WIKA TI.54 Data sheet

Mechanical

Temperature Measurement

Bimetal Thermometer

Model TI.54, All Stainless Steel Construction

Applications

Suitable for fluid medium which does not corrode 304

stainless steel

Special features

Industrial design

Lower (bottom) connection without external reset

All stainless steel construction

Datasheet TI.54

Standard version

Size

5” (127mm)

Accuracy

+ 1.0% full scale value (ASME B40.3)

Ranges

o

-100

F to 1000 oF (and equivalent Celsius)

Working Range

Steady: full scale value

Short time: 110% of full scale value

Under/Over Range Protection

Temporary over or under range tolerance of 50% of scale

up to 500

over range is 800°F; continous. 1000°F intermittent.

Connection

Material: 304 stainless steel

Lower mount (LM), 1/2” NPT

Stem

Material: 304 stainless steel

Diameter: 1/4” (6.35 mm)

Length: 2½” to 24” (63.5 mm to 609.6 mm)

Measuring Element

Bi-metal helix

Dial

White aluminum, dished, with black markings

Datasheet TI.54 · 8/2009

o

F. (260°C). For ranges above 500°F, maximum

Thermometer TI.54

Case

Material: 304 stainless steel

Hermetically sealed

Ingress Protection IP 65

Pointer

Black aluminum

Standard Scales

Single: Fahrenheit or Celsius

Dual: Fahrenheit (outer) and Celsius (inner)

Window Gasket

Neoprene

Silicone (-100

Window

Flat instrument glass

Weight

24 oz. (5” dial)

Add 1 oz for every 2” of stem length

Dampening

Inert gel to minimize pointer oscillation

Movement

Viscous inert gel to enhance pointer operation

Warranty

Limited one year warranty as stated in WIKA’s Terms &

Conditions of Sale

o

F and over 550 oF)

Page 1 of 2

R

Optional Extras

Thermowells

Special scales and dial markings

Acrylic and safety glass windows

Calibration certification traceable to NIST

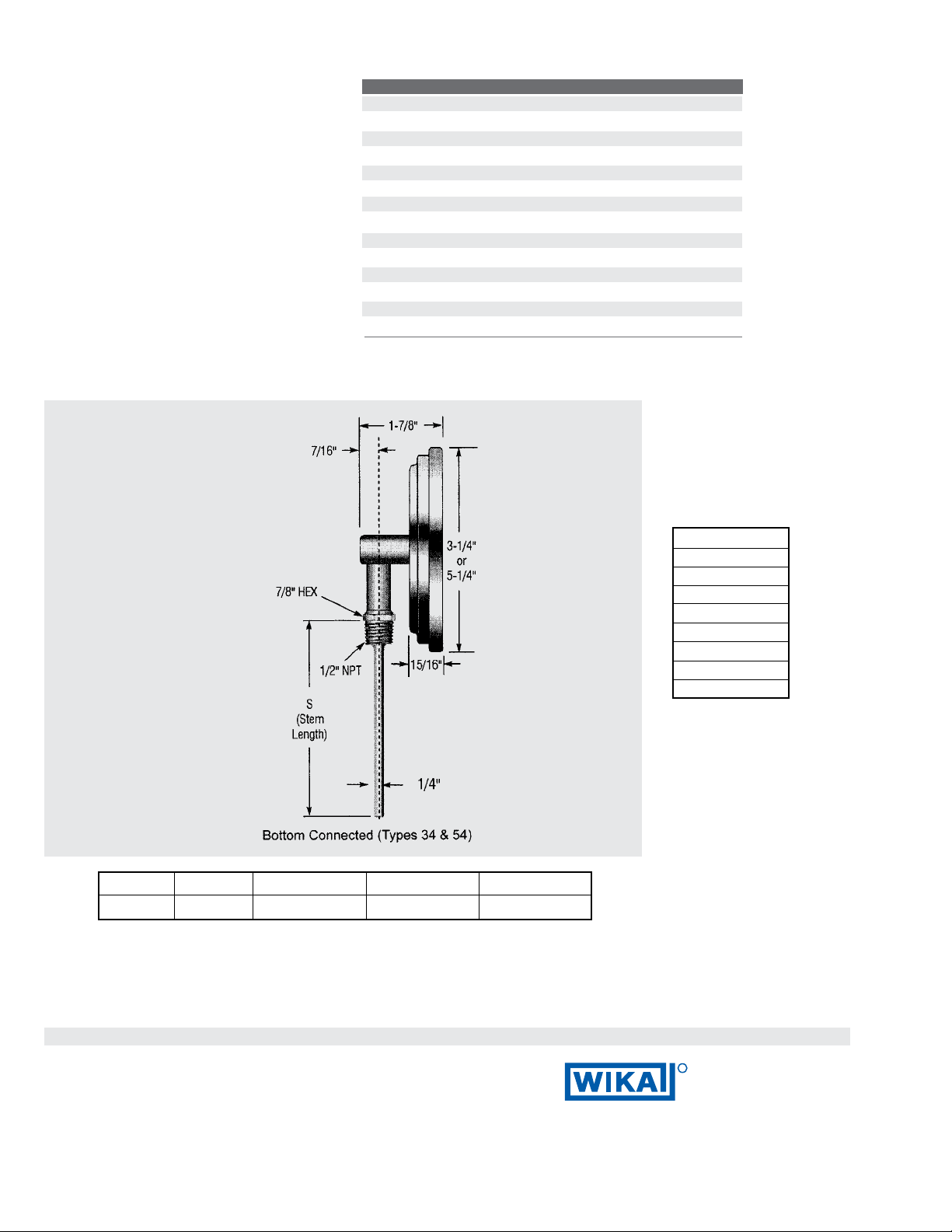

Dimensions

Standard versions

STANDARD RANGES

Fahrenheit Dual Scale F & C Celsius

Single Scale F Outer, C Inner Single Scale

-100/150 F -100/150 F & -70/70 C -50/50 C

-40/120 F 40/120 F & -40/50 C -20/120 C

0/140 F 0/140 F & -20/60 C 0/50 C

1

0/200 F 0/200 F & -15/90 C 0/100 C

0/250 F 0/250 F & -20/120 C 0/150 C

20/240 F 20/240 F & -5/115 C 0/200 C

25/125 F

1

25/125 F & -5/50 C1 0/250 C

50/300 F 50/300 F & 10/150 C 0/300 C

50/400 F 50/400 F & 10/200 C 0/450 C

2

50/550 F 50/500 F & 10/260 C 100/550 C

150/750 F 150/750 F & 65/400 C

200/1000 F

1

Minimum stem length 4“

2

Not recommended for continous service over 800°F (425°C)

2

200/1000 F & 100/540 C2

2

Stem Length

2½” (63.5 mm)

4” (101.6 mm)

6” (152.4 mm)

9” (228.6 mm)

12” (304.8 mm)

15” (381.0 mm)

18” (457.2 mm)

24” (609.6 mm)

WIKA Type DIAL SIZE A B S (Stem Length)

54 5” (76.2 mm) 5-1/4” (127 mm) 1-7/8” (133.4 mm) As Specified

Note: Thermowells for temperature instruments are recommended for all process systems where pressure, velocity, or viscous, abrasive and corrosive materials are present individually or in

combination. A properly selected thermowell protects the temperature instrument from possible damage resulting from these process variables. Furthermore, a thermowell permits removal of

the temperature instrument for replacement, repair or testing without effecting the process media or the system.

Ordering information

State computer part number (if available) /type number/size/range/connection size and locations/options required. WIKA reserves the right to make changes without prior notice.

Datasheet TI.54 · 8/2009Page 2 of 2

R

WIKA Instrument Corporation

1000 Wiegand Boulevard

Lawrenceville, GA 30043

1-888-WIKA-USA /770-513-8200 (in GA)

Fax 770-338-5118

info@wika.com www.wika.com

Loading...

Loading...