Page 1

Operating instructions

Betriebsanleitung

Manuale d'uso

Dry-well temperature calibrator, micro calibration bath, multi-function

calibrator, models CTD9100, CTB9100, CTM9100

Temperatur-Blockkalibrator, Mikrokalibrierbad, Multifunktionskalibrator,

Typen CTD9100, CTB9100, CTM9100

Calibratore di temperatura a secco, microbagno di calibrazione,

calibratore multifunzione, modelli CTD9100, CTB9100, CTM9100

EN

DE

IT

Dry-well temperature calibrator,

CTD9100 series

Micro calibration bath,

CTB9100 series

Multi-function calibrator,

model CTM9100

Page 2

Operating instructions models CTD9100, CTB9100,

EN

CTM9100

Page 3 - 50

Betriebsanleitung Typen CTD9100, CTB9100,

Seite 51 - 98

DE

CTM9100

IT

Manuale d’uso modelli CTD9100, CTB9100, CTM9100 Pagina 99 - 146

Further languages can be found at www.wika.com.

© 07/2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Prima di iniziare ad utilizzare lo strumento, leggere il manuale d‘uso!

Conservare per future consultazioni!

2 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 3

Contents

Contents

1. General information 5

2. Short overview 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Safety 6

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Safety instructions for using calibration liquids . . . . . . . . . . . . . . . . 7

3.7 Personnel qualification . . . . . . . . . . . . . . . . . . . . . . . . 8

3.8 Personal protective equipment. . . . . . . . . . . . . . . . . . . . . . 8

3.9 Labelling, safety marks . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Design and function 10

4.1 Overview of the different instrument models . . . . . . . . . . . . . . . . 10

4.2 Isometric views of the CTD9100 series dry-well temperature calibrators. . . . . . . 11

4.3 Isometric views of the CTB9100 series micro calibration baths . . . . . . . . . . 12

4.4 Isometric views of the model CTM9100-150 multi-function calibrator. . . . . . . . 13

4.5 Description of the operating elements . . . . . . . . . . . . . . . . . . 14

4.6 Data interface . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 Interface protocol . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8 Protective earth monitoring . . . . . . . . . . . . . . . . . . . . . . 15

5. Transport, packaging and storage 16

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Packaging and storage . . . . . . . . . . . . . . . . . . . . . . . 16

6. Commissioning, operation 16

6.1 Operating position . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Inserts with metal block . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Preparation of the micro calibration bath . . . . . . . . . . . . . . . . . 17

6.3.1 Properties of the calibration liquid . . . . . . . . . . . . . . . . . 17

6.3.2 Filling the micro calibration bath . . . . . . . . . . . . . . . . . . 18

6.3.3 Operation of the magnetic stirrer . . . . . . . . . . . . . . . . . . 18

6.3.4 Insert for liquids . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Surface insert (only CTM9100-150) . . . . . . . . . . . . . . . . . . . 19

6.5 Infrared insert (only CTM9100-150) . . . . . . . . . . . . . . . . . . . 19

6.6 Testing of temperature sensors . . . . . . . . . . . . . . . . . . . . 20

6.7 Start-up procedure. . . . . . . . . . . . . . . . . . . . . . . . . 20

6.8 Switching on the calibrator/micro calibration bath . . . . . . . . . . . . . . 20

6.9 Reference and set temperature display . . . . . . . . . . . . . . . . . . 20

6.10 Control of the reference temperature . . . . . . . . . . . . . . . . . . 20

7. Operating elements of the calibrator/micro calibration bath 21

7.1 Selection of the operating modes for the CTM9100-150 . . . . . . . . . . . . 21

7.2 Method of operation in calibration mode within individual operating modes. . . . . . 21

7.3 Calibration (calibration mode) . . . . . . . . . . . . . . . . . . . . . 22

7.4 Setting a temporary set temperature (set-point mode) . . . . . . . . . . . . . 22

11263911.05 03/2019 EN/DE/IT

EN

3WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 4

Contents

7.5 Programming (Main menu) . . . . . . . . . . . . . . . . . . . . . . 23

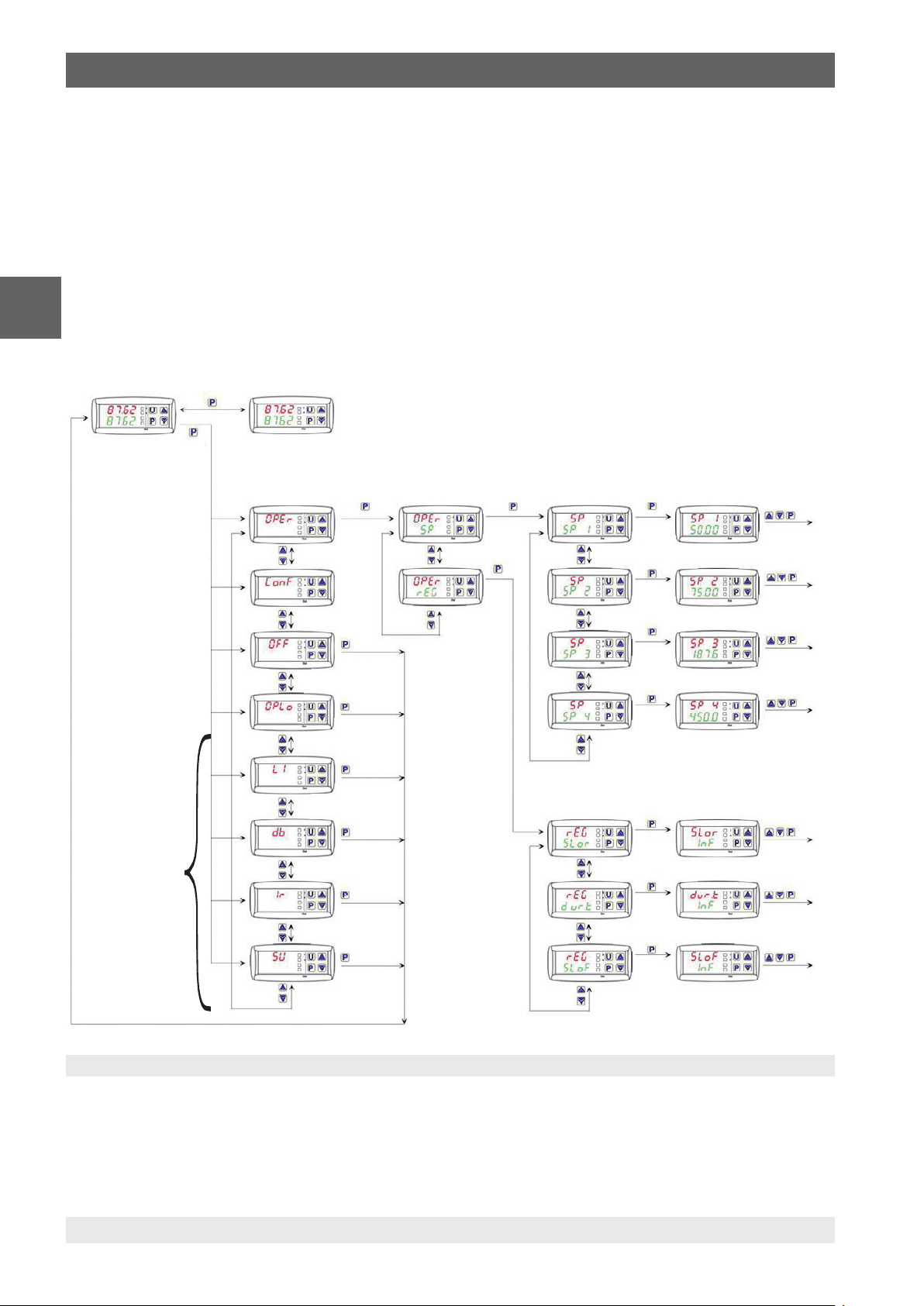

7.5.1 Menu structure, parameter levels. . . . . . . . . . . . . . . . . . 24

7.5.2 Switching off automatic control . . . . . . . . . . . . . . . . . . 25

7.5.3 Switching on automatic control . . . . . . . . . . . . . . . . . . 25

EN

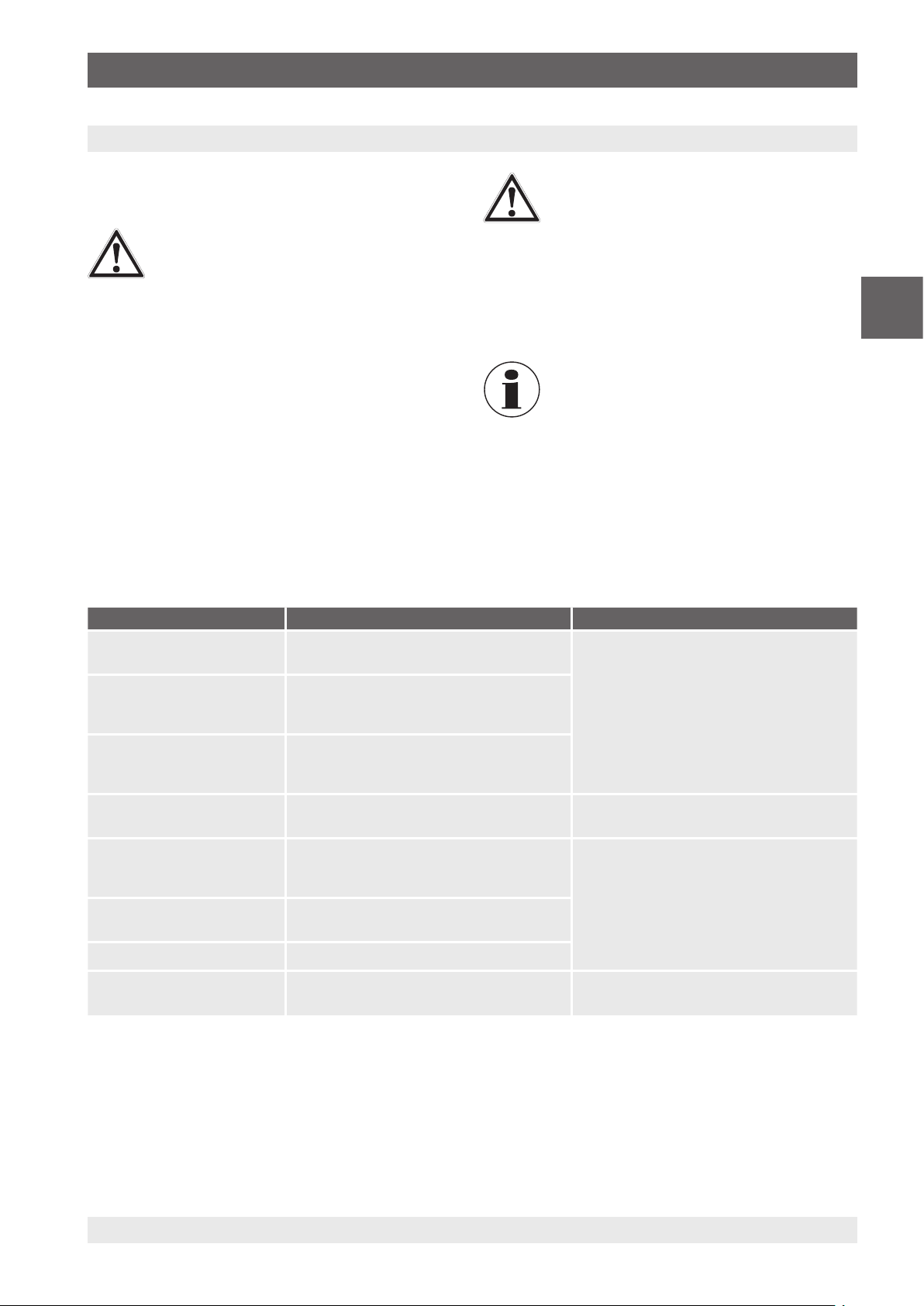

8. Cooling down the metal blocks or micro calibration baths 32

9. Faults 33

10. Maintenance, cleaning and recalibration 34

11. Dismounting, return and disposal 35

12. Specifications 36

13. Accessories 41

14. Heating and cooling times 42

7.5.4 Switching on manual control . . . . . . . . . . . . . . . . . . . 26

7.5.5 Switching off manual control . . . . . . . . . . . . . . . . . . . 26

7.5.6 Setting and storing fixed set temperatures . . . . . . . . . . . . . . 27

7.5.7 Recalling the stored set temperatures . . . . . . . . . . . . . . . . 28

7.5.8 Setting the ramp control and a temperature profile . . . . . . . . . . . . 28

10.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2.1 Cleaning calibrators with inserts . . . . . . . . . . . . . . . . . . 34

10.2.2 Cleaning fan guards . . . . . . . . . . . . . . . . . . . . . . 34

10.2.3 Cleaning the micro calibration bath . . . . . . . . . . . . . . . . . 34

10.2.4 External cleaning . . . . . . . . . . . . . . . . . . . . . . . 34

10.3 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

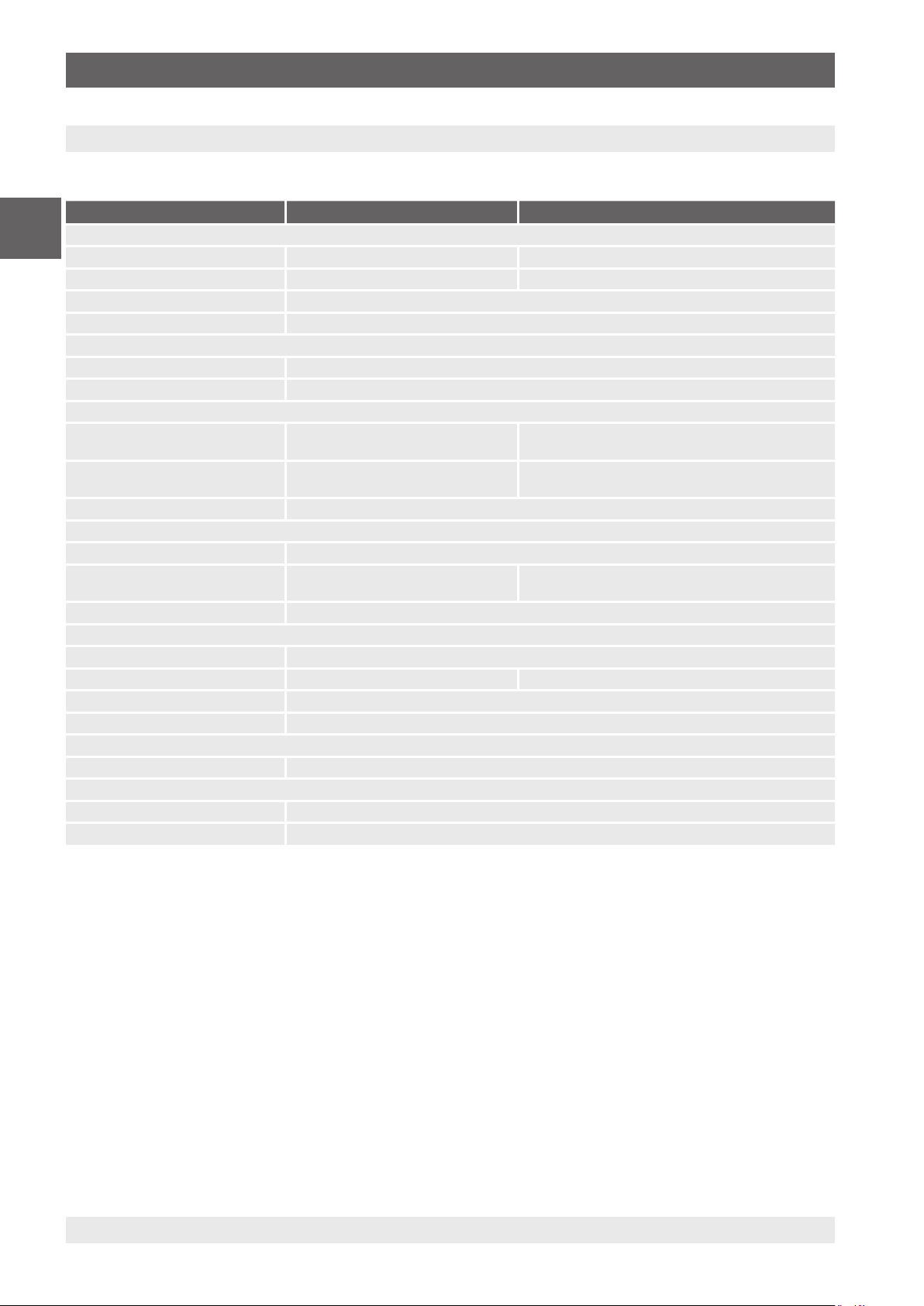

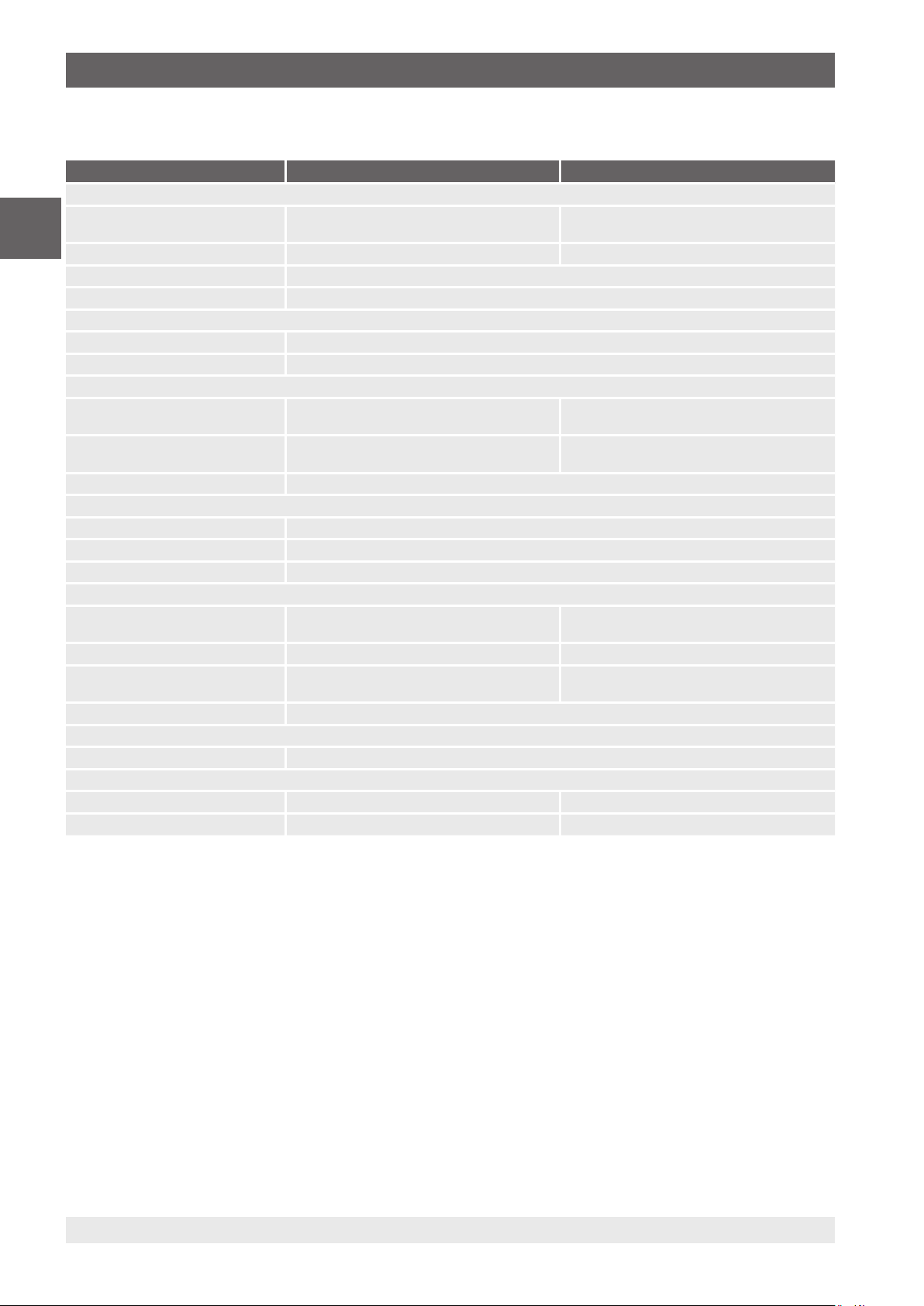

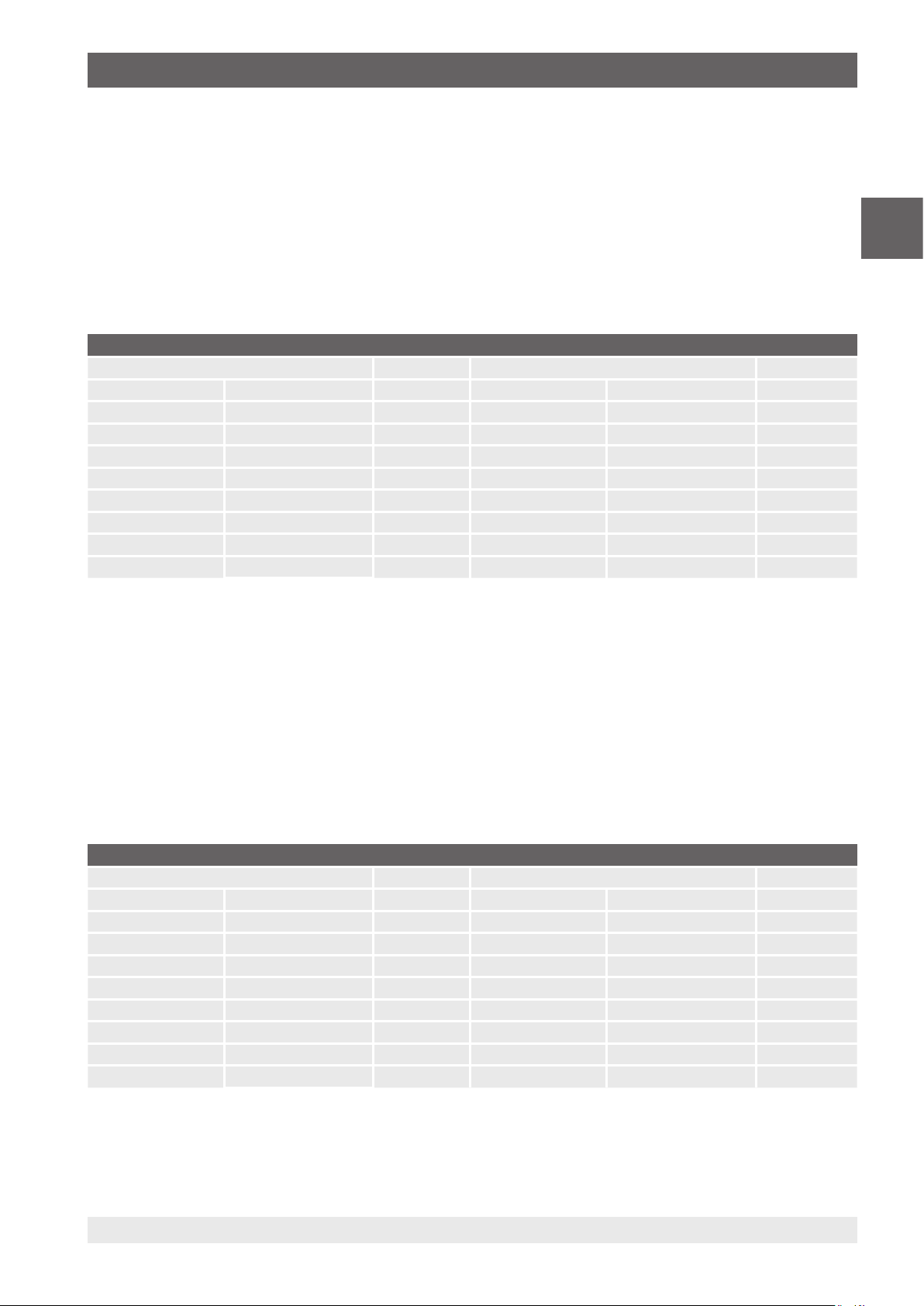

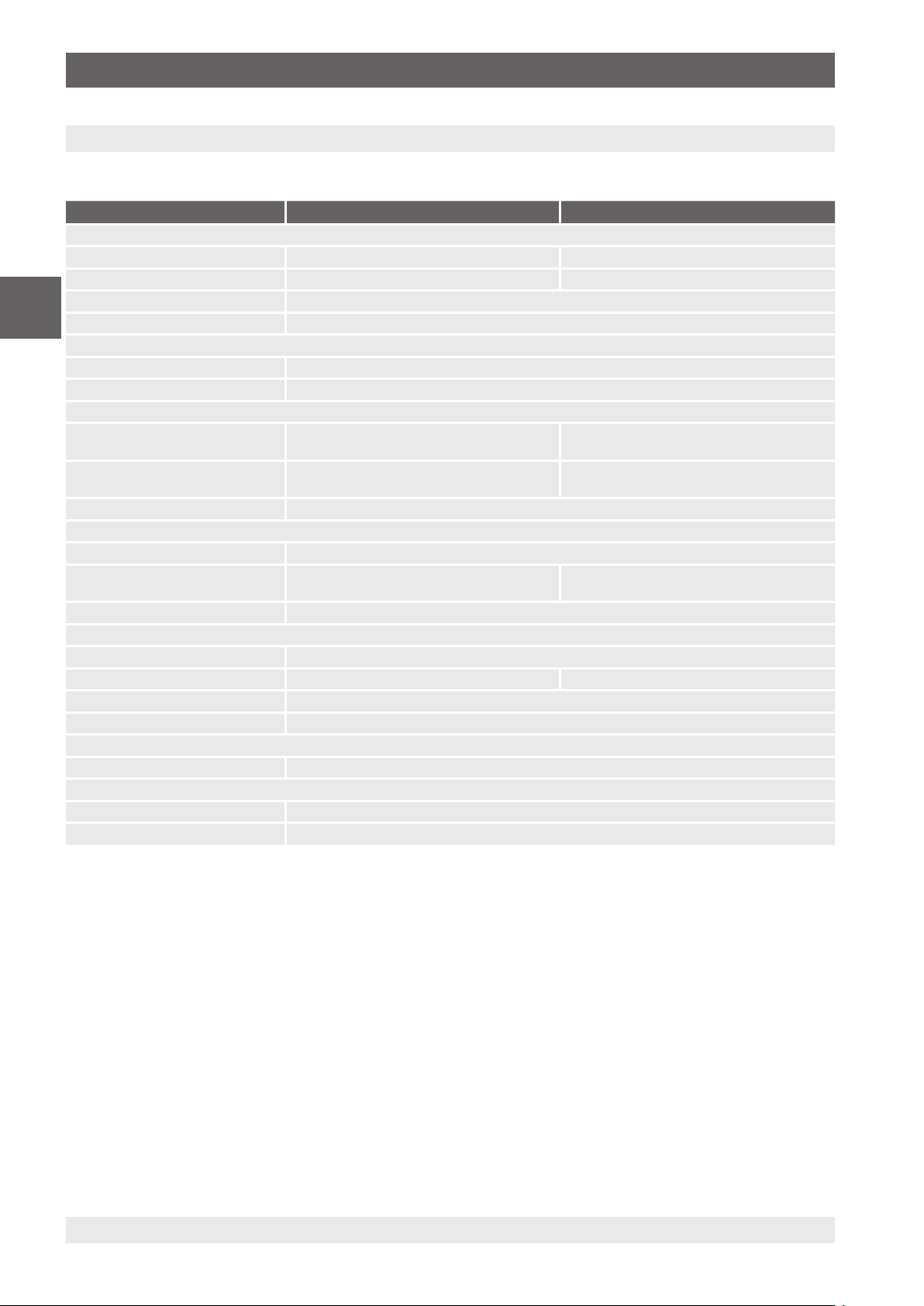

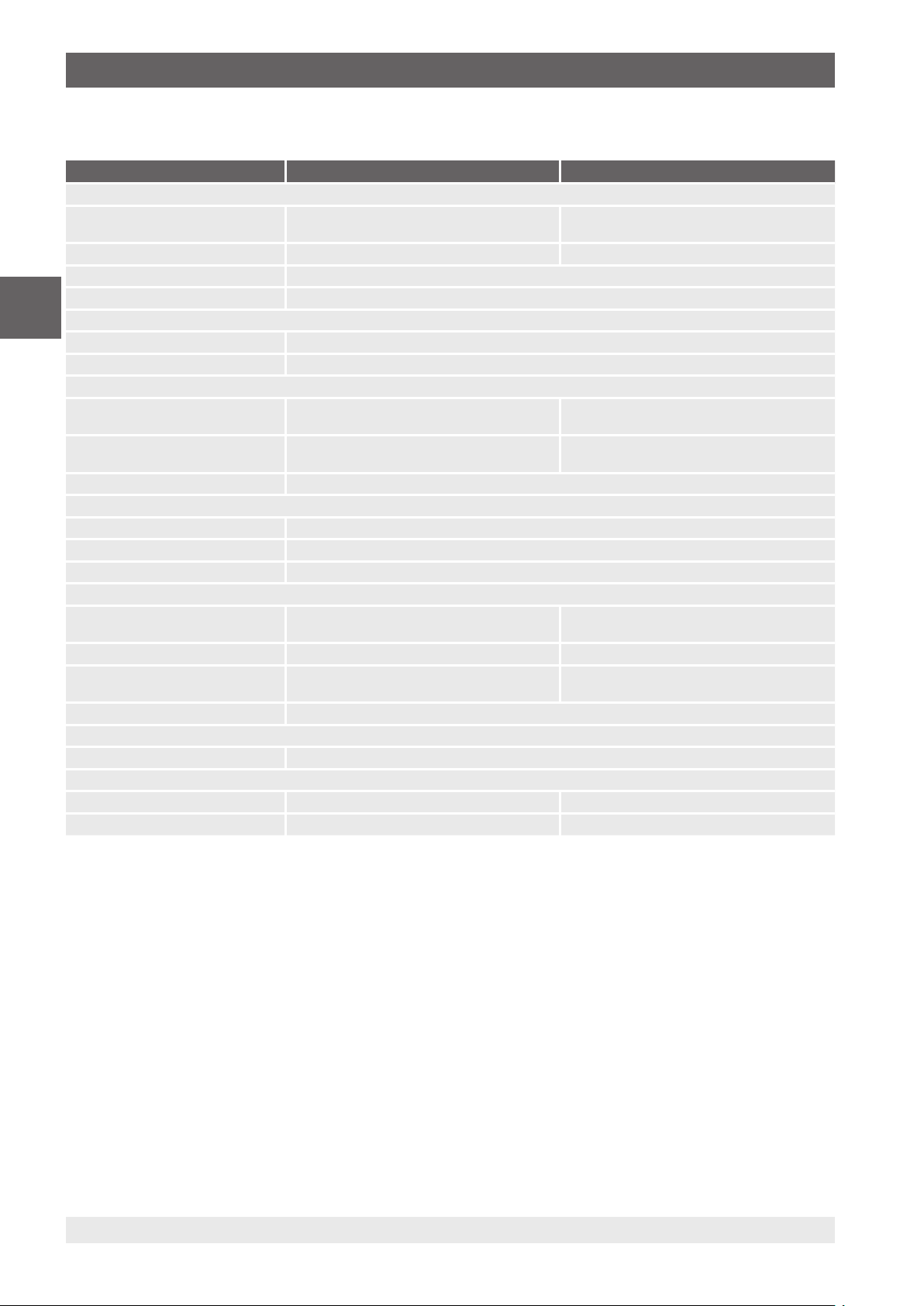

12.1 Dry-well temperature calibrator, CTD9100 series. . . . . . . . . . . . . . 36

12.2 Micro calibration bath, CTB9100 series . . . . . . . . . . . . . . . . . 38

12.3 Multi-function calibrator, model CTM9100-150 . . . . . . . . . . . . . . 40

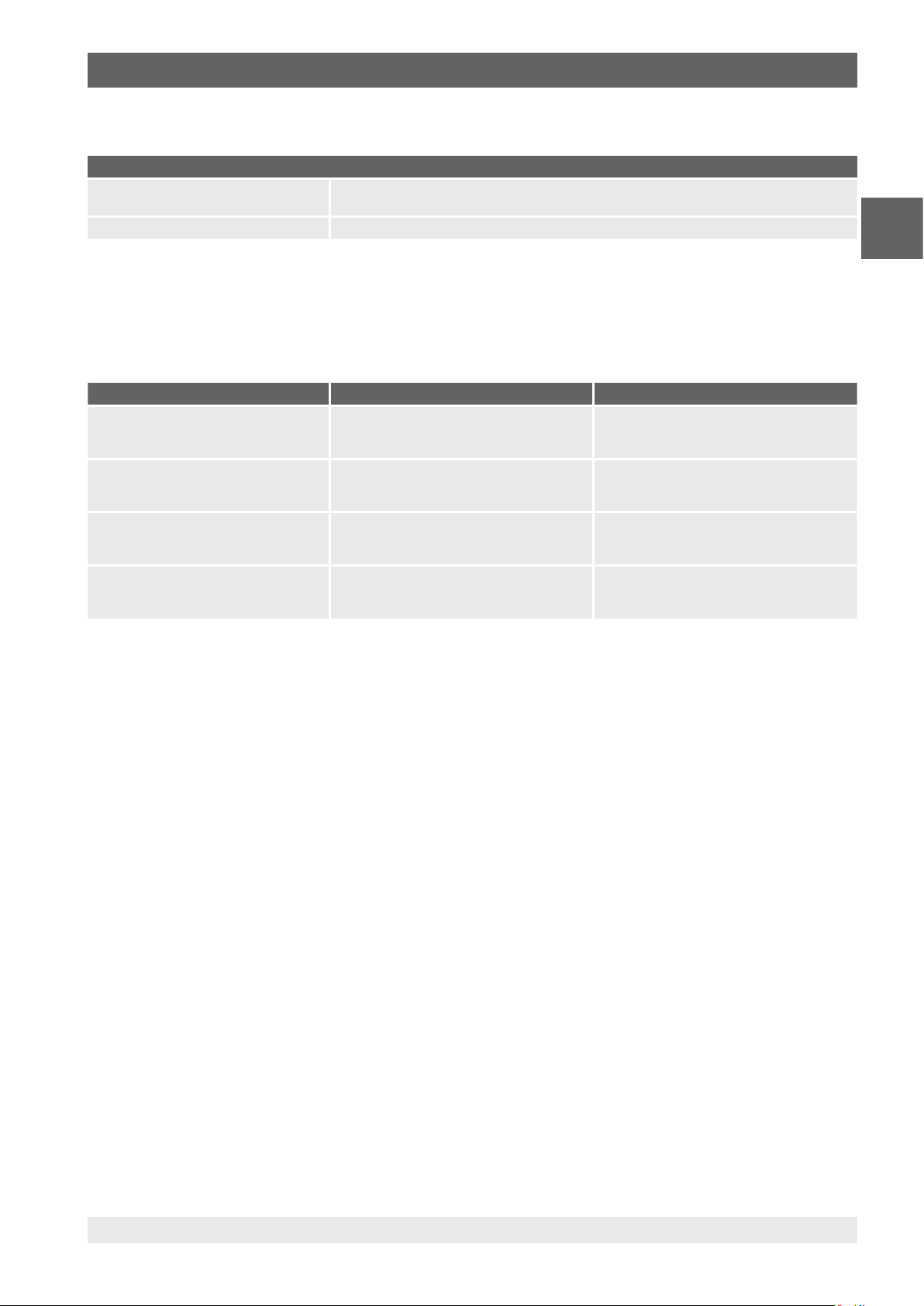

13.1 CTD9100 series . . . . . . . . . . . . . . . . . . . . . . . . . 41

13.2 CTB9100 series . . . . . . . . . . . . . . . . . . . . . . . . . 41

13.3 Model CTM9100-150 . . . . . . . . . . . . . . . . . . . . . . . 41

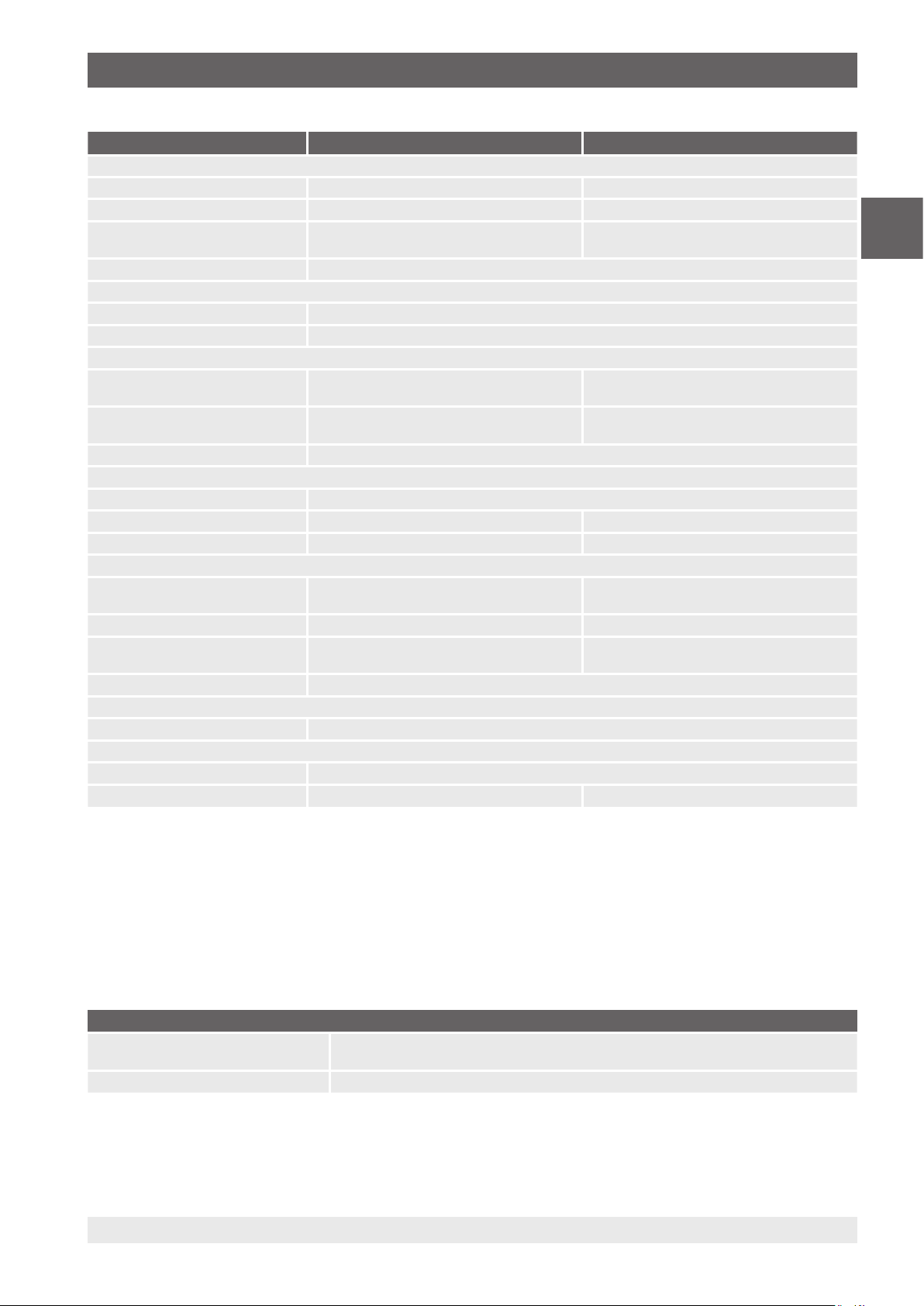

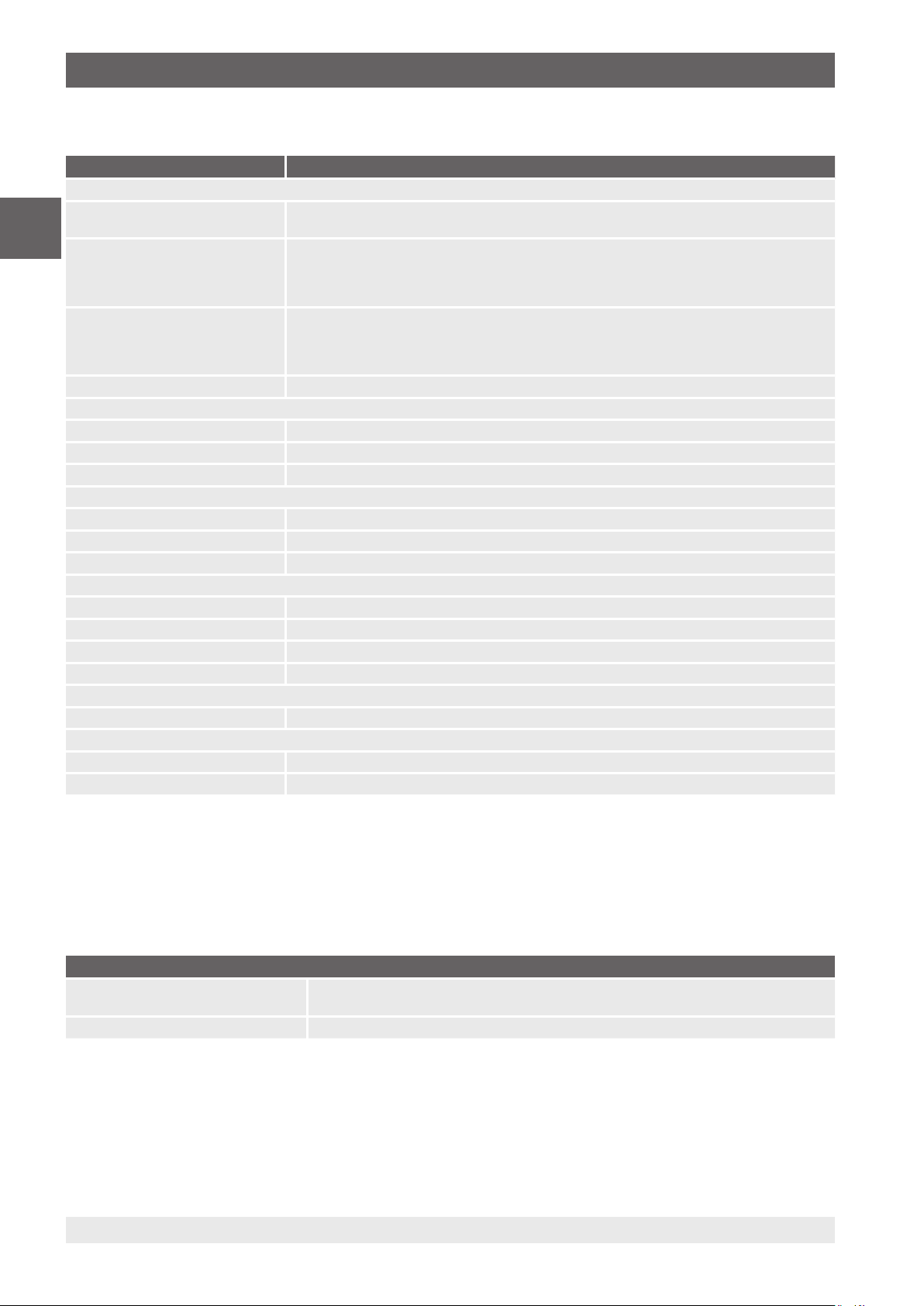

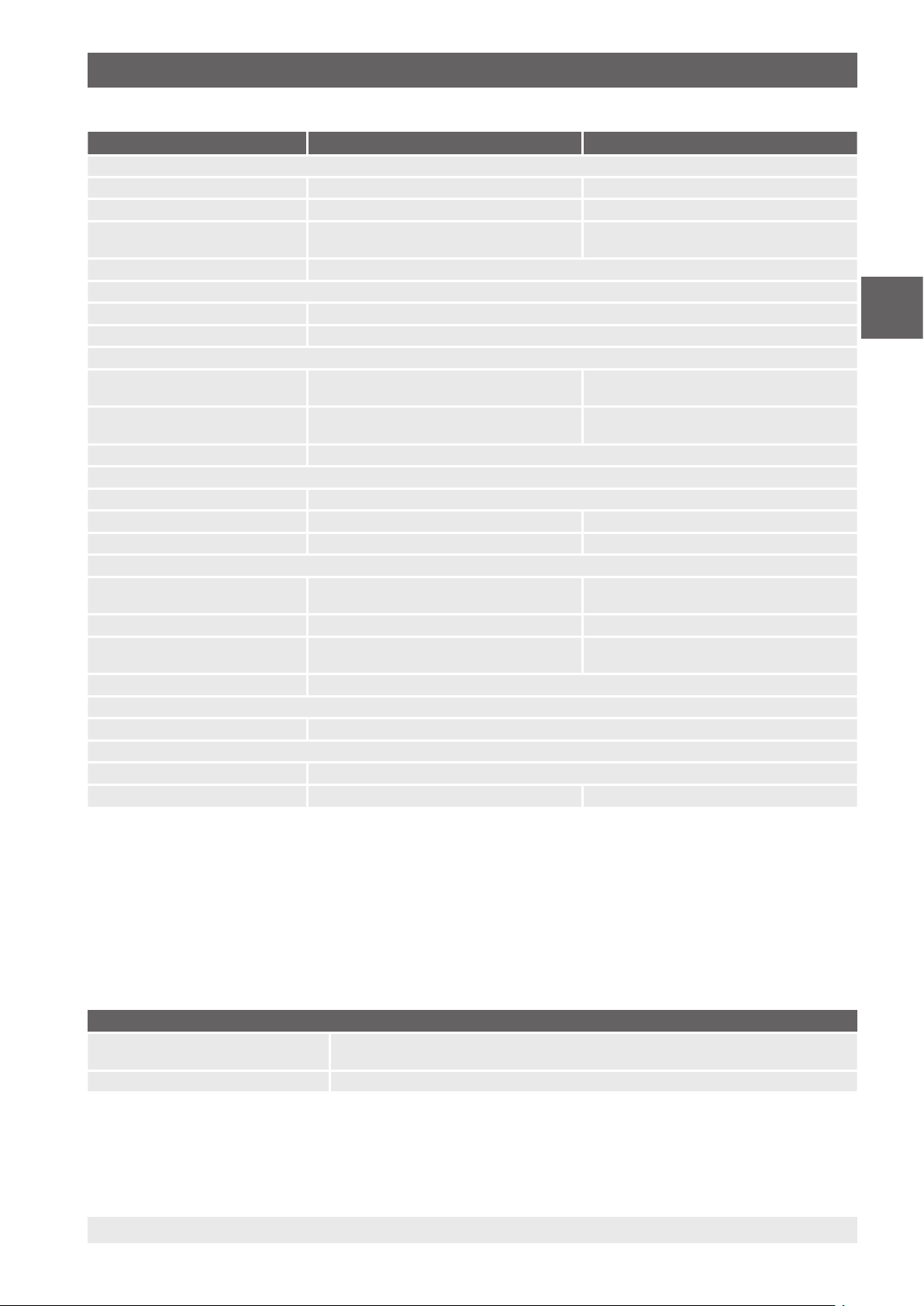

14.1 Dry-well temperature calibrator, model CTD9100-COOL . . . . . . . . . . . 42

14.2 Dry-well temperature calibrator, model CTD9100-165 . . . . . . . . . . . . 42

14.3 Dry-well temperature calibrator, model CTD9100-165-X . . . . . . . . . . . 43

14.4 Dry-well temperature calibrator, model CTD9100-450 . . . . . . . . . . . . 43

14.5 Dry-well temperature calibrator, model CTD9100-650 . . . . . . . . . . . . 44

14.6 Micro calibration bath, model CTB9100-165 . . . . . . . . . . . . . . . 45

14.7 Micro calibration bath, model CTB9100-225 . . . . . . . . . . . . . . . 47

14.8 Model CTM9100-150 as a micro calibration bath. . . . . . . . . . . . . . 48

14.9 Model CTM9100-150 as dry-well temperature calibrator . . . . . . . . . . . 49

14.10 Model CTM9100-150 as an infrared black body source . . . . . . . . . . . 49

14.11 Model CTM9100-150 as surface temperature calibrator . . . . . . . . . . . 50

Declarations of conformity can be found online at www.wika.com.

4 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 5

1. General information / 2. Short overview

1. General information

■

The calibrator or the micro calibration bath described

in the operating instructions has been designed and

manufactured using state-of-the-art technology.

All components are subject to stringent quality and

environmental criteria during production. Our management

systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information

on handling the instrument. Working safely requires that all

safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations

and general safety regulations for the instrument’s range

of use.

■

The operating instructions are part of the product and

must be kept in the immediate vicinity of the instrument

and readily accessible to skilled personnel at any time.

Pass the operating instructions onto the next operator or

owner of the instrument.

■

Skilled personnel must have carefully read and

understood the operating instructions prior to beginning

any work.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried

out in accordance with international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 41.28

CT 41.40

CT 46.30

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

EN

2. Short overview

2.1 Overview

3

2

1

1

Temperature block

2

Controller

3

Handle

11263911.05 03/2019 EN/DE/IT

5WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 6

2. Short overview / 3. Safety

2.2 Description

The calibrator or micro calibration bath is a portable unit, for

service functions and also for industrial and laboratory tasks.

The temperature calibrators and micro calibration baths

from WIKA are provided for the calibration of thermometers,

temperature switches/thermostats, resistance thermometers

EN

and thermocouples. The operational safety of the delivered

instruments is only assured if the equipment is employed for

its intended use (verification of temperature sensors). The

given limit values should never be exceeded (see chapter

12 “Specifications”).

The appropriate instrument should be selected depending on

the application; it should be connected correctly, tests carried

out and all components serviced.

The instrument is manufactured in different versions. The

individual version for any single unit can be found on the

nameplate on the calibrator/micro calibration bath.

2.3 Scope of delivery

The calibrators/micro calibration baths are delivered in

special protective packaging. The packaging must be set

aside so that the calibrator or the micro calibration bath can

be sent safely back to the manufacturer for recalibration or

repair.

Scope of delivery for the model CTD9100 dry-well

temperature calibrator

■

Calibrator

■

Insert replacement tools

■

Standard bored insert

■

Power cord

■

Calibration certificate

■

Operating instructions

Scope of delivery for the model CTB9100 micro

calibration bath

■

Micro calibration bath

■

Transport cover

■

Sensor basket

■

Magnetic stirrer

■

Magnetic lifter

■

Power cord

■

Calibration certificate

■

Operating instructions

Scope of delivery for the model CTM9100 multi-function

calibrator

■

Multi-function calibrator

■

Insert replacement tools (standard and surface)

■

Standard bored insert

■

Transport cover

■

Sensor basket

■

Magnetic stirrer

■

Magnetic lifter

■

Infrared insert

■

Surface insert

■

External reference sensor

■

Power cord

■

Calibration certificate

■

Operating instructions

Cross-check scope of delivery with delivery note.

3. Safety

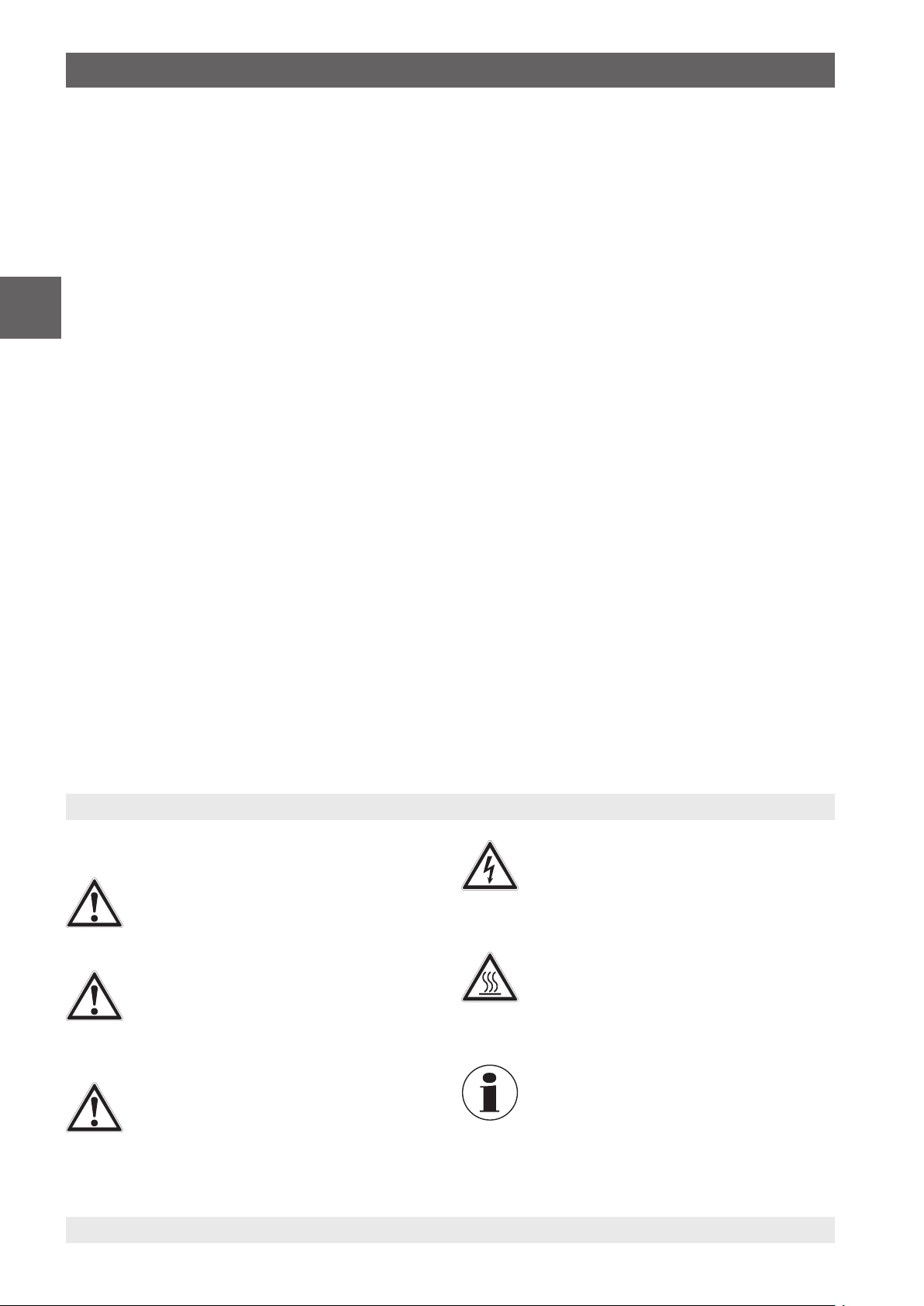

3.1 Explanation of symbols

DANGER!

... indicates a directly dangerous situation

resulting in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation

that can result in serious injury or death, if not

avoided.

CAUTION!

... indicates a potentially dangerous situation

that can result in light injuries or damage to

equipment or the environment, if not avoided.

6 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

DANGER!

... identifies hazards caused by electric power.

Should the safety instructions not be observed,

there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that

can result in burns, caused by hot surfaces or

liquids, if not avoided.

Information

... points out useful tips, recommendations

and information for efficient and trouble-free

operation.

11263911.05 03/2019 EN/DE/IT

Page 7

3. Safety

3.2 Intended use

The calibrator or micro calibration bath is a portable unit, for

service functions and also for industrial and laboratory tasks.

The temperature calibrators and micro calibration baths

from WIKA are provided for the calibration of thermometers,

temperature switches/thermostats, resistance thermometers

and thermocouples.

This instrument is not permitted to be used in hazardous

areas!

The instrument has been designed and built solely for

the intended use described here, and may only be used

accordingly.

The technical specifications contained in these operating

instructions must be observed. Improper handling or

operation of the instrument outside of its technical

specifications requires the instrument to be taken out of

service immediately and inspected by an authorised WIKA

service engineer.

Handle electronic precision measuring instruments with

the required care (protect from humidity, impacts, strong

magnetic fields, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings).

Plugs and sockets must be protected from contamination.

The manufacturer shall not be liable for claims of any type

based on operation contrary to the intended use.

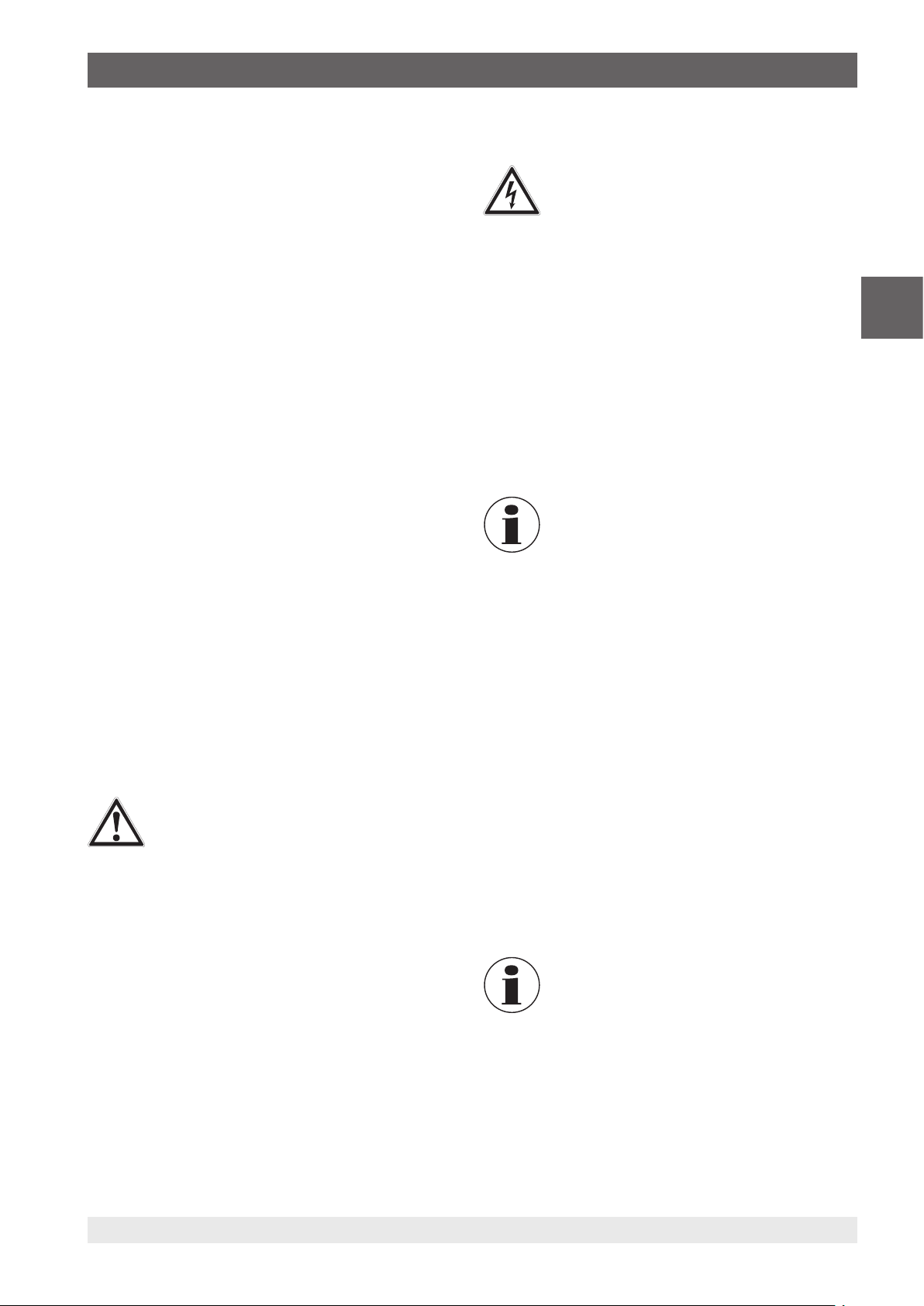

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to

hazardous situations and injuries.

▶

Refrain from unauthorised modifications to

the instrument.

▶

Do not use the instrument within hazardous

areas.

▶

Only ever use the supplied mains cable.

Any use beyond or different to the intended use is considered

as improper use.

Special hazards

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct

danger of death.

▶

The instrument may only be installed and

mounted by skilled personnel.

▶

Before replacing the fuse, cleaning,

maintenance/servicing and in the event of

danger, the calibrator or the micro calibration

bath must be disconnected by unplugging the

mains cable from the power supply outlet.

▶

The mains socket must be freely accessible

at all times!

Thermal fuse

For safety, the calibrator or the micro calibration

bath is fitted with an independently-operating

temperature fuse, which cuts out the heater

power supply if the temperature inside the

enclosure is too high. Once the metal block and

the liquid bath have cooled down, send in the

calibrator or the micro calibration bath to WIKA

for examination.

The calibrator and the micro calibration bath

have been designed as measuring and control

instruments. With any operation of the calibrator/

micro calibration bath not expressly provided

for in these operating instructions, additional

protective measures must be taken.

Since a malfunction of the calibrator/micro

calibration bath can cause personal injury or

damage to property, the equipment must be

protected by additional electro-mechanical

safeguards.

3.4 Safety instructions for using calibration liquids

Calibration liquid, water

Only use distilled water, otherwise the calibrator

tank can become strongly scaled and soiled.

Collect spilled liquids immediately and dispose

of them properly.

EN

11263911.05 03/2019 EN/DE/IT

7WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 8

3. Safety

Calibration liquid, silicone oil

WARNING!

Hazardous substances silicone oils

Improper handling can result to poisoning or

EN

personal injury.

▶

Wear the requisite protective equipment (see

chapter 3.6 “Personal protective equipment”).

▶

Observe the information in the material safety

data sheet for the corresponding medium.

▶

Before working with silicone oil, read the

material data safety sheet. The current

material safety data sheet can be found at

www.wika.de on the respective product page.

▶

Only use the silicone oil included within

the scope of supply or specified in these

operating instructions.

▶

When working with silicone oil, sufficient

ventilation should be ensured in the room

since it can give off pollutants.

▶

Since silicone oil is hygroscopic, after use,

always close the calibration bath using the

transport cover.

▶

Before transporting with silicone oil, allow the

calibrator or micro calibration bath to cool. The

transport cover is fitted with a safety valve. If

the micro calibration bath is closed when it is

still warm, excessive pressure can build up.

In order to avoid overpressuring, which could

lead to damage to the liquid bath, the safety

valve is activated at a pressure of approx.

2.5 bar [36 psi]. This can lead to hot vapour

escaping.

WARNING!

Risk of burns!

Touching the hot metal block or micro calibration

bath, the hot bath liquids or the test item can

lead to acute burns.

▶

Before transporting or touching the metal

block/liquid bath, make sure that it has cooled

down sufficiently.

3.5 Personnel qualification

WARNING!

Risk of injury should qualification be

insufficient!

Improper handling can result in considerable

injury and damage to equipment.

The activities described in these operating

instructions may only be carried out by skilled

personnel who have the qualifications described

below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood

to be personnel who, based on their technical training,

knowledge of measurement and control technology and

on their experience and knowledge of country-specific

regulations, current standards and directives, are capable

of carrying out the work described and independently

recognising potential hazards.

Special operating conditions require further appropriate

knowledge, e.g. of aggressive media.

3.6 Personal protective equipment

The personal protective equipment is designed to protect the

skilled personnel from hazards that could impair their safety

or health during work. When carrying out the various tasks

on and with the instrument, the skilled personnel must wear

personal protective equipment.

Follow the instructions, displayed in the work area,

regarding personal protective equipment!

The required personal protective equipment must be

provided by the operating company.

Wear safety goggles!

Protect eyes from flying particles and liquid

splashes.

Collect spilled liquids immediately and dispose

of them properly.

Wear safety goggles!

Do not allow silicone oil to come into contact with

the eyes.

Wear protective gloves!

Protect hands from friction, abrasion, cuts or

deep injuries and also from contact with hot

surfaces and aggressive media.

8 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Wear protective gloves!

Protect hands from friction, abrasion, cuts or

deep injuries and also from contact with hot

surfaces and aggressive media.

11263911.05 03/2019 EN/DE/IT

Page 9

3. Safety

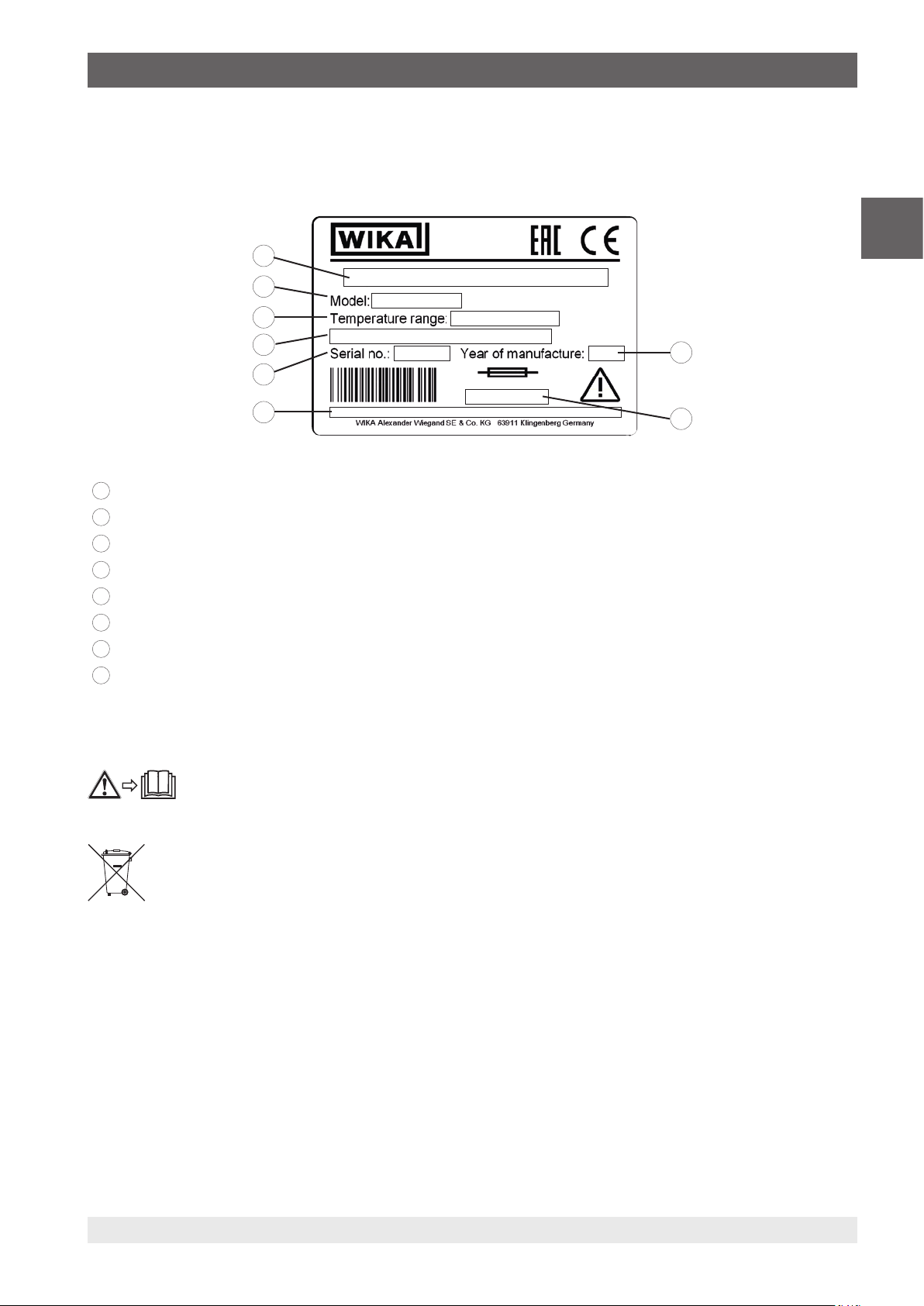

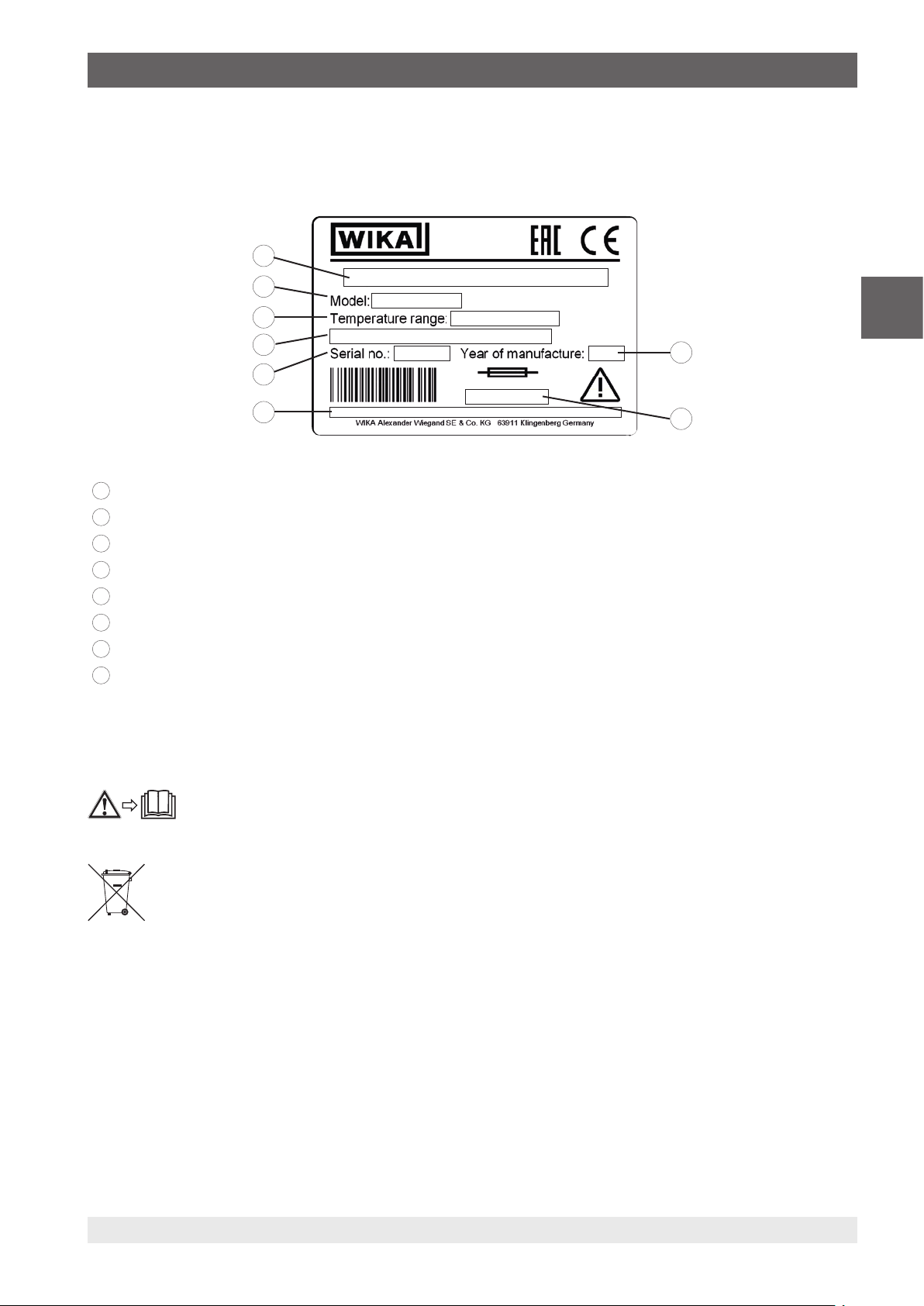

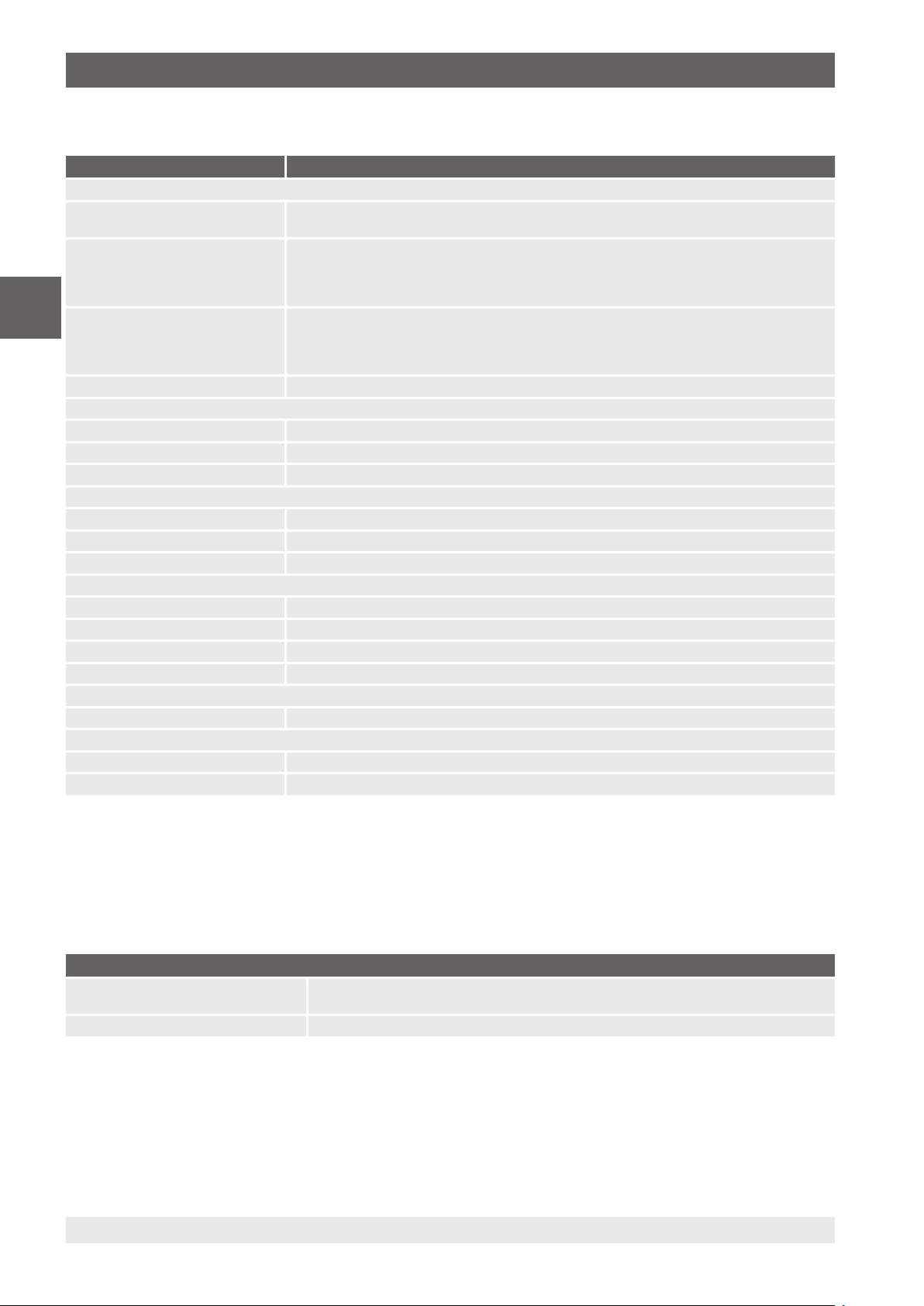

3.7 Labelling, safety marks

Product label (example)

The product label is fixed on the rear of the instrument.

8

7

6

EN

5

4

3

1

Year of manufacture

2

Fuse

3

Notes regarding the safety data sheet

4

Serial no.

5

Power supply

6

Temperature range

7

Model designation

8

Instrument designation

Explanation of symbols

Before mounting and commissioning the

instrument, ensure you read the operating

instructions!

1

2

Do not dispose of with household waste. Ensure

a proper disposal in accordance with national

regulations.

11263911.05 03/2019 EN/DE/IT

9WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 10

4. Design and function

4. Design and function

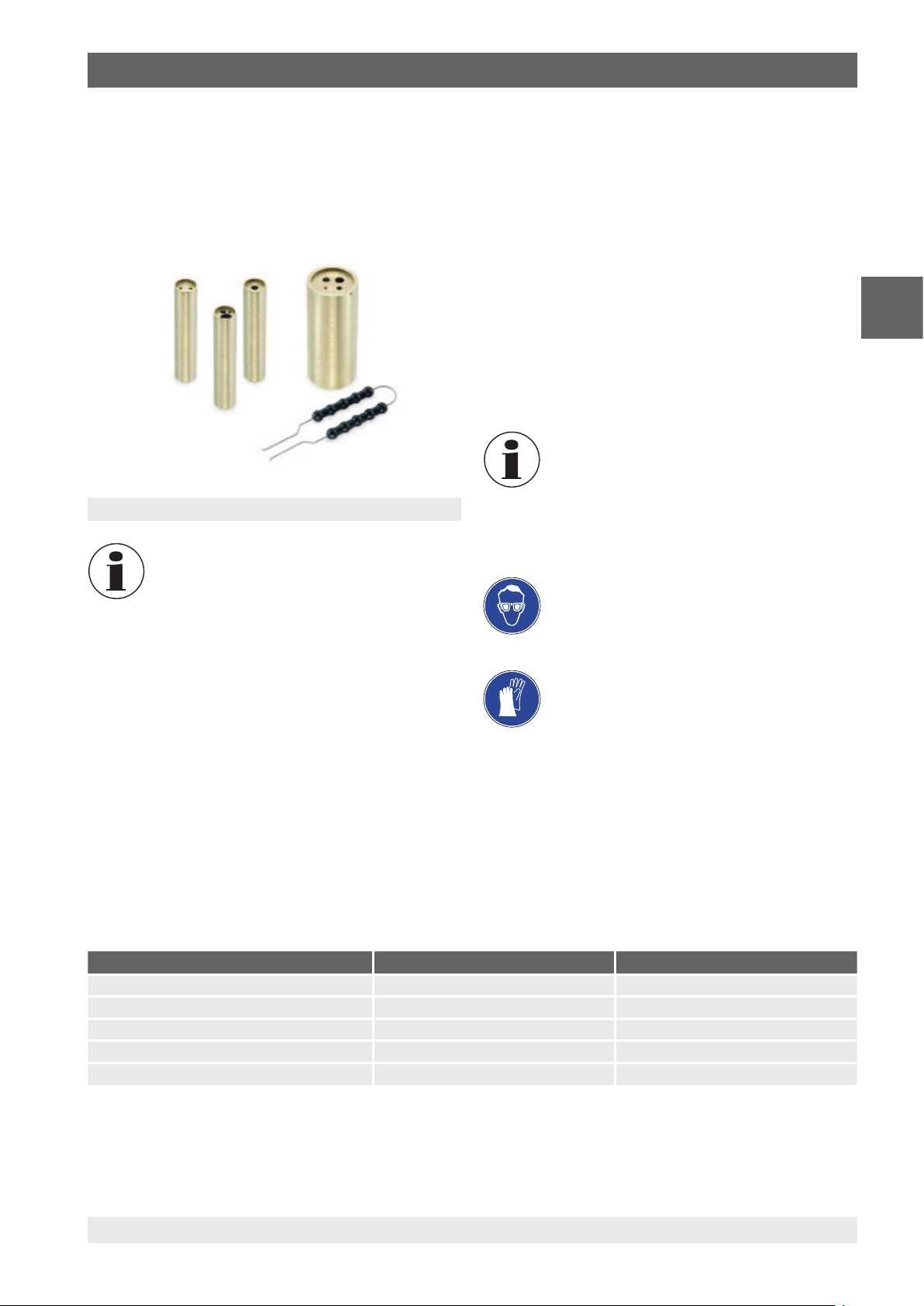

4.1 Overview of the different instrument models

Temperature calibrators

■

EN

CTD9100-COOL (cooling and heating)

■

CTD9100-165 (cooling and heating)

■

CTD9100-450 (heating)

■

CTD9100-650 (heating)

Micro calibration baths

■

CTB9100-165 (cooling and heating)

■

CTB9100-225 (heating)

Multi-function calibrator

■

CTM9100-150 (cooling and heating)

The calibrator and micro calibration bath consist of a robust,

grey-blue-painted steel enclosure, with a carrying handle on

top.

The rear part of the enclosure includes a metal block or

liquid bath with an opening for the test item, accessible from

the top.

The metal block/liquid bath incorporate the heating or cooling

elements and the temperature sensor for determining the

reference temperature.

The metal block and the liquid bath are thermally insulated.

The front part contains the complete electronic unit for

controlling the reference temperature.

Solid state relays (SSR) are used to control the heating and

cooling elements.

On the front panel is the controller, which is fitted with a

7-segment LED (2 rows of 4 digits) for the reference and set

temperature.

The micro calibration bath has an additional knob for

controlling the stirring speed.

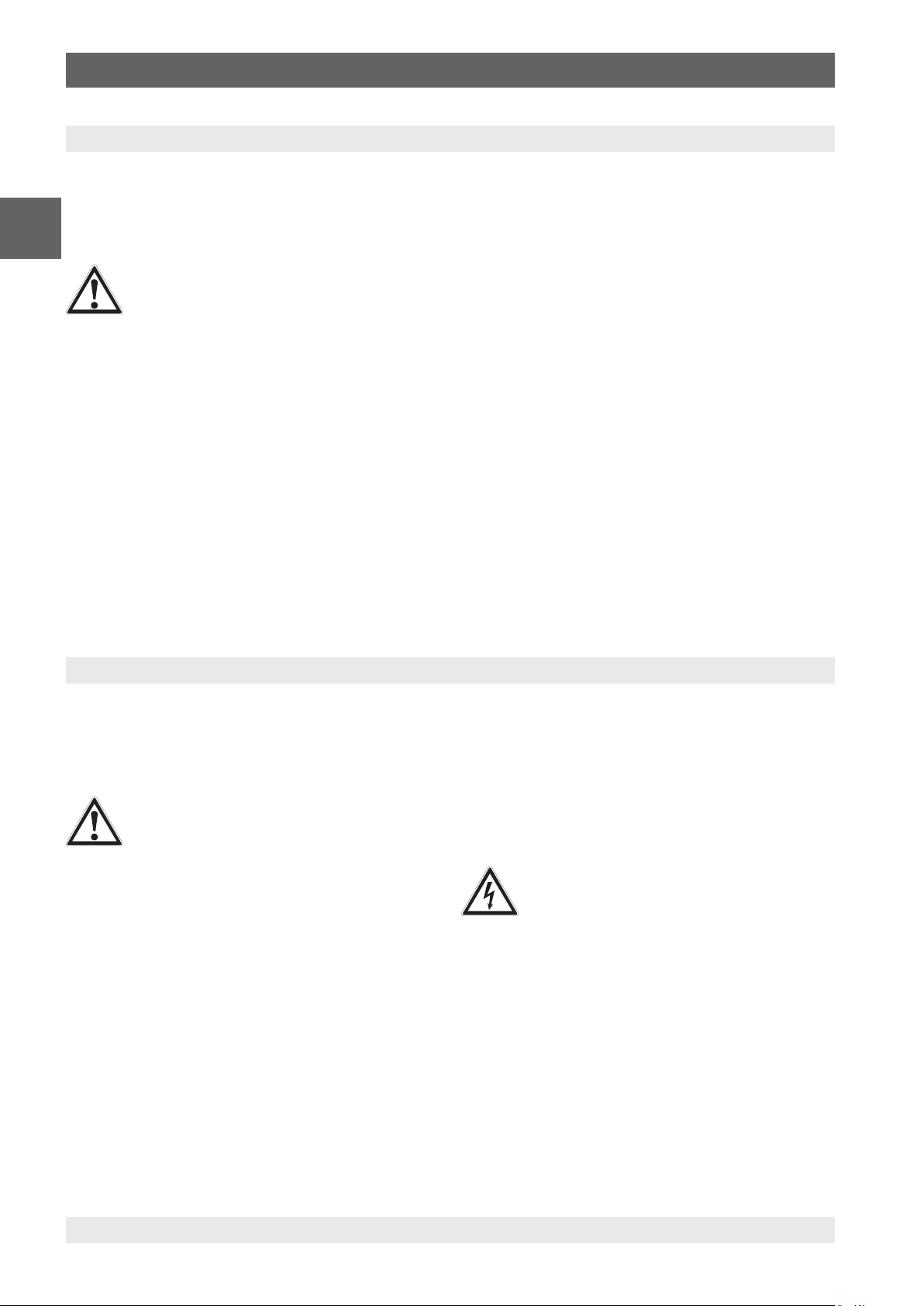

Temperature calibrator, model CTD9100-165 Temperature calibrator, model CTD9100-650

Multi-function calibrator, model CTM9100-150Micro calibration bath, model CTB9100-165

10 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 11

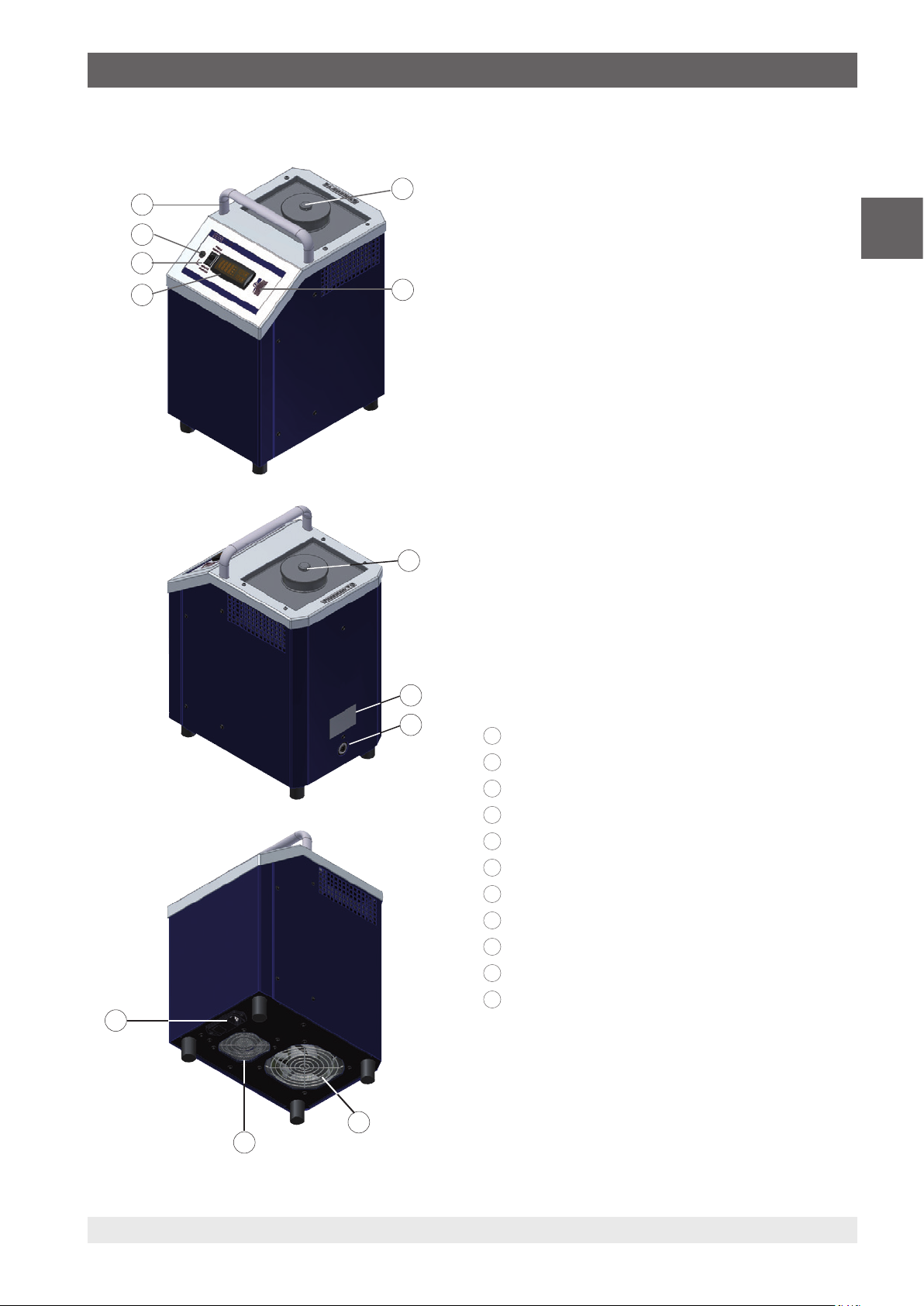

4. Design and function

4.2 Isometric views of the CTD9100 series dry-well temperature calibrators

1

Front and top of the model CTD9100

On the top of the dry-well temperature calibrator, you will find

3

2

the dry well access opening for inserting the inserts.

■

CTD9100-COOL: Ø 28 x 150 mm [Ø 1.10 x 5.91 in]

■

CTD9100-165: Ø 28 x 150 mm [Ø 1.10 x 5.91 in]

■

CTD9100-165-X: Ø 60 x 150 mm [Ø 2.36 x 5.91 in]

■

CTD9100-450: Ø 60 x 150 mm [Ø 2.36 x 5.91 in]

■

CTD9100-650: Ø 28 x 150 mm [Ø 1.10 x 5.91 in]

EN

The controller, with display and controls, is located on the

front of the calibrator.

Rear of the instrument

On the rear of the equipment is the product label with the key

information about the particular model.

■

CTD9100-COOL: -55 ... +200 °C [-67 ... +392 °F]

■

CTD9100-165: -35 ... +165 °C [-31 ... +329 °F]

■

CTD9100-450: 40 ... 450 °C [104 ... 842 °F]

■

CTD9100-650: 40 ... 650 °C [104 ... 1.202 °F]

1

The correct mains voltage and frequency is also given.

■

AC 100 ... 240 V, 50 ... 60 Hz

■

AC 115 V, 50 ... 60 Hz

■

AC 230 V, 50 ... 60 Hz

8

11263911.05 03/2019 EN/DE/IT

4

Furthermore, the individual serial number

(e.g. S/N 550 33 44) as well as the mains voltage and the

5

fuse rating is given.

You will also find the connector for the RS-485 interface here.

Underside of the instrument

On the underside of the instrument are the mains connection

socket and the power switch with its fuse-holder.

These are located in the centre, at the front. Furthermore,

depending on the model, there are one or two air intakes

located on the underside of the instrument.

The air intakes must not be obstructed in any way.

1

Temperature block

2

Controller

3

Handle

4

Product label

5

RS-485 interface

6

Fan 1

6

7

7

Fan 2

8

Mains connection socket with power switch

11WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 12

4. Design and function

4.3 Isometric views of the CTB9100 series micro calibration baths

EN

1

3

2

9

On the top of the micro calibration bath are the block opening

for filling Ø 60 x 150 mm [Ø 2.36 x 5.91 in].

The controller, with display and controls, is located on the

front of the calibrator.

Rear of the instrument

On the rear of the equipment is the product label with the key

information about the particular model.

Furthermore, the individual serial number

(e.g. S/N 550 33 44) as well as the mains voltage and the

fuse rating is given.

You will also find the connector for the RS-485 interface here.

Underside of the instrument

On the underside of the instrument are the mains connection

socket and the power switch with its fuse-holder.

Front and top of the model CTB9100

1

These are located in the centre, at the front. Furthermore,

depending on the model, there are one or two air intakes

located on the underside of the instrument.

The air intakes must not be obstructed in any way.

4

5

8

1

Temperature block

2

Controller

3

Handle

4

Product label

5

RS-485 interface

6

Fan 1

7

Fan 2

8

Mains connection socket with power switch

9

Controller for the stirrer

6

7

12 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 13

4. Design and function

4.4 Isometric views of the model CTM9100-150 multi-function calibrator

Front and top of the model CTM9100-150

1

3

11

On the top of the multi-function calibrator, you will find the dry

well access opening for inserting the different inserts or filling

Ø 60 x 150 mm [Ø 2.36 x 5.91 in].

EN

10

The controller, with display and control elements, is located

2

9

on the front of the calibrator. In addition, the control elements

for the external reference are placed on the front.

Rear of the instrument

On the rear of the equipment is the product label with the key

information about the particular model.

Furthermore, the individual serial number

(e.g. S/N 550 33 44) as well as the mains voltage and the

fuse rating is given.

You will also find the connector for the RS-485 interface here.

Underside of the instrument

1

On the underside of the instrument are the mains connection

socket and the power switch with its fuse-holder.

These are located in the centre, at the front. Furthermore,

there are two air intakes located on the underside of the

instrument.

The air intakes must not be obstructed in any way.

4

5

8

6

7

1

Temperature block

2

Controller

3

Handle

4

Product label

5

RS-485 interface

6

Fan 1

7

Fan 2

8

Mains connection socket with power switch

9

Controller for the stirrer

10

Switch for ext. reference

11

Socket for ext. reference

11263911.05 03/2019 EN/DE/IT

13WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 14

4. Design and function

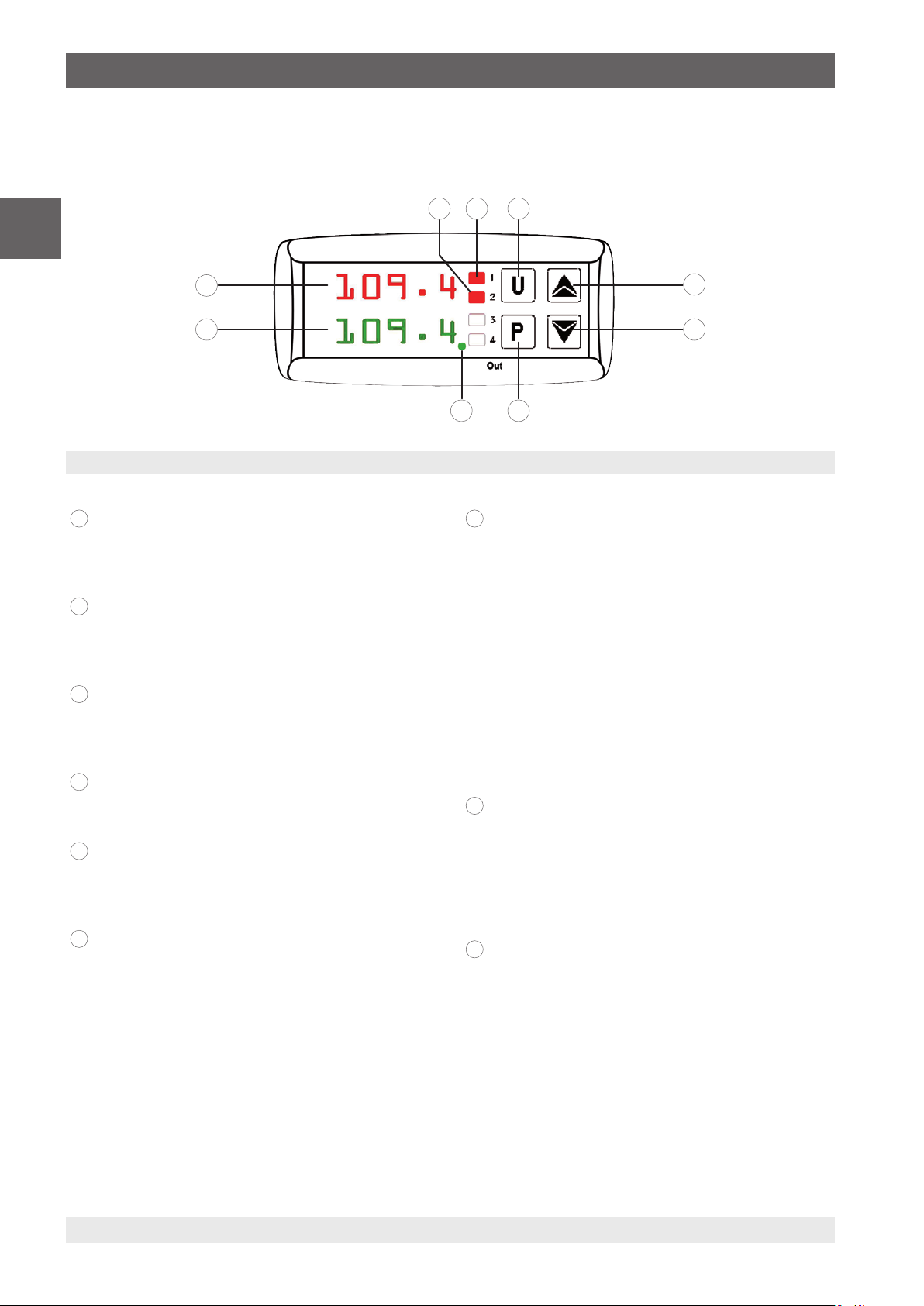

4.5 Description of the operating elements

Front of the controller

EN

7 8 9

6

5

Overview of the operating elements on the front of the controller

Button [▲]

1

■

Increasing value being set

■

Selection of individual menu item

■

Go back up one menu level

Button [▼]

2

■

Reduction of value being set

■

Selection of individual menu item

■

Go back up one menu level

Button [P]

3

■

Access to the set temperature adjustment

■

Access to the menu items and parameters

■

Input confirmation

LED SET

4

Flashing signals access to the individual menu items

and parameters

SV display

5

■

Set temperature display

■

Display of particular parameters in the individual

7

8

modes and the menu options

PV display

6

■

Indication of the current reference temperature

■

Display of the individual modes, menu items and the

9

parameters

1

2

34

LED OUT 2

a) Heating instrument

Signals the status of the outputs for the fan control

■

If LED OUT 2 is on, the fan is running at higher

speed

■

If LED OUT 2 is not on, the fan is running at lower

speed

b) Heating and cooling instrument

Signals the status of the outputs for the temperature

control

■

If LED OUT 1 is on, the calibrator or the micro

calibration bath is cooling

■

If LED OUT 1 is not on, the calibrator or the micro

calibration bath is not cooling

LED OUT 1

Signals the status of the outputs for the temperature

control

■

If LED OUT 1 is on, the calibrator or the micro

calibration bath is heating

■

If LED OUT 1 is not on, the calibrator or the micro

calibration bath is not heating

Button [U]

Recall the stored set temperatures

Further definitions

[XXX] Press XXX button

XXX Menu XXX will be displayed

14 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 15

4. Design and function

4.6 Data interface

The instruments are fitted with an RS-485 communications

interface. Via this interface one can connect to a PC, level

converter or a network.

The software protocol used is a MODBUS-RTU protocol,

which is used in may monitoring programs available on the

market.

The transmission speed (baud rate) is factory set to 9,600

baud. Upon request, other data transmission rates are

possible.

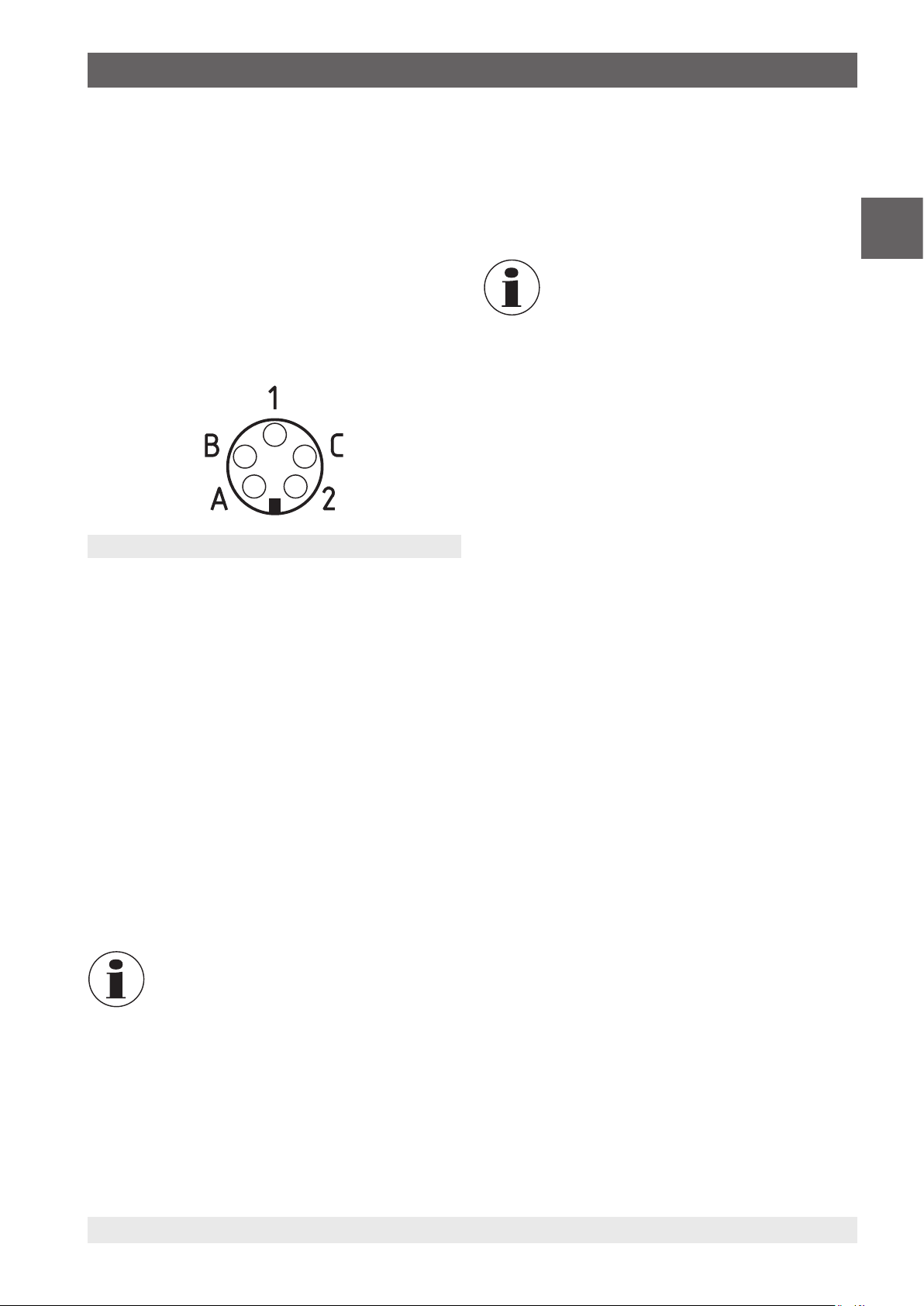

The 5-pin socket has two pins, A and B, that you connect to

the corresponding connections on the PC, level converter or

network.

Plan view of the 5-pin panel socket

4.7 Interface protocol

The interface protocol is available on request for delivery as a

specific additional document.

4.8 Protective earth monitoring

The calibrator is fitted with a protective earth

monitor to keep a check on the base isolation

of the heater. The monitoring unit works

independently of the normal controls and

switches off the heating power supply as soon as

the calibrator no longer has a connection to the

protective earth system of the isolation.

Once reconnected to the protective earth

system, the monitoring unit automatically

switches the power supply back on to the

heating circuit.

EN

To connect to a PC, the RS-485 signal must be externally

converted to an RS-232 or USB signal. The appropriate

converter, including drivers, is available as an option.

The computer records all operational data and allows

programming of all calibrator configuration parameters.

The minimum requirements for operation with a USB

converter are:

■

IBM compatible PC

■

Installed operating system, Microsoft® Windows® 98 SE,

ME, 2000, XP (Home or Prof.) or 7

■

A USB interface (USB 1.1 or USB 2.0)

A network connection enables the connection of up to 32

calibrators/micro-baths on the same network.

To connect to a network, some factory setting is required. For

this, please contact the supplier or WIKA directly.

For access to the programming via the keypad

while the serial interface is communicating, the

message “buSy” appears on the display, and

therefore indicates that it is in an “occupied”

state.

11263911.05 03/2019 EN/DE/IT

15WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 16

4. Design and function / 5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the calibrator or the micro calibration bath for any

damage that may have been caused by transport.

EN

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage

to property can occur.

▶

When unloading packed goods upon delivery

as well as during internal transport, proceed

carefully and observe the symbols on the

packaging.

▶

With internal transport, observe the

instructions in chapter 5.2 “Packaging and

storage”.

If the instrument is transported from a cold into a warm

environment, the formation of condensation may result

in instrument malfunction. Before putting it back into

operation, wait for the instrument temperature and the room

temperature to equalise.

5.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection

during transport (e.g. change in installation site, sending for

repair).

Permissible conditions at the place of storage:

■

Storage temperature: -10 ... +60 °C [14 ... 140 °F]

■

Humidity: 30 ... 95 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down

hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, flammable

atmospheres

Store the calibrator or the micro calibration bath in its original

packaging in a location that fulfils the conditions listed above.

6. Commissioning, operation

Personnel: Skilled personnel

Protective equipment: Protective gloves and safety goggles

Only use original parts (see chapter 13 “Accessories”).

WARNING!

Physical injuries and damage to property

and the environment caused by hazardous

media

Upon contact with hazardous media (e.g.

oxygen, acetylene, flammable or toxic

substances), harmful media (e.g. corrosive,

toxic, carcinogenic, radioactive), and also with

refrigeration plants and compressors, there is

a danger of physical injuries and damage to

property and the environment.

Should a failure occur, aggressive media and/

or with high temperature may be present at the

instrument.

▶

For these media, in addition to all standard

regulations, the appropriate existing codes or

regulations must also be followed.

▶

Wear the requisite protective equipment (see

chapter 3.6 “Personal protective equipment”).

6.1 Operating position

The operating position of the calibrator or the micro

calibration bath is in the vertical orientation, since this

guarantees an optimal temperature distribution in the metal

block or liquid bath.

Voltage supply

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct

danger to life.

▶

Only ever use the supplied mains cable.

The voltage supply of the instrument is made via the power

cable. This is included in the scope of delivery.

16 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 17

6. Commissioning, operation

6.2 Inserts with metal block

In order to achieve the greatest possible accuracy, the use

of exactly matched inserts is necessary. For this, diameter of

the specimen must be accurately determined. The bore for

the insert is obtained by adding +0.5 mm [+0.02 in].

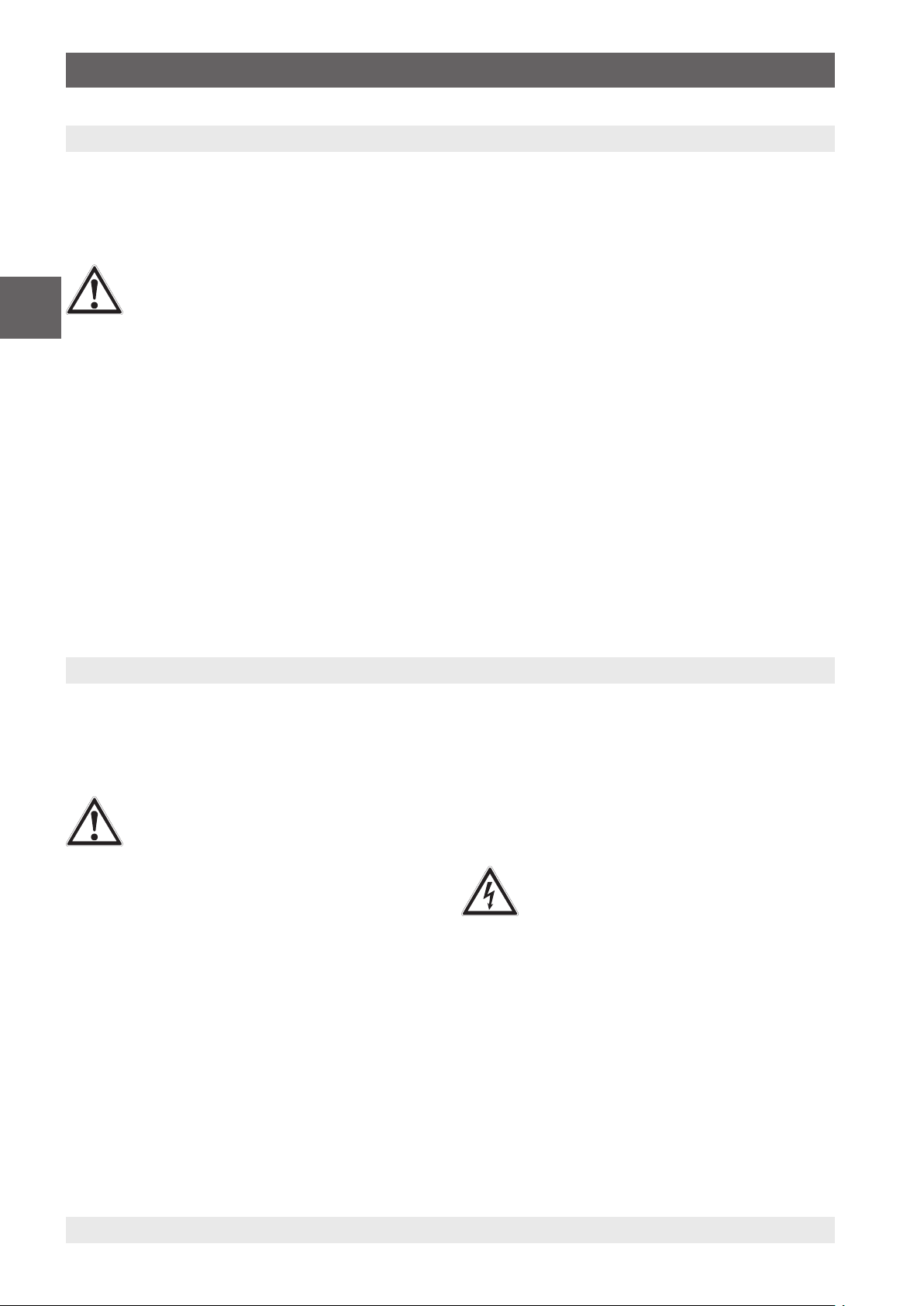

Inserts

Following use, the inserts should be removed

using the replacement tools and then the sleeve

and block should be cleaned. This prevents the

sleeves becoming jammed in the heating block.

Recommended calibration liquids for the different

temperature ranges:

Water as a calibration liquid

■

Only use distilled or demineralised water, otherwise the

calibrator tank can become strongly scaled and soiled.

Silicone oil as a calibration liquid

■

Only use the silicone oil recommended here.

■

When working with silicone oil, sufficient ventilation should

be ensured in the room since it can give off pollutants.

■

Since silicone oil is hygroscopic, after use, always close

the calibration bath using the transport cover.

Only use clean calibration liquids. The

checking of temperature sensors and other

temperature measuring devices may lead to the

contamination of the calibration liquid. These

contaminants, through the rotational movement

of the magnetic stirrer, may cause an abrasive

effect on the bottom tank.

Wear safety goggles!

Do not allow silicone oil to come into contact with

the eyes.

EN

6.3 Preparation of the micro calibration bath

In order to achieve the highest possible accuracy for a

micro calibration bath, it should be filled with an appropriate

calibration liquid.

6.3.1 Properties of the calibration liquid

Different calibration liquids, due to their specific properties,

deliver varying calibration results. A compensation to the

calibration liquid used in each case should, if necessary, be

■

Clean the tank

■

Before calibration, clean the sensors

■

Replace the worn magnetic stirrer

■

Replace the contaminated, cloudy calibration liquid

Wear protective gloves!

Protect hands from friction, abrasion, cuts or

deep injuries and also from contact with hot

surfaces and aggressive media.

performed by the manufacturer at the factory.

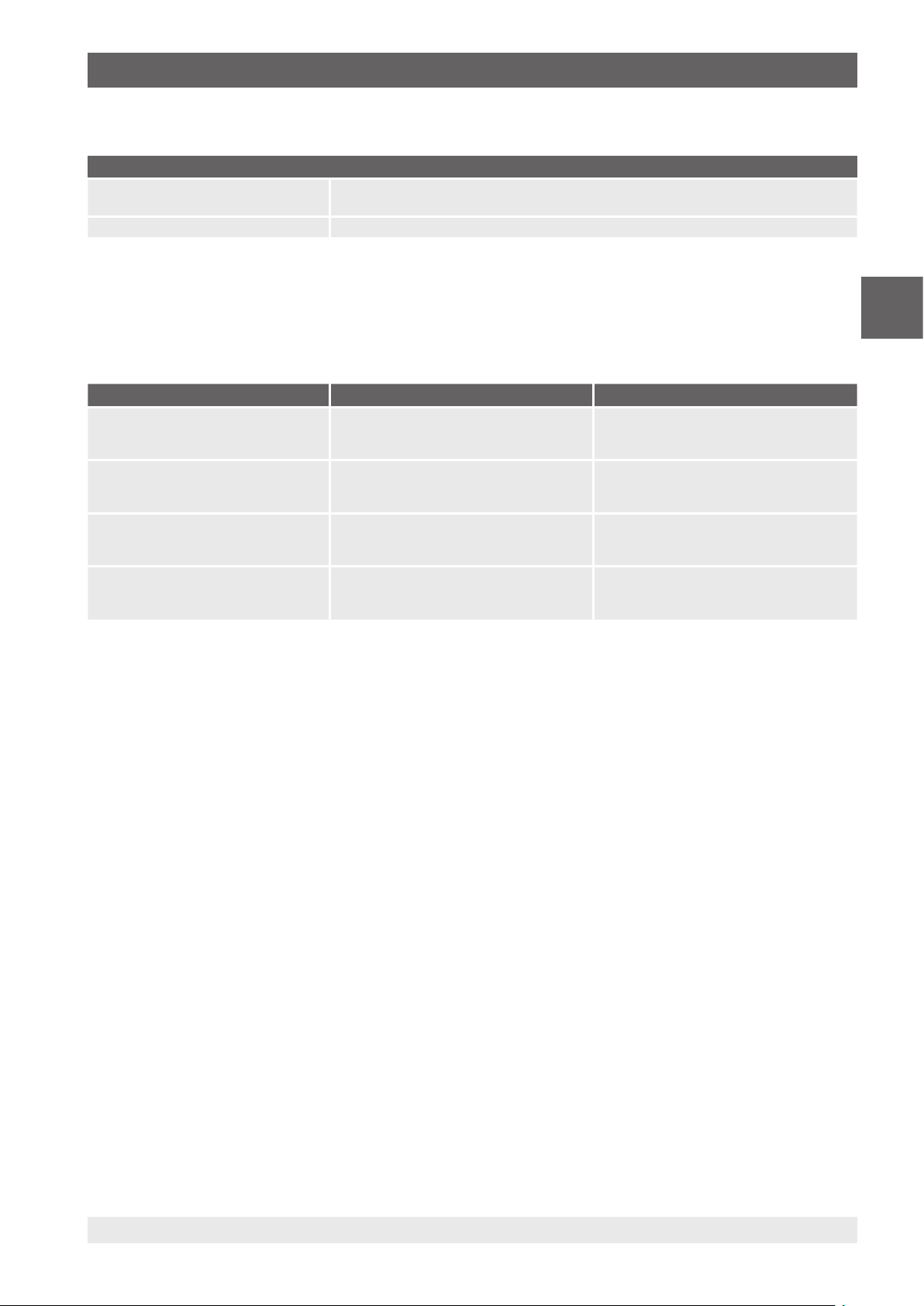

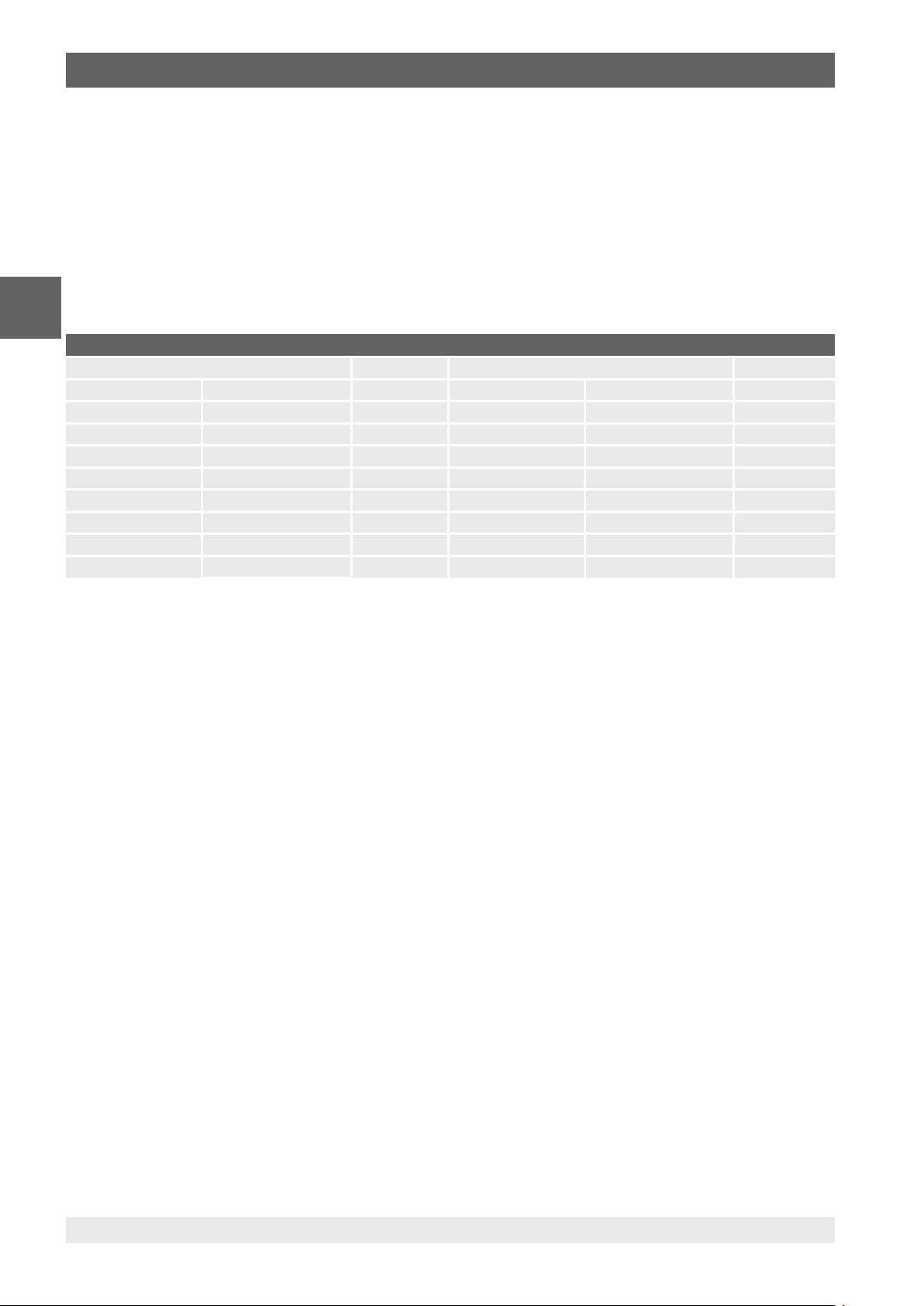

Medium Calibration range Flash point

Distilled water 5 ... 90 °C [51 ... 194 °F] none

Dow Corning 200 Fluid with 5 CS -40 ... +123 °C [-40 ... +253 °F] 133 °C [271 °F]

Dow Corning 200 Fluid with 10 CS -35 ... +155 °C [-31 ... +311 °F] 163 °C [325 °F]

Dow Corning 200 Fluid with 20 CS 7 ... 220 °C [45 ... 428 °F] 232 °C [450 °F]

Dow Corning 200 Fluid with 50 CS 25 ... 270 °C [77 ... 518 °F] 280 °C [536 °F]

11263911.05 03/2019 EN/DE/IT

17WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 18

6. Commissioning, operation

6.3.2 Filling the micro calibration bath

1. Firstly, remove the transport cover.

2. Place the test item in the sensor basket.

3. Fill the tank with calibration liquid.

Following maximum filling heights are recommended:

EN

Calibrator model max. filling height

CTB9100-165 / CTM9100-150 130 mm [5.12 in]

CTB9100-165 / CTM9100-150

with removable insert

CTB9100-225 123 mm [4.84 in]

CTB9100-225 with removable insert 105 mm [4.13 in]

CTB9100-225-X 115 mm [4.53 in]

CTB9100-225-X with removable insert 95 mm [3.74 in]

Following points should be observed at the maximum

filling heights:

■

Measured from the bottom of the sensor basket

■

Non loaded tank

■

WIKA standard filling liquid

■

Pre-filling ex-works with the optimal height

110 mm [4.33 in]

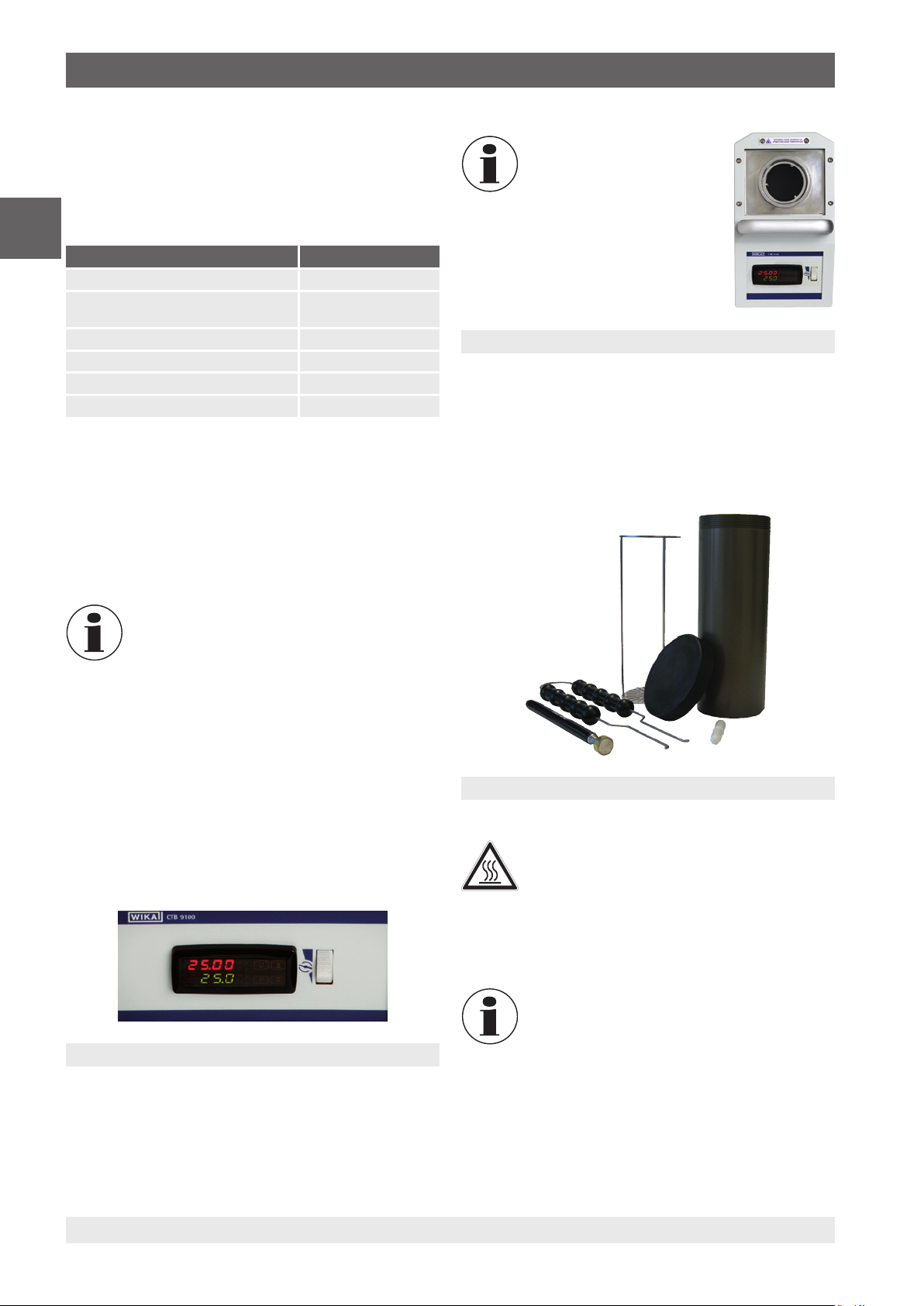

The magnetic stirrer is a

consumable.

Liquid bath

6.3.4 Insert for liquids

The insert for liquids consists of:

■

Insert with leak-proof cover

■

Sensor basket

■

Magnetic stirrer and lifter

■

Replacement tools

The transport cover is fitted with a safety valve.

If the micro calibration bath is closed when it is

still warm, excessive pressure can build up. In

order to avoid overpressuring, which could lead

to damage to the liquid bath, the safety valve

is activated at a pressure of approx. 2.5 bar

[36 psi]. This can lead to hot vapour escaping.

6.3.3 Operation of the magnetic stirrer

The greatest possible homogeneity is achieved by the

agitation of the calibration liquid via a magnetic stirrer.

Set the stirring speed to the maximum possible. Turning the

wheel upwards will increase the speed, turning it downwards

slows down the stirring speed.

Front of the controller with stirrer-speed dial

Insert for liquids

WARNING!

Risk of burns!

Hot liquids can lead to acute burns

▶

The insert for liquids must only be removed if

the calibrator is used at room temperature.

▶

The fill level must be matched the relevant

medium and the temperature.

If the insert for liquids is ordered with a new

model CTB9100 micro calibration bath or a new

model CTM9100 multi-function calibrator, the

instrument will have been matched to the insert

for liquids.

Should the insert for liquids be ordered

afterwards, a re-adjustment of the instrument at

the customer’s will be needed.

18 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 19

6. Commissioning, operation

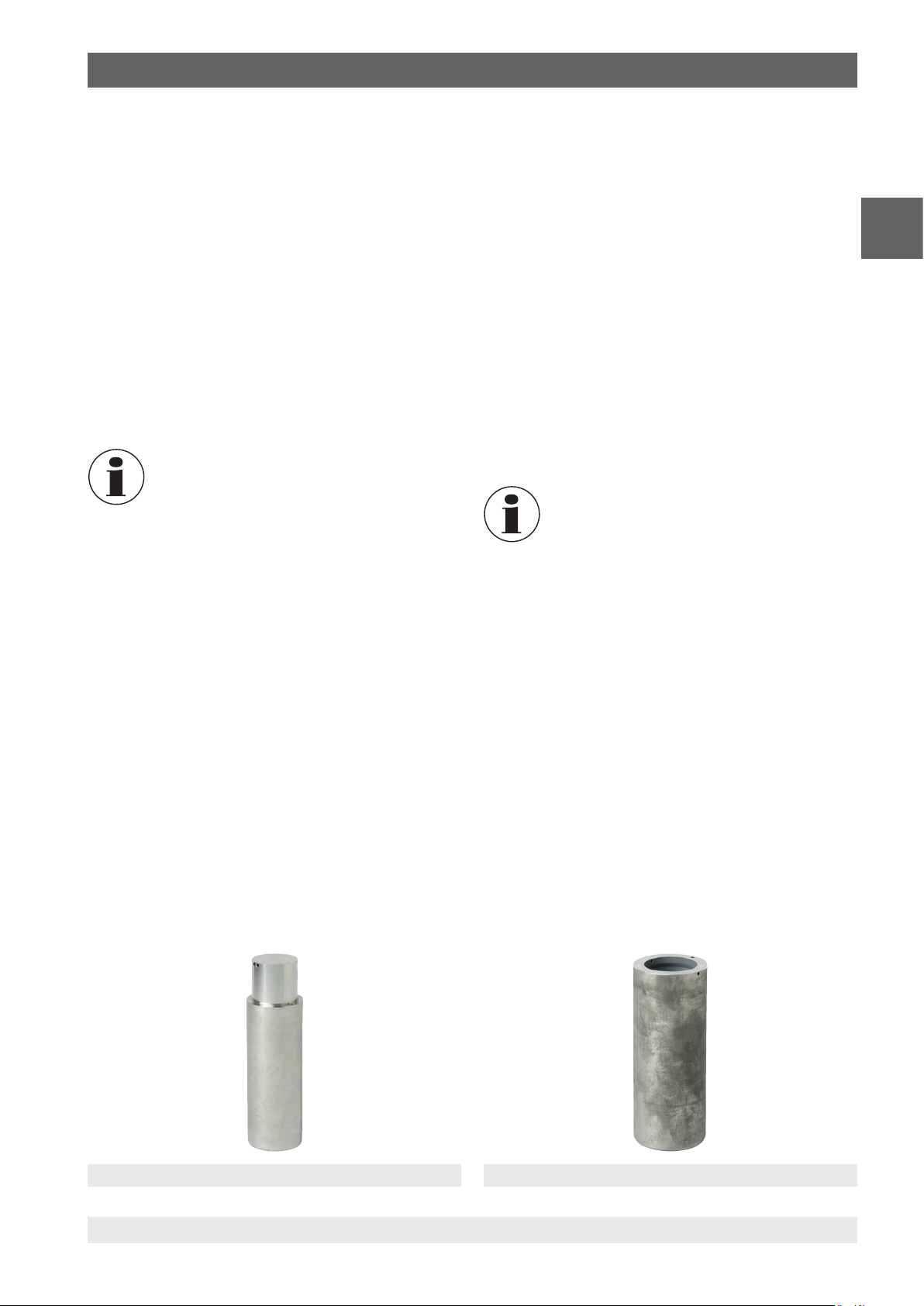

6.4 Surface insert (only CTM9100-150)

The operation of the calibrator with the surface insert is

suited to a simple and the most accurate calibration possible

of surface probes.

Fit the insert, which is hollow and long from the bottom, into

the block using a special replacement tool.

The sleeve also has three bores (1 x 3 mm, 1 x 3.1 mm and

1 x 4 mm [1 x 0.12 in, 1 x 0.12 in and 1 x 0.16 in]) directly

under the surface, so that the correct surface temperature

can be controlled at all times.

Following use, the inserts should be removed using the

specific replacement tools and then the sleeve and block

should be cleaned. This prevents the sleeves becoming

jammed in the heating block.

The calibration of surface thermometers is very

difficult and not fully defined. Thermometers

mounted on surfaces dissipate heat from

the surface and create a cold zone on the

surface being measured. In the multi-function

calibrators, the calibration temperature is created

in a specially designed surface insert and an

external reference thermometer measures the

temperature directly under the surface. The

reference thermometer also determines the

temperature of the cold zone through integration

of the temperature along the sensitive length of

the reference thermometer and thus provides

a true temperature calibration of surface

temperature sensors.

6.5 Infrared insert (only CTM9100-150)

The operation of the calibrator with the infrared insert is

suited to a quick and simple calibration of non-contact

thermometers.

Fit the hollow and specially-designed insert into the

block using a special replacement tool. The sleeve also

has two bores in the edge (1 x 3.5 mm and 1 x 4.5 mm

[1 x 0.14 in and 1 x 0.18 in]) for the accurate monitoring of the

temperature.

The design and surface finish of the sleeve is important, in

order that a defined emissivity of 1 is achieved.

Following use, the inserts should be removed using the

specific replacement tools and then the sleeve and block

should be cleaned. This prevents the sleeves becoming

jammed in the heating block.

With temperatures of < 0 °C [< 32 °F] and higher

air humidity, ice or dew can form in the insert.

This can falsify the calibration. By capping the

measurement opening, the ice or dew formation

can be strongly reduced.

■

Leave the measurement opening closed as

long as possible

■

Open the measurement opening for a short

while for the measurement

■

Remove any ice or dew present by heating

EN

The sleeve is designed so that the supplied

external reference provides the best possible

result, since the depth of the bore is adjusted

to the sensitive length. If a separate external

reference is used for comparison calibration,

ensure that the sensitive length is known and it

lies in the centre of the calibration surface.

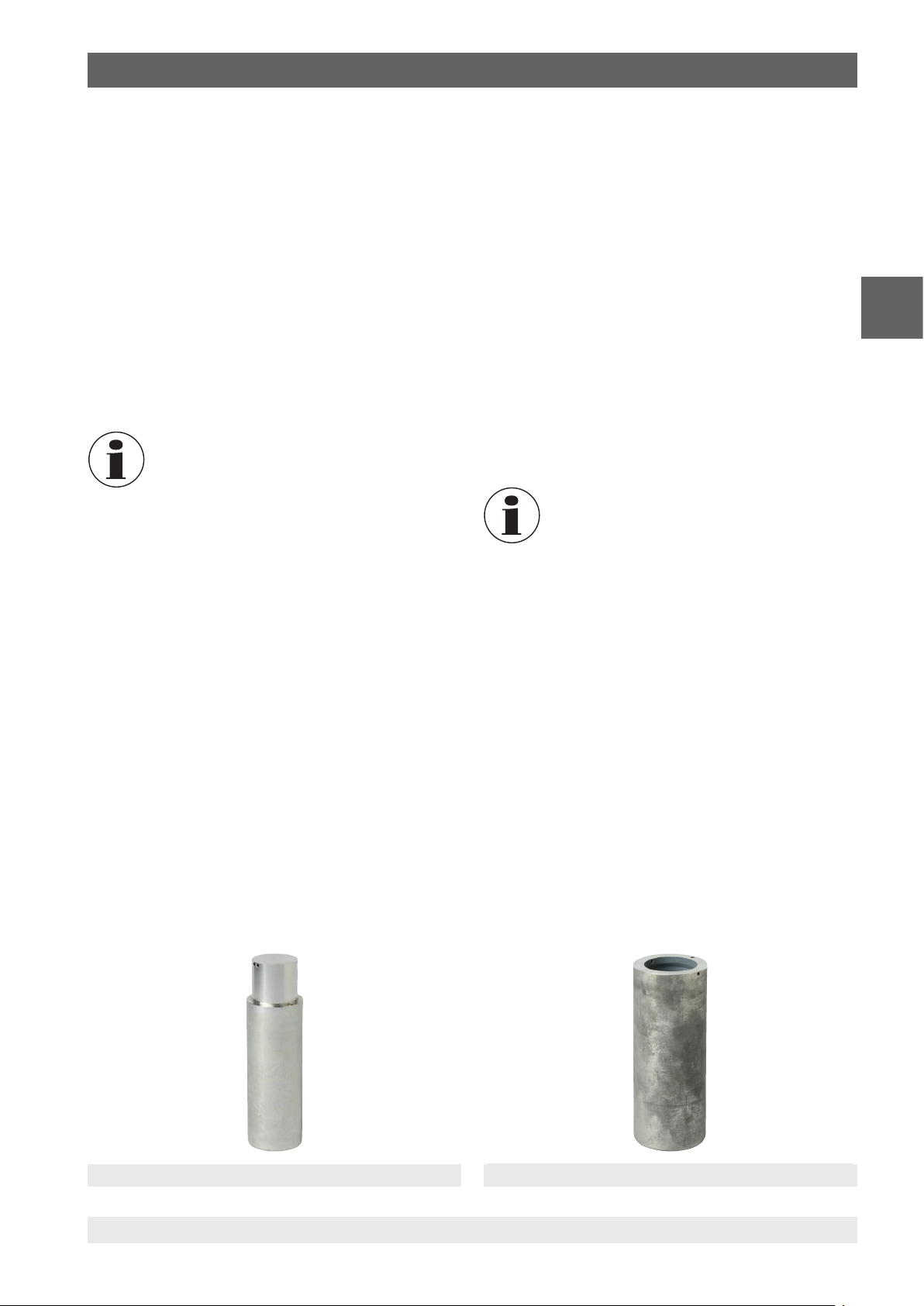

Surface insert

11263911.05 03/2019 EN/DE/IT

Insert for infrared measurements

19WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 20

6. Commissioning, operation

6.6 Testing of temperature sensors

To test temperature sensors, connect a separate

temperature-measuring instrument to the test item. By

comparing the temperature displayed on the external

measuring instrument with the reference temperature,

there is evidence of the status of the test item. This ensured

EN

that the test item requires a short time until it reaches the

temperature of the metal block or liquid bath.

There is no possibility for calibrating earthed

thermocouples, since the heating block is

earthed and this would therefore lead to false

measurement results.

6.7 Start-up procedure

If the calibrator is not used for a long time, because of the

materials used (magnesium oxide), moisture can penetrate

the heating elements.

Following transport or storage of the calibrator in moist

environments, the heating elements must be taken to higher

temperatures slowly.

During the drying process,it should be assumed that the

calibrator has not yet reached the required insulation voltage

for protection class I. The start-up set point is T

[248 °F] with a holding time of T

= 15 min.

n

= 120 °C

anf

Once the set temperature has been reached, through short

switch impulses, the radiated heating energy from the metal

block or liquid bath is delivered, so that the temperature

within remains constant.

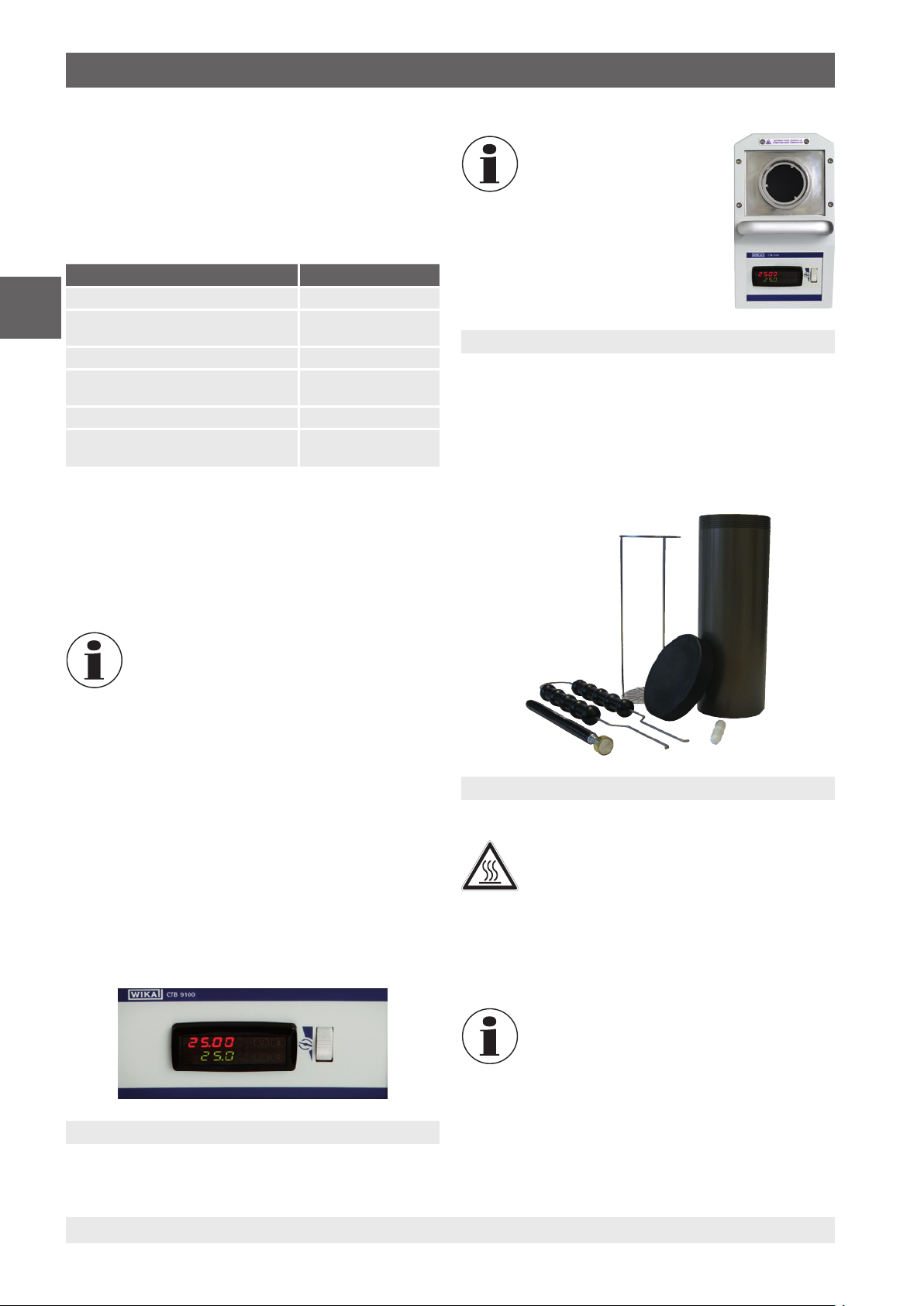

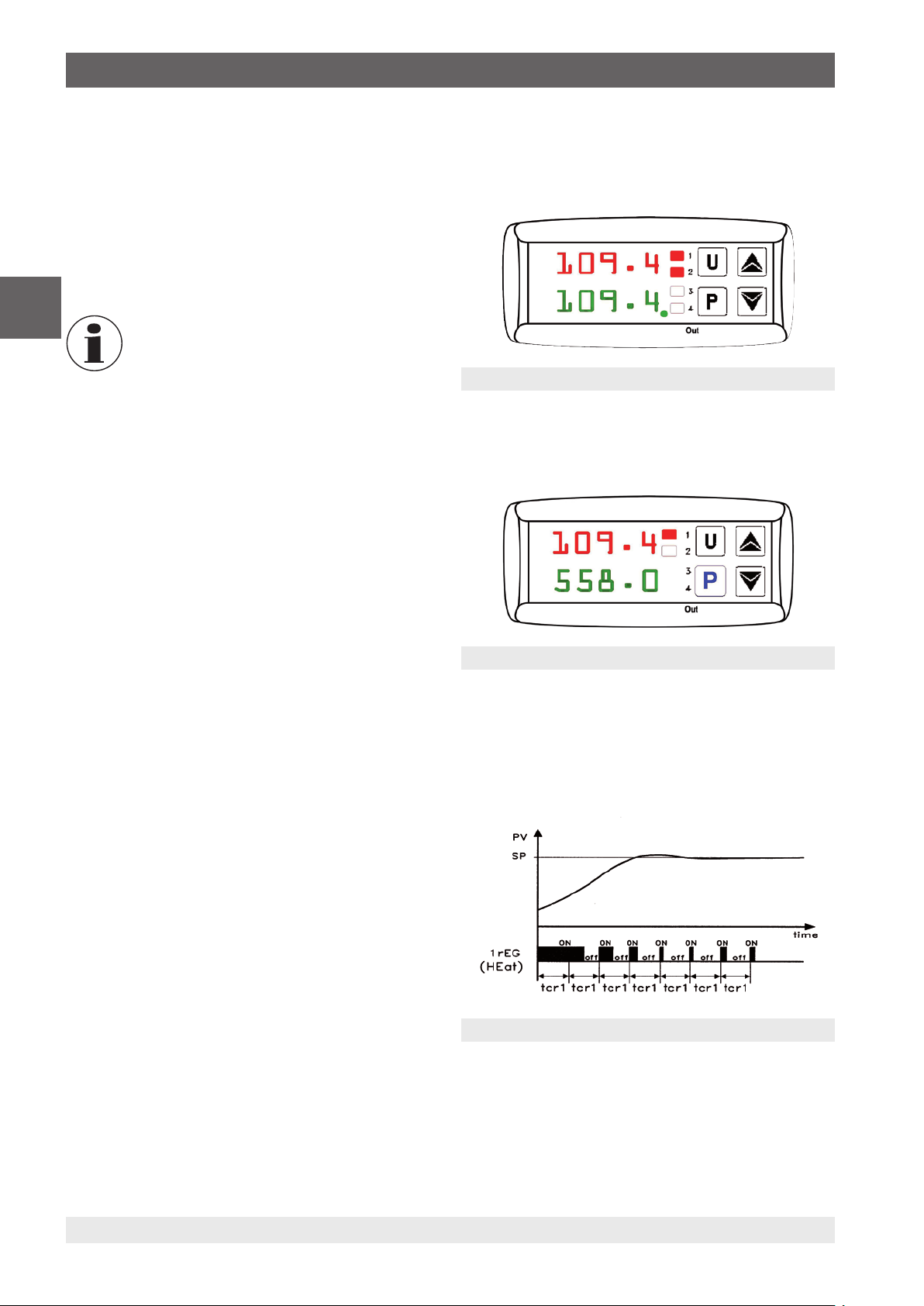

Reference and set temperature display

6.10 Control of the reference temperature

The red LED OUT 1 indicates that the heater is turned on.

6.8 Switching on the calibrator/micro calibration bath

1. Connect to the mains using the mains connector supplied.

2. Switch on the mains switch.

The controller will be initialised.

The upper PV display will show tEst.

In the lower SV display, the version number (e.g. rL 2.2) will

be shown.

After approx. 5 secs, the initialisation will be complete and

the calibration mode will automatically be displayed.

The built-in heating or cooling elements will temper the metal

block automatically from room temperature to the controller’s

set temperature.

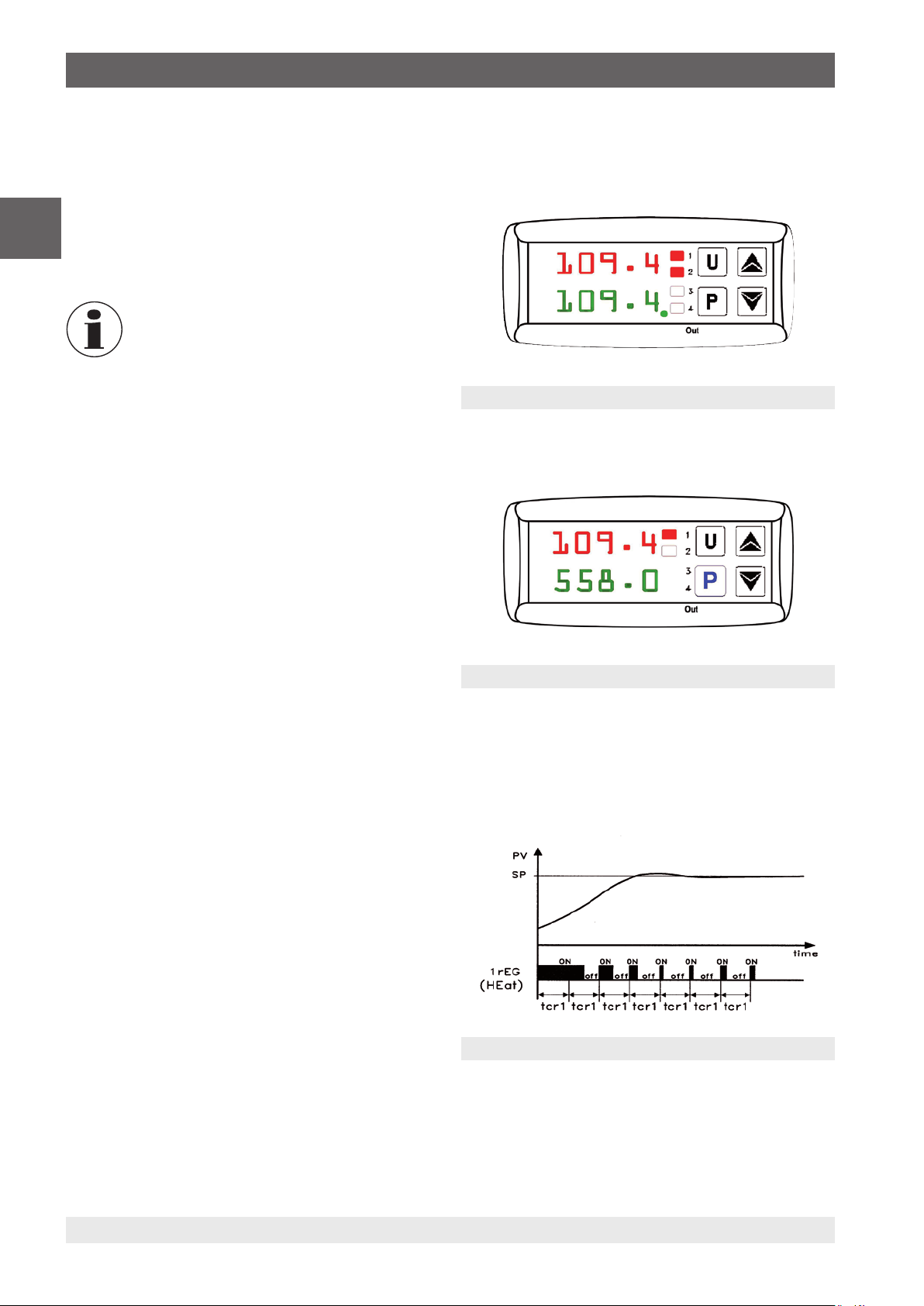

6.9 Reference and set temperature display

Upper PV display:

The red 4-digit, 7-segment display shows the current

temperature of the metal block or liquid bath.

Lower SV display:

The green, 4-digit, 7-segment display shows the current set

temperature of the metal block or the liquid bath.

Display with LED OUT 1

During the heating phase a steady light indicates that heating

energy is being supplied. A flashing LED indicates that the

reference temperature (set temperature) has almost been

reached and therefore the heating energy is only being

supplied in short bursts.

Control achieved via PID algorithm

To ensure good temperature stability, the cycle time of the

controller is set low and the control output is usually raised.

20 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 21

7. Operating elements of the calibrator/micro calibration bath

7. Operating elements of the calibrator/micro calibration bath

There are three modes available for operation

Calibration mode

In this standard operating state the calibration of test items

can be made.

Set-point mode

In this mode, the set temperature is entered.

Main menu

In this mode, all settings, such as specifying the desired

temperature or setting the control parameters are made.

7.1 Selection of the operating modes for the

CTM9100-150

To operate the multi-function calibrator in the desired mode

of operation, first specify the correct linearisation for the

controller. In the main menu (via the [P] button) select the

desired function using the arrow keys.

LI Operates as a micro calibration bath

DB Operates as a dry block

Ir Operates as an infrared black body source

SU Operates as a surface temperature calibrator

Select the liquid used depending upon the desired calibration

temperature.

Dry-block operating mode

1. Cleaning the tank (if needed)

2. Inserting the insert (aluminium)

3. Set the speed of the magnetic stirrer to “0”.

4. In order to ensure the correct linearisation, set DB in the

controller. For this, press the [P] button for approx. 5 secs.

and confirm the appropriate setting in the main menu with

[P].

5. Set the switch to the left of the controller to external

reference. Connect the delivered external reference in to

the socket provided and slide into the appropriate bore in

the insert.

The insert has several bores into which the thermometer

probes being calibrated and the external reference, for

comparative calibration, can be inserted. The block is either

heated or cooled to the desired calibration temperature.

Once a stable temperature has been reached, the

temperature probes to be calibrated can be compared with

the reference thermometer.

EN

The desired function is accepted using the [P] button.

On the main screen, the desired linearisation (LI, DB, Ir or

SU) is displayed in the PV line every 5 secs.

7.2 Method of operation in calibration mode within

individual operating modes

Micro calibration bath operating mode (possible with or

without insert for liquids)

1. Insert the magnetic stirrer and sensor basket.

2. Fill the micro calibration bath (see chapter 6.3.2 “Filling

the micro calibration bath”).

3. Set the speed of the magnetic stirrer, in order to achieve

the best homogeneity possible.

4. In order to ensure the correct linearisation, set LI in the

controller. For this, press the [P] button for approx. 5 secs.

and confirm the appropriate setting in the main menu with

[P].

5. Set the switch to the left of the controller to internal

reference.

Angled thermometers, large-diameter thermometers or

thermometers with special designs cannot be calibrated

with a dry-well calibrator. For this reason the multi-function

calibrator also has the possibility to function as a stirred liquid

bath. The liquid is circulated using a magnetic stirrer and thus

provides very good temperature distribution within the bath.

11263911.05 03/2019 EN/DE/IT

Infrared operating mode

1. Cleaning the tank (if needed)

2. Insert the insert (hollow, ceramic coated)

3. Set the speed of the magnetic stirrer to “0”.

4. In order to ensure the correct linearisation, set Ir in the

controller. For this, press the [P] button for approx. 5 secs.

and confirm the appropriate setting in the main menu with

[P].

5. Set the switch to the left of the controller to external

reference. Connect the delivered external reference into

the socket provided and slide it into into the appropriate

bore on the outer edge of the insert.

The measuring spot of the pyrometer being calibrated must

be smaller than the diameter of the infrared insert.

Surface operating mode

1. Cleaning the tank (if needed)

2. Insert the insert (hollow, fitted with a collar at the top)

3. Set the speed of the magnetic stirrer to “0”.

4. In order to ensure the correct linearisation, set SU in the

controller. For this, press the [P] button for approx. 5 secs.

and confirm the appropriate setting in the main menu with

[P].

5. Set the switch to the left of the controller to external

reference. Connect the delivered external reference in to

the socket provided and slide into the appropriate bore

directly under the surface of the insert.

21WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 22

7. Operating elements of the calibrator/micro calibration bath

The calibration of surface thermometers is very difficult

and not fully defined. Thermometers mounted on surfaces

dissipate heat from the surface and create a cold zone on

the surface being measured. In the multi-function calibrator,

the calibration temperature is created in a specially designed

surface insert and an external reference thermometer

EN

measures the temperature directly under the surface. The

reference thermometer also determines the temperature

of the cold zone through integration of the temperature

along the sensitive length of the reference thermometer

and thus provides a true temperature calibration of surface

temperature sensors.

The sleeve is designed so that the supplied external

reference provides the best possible result, since the depth

of the bore is adjusted to the sensitive length. If a separate

external reference is used for comparison calibration, ensure

that the sensitive length is known and it lies in the centre of

the calibration surface.

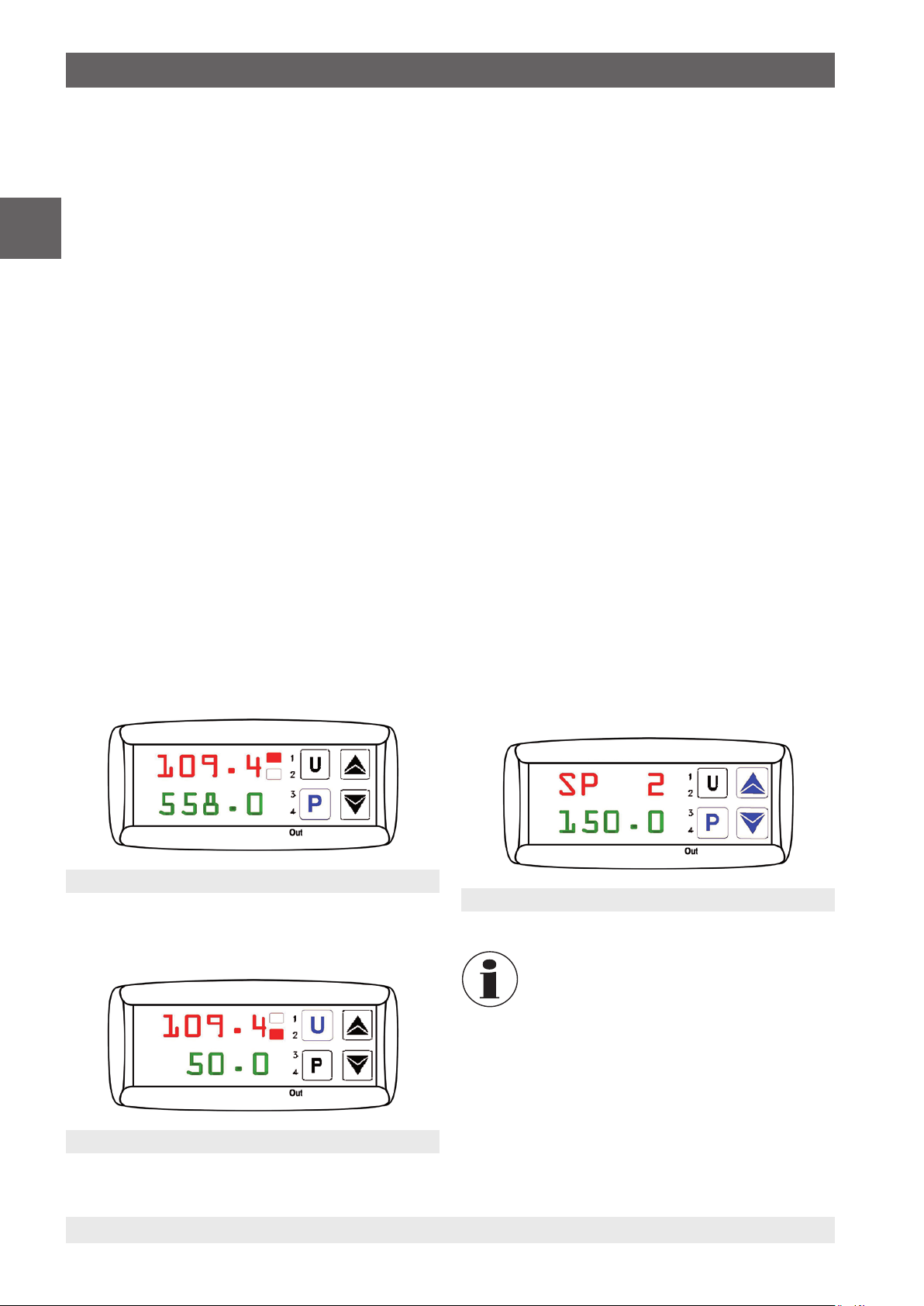

7.3 Calibration (calibration mode)

As soon as the calibrator or micro calibration bath is switched

on, following the initialisation, it defaults to calibration mode.

On the upper PV display, the current reference temperature

is indicated.

On the lower SV display is the set temperature.

The LED OUT 1 signals the status of the outputs for the

heating control:

■

If the LED OUT 1 is on, the temperature will increase.

■

If the LED OUT 1 is not on, the heating is switched off.

a) Heating instrument

The LED OUT 2 signals the status of the outputs for the fan

control:

■

If LED OUT 2 is on, the fan is running at higher speed.

■

If LED OUT 2 is not on, the fan is running at lower speed.

b) Heating and cooling instrument

The LED OUT 2 signals the status of the outputs for the

cooling control:

■

If the LED OUT 2 is on, the temperature will decrease.

■

If the LED OUT 2 is not on, the cooling is switched off.

Two possibilities for setting the set temperature

Either a temporary set temperature is set (see chapter

7.3 “Calibration (calibration mode)”) or a fixed set

temperature (see chapter 7.4 “Setting a temporary set

temperature (set-point mode)”) is stored in the main menu.

7.4 Setting a temporary set temperature (set-point

mode)

In this operating state, a stored set temperature is temporarily

changed.

1. Press button [P] briefly.

On the upper PV display, the currently active set value

memory is displayed, e.g. SP2 (set point 2).

On the lower SV display is the corresponding set

temperature.

2. By pressing button [▲] the set temperature is increased.

By pressing button [▼] the set temperature is reduced.

3. By pressing button [P] again, the new set point is

accepted.

Display in HEATING calibration mode

Temporary set temperature setting

The LED OUT 2 signals the status of the outputs for the fan/

cooling control.

By pressing button [▲] or [▼] the value is

increased or decreased by 0.01 °C [0.01 °F].

If the keys are held down for at least 1 sec.,

however, the value increases or decreases more

rapidly, and after 2 secs. even faster, so that the

desired value can be reached very quickly.

If, in set-point mode, no button has been

pressed for approx. 15 secs., an automatic return

to calibration mode occurs.

Display in FAN or COOLING calibration mode

22 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 23

7. Operating elements of the calibrator/micro calibration bath

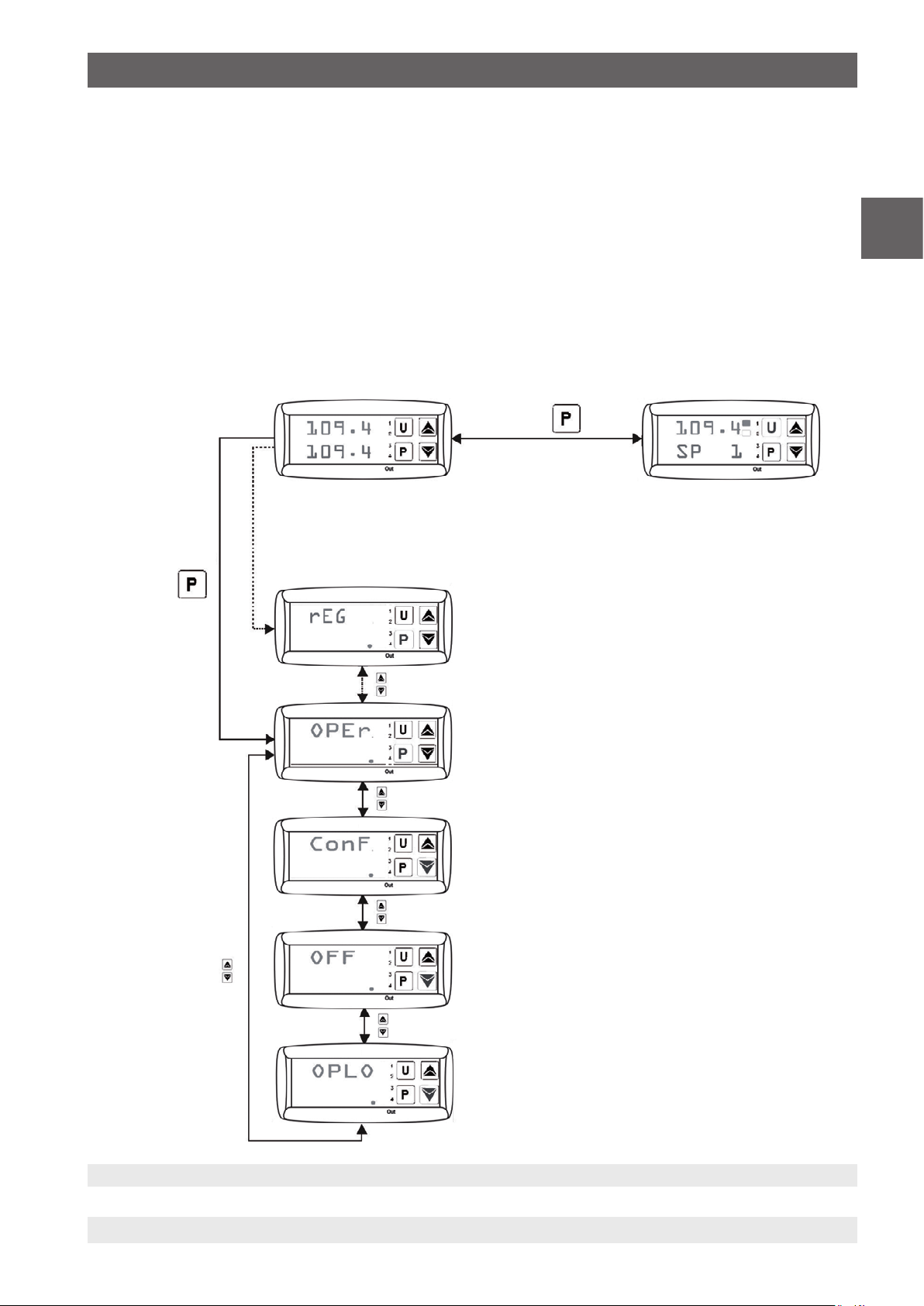

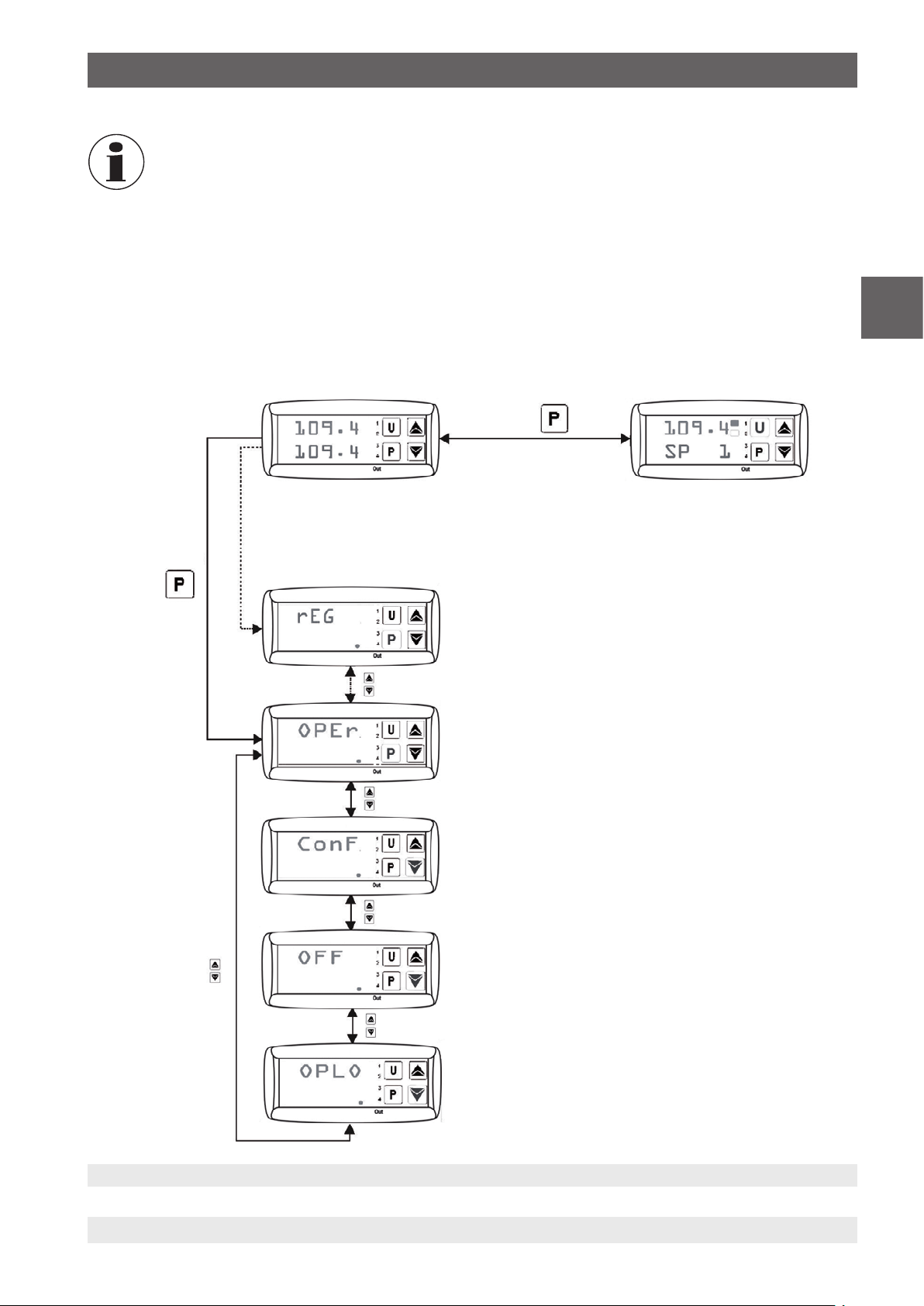

7.5 Programming (Main menu)

In this menu element, all settings can be made.

1. Press button [P] for approx. 5 secs. This opens the main

menu.

2. Select the required main menu using buttons [▲] and [▼]

(see overview).

3. Press button [P] to accept the selected menu point.

EN

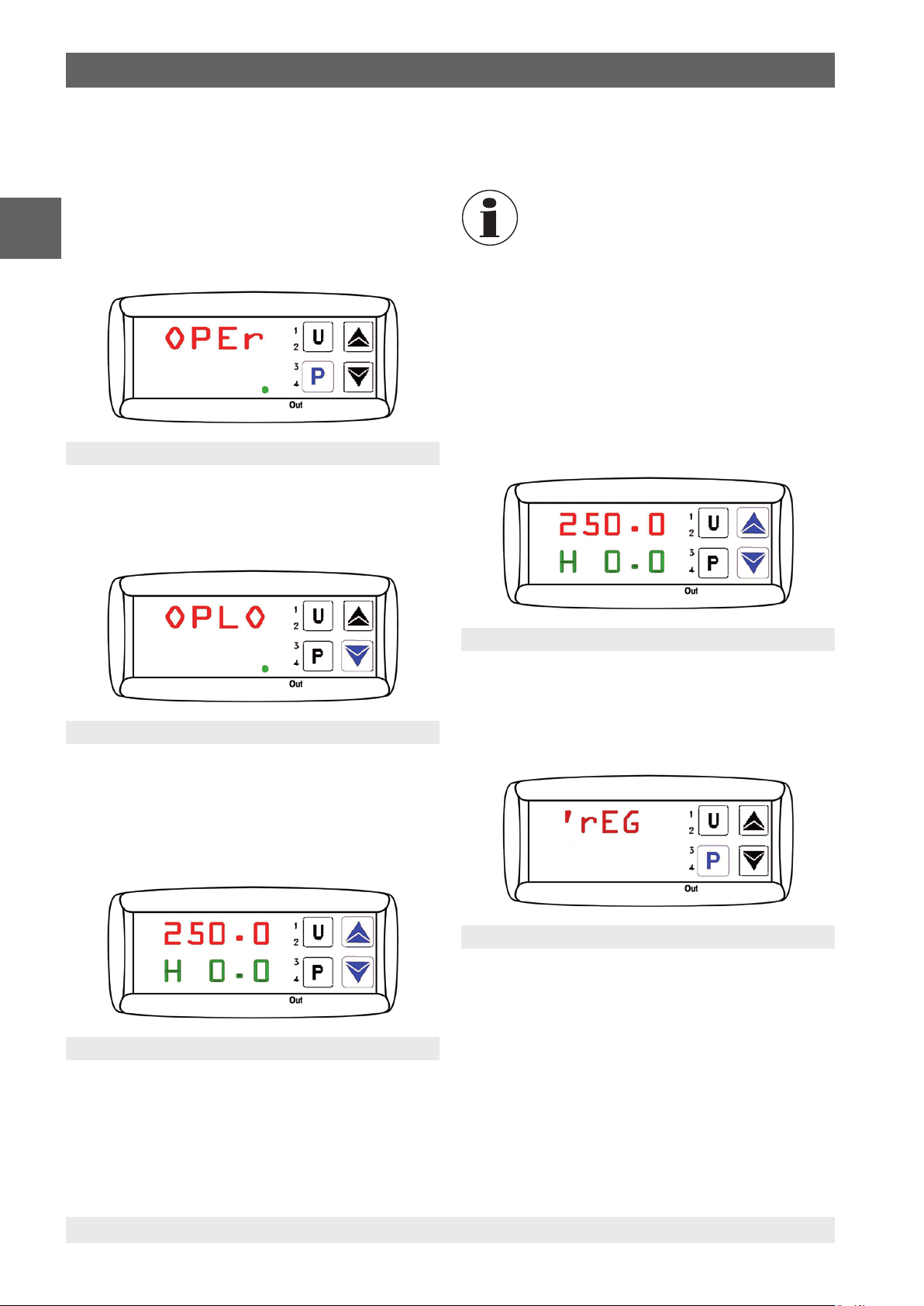

approx. 5 secs.

Calibration mode

Main menu

Set-point mode

Menu structure (main menu)

11263911.05 03/2019 EN/DE/IT

23WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 24

7. Operating elements of the calibrator/micro calibration bath

7.5.1 Menu structure, parameter levels

As shown in the menu structure, via OPEr, the groups and

parameter levels are accessible, in which the settings can

then be made.

EN

Calibration mode

approx. 5 secs.

Set-point mode

Main menu

Return to another level

If, in the main menu, no button has been pressed for

approx. 15 secs., an automatic return to one level above in

calibration mode occurs.

A return can be made by pressing button [▲] or [▼].

Group level Parameter level

Parameter input

Set point 1

Operating modes

for CTM9100-150

Set point 2

Control off

Manual

control

Micro

calibration

bath

Dry well

calibrator

Infrared Dwell time

Surface Falling ramp

Parameter level

Parameter input

Set point 3

Set point 4

Rising ramp

Menu structure

24 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 25

7. Operating elements of the calibrator/micro calibration bath

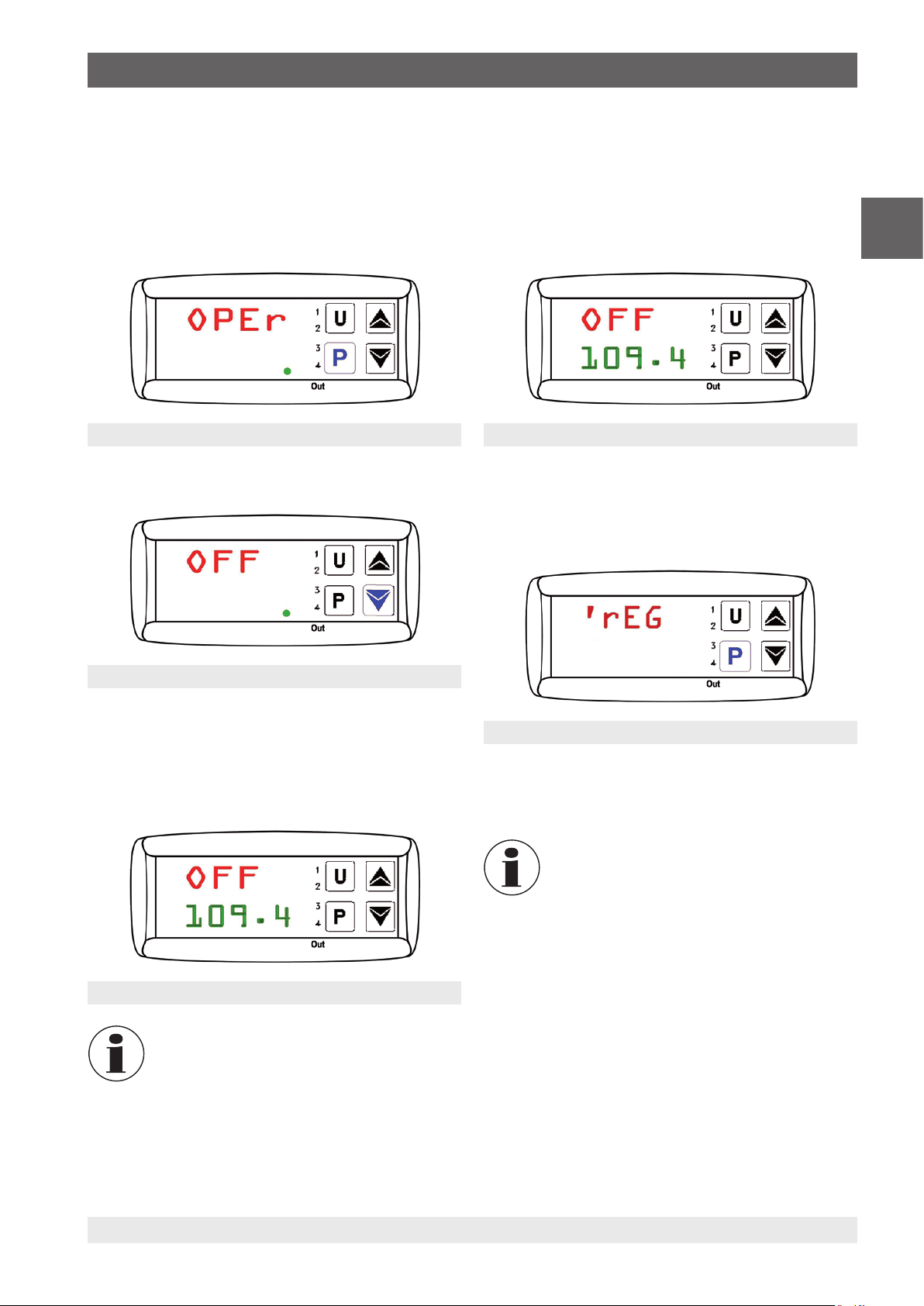

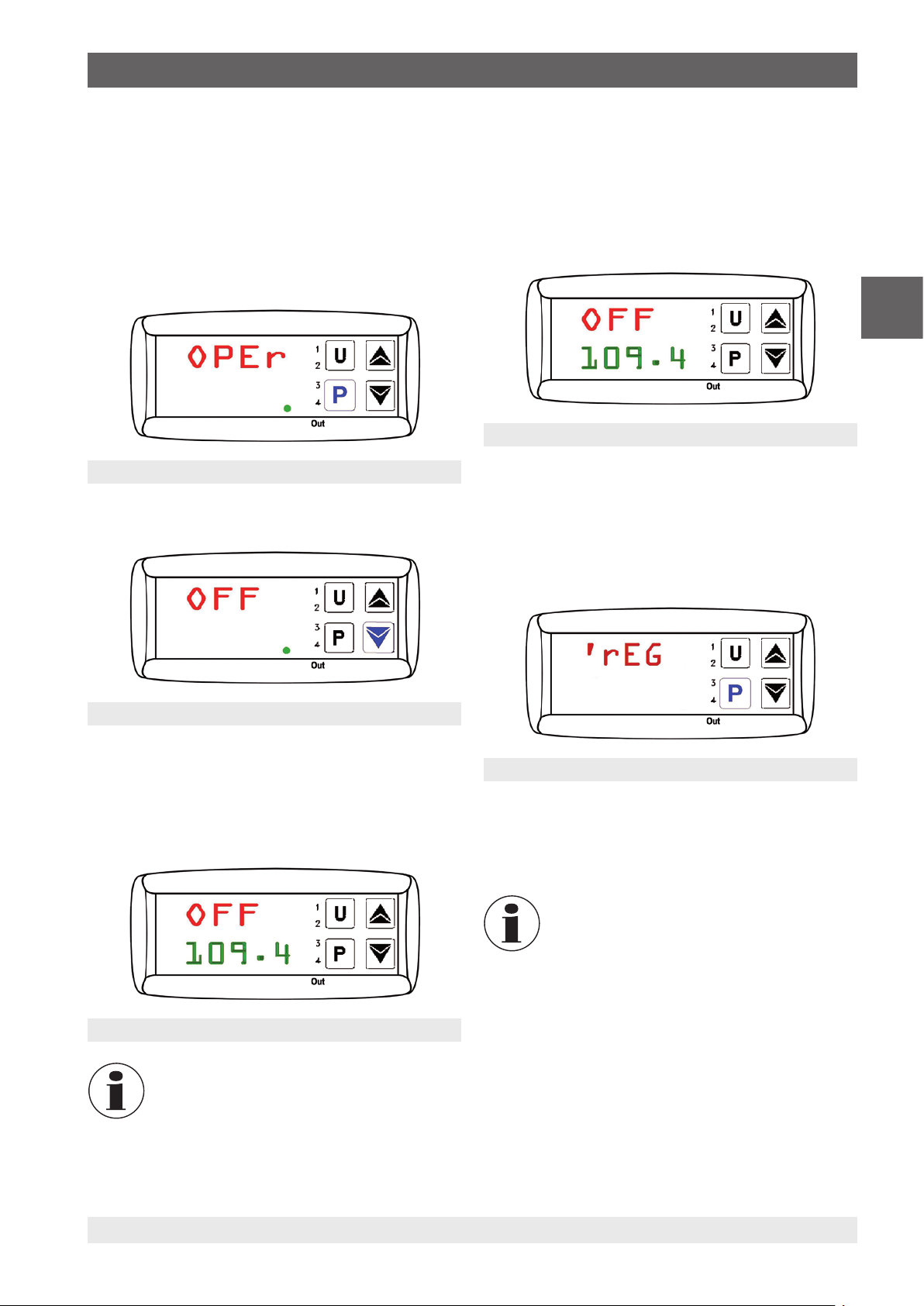

7.5.2 Switching off automatic control

For certain tasks, it is advantageous to switch off control (e.g.

to make settings on the calibrator or micro calibration bath).

In calibration mode, press button [P] for approx. 5 secs., this

opens the main menu.

The upper PV display will show OPEr.

In the lower SV display, the LED SET will blink.

Display in main menu

Press button [▲] or [▼] until OFF is displayed.

7.5.3 Switching on automatic control

The control is switched off when the following display is

shown:

On the upper PV display, the current reference temperature

and OFF are indicated alternately.

On the lower SV display, the currently-selected set

temperature is displayed.

Display with setting Control OFF

The control is switched back on by pressing button [P] for

approx. 5 secs., this opens the main menu.

The upper PV display will show ’rEG.

In the lower SV display, the LED SET will blink.

EN

Control OFF menu

Confirm with button [P].

On the upper PV display, the current reference temperature

and OFF are indicated alternately.

On the lower SV display, the currently-selected set

temperature is displayed.

Display with setting Control OFF

The control is now switched off and the reference

temperature will fall steadily, unless it is

corrected.

Display ‘rEG

Confirm switching the control on by pressing button [P].

Control is now activated. The calibrator or micro

calibration bath will default to calibration mode

and the set temperature will be reached.

11263911.05 03/2019 EN/DE/IT

25WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 26

7. Operating elements of the calibrator/micro calibration bath

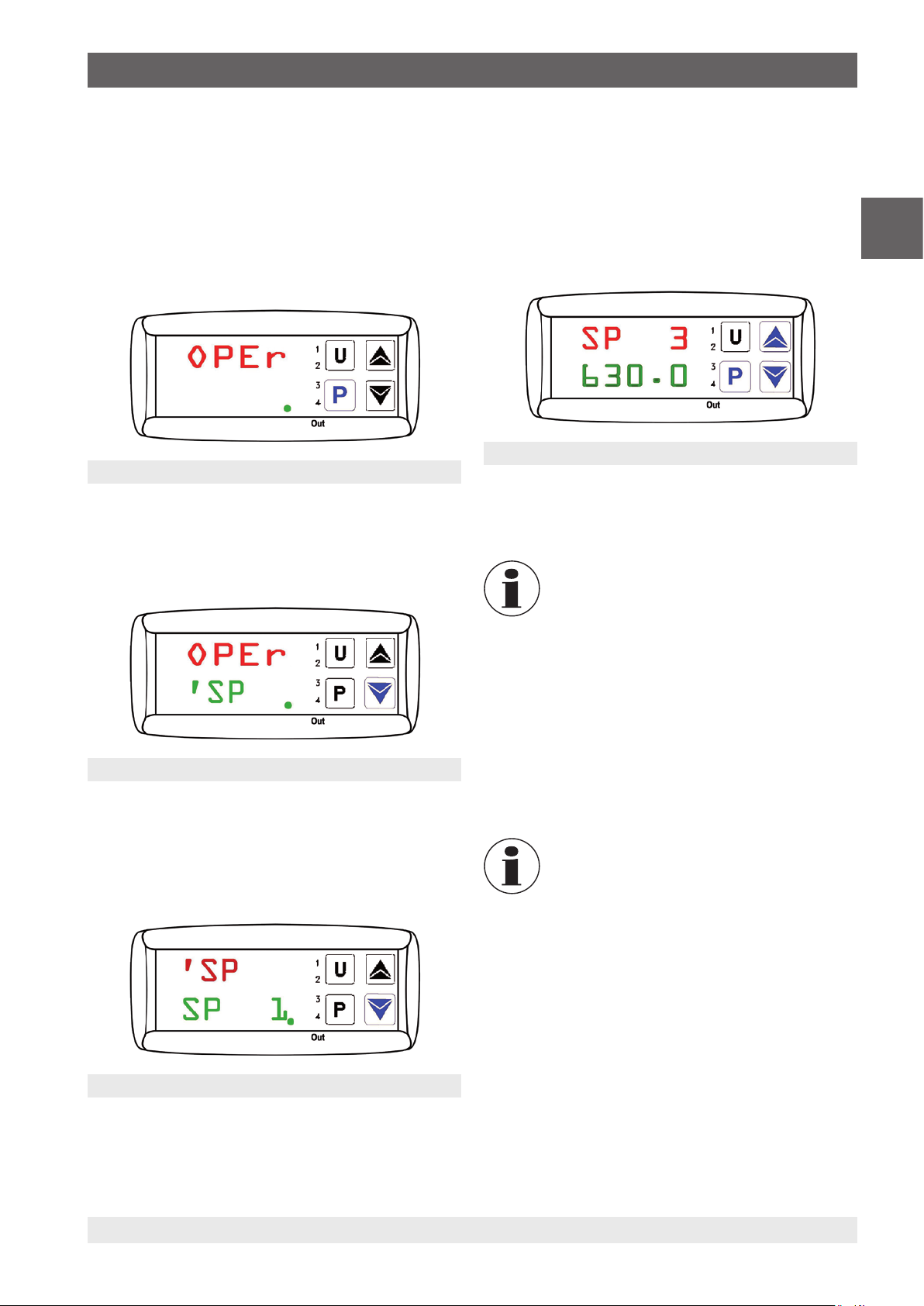

7.5.4 Switching on manual control

Switch off the automatic control of the calibrator or micro

calibration bath, and reach the required temperature with

manual control.

Press button [P] for approx. 5 secs., this opens the main

menu.

EN

The upper PV display will show OPEr.

In the lower SV display, the LED SET will blink.

Display in main menu

Press button [▲] or [▼] until OPLO is displayed.

The upper PV display will show OPLO.

In the lower SV display, the LED SET will blink.

By pressing button [▲], the output power is increased.

By pressing button [▼], the output power is decreased.

By pressing button [▲] or [▼] the value is

increased or decreased by 0.1 %. If the keys are

held down for at least 1 sec., however, the value

increases or decreases more rapidly, and after

2 secs. even faster, so that the desired value can

be reached very quickly.

7.5.5 Switching off manual control

The manual control is switched on if the following display is

shown:

On the upper PV display, the current reference temperature

is indicated.

On the lower SV display, an H and the current set output

power in % is displayed.

Manual control OPLO menu

Confirm by pressing the button [P].

On the upper PV display, the current reference temperature

is indicated.

On the lower SV display, an H and the current set output

power in % is displayed.

Display with setting manual control OPLO

Display with setting manual control OPLO

The manual control is switched back off by pressing button

[P] for approx. 5 secs., this opens the main menu.

The upper PV display will show ’rEG.

In the lower SV display, the LED SET will blink.

Display in main menu

Confirm switching the automatic control on by pressing

button [P].

26 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

11263911.05 03/2019 EN/DE/IT

Page 27

7. Operating elements of the calibrator/micro calibration bath

7.5.6 Setting and storing fixed set temperatures

In order to store the set temperature in the calibrator or micro

calibration bath, the appropriate set-point memory must be

opened.

In calibration mode, press button [P] for approx. 5 secs.,

this opens the main menu.

The upper PV display will show OPEr.

In the lower SV display, the LED SET will blink.

Operator menu OPEr

If button [P] is pressed again, this opens the groups level.

The upper PV display will show OPEr.

In the lower SV display, ’SP is shown and additionally LED

SET will blink.

Select one of the four set-point memories SP1, SP2, SP3 or

SP4 using button [▲] or [▼].

By pressing button [P] the corresponding set-point memory

will then be opened.

In the upper PV display, the selected set-point memory e.g.

SP3 will blink.

On the lower SV display, the corresponding currentlyselected set temperature is displayed.

Input in set-point memory SP3

By pressing button [▲], the set temperature is increased.

By pressing button [▼], the set temperature is decreased.

By pressing button [▲] or [▼] the value is

increased or decreased by 0.01 °C [0.01 °F].

If the keys are held down for at least 1 sec.,

however, the value increases or decreases more

rapidly, and after 2 secs. even faster, so that the

desired value can be reached very quickly.

EN

’SP Group

If button [P] is pressed again, this opens the parameter

level.

The upper PV display will show ’SP.

In the lower SV display, the set-point memory SP1 and

additionally LED SET will blink.

Parameter for set-point memory SP1

By pressing button [P], the newly-set temperature is

accepted.

The set-point memory is left and the screen returns to the

parameter level.

To return to calibration mode, press button [▲] or [▼] for a

long time.

If no button has been pressed for approx.

15 secs., an automatic return to one level above

in calibration mode occurs.

11263911.05 03/2019 EN/DE/IT

27WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 28

7. Operating elements of the calibrator/micro calibration bath

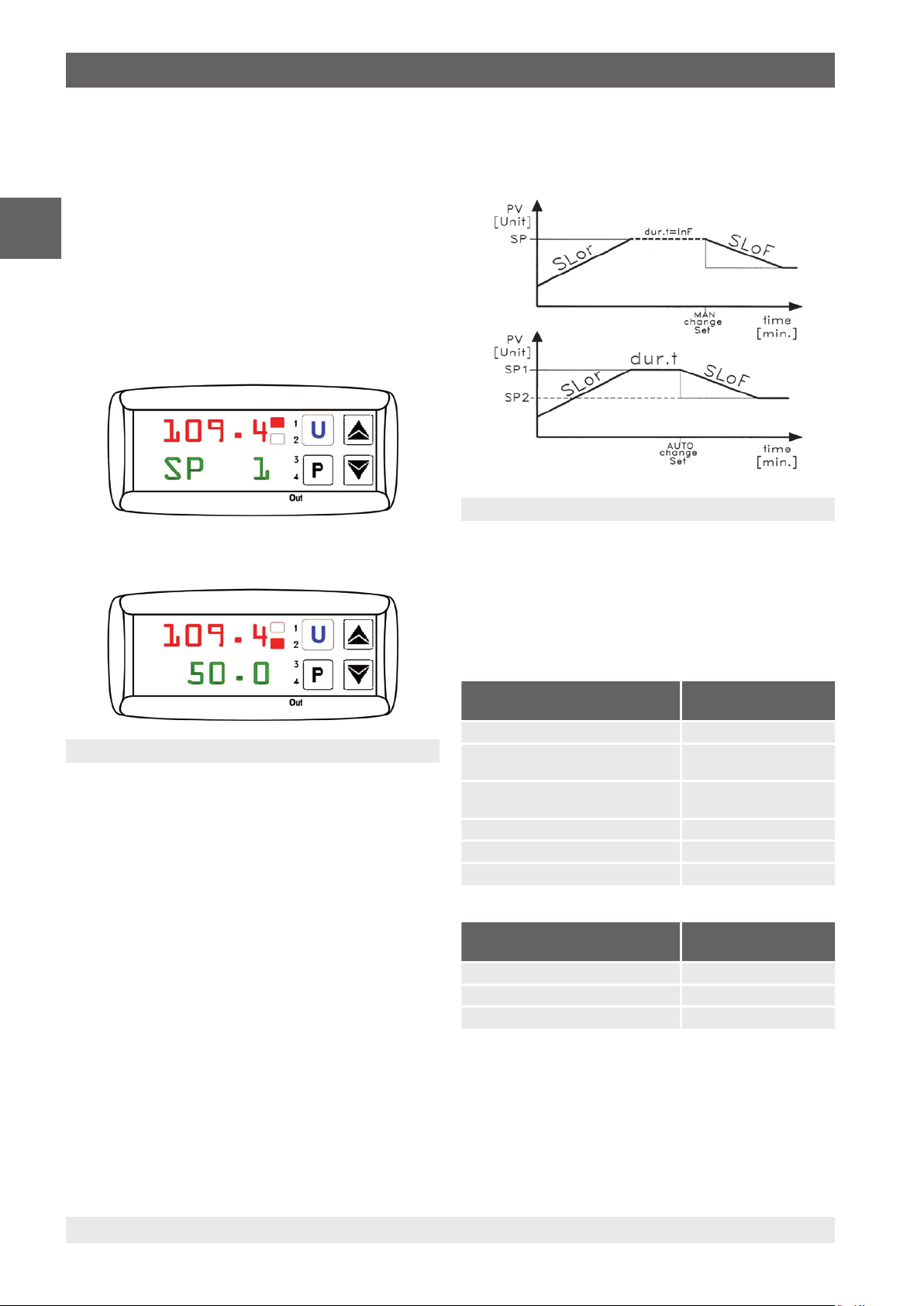

7.5.7 Recalling the stored set temperatures

The set temperature can be called up from calibration mode.

Press button [U] for approx. 2 secs. The current set-point

memory will be opened.

On the upper PV display, the current reference temperature

is indicated.

EN

On the lower SV display, the set-point memory (SP1,

SP2, SP3 or SP4) is shown for 2 secs., and then the

corresponding currently-selected set temperature is

displayed.

It initially displays the set-point memory (SP1, SP2, SP3 or

SP4).

Then it displays the stored set temperature.

A simple temperature profile can be generated.

After switching on the calibrator or micro calibration bath, the

temperature profile will run automatically.

Ramp control and temperature profile

Heating gradient, SLor

The heating gradient, SLor, is active if the reference

temperature is lower than the set temperature.

Each calibrator model has a maximum heating output, and

thus only settings < than this heating power make sense and

actually increase the time taken to achieve a set temperature.

Display on calling the set temperature

In order to retrieve a different stored set point, press button

[U] again.

The selected temperature value will be immediately adopted

and approached.

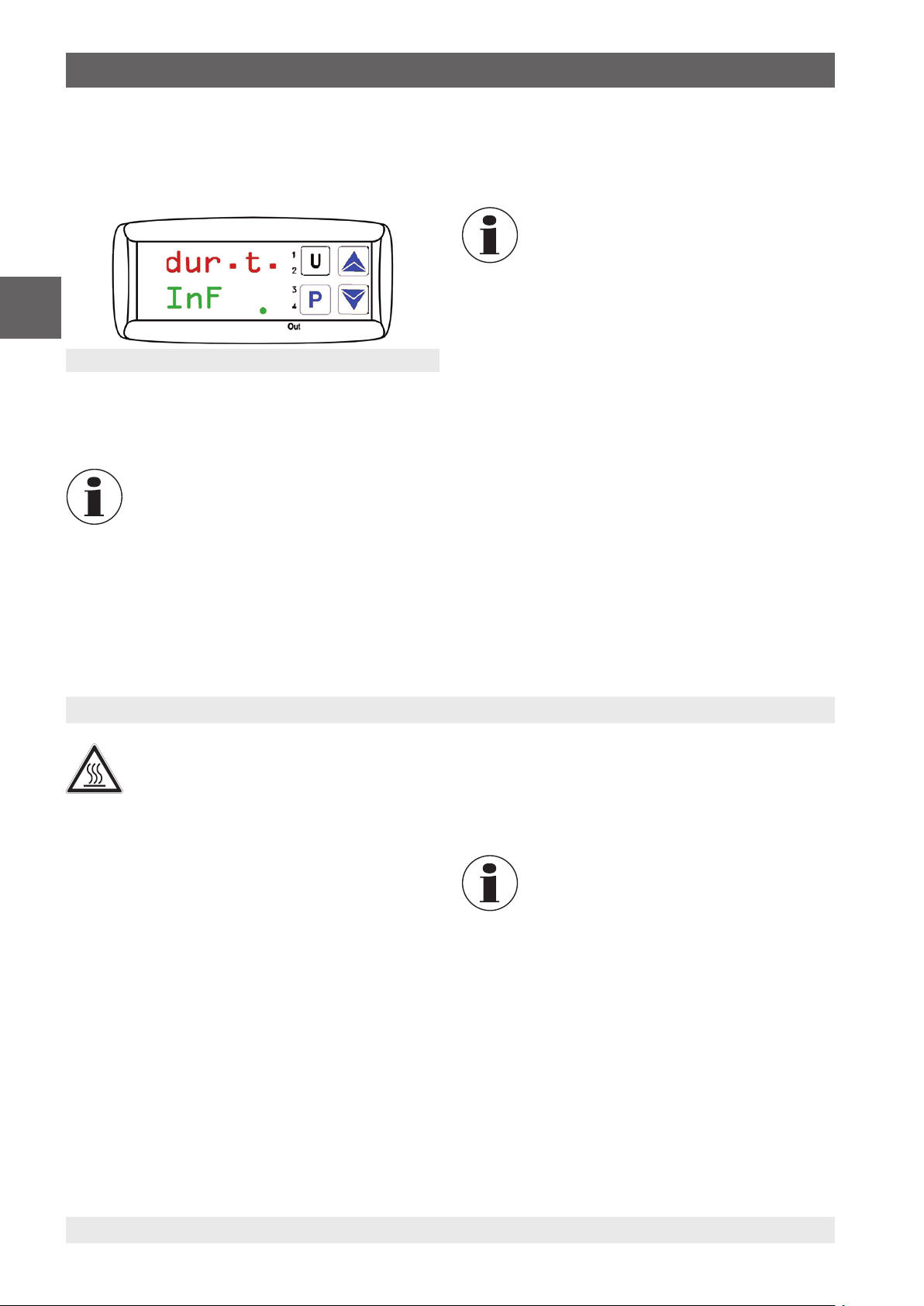

7.5.8 Setting the ramp control and a temperature

profile

Using the ramp control, the time can be defined over

which the target temperature is achieved. This time may be

shorter or longer than that which the calibrator or the micro

calibration bath would normally require.

By changing the set temperature or turning on the calibrator

or micro calibration bath, it is automatically determined which

of the gradients to use (heating gradient, SLor, or cooling

gradient, SLoF).

In the calibrator or in the micro calibration bath, the dwell

time, dur.t, can be programmed so that the set temperature

reached is automatically switched from the set-point memory

SP1 to the set temperature in set-point memory SP2 after a

predetermined time.

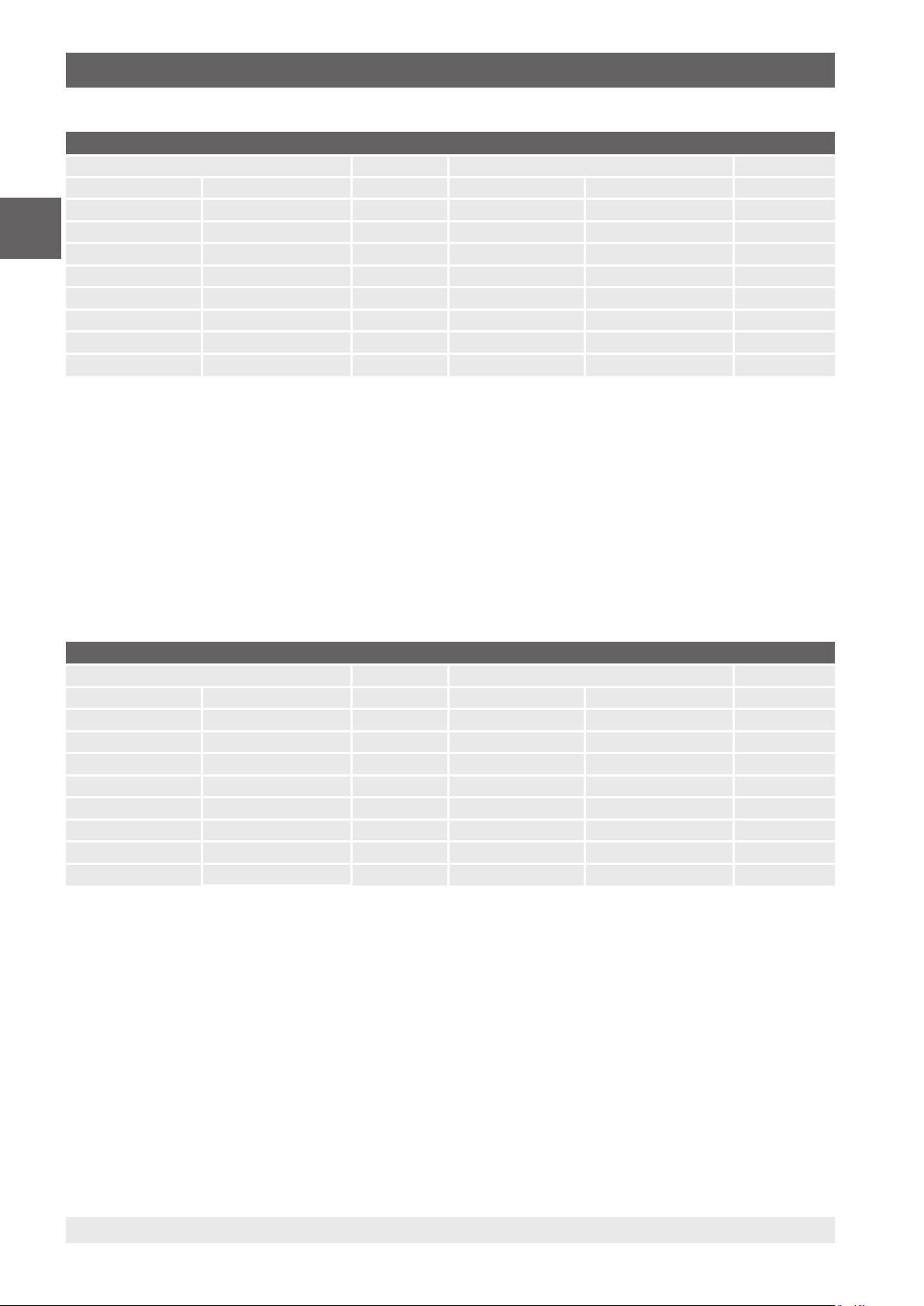

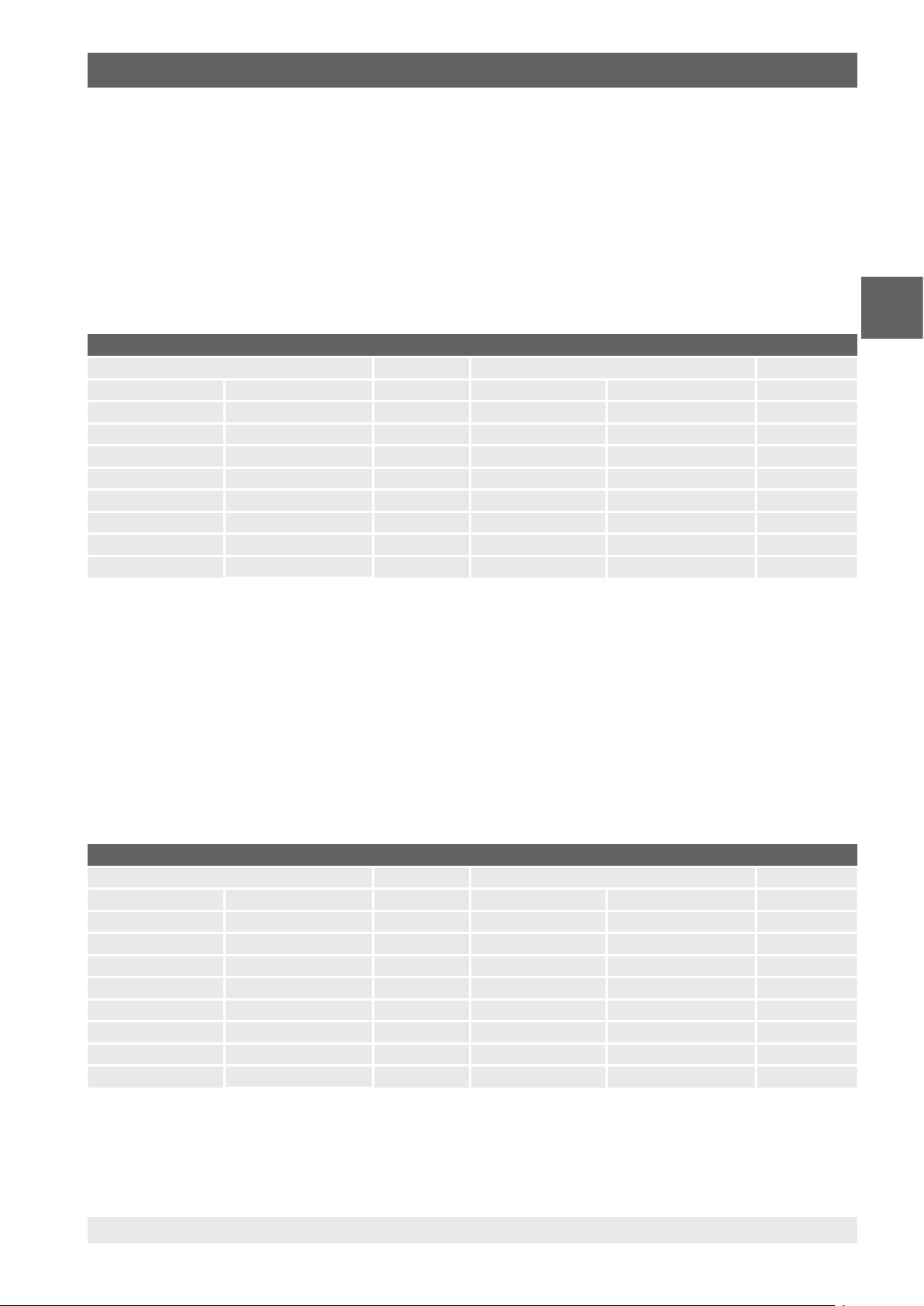

Calibrator model

Setting for SLor

(heating/cooling)

CTD9100-165 < 7 °C/min [< 13 °F/min]

CTB9100-165 / CTM9100-150

with silicone oil 10 CS

CTB9100-165 / CTM9100-150

with distilled water

CTM9100-150 as calibrator < 3 °C/min [< 5 °F/min]

CTM9100-150 as infrared calibrator < 3 °C/min [< 5 °F/min]

CTM9100-150 as surface calibrator < 3 °C/min [< 5 °F/min]

Calibrator model

< 3 °C/min [< 5 °F/min]

< 5 °C/min [< 9 °F/min]

Setting for SLor

(heating)

CTD9100-450 / CTD9100-650 < 35 °C/min [< 63 °F/min]

CTB9100-225 with silicone oil 20 CS < 22 °C/min [< 40 °F/min]

CTB9100-225 with distilled water < 12 °C/min [< 22 °F/min]

11263911.05 03/2019 EN/DE/IT

28 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 29

7. Operating elements of the calibrator/micro calibration bath

Cooling gradient SLoF

The cooling gradient, SLoF, is active if the reference

temperature is higher than the set temperature.

Only settings that are under the heating power of the

calibrator have an effect on the cooling gradient.

Calibrator model

Setting for SLoF

(heating/cooling)

CTD9100-165 < 5 °C/min [< 9 °F/min]

CTB9100-165 / CTM9100-150

with silicone oil 10 CS

CTB9100-165 / CTM9100-150

with distilled water

CTM9100-150 as calibrator < 4 °C/min [< 7 °F/min]

CTM9100-150 as infrared calibrator < 4 °C/min [< 7 °F/min]

CTM9100-150 as surface calibrator < 4 °C/min [< 7 °F/min]

Calibrator model

< 6 °C/min [< 11 °F/min]

< 4 °C/min [< 7 °F/min]

Setting for SLoF

(heating)

CTD9100-450 / CTD9100-650

up to 300 °C [572 °F]

300 °C to 100 °C [572 °F to 212 °F]

CTB9100-225 with silicone oil 20 CS

200 °C to 50 °C [392 °F to 122 °F]

50 °C to 30 °C [122 °F to 86 °F]

CTB9100-225 with distilled water

90 °C to 50 °C [194 °F to 122 °F]

50 °C to 30 °C [122 °F to 86 °F]

< 10 °C/min [< 18 °F/min]

< 5 °C/min [< 9 °F/min]

< 4 °C/min [< 7 °F/min]

< 0,5 °C/min [< 1 °F/min]

< 2 °C/min [< 4 °F/min]

< 0,5 °C/min [< 1 °F/min]

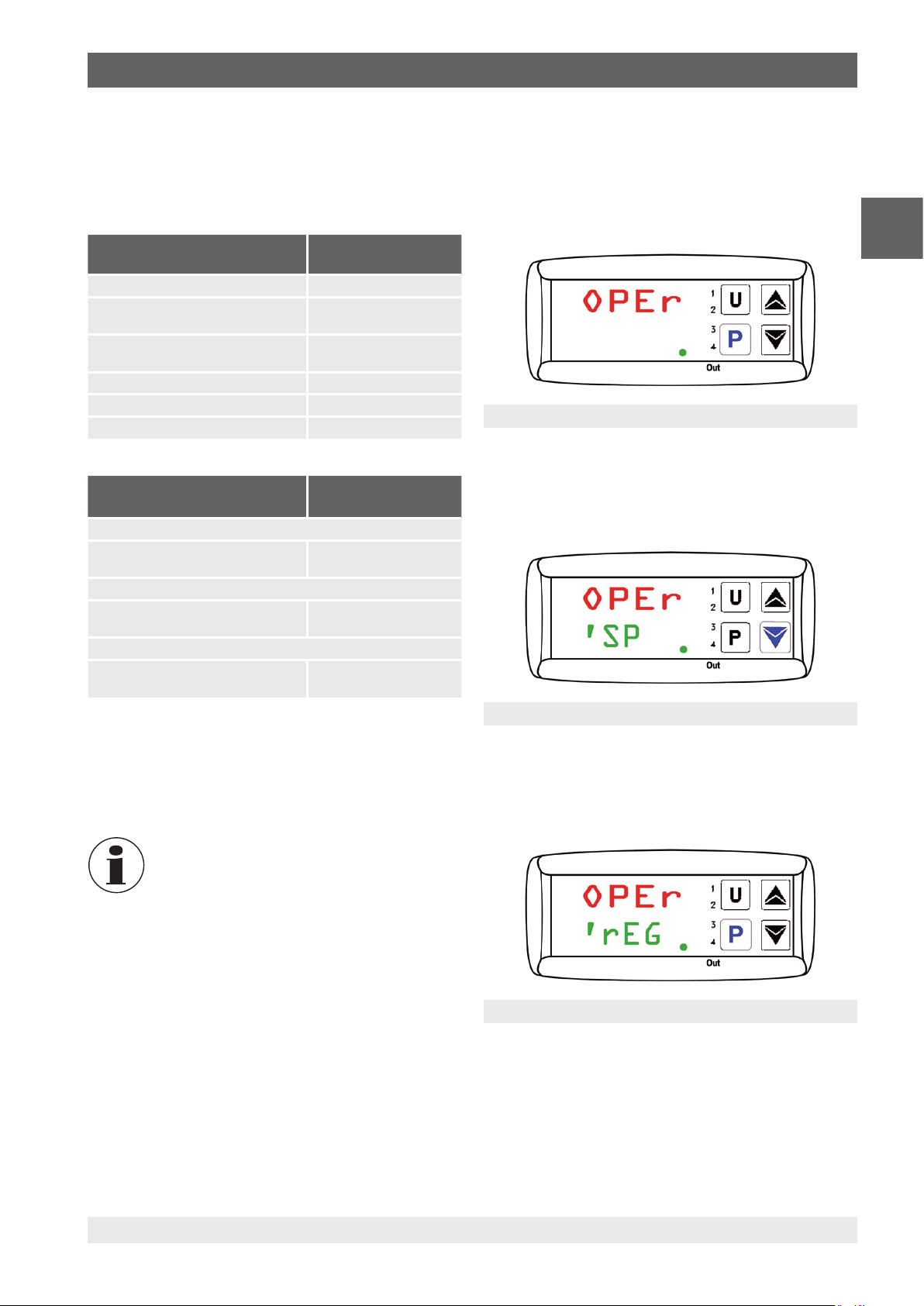

The heating and cooling gradients and the dwell time can

be set via the parameter level, ’rEG. This is achieved by

pressing button P for approx. 5 secs., this opens the main

menu.

The upper PV display will show OPEr.

In the lower SV display, the LED SET will blink.

Operator menu OPEr

If button [P] is pressed again, this opens the groups level.

The upper PV display will show OPEr.

In the lower SV display, ’SP is shown and additionally LED

SET will blink.

EN

The dwell time, dur.t, is active when the set temperature,

SP1, has been reached. Subsequently, the calibrator or micro

calibration bath automatically switches to set temperature

SP2.

If settings have been made for these three

parameters, the calibrator or the micro

calibration bath will not use the new values until

you either change the set temperature or until the

calibrator or the micro calibration bath has been

turned off and then on again.

Another approach would be to switch the

automatic control off before the parameter

change (see chapter 7.5.2 “Switching off

automatic control”), and then turning it back

on (see chapter 7.5.3 “Switching on automatic

control”).

’SP group

Select the group, 'rEG, by pressing button [▼].

The upper PV display will show OPEr.

In the lower SV display, ’rEG is shown and additionally LED

SET will blink.

’rEG group

11263911.05 03/2019 EN/DE/IT

29WIKA operating instructions, models CTD9100, CTB9100, CTM9100

Page 30

7. Operating elements of the calibrator/micro calibration bath

If button [P] is pressed again, this opens the parameter

level.

The upper PV display will show ‘rEG.

In the lower SV display, SLor will blink.

EN

Parameter for heating gradient, SLor

7.5.8.1 Setting the heating gradient

The heating gradient, SLor, is active if the reference

temperature is lower than the set temperature.

The setting range stretches from 99.99 °C/min to 0.00 °C/min

[99.99 °F/min to 0.00 °F/min].

The function is deactivated if SLor = InF (in no

Function) is set.

You are at the parameter level (as described in chapter

7.5.1 “Menu structure, parameter levels”).

The upper PV display will show ‘rEG.

In the lower SV display, SLor will blink.

By pressing button [▲], the heating gradient, SLor, will be

increased.

By pressing button [▼], the heating gradient, SLor, will be

decreased.

By pressing button [▲] or [▼] the value is

increased or decreased by 0.1. If the keys are

held down for at least 1 sec., however, the value

increases or decreases more rapidly, and after

2 secs. even faster, so that the desired value can

be reached very quickly.

By pressing button [P], the newly-set heating gradient, SLor,

is accepted.

The display returns to the parameter level and the other

parameters can be set.

If no button has been pressed for approx.

15 secs., an automatic return to one level above

in calibration mode occurs.

After the setting has been made, the calibrator

or the micro calibration bath will not use the

new values until you either change the set

temperature or the calibrator or the micro

calibration bath has been turned off and then on

again.

7.5.8.2 Setting the cooling gradient

The cooling gradient, SLoF, is active if the reference

temperature is higher than the set temperature.

The setting range stretches from 99.99 °C/min to 0.00 °C/min

[99.99 °F/min to 0.00 °F/min].

The function is deactivated if SLoF = InF (in no

Function) is set.

Parameter for heating gradient, SLor

Press button [P].

On the upper PV display, SLor will blink.

On the lower SV display, the corresponding currently-

selected heating gradient is displayed.

Input of the heating gradient

30 WIKA operating instructions, models CTD9100, CTB9100, CTM9100

You are at the parameter level (as described in chapter

7.5.1 “Menu structure, parameter levels”).

The upper PV display will show ‘rEG.

In the lower SV display, SLor will blink.

Parameter for heating gradient, SLor

11263911.05 03/2019 EN/DE/IT

Page 31

7. Operating elements of the calibrator/micro calibration bath

Select the parameter SLoF with button [▲] or [▼].

The upper PV display will show ‘rEG.

In the lower SV display, SLoF will blink.

Input of the cooling gradient

Press button [P].

On the upper PV display, SLoF will blink.

On the lower SV display, the corresponding currently-

selected cooling gradient is displayed.

After the setting has been made, the calibrator

or the micro calibration bath will not use the

new values until you either change the set

temperature or the calibrator or the micro

calibration bath has been turned off and then on

again.

7.5.8.3 Setting the dwell time

The dwell time, dur.t, is active when the set temperature,

SP1, has been reached. Subsequently, the calibrator or micro

calibration bath automatically switches to set temperature

SP2.

The setting range stretches from 99:59 [hh:min] to

0:00 [hh:min].

The function is deactivated if dur.t = InF (in no

Function) is set.

You are at the parameter level (as described in chapter

7.5.1 “Menu structure, parameter levels”).

The upper PV display will show ‘rEG.

In the lower SV display, SLor will blink.

EN

Display on cooling gradient input

By pressing button [▲], the cooling gradient, SLoF, will be

increased.

By pressing button [▼], the cooling gradient, SLoF, will be

decreased.