Page 1

Temperature dry-well calibrator

Model CTD9100-1100

Applications

■

Testing and calibration of temperature measuring

instruments

■

Reference instrument for works laboratories for the

calibration of thermometers

■

Also suitable for on-site use

Special features

Calibration technology

WIKA data sheet CT 41.29

■

High accuracy and stability at high temperatures

■

Temperature range: 200 ... 1,100 °C

■

Possibility to check temperature switches

■

Low weight and compact design

■

Simple operation

Description

Versatile in application

Nowadays, fast and simple testing of thermometers is a

“must” when it comes to the operational safety of machines

and plants.

The portable calibrators of the CTD9100 family are

particularly suited for on-site calibrations and extremely

user-friendly. Due to their compact design and their low

weight, the instruments can be taken and used almost

anywhere.

The new

source with an intelligent air cooling system, which easily

keeps the temperature low in the upper part of the calibrator.

This enables industrial temperature probes to be calibrated

even more eciently, without overheating the process head

or the handgrip of the thermometer. Regular monitoring of

temperature probes helps to recognise failures promptly and

shorten downtimes.

instrument

concept

brings together

a stable heat

Temperature dry-well calibrator model CTD9100-1100

Easy to use

The temperature dry-well calibrators of the CTD9100

series work with temperature-controlled metal blocks and

interchangeable inserts.

The calibration temperature, adjusted simply using two

buttons on the controller, can be very quickly controlled.

The actual temperature of the heating block is displayed on

a large, 2-line, high-contrast LC display. Thus reading errors

are virtually eliminated.

Thermometers with dierent diameters can be tted into the

calibrator using inserts, drilled to suit. A new block design,

with improved temperature homogeneity at the calibrator's

lower range, leads to smaller measurement uncertainties.

Page 1 of 4WIKA data sheet CT 41.29 ∙ 02/2015

Page 2

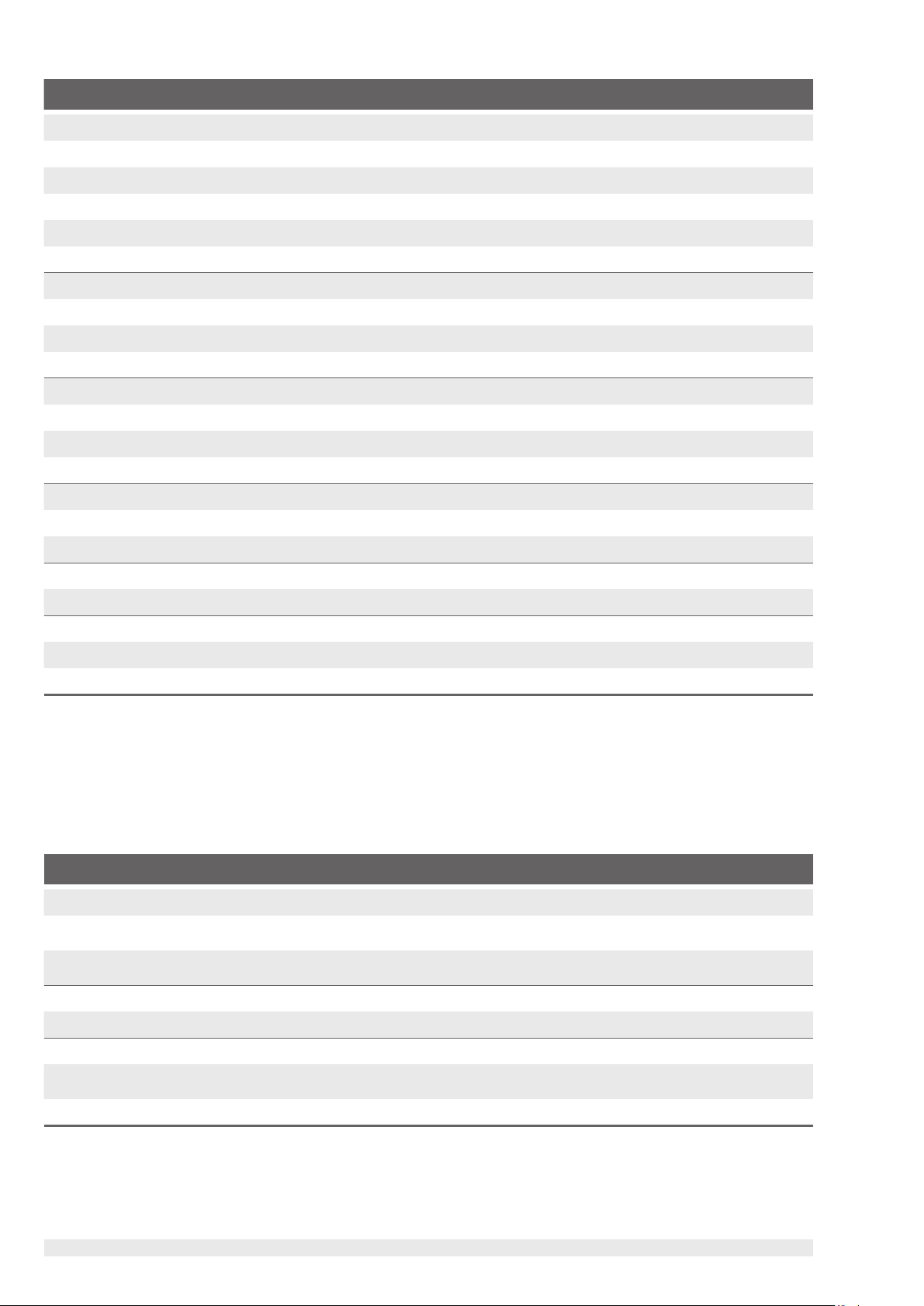

Specications Model CTD9100-1100

Temperature range 200 … 1,100 °C

Accuracy

Stability

Axial homogeneity

Radial homogeneity

1)

2)

3)

4)

Display resolution 0.1 °C / 0.01 °C

Heating time 50 min

Cooling time

Stabilisation time

5)

6)

Immersion depth 175 mm

Sleeve material Ceramic

Immersion depth sleeve 155 mm

Insert dimensions Ø 42.5 x 175 mm

Insulator dimensions Ø 42.5 x 65 mm

Voltage supply

Power supply AC 230 V, 50/60 Hz or AC 110 V, 50/60 Hz

±3 K

±0.4 K at 1,000 °C

±0.4 °C, 60 mm from bottom at 1,000 °C

±0.4 °C, 40 mm from bottom at 1,000 °C

150 min

25 min. at 700 °C

Power consumption 950 W

Communication

Interface RS-232

Case

Dimensions 170 x 390 x 330 mm (W x H x D)

Weight 12 kg

1) Is dened as the measuring deviation between the measured value and the reference value.

2) Maximum temperature dierence at a stable temperature over 30 minutes.

3) Maximum temperature dierence at 40 mm above the bottom.

4) Maximum temperature dierence between the bores (all thermometers inserted to the same depth).

5) from 1,100 °C to 200 °C

6) Time before reaching a stable value.

The measurement uncertainty is dened as the total measurement uncertainty (k = 2), which contains the following shares:

accuracy, measurement uncertainty of reference, stability and homogeneity.

CE conformity, approvals, certicates

CE conformity

EMC directive 2004/108/EC, EN 61000-6-2, interference immunity for industrial environments and EN 61000-6-3,

emitted interference for residential, commercial and light-industrial environments

Low voltage directive 2006/95/EC, EN 61010-1 and EN 61010-2-10, safety requirements for electrical equipment for

measurement, control and laboratory use

Approvals

GOST Metrology/measurement technology, Russia

Certicate

Calibration Standard: 3.1 calibration certicate per DIN EN 10204

Option: DKD/DAkkS calibration certicate

Recommended recalibration interval 1 year (dependent on conditions of use)

Approvals and certicates, see website

Page 2 of 4 WIKA data sheet CT 41.29 ∙ 02/2015

Page 3

Inserts

1. The ceramic insert has several bores into which the thermometer probes being

calibrated and one of the additional customer reference thermometers, for

comparative calibration, can be inserted. The block is either heated or cooled

to the desired calibration temperature. Once a stable temperature has been

reached, the temperature probes to be calibrated can be compared with the

reference thermometer. The documentation of this comparison represents the

calibration.

2. The ceramic insulator is tted onto the insert and its bores are aligned with

respect to the insert. This prevents the handgrip or process head of the

thermometers from overheating.

3. Replacement tools for removing or placing the ceramic insert. The insert must

be aligned in such a way, so that the grooves sit directly over the controlling and

monitoring thermometers.

Dimensions in mm

1

2

3

Front view

Rear view

Side view

Top view

Page 3 of 4WIKA data sheet CT 41.29 ∙ 02/2015

Page 4

Scope of delivery

■

Temperature dry-well calibrator model CTD9100-1100

■

Power cord, 1.5 m with safety plug

■

Insert with four bores: 7 mm, 9 mm, 11 mm and 13.5 mm

■

Drilled ceramic top insulator

■

Replacement tools

■

Connection cable

■

Operating instructions

■

3.1 calibration certicate per DIN EN 10204

Options

■

DKD/DAkkS calibration certicate

Accessories

■

Inserts, undrilled and drilled to specication

■

Transport case

■

Power cord for Switzerland

■

Power cord for USA/Canada

■

Power cord for UK

Ordering information

Model / Power supply / Calibration / Transport case / Power cord / Additional ordering information

© 2010 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

WIKA data sheet CT 41.29 ∙ 02/2015Page 4 of 4

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

02/2015 EN

Loading...

Loading...