Page 1

Operating Instructions

Betriebsanleitung

Temperature Dry Well Calibrator

Temperatur-Blockkalibrator

CTD9300

GB

D

Temperature Dry Well Calibrator CTD9300-165/650

Temperatur-Blockkalibrator CTD9300-165/650

Page 2

GB

Temperature Dry Well Calibrator Page 1 - 66

D

Temperatur-Blockkalibrator Seite 69 - 133

9037926 07/2015

Page 3

Temperature Dry Well Calibrators CTD9300

Contents

Contents

Contents

1. General Instructions 5

2. Device Description 9

3. Moduses and Functions 21

4. Operating the Calibrator 51

5. Technical Data 60

6. Appendix 64

GB

Information!

This symbol identifies information, instructions or useful hints.

Caution!

General point of hazard! Please heed the operating instructions.

Danger!

Hazard of personal injury through electric voltage.

Danger!

Hazard of personal injury through high temperatures.

9037926 07/2015

WIKA Operating Instructions CTD9300 Rev. 1

3

Page 4

Temperature Dry Well Calibrators CTD9300

Preface

GB

Preface

Congratulations on buying a WIKA temperature dry well calibrator

of the CTD9300 family. For the time being, this family of

calibrators comprises two devices for the following temperature

ranges:

CTD9300-165 from -30 °C to 165 °C

CTD9300-650 from 40 °C to 650 °C

Since the operation of the devices is identical, we have decided to

combine the operating instructions for the two devices.

The operating instructions are intended for skilled workers and

semi-skilled workers. Thoroughly read the associated instructions

prior to every work step and adhere to the sequence specified.

Read the "General Instructions" section especially attentively.

Memorise the pictograms and their significance.

The device is designed for calibrating temperature switches,

thermocouples, resistance thermometers and mechanical

thermometers. Please use them in compliance with their intended

use.

If you encounter any problems or if you have any questions, please

revert to your supplier or directly to the manufacturer.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

D-63911 Klingenberg

Germany

Phone no.: (+49) 93 72/132-0

Fax no.: (+49) 93 72/132-406

info@wika.de

www.wika.de

4 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 5

Temperature Dry Well Calibrators CTD9300

1. General Instructions

1. General Instructions

1.1 Fundamental Safety Instructions

When performing any work on the device, always heed the national

safety instructions and accident prevention regulations as well as

the following safety instructions in the present operating

instructions.

Through the power cable, the device is supplied with a voltage

hazardous to people.

The faultless and safe operation of the device requires appropriate

transport, professional storage, setup, and use as intended as well

as cautious operation and servicing.

Applications other than those described in the present operating

instructions is regarded to be improper use and must thus be

excluded.

If faults cannot be eliminated, the device must be shut down

immediately and protected against inadvertent startup.

Danger!

Only the manufacturer is authorized to perform repairs.

Manipulation and modifications of the device are illegal.

Before replacing the safety fuse, the device must be disconnected

from the mains voltage by pulling the power plug out of the mains

socket.

For other important safety instructions, please refer to the

individual sections of these operating instructions.

GB

9037926 07/2015

5WIKA Operating Instructions CTD9300 Rev. 1

Page 6

Temperature Dry Well Calibrators CTD9300

1. General Instructions

GB

1.2 Safety Instructions Relating to Operation of the Device

The temperature dry well calibrators of the CTD9300 series have

been developed and manufactured in compliance with the state of

the art. This applies to the accuracy of measurement, the mode of

operation and the safe operation of the devices. To guarantee safe

operation, however, the operator must behave in an expertly and

safety-conscious manner.

Relevant instructions are included in this section. Warnings relating

especially to individual functional sequences and tasks are also

included in the respective sections of the present operating

instructions. These warnings are identified by special symbols.

Caution:

Use the calibrator exclusively in compliance with the descriptions

included in the present operating instructions. Failure to observe

the safety instructions and operating instructions will impair the

protective measures provided.

Danger!

Before touching the dry well or the adapting sleeve, check the

current dry well temperature since a heated device bears the

imminent risk of burns.

Since there are high temperatures on the top of the calibrator

directly in front of the dry well bore, the following warning has been

attached to this area:

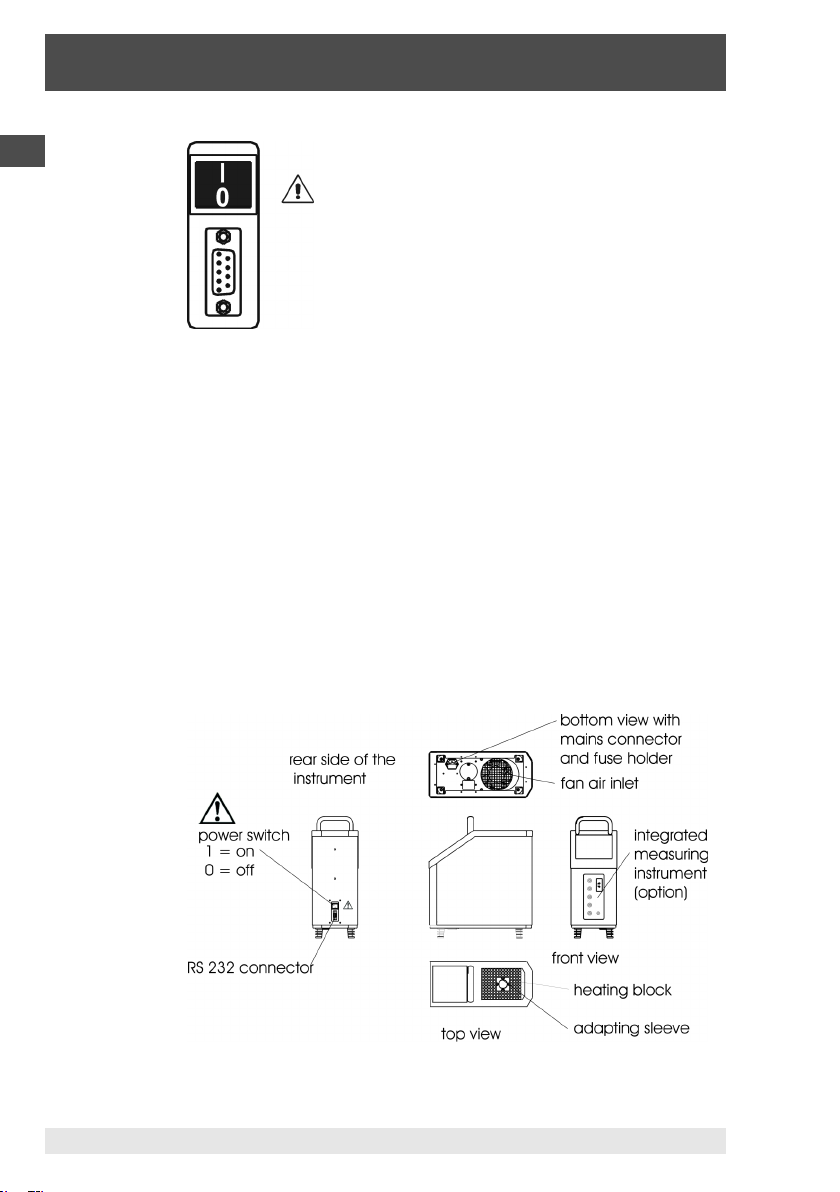

Fig. 1: Warning sign

Caution!

Directly to the right of the power switch the warning symbol is

displayed. It advises you to read the corresponding chapters

(e.g. chapter 2, chapter 3) of the operating instructions.

6

WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 7

Temperature Dry Well Calibrators CTD9300

1. General Instructions

Safety Instructions:

Remove all highly combustible media from the vicinity of the

device and ensure that it cannot come into contact with easily

inflammable or explosive substances.

Make sure that the integrated fans can always deliver sufficient

cooling air. Do not impair the air supply by placing the devices

on a soft, resilient surface.

Connect the devices to a power circuit with minimum risk of a

power failure, since it will no longer be possible to supply

cooling air in the case of a power failure

Make sure that the adapting sleeves and probes are not

contaminated with any substances (e.g. oil) that may cause

ignition or explosion during heating.

Never remove adapting sleeves from a heated dry well since

heated adapter inserts bear a fire hazard.

Never remove probes from a heated dry well since these bear the

imminent risk of burns.

Never leave a heated device unattended.

Always let a heated device cool to below 50 °C before

disconnecting it from the mains.

Never try to repair the device yourself, always revert to the

manufacturer.

Since the housing of the calibrator is made of metal, only power

cables with ground wire may be used. Operate the calibrator

exclusively with the power cable provided. The power cable

connector is on the bottom of the calibrator, i.e. when using a

different type of cable, the calibrator may topple over.

If the calibrator is not used for an extended period of time, humidity

may penetrate into the heating element due to the material used.

After transporting or storing the calibrator in a humid environment,

the heating elements must thus be heated slowly when starting the

calibrator. During the drying process, the calibrator will not have

attained the isolation voltage required for protection class I.

The noise ramps of all dry well calibrators of the CTD9300 series

are below 70 dbA.

GB

9037926 07/2015

7WIKA Operating Instructions CTD9300 Rev. 1

Page 8

Temperature Dry Well Calibrators CTD9300

1. General Instructions

GB

1.3 Ground Wire Monitoring

For checking the basic isolation of the heater, the calibrator is

equipped with a ground wire monitor. The monitoring unit operates

independently of the other controller components and switches off

the power supply of the heater as soon as the calibrator loses the

connection to the ground wire system of the isolation. Once the

connection to the ground wire system has been re-established, the

monitoring unit automatically reconnects the heating circuit to the

power system.

1.4 Duty to Take Due Care of the Operator

For safe operation of the device, the operator must especially

ensure that:

the device is exclusively used as intended (refer to the section

"Intended Use" in chapter "Device Description") and that no

hazardous media are used and all the technical specifications

are adhered to.

the device is operated in faultless, fully functional condition

only.

the present operating instructions are always available in legible

condition and complete at the application site of the device.

only authorised and qualified personnel operates, maintains and

services the device.

the operator of the device is periodically instructed in all

applicable operational safety and environmental protection

issues and that he/she is familiar with the operating

instructions, especially with the safety instructions contained

therein.

8 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 9

Temperature Dry Well Calibrators CTD9300

2. Device Description

2. Device Description

2.1 Intended Use

The calibrators of the CTD9300 series may be used exclusively for

the calibration and verification of thermocouples, resistance

thermometers, mechanical thermometers and temperature

switches.

The introduction of foreign substances such as oil or heat

conductive paste with the aim of enhancing the heat transfer to the

probe can damage the calibrator and the adapting sleeve.

In addition, there is a risk of injury due to abruptly evaporating

fluids and hazardous gases that may form when fluids evaporate.

Always ensure that the testing temperature is not too high for the

probe. Otherwise, the probe may be destroyed.

Remove all highly combustible media from the vicinity of the

device and ensure that the device cannot come into contact

with easily inflammable or explosive media.

2.2 Structure

Temperature dry well calibrators consist of an electrically heated

metal block and a control unit. The two components are

accommodated in a robust metal housing together with a fan. The

metal block is fitted with a bore in its centre for holding the

adapting sleeve. This adapting sleeve contains one or several bores

of different diameters for thermically coupling thermometers of

various thicknesses optimally to the heated metal block. Good

thermal coupling between the block, the adapting sleeve and the

thermometer is very important for keeping measuring uncertainty

during calibration to a minimum.

GB

9037926 07/2015

9WIKA Operating Instructions CTD9300 Rev. 1

Page 10

Temperature Dry Well Calibrators CTD9300

2. Device Description

GB

Calibrators for Low Temperatures

If the calibrator generates temperatures lower than the ambient

temperature, it must be able to cool actively. In this case, the

isothermal block is made of aluminium and is cooled and heated

through Peltier elements. Depending on the polarity of the voltage,

the Peltier element will heat up on the top side while the opposite

side is cooled. One side of the element always makes contact to the

isothermal block. The other side is connected to a cooling element

that is cooled by a strong fan.

Through reversing the polarity and controlling the voltage at the

Peltier elements, the block can be heated and cooled. For technical

reasons, the max. attainable temperature with Peltier elements is

limited to approx. 165 °C. Depending on the model, the min.

attainable temperature is -50 K to -60 K relative to the ambient

temperature.

Calibrators for High Temperatures

High-temperature calibrators for temperature ranges of from 40 °C

to 650 °C generally work with resistance heating elements.

Depending on the upper limit temperature, different block materials

are used. Brass, bronze or scale-resistant steels.

Due to the low temperatures caused by the permanently decreasing

cooling capacity of the air flow surrounding the block, the control

unit starts working sufficiently fast only at 20 K above the

respective ambient temperature. This limits the lower working

temperature of a device of this kind to approx. 40 °C.

The upper limit is defined through the block material used and the

temperature resistance of the heating elements used.

10 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 11

Temperature Dry Well Calibrators CTD9300

2. Device Description

Description of the Controls

Fig. 2: User Interface of a

CTD9300

The control panel with the keyboard, the pilot lamp and the graphic

display are on the front of the calibrator.

Description:

GB

9037926 07/2015

A Standby / On pilot lamp

B Standby / On switch

C Cursor and Select keys for

marking and selecting

D Back key for going back one

step

E Enter and Clear keys for

F Measure / Control switch

G Block of 12 keys for

entering numbers with

sign

H Status bar of the display

I Main display area

K Info line of the display

entering and deleting data

The power socket and the 9-pin Canon socket of the RS 232

interface are on the rear of the device, the power socket and safety

fuse are arranged in the bottom of the device. For this reason, a

power cable with an angled inlet connector must be used.

11WIKA Operating Instructions CTD9300 Rev. 1

Page 12

Temperature Dry Well Calibrators CTD9300

2. Device Description

GB

Fig. 3: Power switch and RS 232 connector

Power switch

The power switch (I/0 toggle switch) on the rear

of the calibrator is used to switch on the power

supply of the calibrator. Switch setting "I"

switches the power supply on, switch setting

"0" switches the power supply off.

Directly to the right of the power switch is a warning symbol.

It means: "Caution, general point of hazard"

RS 232 Connector

Devices that are connected to the RS 232 interface must comply

with the IEC 60950 standard.

The exact location of the power switch can be seen in the

illustration of the mechanical structure in the next section.

Mechanical Structure

Fig. 4: Mechanical structure of a

12 WIKA Operating Instructions CTD9300 Rev. 1

CTD9300

9037926 07/2015

Page 13

Temperature Dry Well Calibrators CTD9300

2. Device Description

2.3 Functional Description

The two devices have identical operating functions, independent of

the different heating principles - Peltier elements in the case of the

165 °C version and resistance heating elements in the case of the

650 °C type.

CTD9300-165 for the range from -30 °C to 165 °C

CTD9300-650 or the range from 40 °C to 650 °C

Both the temperature dry well calibrators are fitted with an

electronic temperature-controlled heating block. This heating block

is fitted with a 28 mm x 150 mm bore for holding the adapting

sleeve.

In this heating block, you can insert adaptor inserts, generally

referred to as adapting sleeves, with one or multiple test bores,

which act as an adapter between the probe (temperature switch,

thermocouple, thermometer or resistance thermometer) and the

heating block bore. The heating block is thermically insulated

against the housing wall.

In the central area of the graphic display (I), the temperature of the

heating block and the set nominal value is displayed with a

resolution of 0.01 K.

The desired heating block temperature is predefined using the

block of 12 keys (G). After confirming the new nominal value with

the ENTER key (E) and switching from measuring to control mode

with the CONTROL key (F), the control unit will start setting the

calibrator to the topical nominal temperature.

In the Info line (K), the displayed mode will change from MEASURE

to CALIBRATE. The operating status HEAT UP, COOL DOWN and

TEMP. STABLE is displayed in the status bar (H).

The temperature is considered STABLE when it changes by less

than 0.1 K within 5 s. Only when the ramp program is enabled does

the STABLE display depend on the set stability criteria tolerance

and duration.

In addition to the topical block temperature, the set nominal value

and the standard deviation or the minimum and maximum values of

the block temperature can be displayed. Using this information, it is

possible to draw a conclusion about the stability of the temperature

in the calibrator at first glance.

GB

9037926 07/2015

13WIKA Operating Instructions CTD9300 Rev. 1

Page 14

Temperature Dry Well Calibrators CTD9300

2. Device Description

GB

Standard deviations as well as the min. and max. values can be

reset at any time by pressing the ENTER (E) key.

2.4 Standard Accessories

Power Cable

A power cable with a 90 ° angled inlet connector for the power

supply is included with every calibrator. Depending on the country

the calibrator is delivered to, the power cable is fitted with the

locally used power plug.

Adapting Sleeve

Each calibrator is delivered ex works with an adapting sleeve with

an inside diameter of 6.5 mm. Most of the industrial thermometers

can be adapted to the calibrator through this sleeve.

If the diameters of your thermometers differ, please order the

desired adapting sleeve with an internal bore matching the diameter

of your thermometer plus 0.5 mm.

Sleeve Removal Tool

A sleeve removal tool for simple and easy removal from and

insertion of the adapting sleeve into the calibrator block is included

in the standard set of accessories of every temperature calibrator of

the CTD9300 series.

Data Cable

A data cable for connecting the calibrator to the RS 232 interface is

included in the scope of delivery of each device. The PIN layout

plan for 9-pin and 25-pin Sub-D connectors can be found in the

Appendix, refer to section 6.6: PC Connection.

2.5 Special Accessories

The special accessories are not included in the standard scope of

delivery.

14 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 15

Temperature Dry Well Calibrators CTD9300

2. Device Description

2.5.1 Special Adapting Sleeves

Sleeves for CTD9300-165 calibrators are made of aluminium,

sleeves for CTD9300-650 calibrators are made of brass. The

outside dimensions of the two sleeves are Ø 28 mm x 150 mm of

length.

Special adapting sleeves can be customized in various designs.

Sleeves with multiple bores are also available. Limits are placed

only by the mechanical machinability of the sleeve blanks.

When choosing the sleeve design, however, please observe that the

overall measurement uncertainty declines with an increasing

number of bore holes and with increasing bore diameter.

The actual measuring uncertainty when using a special adapting

sleeve can be determined only when the bore diameter and the

number of bores as well as the design and material of the

thermometers to be calibrated is exactly known.

If you require multiple sleeves, please take the following into

consideration:

if possible, the bores should be arranged on a pitch circle to

ensure uniform temperature distribution.

for product engineering reasons, there must be a minimum

distance between the bores and to the edge of the sleeve. As a

rule, this distance should not be less than 2 mm.

the bore diameter should be larger than the thermometer to be

tested by at least 7 %.

GB

9037926 07/2015

2.5.2 Transport Case

As an option, we offer a robust transport case for your calibrator.

We recommend the use of a transport case, if you frequently use

the device for on-site calibrations and thus need to transport it

often.

The case does not only protect your calibrator against environmental influences such as dust, dirt and humidity but also against

mechanical damage that may occur due to impacts and vibrations.

15WIKA Operating Instructions CTD9300 Rev. 1

Page 16

Temperature Dry Well Calibrators CTD9300

2. Device Description

GB

2.5.3 Integratable Measurement Value Logging

In the measurement and control workshop, a measuring instrument

is required for connecting the probe that measures thermovoltages, resistance and 4-20 mA standard signals and displays

them in degrees centigrade.

In combination with the calibrators of the CTD9300 family, the

integratable measuring instrument CTI 9350 is a useful supplement

to your calibration equipment. The measuring instrument can be

integrated in the housing of the CTD9300 calibrators. Order the CTI

9350 directly or upgrade your device later on. We offer you the

choice. In the case of an upgrade, the front panel is simply replaced

in the works.

The temperatures of the two thermometers - of the reference and

the probe - can be displayed at the same time and simply compared

to one another.

The following can be connected as probes:

Resistance thermometers: Pt 100, Pt 500 und Pt 1000 in 2, 3 or

4 wire circuits

Thermocouples of the K, J, N, E, R, T, B, S, L and U types

4-20 mA power signals from temperature transducers, with and

without supply voltage

Temperature switches with "normally open" and "normally

closed" contacts.

The reference resistance thermometer is connected using a 7-pole

connector.

Three different connection possibilities have been provided for the

probe:

Binding posts for 4 mm connectors, spade connectors and

blank wires

Standard thermo-connector

Miniature thermo-connector

The 4 mm sockets (1, 2, 3 and 4) are generally used for connecting

the resistance thermometer, temperature switches and 4-20 mA

signals. All the three connection versions are available for

thermocouples.

16 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 17

Temperature Dry Well Calibrators CTD9300

2. Device Description

All the thermometer signals are linearised according to their signal

type and displayed in °C, °F or in K.

The sensor type, input and switch technology are set in the menu

for measuring instrument setup.

Circuit of the Integrated Measuring Instrument

Fig. 5: Connectors of the instrument

External Reference Thermometer

The integrated measuring instrument

permits parallel connection of a probe

and, if desired, of an external reference

resistance thermometer. It takes the

characteristic curve of the reference

thermometer into consideration for the

linearisation using an individual

correction function, refer to the

adjustment menu.

An external reference may be required for certain calibration tasks,

e.g.:

when calibrating especially short sensors

for additional safety

GB

9037926 07/2015

2.5.4 Software

Powerful software is available for all devices of the CTD9300

series. This software enables remote control of the calibrator and

the integrated measuring instrument through a computer and

automatic calibrations. The program runs on all IBM compatible

PCs.

Temperature Ramp Function

The temperature ramp function permits the recording of a

temperature curve that automatically approaches up to 20 settable

test points. This is a typical procedure for calibrating electric

thermometers.

17WIKA Operating Instructions CTD9300 Rev. 1

Page 18

Temperature Dry Well Calibrators CTD9300

2. Device Description

GB

When thermometers are calibrated that cannot be read out

electrically, a dialog box for entering the measured value will be

opened. In this case, an integrated instrument is not required.

Fig. 6: Temperature ramp function

Temperature Cycle Function

The temperature cycle function permits the recording of a

temperature curve that automatically switches between two

adjustable set values. In this case, the dwell time of the lower and

upper temperatures as well as the heating and cooling rates can be

set in K/min. The number of temperature changes is preset in the

beginning.

Series of Probes Testing Function

If multiple probes are to be calibrated at the same temperature, e.g.

when testing goods received, the "Check Series of Measurement"

mode must be selected. After the measured values have been

recorded, they can be output as a table and graphically in the form

of a histogram.

18 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 19

Temperature Dry Well Calibrators CTD9300

2. Device Description

Temperature Switch Testing Function

Recording of the heating and cooling switch points of

temperature switches within an adjustable temperature range.

Fig. 7: Temperature switch test function

GB

9037926 07/2015

Remote Control

This function is used for displaying topical measured values of the

probe and calibrator as well as for programming the temperature

calibrator. It permits a simple check of the communication between

the devices.

Evaluation

Display and printing of the recorded temperature curves in the form

of a table or graphics as well as documentation of the measured

values in the form of a plant calibration certificate. The calibration

data are saved in a database and archived and are thus also

available for evaluations later on.

19WIKA Operating Instructions CTD9300 Rev. 1

Page 20

Temperature Dry Well Calibrators CTD9300

2. Device Description

DGB

System Requirements

IBM-compatible PC with min. 486 processor with Windows 95, 98,

NT 4.0, 9x, ME, 2000 and XP operating system and a main memory

of at least 64 MB, CD-ROM drive or 3 ½" FDD 1,44 MB, VGA

graphics board and monitor, free RS 232 serial interface and

Microsoft-compatible mouse.

2.5.5 DKD Calibration Certificate

The DKD calibration certificate gives the user the certainty that the

calibration results are based on national standards and the errors of

measurement do not exceed the error limits specified.

DKD calibrations are optionally available for all temperature

calibrators. They are an option, the price of which depends on the

number of test points required. For temperature dry well calibrators,

DKD calibrations are generally performed at 6 test temperatures.

The measuring uncertainty specified in the DKD calibration

certificate depends on the device and temperature.

Calibration is a matter of trust. For this reason, entrust only our

competent DKD calibration workshop that has been certified in

compliance with the applicable standard (currently DIN EN ISO/IEC

17025) with the calibration of your valuable devices.

DKD laboratories are subject to periodical inspections by the PTB

(Physikalisch-Technische Bundesanstalt = the German National

laboratory). The laboratory employees are permanently trained and

educated further. Regular inter laboratory comparisons prove that

the minimum measuring uncertainty are really adhered to.

20 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 21

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

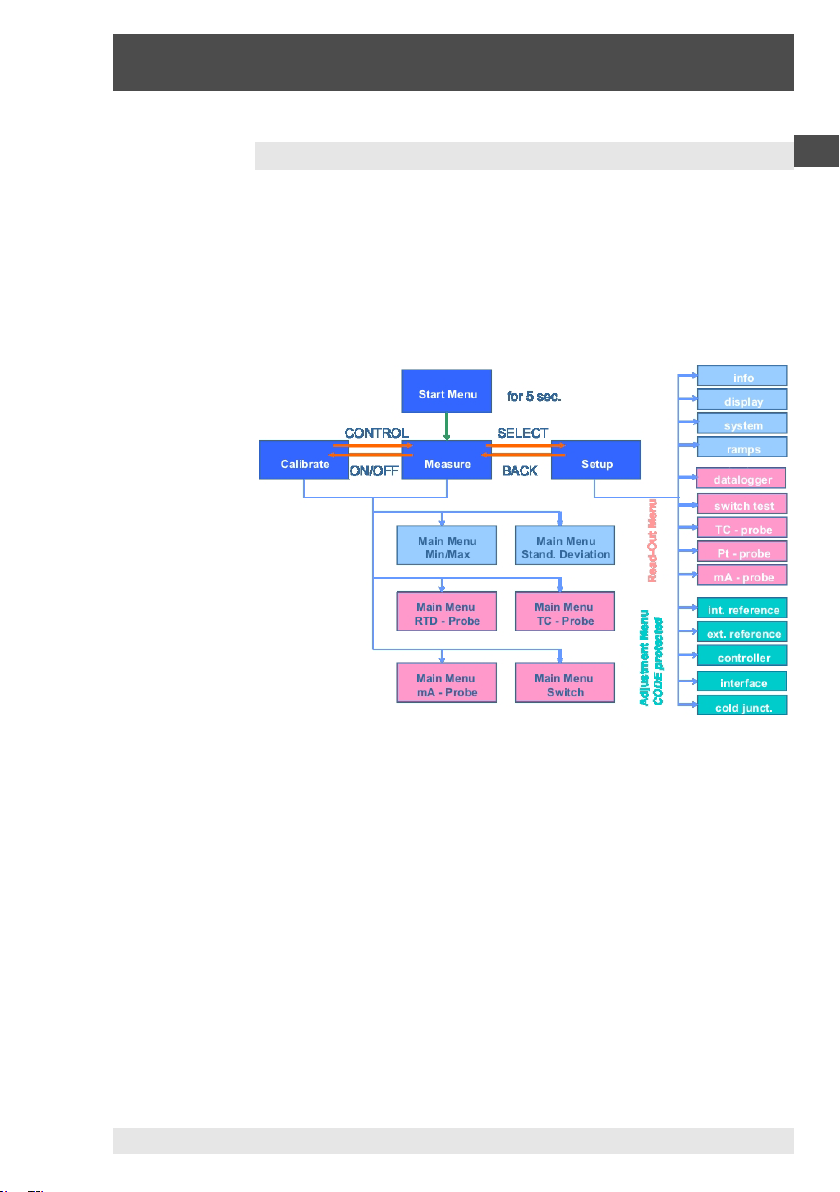

3. Moduses and Functions

After switching on the calibrator, an information window will be

displayed for approx. 5 s. Then the device switches to measuring

mode. The current block temperature is displayed. The control unit

is switched off.

In the following, the menu structure is displayed in simplified form.

GB

9037926 07/2015

Fig. 8: Menu structure of a

CTD9300

The menu items for datalogger, RTD, TC and mA tests as well as

switch tests are accessible only, if a measuring instrument is

integrated, otherwise they will be hidden.

The two operating modes for measuring and calibrating and the

functions of the Setup menu are described in the following.

21WIKA Operating Instructions CTD9300 Rev. 1

Page 22

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1 Setup Menu

Press the SELECT key in the measurement or calibration mode to

access the Setup menu. It is subdivided into:

Basic setup menu

Measuring instrument setup menu

Adjustment setup menu

Select the individual menu items using the cursor keys and the

SELECT key. Press the BACK key to exit the menus.

If you make a selection within a menu, it must be confirmed with

the SELECT key before exiting the menu.

Fig. 9: Setup menu with user interface of a

22 WIKA Operating Instructions CTD9300 Rev. 1

CTD9300

9037926 07/2015

Page 23

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.1.1 Basic Setup Menu

The basic setup menu is used for typical settings relating to the

general operation of the device, e.g. for calling the Info window that

provides information on the current hardware and firmware

versions or enables editing of the system and display parameters.

The step menu, e.g. can be used to create temperature profiles and

approach them cyclically.

3.1.1.1 Info Menu

The Info menu displays data on the measuring range, the date of

the last calibration, the current firmware ramp and the serial number

of the device.

Depending on the device type, one

of the following measuring ranges

will be displayed:

CTD9300-165 the measuring

range of from -30 °C / 165 °C

CTD9300-650 the measuring

range of from 40 °C / 650 °C

Fig. 10: Info menu of a

CTD9300

GB

9037926 07/2015

The user cannot edit the settings in this window. The firmware

ramps will change accordingly after an update.

The individual serial number of the calibrators is displayed in the

Info menu and additionally on the type label on the rear of the

device.

23WIKA Operating Instructions CTD9300 Rev. 1

Page 24

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.1.2 Display

The display menu is used for selecting the unit for displaying the

temperature and the desired calibration menu. In addition, the

averaging function of the temperature display can be set.

The desired menu item is

"enabled" using the cursor keys

and selected by pressing the

SELECT key. Selected units and

functions are identified by an

arrow.

Fig. 11: Display adjustment

Unit Selection

You can choose between degrees Celsius °C, degrees Fahrenheit

°F or Kelvin.

Calibration Menu Selections

If a measuring instrument is not integrated, you can choose

between the min./max. value and standard deviation menu items.

If a measuring instrument is integrated, the selection will be

supplemented with:

TC-Probe

Pt-Probe

mA-Probe

switch test

Only one menu can be selected at a time.

Min/max value

Apart from the current block temperature, the minimum and

maximum value of the block temperature will be displayed. Press

ENTER to set min. and max. to the topical measured value.

Using this function, it is easy to assess the maximum limits of

variation of the block temperature in stationary mode.

24 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 25

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

Standard Deviation

Instead of the min./max. value, the standard deviation is displayed

here, i.e. the mean quadratical error of the block temperature across

the last n measured values. After pressing ENTER, n = 0 is set and

the standard deviation will be recalculated.

Switch Test

Test menu for temperature switches, refer to

section 3.1.2 Measuring Instrument Setup Menu.

TC-Probe Menu

Calibration menu for thermocouples, refer to

section 3.1.2 Measuring Instrument Setup Menu.

Pt-Probe Menu

Calibration menu for resistance thermometers, refer to

section 3.1.2 Measuring Instrument Setup Menu.

mA-Probe Menu

Calibration menu for thermometers with temperature transducers,

refer to section 3.1.2 Measuring Instrument Setup Menu.

Display Averaging

The actual value of the block temperature displayed by the device

can correspond to the current temperature or be an average across

2 to 99 measured values. The average is continuously calculated

from the last n measured values according to the FIFO method. A

measuring rate of approx. 4 values/s, the following settings result

for the number of average values:

1, averaging disabled

40, averaging for 10 s

99, averaging for 25 s

GB

9037926 07/2015

To ensure a steady display, we recommend averaging across 50

measured values, which corresponds to an integration time of 13 s.

25WIKA Operating Instructions CTD9300 Rev. 1

Page 26

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.1.3 System

This menu is used for setting the system functions.

Language Selection

In this menu, the user can

select one of the languages

German, English, French or

Spanish using the cursor keys.

The selection must be

confirmed with SELECT.

Fig. 12: System adjustment

Time and Date

The system time and date are selected block by block using the

cursor keys and entered via the numeric keypad. [ hh -> mm -> ss ]

and [ 20yy -> mm -> dd ]. Confirm your entry with ENTER.

Display Settings

Brightness and contrast can be set via the numeric keypad within

the range of from 0 % to 100 %.

Confirm your entry with ENTER.

The following settings are recommended:

Brightness: 80 %

Contrast: 60 % (contrast settings < 50 % are not advisable)

Alarm

When the preselected alarm temperature is exceeded, "temp. to

high" flashes in the information line. The alarm temperature is

entered via the numeric keypad and must be confirmed with

ENTER.

Cut-out

When the preselected switch-off temperature has been exceeded,

the device will automatically be reset to the measuring mode, i.e.

the control unit is switched off. "temp. to high" will flash in the

information line. The device will cool to ambient temperature. The

switch-off temperature is entered via the numeric keypad and must

be confirmed with ENTER.

26 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 27

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

Operating Hours

The operating hours counter continuously counts the time in

hours, for which the device is switched on.

Heat units

The heat units factor is a characteristic value for the thermic load of

the device. It permits conclusions on the average working

temperature of the temperature calibrator. The average working

temperature in °C is calculated as follows by approximation:

t

= t

average

where t

+ ( heat units x 100 / operation hours )

amb.

is the ambient temperature in °C.

amb.

3.1.1.4 Ramp Program

The ramp program with the associated auxiliary parameters is

enabled in the ramp menu. It is used, e.g. for checking recording

temperature measuring instruments.

Another field of application is

the temperature change test,

which makes it possible to draw

conclusions on the

reproducibility, the hysteresis

and the long-term and shortterm stability of temperature

sensors.

Fig. 13: Ramp menu

GB

9037926 07/2015

If a measuring instrument is integrated in the calibrator, the

measured values of the probes can be recorded at the selected

temperature ramps. Please also refer to the section DataLogger in

Chapter Measuring Instrument Setup Menu.

Temperature Ramp Function

The temperature ramp program is switched on by selecting the UP

and/or DOWN function with the cursor. The default setting is OFF.

In the ramp program, 6 different temperature ramps can be enabled

individually or together. For this purpose, the ramps are selected

with the cursor and enabled/disabled with the SELECT key. Every

single temperature ramp can be set to any desired temperature

27WIKA Operating Instructions CTD9300 Rev. 1

Page 28

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

within the operating range of the calibrator.

The resolution is 0.01 K.

The individual temperature ramps are serially numbered from 1 to 6.

If the "UP" function is enabled, the ramps are approached in the

order 1, 2, 3, 4, 5 and 6. If the "DOWN" function is enabled, the

ramps are approached in the order 6, 5, 4, 3, 2 and 1. If both

functions are enabled, the ramps are approached in the order 1, 2,

3, 4, 5, 6, 5, 4, 3, 2 and 1. Disabled ramps are skipped.

Gradient

Using the gradient function, defined heating and cooling of the

calibrator can be set. The value for the gradient is set in K/min with

a resolution of 1 K.

The upper ramp for the gradient is determined through the heating

power of the respective device. This means that the device with the

gradient function enabled cannot heat at a faster rate than with the

gradient function disabled. The gradient function is primarily used

for checking temperature switches. To prevent the switch point of a

temperature switch from being exceeded during heat-up, the

calibrator is heated only slowly. Gradients between 1 K/min and

5 K/min are typical. Especially for temperature switches with large

immersion tube diameters, this prevents that the temperature of the

switch lags behind that of the calibrator.

Tolerance and Duration

Using the Tolerance and Duration functions, the stability and

length of the dwell time on a temperature ramp can be set. If the

dwell time is to be 5 minutes with a stability of ±0.1 K after the

nominal temperature has been reached, the duration must be set to

5 min and the tolerance to 0.1 K. In this case, the timer will start

when the actual temperature differs by less than 0.1 K from the

nominal temperature. If the temperature remains within this

tolerance for 5 min, the time period for the next ramp will be

approached after the present time period has elapsed. If

fluctuations occur during this time that exceed the set tolerance,

the timer is reset and restarted. When the tolerance has been

reached, TEMP. STABLE is displayed in the status bar.

28 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 29

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

The tolerance can be set within the limits of 0.01 K and 5.00 K,

the duration within the range of from 1 min to 100 min.

Cycles

Using the Cycles function, the calibrator can approach the ramps

continuously. If e.g. the temperature ramps 1, 2 and 3 are enabled

and the "UP" function has been selected, the ramps 1, 2 and 3 are

approached one after the other depending on the set cycles: with a

number of cycles of 3 this would be 1, 2, 3, 1, 2, 3, 1, 2 and 3.

If the "UP" and "DOWN" functions have been selected, the

calibrator will proceed as follows: 1, 2, 3, 2, 1, 2, 3, 2, 1, 2, 3, 2

and 1.

This function is especially useful for temperature change tests on

temperature sensors.

If the ramp program is enabled, set-values cannot be entered

via the keyboard. The keyboard will remain locked until the

temperature ramp function is disabled.

3.1.2 Measuring Instrument Setup Menu

The measuring instrument setup menu is available only if the

calibrator is equipped with an integrated measuring instrument.

The menu is used for configuring the data logger and the

calibration processes of temperature switches, thermocouples,

resistance thermometers and 4-20 mA temperature transmitters.

The menu is hidden if the calibrator is not equipped with an

integrated measuring instrument.

The integrated measuring instrument makes it possible to measure

various sensor signals and to convert them to degrees Centigrade

according to standardised characteristic curves. It is also possible

to detect switch points of temperature switches. The data logging

function permits storing as many as six probe temperatures and the

nominal temperature per probe given by the calibrator. In total, the

calibration data of up to eight probes can be recorded.

GB

9037926 07/2015

29WIKA Operating Instructions CTD9300 Rev. 1

Page 30

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

The following devices are supported:

Pt resistance thermometers with characteristic curves in

compliance with EN 60751

Thermocouples in compliance with EN 60584 and DIN 43710

2-wire temperature transducer with an output signal of

4-20 mA

Temperature switches with "normally closed" or "normally open"

contacts.

3.1.2.1 Data Logger

This menu is used for configuring the data logger. The data logger

permits the storage of calibration results of up to eight calibrations.

In this case, a calibration can include up to six testing

temperatures. A prerequisite is that the ramp program is enabled

and the desired testing temperatures have been set in advance in

this program.

The last cycle is always stored,

independent of whether the

levels were approached from

bottom to top or vice versa. For

this reason, it is best to set the

number of cycles to 1 when

recording measured values.

Fig. 14: "Data Logger"

setup menu

When the data logger is disabled, sets, i.e. the measured value

storages can be selected via the cursor keys. It is possible to select

Set1 to Set8.

One set may hold up to 6 measuring results. If e.g. only four

measurements are made, the remaining two rows of the value table

remain empty.

When the data logger is switched on, the measuring results are

stored in the current set. It is not possible to change the set when

the data logger is enabled.

30 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 31

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

Date and Start time document the beginning of the recording.

Probe specifies the type of thermometer to be calibrated.

TC-Probe

Pt-Probe

mA-Probe

Menu item CL (Clear Logger) is

used to clear the stored

contents of the enabled set. If a

new calibration is started

without deleting the old data,

these data will be overwritten

with the new data.

Fig. 15: Recorded calibration

data

Procedure when using the data logging function:

Select ramp program in the Setup menu:

Select UP or DOWN with the cursor keys.

Change the desired temperature ramps

Set the tolerance to the desired value, e.g. 0.05 K

Set the duration to the desired value, e.g. 2 min

Set the cycles to 1

Select BACK to exit the ramp program:

GB

9037926 07/2015

Select Data Logger in the Setup menu:

Select the desired Set(n), n= 1, 2, ..., 8 with the cursor keys

If required, delete any calibration data stored in the respective

set with CL

Select ON with the cursor keys and enable the logging function

Select BACK to exit the Data Logger

Press BACK again to return to the main menu (Calibrate).

31WIKA Operating Instructions CTD9300 Rev. 1

Page 32

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

During the program run, you can toggle between the main menu

and the data logging menu to display temperature levels already

processed.

Once the program run of the logging program has been completed,

the ramp program and the data logger are automatically set to OFF.

The calibration data recorded can either be displayed in the data

logging menu or downloaded via the RS 232 interface.

3.1.2.2 Switch Test

This menu is used for configuring the temperature switch test. It is

possible to determine switch points and the hysteresis of a

temperature switch.

The switch test program and

the temperature ramp program

are automatic program runs

that exclude one another. When

the program is enabled, all the

functions not used for testing

temperature switches are

disabled.

Fig. 16: Switch test setup

menu

The switch test is started by pressing ENTER and can be aborted at

any time with CONTROL ON/OFF. An interrupted switch test is

identified with the status bar message SWITCH TEST. HEAT UP or

COOL DOWN will be displayed in the status bar during the switch

test.

Rem. temp, T

max

or T

are displayed to the left-hand side of the set

min

temperature. After the test has been completed and the hysteresis

has been calculated, the removal temperature will be controlled

such that a new switch test can be started. If the temperature

fluctuations are < 0.1 K, TEMP.STABLE will be displayed in the

status bar.

32 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 33

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

Checking Temperature Switches

The approximate switch point

should be known for testing

temperature switches. In the

Setup, below the switch point

to be expected, a removal

temperature will be set at

which the probe can be

removed without risk.

Fig. 17: Switch test diagram

A lower and an upper limit temperature, UGT (lower limit temp.) and

OGT (upper limit temp.) are defined approx. 5 K above and below

the switch point.

At program start, the calibrator will control the temperature to the

removal temperature. After ENTER was pressed, the calibrator will

heat up to the lower limit temperature (UGT) with full heating

power. From there on, it will maximally heat to the upper limit

temperature (OGT) with the set gradient. If there is no switching

between the lower limit temperature (UGT) and the upper limit

temperature (OGT), the device will heat to the predefined removal

temperature.

If the device switches as expected between the lower (UGT) and

upper (OGT) limit temperatures, the switch temperature is displayed

as "t-up". The calibrator immediately starts to cool to record the

second switch point "t-down" in downward direction. Thereafter,

the removal temperature is controlled. The hysteresis is the

difference between the "t-up" and "t-down" temperatures.

GB

9037926 07/2015

Defective Temperature Switches

If the temperature switch does not switch within the selected range,

the calibrator will maximally heat to the upper limit temperature

(OGT) and then cool to removal temperature.

33WIKA Operating Instructions CTD9300 Rev. 1

Page 34

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.2.3 TC-Probe

This menu is used for configuring the thermocouple calibration.

To calibrate thermocouples, the

respective type of

thermocouple is selected with

the cursor keys and confirmed

with the SELECT key.

Subsequently, the input

sockets must be defined.

Fig. 18: TC-probe setup

menu

There are two possibilities:

binding posts 2 and 3

-> input 2

Thermo-socket TC

-> input 3

Fig. 19: Connectors of the

instrument

Binding Posts

The binding posts are suitable for connecting blank wire ends,

spade connectors and 4 mm banana plugs.

Thermo-Socket

The thermo-socket can be used to connect standard thermoconnectors and miniature thermo-connectors.

Always observe the correct polarity when connecting thermocouples. If thermocouples need to be extended, the thermo-cable

or extension cable of the respective thermocouple type must be

used.

34 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 35

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.1.2.4 Pt-Probe

This menu is used for configuring the Pt resistance thermometer

calibration.

To calibrate Pt resistance

thermometers, the respective

type of thermometer and

connection is selected with the

cursor keys and confirmed with

the SELECT key. The

connection is established

exclusively via the binding

Fig. 20: Pt-probe

setup menu

posts.

Binding posts

The binding posts are suitable for connecting blank wire ends,

spade connectors lugs and 4 mm banana plugs. Take the required

wiring technology into consideration for establishing connections.

There are three possibilities:

2-wires: terminals 2 + 3

3-wires: Terminals 3 + 4 loop, 2 + 3 Pt resistance

4-wires: Terminals 1 + 2/3 + 4 loop, 2 + 3 Pt resistance

Interchanging the connectors results in measurement faults.

GB

9037926 07/2015

35WIKA Operating Instructions CTD9300 Rev. 1

Page 36

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.2.5 mA-Probe

This menu is used for configuring the temperature transducer

calibration.

Setting the Current Range

If the probe is a 2-wire

transducer, the current range

must be set to 4-20 mA, for

3-wire transducers that are

generally supplied with

operating voltage externally, a

range of 0-20 mA can be set.

Fig. 21: mA-probe

setup menu

Setting the Temperature Range

To be able to convert the output current of the transducer properly

to a temperature signal, the measuring instrument must know the

limit temperatures for 4 mA (0 mA) and 20 mA. They must be

entered according to the specifications at the transducer.

Setting the Supply

Prior to a transducer calibration you must define whether the

calibrator is to supply the transducer with 24 V DC operating

voltage or not. Generally, this is the case. If it is supplied through

an external voltage source, the internal supply must be switched

off.

36 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 37

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.1.3 Adjustment Setup Menu

The Adjustment setup menu is password-protected. The menu

provides setting options for control parameters, linearisation

parameters for internal and external reference sensors and the

interface parameters. These settings are made ex works and

generally need not be edited by the user.

The "int. reference" and "ext. reference" menus specify the

coefficients for linearising the reference thermometer of the

calibrator. If errors of

measurement larger than

those specified are detected

when calibrating the device,

the coefficients can be edited

in this menu for adjustment

purposes.

Fig. 22: Adjustment setup

menu

In the same way, the control parameters and settings of the serial

interface can be edited.

Caution!

Editing the parameters in the Adjustment setup menu may

result in serious errors of the temperature display and to

changed control characteristics!

Entering wrong parameters may cause irreversible damage to

the dry well calibrator!

GB

9037926 07/2015

The Cold junction menu item permits enabling/disabling the cold

junction compensation for testing purposes.

37WIKA Operating Instructions CTD9300 Rev. 1

Page 38

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.3.1 Internal Reference

This menu comprises the parameters for linearising the internal

reference thermometer.

The internal reference

thermometer is linearised in two

stages. First of all, using a basic

linearisation that is always

performed and thereafter using

an individual fine linearisation.

In this case, "t'" is the

temperature following the basic

Fig. 23: Internal reference

parameter set

linearisation.

t display = P0 + P1 * t' + P2 * t' ² + P3 * t' ³ + P4 * t' 4

Linearisation CTD9300-650 CTD9300-165

parameters

P0 0 0

P1 1 1

P2 0 0

P3 0 0

P4 0 0

Using these parameters, only the general basic linearisation is

enabled and fine linearisation is switched off. In the case of DKD

calibration of the temperature calibrators, the errors of

measurement of the reference are exactly determined and the

parameters P0 to P4 are set to the optimum.

Fine linearisation can be disabled by setting the switch to OFF.

This function simplifies the determination of new parameters Pn

for adjusting the reference, at an autuorised laboatory.

The user should not edit these settings.

38 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 39

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.1.3.2 External Reference

This menu comprises the parameters for linearising the external

reference thermometer.

The external reference

thermometer is also linearised

in two stages. First of all, using

a basic linearisation that is

always performed and

thereafter using an individual

fine linearisation. In this case,

"t'" is the temperature following

Fig. 24: External reference

parameter set

the basic linearisation.

t display = P0 + P1 * t' + P2 * t' ² + P3 * t' ³ + P4 * t' 4.

Linearisation CTD9300-650 CTD9300-165

parameters

P0 0 0

P1 1 1

P2 0 0

P3 0 0

P4 0 0

GB

9037926 07/2015

Using these parameters, only the general basic linearisation is

enabled and fine linearisation is switched off. In the case of DKD

calibration of the temperature calibrators, the errors of

measurement of the reference are exactly determined and the

parameters P0 to P4 are set to the optimum.

Fine linearisation can be disabled by setting the switch to OFF.

This function simplifies the determination of new parameters Pn

for adjusting the reference, at an autuorised laboatory.

The user should not edit these settings.

39WIKA Operating Instructions CTD9300 Rev. 1

Page 40

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.3.3 Controler

This menu is used to set the control parameters.

Fig. 25: Control parameter set

The parameter set in the basic configuration is as follows (devicedependent):

Control parameter CTD9300-650

P0 1.00000E+00

P1 1.00000E-03

P2 1.00000E+00

P3 0.00000E+00

P4 1.00000E-01

CTD9300-165

1.00000E+00

1.00000E-02

1.00000E+00

0.00000E+00

1.00000E-01

Where:

Control parameter Designation

P0 internal amplification

P1 adjustment of the disturbance variable

P2 time constant

P3 test parameter

P4 safety limit of the dynamic

Warning!

Ex works, the control parameters are set for an optimum

control behaviour.

The user should not edit these settings.

40 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 41

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.1.3.4 Interface

The Interface menu is used to set the baud rate for data

transmission via the RS 232 interface and the protocol to be used.

Baud rate

2400 Baud, 4800 Baud and

9600 Baud are supported. They

are selected with the cursor

keys and enabled with the

SELECT key.

Fig. 26: Interface parameters

Protocol

The default setting is the standard protocol, which must always be

set when the calibrators are operated in combination with our

software. The following settings are possible:

Standard: standard protocol

Test: in-plant test protocol

Display: in-plant test protocol

The protocols are selected with the cursor keys and enabled with

the SELECT key.

GB

9037926 07/2015

Parity

For setting the parity. Default setting is "no". Other possible

settings are "even" and "odd".

41WIKA Operating Instructions CTD9300 Rev. 1

Page 42

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.1.3.5 Cold Junction

In the Cold Junction menu, the internal cold junction

compensation can be disabled. The internal cold junction

compensation is normally

disabled for service purposes

only.

The user should not change

these settings, except when an

external cold junction

compensation is used.

Fig. 27: Cold Junction menu

42 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 43

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.2 Measuring Mode

Press the CONTROL key to switch between the measuring and

calibration mode. As opposed to calibration mode, the control unit

is switched off in measuring mode.

"Measure" is displayed in the

top left-hand side of the status

bar. The fan cools the calibrator.

If a new nominal value is not

defined, the calibrator will reach

ambient temperature sooner or

later, depending on the

previous application

Fig. 28: Main menu,

measuring mode

temperature.

Measuring mode is active after:

switching on the device

activating the temperature cut-out

a fault occurred

Apart from the current block temperature, the standard deviation

across the last n measured values (n = 1 ... 99) as well as the

gradient, the temperature change per minute, is displayed.

GB

9037926 07/2015

If an external reference thermometer is connected, the selection

"t- intern" and "t-extern" will be displayed underneath the nominal

value display. This permits the user to select between an internal

and external reference thermometer. The external reference

thermometer takes on all the functions of the internal thermometer.

Generally, it is used for calibrating very short thermometers only.

43WIKA Operating Instructions CTD9300 Rev. 1

Page 44

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.3 Calibration Mode

Press the CONTROL key to switch between the measurement and

calibration mode. The control unit is active in calibration mode.

"Calibrate" will be displayed in the top left-hand side of the status

bar.

The standard menu can always

be accessed, independent of

whether an integrated

measuring instrument is

integrated or not.

The following generally applies:

In calibration mode and in

measuring mode, the current

Fig. 29: Main menu,

calibration mode

block temperature and the

nominal temperature last

selected are displayed independent of the selected menu.

In addition, the gradient is specified in K/min in the last menu line.

The gradient permits conclusions on the current temperature

change rate.

If an integrated measuring instrument is available, additional

connection possibilities and menus. These are described in the

section on the measuring menu.

The current status is displayed in the info line. Heating, cooling or

stable. Depending on the availability of an integrated measuring

instrument, the following calibration and display modes are

available.

Prompting in a set-value

You can define a new set-value using the block of 12 keys. After

confirming your entry with the ENTER key, the controller will save

the value. Now press the CONTROL key once to start the control

unit. In the Info line, the mode will change from measuring to

calibration. In parallel, the operating status of the control unit is

displayed in the status line:

heating when the temperature in the block is increased

44 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 45

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

cooling when the block is cooled

temp. stable when a constant temperature has set in the block.

Selection between Internal and External Reference

Thermometer

If an external reference thermometer is connected, the selection

"t- intern" and "t-extern" will be displayed underneath the nominal

value display. This permits the user to select between an internal

and external reference thermometer. The external reference

thermometer takes on all the functions of the internal thermometer.

Generally, it is used for calibrating extremely short thermometers

only.

3.3.1 Standard Menus

In the standard menu, the following values can be displayed on the

calibrator without an integrated measuring instrument.

Min/Max value

Standard Deviation

When the ramp program menu

is enabled, the current

temperature ramps 1 to 6 are

displayed in the calibration and

measuring modes instead of

the set temperature.

GB

9037926 07/2015

Fig. 30: Calibration menu

"Data Logger"

45WIKA Operating Instructions CTD9300 Rev. 1

Page 46

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.3.1.1 Calibration Menu “min/max”

In addition to the temperature

display, the min. and max.

values of the current block

temperature are displayed. The

two values are displayed

continuously. The registration of

the min. and max. values is

restarted with the ENTER key.

Fig. 31: Calibration menu

“min/max”

The variation limits of the

temperature in the calibrator can

easily be displayed through the

min. and max. temperatures.

3.3.1.2 Calibration Menu “sta. dev.”

In addition to the temperature

display, the standard deviation

of the current block temperature

is continuously displayed. The

recalculation of the standard

deviation is restarted with the

ENTER key.

The stability of the temperature

Fig. 32: Calibration menu

“standard deviation”

in the calibrator can easily be

displayed through the standard

deviation.

46 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 47

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.3.2 Measuring Instrument Menus

If the calibrator is equipped with an integrated measuring

instrument, a measuring instrument menu is available in addition to

the standard menu. This comprises the following functions:

Temperature switch test

Thermocouple calibration

Pt resistance thermometer calibration

4-20 mA transducer calibration

The selection of external and internal reference thermometer is

provided only, if an external reference thermometer is connected.

The deviation of the probe is either specified in comparison to the

internal or external reference, depending on which of the two

references is enabled.

If the "Ramp Program" menu or

the "Data Logger" function is

enabled, the current

temperature ramps 1 to 6 will

be displayed in the calibration

and measuring modes instead

of the set temperature.

Fig. 33: Calibration menu

"Data Logger"

GB

9037926 07/2015

3.3.2.1 Calibration Menu “Switch Test”

In this menu, the switching

temperatures can be displayed

in addition to the nominal and

actual temperatures of the

calibrator.

Fig. 34: Calibration menu

"switch test"

47WIKA Operating Instructions CTD9300 Rev. 1

Page 48

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

The following information is provided:

Designation

Probe

t-open

t-close

Hysteresis

Information

Type of probe

opening temperature

of the switch

closing temperature

of the switch

The difference between

"t-open" and "t-close"

3.3.2.2 Calibration Menu “TC-Probe”

In this menu, the output signal

of a thermocouple can be

displayed in addition to the

nominal and actual

temperatures of the calibrator.

Fig. 35: Calibration menu

“TC-probe”

Note

Temperature switch

in this example: 107.32 °C

in this example: 103.98 °C

in this case: 3.34 K

The following information is provided:

Designation

Probe

t-Probe

Error

Signal

48 WIKA Operating Instructions CTD9300 Rev. 1

Information

Type of probe

Temperature of the

probe

Error of the probe

in K

Electric output signal

of the probe

Note

Thermocouple: TCJ-3, i.e.

Thermocouple J at input 3

in this example: 102.67 °C

Deviation from the int. (ext.)

reference thermometer

In the case of the thermocouple,

the thermal voltage in µV

9037926 07/2015

Page 49

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

3.3.2.3 Calibration Menu “Pt-Probe”

In this menu, the output signal

of a Pt resistance thermometer

can be displayed in addition to

the nominal and actual

temperatures of the calibrator.

Fig. 36: Calibration menu

“Pt-probe”

The following information is provided:

Designation

Probe

t-Probe

Error

Signal

Information

Type of probe

Temperature of the

probe

Error of the probe

in K

Electric output signal

of the probe

GB

Note

Pt resistance thermometer:

Pt 100-3, i.e.

Pt 100 in 3-wire circuits

in this example: 102.99 °C

Deviation from the int. (ext.)

reference thermometer

In the case of the Pt resistance

thermometer, the resistance in

Ohm

9037926 07/2015

49WIKA Operating Instructions CTD9300 Rev. 1

Page 50

Temperature Dry Well Calibrators CTD9300

3. Moduses and Functions

GB

3.3.2.3 Calibration Menu “mA-Probe”

In this menu, the output signal

of an electric thermometer can

be displayed in addition to the

nominal and actual

temperatures of the calibrator.

Fig. 37: Calibration menu

“mA-probe”

The following information is provided:

Designation

Probe

t-Probe

Error

Signal

Information

Type of probe

Temperature of the

probe

Error of the probe

in K

Electric output signal

of the probe

Note

Transducer

in this example: 99.94 °C

Deviation from the int. (ext.)

reference thermometer

In the case of the transducer,

the current in mA

50 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 51

Temperature Dry Well Calibrators CTD9300

4. Operating the Calibrator

4. Operating the Calibrator

4.1 Setup and Connection

Connect the power cable supplied to the calibrator and plug the

power connector into the mains socket. Set up the calibrator such

that the fan on the bottom of the device has sufficient free space to

be able to circulate a sufficient cooling air rate. Insufficient venting

may cause damage leading to the destruction of the calibrator.

Set up the calibrator such that the power switch (switch for power

supply) is easily accessible and can be actuated without any

problems.

Caution!

Since the housing of the calibrator is made of metal, only power

cables with ground wire may be used. Use the power cable

supplied.

Caution!

Ensure that all the bores of the heating block are clean and free

of damage. Do not use any filling media.

Place the calibrator in an upright position for the calibration

procedure to ensure optimum temperature distribution and

transmission.

GB

9037926 07/2015

Additionally take the following into consideration:

the probe

the adapting sleeve and

the bore of the heating block

must exactly match.

Keep the thermal contact resistance as low as possible by using

adapting sleeves with test bores, the inside diameters of which are

approx. 0.2 mm to max. 0.5 mm larger than the diameter of the

probe.

51WIKA Operating Instructions CTD9300 Rev. 1

Page 52

Temperature Dry Well Calibrators CTD9300

4. Operating the Calibrator

GB

Connect the device to a power circuit with minimum risk of a power

failure, since it will no longer be possible to supply cooling air in

the case of a power failure.

4.2 Starting Procedure

If the calibrator is not used for an extended period of time, a small

amount of humidity may collect due to the hygroscopic

characteristic of the magnesium oxide used as insulating material

in the heating system.

After transporting or storing the device in a humid environment,the

heating elements must thus be heated slowly when starting the

calibrator. During the drying process, the device will not have

attained the isolation voltage required for protection class I.

The nominal startup value is T

t

= 15 min.

h

= 120 °C at a dwell time of

anf

4.3 Initial Use

Checks prior to initial use

Prior to initial use, the devices must be moved to their standard

upright operating position. When installing the device, make sure

that the fan on the bottom can circulate a sufficient rate of air. Do

not use soft, resilient surfaces.

Remove all highly combustible material from the vicinity of the

device and ensure that the device cannot come into contact with

easily inflammable or explosive media.

Proceed as follows:

Check the technical data specified on the type label.

Always place the CTD9300 in an upright position. Otherwise

uniform temperature distribution in the block cannot be

ensured.

Do not use any filling media.

52 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 53

Temperature Dry Well Calibrators CTD9300

4. Operating the Calibrator

Check and ensure the following:

The calibrator must be complete. An adapting sleeve with an

inside diameter of 6.5 mm, appropriate for probes with a

diameter of 6 mm, a sleeve removal tool, a power cable, an

RS 232 interface cable and operating instructions are standard

accessories.

The probe and the adapting sleeve as well as the bore of the

block must match exactly to keep the thermal contact resistance

as low as possible.

The mains voltage must match the supply voltage specified on

the type label.

The device must be connected to a power circuit with minimum

risk of a power failure, since it will no longer be possible to

supply cooling air in the case of a power failure.

All the bores of the adapting sleeve must be clean and free of

damage and foreign matters.

After activation via the power switch and switchover from

standby to standard operation, the fan must start when button

(B) is pressed.

4.4 Cooling of the Block and Replacing the Sleeve

Calibrators with a hot dry well always bear an imminent hazard of

burns.

GB

9037926 07/2015

Risk of burns!

Depending on the type, the dry well of a calibrator may reach

temperatures of up to 650 °C.

Let the calibrator cool after use. Only transport the calibrator after it

has cooled completely. The dry well temperature should be below

30 °C.

When touching the surface of the heating block, the adapting

sleeve or the probe, or even when approaching them, there may be

an imminent hazard of burns. Never touch these surfaces if you are

not absolutely sure that these parts are cold.

53WIKA Operating Instructions CTD9300 Rev. 1

Page 54

Temperature Dry Well Calibrators CTD9300

4. Operating the Calibrator

GB

Never leave the temperature calibrator unattended during or after

use. Wait until the heating block has reached room temperature, i.e.

25 °C before packaging it.

You can accelerate the cooling process by setting the testing

temperature to the smallest value possible.

Also take care when replacing the adapting sleeves!

Risk of burns!

The adapting sleeves may reach temperatures of up to 650 °C.

Remove the inserts only when they have cooled.

Use a sleeve removal tool for removing the adapting sleeve, press it

together and insert it into the bores provided on the adapting

sleeve.

Then cautiously pull the sleeve straight up out of the block without

canting it.

Place the sleeve on a solid, temperature resistant surface.

Do not let the adapting sleeve inserts fall. The edges may be

damaged which may lead to jamming of the sleeve when sliding it

back in the block.

4.5 Application Examples

Type CTD9300-165 for the range of from - 30 °C to 165 °C

In the bio-pharmaceutical and food industry as well as in the field

of heating, air conditioning and ventilation, temperatures between

0 °C and 100 °C are often measured. With its fast Peltier elements,

each temperature can be attained within a few minutes. The

aluminium block accommodates adapting sleeves of the

dimensions Ø 28 mm x 150 mm. It can even be used to calibrate

multiple typical thermometers at the same time.

Type CTD9300-650 for the range of from 40 °C to 650 °C

In the technical service and measurement and control workshop,

temperature dry well calibrators are used for calibrating electric

thermometers and for adjusting temperature transducers. With its

54 WIKA Operating Instructions CTD9300 Rev. 1

9037926 07/2015

Page 55

Temperature Dry Well Calibrators CTD9300

4. Operating the Calibrator

large temperature range of from 40 °C to 650 °C, the CTD9300650 is a universally applicable allround calibrator that can be

adapted to various calibration requirements.

Irrespective of whether transducers are to be adjusted or

temperature sensors are to be calibrated on test benches, the

CTD9300650 has been proven and tested in numerous calibration

tasks, in the laboratory, in the workshop and on site.

Calibrating Thermometers < 150 mm

If probes cannot be inserted down to the bottom of the adapting

sleeve due to insufficient sheath length, the heat dissipation error

produced can be considerably reduced by using an external

reference thermometer. For this purpose, an adapting sleeve with

two test bores is used.