Page 1

Operating instructions

Betriebsanleitung

Manuale d'uso

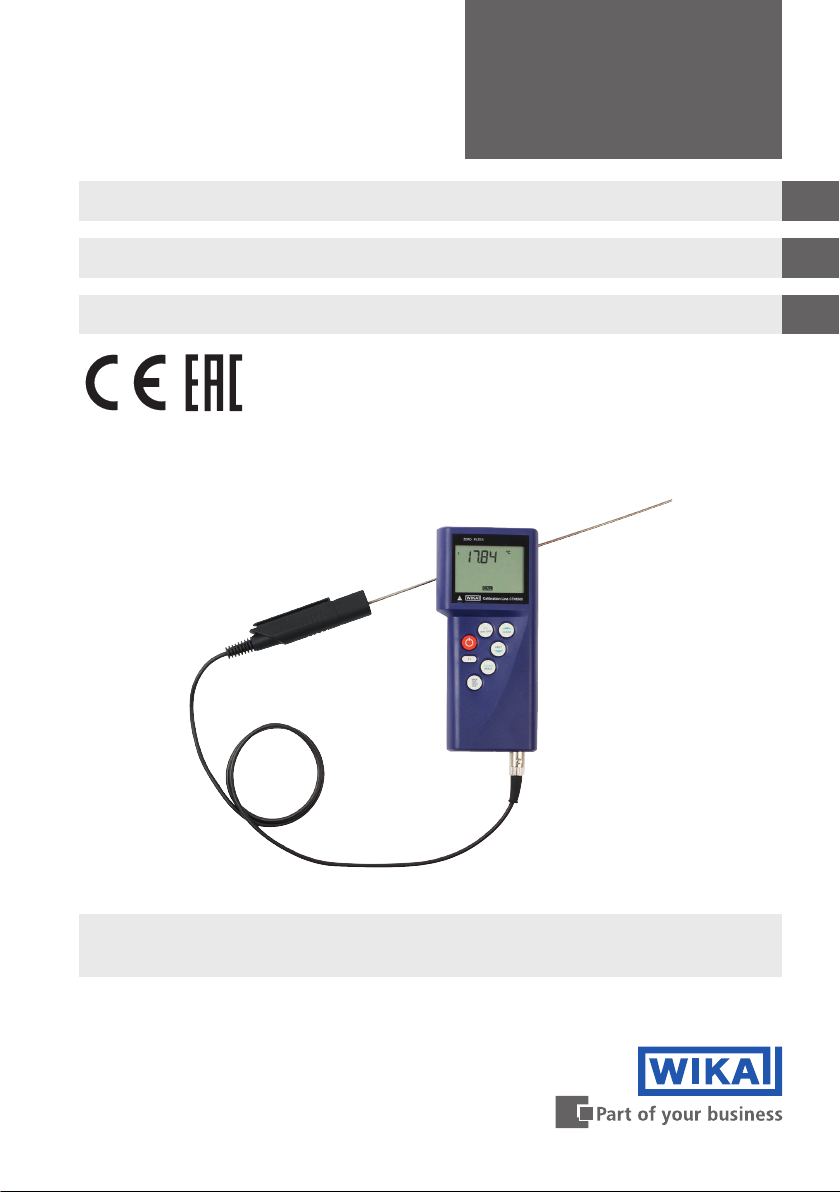

Hand-Held thermometer, models CTH6300 and CTH6500

Hand-Held Thermometer, Typen CTH6300 und CTH6500

Termometri portatili, modello CTH6300 e CTH6500

EN

DE

IT

Hand-Held thermometer, models CTH6300 and CTH6500

Page 2

Operating instructions, models CTH6300 and CTH6500 Page 3 - 40

EN

Betriebsanleitung, Typen CTH6300 und CTH6500 Seite 41 - 78

DE

Manuale d'uso, modelli CTH6300 e CTH6500 Pagina 79 - 119

IT

Further languages can be found at www.wika.com.

© 04/2013 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Prima di iniziare ad utilizzare lo strumento, leggere il manuale d‘uso!

Conservare per future consultazioni!

2

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 3

Contents

Contents

1. General information 5

2. Safety 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Personnel qualification . . . . . . . . . . . . . . . . . . . 7

2.3 Special hazards . . . . . . . . . . . . . . . . . . . . . 8

3. Specifications 9

4. Design and function 12

4.1 Description . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . .12

4.3 Operating and display elements . . . . . . . . . . . . . . . .13

4.4 Keypad . . . . . . . . . . . . . . . . . . . . . . . .14

4.5 Voltage supply . . . . . . . . . . . . . . . . . . . . . .15

4.6 Battery replacement . . . . . . . . . . . . . . . . . . . .15

4.7 Temperature probes . . . . . . . . . . . . . . . . . . . .16

4.8 Connecting/replacing the temperature probe . . . . . . . . . . . 17

4.9 Connector assignment . . . . . . . . . . . . . . . . . . . 17

4.9.1 Probe connection, Pt100, 4-wire 17

4.9.2 Probe connection, thermocouple 18

4.9.3 Probe connection, Vane, Mini Air 19

4.9.4 Adapter, DIN connector to thermocouple terminal 19

5. Transport, packaging and storage 20

5.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Packaging . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . 20

6. Commissioning, operation 21

6.1 Commissioning . . . . . . . . . . . . . . . . . . . . .21

6.2 Switching on/Switching off . . . . . . . . . . . . . . . . . .21

6.3 Menu structure and settings . . . . . . . . . . . . . . . . . 22

6.4 Menu tree . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.1 Unit switching °C and °F or % rH, td or g/m³ [Unit] 23

6.4.2 Probe selection Prob 23

6.4.3 Activating/deactivating differential temperature display option [Lin2]

(only for 2-channel instruments) 25

6.4.4 Calibration mode CAL 25

6.4.5 Activating/deactivating measuring channels [Chnl] (only for 2-channel

instruments) 31

6.4.6 Area entry for volume flow [ArEA] 32

6.4.7 Storage management [Lo6] (not possible for CTH6300) 33

2079988.08 02/2018 EN/DE/IT

EN

WIKA operating instructions, models CTH6300 and CTH6500

3

Page 4

Contents

6.5 Memory request [HOLD-MAX-MIN-AVE] . . . . . . . . . . . . .33

6.6 Change measurement cycle (FAST mode) . . . . . . . . . . . . 34

6.7 AUTO-OFF function . . . . . . . . . . . . . . . . . . . . 34

EN

6.8 Special functions . . . . . . . . . . . . . . . . . . . . .35

6.8.1 Ohm/Microvolt/Volt/Hertz display 35

6.8.2 Zero adjustment (zero) 35

6.8.3 Deactivation of channel 2 (toggle) 35

7. USB interface protocol 35

8. Maintenance, cleaning and recalibration 37

8.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . 37

8.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . .37

8.3 Recalibration . . . . . . . . . . . . . . . . . . . . . .37

9. Faults 37

10. Dismounting, return and disposal 39

10.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . 39

10.2 Return . . . . . . . . . . . . . . . . . . . . . . . . 39

10.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . 39

11. Accessories 40

Declarations of conformity can be found online at www.wika.com.

2079988.08 02/2018 EN/DE/IT

4

WIKA operating instructions, models CTH6300 and CTH6500

Page 5

1. General information

1. General information

■

The hand-held thermometers model CTH6300 and CTH6500 described in the

operating instructions have been designed and manufactured using state-of-the-art

technology. All components are subject to stringent quality and environmental criteria

during production. Our management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions onto the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

EN

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 51.05 and CT 55.10

- Application consultant: Tel.: +49 9372 132-9986

Fax: +49 9372 132-8767

testequip@wika.com

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

5

Page 6

1. General information / 2. Safety

Explanation of symbols

WARNING!

EN

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to equipment or the environment, if not avoided.

DANGER!

... identifies hazards caused by electric power. Should the safety instructions

not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused

by hot surfaces or liquids, if not avoided.

2. Safety

6

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

hand-held thermometer and/or temperature probe have been selected in

terms of measuring range, design and specific measuring conditions.

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual chapters

of these operating instructions.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

Page 7

2. Safety

2.1 Intended use

These general-purpose hand-held thermometers for advanced temperature

measurement process the signals of typical thermometers. Thus temperatures from

-200 ... +1,500 °C (-328 ... +2,732 °F) can be measured.

This instrument is not permitted to be used in hazardous areas!

The instruments have been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

2.2 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury and damage to

equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

EN

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specific regulations, current standards and directives, are capable

of carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

7

Page 8

2. Safety

2.3 Special hazards

EN

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

■

Operation or charging using a defective power supply unit (e.g. short

circuit from the mains voltage to the output voltage) can result in

life-threatening voltages at the instrument!

■

Only use the mains connector approved by WIKA for the precision

hand-held thermometer.

■

Never use a damaged or worn-looking battery charger.

WARNING!

Residual media at the dismounted hand-held thermometer and/or

temperature probe can result in a risk to persons, the environment and

equipment.

Take sufficient precautionary measures.

WARNING!

■

Observe the working conditions in accordance with chapter

3 “Specifications”.

■

Do not apply force to plug the connector into the sockets. The measuring

channel and interface connectors are different.

■

If no probe is connected to the measuring instrument during switching on,

“open” is indicated on the display (see chapter 9 “Faults”).

■

Do not use the hand-held thermometer in damaged condition. Before

using the instrument, check that there are no cracks or missing plastic

parts on the case. Pay particular attention to the insulation of the

connectors.

■

Select the correct temperature probe and correct measuring range for the

measurement.

■

The battery cover must be closed and locked in place before the

instrument is operated.

■

Do not use the instrument if it is not working properly. The instrument

protection might be compromised. If in doubt, have the instrument

checked.

■

Do not operate the instrument in areas with explosive gases, vapours or

dust.

■

To avoid false readings, which could lead to possible electric shock

or personal injury, replace the battery as soon as the battery indicator

appears.

2079988.08 02/2018 EN/DE/IT

8

WIKA operating instructions, models CTH6300 and CTH6500

Page 9

2. Safety / 3. Specifications

The safety of the operator may be endangered if, for example:

■

there is visible damage to the instrument.

■

the instrument is not working as specified.

■

the instrument has been stored under unsuitable conditions for an extended period of

time.

If there is any doubt, please return the instrument to the manufacturer for repair or

maintenance.

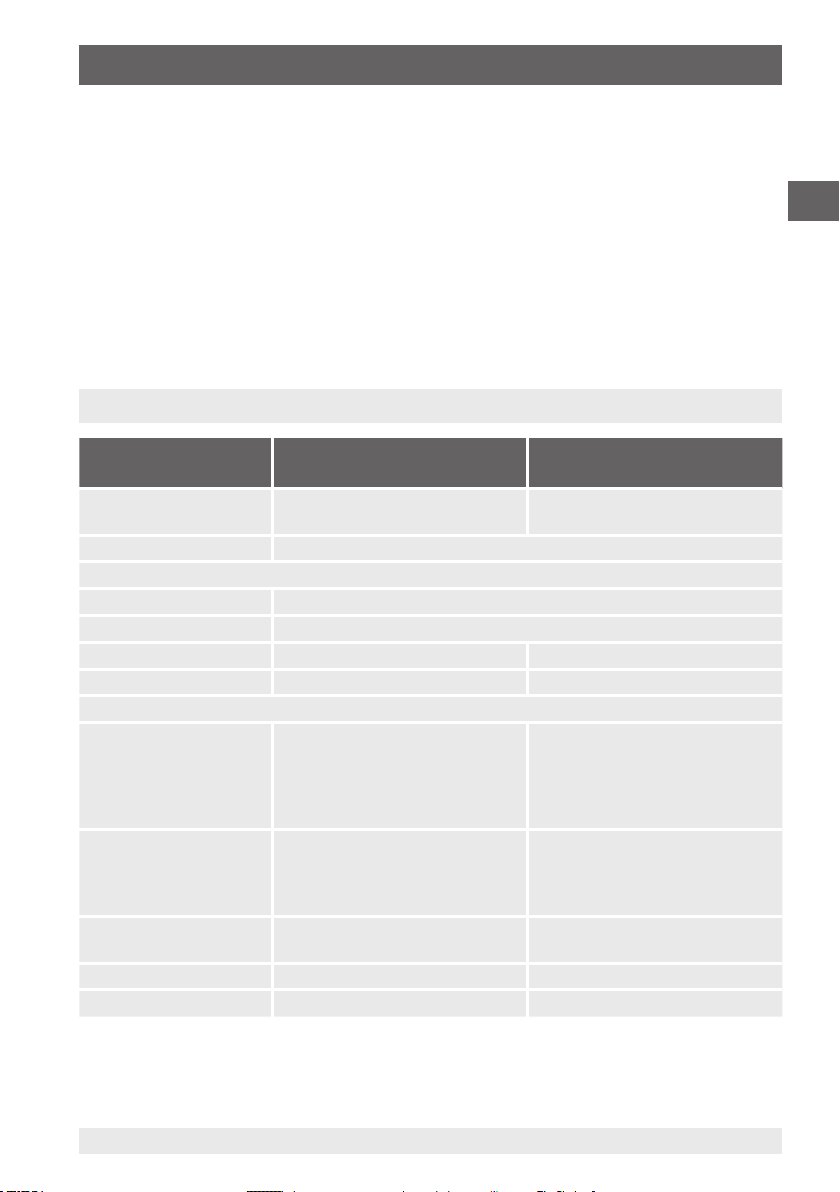

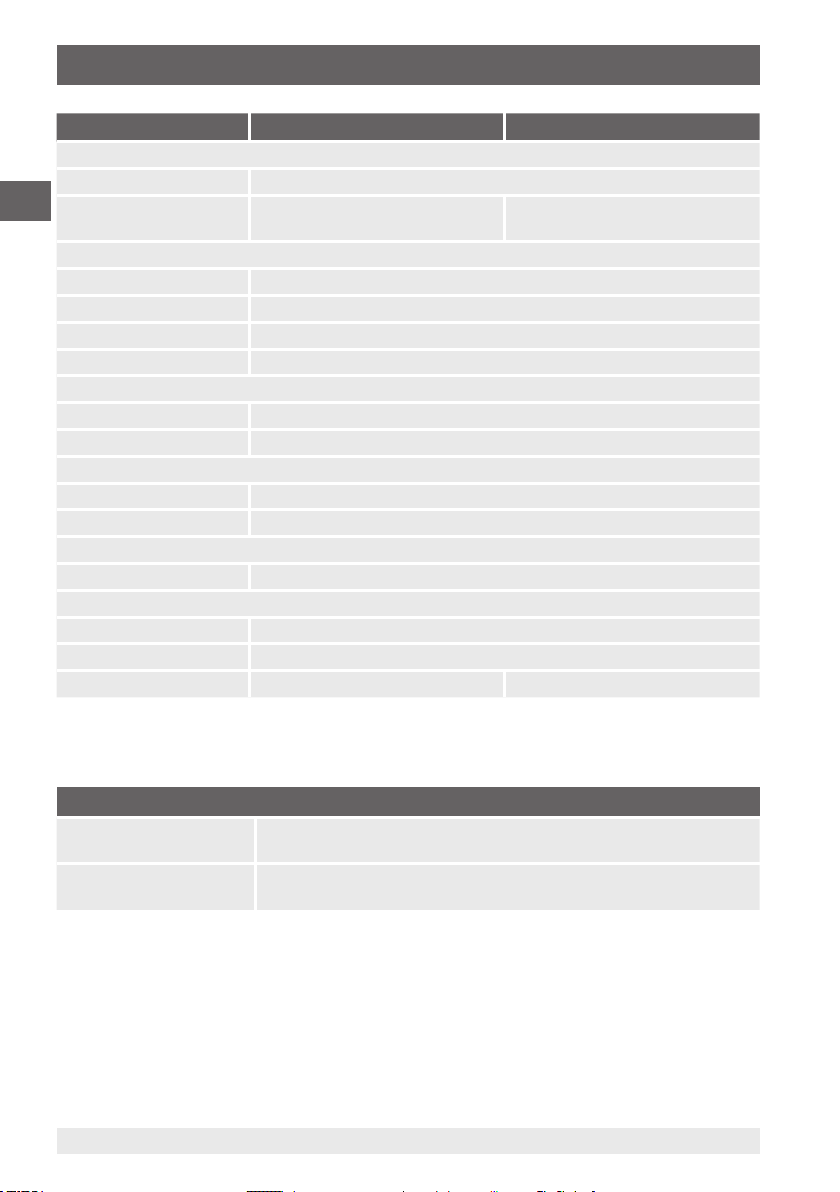

3. Specifications

EN

Hand-held

Model CTH6300 Model CTH6500

thermometers

Probe types Pt100, thermocouples Pt100, thermocouples, humidity,

ow

Measuring inputs 1 or 2

Measuring ranges

Pt100 -200 ... +600 °C (-392 ... +1,112 °F)

Thermocouples -200 ... +1,500 °C (-392 ... + 2,732 °F)

Humidity

Flow

Accuracies

Resistance

thermometer,

model Pt100

Thermocouple types K,

J, L, N and T

Thermocouple types R

and S

Humidity

Flow

--

--

0.1 K of -100 ... +200 °C

(-148 ... +392 °F)

otherwise 0.1 % of reading

0.3 K of 0 ... 200 °C (32 ... 392 °F)

1 K of 200 ... 1,000 °C

(392 ... 1,832 °F)

1.5 K above 1,000 °C 1,832 °F)

1 K + 0.1 % of reading 1 K + 0.1 % of reading

--

--

0 ... 100 % r. h.

0 ... 40 m/s

0.03 K of -50 ... +199.99 °C

(-58 ... +394.98 °F)

0.05 K of -200 ... -50.01 °C

(-328 ... -58.02 °F)

otherwise 0.05 % of reading

0.2 K of 0 ... 200 °C (32 ... 392 °F)

0.5 K of 200 ... 1,000 °C

(392 ... 1,832 °F)

1 K above 1,000 °C (1,832 °F)

1.5 % r. h.

0.5 % of full scale value

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

9

Page 10

3. Specifications

Digital indicator Model CTH6300 Model CTH6500

Display

Display Large, 4 1/2-digit, 2-line LC display with backlighting

EN

Resolution 0.1 K 0.01 K up to 200 °C (392 °F), then

0.1 K

Functions

Measuring rate 4/s (“fast”); 1/s (“slow”)

Memory Min./Max.

Functions via key press Min./Max. memory, Hold, Tare, Zero-point adjustment

Real-time clock integrated clock with date

Voltage supply

Power supply DC 9 V, battery or rechargeable battery

Battery life approx. 20 hours of operation with battery

Permissible ambient conditions

Operating temperature 0 ... 40 °C (32 ... 104 °F)

Storage temperature -10 ... +50 °C (14 ... 122 °F)

Communication

Interface USB via interface cable

Case

Material impact-resistant ABS plastic, transparent screen

Dimension (L x W x H) 200 x 93 x 44 mm (7.87 x 3.66 x 1.73 in)

Weight 300 g (0.66 lbs.) 350 g (0.77 lbs.)

Certificates

Certicate

Calibration Standard: 3.1 calibration certicate per DIN EN 10204

Option: DKD/DAkkS calibration certicate

Recommended

recalibration interval

1 year (dependent on conditions of use)

Approvals and certificates, see website

For further specifications, see WIKA data sheet CT 51.05 and CT 55.10 and the order

documentation.

10

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 11

44 (1.73)

93 (3.66)

3. Specifications

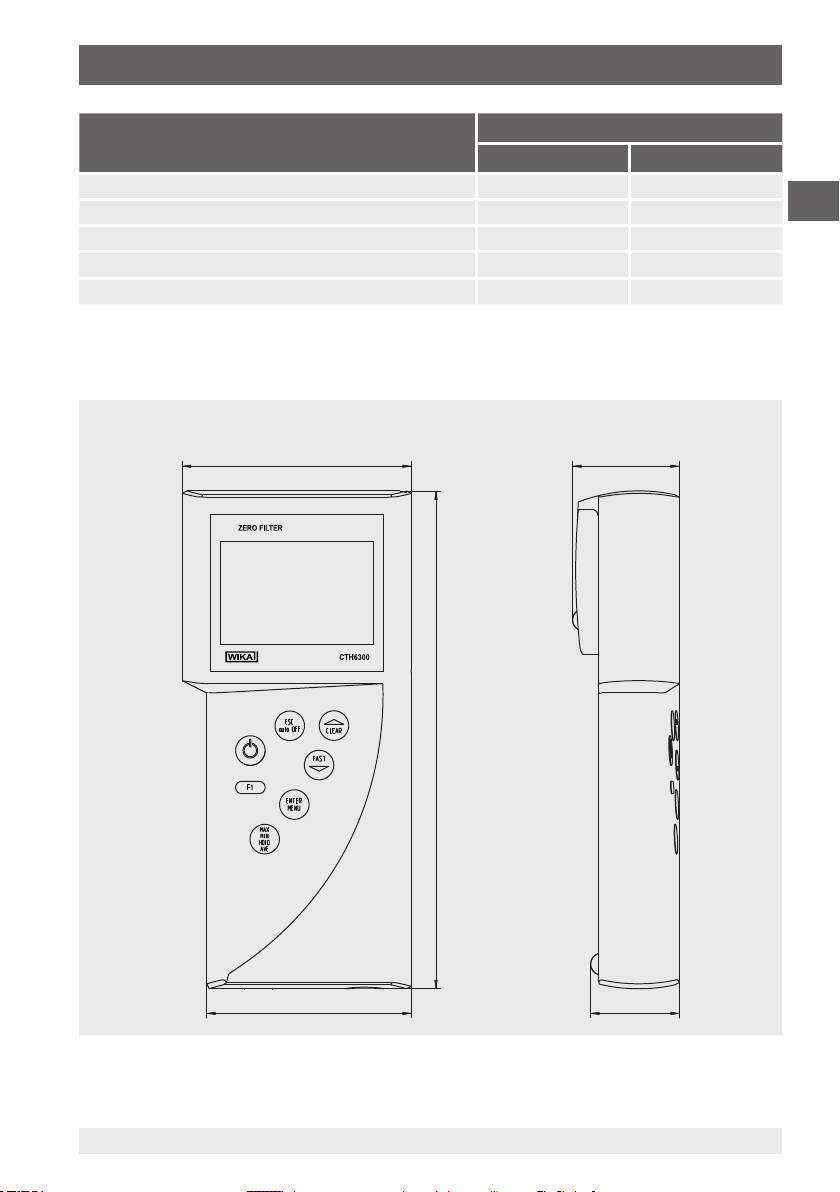

Standard probe (immersion probe) Temperature range

°C °F

Pt100, d = 3 mm, l = 150 mm (d = 0.12 in, l = 5.91 in) -200 ... +450 -392 ... +842

Pt100, d = 3 mm, l = 300 mm (d = 0.12 in, l = 11.81 in) -200 ... +450 -392 ... +842

Pt100, d = 6 mm, l = 300 mm (d = 0.24 in, l = 11.81 in) -200 ... +450 -392 ... +842

TC K, d = 3 mm, l = 300 mm (d = 0.12 in, l = 11.81 in) -200 ... +1,100 -392 ... +2,012

TC K, d = 3 mm, l = 500 mm (d = 0.12 in, l = 19.69 in) -200 ... +1,100 -392 ... +2,012

Dimensions in mm (in)

Front view Side view (left)

EN

83 (3.27)

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

202 (7.95)

37 (1.46)

11

Page 12

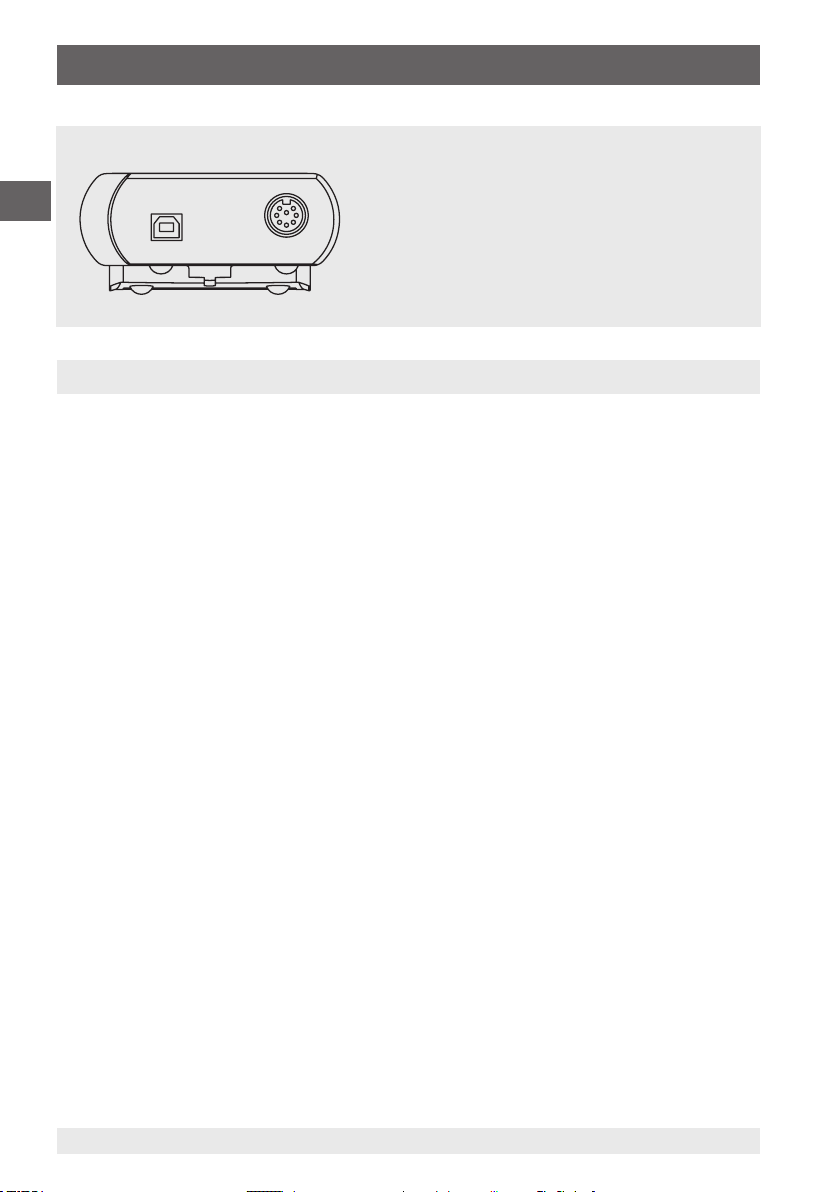

3. Specifications / 4. Design and function

Bottom view (1-channel instrument)

EN

4. Design and function

4.1 Description

Universally applicable hand-held thermometers for demanding, mobile temperature

measurement, distinguished by flexibility and easy handling. In addition to Pt100

resistance thermometers, they can also process signals from typical thermocouples. Thus

temperatures from -200 ... +1,500 °C (-392 ... +2,732 °F) can be measured.

Low-drift measuring amplifiers ensure small measurement errors, while easy-to-use

adjustment features considerably simplify adjustments and calibrations:

■

Calibration by code for fast setting of standard probes via key data

■

Physical calibration of probe and display at one, two or three different temperatures

In this way it is possible to reduce measuring errors to a minimum and ensure a high

indication accuracy.

Hand-held thermometer, model CTH6300, industrial version

Its design makes the CTH6300 especially suitable for the commissioning, maintenance

and service/calibration of temperature instruments and equipment.

Hand-held thermometer, model CTH6500, precision version

Due to its high accuracy of 0.03 K in the range from -100 ... +150 °C (-148 ... +302 °F), the

CTH6500 can be used as a reference instrument in the biotechnology, pharmaceutical

and food industries. The CTH6500 is thus ideal for all service and maintenance tasks.

4.2 Scope of delivery

CTH6300

■

Hand-held thermometer, model CTH6300, industrial version, incl. 9 V battery

■

3.1 calibration certificate per DIN EN 10204

■

Choice of temperature probes

12

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 13

4. Design and function

CTH6500

■

Hand-held thermometer, model CTH6500, precision version, incl. 9 V battery

■

3.1 calibration certificate per DIN EN 10204

■

Choice of temperature probes

Cross-check scope of delivery with delivery note.

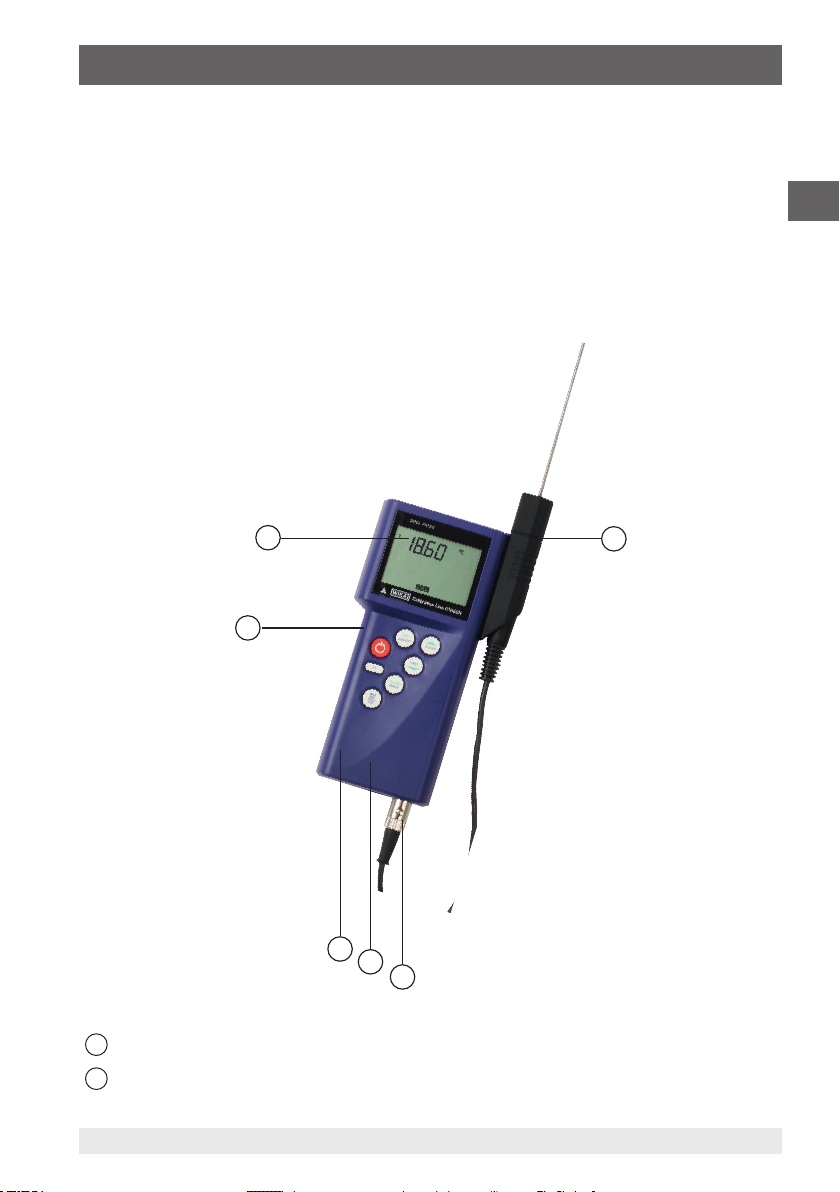

4.3 Operating and display elements

EN

1

Probe holder

2

2079988.08 02/2018 EN/DE/IT

First connection port for temperature probe

6

1

5

4

3

2

WIKA operating instructions, models CTH6300 and CTH6500

13

Page 14

4. Design and function

3

Second connection port for temperature probe

4

USB connection port for PC

5

EN

Keypad

6

Large LC display

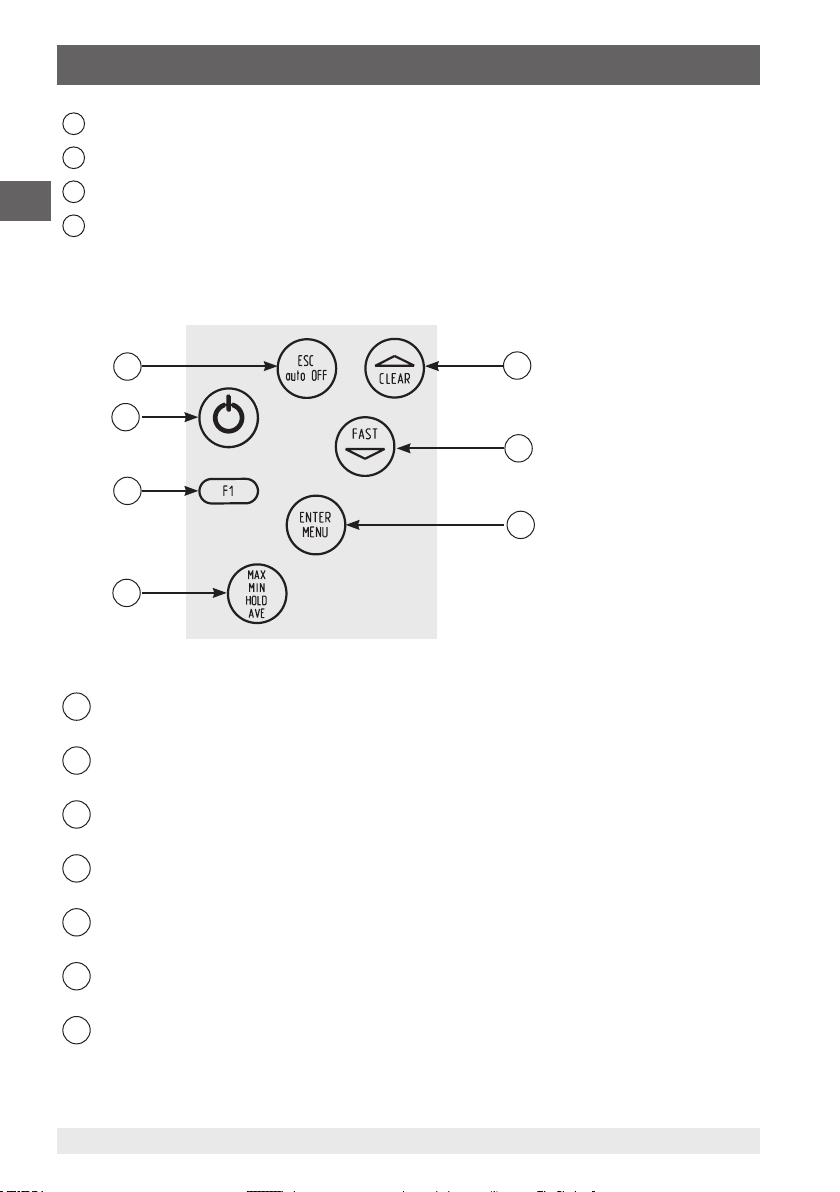

4.4 Keypad

7

6

5

4

Arrow key CLEAR

1

Selection of menu items

Arrow key FAST

2

Selection of menu items

ENTER/MENU key

3

Access to the main menu, confirming the function

MIN/MAX/HOLD/AVE key

4

Setting MIN and MAX, HOLD and AVE

Function keys

5

Configuring the instrument

ON/OFF key

6

Turning the instrument on and off

ESC key

7

Back to measuring mode

1

2

3

14

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

Page 15

4. Design and function

4.5 Voltage supply

The battery life is approx. 20 hours for continuous operation.

The BAT segment indicates that the battery must be replaced soon. From this point,

correct measurements can be performed for approx. 1 hour. A 9 V battery is used as

voltage supply of the instrument. For information on the battery see chapter 4.6 “Battery

replacement”.

4.6 Battery replacement

For battery replacement switch off the instrument and open the battery compartment

attached on the rear side. After that remove the battery and disconnect the connection

cable. Then insert the new batteries into the battery compartment.

Switch in the battery compartment on the rear side allows to specify whether the

instrument is operated with a battery or a rechargeable battery.

■

With the setting Batt, the charging current supplied via USB interface is not directed to

the battery, so that this does not damage it.

■

With the setting Accu, the rechargeable battery is charged only via the USB interface.

While the rechargeable battery is supplied with a charging current, this is not, however,

enough to charge the battery fully.

EN

If the instrument is not used for a long time, remove the battery.

When closing the battery compartment make sure that the battery

connection wires are not jammed or damaged.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

15

Page 16

4. Design and function

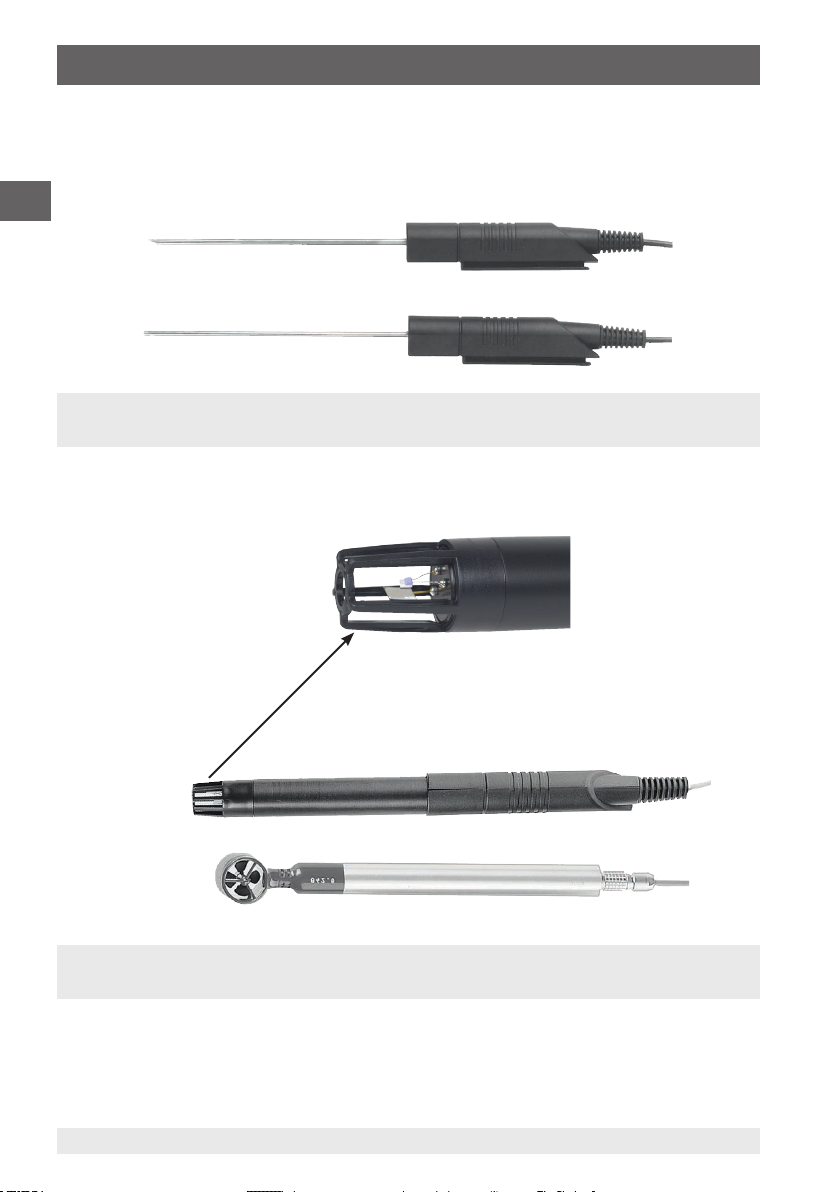

4.7 Temperature probes

Different connection options of different temperature probes guarantee flexibility.

Temperature probes for model CTH6300/CTH6500

EN

Fig. top: penetration probe

Fig. bottom: immersion probe

Additional temperature probes for model CTH6500

Section through the

combined temperaturehumidity probe

Fig. top: combined temperature-humidity probe

Fig. bottom: vane flow probe

16

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 17

4. Design and function

4.8 Connecting/replacing the temperature probe

WARNING!

Only use the supplied temperature probes!

▶

Switch off the instrument for probe replacement.

▶

Before switching the instrument on, connect the probe, otherwise it may

not be correctly identified by the instrument.

The digital instrument and the temperature probe are connected to each other electrically

by means of a separate connection cable. For probe replacement, it is preferable to use

the 8-pin plug contact at the probe.

■

To connect a temperature probe to the hand-held thermometer plug the 8-pin plug

connection according to the guiding into the connection port for temperature probes.

■

Connect the connector without crossing the threads. If the connector is positioned

correctly, it can be plugged in without any significant effort.

■

To disconnect the probe, do not pull on the cable, but rather only on the connector

sleeve.

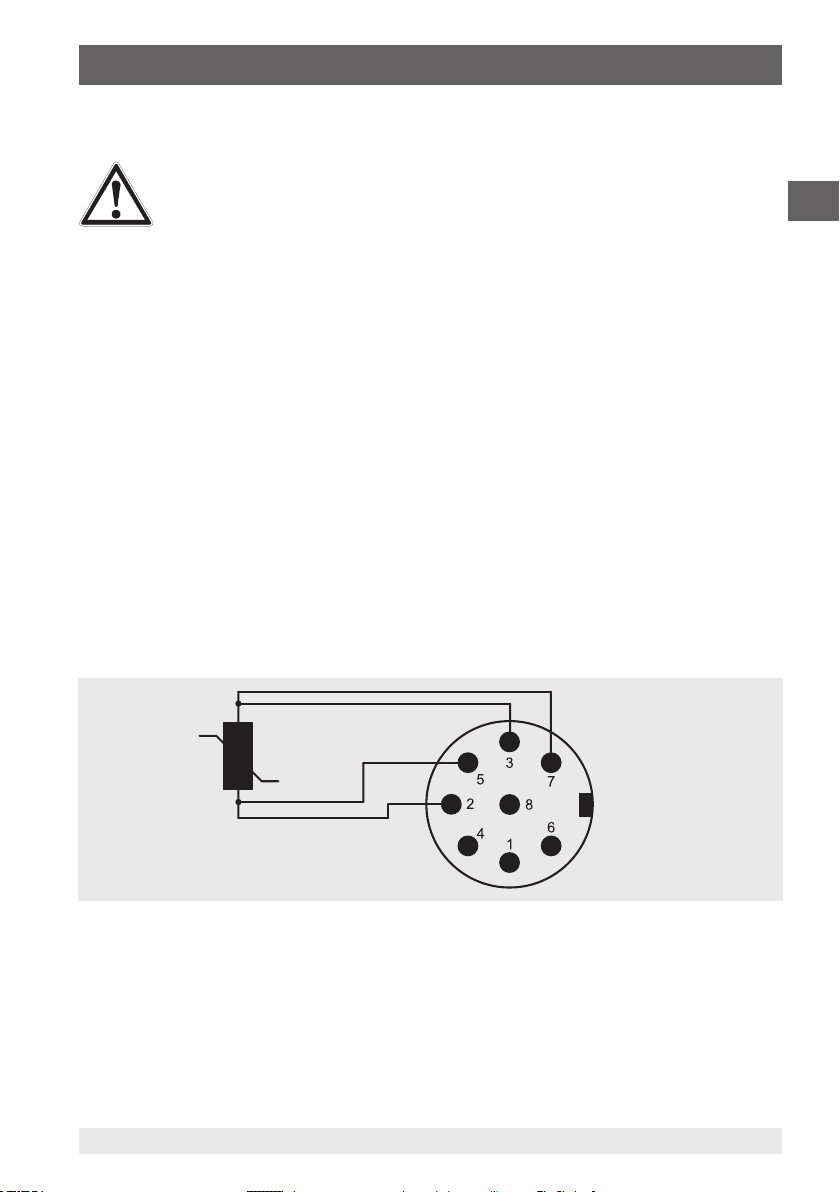

4.9 Connector assignment

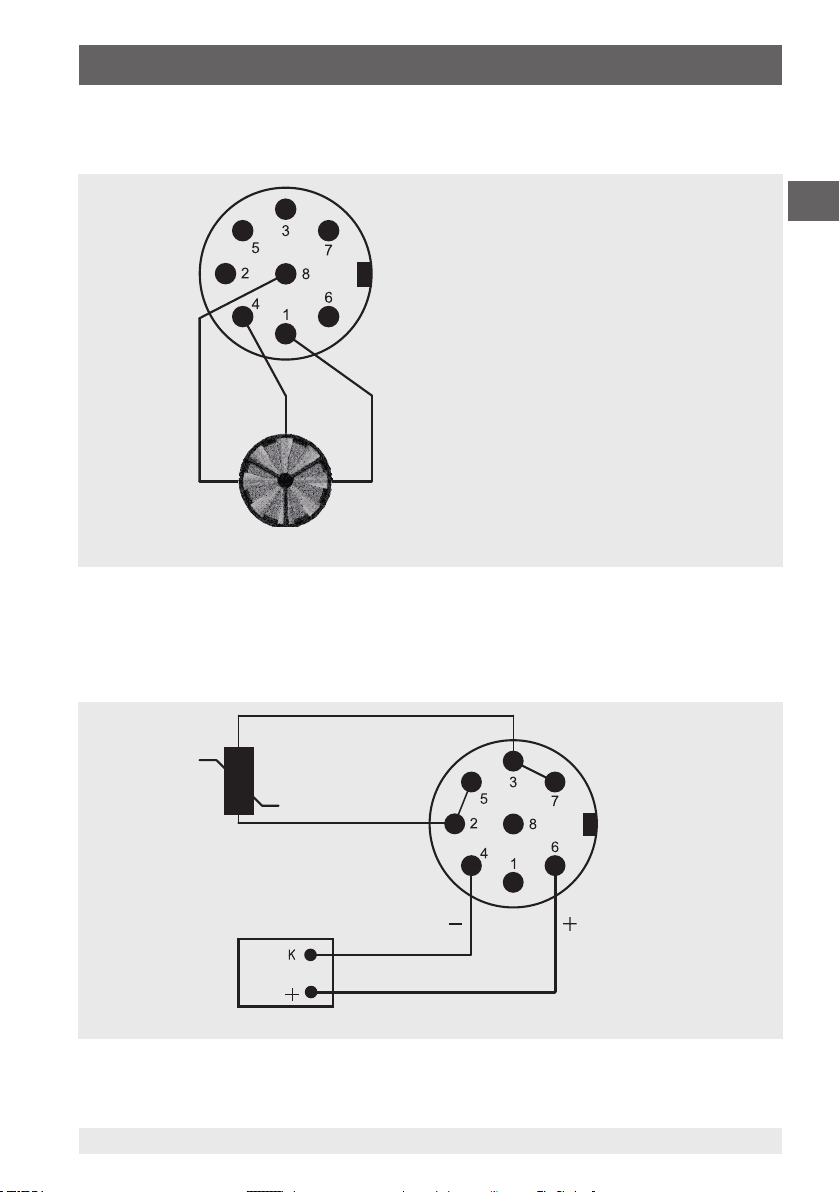

4.9.1 Probe connection, Pt100, 4-wire

Measuring channel 1 and 2

EN

Pt100 4-wire

Soldering side

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

17

Page 18

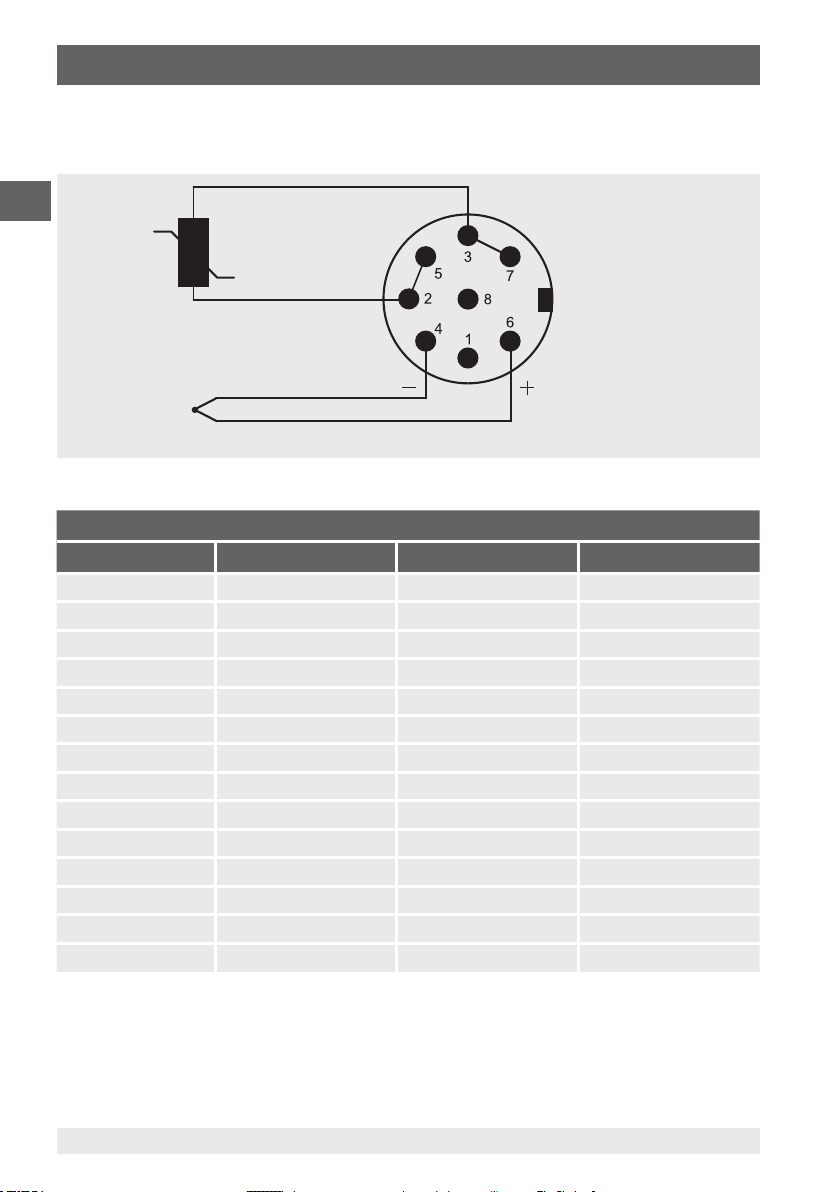

4. Design and function

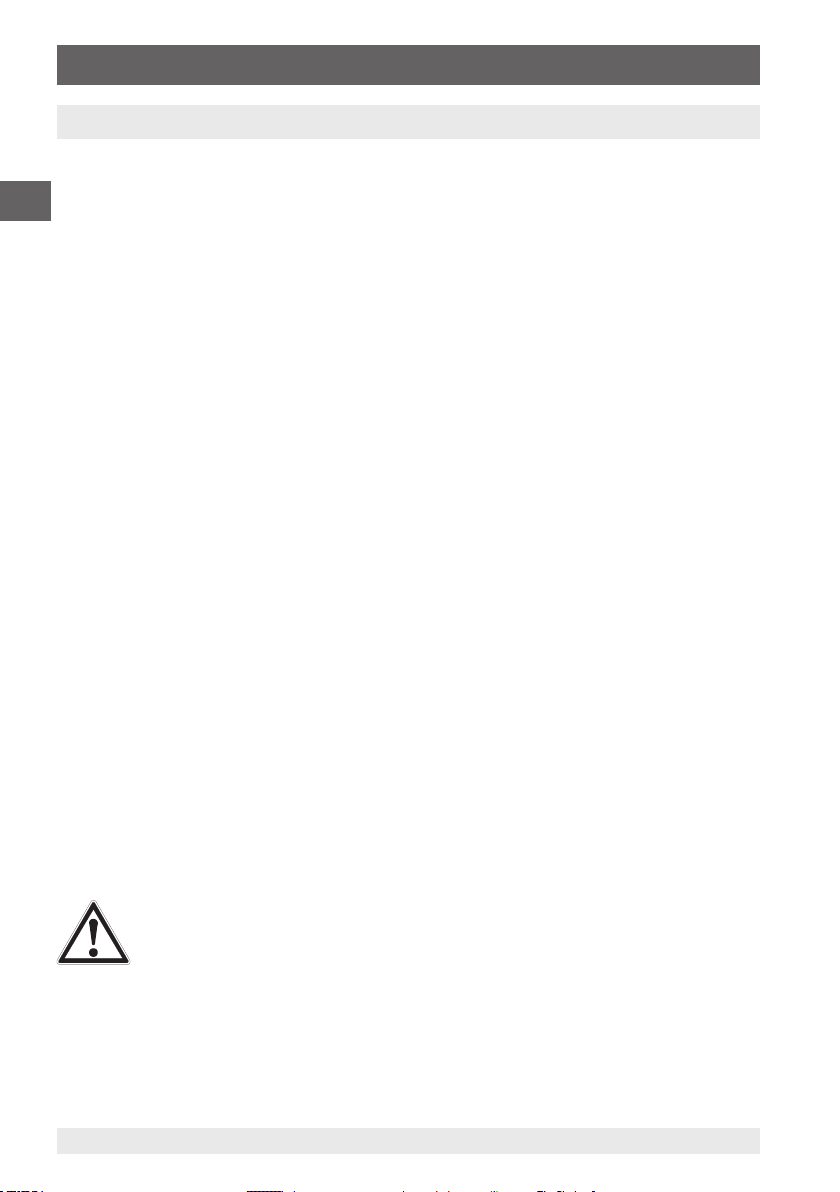

4.9.2 Probe connection, thermocouple

Measuring channel 1 and 2

EN

Pt100 2-wire

Soldering side

NiCr-Ni thermocouple

International colour code for thermocouples

Thermocouple DIN 43722 DIN 43710 ANSI MC 96.1

Type R orange white green

Pt13Rh-Pt + orange - white + red - white + black - red

Type S orange white green

Pt10Rh-Pt + orange - white + red - white + black - red

Type J black black

Fe-CuNi + black - white + white - red

Type T brown blue

Cu-CuNi + brown - white + blue - red

Type K green green yellow

NiCr-Ni + green - white + red - green + yellow - red

Type N pink

NiCrSi-NiSi + pink - white

Type L brown

Fe-CuNi + red - blue

18

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

Page 19

4. Design and function

4.9.3 Probe connection, Vane, Mini Air

Measuring channel 1 and 2

Soldering side

blackwhiteyellow

Mini Air vane

EN

4.9.4 Adapter, DIN connector to thermocouple terminal

Measuring channel 1 and 2

Pt100 2-wire

gn (ws)

Miniature

thermocouple

terminal

rt (gn) Cable length 12 cm

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

Soldering side

19

Page 20

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check hand-held thermometer for any damage that may have been caused by transport.

EN

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -10 ... +50 °C (14 ... 122 °F)

■

Relative humidity: 35 ... 85 % r. h. (non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the hand-held thermometer in its original packaging in a location that fulfils the

conditions listed above. If the original packaging is not available, pack and store the

instrument as described below:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to health,

e.g. caustic, toxic, carcinogenic, radioactive, etc.

20

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 21

6. Commissioning, operation

6. Commissioning, operation

6.1 Commissioning

Before switching on, connect the measuring probe(s) to the intended female connector

of the measuring instrument and make sure that a fully charged 9 V battery is inserted (2

batteries are included in the scope of delivery). The probe connection sockets are marked

on the instrument case with 1 or 2 correspondingly. The USB interface is marked next to

them.

6.2 Switching on/Switching off

To switch the measuring instrument on and off, press the ON/OFF key. After switching

the instrument on all segments are indicated on the display for approx. 1.5 seconds (full

segment indication). For the next approx. 1.5 seconds the instrument indicates the set

probe calibration code as well as the set measurement parameter for channel 1 (e.g.

CoFF for DIN characteristic curve and P for Pt100). After that the calibration data for the

2nd channel are displayed.

Finally, the instrument switches automatically to the measuring mode and displays the

current measurement parameter. In the upper display line (large display) the measured

value is displayed, a bar graph is located beneath it for graphical measured value

representation. In all 2-channel instruments the 2nd channel is displayed in the lower

display line (small display).

EN

Channel 1

Line 1: CoFF P = calibration on channel 1 per DIN, probe selection set to Pt100.

Channel 2

Line 2: CoFF P = calibration on channel 2 per DIN, probe selection set to Pt100.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

21

Page 22

6. Commissioning, operation

For all measuring instruments the measuring channels can be selected

according to the model-specific measurement parameters. For the version

with only one probe the correct measurement parameter is already set.

EN

When using measuring instruments with several channels and/or different

probes make sure that the correct measurement parameter is set. See

chapter 6.4.2 “Probe selection Prob”.

6.3 Menu structure and settings

Instrument settings such as measurement parameters, probe calibration, channel

deactivation, arrow keys, etc. are adjusted using a menu tree.

■

To open the main menu, press the ENTER/MENU key.

■

The ▲▼ arrow keys are used to select the desired menu items.

■

By pressing ESC, one returns to the measuring mode.

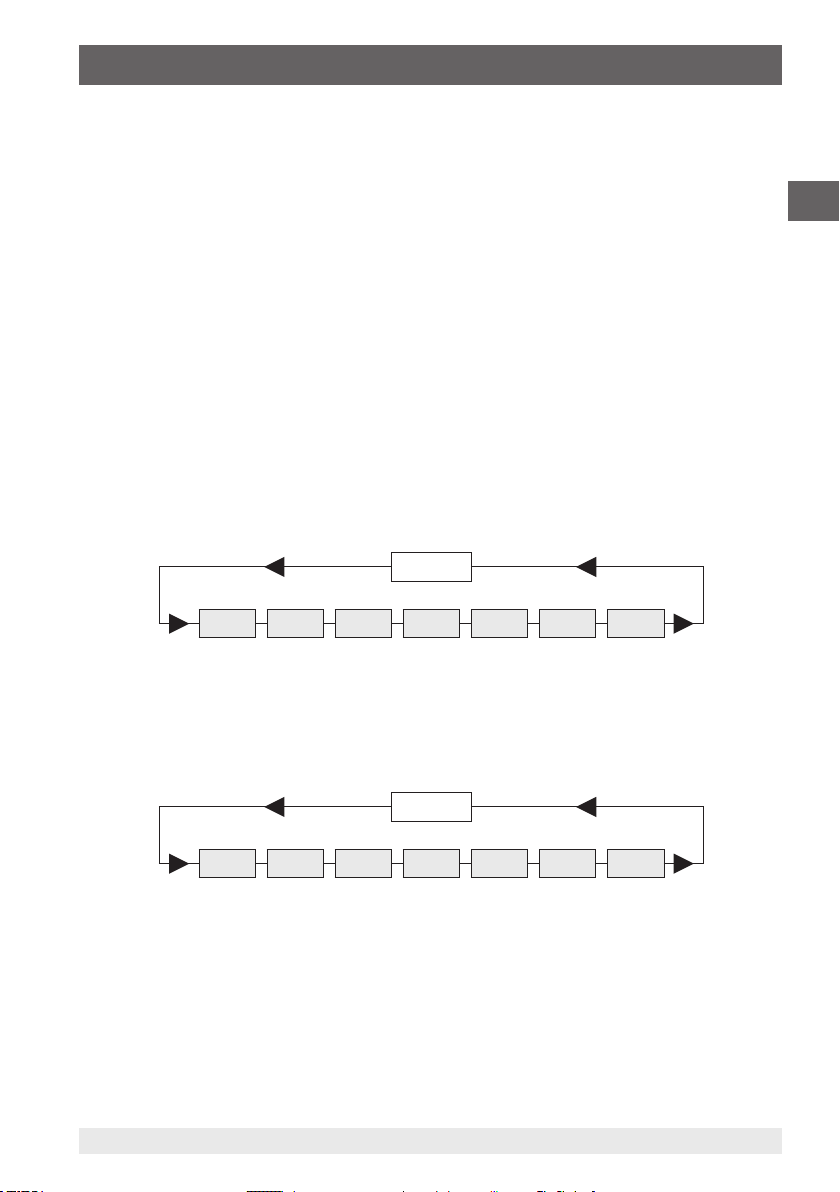

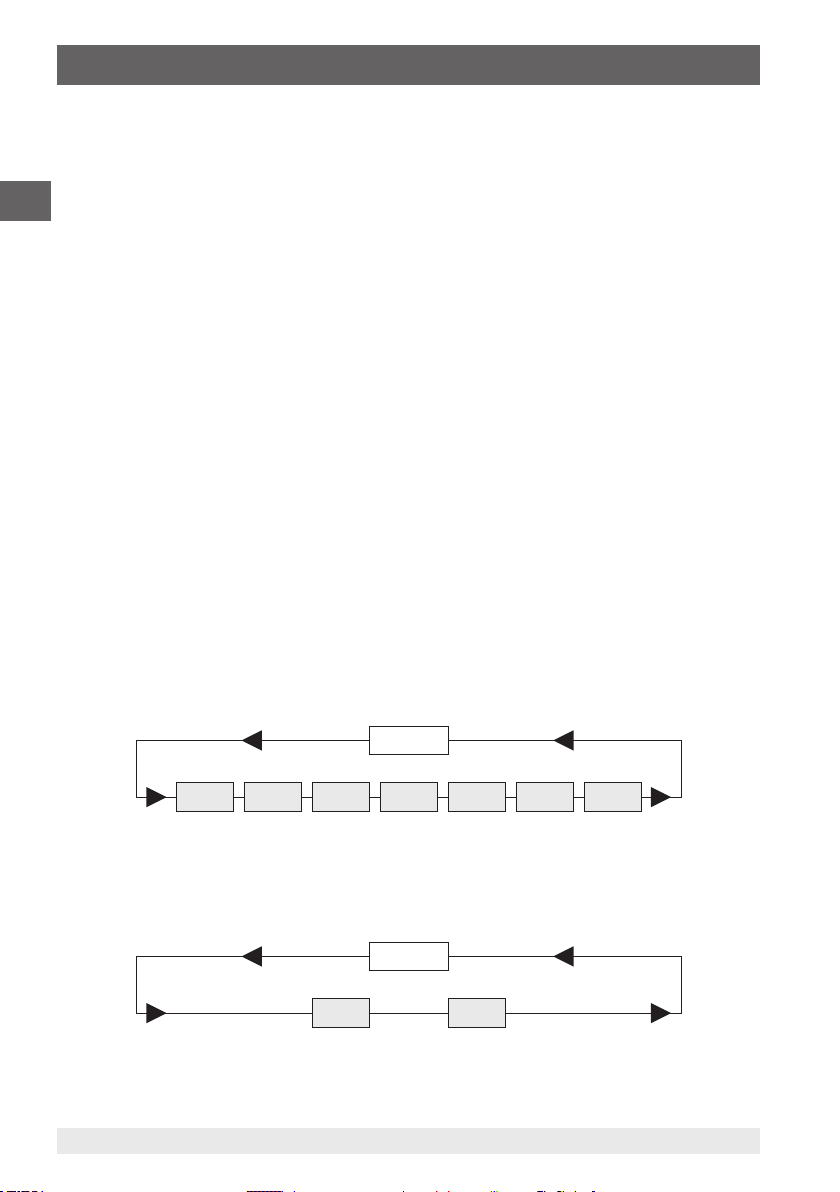

6.4 Menu tree

Unit Prob Lin2 CAL Chnl ArEA Lo6

°C P T1-T2 OFF OFF c OFF

°F J oP1 ON m ON

m/s K oP2

%rh L

g/m³ N

°C td R

°F td S

Pa T

hPa RH

m³/s D

22

Pr

H

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

Page 23

6. Commissioning, operation

6.4.1 Unit switching °C and °F or % rH, td or g/m³ [Unit]

Unit

Measuring unit temperature (°C = Celsius, °F = Fahrenheit)

Measuring unit humidity (% rH = relative humidity, td = dew point, g/m³ = absolute

humidity)

1. Press the ENTER/MENU key and select Unit using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

A small 1 appears on the left side of the display, it indicates the channel. (Channel

⇒

selection is only possible with 2-channel instruments).

3. Use the ▲▼ arrow keys to select the channel for which the displayed unit needs to be

changed.

4. Confirm by pressing ENTER/MENU.

Depending on the set probe, °C/°F or % rH/td/gm³ is displayed on the right side of

⇒

the display (see chapter 6.4.2 “Probe selection Prob”).

5. Select the required unit using the ▲▼ arrow keys and confirm it by pressing ENTER/

MENU.

6. Use ESC to return to the measuring mode.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

EN

6.4.2 Probe selection Prob

1. Press the ENTER/MENU key and select Prob using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

A small 1 appears on the left side of the display, it indicates the channel.

⇒

3. Using the ▲▼ arrow keys, switch the channel for which a probe should be selected.

4. Confirm the selection by pressing ENTER/MENU.

5. Now select the following probes using the ▲▼ arrow keys (see following table):

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

23

Page 24

6. Commissioning, operation

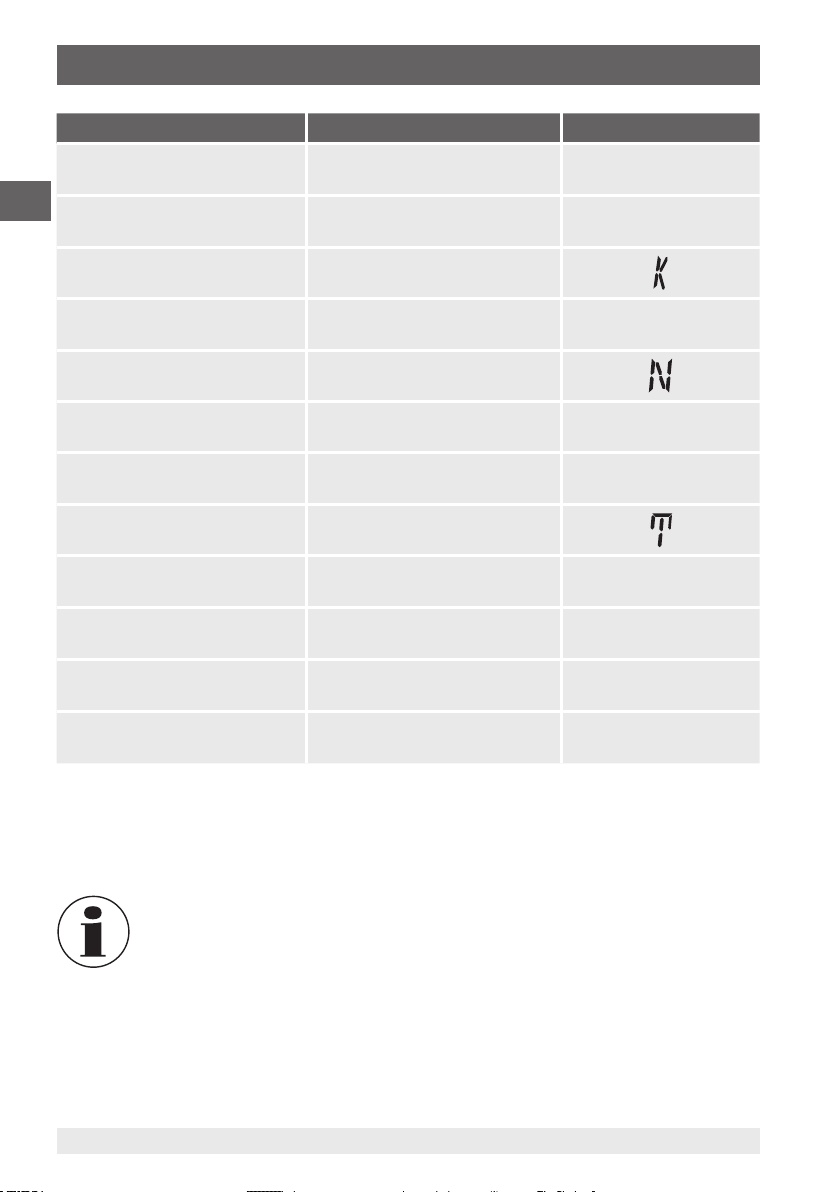

Measurement parameter Probe selection (Prob) LC display

Temperature Pt100 (RTD)

EN

Temperature Fe-CuNi type J

Temperature NiCr-Ni type K

Temperature Fe-CuNi type L

Temperature NiCrSi-NiSi type N

Temperature Pt13Rh-Pt type R

Temperature Pt10Rh-Pt type S

Temperature Cu-CuNi type T

Humidity % r. h.

Flow m/s

Pressure Pa

Hot wire m/s

P

)

L

R

S

r

h

d

PR

H

6. Press ENTER/MENU to confirm the desired setting.

7. Use ESC to return to the measuring mode.

Make sure that the correct measurement parameter is set for the connected

probe. If a measurement parameter is changed in the Prob menu and the

change is confirmed by pressing the Enter key, the standard calibration is

used automatically.

Note on combined probes (temperature and humidity):

Ensure that “relative humidity” is set as a measurement parameter for the

measuring channel to which the combined probe is connected.

24

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 25

6. Commissioning, operation

If the temperature value of the connected combined probe is to be displayed

as well, deactivate the channel to which no combined probe is connected

(see chapter 6.4.5 “Activating/deactivating measuring channels [Chnl] (only

for 2-channel instruments)”)”.

6.4.3 Activating/deactivating differential temperature display option [Lin2]

(only for 2-channel instruments)

1. Press the ENTER/MENU key and select Lin2 using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

3. Now activate or deactivate the display “Differential temperature” T1-T2 using the ▲▼

arrow keys.

If

⇒

4. Press ENTER/MENU to confirm the desired setting.

5. Use ESC to return to the measuring mode.

is visible on the LC display, the differential temperature is active.

T1-T2

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

To display differential temperature, both channels must be activated.

EN

6.4.4 Calibration mode CAL

This measuring instrument offers the possibility to perform a simple calibration when

replacing the probes in order to compensate the manufacturer-specific tolerances of the

probes and guarantee a consistently high accuracy for your measuring chain.

The instrument has 3 different calibration modes:

[OFF]: Standard characteristic curve

for example, for Pt100 resistance measurements DIN IEC 60751

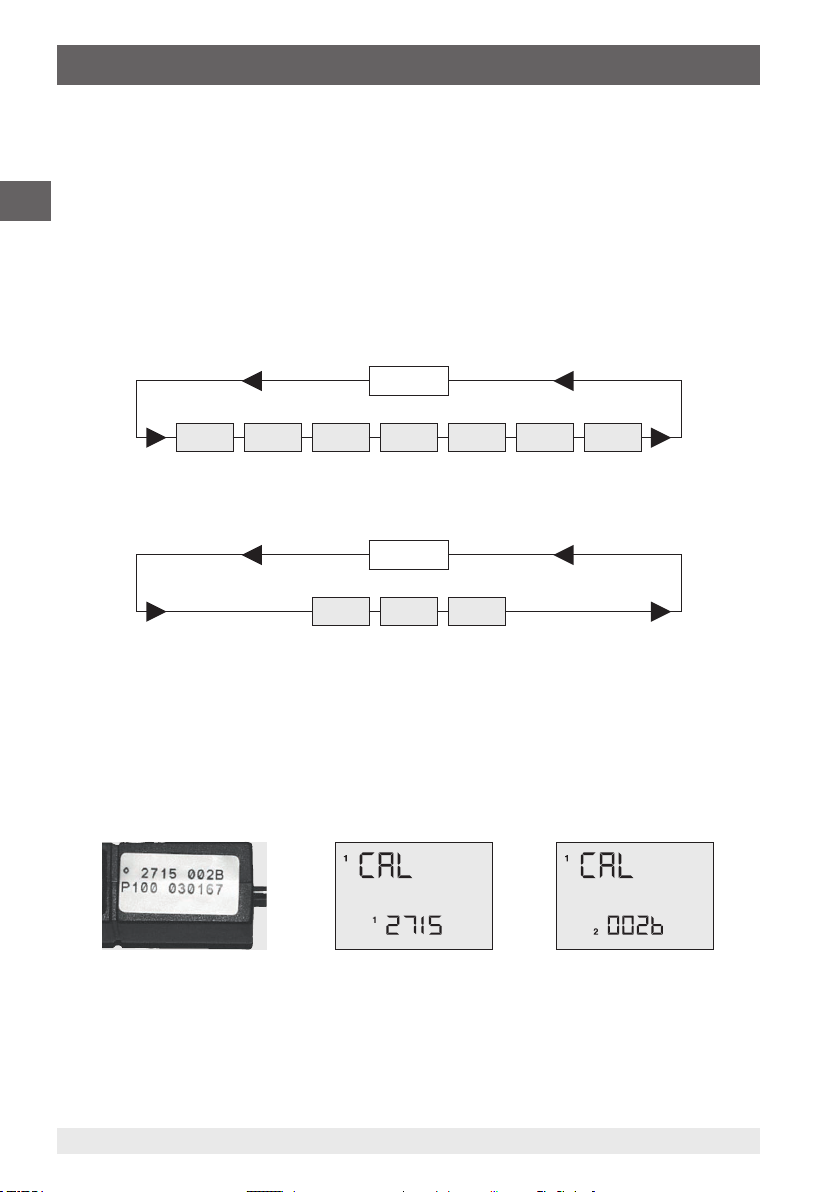

oP1: Calibration by code

The 2 x 4-digit code, clearly and visibly displayed on the handles of our probes,

corresponds to a 2-point calibration

oP2: Physical calibration

Calibration with reference standards: 1-point, 2-point or 3-point calibration

possible

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

25

Page 26

6. Commissioning, operation

The current calibration coefficients are shown in the accompanying traceable calibration

certificate.

CAL = calibrate

EN

1. Press the ENTER/MENU key and select CAL using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

A small 1 appears on the left side of the display, it indicates the channel.

⇒

3. Use the ▲▼ arrow keys to select the channel (1 or 2) to be calibrated (channel

selection only possible with 2-channel instruments).

4. Confirm the selection by pressing ENTER/MENU.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

5. Now use the ▲▼ arrow keys to select the desired calibration function.

CAL

CoFF oP1 oP2

Standard linearisation in accordance with DIN IEC 60751 [oFF

1. Use the ▲▼ arrow keys to select CoFF.

2. Press ENTER/MENU to confirm the desired setting.

3. Use ESC to return to the measuring mode.

Calibration by code oP1

1. Use the ▲▼ arrow keys to select oP1.

2. Press ENTER/MENU to confirm the desired setting.

A small 1 appears in the lower part of the display. 4 characters follow it (hex code

⇒

/ 0 ... F).

26

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 27

6. Commissioning, operation

3. Change the 4 characters using the ▲ arrow key.

4. Press the ▼ arrow key to go to the next position.

5. When all 4 characters are entered as required, confirm by pressing ENTER/MENU.

A small 2 appears and the following 4 characters can be changed as well.

⇒

6. Use ESC to return to the measuring mode.

When accessing oP1 using ENTER/MENU, the oP1 function (calibration by

code) is activated, even if the menu has been exited by pressing ESC.

Example of the measured value display after entering a probe calibration code:

The small 1 in the left corner, in combination with the display segment CAL in the centre

of the display, indicates that the calibration by code oP1 has been activated.

EN

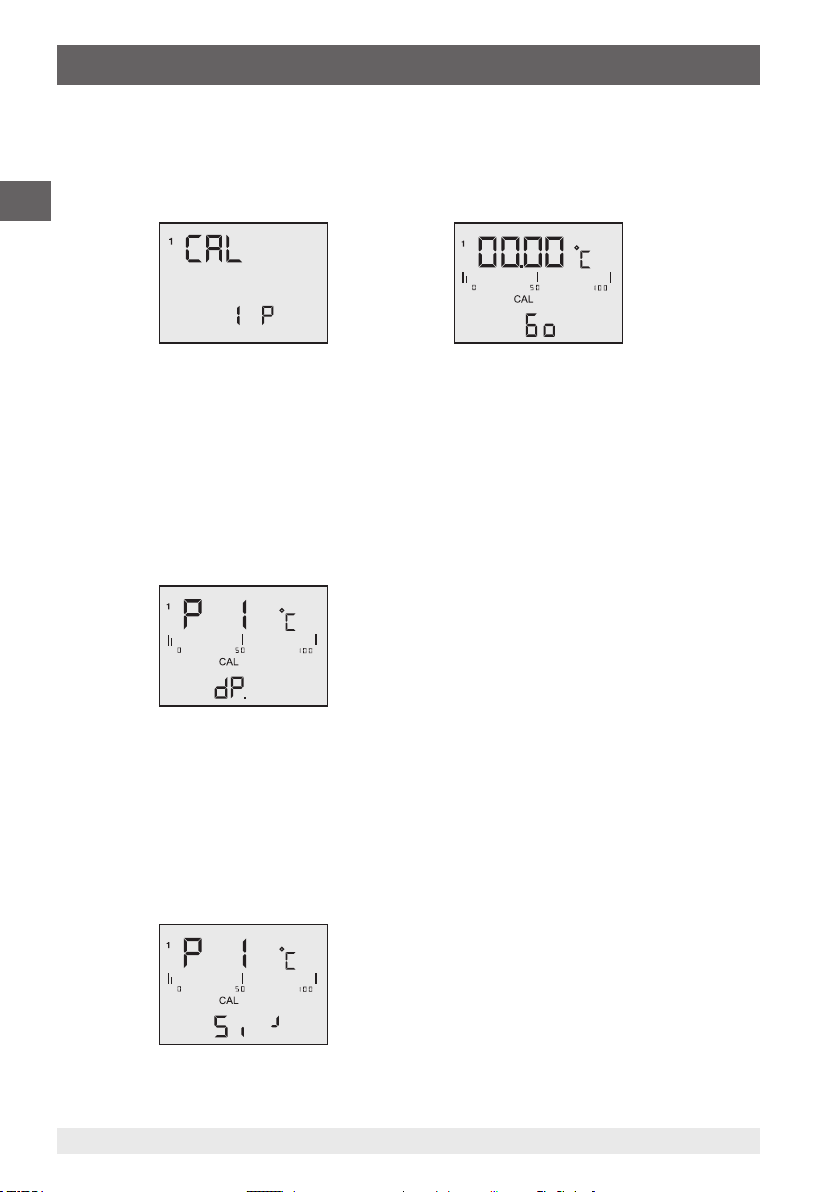

Physical calibration oP2

1. Use the ▲▼ arrow keys to select oP2.

2. Press ENTER/MENU to confirm the desired setting.

1 P is displayed in the lower part of the display.

⇒

3. Use the ▲▼ arrow keys to select from 1-point 1 P-, 2-point 2 P- and 3-point 3

P-calibration.

oP2

1 P 2 P 3 P

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

27

Page 28

6. Commissioning, operation

Example of 1-point calibration:

1. Confirm 1-point calibration 1 P by pressing ENTER/MENU.

Go appears on the display.

⇒

2. Once the measured value is stable, confirm by pressing ENTER/MENU.

EN

After approx. 2 seconds P1 appears in the first display line for measured value 1, dP

appears in the 2nd line for the decimal point.

3. Use the ▲▼ arrow keys to select the desired number of decimal places:

d P. = two decimal places

dP . = one decimal place (decimal point moves one position to the right)

4. Press ENTER/MENU to confirm the desired setting.

Si_ appears on the display.

⇒

5. Use the ▲▼ arrow keys to select the sign:

Si_ = the number to be entered is in the negative range (below 0.00 °C)

Si┘= the number to be entered is in the positive range

28

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 29

6. Commissioning, operation

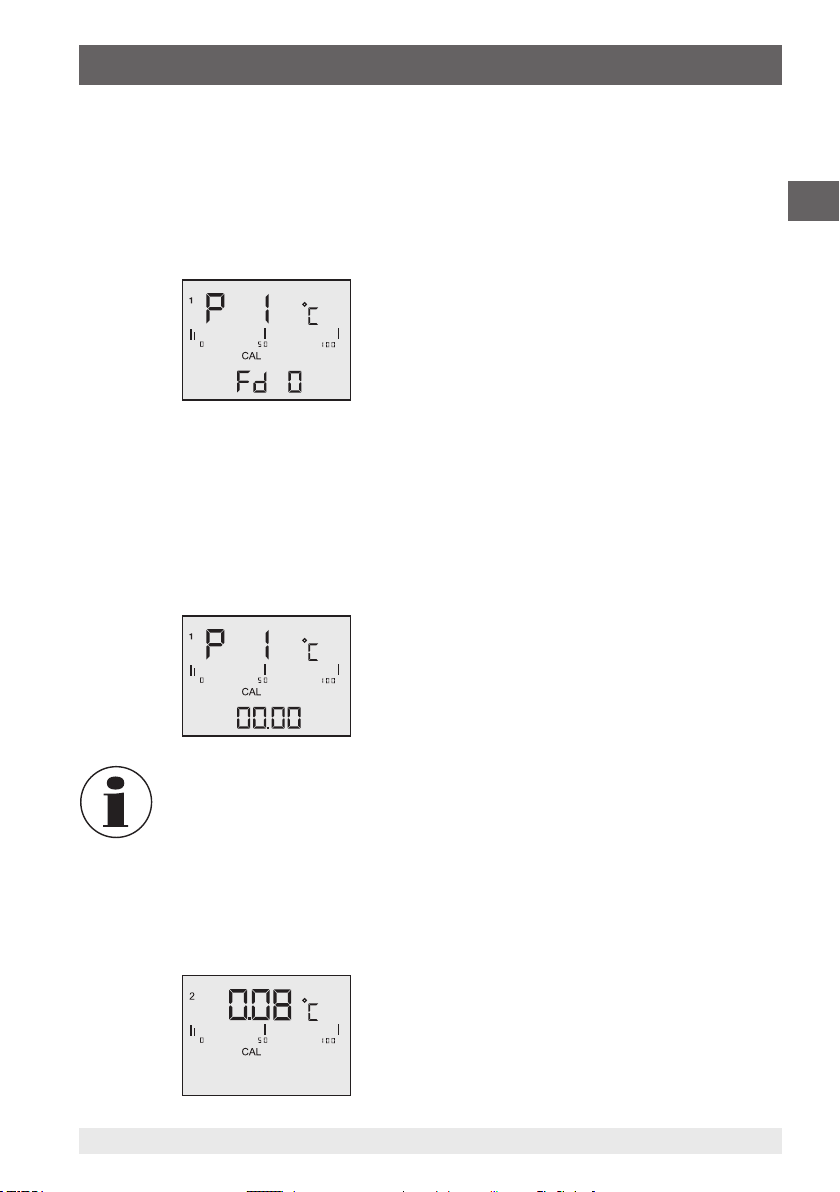

6. Press ENTER/MENU to confirm the desired setting.

Fd 0 appears on the display.

⇒

7. Use the ▲▼ arrow keys to select the range.

Fd 0 = below 1,000 °C

Fd 1 = above 1,000 °C

8. Press ENTER/MENU to confirm the desired setting.

00.00 appears on the display (or similar).

⇒

9. Enter the temperature of the reference at this point.

10. Change the digits using the ▲ arrow key.

11. Use the ▼ arrow key to switch to the next digit.

12. After completing the input of the temperature, confirm by pressing ENTER/MENU.

13. Use ESC to return to the measuring mode.

The physical calibration oP2 cannot be cancelled using the ESC key. If

required, the calibration can be cancelled by switching off the measuring

instrument.

EN

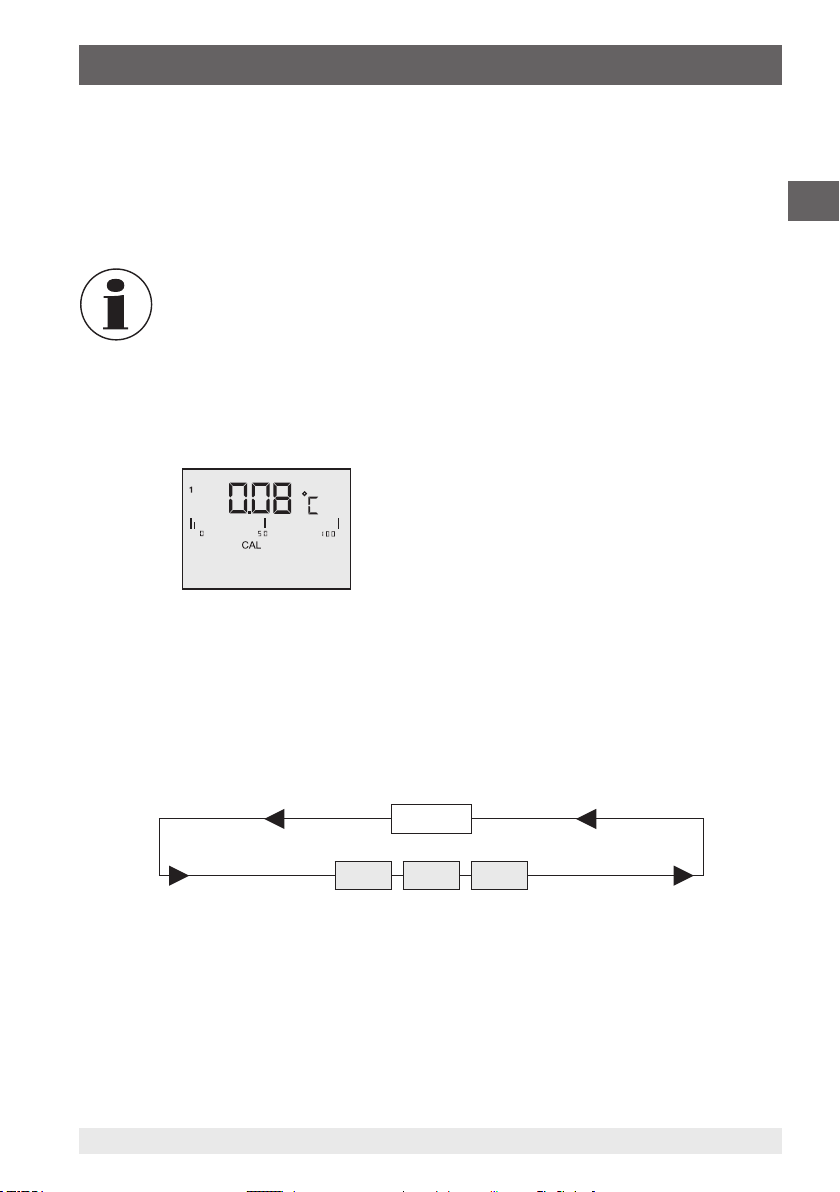

Example of the measured value display after physical calibration against a

reference standard:

The small 2 in the left corner, in combination with the display segment CAL in the centre

of the display, indicates that the physical probe calibration oP2 has been activated.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

29

Page 30

6. Commissioning, operation

6.4.4.1 Calibration function combined probe (humidity/temperature), CAL

All humidity probes by WIKA are combined probes.

This means that besides the humidity sensor they also contain a temperature sensor.

Both measurement parameters are connected to the same measuring channel using one

EN

probe connector. To calibrate both measurement parameters, humidity and temperature,

the measurement parameter rH (rel. humidity) must first be set (see chapter 6.4.2 “Probe

selection Prob”).

The instrument has 3 different calibration modes:

OFF Standard characteristic curve

no probe-specific correction is performed

oP1 Calibration by code

The 2 x 4-digit code, clearly and visibly displayed on the handles of our probes

(rH = humidity and P °C = temperature), corresponds to a 2-point calibration

oP2 Physical calibration

Calibration with reference standards: 1-point, 2-point or 3-point calibration is

only possible for the measurement parameter rH humidity.

CAL = calibrate

1. Press the ENTER/MENU key and select CAL using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

A small 1 appears on the left side of the display, it indicates the channel.

⇒

3. Use the ▲▼ arrow keys to select the channel (1 or 2) to be calibrated.

4. Confirm the selection by pressing ENTER/MENU.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

5. Now use the ▲▼ arrow keys to choose between rH for humidity calibration and P °C

for temperature calibration.

CAL

rH P°C

30

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 31

6. Commissioning, operation

6. Use the ▲▼ arrow keys to select the desired calibration function.

CAL

CoFF oP1 oP2

Standard characteristic curve oFF

1. Use the ▲▼ arrow keys to select oFF.

2. Press ENTER/MENU to confirm the desired setting.

3. Use ESC to return to the measuring mode.

Calibration by code oP1

1. Use the ▲▼ arrow keys to select oP1.

2. Press ENTER/MENU to confirm the desired setting.

A small 1 appears in the lower part of the display. 4 characters follow it (hex code

⇒

/ 0 ... F).

3. Change the 4 characters using the ▲ arrow key.

4. Press the ▼ arrow key to go to the next position.

5. When all 4 characters are entered as required, confirm by pressing ENTER/MENU.

A small 2 appears and the following 4 characters can be changed as well.

⇒

6. Use ESC to return to the measuring mode.

EN

6.4.5 Activating/deactivating measuring channels [Chnl] (only for 2-channel

instruments)

Chnl = Channel = select

1. Press the ENTER/MENU key and select Chnl using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

A small 1 appears on the left side of the display, it indicates the channel.

⇒

3. Use the ▲▼ arrow keys to select the channel to be activated or deactivated.

4. Confirm the selection by pressing ENTER/MENU.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

31

Page 32

6. Commissioning, operation

5. Now use the ▲▼ arrow keys to activate on or deactivate off the set channel.

6. Press ENTER/MENU to confirm the desired setting.

7. Use ESC to return to the measuring mode.

EN

Alternative: keep the HOLD/MAX/MIN/AVE key pressed for 2 seconds; this deactivates

or activates channel 2.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

At least one channel is always active!

6.4.6 Area entry for volume flow [ArEA]

The area dimensions can be entered only on instruments for flow measurement.

1. Press the ENTER/MENU key and select ArEA using the ▲▼ arrow keys.

2. Press the ENTER/MENU key once again.

A small 1 appears on the left side of the display, it indicates the channel.

⇒

3. Use the ▲▼ arrow keys to select the channel.

4. Confirm the selection by pressing ENTER/MENU.

5. Use the ▲▼ arrow keys to select the unit of measure:

c = centimeter²

m = meter²

6. Confirm the selection by pressing ENTER/MENU.

00.00 is displayed now in the lower line of the display.

⇒

7. Change the blinking number by pressing the ▲ arrow key.

8. Press the ▼ arrow key to go to the next position.

9. Confirm the input by pressing ENTER/MENU.

10. Use ESC to return to the measuring mode.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

32

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 33

6. Commissioning, operation

6.4.7 Storage management [Lo6] (not possible for CTH6300)

1. Press the ENTER/MENU key and select Lo6 using the ▲▼ arrow keys (only when the

data logger version has been ordered).

2. Press the ENTER/MENU key once again.

OFF is shown in the lower line of the display.

⇒

3. Now use the ▲▼ arrow keys to start the logger mode with ON.

4. Confirm the selection by pressing ENTER/MENU.

MENU

Unit Prob Lin2 CAL Chnl ArEA Lo6

5. Use the ▲▼ arrow keys to choose between the automatic Auto or manual SPot

memory.

6. Confirm by pressing ENTER/MENU.

7. Decide between adding or creating a new log file by selecting Add or nLo6.

When selecting the automatic memory, there is a prompt to select the measuring

⇒

interval:

1S = 1 second 1M = 1 minute

5S = 5 seconds 2M = 2 minutes

10S = 10 seconds 5M = 5 minutes

20S = 20 seconds 10M = 10 minutes

30S = 30 seconds 20M = 20 minutes

EN

8. Confirm the input by pressing ENTER/MENU.

9. Use ESC to return to the measuring mode.

Manual saving using SPot. Press the ESC key to save individual measured values

manually.

6.5 Memory request [HOLD-MAX-MIN-AVE]

After pressing the HOLD-MAX-MIN-AVE key for the first time, the current measured

values at the moment of actuation are “frozen” and indicated on the display as hold

values. Press this key repeatedly to request saved maximum, minimum and average

values in the lower line (small display).

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

33

Page 34

6. Commissioning, operation

Note for 2-channel instruments:

After displaying the hold values for both channels (large and small display),

the MAX-MIN-AVE values of the first channel are displayed in the lower line

EN

Clear memory (MAX-MIN-AVE)

▶

Press the CLEAR key once.

6.6 Change measurement cycle (FAST mode)

1. Press the FAST/▼ key once.

2. Press FAST/▼ key again

(small display), after that, the values of the second channel are displayed. If

only one probe is connected to a 2-channel measuring instrument, deactivate

the 2nd channel (see chapter 6.4.5 “Activating/deactivating measuring

channels [Chnl] (only for 2-channel instruments)”).

During the memory request, the extremes MAX-MIN and the average value

AVE are not updated or calculated.

Clr appears on the display. All extremes (MAX-MIN and AVE) measured up to

⇒

this moment are deleted. After deletion of the memory the measuring instrument

switches back to the measuring mode automatically.

Fast mode is initiated. The measuring instrument measures 4 times per second

⇒

now.

Return to the normal mode with 1 measured value per second again.

⇒

Note that the battery consumption in the Fast mode is approximately three

times higher than it is in the normal mode.

This setting is deactivated by switching off.

6.7 AUTO-OFF function

1. Press the ESC-AUTO-OFF key.

dAoF will be shown on the display. The Auto-Off function is deactivated now.

⇒

2. Press the ESC-AUTO-OFF key.

EAoF will be shown on the display. The measuring instrument is shut down

⇒

automatically after 30 minutes.

dAoF = Disable Auto-off

EAoF = Enable Auto-off

34

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

Page 35

6. Commissioning, operation / 7. USB interface protocol

This setting is deactivated by switching off (default setting is EAoF).

6.8 Special functions

6.8.1 Ohm/Microvolt/Volt/Hertz display

To display the indicated values in the corresponding basic unit, during switching on

simultaneously press the FAST/▼ key and the ON/OFF key and keep them pressed for

approx. 3 seconds until the following basic unit is displayed:

o = Ohm (Pt100)

H = Hertz (flow m/s)

u = Microvolt (thermocouples)

U = Volt (humidity)

6.8.2 Zero adjustment (zero)

Keep the Clear key pressed (for approx. 3 seconds) to set the displayed value to 0.

Before pressing the key make sure that the actual value is also 0 (no flows/pressure

present at the probe).

6.8.3 Deactivation of channel 2 (toggle)

Keep the Hold key pressed (for approx. 3 seconds) to deactivate or activate the 2nd

measuring channel.

7. USB interface protocol

EN

With the CTH6x00 instrument series, a USB-/RS-232 driver from the manufacturer FTDI

is used.

Parameters

Baud rate 2,400 baud

Data bits 8

Stop bits 2

Parity None

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

35

Page 36

7. USB interface protocol

To transfer the measured values, the following requests must be sent to the measuring

instrument. The following table illustrates which values can be requested via the interface.

CTH6500

EN

Recognise MEASURED VALUE 1 + 2 automatically

Processor version 6E (hex) 110 (dez.) n (ASCII)

Instrument type - - V (ASCII)

Instrument serial number - 83 (dez.) S (ASCII)

Read storage (only for instruments with

data logger)

Enable keyboard 0 (hex) 0 (dez.) -

Command clarification

Commands must each be finished with Cr Lf (0D 0A or Hex value &0D&0A)

■

“FC” (hex) delivers the current data set e.g. “23.351 25.462”

■

“S” delivers the serial number e.g. “79506000108”

■

“n” delivers the version, e.g. “V3.03”

■

“l” (lower-case l) Read – delivers a dump of all values from the memory in the format

e.g. “23.35 25.46 Cr Lf”

FC (hex) 252 (dez.) ü (ASCII)

6C (hex) 108 (dez.) l (ASCII)

If data are read out from the instrument using the FC (hex) command, the

keyboard is locked. It can be enabled again using the 0 (hex) command.

The data are sent by the instrument in the following format.

Data type = String

The string length depends on whether it is a 1-channel or a 2-channel instrument. With a

2-channel instrument, the string can only be a max. 18 characters long.

36

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 37

8. Maintenance, cleaning and recalibration / 9. Faults

8. Maintenance, cleaning and recalibration

8.1 Maintenance

These hand-held thermometers are maintenance-free.

Repairs must only be carried out by the manufacturer.

This does not apply to the battery replacement.

8.2 Cleaning

CAUTION!

■

Before cleaning, switch off and disconnect the hand-held thermometer

from the mains.

■

Clean the instrument with a moist cloth.

■

Do not use any aggressive cleaning agents.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument or temperature probe before

returning it, in order to protect persons and the environment from exposure

to residual media.

■

Residual media at the dismounted hand-held thermometer and/or

temperature probe can result in a risk to persons, the environment and

equipment. Take sufficient precautionary measures.

EN

For information on returning the instrument see chapter 10.2 “Return”.

8.3 Recalibration

DKD/DAkkS certificate - official certificates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. The basic settings will be corrected if necessary.

9. Faults

In the event of maloperation or faults the instrument helps the operator by means of the

following error messages.

Display Cause Measures

Wrong probe or no probe connected Connect probe or connect correct

open

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

probe.

37

Page 38

9. Faults

Display Cause Measures

“too low” underrange of the

7olo

measuring range

EN

“too high” overrange of the

7o

h

measuring range

'

Temperature of the reference

7E

r

7Er2

E15

E19

E1dh

E16

E1oh

E1eh

E23

measuring point exceeds the upper

i

limit of the measuring range

Temperature of the reference

measuring point is below the lower

limit of the measuring range

Battery is completely discharged Insert new batteries

Interruption of the Auto-o function Switch on the Auto-o function

EE-prom content destroyed Send in for repair

Use the temperature probe according

to the technical specications. See

chapter 3 “Specications”.

Use the temperature probe according

to the technical specications. See

chapter 3 “Specications”.

Use the temperature probe according

to the technical specications. See

chapter 3 “Specications”.

Use the temperature probe according

to the technical specications. See

chapter 3 “Specications”.

again, see chapter 6.7 “AUTO-OFF

function”.

E25

E12

E31

38

Overow Remove the battery and then re-

insert it.

Temperature of the reference

measuring point is outside of the

measuring range

CAUTION!

If faults cannot be eliminated by means of the measures listed above, the

hand-held thermometer must be shut down immediately.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

10.2 “Return”.

WIKA operating instructions, models CTH6300 and CTH6500

Use the temperature probe according

to the technical specications. See

chapter 3 “Specications”.

2079988.08 02/2018 EN/DE/IT

Page 39

10. Dismounting, return and disposal

10. Dismounting, return and disposal

WARNING!

Residual media at the dismounted hand-held thermometer and/or

temperature probe can result in a risk to persons, the environment and

equipment.

Take sufficient precautionary measures.

10.1 Dismounting

WARNING!

Risk of burns!

Let the temperature probe cool down sufficiently before dismounting it!

10.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions etc.).

EN

When returning the instrument, use the original packaging or a suitable transport

package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with shock-absorbent material, in the packaging. Place

shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our local

website.

10.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

2079988.08 02/2018 EN/DE/IT

WIKA operating instructions, models CTH6300 and CTH6500

39

Page 40

10. Dismounting, return and disposal / 11. Accessories

This marking on the instruments indicates that they must not be disposed of

in domestic waste. The disposal is carried out by return to the manufacturer

or by the corresponding municipal authorities.

EN

11. Accessories

Temperature probe

■

Immersion probe

■

Penetration probe

■

Surface probe (only for CTH6500)

■

Combined humidity-temperature probe (only for CTH6500)

■

Customer-specific probes are available on request

■

Adapter for thermocouples, DIN on TC miniature connector

■

Spare DIN connector for the probe

Voltage supply

■

AC adapter

■

9 V rechargeable battery and charger

■

9 V battery

Test case

■

Transport case, robust

■

Case set with rechargeable battery, charger, power supply unit, interface cable and

software

■

Case set with power supply unit AC 100 ... 260 V, interface cable and software

Software

■

DE-Graph software

■

PC adapter cable USB

Other

■

DKD/DAkkS calibration certificate

40

WIKA operating instructions, models CTH6300 and CTH6500

2079988.08 02/2018 EN/DE/IT

Page 41

Inhalt

Inhalt

1. Allgemeines 43

2. Sicherheit 44

2.1 Bestimmungsgemäße Verwendung. . . . . . . . . . . . . . . 45

2.2 Personalqualifikation. . . . . . . . . . . . . . . . . . . . 45

2.3 Besondere Gefahren. . . . . . . . . . . . . . . . . . . . 46

3. Technische Daten 47

4. Aufbau und Funktion 50

4.1 Beschreibung . . . . . . . . . . . . . . . . . . . . . . 50

4.2 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . 50

4.3 Bedien- und Anzeigeelemente . . . . . . . . . . . . . . . . 51

4.4 Tastenfeld . . . . . . . . . . . . . . . . . . . . . . .52

4.5 Spannungsversorgung . . . . . . . . . . . . . . . . . . . 53

4.6 Batteriewechsel . . . . . . . . . . . . . . . . . . . . . 53

4.7 Temperaturfühler . . . . . . . . . . . . . . . . . . . . . 54

4.8 Temperaturfühler anstecken/wechseln. . . . . . . . . . . . . . 55

4.9 Steckerbelegung . . . . . . . . . . . . . . . . . . . . .55

4.9.1 Fühleranschluss Pt100 4-Leiter 55

4.9.2 Fühleranschluss Thermoelement 56

4.9.3 Fühleranschluss Flügelrad Mini Air 57

4.9.4 Adapter DIN-Stecker auf Thermoelementbuchse 57

5. Transport, Verpackung und Lagerung 58

5.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . 58

5.2 Verpackung . . . . . . . . . . . . . . . . . . . . . . .58

5.3 Lagerung. . . . . . . . . . . . . . . . . . . . . . . . 58

6. Inbetriebnahme, Betrieb 59

6.1 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . 59

6.2 Ein-/Ausschalten . . . . . . . . . . . . . . . . . . . . . 59

6.3 Menüstruktur und Einstellungen . . . . . . . . . . . . . . . .60

6.4 Menübaum . . . . . . . . . . . . . . . . . . . . . . . 60

6.4.1 Einheitenumschaltung °C und °F bzw. % rH, td oder g/m³ [Unit] 61

6.4.2 Fühlerauswahl Prob 61

6.4.3 Anzeigeoption Differenztemperatur aktivieren/deaktivieren [Lin2]

(Nur für 2-Kanalgeräte) 63

6.4.4 Kalibriermodus CAL 63

6.4.5 Messkanäle aktivieren/deaktivieren [Chnl] (nur für 2-Kanalgeräte) 69

6.4.6 Flächeneingabe für Volumenstrom [ArEA] 70

6.4.7 Speicherverwaltung [Lo6] (nicht möglich bei CTH6300) 71

6.5 Speicherabfrage [HOLD-MAX-MIN-AVE] . . . . . . . . . . . . .71

2079988.08 02/2018 EN/DE/IT

DE

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

41

Page 42

Inhalt

6.6 Messzyklus ändern (FAST-Modus) . . . . . . . . . . . . . . .72

6.7 AUTO-OFF-Funktion . . . . . . . . . . . . . . . . . . . . 72

6.8 Sonderfunktionen . . . . . . . . . . . . . . . . . . . . .73

6.8.1 Ohm/Microvolt/Volt/Hertz-Anzeige 73

6.8.2 Nullpunktabgleich (Zero) 73

6.8.3 Kanal 2 Deaktivierung (Toggle) 73

DE

7. Schnittstellenprotokoll USB 73

8. Wartung, Reinigung und Rekalibrierung 75

8.1 Wartung . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2 Reinigung . . . . . . . . . . . . . . . . . . . . . . . 75

8.3 Rekalibrierung . . . . . . . . . . . . . . . . . . . . . .75

9. Störungen 75

10. Demontage, Rücksendung und Entsorgung 77

10.1 Demontage . . . . . . . . . . . . . . . . . . . . . .77

10.2 Rücksendung. . . . . . . . . . . . . . . . . . . . . .77

10.3 Entsorgung . . . . . . . . . . . . . . . . . . . . . . 77

11. Zubehör 78

Konformitätserklärungen finden Sie online unter www.wika.de.

42

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

Page 43

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Hand-Held Thermometer Typ CTH6300

und Typ CTH6500 werden nach dem aktuellen Stand der Technik konstruiert und

gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitätsund Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO

14001 zertifiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

DE

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: CT 51.05 und CT 55.10

- Anwendungsberater: Tel.: +49 9372 132-9986

Fax: +49 9372 132-8767

testequip@wika.com

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

43

Page 44

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

DE

2. Sicherheit

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann,

wenn sie nicht gemieden wird.

GEFAHR!

… kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberflächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie

nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

44

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Hand-Held Thermometer und/oder Temperaturfühler hinsichtlich

Messbereich, Ausführung und spezifischen Messbedingungen ausgewählt

wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise befinden sich in den einzelnen Kapiteln

dieser Betriebsanleitung.

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

Page 45

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Die universell einsetzbaren Hand-Held Thermometer für die mobile, anspruchsvolle

Temperaturmessung verarbeiten die Signale typischer Thermometer. So können Temperaturen von -200 ... +1.500 °C (-328 ... +2.732 °F) gemessen werden.

Dieses Gerät ist nicht für den Einsatz in explosionsgefährdeten Bereichen zugelassen!

Die Geräte sind ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und dürfen nur dementsprechend verwendet werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualifikation durchführen

lassen.

DE

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der

landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der Lage, die

beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

45

Page 46

2. Sicherheit

2.3 Besondere Gefahren

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare Lebens-

DE

gefahr.

WARNUNG!

Messstoffreste am ausgebauten Hand-Held Thermometer und/oder

Temperaturfühler können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

WARNUNG!

■

Bei Betrieb oder Laden mit einem defekten Netzgerät (z. B. Kurzschluss

von Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche Spannungen auftreten!

■

Nur das von WIKA für das Präzisions-Hand-Held Thermometer zugelassene Netzgerät verwenden.

■

Kein schadhaftes oder abgenutztes Ladegerät verwenden.

■

Betriebsparameter gemäß Kapitel 3 „Technische Daten“ beachten.

■

Stecker nicht mit Gewalt in die Buchsen einstecken. Die Messkanal- und

Schnittstellenstecker sind unterschiedlich.

■

Sollte beim Einschalten kein Fühler am Messgerät angeschlossen sein,

so zeigt das Display „open” (siehe Kapitel 9 „Störungen“).

■

Das Hand-Held Thermometer nicht in beschädigtem Zustand verwenden. Vor dem Verwenden des Gerätes prüfen, ob das Gehäuse Risse

oder fehlende Kunststoffteile aufweist. Besonders auf die Isolierung der

Stecker achten.Für die Messung den richtigen Temperaturfühler und den

richtigen Messbereich auswählen.

■

Die Batterieabdeckung muss geschlossen und eingerastet sein, bevor

das Gerät verwendet wird.

■

Das Gerät nicht verwenden, wenn es nicht normal funktioniert. Der

Geräteschutz kann beeinträchtigt sein. Im Zweifelsfall das Gerät überprüfen lassen.

■

Das Gerät nicht im Bereich von explosiven Gasen, Dämpfen oder Staub

verwenden.

■

Zur Vermeidung einer falschen Anzeige, die zu einem elektrischen Schlag

oder zu Verletzungen führen können, die Batterie ersetzen, sobald die

Batterieanzeige erscheint.

2079988.08 02/2018 EN/DE/IT

46

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

Page 47

2. Sicherheit / 3. Technische Daten

Die Sicherheit des Benutzers kann durch das Gerät beeinträchtigt sein, wenn es zum

Beispiel:

■

sichtbare Schäden aufweist.

■

nicht mehr wie vorgeschrieben arbeitet.

■

längere Zeit unter ungeeigneten Bedingungen gelagert wurde.

In Zweifelsfällen das Gerät grundsätzlich an den Hersteller zur Reparatur bzw. Wartung

einschicken.

3. Technische Daten

Hand-Held Thermometer Typ CTH6300 Typ CTH6500

Fühlertypen Pt100, Thermoelemente Pt100, Thermoelemente,

Feuchte, Strömung

Messeingänge 1 oder 2

Messbereiche

Pt100 -200 ... +600 °C (-392 ... +1.112 °F)

Thermoelemente -200 ... +1.500 °C (-392 ... + 2.732 °F)

Feuchte

Strömung

Genauigkeiten

Widerstandsthermometer

Typ Pt100

Thermoelement Typen K, J,

L, N und T

Thermoelement Typen R

und S

Feuchte

Strömung

--

--

0,1 K von -100 ... +200 °C

(-148 ... +392 °F)

sonst 0,1 % v. MW

0,3 K von 0 ... 200 °C

(32 ... 392 °F)

1 K von 200 ... 1.000 °C

(392 ... 1.832 °F)

1,5 K oberhalb 1.000 °C

(1.832 °F)

1 K + 0,1 % v. MW 1 K + 0,1 % v. MW

--

--

0 ... 100 % r. F.

0 ... 40 m/s

0,03 K von -50 ... +199,99 °C

(-58 ... +394,98 °F)

0,05 K von -200 ... -50,01 °C

(-328 ... -58,02 °F)

sonst 0,05 % v. MW

0,2 K von 0 ... 200 °C

(32 ... 392 °F)

0,5 K von 200 ... 1.000 °C

(392 ... 1.832 °F)

1 K oberhalb 1.000 °C

(1.832 °F)

1,5 % r. F.

0,5 % vom Endwert

DE

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

47

Page 48

3. Technische Daten

Digitales Anzeigegerät Typ CTH6300 Typ CTH6500

Anzeige

Display 4 1/2-stellige, große 2-zeilige LC-Display mit

Hintergrundbeleuchtung

Auösung 0,1 K 0,01 K bis 200 °C (392 °F),

DE

Funktionen

Messrate 4/s („fast“); 1/s („slow“)

Speicher Min./Max.

Funktionen via Tastendruck Min.-/Max.-Speicher, Hold, Nullpunktabgleich

Echtzeituhr integrierte Uhr mit Datum

Spannungsversorgung

Hilfsenergie DC 9 V, Blockbatterie oder Akku

Batterielebensdauer ca. 20 Betriebsstunden mit Batterie

Zulässige Umgebungsbedingungen

Betriebstemperatur 0 ... 40 °C (32 ... 104 °F)

Lagertemperatur -10 ... +50 °C (14 ... 122 °F)

Kommunikation

Schnittstelle USB via Schnittstellenkabel

Gehäuse

Material schlagfester ABS-Kunststo, Klarsichtscheibe

Abmessungen (L x B x H) 200 x 93 x 44 mm (7.87 x 3.66 x 1.73 in)

Gewicht 300 g (0,66 lbs.) 350 g (0,77 lbs.)

dann 0,1 K

Zertifikate/Zeugnisse

Zertikat

Kalibrierung Standard: Kalibrierzertikat 3.1 nach DIN EN 10204

Option: DKD/DAkkS-Kalibrierzertikat

Empfohlenes

Rekalibrierungsinterval

1 Jahr (abhängig von den Nutzungsbedingungen)

Zulassungen und Zertifikate siehe Internetseite

Weitere technische Daten siehe WIKA-Datenblatt CT 51.05 und CT 55.10 und Bestellunterlagen.

48

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

2079988.08 02/2018 EN/DE/IT

Page 49

44 (1.73)

93 (3.66)

3. Technische Daten

Standardfühler (Eintauchfühler) Temperaturbereich

°C °F

Pt100, d = 3 mm, l = 150 mm (d = 0,12 in, l = 5,91 in) -200 ... +450 -392 ... +842

Pt100, d = 3 mm, l = 300 mm (d = 0,12 in, l = 11,81 in) -200 ... +450 -392 ... +842

Pt100, d = 6 mm, l = 300 mm (d = 0,24 in, l = 11,81 in) -200 ... +450 -392 ... +842

TC K, d = 3 mm, l = 300 mm (d = 0,12 in, l = 11,81 in) -200 ... +1.100 -392 ... +2.012

TC K, d = 3 mm, l = 500 mm (d = 0,12 in, l = 19,69 in) -200 ... +1.100 -392 ... +2.012

Abmessungen in mm (in)

Ansicht von vorn Ansicht von der Seite (links)

DE

83 (3.27)

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

202 (7.95)

37 (1.46)

49

Page 50

3. Technische Daten / 4. Aufbau und Funktion

Ansicht von unten (1-Kanal-Gerät)

DE

4. Aufbau und Funktion

4.1 Beschreibung

Die universell einsetzbaren Hand-Held Thermometer für die mobile, anspruchsvolle

Temperaturmessung bestechen durch Flexibilität und leichte Handhabung. Neben

Pt100-Widerstandsthermometern verarbeiten sie die Signale typischer Thermoelemente.

So können Temperaturen von -200 ... +1.500 °C (-392 ... + 2.732 °F) gemessen werden.

Driftarme Messverstärker gewährleisten kleine Messabweichungen und leicht anwendbare Justierfunktionen vereinfachen die Justage und die Kalibrierung deutlich:

■

Nummernkalibrierung zur schnellen Anpassung von Standardfühlern über Kennzahlen

■

Physikalische Kalibrierung von Fühler und Anzeige an einer, zwei oder drei beliebigen

Temperaturen

Auf diese Weise ist es möglich, Messfehler auf ein Minimum zu reduzieren und eine hohe

Anzeigegenauigkeit zu sichern.

Hand-Held Thermometer Typ CTH6300, industrielle Ausführung

Aufgrund seiner Ausführung ist der CTH6300 besonders geeignet für Inbetriebnahme,

Wartung und den Service/Kalibrierung von Temperaturinstrumenten und Anlagen.

Hand-Held Thermometer Typ CTH6500, präzise Ausführung

Durch seine hohe Genauigkeit von 0,03 K im Bereich von -100 ... +150 °C

(-148 ... +302 °F) kann das CTH6500 als Referenzmessgerät im Bio-, Pharma- und

Lebensmittelbereich eingesetzt werden. Das CTH6500 ist damit auch bestens für alle

Wartungs- und Serviceaufgaben geeignet.

4.2 Lieferumfang

CTH6300

■

Hand-Held Thermometer Typ CTH6300, industrielle Ausführung, inkl. 9-V-Blockbatterie

■

Kalibrierzertifikat 3.1 nach DIN EN 10204

■

Temperaturfühler nach Wahl

50

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

2079988.08 02/2018 EN/DE/IT

Page 51

4. Aufbau und Funktion

CTH6500

■

Hand-Held Thermometer Typ CTH6500, präzise Ausführung, inkl. 9-V-Blockbatterie

■

Kalibrierzertifikat 3.1 nach DIN EN 10204

■

Temperaturfühler nach Wahl

Lieferumfang mit dem Lieferschein abgleichen.

4.3 Bedien- und Anzeigeelemente

DE

1

Fühlerhalterung

2

2079988.08 02/2018 EN/DE/IT

Erster Anschlussport für Temperaturfühler

6

1

5

4

3

2

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

51

Page 52

4. Aufbau und Funktion

3

Zweiter Anschlussport für Temperaturfühler

4

USB-Anschlussport für PC

5

Tastatur

6

Große LC-Display

DE

4.4 Tastenfeld

7

6

5

4

Pfeiltaste CLEAR

1

Auswahl der Menüpunkte

Pfeiltaste FAST

2

Auswahl der Menüpunkte

ENTER/MENU-Taste

3

Zugang zum Hauptmenü, Bestätigen der Funktion

MIN/MAX/HOLD/AVE-Taste

4

Einstellen von MIN und MAX, HOLD und AVE

Funktionstasten

5

Konfigurieren des Gerätes

EIN-/AUS-Taste

6

Ein- und Ausschalten des Gerätes

ESC-Taste

7

Zurück zum Messmodus

1

2

3

52

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

Page 53

4. Aufbau und Funktion

4.5 Spannungsversorgung

Die Batterielebensdauer beträgt ca. 20 Stunden bei Dauerbetrieb.

Das Segment BAT zeigt an, dass die Batterie in Kürze ausgewechselt werden

müssen. Es können jetzt noch ca. 1 Std. korrekte Messungen durchgeführt werden. Als

Spannungsversorgung des Gerätes dient eine 9-V-Blockbatterie. Hinweise zur Batterie

siehe Kapitel 4.6 „Batteriewechsel“.

4.6 Batteriewechsel

Zum Wechseln der Batterie das Gerät ausschalten und das auf der Rückseite angebrachte Batteriefach öffnen. Danach die Batterie entnehmen und das Anschlusskabel abziehen. Die neuen Batterien dann wieder in das Batteriefach einlegen.

Mit dem Umschalter im Batteriefach auf der Rückseite des Gerätes kann eingestellt

werden, ob das Gerät mit einer Batterie oder mit einem Akku betrieben wird.

■

In der Einstellung Batt wird der Ladestrom, der über die USB-Schnittstelle kommt

nicht auf die Batterie geleitet, so dass diese kein Schaden nimmt.

■

In der Einstellung Accu wird der Akku lediglich über die USB-Schnittstelle gespeist.

Der Akku wird zwar in dieser Einstellung mit einem Ladestrom versorgt, allerdings

reicht dieser nicht aus um den Akku vollständig zu laden.

DE

Wird das Gerät längere Zeit nicht benutzt, die Batterie herausnehmen.

Beim Schließen des Batteriefaches darauf achten, dass die Batterieanschlussdrähte nicht gequetscht oder beschädigt werden.

2079988.08 02/2018 EN/DE/IT

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

53

Page 54

4. Aufbau und Funktion

4.7 Temperaturfühler

Verschiedene Anschlussmöglichkeiten verschiedener Temperaturfühler gewährleisten

Flexibilität.

Temperaturfühler für Typ CTH6300/CTH6500

DE

Abb. oben: Einstechfühler

Abb. unten: Eintauchfühler

Zusätzliche Temperaturfühler für Typ CTH6500

Ausschnitt des

Temperatur-Feuchte-Kombifühlers

Abb. oben: Temperatur-Feuchte-Kombifühler

Abb. unten: Flügelrad-Strömungsfühler

54

WIKA Betriebsanleitung, Typen CTH6300 und CTH6500

2079988.08 02/2018 EN/DE/IT

Page 55

4. Aufbau und Funktion

4.8 Temperaturfühler anstecken/wechseln

WARNUNG!

Nur die mitgelieferten Temperaturfühler verwenden!

▶

Zum Fühlerwechsel Gerät ausschalten.

▶

Fühler vor dem Einschalten des Gerätes anstecken, sonst wird er vom

Gerät evtl. nicht richtig erkannt.

Digitalgerät und Temperaturfühler werden mittels eines separaten Verbindungskabels

elektrisch miteinander verbunden.

Für den Fühlerwechsel sollte bevorzugt der 8-polige Steckkontakt am Fühler benutzt

werden.

■

Zum Anschluss des Temperaturfühlers an das Hand-Held Thermometer die 8-polige

Steckverbindung gemäß der Orientierungsführung in den Anschlussport für

Temperaturfühler stecken.

■

Stecker nicht verkantet anstecken. Bei richtig angesetztem Stecker kann dieser ohne

größeren Kraftaufwand eingesteckt werden.

■