Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Manuale d'uso

Hydraulic hand test pumps,

models CPP700-H and CPP1000-H

Hydraulische Handprüfpumpen,

Typen CPP700-H und CPP1000-H

Pompes à main,

types CPP700-H et CPP1000-H

Bombas de prueba manuales,

modelos CPP700-H y CPP1000-H

Pompe idrauliche manuali,

modelli CPP700-H e CPP1000-H

EN

DE

FR

ES

IT

Hydraulic hand test pump, model CPP700-H

Page 2

Operating instructions models CPP700-H

EN

and CPP1000-H

Page 3 - 24

Betriebsanleitung Typen CPP700-H und

DE

CPP1000-H

Mode d'emploi types CPP700-H et

FR

CPP1000-H

Manual de instrucciones modelos

ES

CPP700-H y CPP1000-H

Manuale d'uso modelli CPP700-H e

IT

CPP1000-H

Further languages can be found at www.wika.com.

© 06/2017 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Seite 25 - 46

Page 47 - 68

Página 69 - 90

Pagina 91 - 115

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Prima di iniziare ad utilizzare lo strumento, leggere il manuale d‘uso!

Conservare per future consultazioni!

2

WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 3

Contents

Contents

1. General information 4

2. Design and function 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . 6

2.4 Pressure transmission medium. . . . . . . . . . . . . . . . . 6

3. Safety 7

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . 7

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Personnel qualification . . . . . . . . . . . . . . . . . . . 8

3.5 Personal protective equipment . . . . . . . . . . . . . . . . . 9

3.6 Labelling, safety marks . . . . . . . . . . . . . . . . . . . 9

4. Transport, packaging and storage 10

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Packaging and storage . . . . . . . . . . . . . . . . . . . 10

5. Commissioning, operation 11

5.1 Unpacking the hand test pump . . . . . . . . . . . . . . . . . 11

5.2 Ambient conditions . . . . . . . . . . . . . . . . . . . . .11

5.3 Design . . . . . . . . . . . . . . . . . . . . . . . . .11

5.4 Filling the hand test pump with the pressure transmission medium. . . . . 12

5.5 Replacing the pressure transmission medium. . . . . . . . . . . .12

5.6 Mechanical mounting . . . . . . . . . . . . . . . . . . . .13

5.7 Generating pressure . . . . . . . . . . . . . . . . . . . . 14

5.8 Reducing pressure . . . . . . . . . . . . . . . . . . . . .15

5.9 Recommended reference pressure measuring instruments . . . . . . . 16

5.10 Use with WIKA-Cal calibration software . . . . . . . . . . . . .17

5.11 Calibration case available . . . . . . . . . . . . . . . . . . 17

6. Faults 18

7. Maintenance and cleaning 19

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . .19

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 20

8. Dismounting, return and disposal 21

8.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . . 21

8.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . 23

9. Specifications 23

10. Accessories 24

EN

14209601.01 06/2017 EN/DE/FR/ES/IT

3WIKA operating instructions, models CPP700-H and CPP1000-H

Page 4

1. General information

1. General information

■

The hand test pumps CPP700-H and CPP1000-H described in the operating

instructions have been designed and manufactured using state-of-the-art technology.

EN

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions onto the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 91.07

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

4 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 5

2. Design and function

2. Design and function

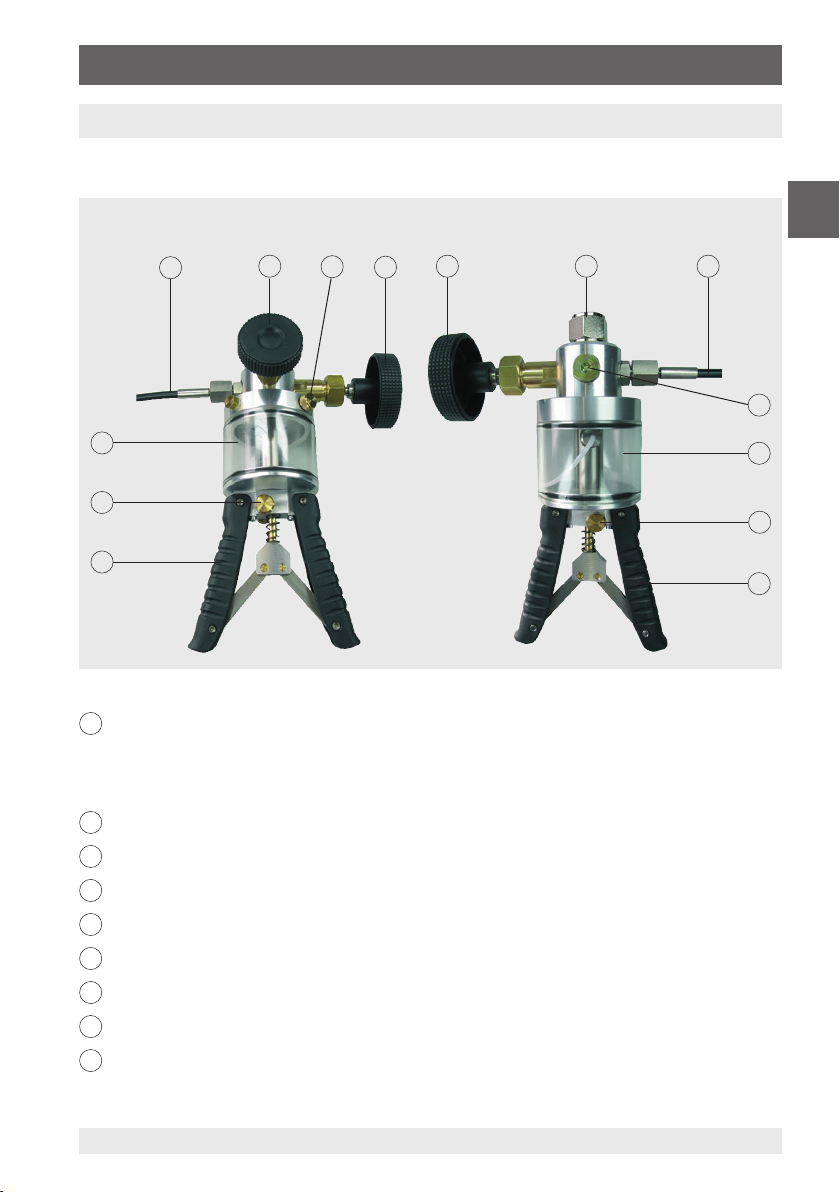

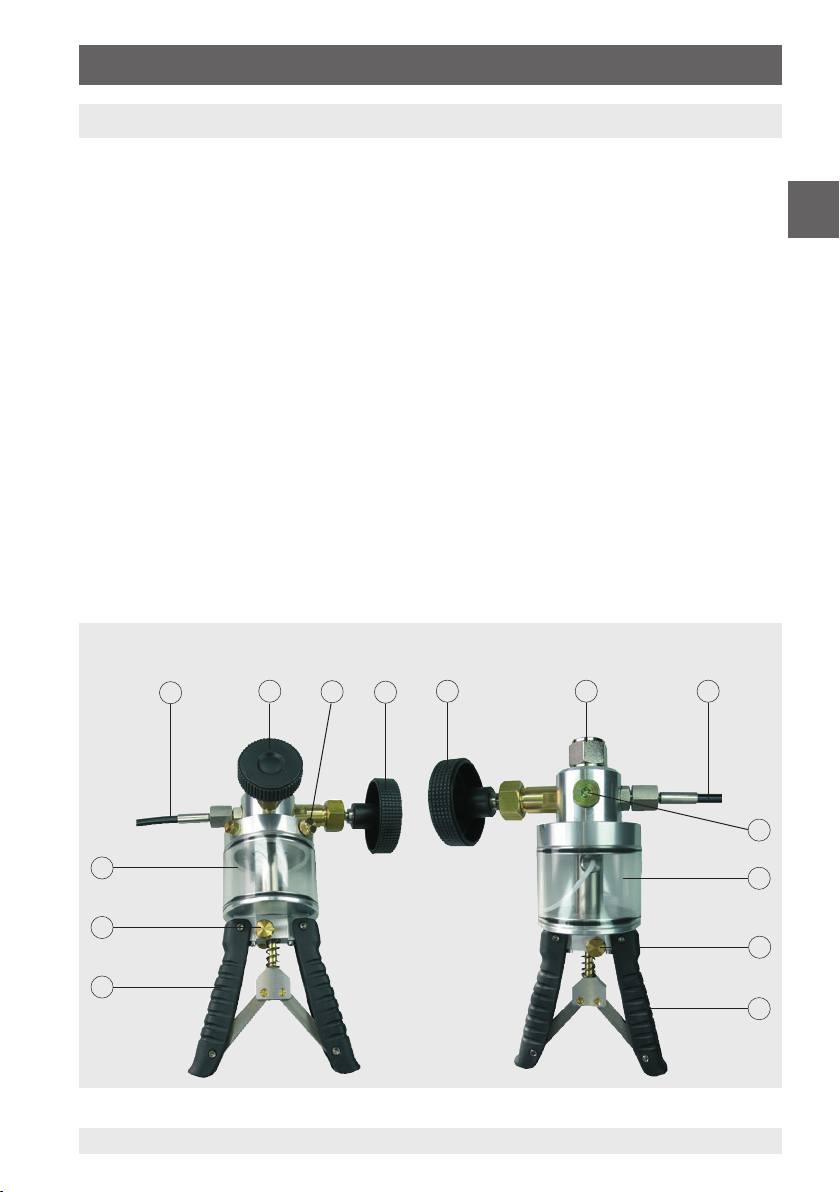

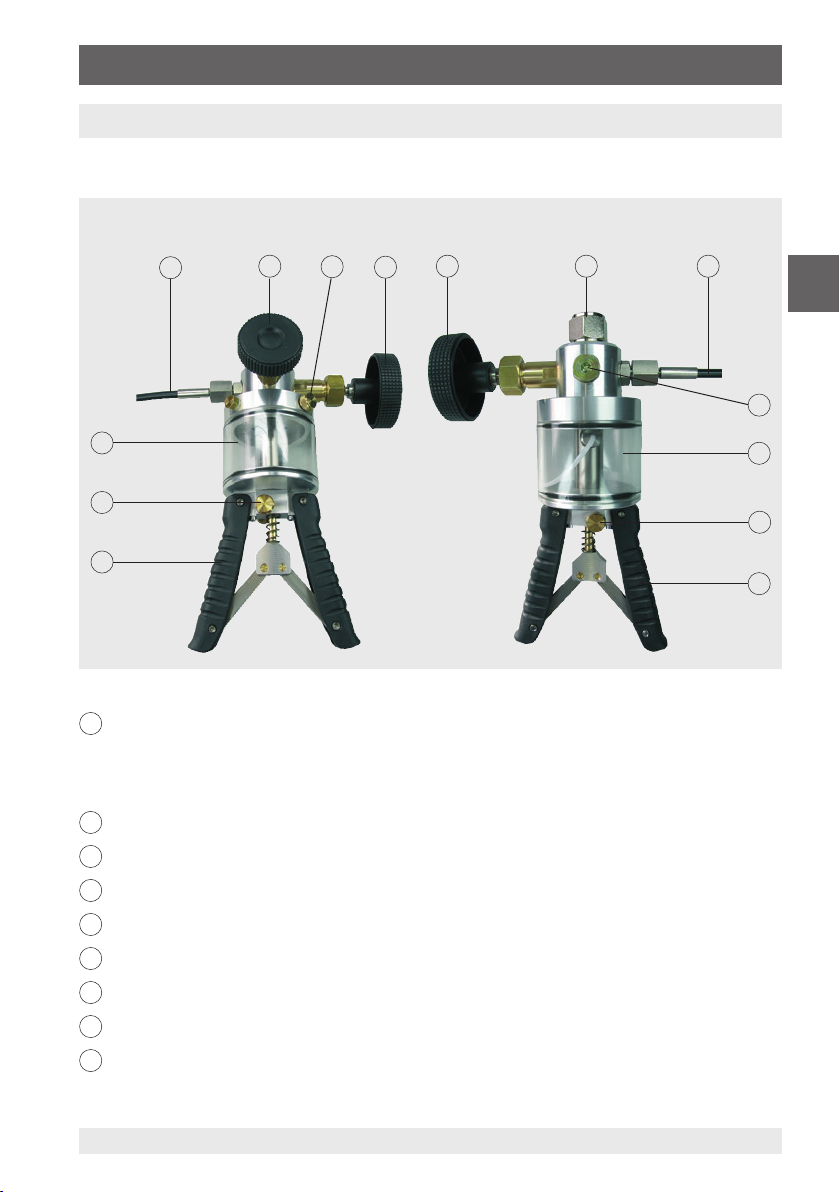

2.1 Overview

Front view

1

7

6

5

1

Test item connection hose

2

CPP700-H: Minimess

3

4

®

system with a G ¼ female pressure gauge bulkhead

4 8 1

connector

CPP1000-H: G ¼ female

2

Pressure relief valve

3

Plug screw for fluid reservoir

4

Fine adjustment valve (volume adjustment)

5

Pump handles

6

Toggle control, system and high-pressure generation

7

Fluid reservoir

8

Connection G ½ female, freely rotating for reference instruments

9

Blind plug, do not open!

Rear view

EN

9

7

6

5

14209601.01 06/2017 EN/DE/FR/ES/IT

5WIKA operating instructions, models CPP700-H and CPP1000-H

Page 6

2. Design and function

2.2 Description

The hand test pumps CPP700-H and CPP1000-H serve as pressure generators for the

testing, adjustment and calibration of mechanical and electronic pressure measuring

instruments through comparative measurements. These pressure tests can take place in

the laboratory or workshop, or on site at the measuring point.

EN

By connecting the pressure measuring instrument to be tested and a sufficiently accurate

reference measuring instrument to the CPP700-H or CPP1000-H, on actuating the pump,

the same pressure will act on both measuring instruments. By comparison of the two

measured values at any given pressure value, a check of the accuracy and/or adjustment

of the pressure measuring instrument under test can be carried out.

The hand test pumps, despite their very compact dimensions, enable simple and

accurate pressure generation. The CPP700-H and CPP1000-H have a fine adjustment

valve for precise adjustment, so as to ensure an accurate comparison test. The reference

instrument is screwed directly to the top of the pump, and the test item is connected using

the connecting hose included in delivery.

2.3 Scope of delivery

CPP700-H

■

Hand test pump, model CPP700-H, oil/water

■

Minimess® test item hose, length 1 m (3.28 ft)

■

Bulkhead connector, G ¼ female

■

Operating instructions

CPP1000-H

■

Hand test pump, model CPP1000-H, oil/water

■

High-pressure test item hose, length 1 m (3.28 ft)

■

Connection, G ¼ female

■

Operating instructions

Cross-check scope of delivery with delivery note.

2.4 Pressure transmission medium

For CPP700-H and CPP1000-H, the following media are suitable as pressure

transmission media:

■

Hydraulic fluids based on mineral oil (water-based hydraulic fluids are not suitable)

■

Simple distilled water

Other pressure transmission media on request.

6 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 7

2. Design and function / 3. Safety

Handling of mineral oils

WIKA delivers hydraulic fluid based on mineral oil in containers of 1 litre, labelled “Shell

Tellus S2 M22”, for use in hand test pumps with up to 1,000 bar (14,500 psi). It is no more

hazardous than other common lubricating oils.

Before working with hydraulic fluids, read the material safety data sheet.

The current material safety data sheet can be found at www.wika.de on the

product page of the respective product.

3. Safety

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to property or the environment, if not avoided.

EN

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

3.2 Intended use

Test pumps serve as pressure generators for the testing, adjustment and calibration

of mechanical and electronic pressure measuring instruments through comparative

measurements.

These pressure tests can take place in the laboratory or workshop, or on site at the

measuring point. The model CPP700-H and CPP1000-H hand test pumps have been

specifically developed for test pressure generation on site.

The hand test pumps, despite their very compact dimensions, enable simple

and accurate test pressure generation of up to a max. of 700 bar (10,000 psi) or

1,000 bar (14,500 psi) respectively, with an integrated switching from initial pressure to

high-pressure generation.

14209601.01 06/2017 EN/DE/FR/ES/IT

7WIKA operating instructions, models CPP700-H and CPP1000-H

Page 8

3. Safety

This instrument is not permitted to be used in hazardous areas!

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

EN

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specifications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

Handle the test pump with the required care (protect from humidity, impacts, strong

magnetic fields, static electricity and extreme temperatures, do not insert any objects into

the instrument or its openings). Plugs and sockets must be protected from contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

▶

Do not use the instrument with abrasive or viscous media.

Any use beyond or different to the intended use is considered as improper use.

3.4 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to

equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who,

based on their technical training, knowledge of measurement and control technology and

on their experience and knowledge of country-specific regulations, current standards and

8 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 9

3. Safety

directives, are capable of carrying out the work described and independently recognising

potential hazards.

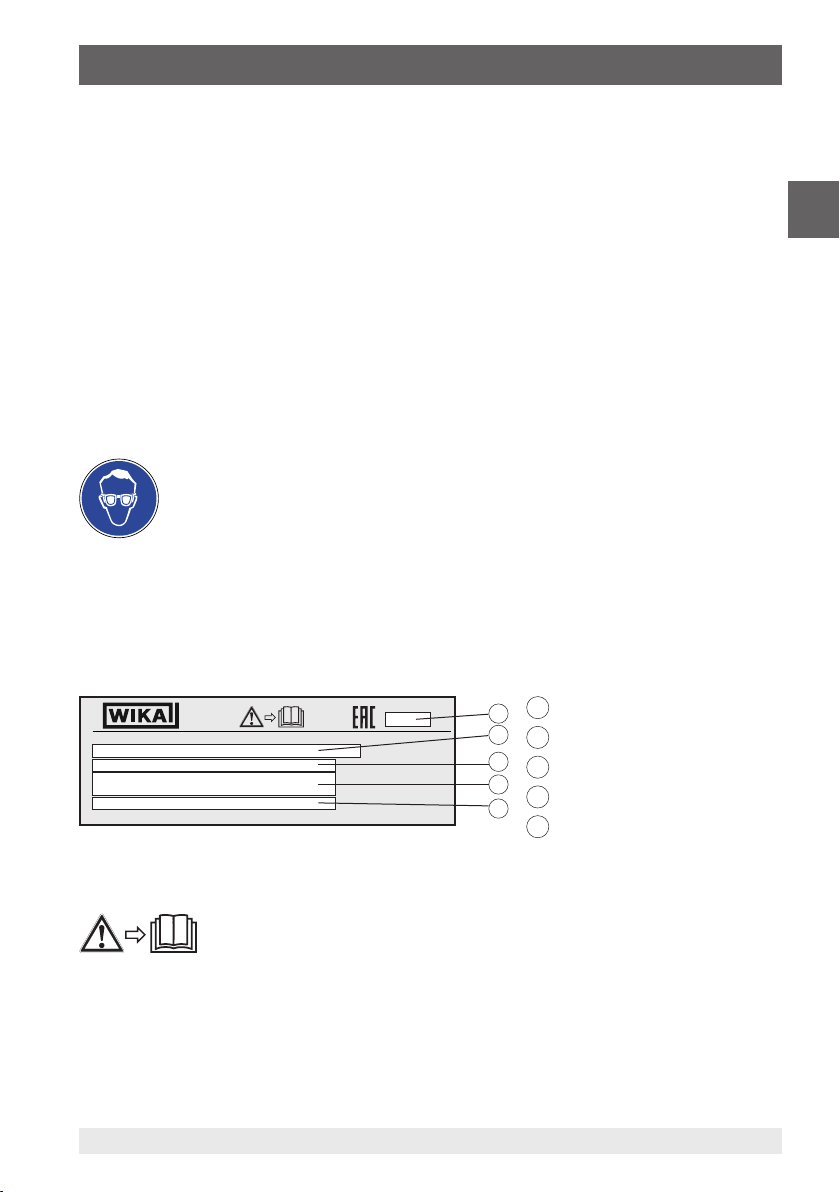

3.5 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out the various

tasks on and with the instrument, the skilled personnel must wear personal protective

equipment.

Follow the instructions displayed in the work area regarding personal protective

equipment!

The requisite personal protective equipment must be provided by the operating company.

Wear safety goggles!

Protect eyes from flying particles and liquid splashes.

3.6 Labelling, safety marks

Product label

The product label is attached to the glass body of the fluid reservoir.

1

Kalibriertechnik / Calibration Technology

Handprüfpumpe / Hand test pump

Druckbereich / Pressure range:

Medium / medium:

Serien-Nr. / serial no.:

Alexander Wiegand SE & Co. KG 63911 Klingenberg / Germany www.wika.com

CPP700-H

0 ... 700 bar

7XXXX

11/2015

1

2

3

4

5

Date of manufacture

2

Model

3

Pressure range

4

Medium

5

Serial no.

EN

Symbol

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

14209601.01 06/2017 EN/DE/FR/ES/IT

9WIKA operating instructions, models CPP700-H and CPP1000-H

Page 10

4. Transport, packaging and storage

4. Transport, packaging and storage

4.1 Transport

Check the hand test pump for any damage that may have been caused by transport.

EN

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal

transport, proceed carefully and observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter 4.2 “Packaging

and storage”.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

Permissible conditions at the place of storage:

■

Storage temperature: 0 ... 55 °C (32 ... 131 °F)

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

■

Corrosive liquids

Store the hand test pump in its original packaging in a location that fulfils the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

1. Place the instrument, along with the shock-absorbent material, in the packaging.

2. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

10 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 11

5. Commissioning, operation

5. Commissioning, operation

Personnel: Skilled personnel

Protective equipment: Safety goggles,

Tools: Syringe and a special needle for filling or cleaning the fluid reservoir

Only use original parts (see chapter 10 “Accessories”).

5.1 Unpacking the hand test pump

As soon as possible after delivery open the packaging of the hand test pump and check

that all the items detailed in the packing list (see chapter 2.3 “Scope of delivery”) are

included.

Unpacking the items, check them for any damage that may have been caused by

transport. If any items are missing, please contact WIKA immediately.

5.2 Ambient conditions

The pressure tests can take place in the laboratory or workshop, or on site at the

measuring point.

5.3 Design

EN

Front view

1

7

6

5

14209601.01 06/2017 EN/DE/FR/ES/IT

2

Rear view

3

4

4 8 1

9

7

6

5

11WIKA operating instructions, models CPP700-H and CPP1000-H

Page 12

5. Commissioning, operation

1

Test item connection hose

CPP700-H: Minimess

connector

CPP1000-H: G ¼ female

EN

2

Pressure relief valve

3

Plug screw for fluid reservoir

4

Fine adjustment valve (volume adjustment)

5

Pump handles

6

Toggle control, system and high-pressure generation

7

Fluid reservoir

8

Connection G ½ female, freely rotating for reference instruments

9

Blind plug, do not open!

5.4 Filling the hand test pump with the pressure transmission medium

1. Open the fluid reservoir

2. Fill the pressure transmission medium in the pump using the syringe or a special

needle. For suitable medium, see chapter 2.4 “Pressure transmission medium”.

CAUTION!

Damage to the hand test pump due to an unsuitable pressure

transmission medium

Unsuitable pressure transmission media attack the sealings and may lead to

leaks and damage of the hand test pump.

▶

Only use the oils supplied by us or authorized spare oils for hydraulic

systems.

▶

Do not use any other liquids such as castor oils, Skydrol, solvents or the

like.

®

system with a G ¼ female pressure gauge bulkhead

7

. To do so, unscrew the plug screws 3.

The maximum permissible temperature of the pressure transmission

medium is 70 °C.

7

3. The fluid reservoir

4. Screw in the plug screw

must not be filled to 100 %.

3

again.

5.5 Replacing the pressure transmission medium

7

1. Open the fluid reservoir

. To do so, unscrew the plug screws 3.

2. Remove the pressure transmission medium from the pump using the syringe or a

special needle.

12 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 13

5. Commissioning, operation

3. Rinse the fluid reservoir using water or gentle cleaning agents.

To do so, use a syringe specially designed for cleaning.

⇒

The use of alcohol, spirit, acetone or benzene can cause the container

material to crack or lead to damage of the container.

4. Fill the new pressure transmission medium in the pump using the syringe or a special

needle.

5. The fluid reservoir 7 must not be filled to 100 %.

3

6. Screw in the plug screw

If water is used as test or calibration medium, the test pump must be

emptied after EACH use.

As soon as contamination is visible in the calibration medium, the medium

must be replaced.

5.6 Mechanical mounting

WARNING!

Breakage of the test item hose

Air pockets in the calibration circuit can cause the test item hose to break

during pressure generation.

To prevent this and to maintain a more constant pressure, the following must

be ensured.

▶

Prior to using the hose, fill it with the service liquid.

▶

Fill up with the missing pressure transmission medium, see chapter

5.4 “Filling the hand test pump with the pressure transmission medium”.

again.

EN

CAUTION!

Damage to the hand test pump due to external pressure

To prevent this, the following must be ensured.

▶

Do not connect any external pressure sources to the pump.

▶

Generate pressure only using the hand test pump.

1. Mount the reference pressure measuring instrument on the top side

test pump.

It is sufficient to tighten it by hand.

The reference pressure measuring instrument is sealed by means of the O-ring

⇒

14209601.01 06/2017 EN/DE/FR/ES/IT

integrated in the reference instrument connection.

8

of the hand

13WIKA operating instructions, models CPP700-H and CPP1000-H

Page 14

5. Commissioning, operation

2. Mount the test item at the end of the test item hose 1.

G 1/4 female thread as a standard

3. Tighten adapters, if used, to a maximum torque of 15 Nm.

EN

A stainless steel set of adapters is available as accessories. The set

contains a set of high-quality nylon sealings or O-rings.

Dirty or chemically contaminated test items should not be fitted as they

contaminate the system unless they are first cleaned.

Alternative mounting of the test item

1

1. Remove the test item hose

from the pump by turning it.

2. Select an adapter suitable for the desired test item (optional set of adapters available

on request).

3. Mount the adapter on the hand test pump (G 1/4 female thread).

4. Mount the test item on the adapter.

This makes it possible to substantially reduce volume and to facilitate the test

⇒

pressure generation.

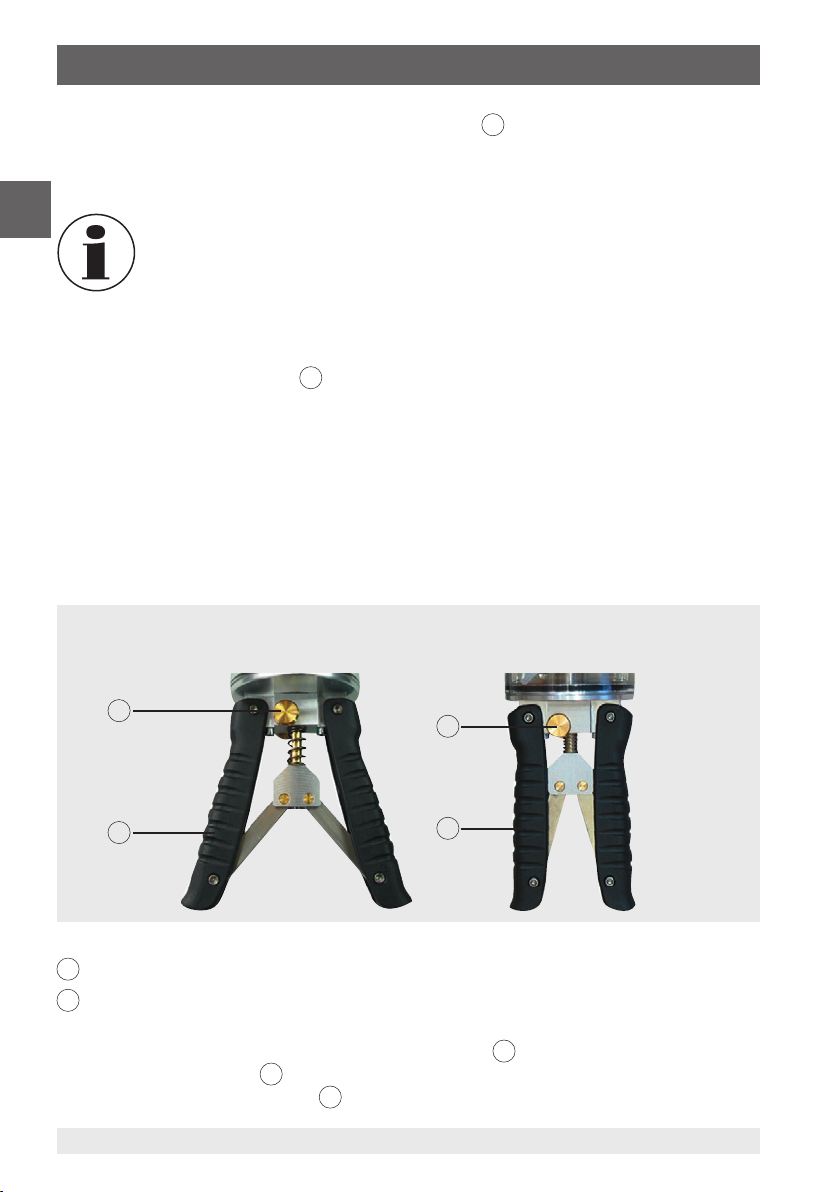

5.7 Generating pressure

Handles for initial pressure

generation

6

Handles for high-pressure

generation

6

5

5

Pump handles

6

Toggle control, system and high-pressure generation

1. Before generating pressure, press the toggle control

The pump handles 5 are positioned apart (“initial pressure generation” position).

⇒

2. Open the pressure relief valve

14 WIKA operating instructions, models CPP700-H and CPP1000-H

2

.

5

6

, if necessary.

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 15

5. Commissioning, operation

3. Unscrew the fine adjustment valve 4 by turning it counter-clockwise, until it slightly

stops.

2

4. Carefully screw the pressure relief valve

closes securely.

5

5. By means of the pump handle

generated.

The handles can now hardly be pressed together. Depending on the volume of the

⇒

calibration circuit, a pressure of 200 ... 400 bar (2,900 ... 5,800 psi) is generated in

the “initial pressure generation” position.

5

6. Hold the handles

The pump handles 5 are now in the “high-pressure generation” position.

⇒

If too high an initial pressure has been generated, the pump handles

no longer be completely pressed together and the toggle control

longer be actuated

In this case, drain the built-up initial pressure by unscrewing the pressure

relief valve

pressed together and press the toggle control 6.

2

.

, pump the system until an initial pressure is

by turning it clockwise, until the valve

6

can no

5

can

EN

7. Now, by means of the pump handles

reached, but up to a maximum of about 600 bar (8,700 psi).

A test pressure higher than about 600 bar (8,700 psi) is achieved only by turning

⇒

the fine adjustment valve

After increasing the pressure, the value displayed can drop slightly again

for about 30 seconds. The causes can be thermodynamic effects, the hose

connection and the sealings.

Readjust the test pressure using the fine adjustment valve

continues to drop, check the measuring circuit for leaks.

5.8 Reducing pressure

Do not disassemble the reference instrument or the test item until the

pressure relief valve

1. To reduce the pressure, turn the fine adjustment valve counterclockwise.

2. Carefully open the pressure relief valve

Pressure is reduced and there is no pressure on the hand test pump.

⇒

3. Dismount the reference pressure measuring instrument and/or the test item.

4. After the pressure has been relieved, close the pressure relief valve

clockwise.

14209601.01 06/2017 EN/DE/FR/ES/IT

4

clockwise.

2

, pump until the desired test pressure is

5

is open and there is no pressure in the test pump.

2

by turning it clockwise no more than once.

4

. If pressure

2

by turning it

15WIKA operating instructions, models CPP700-H and CPP1000-H

Page 16

5. Commissioning, operation

5.9 Recommended reference pressure measuring instruments

Precision digital pressure gauge model CPG1500

Measuring ranges

EN

Accuracy

For further specifications see data sheet CT 10.51

Hand-held pressure indicator model CPH6200

Measuring ranges

Accuracy

For further specifications see data sheet CT 11.01

Hand-held pressure indicator model CPH6300

Measuring ranges

Accuracy

For further specifications see data sheet CT 12.01

up to 1,000 bar (15,000 psi)

0.05 % of span

up to 1,000 bar (14,500 psi)

0.2 % of span

up to 1,000 bar (14,500 psi)

0.2 % of span

Precision hand-held pressure indicator model

CPH6400

Measuring ranges

Accuracy

For further specifications see data sheet CT 14.01

16 WIKA operating instructions, models CPP700-H and CPP1000-H

up to 6,000 bar (85,000 psi)

up to 0.025 % of span

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 17

5. Commissioning, operation

ProcessCalibrator model CPH6000

Measuring ranges

Accuracy

up to 8,000 bar (115,000 psi)

up to 0.025 % of span

For further specifications see data sheet CT 15.01

5.10 Use with WIKA-Cal calibration software

WIKA-Cal calibration software for creating

calibration certificates or logger protocols

For specifications see data sheet CT 95.10

5.11 Calibration case available

Consisting of:

■

Plastic service case with foam insert

■

Precision digital pressure gauge model CPG1500

■

Hydraulic hand test pump model CPP700-H

EN

14209601.01 06/2017 EN/DE/FR/ES/IT

17WIKA operating instructions, models CPP700-H and CPP1000-H

Page 18

6. Faults

6. Faults

Personnel: Skilled personnel

Protective equipment: Safety goggles

EN

Tools: Syringe and a special needle for filling or cleaning the fluid reservoir

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the hand test

pump must be taken out of operation immediately.

▶

Ensure that pressure or signal is no longer present and protect against

accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter

8.2 “Return”.

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

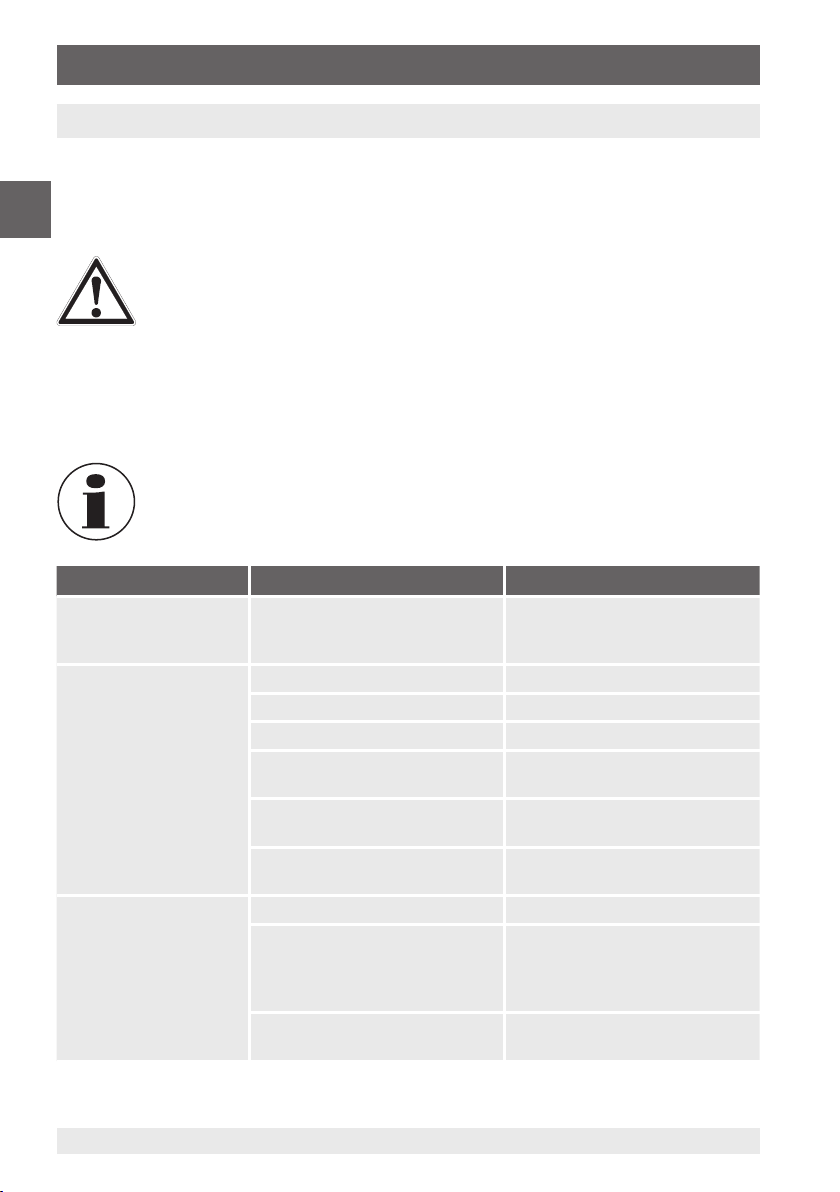

Faults Causes Measures

The hand test pump is

sluggish

Instable output

pressure

System provides

pressure but pressure

decays to zero.

The hand test pump has not been

used for a long time

The drain valve is open Close drain valve

Incorrect sealing Insert the correct sealing

Incorrectly seated sealing Position the sealing correctly

Sealing is defective Replace the sealing with a new

Incorrect adapter or the adapter

has not been mounted properly

If unable to locate a cause. Return the hand test pump for

The drain valve is open Close drain valve

Incorrect operating procedure

being used.

If unable to locate a cause. Return the hand test pump for

The first stroke is somehow

sluggish. This effect has

disappeared further operation.

one

Check the adapter at the test item

side and mount it properly

checking

Ensure that correct operating

procedure is being followed

(see chapter 5.7 “Generating

pressure”)

checking

18 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 19

6. Faults / 7. Maintenance and cleaning

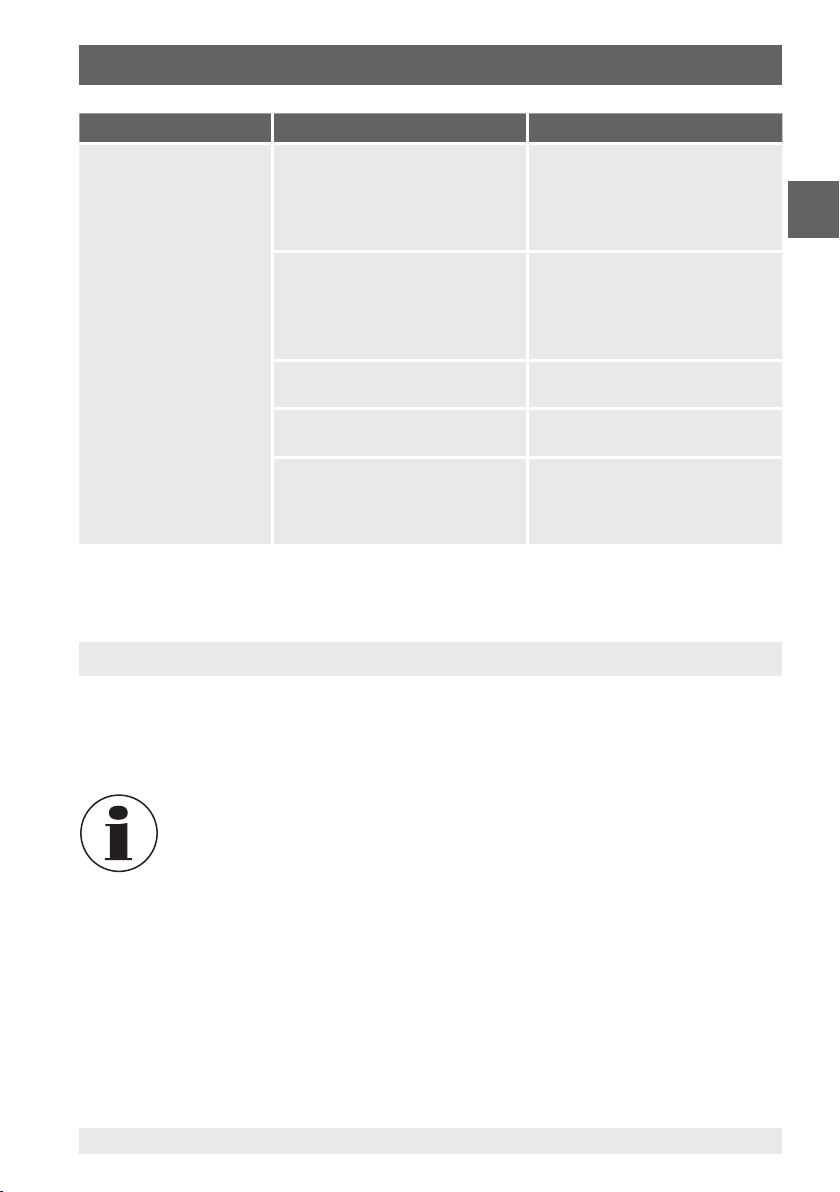

Faults Causes Measures

System provides

pressure but pressure

decays to lower value

then remains steady.

Insufficient liquid in the hand test

pump.

Air in the system Fill the fluid reservoir with

If unable to locate a cause. Return the hand test pump for

Internal damage Return the hand test pump for

Incorrect operating procedure

being used.

Fill the fluid reservoir with

the correct fluid (see chapter

5.4 “Filling the hand test pump

with the pressure transmission

medium”)

the correct fluid (see chapter

5.4 “Filling the hand test pump

with the pressure transmission

medium”)

checking

checking

Ensure that correct operating

procedure is being followed

(see chapter 5.7 “Generating

pressure”)

EN

7. Maintenance and cleaning

Personnel: Skilled personnel

Protective equipment: Safety goggles

Tools: Syringe and a special needle for filling or cleaning the fluid reservoir

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

7.1 Maintenance

Repairs must only be carried out by the manufacturer.

Only use original parts (see chapter 10 “Accessories”).

▶

Before adapting the reference instrument and the test item, check the sealings in the

two connections for correct seating and wear.

▶

Replace the sealings, if necessary.

14209601.01 06/2017 EN/DE/FR/ES/IT

19WIKA operating instructions, models CPP700-H and CPP1000-H

Page 20

7. Maintenance and cleaning

7.2 Cleaning

CAUTION!

Physical injuries and damage to property and the environment

EN

1. Before cleaning, correctly disconnect the instrument from the pressure supply.

2. Use the requisite protective equipment.

3. Clean the instrument with a moist cloth.

Improper cleaning may lead to physical injuries and damage to property and

the environment. Residual media in the dismounted instrument can result in

a risk to persons, the environment and equipment.

▶

Carry out the cleaning process as described below.

CAUTION!

Damage to the instrument

Improper cleaning may lead to damage to the instrument!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any pointed and hard objects for cleaning.

▶

Only clean the fluid reservoir using water or gentle cleaning agents.

The use of alcohol, spirit, acetone or benzol can cause the container

material to crack or lead to damage of the container.

4. Wash or clean the dismounted instrument, in order to protect persons and the

environment from exposure to residual media.

Cleaning the fluid reservoir

Clean the fluid reservoir, see chapter 5.5 “Replacing the pressure transmission medium”.

20 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 21

8. Dismounting, return and disposal

8. Dismounting, return and disposal

Personnel: Skilled personnel

Protective equipment: Safety goggles

Tools: Syringe and a special needle for filling or cleaning the fluid reservoir

8.1 Dismounting

WARNING!

Physical injuries and damage to property and the environment

through residual media

When dismounting, there is a danger from aggressive media and high

pressures.

▶

Before storage of the dismounted instrument (following use) wash or

clean it, in order to protect persons and the environment from exposure to

residual media.

▶

Wear the requisite protective equipment (see chapter 3.5 “Personal

protective equipment”).

▶

Observe the information in the material safety data sheet for the

corresponding medium.

▶

Only disconnect the measuring assembly/test and calibration installations

once the system has been depressurised.

EN

Do not disassemble the reference instrument or the test item until the

2

pressure relief valve

1. To reduce the pressure, turn the fine adjustment valve counterclockwise.

2. Carefully open the pressure relief valve

Pressure is reduced and there is no pressure on the hand test pump.

⇒

3. Dismount the reference pressure measuring instrument and/or the test item.

4. Remove the sealings used.

5. Dismount the adapter, if used, from the hand test pump.

6. Remove the test item hose

7. After the pressure has been relieved, close the pressure relief valve

clockwise.

Emptying the fluid reservoir

8. Open the fluid reservoir

9. Remove the pressure transmission medium from the pump using a syringe or a

special needle.

14209601.01 06/2017 EN/DE/FR/ES/IT

7

is open and there is no pressure in the test pump.

2

by turning it clockwise no more than once.

1

from the pump by turning it.

2

. To do so, unscrew the plug screws 3.

by turning it

21WIKA operating instructions, models CPP700-H and CPP1000-H

Page 22

8. Dismounting, return and disposal

10. Rinse the fluid reservoir using water or gentle cleaning agents.

To do so, use the syringe specially designed for cleaning.

⇒

EN

11. Screw in the plug screws

8.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

The use of alcohol, spirit, acetone or benzol can cause the container

material to crack or lead to damage of the container.

3

again.

If water is used as test or calibration medium, the test pump must be

emptied after EACH use.

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media at the hand test pump can result in a risk to persons, the

environment and equipment.

▶

With hazardous substances, include the material safety data sheet for the

corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

When returning the instrument, use the original packaging or a suitable transport

packaging.

To avoid damage:

1. Place the instrument, along with the shock-absorbent material, in the packaging. Place

shock-absorbent material evenly on all sides of the transport packaging.

2. If possible, place a bag, containing a desiccant, inside the packaging.

3. Label the shipment as transport of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our local

website.

22 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 23

8. Dismounting, return and disposal / 9. Specifications

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

Dispose of the hydraulic fluids as described in the material safety data sheet.

The current material safety data sheet can be found at www.wika.de on the

product page of the respective product.

9. Specifications

Specifications Model CPP700-H Model CPP1000-H

Pressure range 0 ... 700 bar

(0 … 10,000 psi)

Pressure transmission

medium

Fluid reservoir 200 cm³

Pressure connections

For reference instrument G ½ female thread, freely rotating.

For test item G ¼ female at test connection

Fine adjustment Fine adjustment valve / volume adjustment

Material anodised aluminium, brass, stainless steel, ABS

Sealings FKM and NBR (standard)

Dimensions (L x W x H) 280 x 170 x 120 mm

Weight 1.9 kg

1) Other pressure transmission media on request.

Hydraulic fluid based on mineral oil or single distilled water

(water-based hydraulic fluids are not suitable)

The connection can be disconnected using an Allen key. Then a

G ⅜ female thread is available.

hose, length 1 m (3.28 ft),

Minimess

(11.0 x 6.7 x 4.7 in)

(4.2 lbs)

®

1620 system

0 … 1,000 bar

(0 … 14,500 psi)

1)

G ¼ female, freely rotating at

test connection hose, length

1 m (3.28 ft)

EN

Approvals and certificates, see website

For further specifications see WIKA data sheet CT 91.07 and the order documentation.

14209601.01 06/2017 EN/DE/FR/ES/IT

23WIKA operating instructions, models CPP700-H and CPP1000-H

Page 24

10. Accessories

10. Accessories

Adapter set

■

Adapter and sealing set, “BSP” for test item hose, G ¼ male to G ⅛, G ⅜ and G ½

EN

female

■

Adapter and sealing set, “metric” for test item hose, G ¼ male to M12 x 1.5, M20 x 1.5

and Minimess

■

Adapter and sealing set, “NPT” for test item hose, G ¼ male to ⅛ NPT, ¼ NPT, ⅜ NPT

®

and ½ NPT female

Case

■

Plastic case, incl. foam insert with free spaces for model CPP700-H or CPP1000-H;

Dimensions (W x H x D): 440 x 370 x 140 mm (17.3 x 14.6 x 5.5 in)

Pressure transmission medium

■

Special oil for CPP1000 and CPP1600 test pump series in plastic bottle, contents

1 litre

■

Hydraulic fluid based on “Shell Tellus S2 M22” mineral oil in plastic bottle, content

1 litre

Other

■

Connection adapter, G ¼ male to G ½ female, material: stainless steel

■

Sealing and maintenance set for model CPP700-H or CPP1000-H

■

Spare hose for model CPP700-H or CPP1000-H, length 1 m (3.28 ft)

24 WIKA operating instructions, models CPP700-H and CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 25

Inhalt

Inhalt

1. Allgemeines 26

2. Aufbau und Funktion 27

2.1 Überblick . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 Beschreibung. . . . . . . . . . . . . . . . . . . . . . . 28

2.3 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . .28

2.4 Druckübertragungsmedium . . . . . . . . . . . . . . . . . .28

3. Sicherheit 29

3.1 Symbolerklärung . . . . . . . . . . . . . . . . . . . . .29

3.2 Bestimmungsgemäße Verwendung . . . . . . . . . . . . . . .29

3.3 Fehlgebrauch. . . . . . . . . . . . . . . . . . . . . . . 30

3.4 Personalqualifikation . . . . . . . . . . . . . . . . . . . . 30

3.5 Persönliche Schutzausrüstung . . . . . . . . . . . . . . . . .31

3.6 Beschilderung, Sicherheitskennzeichnungen . . . . . . . . . . . .31

4. Transport, Verpackung und Lagerung 32

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2 Verpackung und Lagerung . . . . . . . . . . . . . . . . . . 32

5. Inbetriebnahme, Betrieb 33

5.1 Auspacken der Handprüfpumpe . . . . . . . . . . . . . . . .33

5.2 Umgebungsbedingungen . . . . . . . . . . . . . . . . . . 33

5.3 Aufbau . . . . . . . . . . . . . . . . . . . . . . . . .33

5.4 Befüllen der Handprüfpumpe mit Druckübertragungsmedium . . . . . .34

5.5 Austauschen von Druckübertragungsmedium. . . . . . . . . . . . 34

5.6 Mechanische Montage . . . . . . . . . . . . . . . . . . .35

5.7 Druckerzeugung. . . . . . . . . . . . . . . . . . . . . .36

5.8 Reduzierung des Drucks . . . . . . . . . . . . . . . . . . .37

5.9 Empfohlene Referenz-Druckmessgeräte . . . . . . . . . . . . . 38

5.10 Einsatz mit Kalibriersoftware WIKA-Cal . . . . . . . . . . . . .39

5.11 Lieferbarer Kalibrierkoffer . . . . . . . . . . . . . . . . . . 39

6. Störungen 40

7. Wartung und Reinigung 41

7.1 Wartung . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2 Reinigung . . . . . . . . . . . . . . . . . . . . . . . .42

8. Demontage, Rücksendung und Entsorgung 43

8.1 Demontage . . . . . . . . . . . . . . . . . . . . . . . 43

8.2 Rücksendung. . . . . . . . . . . . . . . . . . . . . . . 44

8.3 Entsorgung . . . . . . . . . . . . . . . . . . . . . . . 45

9. Technische Daten 45

10. Zubehör 46

DE

14209601.01 06/2017 EN/DE/FR/ES/IT

25WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 26

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Handprüfpumpen CPP700-H und

CPP1000-H werden nach dem aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

zertifiziert.

DE

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe

des Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Zugehöriges Datenblatt: CT 91.07

- Anwendungsberater: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

26 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 27

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Überblick

Ansicht von vorn

1

7

6

5

1

Prüflingsanschlussschlauch

2

CPP700-H: System Minimess

3

4

®

mit Manometer-Schottverschraubung auf

4 8 1

G ¼-Innengewinde

CPP1000-H: G ¼-Innengewinde

2

Druckablassventil

3

Verschlussschraube für Flüssigkeitsreservoir

4

Feinregulierventil (Volumenvariator)

5

Pumpenhandgriffe

6

Umschaltknopf Vor- und Hochdruckerzeugung

7

Flüssigkeitsreservoir

8

Anschluss G ½ innen, freilaufend für Referenzgeräte

9

Blindstopfen, nicht öffnen!

Ansicht von hinten

DE

9

7

6

5

14209601.01 06/2017 EN/DE/FR/ES/IT

27WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 28

2. Aufbau und Funktion

2.2 Beschreibung

Die Handprüfpumpen CPP700-H und CPP1000-H dienen zur Druckerzeugung für

die Überprüfung, Justage und Kalibrierung von mechanischen und elektronischen

Druckmessgeräten durch Vergleichsmessungen. Diese Druckprüfungen können stationär

im Labor, Werkstatt oder vor Ort an der Messstelle stattfinden.

Schließt man das zu prüfende Druckmessgerät und ein hinreichend genaues ReferenzMessgerät an der CPP700-H oder CPP1000-H an, so wirkt bei Betätigung der Pumpe

DE

auf beide Messgeräte der gleiche Druck. Durch Vergleich der beiden Messwerte bei

beliebigen Druckwerten kann eine Überprüfung der Genauigkeit bzw. eine Justage des

zu prüfenden Druckmessgerätes erfolgen.

Die Handprüfpumpen ermöglichen trotz sehr kompakter Abmessungen eine einfache

und exakte Prüfdruckerzeugung. Für präzise Einstellung zur genauen Vergleichsprüfung

besitzen die CPP700-H und CPP1000-H ein Feinregulierventil. Das Referenzgerät wird

direkt oben auf die Pumpe aufgeschraubt und der Prüfling wird über den im Lieferumfang

enthaltenen Anschlussschlauch adaptiert.

2.3 Lieferumfang

CPP700-H

■

Handprüfpumpe Typ CPP700-H Öl/Wasser

■

Minimess® Prüflingsschlauch, Länge 1 m (3,28 ft)

■

Schottverschraubung G ¼ innen

■

Betriebsanleitung

CPP1000-H

■

Handprüfpumpe Typ CPP1000-H Öl/Wasser

■

Hochdruck-Prüflingsschlauch, Länge 1 m (3,28 ft)

■

Anschluss G ¼ innen

■

Betriebsanleitung

Lieferumfang mit dem Lieferschein abgleichen.

2.4 Druckübertragungsmedium

Als Druckübertragungsmedium ist für die CPP700-H und CPP1000-H ausschließlich

geeignet:

■

Hydraulikflüssigkeiten auf Mineralölbasis (Nicht geeignet sind wasserbasierende

Hydraulikflüssigkeiten)

■

Einfach destilliertes Wasser

Andere Druckübertragungsmedien auf Anfrage.

28 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 29

2. Aufbau und Funktion / 3. Sicherheit

Umgang mit Mineralölen

WIKA liefert Hydraulikflüssigkeit auf Mineralölbasis in Behältern zu 1 Liter, beschriftet

mit „Shell Tellus S2 M22“ zur Verwendung in Handprüfpumpen mit bis zu 1.000 bar

(14.500 psi). Es ist nicht gefährlicher als andere Schmieröle.

Bevor mit Hydraulikflüssigkeiten gearbeitet wird, das Sicherheitsdatenblatt

durchlesen.

Das aktuelle Sicherheitsdatenblatt befindet sich unter www.wika.de auf der

Produktseite des jeweiligen Produkts.

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu

geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden

führen kann, wenn sie nicht gemieden wird.

DE

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

3.2 Bestimmungsgemäße Verwendung

Prüfpumpen dienen zur Druckerzeugung für die Überprüfung, Justage und Kalibrierung

von mechanischen und elektronischen Druckmessgeräten durch Vergleichsmessungen.

Diese Druckprüfungen können stationär in Labor, Werkstatt oder vor Ort an der

Messstelle stattfinden. Die Handprüfpumpen Typ CPP700-H und CPP1000-H wurden

speziell für die Prüfdruckerzeugung vor Ort entwickelt.

Die Handprüfpumpen ermöglichen trotz sehr kompakter Abmessungen eine einfache und

exakte Prüfdruckerzeugung bis max. 700 bar (10.000 psi) bzw. 1.000 bar (14.500 psi) mit

integrierter Umschaltung von Vordruck- auf Hochdruckerzeugung.

14209601.01 06/2017 EN/DE/FR/ES/IT

29WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 30

3. Sicherheit

Dieses Gerät ist nicht für den Einsatz in explosionsgefährdeten Bereichen zugelassen!

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet

werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen

DE

Spezifikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Prüfpumpe mit erforderlicher Sorgfalt behandeln (vor Nässe, Stößen, starken

Magnetfeldern, statischer Elektrizität und extremen Temperaturen schützen, keine

Gegenstände in das Gerät bzw. Öffnungen einführen). Stecker und Buchsen vor

Verschmutzung schützen.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

3.3 Fehlgebrauch

WARNUNG!

Verletzungen durch Fehlgebrauch

Fehlgebrauch des Gerätes kann zu gefährlichen Situationen und

Verletzungen führen.

▶

Eigenmächtige Umbauten am Gerät unterlassen.

▶

Gerät nicht in explosionsgefährdeten Bereichen einsetzen.

▶

Gerät nicht für abrasive und viskose Messstoffe verwenden.

Jede über die bestimmungsgemäße Verwendung hinausgehende oder andersartige

Benutzung gilt als Fehlgebrauch.

3.4 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualifikation durchführen

lassen.

30 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 31

3. Sicherheit

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner fachlichen Ausbildung,

seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie

Kenntnis der landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der

Lage, die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

3.5 Persönliche Schutzausrüstung

Die persönliche Schutzausrüstung dient dazu, das Fachpersonal gegen Gefahren

zu schützen, die dessen Sicherheit oder Gesundheit bei der Arbeit beeinträchtigen

könnten. Beim Ausführen der verschiedenen Arbeiten an und mit dem Gerät muss das

Fachpersonal persönliche Schutzausrüstung tragen.

Im Arbeitsbereich angebrachte Hinweise zur persönlichen Schutzausrüstung

befolgen!

Die erforderliche persönliche Schutzausrüstung muss vom Betreiber zur Verfügung

gestellt werden.

Schutzbrille tragen!

Schutz der Augen vor umherfliegenden Teilen und Flüssigkeitsspritzern.

3.6 Beschilderung, Sicherheitskennzeichnungen

Typenschild

Das Typenschild ist auf dem Glaskörper des Flüssigkeitsreservoirs angebracht.

1

Kalibriertechnik / Calibration Technology

Handprüfpumpe / Hand test pump

Druckbereich / Pressure range:

Medium / medium:

Serien-Nr. / serial no.:

Alexander Wiegand SE & Co. KG 63911 Klingenberg / Germany www.wika.com

CPP700-H

0 ... 700 bar

7XXXX

11/2015

1

2

3

4

5

Herstellungsdatum

2

Typ

3

Druckbereich

4

Medium

5

Serien-Nr.

DE

Symbol

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

14209601.01 06/2017 EN/DE/FR/ES/IT

31WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 32

4. Transport, Verpackung und Lagerung

4. Transport, Verpackung und Lagerung

4.1 Transport

Handprüfpumpe auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

DE

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur

abwarten.

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

Beschädigungen durch unsachgemäßen Transport

Bei unsachgemäßem Transport können Sachschäden in erheblicher Höhe

entstehen.

▶

Beim Abladen der Packstücke bei Anlieferung sowie innerbetrieblichem

Transport vorsichtig vorgehen und die Symbole auf der Verpackung

beachten.

▶

Bei innerbetrieblichem Transport die Hinweise unter Kapitel

4.2 „Verpackung und Lagerung“ beachten.

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: 0 ... 55 °C (32 ... 131 °F)

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Folgende Einflüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

■

Korrosiven Flüssigkeiten

Die Handprüfpumpe in der Originalverpackung an einem Ort lagern, der die oben

gelisteten Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann

das Gerät wie folgt verpacken und lagern:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

2. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

32 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 33

5. Inbetriebnahme, Betrieb

5. Inbetriebnahme, Betrieb

Personal: Fachpersonal

Schutzausrüstung: Schutzbrille

Werkzeuge: Spritze mit spezieller Nadel für die Befüllung oder Reinigung des

Flüssigkeitsreservoirs

Nur Originalteile verwenden (siehe Kapitel 10 „Zubehör“).

5.1 Auspacken der Handprüfpumpe

Die Verpackung der Handprüfpumpe baldmöglichst nach der Lieferung öffnen und

überprüfen, ob alle in der Packliste (siehe Kapitel 2.3 „Lieferumfang“) angegebenen Teile

enthalten sind.

Die Teile beim Auspacken auf Transportschäden überprüfen. Sollten Teile fehlen, sofort

WIKA kontaktieren.

5.2 Umgebungsbedingungen

Die Druckprüfungen können stationär in Labor, Werkstatt oder vor Ort an der Messstelle

stattfinden.

5.3 Aufbau

Ansicht von vorn

1

2

3

4

4 8 1

Ansicht von hinten

9

DE

7

6

5

14209601.01 06/2017 EN/DE/FR/ES/IT

7

6

5

33WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 34

5. Inbetriebnahme, Betrieb

1

Prüflingsanschlussschlauch

CPP700-H: System Minimess

Innengewinde

CPP1000-H: G ¼ Innengewinde

2

Druckablassventil

3

Verschlussschraube für Flüssigkeitsreservoir

4

DE

Feinregulierventil (Volumenvariator)

5

Pumpenhandgriffe

6

Umschaltknopf Vor- und Hochdruckerzeugung

7

Flüssigkeitsreservoir

8

Anschluss G ½ innen, freilaufend für Referenzgeräte

9

Blindstopfen, nicht öffnen!

5.4 Befüllen der Handprüfpumpe mit Druckübertragungsmedium

1. Das Flüssigkeitsreservoir

2. Das Druckübertragungsmedium mit Hilfe einer Spritze mit spezieller Nadel in die

Pumpe einfüllen. Geeignetes Medium siehe Kapitel 2.4 „Druckübertragungsmedium“.

VORSICHT!

Beschädigung der Handprüfpumpe durch falsches

Druckübertragungsmedium

Falsches Druckübertragungsmedium greifen die Dichtungen an und können

zu Undichtigkeiten führen und die Handprüfpumpe beschädigen.

▶

Nur die gelieferten Öle oder zugelassene Ersatzöle für Hydraulikanlagen

verwenden.

▶

Keine anderen Flüssigkeiten wie Kastoröle, Skydrol, Lösungsmittel oder

ähnliches verwenden!

®

mit Manometer-Schottverschraubung auf G ¼

7

öffnen. Hierzu die Verschlussschraube 3 herausdrehen.

Die maximal zulässige Temperatur des Druckübertragungsmediums beträgt

70 °C.

7

3. Das Flüssigkeitsreservoir

4. Verschlussschraube

nicht zu 100 % füllen.

3

wieder eindrehen.

5.5 Austauschen von Druckübertragungsmedium

7

1. Das Flüssigkeitsreservoir

öffnen. Hierzu die Verschlussschraube 3 herausdrehen.

2. Das Druckübertragungsmedium mit Hilfe einer Spritze mit spezieller Nadel aus der

Pumpe herausziehen.

34 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 35

5. Inbetriebnahme, Betrieb

3. Das Flüssigkeitsreservoir mit Wasser oder sanften Reinigungsmitteln spülen.

Hierfür eine Spritze speziell nur für die Reinigung verwenden.

⇒

Durch die Anwendung von Alkohol, Spiritus, Aceton oder Benzole kann es

zu Rissbildungen im Behältermaterial und zur Beschädigung des Behälters

kommen.

4. Neues Druckübertragungsmedium mit Hilfe einer Spritze mit spezieller Nadel in die

Pumpe einfüllen.

7

5. Das Flüssigkeitsreservoir

6. Verschlussschraube

Bei Verwendung von Wasser als Prüf- bzw. Kalibriermedium muss die

Prüfpumpe nach JEDER Benutzung entleert werden.

Sobald erste Verschmutzungen im Kalibriermedium sichtbar werden, muss

dieses ausgetauscht werden.

5.6 Mechanische Montage

WARNUNG!

Bersten des Prüflingsschlauchs

Lufteinschlüsse im Kalibrierkreislauf können bei der Druckerzeugung den

Prüflingsschlauch bersten lassen.

Um dies zu verhindern und eine stabilere Druckhaltung zu erreichen muss

folgendes gewährleistet sein.

▶

Vor der Verwendung den Schlauch mit der Betriebsflüssigkeit füllen.

▶

Fehlendes Druckübertragungsmedium auffüllen siehe Kapitel 5.4

„Befüllen der Handprüfpumpe mit Druckübertragungsmedium“.

VORSICHT!

Beschädigung der Handprüfpumpe durch externen Druck

Um dies zu verhindern muss folgendes gewährleistet sein.

▶

Keine externen Druckquellen an die Pumpe anschließen.

▶

Nur mit der Handprüfpumpe einen Druck erzeugen.

nicht zu 100 % füllen.

3

wieder eindrehen.

DE

8

1. Das Referenz-Druckmessgerät an die Oberseite

Es genügt ein gut handfestes Anziehen.

Abgedichtet wird das Referenz-Druckmessgerät über den am Referenz-

⇒

Geräteanschluss integrierten O-Ring.

2. Den Prüfling an das Ende des Prüflingsanschlussschlauches

Standardmäßig G 1/4 Innengewinde.

14209601.01 06/2017 EN/DE/FR/ES/IT

der Handprüfpumpe montieren.

1

montieren.

35WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 36

5. Inbetriebnahme, Betrieb

3. Ggf. verwendeten Adapter mit einem maximalen Drehmoment von 15 Nm festziehen.

Als Zubehör ist ein CrNi-Stahl-Adaptersatz für den Prüflingsanschluss

erhältlich. Hier ist auch jeweils ein Satz hochwertiger Nylon-Dichtungen oder

O-Ringe enthalten.

Schmutzige oder chemisch verunreinigte Prüflinge vor der Montage

DE

Alternative Montage des Prüflings

1. Den Prüflingsanschlussschlauches

2. Passenden Adapter für den gewünschten Prüfling auswählen (optionale Adaptersätze

auf Anfrage).

3. Adapter an die Handprüfpumpe montieren (G 1/4 Innengewinde).

4. Prüfling auf den Adapter montieren.

5.7 Druckerzeugung

reinigen, da sie das System verschmutzen können.

1

von der Pumpe abdrehen.

Hierdurch wird das Volumen spürbar verringert und die Prüfdruckerzeugung

⇒

erleichtert.

Hangriffe bei der

Vordruckerzeugung

6

5

5

Pumpenhandgriffe

6

Umschaltknopf Vor- und Hochdruckerzeugung

1. Vor einer Druckerzeugung ggf. den Umschaltknopf

Die Pumpenhandgriffe 5 stehen weiter auseinander (Position

⇒

Hangriffe bei der

Hochdruckerzeugung

6

5

6

betätigen.

“Vordruckerzeugung”).

2

2. Das Druckablassventil

36 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

öffnen.

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 37

5. Inbetriebnahme, Betrieb

3. Das Feinregulierventil 4 entgegen der Uhrzeigerrichtung herausdrehen, bis ein

leichter Anschlag zu spüren ist.

2

4. Das Druckablassventil

schließt.

5. Mit Hilfe der Pumpenhandgriffe

Die Handgriffe lassen sich gerade noch vollständig zusammendrücken. Je nach

⇒

Volumen des Kalibrierkreislaufs wird in der Position “Vordruckerzeugung” ein Druck

von 200 ... 400 bar (2.900 ... 5.800 psi) erzeugt.

6. Die Pumpenhandgriffe

drücken.

Die Pumpenhandgriffe

⇒

Wurde ein zu hoher Vordruck erzeugt lassen sich die Pumpenhandgriffe

5

nicht mehr vollständig zusammendrücken und somit auch der

Umschaltknopf

In diesem Fall den aufgebauten Vordruck durch Aufdrehen des

Druckablassventil

7. Jetzt mit Hilfe der Pumpenhandgriffe

Prüfdruck knapp erreicht ist, max. jedoch bis ca. 600 bar (8.700 psi).

Einen höheren Prüfdruck als ca. 600 bar (8.700 psi) wird nur durch das Eindrehen

⇒

des Feinregulierventil

vorsichtig im Uhrzeigersinn eindrehen, bis das Ventil sicher

5

so lange pumpen, bis ein Vordruck erzeugt ist.

5

zusammengedrückt halten und den Umschaltknopf 6

5

befinden sich nun in der Position “Hochdruckerzeugung”.

6

nicht mehr betätigen.

2

ablassen.

5

so lange pumpen, bis der gewünschte

4

im Uhrzeigersinn erreicht.

DE

Nach Erhöhung des Druckes kann die Anzeige für etwa 30 Sekunden

wieder leicht absinken. Thermodynamische Effekte, die Schlauchverbindung

und die Dichtungen sind hierfür die Ursache.

Den Prüfdruck mit dem Feinregulierventil

Kommt der Druckabfall nicht zum Stillstand, den Messkreis auf Dichtheit

prüfen.

5.8 Reduzierung des Drucks

Das Referenzgerät oder den Prüfling erst demontieren, wenn das

2

Druckablassventil

Prüfpumpe befindet.

1. Zur Druckreduzierung zunächst das Feinregulierventil

Uhrzeigersinn drehen.

2. Vorsichtig das Druckablassventil

dem Uhrzeigersinn herausdrehen.

Druck wird reduziert und es befindet sich anschließend kein Druck mehr auf der

⇒

14209601.01 06/2017 EN/DE/FR/ES/IT

Handprüfpumpe.

geöffnet ist und sich dadurch kein Druck mehr in der

2

öffnen, dabei nur max. eine Umdrehung entgegen

4

entsprechend nachregeln.

4

entgegen dem

37WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 38

5. Inbetriebnahme, Betrieb

3. Das Referenz-Druckmessgerät und/oder den Prüfling demontieren.

4. Nachdem der Druck abgebaut wurde das Druckablassventil

Uhrzeigersinn wieder schließen.

5.9 Empfohlene Referenz-Druckmessgeräte

Präzisions-Digitalmanometer Typ CPG1500

DE

Messbereiche

Genauigkeit

Weitere technische Daten siehe Datenblatt CT 10.51

Hand-Held Druckmessgerät Typ CPH6200

bis 1.000 bar (15.000 psi)

0,05 % der Spanne

2

durch Drehen im

Messbereiche

Genauigkeit

Weitere technische Daten siehe Datenblatt CT 11.01

Hand-Held Druckmessgerät Typ CPH6300

Messbereiche

Genauigkeit

Weitere technische Daten siehe Datenblatt CT 12.01

Präzisions-Hand-Held Druckmessgerät

Typ CPH6400

Messbereiche

Genauigkeit

Weitere technische Daten siehe Datenblatt CT 14.01

bis 1.000 bar (14.500 psi)

0,2 % der Spanne

bis 1.000 bar (14.500 psi)

0,2 % der Spanne

bis 6.000 bar (85.000 psi)

bis 0,025 % der Spanne

38 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 39

5. Inbetriebnahme, Betrieb

ProzessKalibrator Typ CPH6000

Messbereiche

Genauigkeit

bis 8.000 bar (115.000 psi)

bis 0,025 % der Spanne

Weitere technische Daten siehe Datenblatt CT 15.01

5.10 Einsatz mit Kalibriersoftware WIKA-Cal

Kalibriersoftware WIKA-Cal zur Erstellung von

Kalibrierzeugnissen oder Loggerprotokollen

Technische Daten siehe Datenblatt CT 95.10

5.11 Lieferbarer Kalibrierkoffer

Bestehend aus:

■

Bereitschaftskoffer aus Kunststoff mit

Schaumstoffeinlage

■

Präzisions-Digitalmanometer Typ CPG1500

■

Hydraulische Handprüfpumpe Typ CPP700-H

DE

14209601.01 06/2017 EN/DE/FR/ES/IT

39WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 40

6. Störungen

6. Störungen

Personal: Fachpersonal

Schutzausrüstung: Schutzbrille

Werkzeuge: Spritze mit spezieller Nadel für die Befüllung oder Reinigung des

Flüssigkeitsreservoirs

DE

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Können Störungen mit Hilfe der aufgeführten Maßnahmen nicht beseitigt

werden, Handprüfpumpe unverzüglich außer Betrieb setzen.

▶

Sicherstellen, dass kein Druck bzw. Signal mehr anliegt und gegen

versehentliche Inbetriebnahme schützen.

▶

Kontakt mit dem Hersteller aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel

8.2 „Rücksendung“ beachten.

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der

Betriebsanleitung.

Störungen Ursachen Maßnahmen

Handprüfpumpe geht

schwergängig

Instabiler

Ausgangsdruck

System liefert Druck,

aber der Druck fällt auf

Null ab.

Handprüfpumpe längere Zeit

nicht benutzt

Ablassventil ist offen Ablassventil schließen

Falsche Dichtung Korrekte Dichtung einsetzen

Falsch sitzende Dichtung Dichtung richtig einsetzen

Dichtung defekt Dichtung durch eine neue

Falscher Adapter oder nicht

korrekt montiert

Wenn die Ursache nicht gefunden

werden kann.

Ablassventil ist offen Ablassventil schließen

Der erste Hub ist etwas

schwergängiger. Dieser Effekt

ist bei weiterem Betrieb wieder

verschwunden.

ersetzen

Verwendete Adapter an der

Prüflingsseite überprüfen und

korrekt montieren

Handprüfpumpe zur

Untersuchung zurückschicken

40 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 41

6. Störungen / 7. Wartung und Reinigung

Störungen Ursachen Maßnahmen

System liefert Druck,

aber der Druck fällt auf

Null ab.

System liefert Druck,

aber der Druck fällt auf

einen niederen Wert

ab und bleibt dann

stabil.

Vorgehensweise nicht korrekt. Sicherstellen, dass die

korrekte Vorgehensweise

angewandt wird (siehe Kapitel

5.7 „Druckerzeugung“)

Wenn die Ursache nicht gefunden

werden kann.

Nicht genügend Flüssigkeit in der

Handprüfpumpe.

Luft im System Flüssigkeitsreservoir mit der

Wenn die Ursache nicht gefunden

werden kann.

Interne Beschädigung Handprüfpumpe zur

Vorgehensweise nicht korrekt. Sicherstellen, dass die

Handprüfpumpe zur

Untersuchung zurückschicken

Flüssigkeitsreservoir mit der

korrekten Flüssigkeit füllen

(siehe Kapitel 5.4 „Befüllen

der Handprüfpumpe mit

Druckübertragungsmedium“)

korrekten Flüssigkeit füllen

(siehe Kapitel 5.4 „Befüllen

der Handprüfpumpe mit

Druckübertragungsmedium“)

Handprüfpumpe zur

Untersuchung zurückschicken

Untersuchung zurückschicken

korrekte Vorgehensweise

angewandt wird (siehe Kapitel

5.7 „Druckerzeugung“)

DE

7. Wartung und Reinigung

Personal: Fachpersonal

Schutzausrüstung: Schutzbrille

Werkzeuge: Spritze mit spezieller Nadel für die Befüllung oder Reinigung des

Flüssigkeitsreservoirs

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der

Betriebsanleitung.

7.1 Wartung

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

Nur Originalteile verwenden (siehe Kapitel 10 „Zubehör“).

14209601.01 06/2017 EN/DE/FR/ES/IT

41WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 42

7. Wartung und Reinigung

▶

Vor dem Adaptieren von Referenzgerät und Prüfling die Dichtungen in den beiden

Anschlüssen auf richtigen Sitz und Verschleiß prüfen.

▶

Bei Bedarf Dichtungen austauschen.

7.2 Reinigung

DE

1. Vor der Reinigung das Gerät ordnungsgemäß von der Druckversorgung trennen.

2. Notwendige Schutzausrüstung verwenden.

3. Das Gerät mit einem feuchten Tuch reinigen.

4. Ausgebautes Gerät spülen bzw. säubern, um Personen und Umwelt vor Gefährdung

durch anhaftende Messstoffreste zu schützen.

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Eine unsachgemäße Reinigung führt zu Körperverletzungen, Sach- und

Umweltschäden. Messstoffreste im ausgebauten Gerät können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Reinigungsvorgang wie folgt beschrieben durchführen.

VORSICHT!

Beschädigung des Gerätes

Eine unsachgemäße Reinigung führt zur Beschädigung des Gerätes!

▶

Keine aggressiven Reinigungsmittel verwenden.

▶

Keine harten und spitzen Gegenstände zur Reinigung verwenden.

▶

Das Flüssigkeitsreservoir nur mit Wasser oder sanften Reinigungsmitteln

reinigen.

Durch die Anwendung von Alkohol, Spiritus, Aceton oder Benzole kann es

zu Rissbildungen im Behältermaterial und zur Beschädigung des Behälters

kommen.

Reinigung des Flüssigkeitsreservoirs

Reinigen des Flüssigkeitsreservoirs siehe Kapitel 5.5 „Austauschen von

Druckübertragungsmedium“.

42 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 43

8. Demontage, Rücksendung und Entsorgung

8. Demontage, Rücksendung und Entsorgung

Personal: Fachpersonal

Schutzausrüstung: Schutzbrille

Werkzeuge: Spritze mit spezieller Nadel für die Befüllung oder Reinigung des

Flüssigkeitsreservoirs

8.1 Demontage

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch Messstoffreste

Bei der Demontage besteht Gefahr durch aggressive Medien und hohe

Drücke.

▶

Vor der Einlagerung das ausgebaute Gerät (nach Betrieb) spülen bzw.

säubern, um Personen und Umwelt vor Gefährdung durch anhaftende

Messstoffreste zu schützen.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.5 „Persönliche

Schutzausrüstung“).

▶

Angaben im Sicherheitsdatenblatt für den entsprechenden Messstoff

beachten.

▶

Messanordnung/Prüf- und Kalibrieraufbauten im drucklosen Zustand

demontieren.

DE

Das Referenzgerät oder den Prüfling erst demontieren, wenn das

2

Druckablassventil

Prüfpumpe befindet.

1. Zur Druckreduzierung zunächst das Feinregulierventil

Uhrzeigersinn drehen.

2. Vorsichtig das Druckablassventil

dem Uhrzeigersinn herausdrehen.

Druck wird reduziert und es befindet sich anschließend kein Druck mehr auf der

⇒

Handprüfpumpe.

3. Das Referenz-Druckmessgerät und/oder den Prüfling demontieren.

4. Verwendete Dichtungen entfernen.

5. Ggf. verwendeten Adapter von der Handprüfpumpe demontieren.

6. Den Prüflingsschlauch

7. Nachdem der Druck abgebaut wurde das Druckablassventil

Uhrzeigersinn wieder schließen.

14209601.01 06/2017 EN/DE/FR/ES/IT

geöffnet ist und sich dadurch kein Druck mehr in der

4

entgegen dem

2

öffnen, dabei nur max. eine Umdrehung entgegen

1

von der Pumpe abdrehen.

2

durch Drehen im

43WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 44

8. Demontage, Rücksendung und Entsorgung

Flüssigkeitsreservoir leeren

7

8. Das Flüssigkeitsreservoir

herausdrehen.

9. Das Druckübertragungsmedium mit Hilfe der Spritze und speziellen Nadel aus der

Pumpe herausziehen.

10. Das Flüssigkeitsreservoir mit Wasser oder sanften Reinigungsmitteln spülen.

Hierfür eine Spritze speziell nur für die Reinigung verwenden.

⇒

öffnen. Hierzu die Verschlussschraube 3

DE

Durch die Anwendung von Alkohol, Spiritus, Aceton oder Benzole kann es

zu Rissbildungen im Behältermaterial und zur Beschädigung des Behälters

kommen.

3

11. Verschlussschraube

Bei Verwendung von Wasser als Prüf- bzw. Kalibriermedium muss die

Prüfpumpe nach JEDER Benutzung entleert werden.

8.2 Rücksendung

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoffen (Säuren, Laugen,

Lösungen, etc.) sein und sind daher vor der Rücksendung zu reinigen.

wieder eindrehen.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch Messstoffreste

Messstoffreste an der Handprüfpumpe können zur Gefährdung von

Personen, Umwelt und Einrichtung führen.

▶

Bei Gefahrenstoffen das Sicherheitsdatenblatt für den entsprechenden

Messstoff beilegen.

▶

Gerät reinigen, siehe Kapitel 7.2 „Reinigung“.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete

Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren. Zu allen Seiten der

Transportverpackung gleichmäßig dämmen.

2. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

3. Sendung als Transport eines hochempfindlichen Messgerätes kennzeichnen.

44 WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

14209601.01 06/2017 EN/DE/FR/ES/IT

Page 45

8. Demontage, Rücksendung und ... / 9. Technische Daten

Hinweise zur Rücksendung befinden sich in der Rubrik „Service“ auf unserer

lokalen Internetseite.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezifischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

Entsorgen Sie die Hydraulikflüssigkeiten wie im Sicherheitsdatenblatt

beschrieben.

Das aktuelle Sicherheitsdatenblatt befindet sich unter www.wika.de auf der

Produktseite des jeweiligen Produkts.

9. Technische Daten

Technische Daten Typ CPP700-H Typ CPP1000-H

Druckbereich 0 ... 700 bar

(0 … 10.000 psi)

Druckübertragungsmedium Hydraulikflüssigkeiten auf Mineralölbasis oder einfach

destilliertes Wasser

(Nicht geeignet sind wasserbasierende Hydraulikflüssigkeiten)

Flüssigkeitsreservoir 200 cm³

Druckanschlüsse

Für Referenzgerät G ½ Innengewinde, freilaufend.

Dieser Anschluss kann mittels eines Inbusschlüssels demontiert

werden. Dann steht ein Innengewinde G ⅜ zur Verfügung.

Für Prüfling G ¼ Innengewinde am

Prüfanschlussschlauch,

Länge 1 m (3,28 ft), System

Minimess

Feineinstellung Feinregulierventil / Volumenvariator

Material anodisiertes Aluminium, Messing, CrNi-Stahl, ABS

Dichtungen FKM und NBR (Standard)

1) Andere Druckübertragungsmedien auf Anfrage.

®

1620

1)

0 … 1.000 bar

(0 … 14.500 psi)

G ¼ Innengewinde freilaufend

am Prüfanschlussschlauch,

Länge 1 m (3,28 ft)

DE

14209601.01 06/2017 EN/DE/FR/ES/IT

45WIKA Betriebsanleitung, Typen CPP700-H und CPP1000-H

Page 46

9. Technische Daten / 10. Zubehör

Technische Daten Typ CPP700-H Typ CPP1000-H

Abmessungen (L x B x H) 280 x 170 x 120 mm

(11,0 x 6,7 x 4,7 in)

Gewicht 1,9 kg

(4,2 lbs)

1) Andere Druckübertragungsmedien auf Anfrage.

DE

Zulassungen und Zertifikate siehe Internetseite

Weitere technische Daten siehe WIKA-Datenblatt CT 91.07 und Bestellunterlagen.

10. Zubehör

Adapterset

■