary measures.

Do not use this instrument in safety or Emergency Stop devices. Incorrect use of the

instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature and under

high pressure or vacuum may be present at the instrument.

11208287.06 10/2013 GB/D/F/E

6

WIKA operating instructions resistance thermometers, thermocouples

Page 7

2. Safety

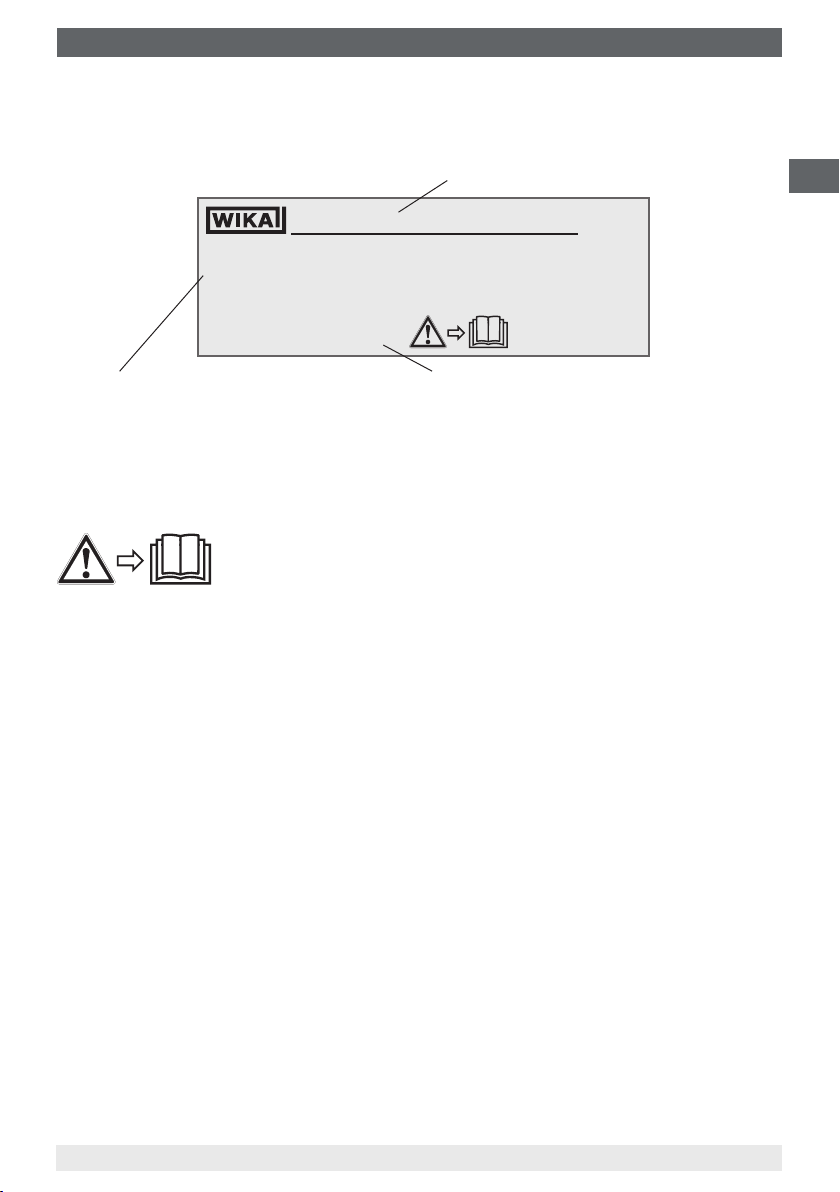

2.4 Labelling, safety marks

Product labels for resistance thermometers (example)

1 x Pt100 / A / 3 (F) -50 ... +250 °C

Made in Germany 2013

Sensor in accordance with standard

■

F Thin-lm resistor

■

W Wire-wound resistor

Explanation of symbols

Before mounting and commissioning the instrument, make sure you read

the operating instructions!

TR10-B

Model

11012345

EN 60751

Year of manufacture

GB

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

7

Page 8

3. Specications

3. Specications

3.1 Resistance thermometer

GB

Sensor connection method

■

2-wire

■

3-wire

■

4-wire

Sensor tolerance value per DIN EN 60751

■

Class B

■

Class A

■

Class AA

The combinations of a 2-wire connection with class A or class AA are not permissible, since the

lead resistance of the measuring insert negates the higher sensor accuracy.

Basic values and tolerance values

Basic values and tolerance values for the platinum measurement resistances are laid down in

DIN EN 60751.

The nominal value of Pt100 sensors is 100 Ω at 0 °C. The temperature coecient α can be stated

simply to be between 0 °C and 100 °C with:

-3

-1

α = 3.85 ∙ 10

The relationship between temperature and electrical resistance is described by polynomials,

which are also dened in DIN EN 60751. Moreover, this standard species the basic values in

°C steps in tabular form. Moreover, this standard species the basic values in °C steps in tabular

form.

Class

B -196 … +600 °C -50 … +500 °C ±(0.30 + 0.0050 | t |)

A -100 … +450 °C -30 … +300 °C ±(0.15 + 0.0020 | t |)

AA -50 … +250 °C 0 … 150 °C ±(0.10 + 0.0017 | t |)

Temperature range

Wire-wound (W) Thin-lm (F)

°C

Tolerance value in °C

1)

1)

1)

1) | t | is the value of the temperature in °C without consideration of the sign.

Bold: Standard version

For further technical information, see WIKA data sheet and the technical information sheet

IN 00.17 “Usage limitations and accuracies of platinum resistance thermometers per

EN 60751: 2008”.

8

WIKA operating instructions resistance thermometers, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 9

3. Specications

3.2 Thermocouples

3.2.1 Sensor types

Model

K 1,200 °C

J 800 °C

E 800 °C

N 1,200 °C

3.2.2 Potential measurement uncertainties

Important factors which counteract the long-term stability of thermocouples.

Ageing eects/poisoning

■

Oxidation processes in thermocouples which are not appropriately protected (“bare”

thermocouple wires) result in falsications of the characteristic curves.

■

Foreign atoms (poisoning) that diuse into the original alloys lead to changes of these original

alloys and thus falsify the characteristic curve.

■

The inuence of hydrogen leads to the embrittlement of the thermocouples.

The Ni leg of the type K thermocouple is often damaged by sulphur which is contained in exhaust

gases, for example. Thermocouple types J and T age slightly, as the pure metal leg oxidises rst.

In general, rising temperatures cause accelerated ageing eects.

Green rot

If type K thermocouples are used at temperatures from approx. 800 °C to 1,050 °C, considerable

changes of the thermoelectric voltage can occur. The cause of this is a chromium depletion or

the chrome oxidation in the NiCr leg (+ leg). The precondition for this is a low concentration of

oxygen or steam in the immediate environment of the thermocouple. The nickel leg is not aected

by it. The consequence of this eect is a drift of the measured value caused by decreasing

thermoelectric voltage. This eect is accelerated if there is a shortage of oxygen (reducing

atmosphere), since a complete oxide layer, which would protect it from further oxidation of the

chromium, cannot be formed on the surface of the thermocouple.

Recommended max. operating temperature

GB

The thermocouple is permanently destroyed by this process. The name green rot is derived from

the greenish shimmering colouration on the breaking point of the wire.

The thermocouple type N has in this regard an advantage due to its silicium content. Here, a

protective oxide layer forms on its surface under the same conditions.

K eect

The NiCr leg of a type K thermocouple has an ordered alignment with respect to the alignment

in the crystal lattice below approx. 400 °C. If the thermocouple is heated further, a transition to

a disordered state occurs in the temperature range between approx. 400 °C and 600 °C. Above

600 °C, an ordered crystal lattice is restored.

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

9

Page 10

3. Specications / 4. Design and function

If these thermocouples cool too quickly (quicker than approx. 100 °C per hour), the undesirable

disordered crystal lattice occurs again during cooling in the range from approx. 600 °C to

approx. 400 °C. In the characteristic curve of type K, however, a consistently ordered alignment

state is assumed and provided with values. This results in a fault of thermoelectric voltage of up

GB

to approx. 0.8 mV (approx. 5 °C) in this range. The K eect is reversible and is largely eliminated

again by annealing above 700 °C, followed by correspondingly slow cooling.

Thin sheathed thermocouples are particularly sensitive in this respect. Cooling in resting air can

already lead to deviations of 1 K.

In type N thermocouple, it has been possible to reduce this short-range-order eect by alloying

both legs with silicium.

The application range of these thermometers is limited both by the permissible maximum

temperature of the thermocouple and by the max. temperature of the thermowell material.

Listed models are available both as single or dual thermocouples. The thermocouple will be

delivered with an insulated measuring point, unless explicitly specied otherwise.

Tolerance value

For the tolerance value of thermocouples, a cold junction temperature of 0 °C has been taken as

the basis. When using a compensating cable or thermocouple cable, an additional measuring

error must be considered.

For limiting deviations and further specications, see the corresponding WIKA data sheet and

technical information sheet IN 00.23, “Application of thermocouples”.

4. Design and function

4.1 Description

These thermometers (resistance thermometers and thermocouples) detect temperatures in

processes. These thermometers are suitable, depending on the version, for low, medium and high

process requirements.

They can be assembled as cable probes or as thermometers with a connection head. Optionally,

a temperature transmitter can be built into the connection head. For this temperature transmitter,

separate operating instructions will be enclosed.

Certain thermometer versions can be combined with a large number of thermowell designs.

Operation of these thermometers without a thermowell is only appropriate in special cases.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

10

WIKA operating instructions resistance thermometers, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 11

5. Transport, packaging and storage / 6. Commissioning, operation

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused by transport. Obvious damage

must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature:

Instruments without built-in transmitter: -40 ... +85 °C

Instruments with built-in transmitter: see operating instructions of the corresponding

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

transmitter

GB

Store the instrument in its original packaging in a location that fullls the conditions listed above. If

the original packaging is not available, pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual media. This

is of particular importance if the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

6. Commissioning, operation

WARNING!

When the thermometer is mounted, the temperature must not drop below the allowed

operating temperature (environment, medium) or exceed it, even when taking

convection and heat radiation into account!

WARNING!

Thermometers must be earthed if dangerous voltages could be expected at the

connection wires (caused, for example, by mechanical damage, electrostatic

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

discharge or induction)!

11

Page 12

6. Commissioning, operation

6.1 Electrical connection

CAUTION!

■

Damage to cables and wires, and to connection points must be avoided

GB

The electrical connection is to be made according to the sensor connections/pin assignments

shown below:

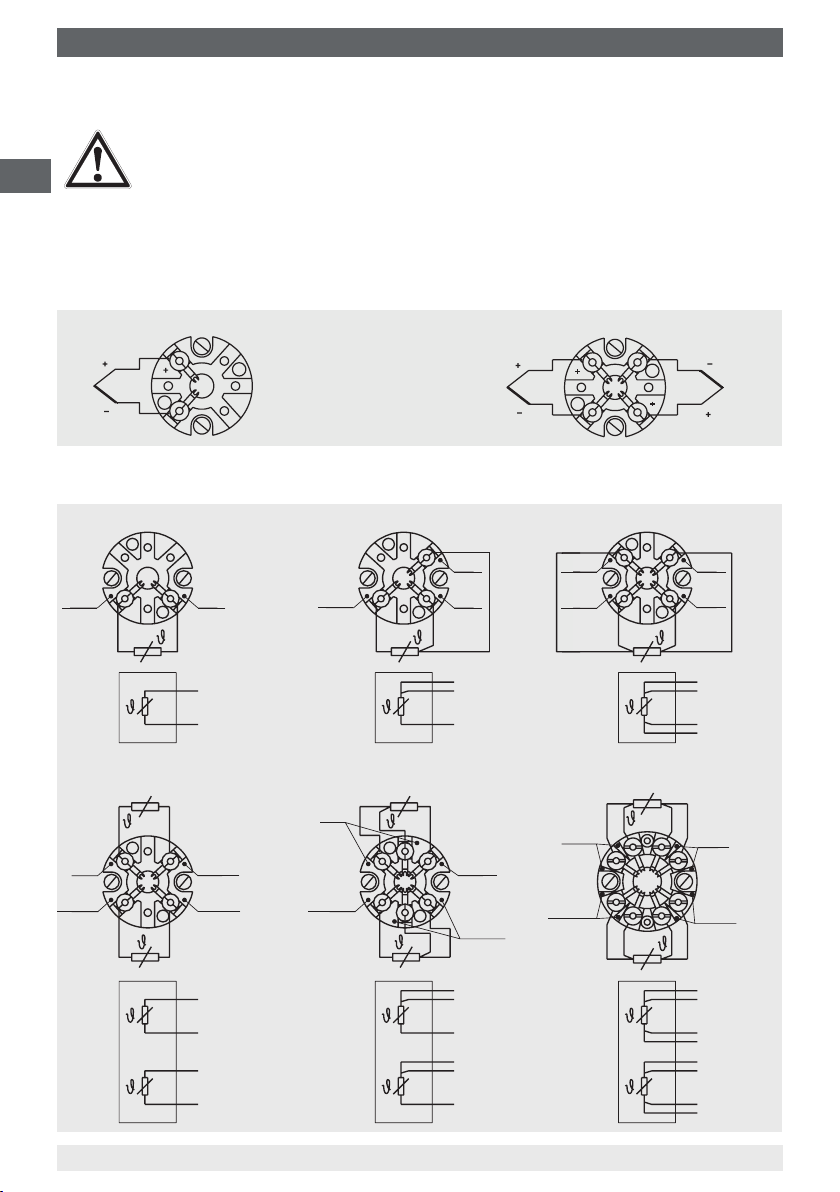

Thermocouples with terminal block

Resistance thermometers with terminal block

1 x Pt100, 2-wire 1 x Pt100, 3-wire 1 x Pt100, 4-wire

■

Flying leads with bare ends must be nished with ferrule ends (cable preparation)

■

Both the internal capacitance and inductance must be considered

Single thermocouple

The colour coding at the

positive connection to the

devices always decides the

correlation of polarity and

connection terminal.

Dual thermocouple

white

red

red

white

white

2 x Pt100, 2-wire 2 x Pt100, 3-wire

red

red

yellow

12

white

black

red

white

black

yellow

yellow

WIKA operating instructions resistance thermometers, thermocouples

red

red

red

red

white

white

black

red

red

white

black

black

yellow

white

white

2 x Pt100, 4-wire

white

yellow

red

red

red

red

white

white

red

black

red

red

white

white

black

black

yellow

yellow

3160629.06

11208287.06 10/2013 GB/D/F/E

Page 13

6. Commissioning, operation

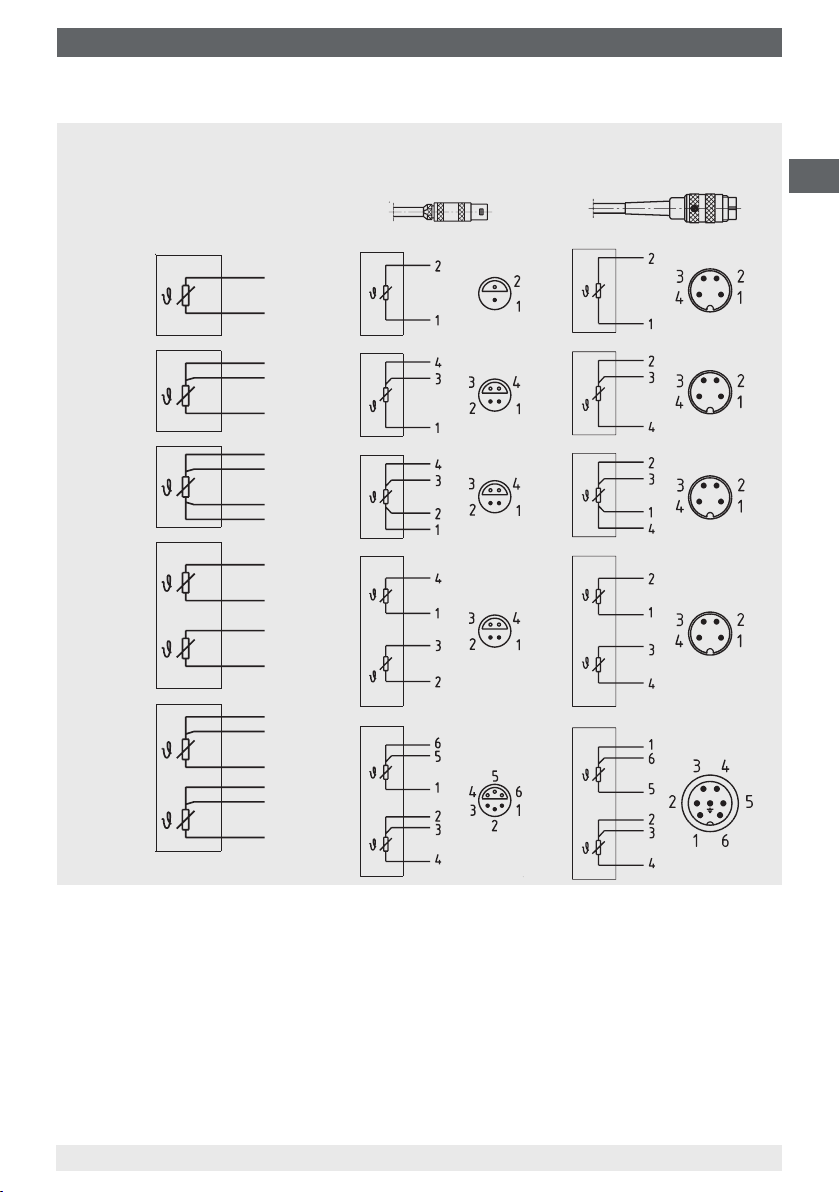

Resistance thermometers with cable connection or male connector

1 x Pt100

2-wire

1 x Pt100

3-wire

1 x Pt100

4-wire

2 x Pt100

2-wire

2 x Pt100

3-wire

Cable

red

white

red

red

white

red

red

white

white

red

white

black

yellow

red

red

white

black

black

Lemosa connector,

(male) on cable

Binder male connector,

tted to cable

GB

yellow

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

13

Page 14

6. Commissioning, operation

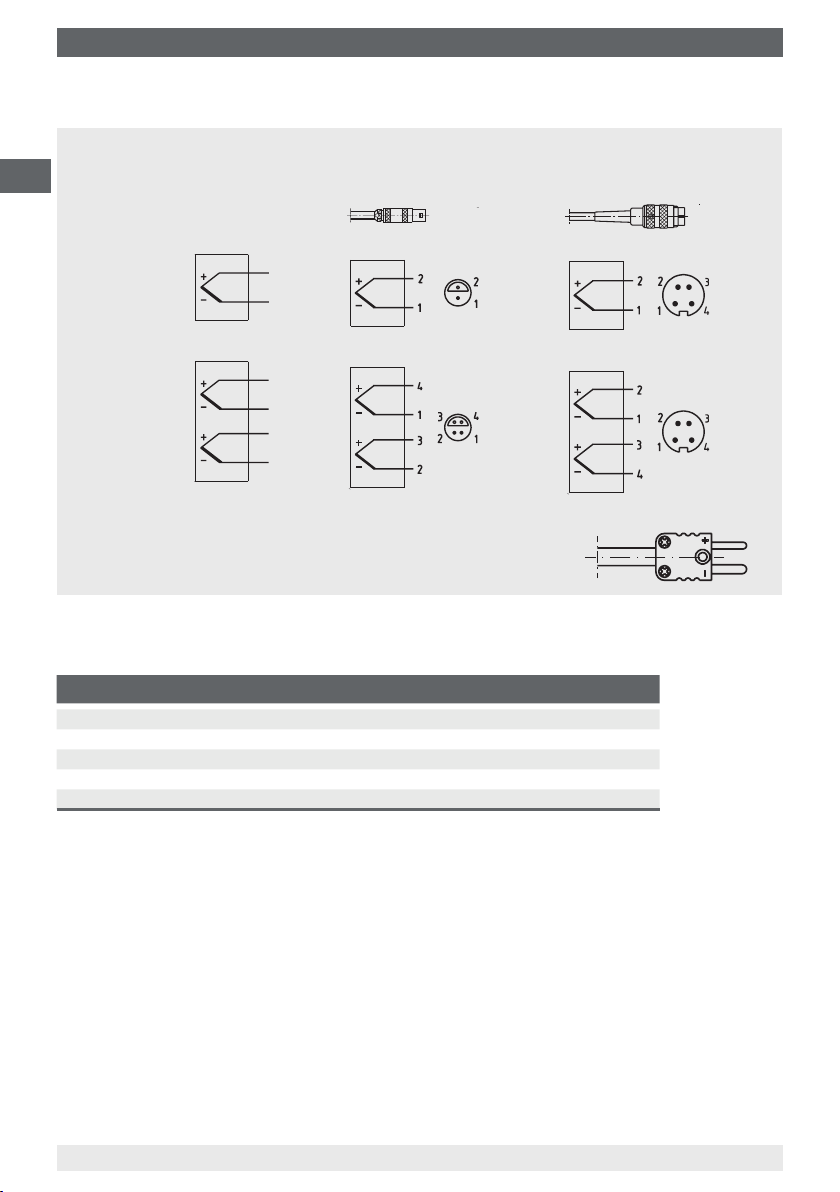

Thermocouples with cable connection or male connector

GB

Single

thermocouple

Dual

thermocouple

Thermo connector

Cable

Colour coding of

the wire ends see

table

Positive and negative terminal are marked. Two

miniature size thermo connectors are used with

dual thermocouples.

Lemosa connector,

(male) on cable

Binder connector,

(male) on cable

(threaded plug connection)

Colour code of cable

Type of sensor Standard Positive terminal Negative terminal

K DIN EN 60584 green white

J DIN EN 60584 black white

E DIN EN 60584 violet white

T DIN EN 60584 brown white

N DIN EN 60584 pink white

14

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

Page 15

6. Commissioning, operation

6.2 Cable connections

The cable gland must be optimally sealed, to ensure that the required protection class is reached.

Requirements for meeting ingress protection

■

Only use cable glands within their indicated clamping range (cable diameter suitable for the

cable gland)

■

Do not use the lower clamping area with very soft cable types

■

Only use circular cross-section cables (if necessary, slightly oval in cross-section)

■

Do not twist the cable

■

Repeated opening/closing is possible; however only if necessary, as it might have a detrimental

eect on the protection class

■

For cable with a pronounced cold-ow behaviour the screw connection must be fully tightened

CAUTION!

■

The protection class is not valid with armoured cables (stainless steel sheathed)

■

Seal should be checked for signs of brittleness and, if necessary, replaced

6.3 Parallel threads

If the thermometer connecting head, extension neck, thermowell or process connection are

connected to parallel threads (e.g. G ½, M20 x 1.5 ...), these threads must be secured using seals

which prevent liquids from penetrating into the thermometer.

As standard, WIKA uses copper prole seals for the connection between the neck tube and the

thermowell, and at paper seals for the connection of the connection head and the extension neck

or thermowell.

If the thermometer and the thermowell are already connected, the seals will already be mounted.

The plant operator must check whether the seals are suitable for the operating conditions and

must replace them, if necessary, with suitable seals.

For thermometers without a thermowell, and/or where these are delivered separately, the seals

are not included and must be ordered separately.

GB

Tighten the threads by hand when carrying out the nal assembly on the plant. This will

correspond to the delivery status of the premounted components. The nal tightening torque

should be applied using a spanner (half rotation).

The seals must be replaced after dismantling!

The seals can be ordered from WIKA, indicating the WIKA order number and/or the

designation (see table).

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

15

Page 16

6. Commissioning, operation / 7. Maintenance and cleaning

WIKA order no.

11349981 per DIN 7603 Form C 14 x 18 x 2 -CuFA G ¼, M14 x 1,5

11349990 per DIN 7603 Form C 18 x 22 x 2 -CuFA M18 x 1,5, G ⅜

GB

11350008 per DIN 7603 Form C 21 x 26 x 2 -CuFA G ½, M20 x 1,5

11350016 per DIN 7603 Form C 27 x 32 x 2.5 -CuFA G ¾, M27 x 2

11367416 per DIN 7603 Form C20 x 24 x 2 -CuFA M20 x 1,5

1248278 per DIN 7603 D21.2 x D25.9 x 1.5 -Al G ½, M20 x 1,5

3153134

3361485

Legend:

CuFA = Copper, max. 45 HB

Al = Aluminium Al99

F11, 32 to 45 HB

StFA = Soft iron, 80 to 95 HBa, with a lling made of asbestos-free sealing material

Designation Suitable for threads

per DIN 7603 Form C D14.2 x D17.9 x 2 -StFA

per DIN 7603 Form C D33.3 x D38.9 x 2.5 -

a

, with a lling made of asbestos-free sealing material

b

StFA

G ¼, M14 x 1,5

G 1

6.4 Tapered threads (NPT)

Connections with tapered threads (NPT) are self-sealing and normally must not be sealed. It

should be checked whether it may be necessary to seal them additionally with PTFE tape or

hemp. The threads must be lubricated with a suitable lubricant before tting.

Tighten the threads by hand when carrying out the nal assembly on the plant. This will

correspond to the delivery status of the premounted components. The nal tightening and sealing

must be made with a spanner (1.5 to 3 rotations).

7. Maintenance and cleaning

7.1 Maintenance

These thermometers are maintenance-free.

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

■

Before cleaning, correctly disconnect the instrument from the pressure supply,

switch it o and disconnect it from the mains.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to protect

personnel and the environment from exposure to residual media.

■

Residual media in dismounted instruments can result in a risk to personnel, the

environment and equipment. Take sucient precautionary measures.

For information on returning the instrument see chapter 9.2 “Return”.

16

WIKA operating instructions resistance thermometers, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 17

8. Faults

7.3 Calibration, Recalibration

It is recommended that the measuring insert is recalibrated at regular intervals (resistance

thermometers: approx. 24 months, thermocouples: approx. 12 months). This period can be

reduced, depending on the particular application. The calibration can be carried out by the

manufacturer, as well as on site by qualied technical sta with calibration instruments.

8. Faults

Faults Causes Measures

No signal/line breakage

Erroneous measured values

Erroneous measured values

(too low)

Erroneous measured values

and response times too long

Erroneous measured values

(of thermocouples)

Indication of the measured

value jumps

Corrosion

Signal interference

Mechanical load too high or

overtemperature

Sensor drift caused by

overtemperature

Sensor drift caused by chemical attack

Entry of moisture into cable or

measuring insert

Wrong mounting geometry, for example

mounting depth too deep or heat

dissipation too high

Deposits on the sensor or thermowell Remove deposits

Parasitic voltages (thermal voltages,

galvanic voltage) or wrong equalisation

line

Cable break in connecting cable or

loose contact caused by mechanical

overload

Composition of the medium not

as expected or modied or wrong

thermowell material selected

Stray currents caused by electric elds

or earth loops

Earth circuits Elimination of potentials, use of

Replace probe or measuring insert

with a suitable design

Replace probe or measuring insert

with a suitable design

Use a design with thermowell

Replace probe or measuring insert

with a suitable design

The temperature-sensitive area of the

sensor must be inside the medium,

and surfaces must be isolated.

Use a suitable equalisation line

Replace probe or measuring insert

with a suitable design, for example

equipped with a strain relief or a

thicker conductor cross-section

Analyse medium and then select a

more-suitable material or replace

thermowell regularly

Use of screened connecting cables,

increase in the distance to motors and

power lines

galvanically isolated transmitter supply

isolators or transmitters

GB

CAUTION!

If deciencies cannot be eliminated by means of the measures listed above, shut

down the instrument immediately, and ensure that pressure and/or signal are no

longer present, and secure the instrument from being put back into operation

inadvertently.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions see chapter 9.2 “Return”.

11208287.06 10/2013 GB/D/F/E

WIKA operating instructions resistance thermometers, thermocouples

17

Page 18

9. Dismounting, return and disposal

9. Dismounting, return and disposal

WARNING!

GB

9.1 Dismounting

Only disconnect the thermometer once the system has been depressurised!

9.2 Return

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbing material, in the packaging.

Place shock-absorbing material evenly on all sides of the shipping packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment. Take sucient precautionary measures.

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting it! When dismounting it,

there is a risk that dangerously hot pressure media may escape.

WARNING!

Strictly observe when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, leachate, solutions, etc.).

Information on returns can be found under the heading “Service” on our local website.

9.3 Disposal

Incorrect disposal may endanger the environment.

Dispose of instrument components and packaging materials in an environmentally compatible

way and in accordance with the country-specic waste disposal regulations.

18

WIKA operating instructions resistance thermometers, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 19

Inhalt

Inhalt

1. Allgemeines 20

2. Sicherheit 21

3. Technische Daten 24

4. Aufbau und Funktion 26

5. Transport, Verpackung und Lagerung 27

6. Inbetriebnahme, Betrieb 27

Wartung und Reinigung

7.

8. Störungen 33

9. Demontage, Rücksendung und Entsorgung 34

32

D

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

19

Page 20

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach dem aktuellen Stand der Technik

gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung

D

für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und

Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und

allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für

das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung,

Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten Fachpersonals

sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder

leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten

und störungsfreien Betrieb hervor.

GEFAHR!

… kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der

Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher Verletzungen.

20

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

Page 21

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Thermo-

meter hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen

ausgewählt wurde.

Schutzrohr hinsichtlich Maximaldruck und -temperatur (z. B. Belastungsdiagramme in

DIN 43772) auswählen.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden

auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln dieser

Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Diese Widerstandsthermometer und Thermoelemente dienen zur Temperaturmessung in industriellen Anwendungen.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezikationen

macht die sofortige Stilllegung und Überprüfung durch einen autorisierten WIKA-Servicemitarbeiter erforderlich.

D

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die

Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal

nachfolgend beschriebener Qualikation durchführen lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess- und

Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften,

geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen und

mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über agressive

Medien.

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

21

Page 22

2. Sicherheit

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen

Stoen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die gesamten allge-

D

meinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

WARNUNG!

Schutz vor elektrostatischer Entladung (ESD) erforderlich! Die ordnungsgemäße

Verwendung geerdeter Arbeitsächen und persönlicher Armbänder ist bei Arbeiten

mit oenen Schaltkreisen (Leiterplatten) erforderlich, um die Beschädigung empnd-

licher elektronischer Bauteile durch elektrostatische Entladung zu vermeiden.

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei Bedarf

jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen von Arbeits-

sicherheit, Erste-Hilfe und Umweltschutz unterwiesen wird, sowie die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare Lebensgefahr.

■

Einbau und Montage des elektrischen Gerätes dürfen nur durch das Elektrofachpersonal erfolgen.

■

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von Netzspannung zur

Ausgangsspannung) können am Gerät lebensgefährliche Spannungen auftreten!

22

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen. Fehlerhafte Anwendungen des Gerätes können zu Verletzungen führen.

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur und unter

hohem Druck oder Vakuum anliegen.

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

Page 23

2. Sicherheit

2.4 Beschilderung, Sicherheitskennzeichnungen

Typenschild für Widerstandsthermometer (Beispiel)

Typ

Sensor gemäß Norm

■

F Dünnlm-Messwiderstand

■

W Drahtgewickelter Messwiderstand

Symbolerklärung

TR10-B

11012345

EN 60751

1 x Pt100 / A / 3 (F) -50 ... +250 °C

Made in Germany 2013

Herstellungsjahr

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

D

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

23

Page 24

3. Technische Daten

3. Technische Daten

3.1 Widerstandsthermometer

Sensor-Schaltungsart

■

2-Leiter

■

3-Leiter

D

■

4-Leiter

Grenzabweichung des Sensors nach DIN EN 60751

■

Klasse B

■

Klasse A

■

Klasse AA

Die Kombinationen 2-Leiter-Schaltungsart und Klasse A oder Klasse AA sind nicht zulässig, da

der Leitungswiderstand des Messeinsatzes der höheren Sensorgenauigkeit entgegen wirkt.

Grundwerte und Grenzabweichungen

Grundwerte und Grenzabweichungen von Platin-Messwiderständen sind festgelegt in

DIN EN 60751.

Der Nennwert von Pt100 Sensoren beträgt 100 Ω bei 0 °C. Der Temperaturkoezient α kann

zwischen 0 °C und 100 °C vereinfacht angegeben werden mit:

-3

-1

α = 3,85 ∙ 10

Der Zusammenhang zwischen der Temperatur und dem elektrischen Widerstand wird durch

Polynome beschrieben, die ebenfalls in DIN EN 60751 deniert sind. Weiterhin legt diese Norm

die Grundwerte in °C-Schritten tabellarisch fest.

Klasse

B -196 … +600 °C -50 … +500 °C ±(0,30 + 0,0050 | t |)

A -100 … +450 °C -30 … +300 °C ±(0,15 + 0,0020 | t |)

AA -50 … +250 °C 0 … +150 °C ±(0,10 + 0,0017 | t |)

Temperaturbereich

Drahtgewickelt (W) Dünnschicht (F)

°C

Grenzabweichung in °C

1)

1)

1)

1) | t | ist der Zahlenwert der Temperatur in °C ohne Berücksichtigung des Vorzeichens.

Fett gedruckt: Standardausführung

Weitere technische Daten siehe WIKA-Datenblatt und Technische Information IN 00.17 „Einsatzgrenzen und Genauigkeiten von Platin-Widerstandsthermometern nach EN 60751: 2008“.

24

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

11208287.06 10/2013 GB/D/F/E

Page 25

3. Technische Daten

3.2 Thermoelemente

3.2.1 Sensortypen

Typ

K 1.200 °C

J 800 °C

E 800 °C

N 1.200 °C

3.2.2 Potenzielle Messunsicherheiten

Wichtige Faktoren, die der Langzeitstabilität von Thermoelementen entgegenwirken.

Alterungserscheinungen/Vergiftungen

■

Oxidationsvorgänge führen bei nicht entsprechend geschützten Thermoelementen („blanke“

Thermodrähte) zu Kennlinienverfälschungen.

■

Eindiundierende Fremdatome (Vergiftungen) führen zu Veränderungen der Ursprungslegierungen und damit zu Verfälschungen der Kennlinie.

■

Der Einuss von Wassersto führt zur Versprödung der Thermoelemente.

Der Ni-Schenkel des Typ K-Thermoelementes wird häug durch Schwefel, der z. B. in Rauchga-

sen vorkommt, geschädigt. Thermoelemente der Typen J und T altern gering, weil zunächst der

Reinmetallschenkel oxydiert.

Generell nehmen die Alterungserscheinungen mit steigenden Temperaturen zu.

Empfohlene max. Betriebstemperatur

D

Grünfäule

Bei Typ K-Thermoelementen können beim Einsatz in Temperaturen von ca. 800 °C bis 1.050 °C

erhebliche Veränderungen der Thermospannung auftreten. Die Ursache hierfür ist eine Chromverarmung bzw. Oxidation des Chroms im NiCr-Schenkel (+ Schenkel). Voraussetzung hierfür

ist eine geringe Konzentration Sauersto oder Wasserdampf in der direkten Umgebung des

Thermoelementes. Der Nickel-Schenkel ist hiervon nicht betroen. Die Folge dieses Eekts ist

eine Drift des Messwertes durch sinkende Thermospannung. Bei Sauerstomangel (reduzierende

Atmosphäre) wird dieser Eekt noch beschleunigt, da sich keine vollständigen Oxidhäute auf der

Oberäche des Thermoelementes ausbilden können, die einer weiteren Oxidation des Chroms

entgegenwirken.

Das Thermoelement wird auf Dauer durch diesen Vorgang zerstört. Der Name Grünfäule kommt

von der grünlichen schimmernden Färbung an der Bruchstelle des Drahtes.

Das Thermoelement Typ N ist bedingt durch seinen Siliziumgehalt in dieser Beziehung im Vorteil.

Hier bildet sich unter gleichen Bedingungen eine schützende Oxidschicht auf seiner Oberäche

aus.

K-Eekt

Der NiCr-Schenkel eines Typ K-Thermoelementes besitzt bezüglich der Ausrichtung im Kristallgit-

ter unterhalb ca. 400 °C eine geordnete Ausrichtung. Wird das Thermoelement weiter erhitzt, so

ndet im Temperaturbereich zwischen ca. 400 °C und 600 °C ein Übergang in einen ungeordneten Zustand statt. Oberhalb von 600 °C stellt sich wieder ein geordnetes Kristallgitter ein.

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

25

Page 26

3. Technische Daten / 4. Aufbau und Funktion

Bei einem zu schnellen Abkühlen dieser Thermoelemente (schneller als ca. 100 °C pro Stunde)

kommt es während der Abkühlung im Bereich von ca. 600 °C bis ca. 400 °C wieder zum

unerwünschten ungeordneten Kristallgitter. In der Kennlinie von Typ K ist aber ein durchgängig

geordneter Ausrichtungszustand vorausgesetzt und mit Werten hinterlegt. Ein Thermospannungs-

fehler von bis zu ca. 0,8 mV (ca. 5 °C) in diesem Bereich ist die Folge. Der K-Eekt ist reversibel

und wird durch Glühen oberhalb 700 °C mit anschließender entsprechend langsamer Abkühlung

D

größtenteils wieder abgebaut.

Dünne Mantel-Thermoelemente reagieren hier besonders empndlich. Schon eine Abkühlung an

ruhender Luft kann Abweichungen von 1 °C zur Folge haben.

Beim Typ N-Thermoelement hat man diesen Nahordnungseekt durch Legieren beider Schenkel

mit Silizium verringern können.

Die tatsächliche Gebrauchstemperatur des Thermometers wird begrenzt sowohl durch die

maximal zulässige Einsatztemperatur des Thermoelementes, als auch durch die maximal zulässi-

ge Einsatztemperatur des Schutzrohrwerkstoes.

Gelistete Typen sind als einfaches Thermopaar oder als doppeltes Thermopaar lieferbar. Das

Thermoelement wird mit isolierter Messstelle geliefert, wenn nicht ausdrücklich anders speziziert

wurde.

Grenzabweichung

Bei der Grenzabweichung von Thermopaaren ist eine Vergleichsstellentemperatur von 0 °C

zugrunde gelegt. Bei Verwendung einer Ausgleichs- oder Thermoleitung muss eine zusätzliche

Messabweichung berücksichtigt werden.

Grenzabweichungen und weitere technische Daten siehe entsprechendes WIKA-Datenblatt und

Technische Information IN 00.23 „Einsatz von Thermoelementen“.

4. Aufbau und Funktion

4.1 Beschreibung

Mit Hilfe dieser Thermometer (Widerstandsthermometer und Thermoelemente) werden Temperaturen in Prozessen erfasst. Diese Thermometer eignen sich je nach Ausführung für niedrige,

mittlere und hohe Prozessanforderungen.

Sie können als Kabelfühler oder als Thermometer mit Anschlusskopf aufgebaut werden. Optional

kann ein Temperatur-Transmitter im Anschlusskopf eingebaut werden. Für diesen TemperaturTransmitter wird eine eigene Betriebsanleitung beigelegt.

Bestimmte Thermometerausführungen können mit einer Vielzahl von Schutzrohrbauformen

kombiniert werden. Ein Betrieb dieser Thermometer ohne Schutzrohr ist nur in speziellen Fällen

zweckmäßig.

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

26

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

11208287.06 10/2013 GB/D/F/E

Page 27

5. Transport, Verpackung und Lagerung / 6. Inbetriebnahme, Betrieb

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen Schutz

(z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur:

Geräte ohne eingebauten Transmitter: -40 ... +85 °C

Geräte mit eingebautem Transmitter: siehe Betriebsanleitung des entspr. Transmitters

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Vermeidung folgender Einüsse:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort, der die oben gelisteten Bedingungen erfüllt,

lagern. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät wie folgt verpacken und

lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der Verpackung

beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden Messstoreste

entfernen. Dies ist besonders wichtig, wenn der Messsto gesundheitsgefährdend ist,

wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

D

6. Inbetriebnahme, Betrieb

WARNUNG!

Bei der Montage des Thermometers die zulässige Betriebstemperatur (Umgebung,

Messsto), auch unter Berücksichtigung von Konvektion und Wärmestrahlung nicht

unter- oder überschreiten!

WARNUNG!

Thermometer müssen geerdet sein, wenn an den Anschlussdrähten mit gefährlichen

Spannungen zu rechnen ist (hervorgerufen durch z. B. mechanische Beschädigung,

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

elektrostatische Auadung oder Induktion)!

27

Page 28

6. Inbetriebnahme, Betrieb

6.1 Elektrischer Anschluss

VORSICHT!

■

Beschädigung an Kabeln und Leitungen, sowie Verbindungsstellen vermeiden

■

Feindrähtige Leiterenden mit Aderendhülsen versehen (Kabelkonfektionierung)

■

Innere wirksame Kapazität und Induktivität beachten

D

Elektrischer Anschluss gemäß nachfolgend aufgezeigter Sensoranschlüsse/Klemmenbelegungen:

Thermoelemente mit Anschlusssockel

Einfaches Thermopaar

Für die Zuordnung Polarität Klemme gilt immer die

farbliche Kennzeichnung der

Plus-Pole am Gerät.

Widerstandsthermometer mit Anschlusssockel

1 x Pt100, 2-Leiter 1 x Pt100, 3-Leiter 1 x Pt100, 4-Leiter

Doppeltes Thermopaar

weiß

rot

rot

weiß

weiß

2 x Pt100, 2-Leiter 2 x Pt100, 3-Leiter

rot

rot

gelb

28

weiß

schwarz

rot

weiß

schwarz

gelb

gelb

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

rot

rot

rot

rot

weiß

weiß

schwarz

rot

rot

weiß

schwarz

schwarz

gelb

weiß

weiß

2 x Pt100, 4-Leiter

weiß

gelb

rot

rot

rot

rot

weiß

weiß

rot

schwarz

rot

rot

weiß

weiß

schwarz

schwarz

gelb

gelb

3160629.06

11208287.06 10/2013 GB/D/F/E

Page 29

6. Inbetriebnahme, Betrieb

Widerstandsthermometer mit Anschlusskabel oder -stecker

1 x Pt100

2-Leiter

1 x Pt100

3-Leiter

1 x Pt100

4-Leiter

2 x Pt100

2-Leiter

2 x Pt100

3-Leiter

Kabel

rot

weiß

rot

rot

weiß

rot

rot

weiß

weiß

rot

weiß

schwarz

gelb

rot

rot

weiß

schwarz

schwarz

Lemosa-Stecker,

male am Kabel

Binder-Stecker,

male am Kabel

D

gelb

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

29

Page 30

6. Inbetriebnahme, Betrieb

Thermoelemente mit Anschlusskabel oder -stecker

Lemosa-Stecker,

male am Kabel

D

Einfaches

Thermopaar

Doppeltes

Thermopaar

Thermostecker

Kabel

Kennzeichnung

der Adernenden

siehe Tabelle

Plus-Pol und Minus-Pol sind gekennzeichnet.

Bei doppelten Thermopaaren werden zwei

Thermo-Stecker verwendet.

Farbkennzeichnung der Kabel

Sensortyp Norm Plus-Pol Minus-Pol

K DIN EN 60584 grün weiß

J DIN EN 60584 schwarz weiß

E DIN EN 60584 violett weiß

T DIN EN 60584 braun weiß

N DIN EN 60584 rosa weiß

Binder-Stecker,

male am Kabel

(Schraub-Steck-Verbindung)

30

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

Page 31

6. Inbetriebnahme, Betrieb

6.2 Kabelverschraubungen

Die Abdichtung der Kabelverschraubung muss optimal erfolgen, damit die erforderliche Schutzart

erreicht wird.

Voraussetzungen zur Erreichung der Schutzart

■

Kabelverschraubung nur im angegebenen Klemmbereich (Kabeldurchmesser passend zur

Kabelverschraubung) verwenden

■

Bei Verwendung sehr weicher Kabeltypen nicht den unteren Klemmbereich verwenden

■

Nur Rundkabel verwenden (ggf. leicht ovaler Querschnitt)

■

Kabel nicht verdrillen

■

Mehrmaliges Önen/Schließen möglich; hat ggf. jedoch negative Auswirkung auf die Schutzart

■

Bei Kabel mit ausgeprägtem Kaltießverhalten Verschraubung nachziehen

VORSICHT!

■

Schutzart ist bei armierten Kabel (VA-Geecht) nicht gegeben

■

Dichtungen sind auf Versprödungen zu überprüfen und ggf. zu ersetzen

6.3 Zylindrische Gewinde

Wenn Thermometeranschlusskopf, Halsrohr, Schutzrohr oder Prozess-anschluss mit zylindrischen Gewinden (z. B. G ½, M20 x 1,5 ...) verbunden werden, müssen diese Gewinde mit

Dichtungen gegen den Eintritt von Flüssigkeiten in das Thermometer gesichert werden.

WIKA verwendet standardmäßig eine Kupfer-Proldichtung für die Verbindung Halsrohr zum

Schutzrohr und eine Papier-Flachdichtung für die Verbindung Anschlusskopf zum Halsrohr oder

Schutzrohr.

D

Bei Zusammenbauten von Thermometer und Schutzrohr sind diese Dichtungen bereits vormontiert. Es obliegt dem Betreiber der Anlage, die Eignung dieser Dichtung im Hinblick auf die

Einsatzbedingungen zu überprüfen und ggfs. durch eine geeignete Dichtung zu ersetzen.

Bei Thermometern ohne Schutzrohr bzw. getrennter Lieferung liegen Dichtungen nicht bei und

müssen vom Anwender getrennt bestellt werden.

Bei der Endmontage in die Anlage sind die Gewinde zunächst handfest anzuziehen. Das

entspricht auch dem Auslieferungszustand bei vormontierten Zusammenbauten. Die Endfestigkeit

muss mit einer halben Schraubenschlüssel-Umdrehung hergestellt werden.

Dichtungen sind nach einer Demontage zu ersetzen!

Dichtungen können unter Angabe der Gewinde mit WIKA-Bestell-Nr. und/oder

Bezeichnung (siehe Tabelle) bei WIKA bezogen werden.

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

31

Page 32

6. Inbetriebnahme, Betrieb / 7. Wartung und Reinigung

WIKA

Bestell-Nr.

11349981 nach DIN 7603 Form C 14 x 18 x 2 -CuFA G ¼, M14 x 1,5

11349990 nach DIN 7603 Form C 18 x 22 x 2 -CuFA M18 x 1,5, G ⅜

11350008 nach DIN 7603 Form C 21 x 26 x 2 -CuFA G ½, M20 x 1,5

11350016 nach DIN 7603 Form C 27 x 32 x 2,5 -CuFA G ¾, M27 x 2

D

11367416 nach DIN 7603 Form C 20 x 24 x 2 -CuFA M20 x 1,5

1248278 nach DIN 7603 D21,2 x D25,9 x 1,5 -Al G ½, M20 x 1,5

3153134

3361485

Legende:

CuFA= Kupfer, max. 45HB

Al = Aluminium Al99

F11, 32 bis 45 HB

StFA = Weicheisen, 80 bis 95 HBa, mit einer Füllung aus asbestfreiem Dichtungsmaterial

Bezeichnung Geeignet für

Gewinde

nach DIN 7603 Form C D14,2 x D17,9 x 2 -StFA

nach DIN 7603 Form C D33,3 x D38,9 x 2,5 -StFA

a

, mit einer Füllung aus asbestfreiem Dichtungsmaterial

b

G ¼, M14 x 1,5

G 1

6.4 Konische Gewinde (NPT)

Verbindungen mit kegeligen Gewinden (NPT) sind selbstdichtend und müssen grundsätzlich

nicht gesichert werden. Die Notwendigkeit einer zusätzlichen Dichtung mittels PTFE-Band oder

Hanf ist jedoch zu prüfen. Die Gewinde sollten vor der Montage mit einem geeigneten Mittel

geschmiert werden.

Bei der Endmontage in die Anlage sind die Gewinde zunächst handfest anzuziehen. Das

entspricht auch dem Auslieferungszustand bei vormontierten Zusammenbauten. Die Endfestigkeit und Dichtheit muss mit einer 1,5 bis 3-fachen Schraubenschlüssel-Umdrehung hergestellt

werden.

7. Wartung und Reinigung

7.1 Wartung

Diese Thermometer sind wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

7.2 Reinigung

VORSICHT!

■

Vor der Reinigung das Gerät ordnungsgemäß von der Druckversorgung trennen,

ausschalten und vom Netz trennen.

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

■

Ausgebautes Gerät vor der Rücksendung spülen bzw. säubern, um Mitarbeiter und

Umwelt vor Gefährdung durch anhaftende Messstoreste zu schützen.

■

Messstoreste in ausgebauten Geräten können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 9.2 „Rücksendung“.

32

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

11208287.06 10/2013 GB/D/F/E

Page 33

8. Störungen

7.3 Kalibrierung, Rekalibrierung

Es wird empfohlen, den Messeinsatz in regelmäßigen Zeitabständen zu rekalibrieren (Widerstandsthermometer: ca. 24 Monate, Thermoelemente: ca. 12 Monate). Dieser Zeitraum verringert

sich abhängig vom Einsatzfall. Die Kalibrierung kann durch den Hersteller sowie mit Kalibriergerä-

ten vor Ort durch qualiziertes Fachpersonal erfolgen.

8. Störungen

Störungen Ursachen Maßnahmen

Kein Signal/

Leitungsbruch

Fehlerhafte Messwerte

Fehlerhafte Messwerte

(zu gering)

Fehlerhafte Messwerte

und zu lange Ansprechzeiten

Fehlerhafte Messwerte

(bei Thermoelementen)

Anzeige des Messwertes

springt

Korrosion

Signal gestört

Zu hohe mechanische Belastung oder

Übertemperatur

Sensordrt durch Übertemperatur Ersatz des Fühlers oder Messeinsatzes

Sensordrift durch chemischen Angri Verwendung einer Ausführung mit

Feuchtigkeitseintritt an Kabel oder

Messeinsatz

Falsche Einbaugeometrie, z. B. zu

geringe Einbautiefe oder zu hohe

Wärmeableitung

Ablagerungen auf dem Sensor oder

Schutzrohr

Parasitäre Spannungen (Thermospannungen, galvanische Spannung) oder

falsche Ausgleichsleitung

Leitungsbruch im Anschlusskabel oder

Wackelkontakt durch mechanische

Überbelastung

Zusammensetzung des Mediums nicht

wie angenommen oder geändert oder

falsches Schutzrohrmaterial gewählt

Einstreuung durch elektrische Felder

oder Erdschleifen

Erdschleifen Beseitigung von Potentialen, Verwen-

Ersatz des Fühlers oder Messeinsatzes

durch eine geeignete Ausführung

durch eine geeignete Ausführung

Schutzrohr

Ersatz des Fühlers oder Messeinsatzes

durch eine geeignete Ausführung

Der temperaturempndliche Bereich des

Sensors muss innerhalb des Mediums

liegen, Oberächenmessungen müssen

isoliert sein

Ablagerungen entfernen

Verwendung der geeigneten Ausgleichsleitung

Ersatz des Fühlers oder Messeinsatzes

durch eine geeignete Ausführung z.B.

mit Knickschutzfeder oder dickerem

Leitungsquerschnitt

Medium analysieren und danach besser

geeignetes Material wählen oder Schutzrohr regelmäßig erneuern

Verwendung von geschirmten Anschlussleitungen, Erhöhung des

Abstandes zu Motoren und leistungsführenden Leitungen

dung von galvanisch getrennten Speisetrennern oder Transmittern

D

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht beseitigt werden,

ist das Gerät unverzüglich außer Betrieb zu setzen, sicherzustellen, dass kein Druck

bzw. Signal mehr anliegt und gegen versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise siehe Kapitel 9.2 „Rücksendung“

beachten.

11208287.06 10/2013 GB/D/F/E

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

33

Page 34

9. Demontage, Rücksendung und Entsorgung

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von Personen,

Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

D

9.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen! Beim Ausbau besteht

Gefahr durch austretende, gefährlich heiße Messstoe.

Thermometer nur im drucklosen Zustand demontieren!

9.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren, Laugen,

Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung

verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf unserer lokalen

Internetseite.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

34

WIKA Betriebsanleitung Widerstandsthermometer, Thermoelemente

11208287.06 10/2013 GB/D/F/E

Page 35

Sommaire

Sommaire

1. Généralités 36

2. Sécurité 37

3. Caractéristiques techniques 40

4. Conception et fonction 42

5. Transport, emballage et stockage 43

6. Mise en service, exploitation 43

F

Entretien et nettoyage

8.

9. Dysfonctionnements 49

10. Démontage, retour et mise au rebut 50

48

11208287.06 10/2013 GB/D/F/E

WIKA mode d'emploi sondes à résistance, thermocouples

35

Page 36

1. Généralités

1. Généralités

■

L'appareil décrit dans le mode d'emploi est fabriqué selon les dernières technologies en

vigueur. Tous les composants sont soumis à des critères de qualité et d'environnement stricts

durant la fabrication. Nos systèmes de gestion sont certiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de l'appareil. Il est

possible de travailler en toute sécurité avec ce produit en respectant toutes les consignes de

sécurité et d'utilisation.

F

■

Respecter les prescriptions locales de prévention contre les accidents et les prescriptions

générales de sécurité en vigueur pour le domaine d'application de l‘appareil.

■

Le mode d'emploi fait partie de l'appareil et doit être conservé à proximité immédiate de

l'appareil et accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement et

compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par une

utilisation non conforme à l'usage prévu, de non respect de ce mode d'emploi, d'utilisation

de personnel peu qualié de même qu'en cas de modications de l'appareil eectuées par

l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente sappliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations:

- Consulter notre site internet :

- Conseiller applications :

www.wika.fr

Tel. : +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou

des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de provoquer de

légères blessures ou des dommages matériels et pour l'environnement si elle n'est

pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

DANGER !

… indique les dangers liés au courant électrique. Danger de blessures graves ou

mortelles en cas de non respect des consignes de sécurité.

36

11208287.06 10/2013 GB/D/F/E

WIKA mode d'emploi sondes à résistance, thermocouples

Page 37

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que la sonde a

été choisie de façon adéquate, en ce qui concerne la plage de mesure, la version et

les conditions de mesure spéciques.

Sélectionner la gaine en ce qui concerne la pression et la température maximale (par

ex. diagramme de charge dans la norme DIN 43772).

Un non respect de cette consigne peut entraîner des blessures corporelles graves et/

ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections individuelles du

présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Ces sondes à résistance et ces thermocouples servent à la mesure de la température dans dans

le cadre d'applications industrielles.

L'appareil est conçu et construit exclusivement pour une utilisation conforme à lusage prévu décrit

ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respectées.

En cas d'utilisation inadéquate ou de fonctionnement de l'appareil en dehors des spécications

techniques, un arrêt et contrôle doivent être immédiatement eectués par un collaborateur

autorisé du service de WIKA.

F

Si l'appareil est transporté d'un environnement froid dans un environnement chaud, la formation

de condensation peut provoquer un dysfonctionnement fonctionnel de l'appareil. Il est nécessaire

d'attendre que la température de l'appareil se soit adaptée à la température ambiante avant une

nouvelle mise en service.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages corporels et

matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées que par

un personnel ayant la qualication décrite ci-après.

■

Tenir le personnel non qualié à l'écart des zones dangereuses.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances dans le

domaine de la technique de mesure et de régulation et de ses expériences de même que de

sa connaissance des prescriptions nationales, des normes et directives en vigueur, en mesure

d'eectuer les travaux décrits et de reconnaître automatiquement les dangers potentiels.

11208287.06 10/2013 GB/D/F/E

WIKA mode d'emploi sondes à résistance, thermocouples

37

Page 38

2. Sécurité

Les conditions d'utilisation spéciales exigent également une connaissance adéquate par exemple

des liquides agressifs.

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l'oxygène,

F

l'acétylène, des substances combustibles ou toxiques, ainsi que dans le cas

d'installations de réfrigération, de compresseurs etc., les directives appropriées

existantes doivent être observées en plus de l'ensemble des règles générales.

AVERTISSEMENT !

Protection nécessaire contre les décharges électrostatique (DES) ! L'utilisation

conforme des surfaces de travail mises à la terre et des bracelets personnels est

nécessaire lors des opérations eectuées avec des circuits ouverts (circuits imprimés)

an d'éviter une détérioration des composants électroniques sensibles due à une

décharge électrostatique.

An de travailler en toute sécurité sur l'appareil, l'utilisateur doit s'assurer

■

qu'un équipement de premier secours adapté est disponible et que les premiers

soins peuvent être dispensés sur place à tout moment en cas de besoin.

■

qu'il reçoit à intervalles réguliers des instructions relatives à toutes les questions

pertinentes concernant la sécurité du travail, les premiers secours et la protection

de l'environnement et qu'il connaît le mode d'emploi et particulièrement les

consignes de sécurité contenues dans celui-ci.

38

DANGER !

Danger de mort lié au courant électrique

Danger de mort en cas de contact avec les pièces sous tension.

■

Le montage de l'appareil électrique ne doit être eectué que par un électricien

qualié.

■

En cas d'utilisation avec un appareil d'alimentation défectueux (p. ex. court-circuit

entre la tension du secteur et la tension de sortie), des tensions présentant un

danger de mort peuvent apparaître sur l'appareil !

AVERTISSEMENT !

Les restes de uides se trouvant dans des appareils démontés peuvent mettre en

danger les personnes, l'environnement ainsi que l'installation. Prendre des mesures

de sécurité susantes.

Ne pas utiliser cet appareil dans des équipements de sécurité ou d'arrêt d'urgence.

Les applications incorrectes de l'appareil peuvent entraîner des blessures.

En cas d'erreur, des uides agressifs peuvent être disponibles à une température

extrême et sous une pression élevée ou sous vide au niveau de l'appareil.

WIKA mode d'emploi sondes à résistance, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 39

2. Sécurité

2.4 Etiquetage, marquages de sécurité

Etiquettes de produit pour sondes à résistance (exemple)

Type

1 x Pt100 / A / 3 (F) -50 ... +250 °C

Made in Germany 2013

Capteur conforme à la norme

■

F Résistance à couche mince

■

W Résistance bobinée

Explication des symboles

Lire impérativement le mode d‘emploi avant le montage et la mise en

service de l‘instrument !

TR10-B

11012345

EN 60751

F

Année de fabrication

11208287.06 10/2013 GB/D/F/E

WIKA mode d'emploi sondes à résistance, thermocouples

39

Page 40

3. Caractéristiques techniques

3. Caractéristiques techniques

3.1 Sonde à résistance

Connexion du capteur

■

2 ls

■

3 ls

■

4 ls

F

Précision du capteur selon DIN EN 60751

■

Classe B

■

Classe A

■

Classe AA

Les combinaisons d'un raccordement à 2 ls de classe A / classe AA ne sont pas autorisées car

la résistance de ligne de l'insert de mesure annule la plus grande précision du capteur.

Valeurs de base et valeurs de tolérance

Les valeurs de base et les valeurs de tolérance pour les résistances de mesure en platine sont

xées dans la norme DIN EN 60751.

La valeur nominale des capteurs Pt100 est de 100 Ω pour une température de 0 °C. Le coecient

de température α peut être indiqué simplement entre 0 °C et 100 °C par :

-3

-1

α = 3.85 ∙ 10

La relation existante entre la température et la résistance électrique est décrite par des

polynômes, eux-mêmes dénis dans la norme DIN EN 60751. Par ailleurs, cette norme spécie

les valeurs de base en incréments de °C sous forme d'un tableau.

Classe

B -196 … +600 °C -50 … +500 °C ±(0,30 + 0,0050 | t |)

A -100 … +450 °C -30 … +300 °C ±(0,15 + 0,0020 | t |)

AA -50 … +250 °C 0 … +150 °C ±(0,10 + 0,0017 | t |)

Plage de température

Bobiné (W) Couche mince (F)

°C

Valeur de tolérance en °C

1)

1)

1)

1) | t | est la valeur de température en °C sans prendre en compte le signe.

En gras : version standard

Pour de plus amples informations techniques, voir la che technique WIKA et la che

d'informations techniques IN 00.17 “Limitations d'utilisation et précisions des sondes à résistance

en platine selon EN 60751: 2008”.

40

WIKA mode d'emploi sondes à résistance, thermocouples

11208287.06 10/2013 GB/D/F/E

Page 41

3. Caractéristiques techniques

3.2 Thermocouples

3.2.1 Types de capteur

Type

K 1.200 °C

J 800 °C

E 800 °C

N 1.200 °C

3.2.2 Incertitudes de mesure potentielles

Des facteurs importants qui contrarient la stabilité à long terme des thermocouples.

Eets de vieillissement/empoisonnement

■

■

■

Le corps Ni du thermocouple type K est souvent endommagée par du soufre contenu dans des

gaz d'échappement par exemple. Les thermocouples de type J et T vieillissent légèrement car le

métal pur s'oxyde en premier.

En général, l'augmentation des températures cause des eets de vieillissement accélérés.

Température d'exploitation max. conseillée

Les processus d'oxydation sur des thermocouples qui ne sont pas protégés correctement (ls

de thermocouples “nus”) ont pour résultat de fausser les courbes caractéristiques.

Les atomes étrangers (empoisonnement) qui se diusent dans les alliages d'origine

conduisent à des modications de ces alliages et faussent ainsi la courbe caractéristique.

L'action de l'hydrogène conduit à un eritement des thermocouples.

F

Moisissure verte

Si on utilise des thermocouples de type K à des températures allant d'environ 800 °C à 1.050 °C,

des modications considérables de tension thermo-électrique peuvent se produire. La cause

est qu'il se produit une diminution de la teneur en chrome ou une oxydation du corps NiCr

(corps +). La condition préalable à cela est une faible concentration d'oxygène ou de vapeur

dans l'environnement immédiat du thermocouple. Le corps en nickel n'est pas aectée par

cela. La conséquence de cet eet est un écart de la valeur mesurée causé par une tension

thermo-électrique qui diminue. Cet eet est accéléré s'il y a une pénurie d'oxygène (réduction de

l'atmosphère), parce qu'une couche complète d'oxyde, qui protégerait d'une oxydation encore

plus importante du chrome, ne peut pas être formée à la surface du thermocouple.

Le thermocouple est détruit en permanence par ce processus. Le nom de pourrissement vert

provient de la coloration verdâtre brillante qui apparaît sur le point de cassure du l.

Le thermocouple type N a, à cet égard, un avantage dû à sa teneur en silicium. Ici, une couche

oxydée protectrice se forme sur sa surface dans les mêmes conditions.

L'eet K

Le corps NiCr d'un thermocouple de type K a un alignement ordonné qui respecte l'alignement

dans le réseau cristallin en-dessous d'environ 400 °C. Si on continue de chauer le thermocouple,

une transition vers un état désordonné se produit dans la plage de température entre environ

400 °C et 600 °C. Au-dessus de 600 °C, un réseau cristallin ordonné est rétabli.

11208287.06 10/2013 GB/D/F/E

WIKA mode d'emploi sondes à résistance, thermocouples

41

Page 42

3. Caractéristiques techniques / 4. Conception et fonction

Si ces thermocouples refroidissent trop rapidement (plus vite qu'environ 100 °C par heure),

le réseau cristallin désordonné indésirable se produit à nouveau pendant le refroidissement

dans la plage entre environ 600 °C à environ 400 °C. Dans la courbe caractéristique du type K,

cependant, on suppose un état d'alignement systématiquement ordonné et on fournit des

valeurs. Ceci a pour conséquence une erreur de tension thermo-électrique d'environ 0,8 mV (5 °C

environ) dans cette plage. L'eet K est réversible et peut être largement éliminé en recuisant à

une température supérieure à 700 °C, avant de procéder à un refroidissement qui sera lent en

conséquence.

F

Les thermocouples à petit diamètre sont particulièrement sensibles à cet égard. Un

refroidissement en état de repos peut conduire à des écarts de 1 K.

Il s'est révélé possible de réduire cet eet à court terme pour le thermocouple de type N en alliant

les deux corps avec du silicium.

La plage d'utilisation de ces sondes est limitée aussi bien par la température maximale autorisée

du thermocouple que par la température maximale du matériau qui compose le doigt de gant.

Les types listés sont disponibles en tant que thermocouples simples ou doubles. Le thermocouple

est livré avec un point de mesure isolé en cas d'absence de toute autre spécication explicite.

Précision du capteur

Pour la valeur de tolérance des thermocouples, une température de fonction à froid de 0 °C a été