Page 1

Operating Instructions

Betriebsanleitung

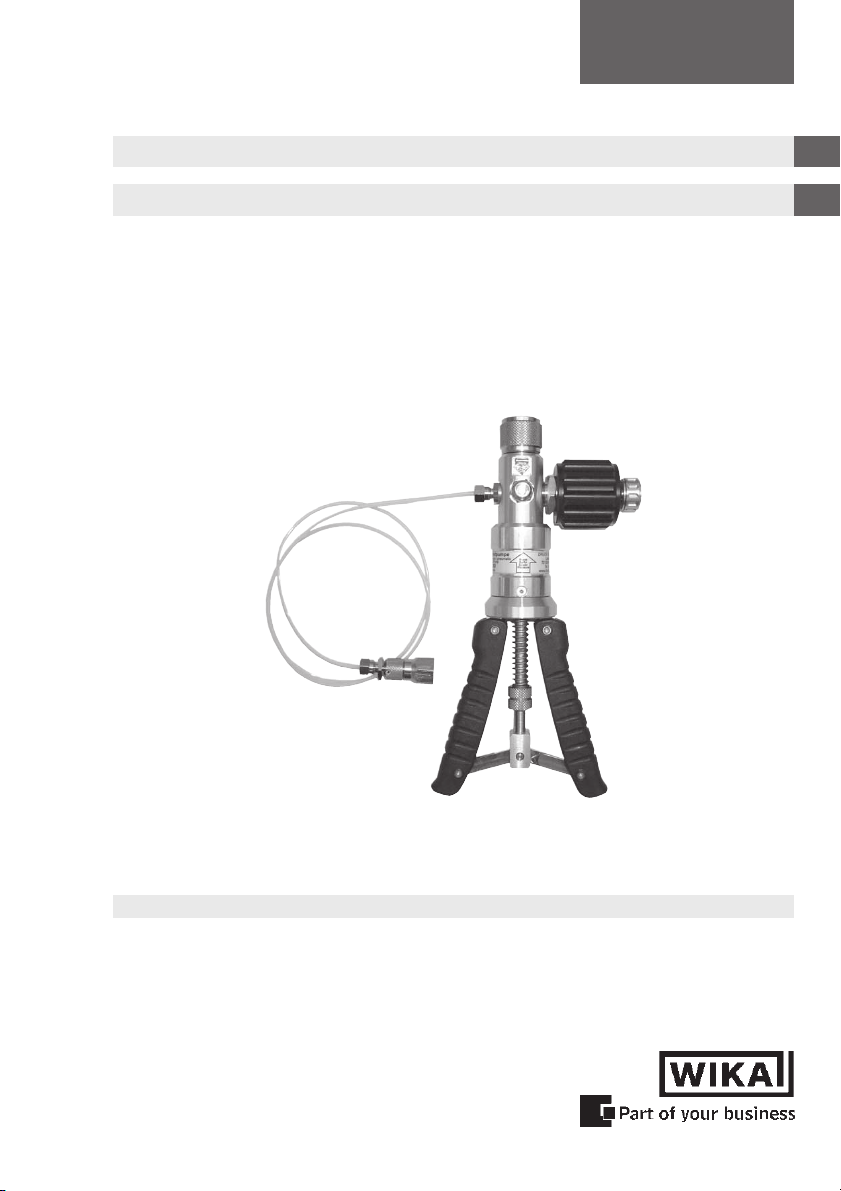

Test Pump

Prüfpumpe

GB

D

Typ CPP30

Test Pump CPP30

Page 2

Test Pump

CPP30

GB

Operating Instructions Test Pump Page 3 - 12

D

Betriebsanleitung Prüfpumpe Seite 13 - 22

WIKA Betriebsanleitung Hand-Held Thermometer2

WIKA Operating Instructions Test Pump

11044608.02 07/2006 D/GB

Page 3

Test Pump

CPP30

Contents

Contents

1. Safety Instructions 4

2. Product Description 4

3. Mounting Instructions 5

4. Operation of the Test Pump 6

4.1 Generation of pressure 6

4.2 Generation of vacuum 8

5. Maintenance Instructions 10

6. Cause of fault 10

7. Technical Data 11

8. Order Data / Accessories 11

GB

Information

This symbol provides you with information, notes and tips.

Warning!

This Symbol warns you against actions that can cause

damage to persons or to the instrument.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Hand-Held Thermometer 3

WIKA Operating Instructions Test Pump

Page 4

Test Pump

CPP30

GB

1. Safety Instructions

Read these operating instructions carefully prior to operating

the pneumatic hand test pump CPP30. The pressure inside the

pump can be extremely high. Ensure that all pressure connections have been established correctly.

2. Product Description

Test pumps are used to generate pressures for checking, adjusting

and calibrating mechanical and electronic pressure measuring

instruments by comparative measurements. These pressure tests

may be carried out in laboratories, workshop or on site at the

measuring point.

If the instrument to be tested and a sufficiently accurate referencemeasuring instrument are connected up to the test pump, the

same pressure is applied to the two measuring instruments when

the pump is operated. By comparing the two measured values at

random pressure values, the accuracy can be verified or the

Instrument under test can be adjusted.

Despite its compact dimensions, the hand test pump model

CPP30 is easy to operate and allows for exact generation of the

required test pressures; a change-over switch enables the generation of vacuum as well. The pump is fitted with a fine adjustment

valve for the precise adjustment of pressures. The reference

instrument is screwed directly on to the top of the pump and the

unit under test is connected by means of the connection tube

incorporating an adapter 1/4" BSP female thread, contained in the

scope of delivery.

WIKA Betriebsanleitung Hand-Held Thermometer4

WIKA Operating Instructions Test Pump

11044608.02 07/2006 D/GB

Page 5

Test Pump

CPP30

3. Mounting Instructions

The reference instrument is fitted to the upper side of the hand

test pump CPP30. Fingertight fastening of the reference instrument with the knurled nut is sufficient. The reference instrument

is sealed by the integral O-ring sealing gasket.

The unit under test is mounted to the end of the flexible tube.

Please use a suitable sealing gasket from the adapter set

purchased separately as an accessory. Tighten the connector to

prevent any leaks to a maximum torque of 15 Nm.

In order to adapt the different connection threads of the unit

under test, the test tube can be fitted with different adapters

from the optional set of adapters.

Do not use teflon tape, this may damage your test pump.

You can unscrew the tube and also directly attach the test

specimen with the same adapter to the pump (to minimize

volume of your test system, for more easy operating the

CPP30 pump).

GB

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Hand-Held Thermometer 5

WIKA Operating Instructions Test Pump

Page 6

Test Pump

CPP30

GB

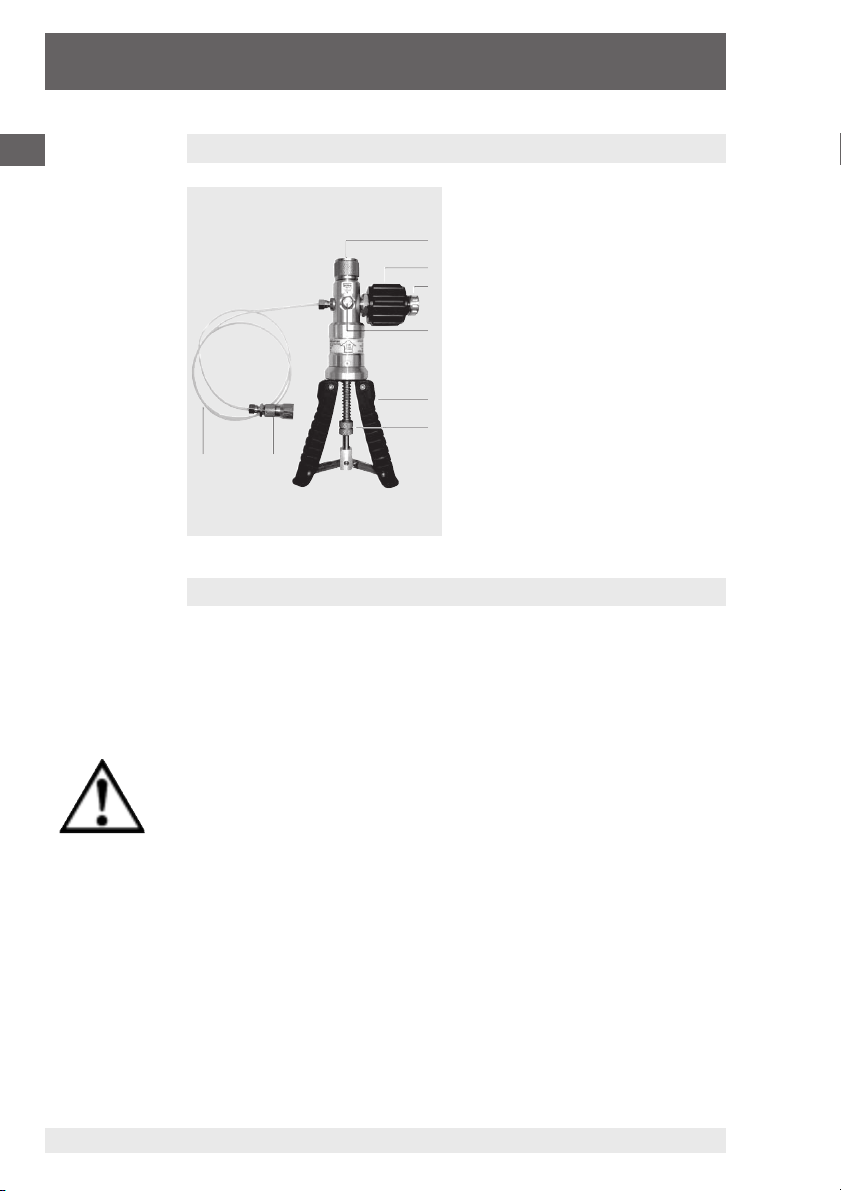

4. Operation of the Test Pump

(1) Pressure connector for refer-

ence instrument, G ½“

1

2

3

female rotating

(2) Fine adjustment valve

(3) Pressure relief valve

(4) Change-over switch for

4

pressure/vacuum generation

(5) Handles

(6) Adjustable knurled nut for

5

6

8 7

the adjustment of the

delivery rate of the pump

(7) Pressure connection for test

specimen, G ¼ “

(8) Test tube length 1 m

4.1 Generation of pressure

First, check wether the change-over valve (4) has to be actu-

ated (see sticker on the device). For this purpose use a pen or a

small screw-driver. The encasement of the switch is intended to

help prevent unintentional actuation.

Never actuate the change-over valve (4) when the hand test

pump is under pressure or vacuum! Actuate the change-over

valve only when the relief valve is open.

Please make sure that the pressure relief valve (3) is not closed

completely.

Turn the fine adjustment valve (2) anticlockwise up to the end

(smooth “stop” can be felt).

Carefully turn in the pressure relief valve (3) until the valve

closes. You will not notice any “hard stop”.

WIKA Betriebsanleitung Hand-Held Thermometer6

WIKA Operating Instructions Test Pump

11044608.02 07/2006 D/GB

Page 7

Test Pump

CPP30

Operate the hand pump (5) until the approximate pressure has

been reached, but max. to 20 to 25 bar.

Turn the fine adjustment valve clockwise to increase the

pressure or anti-clockwise to decrease the pressure until the

requested test pressure has been reached precisely (to be read

on the reference measuring instrument).

If you have prepared at previous step a pressure of about

20 to 25 bar, with the fine adjustment valve (2) you can increase

the pressure now to 35 bar (up to 40 bar, depending on the volume

of the measuring circuit).

After increasing the pressure, the reading may slightly drop again

for about 30 seconds, which is caused by thermodynamic effects,

the tube connection and the sealing gaskets. If the pressure drop

does not come to a standstill, check the measuring circuit for

tightness.

Due to the low volume of each compression stroke of the hand

test pump, only small volume test specimens should be tested.

A pressure reduction is achieved by turning the fine adjustment

valve (2) counter-clockwise first and then by carefully opening

the relief valve (3).

GB

Never actuate the change-over valve when the hand test pump

is under pressure or vacuum! Actuate the change-over valve

only when the relief valve is open.

Remove the reference instrument or the test specimen only

when the relief valve (3) is open and no pressure is in the hand

test pump any more.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Hand-Held Thermometer 7

WIKA Operating Instructions Test Pump

Page 8

Test Pump

CPP30

GB

4.2 Generation of vacuum

First, check wether the change-over valve (4) has to be actu-

ated (see sticker on the device). For this purpose use a pen or a

small screw-driver. The encasement of the switch is intended to

help prevent unintentional actuation.

Never actuate the change-over valve (4) when the hand test

pump is under pressure or vacuum! Actuate the change-over

valve only when the relief valve is open.

Please make sure that the pressure relief valve (3) is not closed

completely.

Turn the fine adjustment valve (2) clockwise up to the end

(“stop” can be felt).

Make sure that the adjustable knurled nut and counter nut (6)

are in such a position that the spring visible above the nut has

some clearance when the handles (5) are pressed together.

Carefully turn in the pressure relief valve (3) until the valve

closes. You will not notice any “hard stop”.

Operate the handles (5) smoothly and slowly until a vacuum of

max. -0.9 bar is reached.

Turn the fine adjustment valve (2) anti-clockwise to increase the

vacuum up to -0.95 bar. Turn this valve for fine adjustment.

After increasing the vacuum, the reading may slightly increase

again for about 30 seconds, which is caused by thermodynamic

effects, the tube connection and the sealing gaskets. If the

vacuum drop does not come to a standstill, check the measuring

circuit for tightness.

Due to the low volume of each compression stroke of the hand

test pump, only small volume test specimens should be tested.

WIKA Betriebsanleitung Hand-Held Thermometer8

WIKA Operating Instructions Test Pump

11044608.02 07/2006 D/GB

Page 9

Test Pump

CPP30

A vacuum reduction is achieved by carefully opening the relief

valve (3)

Never actuate the change-over valve when the hand test pump

is under pressure or vacuum! Actuate the change-over valve

only when the relief valve is open.

Remove the reference instrument or the test specimen only

when the relief valve (3) is open and no vacuum is in the hand

test pump any more.

For a maximum performance of

the CPP30 pump, please make

sure that the adjustable knurled

nut with counter nut (6) is

adjusted to such a position that

the spring visible above the nut

gets some small clearance.

If you operate with a reference

or test item with a small

pressure range, you can reduce

the performance of the pump

by turning the adjustable

knurled nut and counter nut (6)

clockwise (upwards). This

reduces the pressure you get

by every handle-stroke.

Overpressure protective device

Afterwards turn the knurled nut

with counter nut (6) anticlockwise (downwards) to

achieve maximum performance

again.

GB

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Hand-Held Thermometer 9

WIKA Operating Instructions Test Pump

Page 10

Test Pump

CPP30

GB

5. Maintenance Instructions

Prior to connecting the reference instrument and the test specimen, the sealing gaskets in the two connectors should be checked

for correct position and wear, and should be replaced, if and when

necessary.

A service kit, consisting of spare sealing gaskets and o-rings, is

available as an accessory.

The hand test pump CPP30 must not be soiled, and in particular it

must not get into contact with fluid or aggressive media.

6. Cause of fault

If the pressure or vacuum cannot be generated correctly or if

the set pressure or vacuum does not stay stable, this is likely to

be caused by the incorrectly positioned or selected sealing

gaskets. Please also check whether any adapters used on the

test specimen side have been tightened sufficiently to eliminate

leaks.

Before assuming there is a leak in the hand test pump: First of

all, check if the relief valve is closed and if the pressure /

vacuum change-over switch is correctly positioned and has not

come to rest in a "centre position".

If the hand test pump has not been used for a longer period of

time, the first lift may be somewhat sluggish. This effect will

disappear again during further operation.

By no means apply any force to the operating elements of the

hand test pump.

Never connect an external pressure supply system to the test

pump.

WIKA Betriebsanleitung Hand-Held Thermometer10

WIKA Operating Instructions Test Pump

11044608.02 07/2006 D/GB

Page 11

Test Pump

CPP30

7. Technical Data

Pressure range -0.95 ... +35.0 bar

Medium air

Pressure connections G ½“ female rotating for reference

instrument, G ¼“ female for unit

under test

Pressure fine adjustment fine adjustment valve

Overpressure protection adjustable by means of knurled

nut

Material chromium-plated brass, ABS and

anodised aluminium

Dimensions 220 (L) x 105 (W) x 63 (D) mm

Weight 0.51 kg

Standard accessories Test specimen connection tube,

length1 m

8. Order Data / Accessories

Hand test pump CPP30 Order No.: 12139671

Plastic case with foams for CPP30 Order No.: 12139573

Dimensions in mm: (W/H/D) 395 x 295

x 106

Set of adapters and set of seals for Order No.: 12139689

CPP30 for test item connection G ¼“

male on G E“, G F“ and G ½“ female

Set of adapters and set of seals for Order No.: 12140422

CPP30 for test item connection G ¼“

male on M 12 x 1.5, M 20 x 1.5 and

Minimess

®

Set of adapters and set of seals for Order No.: 12139701

CPP30 for test item connection G ¼“

male on E“ NPT, ¼“ NPT, F“ NPT and

½“ NPT female

Service kit for hand test pump CPP30 Order No.: 12139786

with various O-rings and seals

GB

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Hand-Held Thermometer 11

WIKA Operating Instructions Test Pump

Page 12

Test Pump

CPP30

For your notes

GB

WIKA Betriebsanleitung Hand-Held Thermometer12

WIKA Operating Instructions Test Pump

11044608.02 07/2006 D/GB

Page 13

Prüfpumpe

CPP30

Inhalt

Inhalt

1. Sicherheitshinweise 14

2. Produktbeschreibung 14

3. Montagehinweise 15

4. Bedienung der Prüfpumpe 16

4.1 Druckerzeugung 16

4.2 Vakuumerzeugung 18

5. Wartungshinweise 20

6. Fehlerursache 20

7. Technische Daten 21

8. Bestelldaten / Zubehör 21

D

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise oder Tipps.

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

Personen oder am Gerät verursachen können.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

13

Page 14

Prüfpumpe

CPP30

1. Sicherheitshinweise

D

Lesen Sie diese Bedienungsanleitung sorgfältig, bevor Sie die

pneumatische Handprüfpumpe CPP30 einsetzen. Der Druck im

Inneren der Pumpe kann extrem hoch sein. Stellen Sie sicher,

dass alle Druckanschlüsse korrekt durchgeführt wurden.

2. Produktbeschreibung

Prüfpumpen dienen zur Druckerzeugung für die Überprüfung,

Justage und Kalibrierung von mechanischen und elektronischen

Druckmessgeräten durch Vergleichsmessungen. Diese Druckprüfungen können stationär in Labor, Werkstatt oder vor Ort an der

Messstelle stattfinden.

Schließt man das zu prüfende Gerät und ein hinreichend genaues

Referenz-Messgerät an der Prüfpumpe an, so wirkt bei Betätigung

der Pumpe auf beide Messgeräte der gleiche Druck. Durch

Vergleich der beiden Messwerte bei beliebigen Druckwerten kann

eine Überprüfung der Genauigkeit bzw. eine Justage des zu

prüfenden Druckmessgerätes erfolgen.

Die Handprüfpumpe Typ CPP30 ermöglicht trotz sehr kompakten

Abmessungen eine einfache und exakte Prüfdruckerzeugung mit

Umschaltung auf Vakuumerzeugung. Für die präzise Einstellung

zur genauen Vergleichsprüfung besitzt die Pumpe ein Feinregulierventil. Das Referenzgerät wird direkt oben auf die Pumpe aufgeschraubt und der Prüfling wird über einen im Lieferumfang enthaltenen Anschlussschlauch adaptiert.

14

WIKA Betriebsanleitung Prüfpumpe

11044608.02 07/2006 D/GB

Page 15

Prüfpumpe

CPP30

3. Montagehinweis

Das Referenz-Messgerät wird an die Oberseite der Handprüf-

pumpe montiert. Es genügt ein handfestes Anziehen der

Rändelmutter. Abgedichtet wird das Druckmessgerät über den

am Referenzgeräteanschluss (1) integrierten O-Ring.

Der Prüfling wird an das Ende des flexiblen Schlauches mon-

tiert. Hierzu verwenden Sie bitte eine passende Dichtung aus

dem Lieferumfang des als Zubehör erhältlichen Adaptersets im

Koffer. Ziehen Sie den Anschluss fest an, um Undichtigkeiten zu

vermeiden. Die Adapter dürfen mit einem maximalen Drehmoment von 15 Nm festgezogen werden.

Um unterschiedliche Anschlussgewinde der Prüflinge zu

adaptieren, sind als Zubehör Adaptersätze für metrische Gewinde, Rohrgewinde und NPT-Gewinde erhältlich.

Bei Verwendung der Handprüfpumpe CPP30 darf der Referenzoder Prüflinganschluss niemals mit Teflonband abgedichtet

werden. Teflonpartikel können in die Pumpe eindringen und

die Funktion stark beeinträchtigen.

Sie können den Schlauch auch von der Pumpe abdrehen und

über einen Adapter aus den optionalen Adaptersätzen einen

geeigneten Prüfling direkt an den Pumpenkörper montieren.

Hierdurch wird das Volumen spürbar verringert und die Prüfdruckerzeugung erleichtert. Die Adapter aus den Adaptersätzen

lassen sich sowohl am Prüflingsschlauch als auch direkt am

Pumpenkörper montieren.

D

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

15

Page 16

Prüfpumpe

CPP30

4. Bedienung der Prüfpumpe

D

(1) Druckanschluss für Referenz-

1

2

3

gerät, G ½“ Innengewinde

(2) Feinregulierventil

(3) Druckablassventil

(4) Umschaltung Druck-/Vaku-

4

umerzeugung

(5) Pumpengriffe

(6) Verstellbare Rändelmutter zur

5

6

8 7

Einstellung der Pumpleistung

(7) Druckanschluss für Prüfling,

G ¼“ Innengewinde

(8) Schlauchleitung für Prüflings-

anschluss, Länge 1 m

4.1 Druckerzeugung

Vor einer Druckerzeugung muss ggf. das Umschaltventil (4)

betätigt werden (siehe Aufkleber an der Pumpe). Verwenden Sie

hierzu einen Stift oder einen kleinen Schraubendreher. Die

Umhüllung des Umschalters soll unbeabsichtigte Betätigung

vermeiden helfen.

Betätigen Sie das Umschaltventil (4) niemals wenn die Handprüfpumpe unter Druck oder Vakuum steht! Schalten Sie nur

bei geöffnetem Ablassventil (3) um.

16

Vergewissern Sie sich, dass das Druckablassventil (3) nicht

ganz geschlossen ist.

Drehen Sie das Feinregulierventil (2) durch Drehen entgegen der

Uhrzeigerlaufrichtung fast ganz heraus, bis ein leichter Anschlag

zu spüren ist (das Gewinde wird kurz vor dem “Anschlag” sehr

leichtgängig).

Drehen Sie das Druckablassventil (3) vorsichtig im Uhrzeiger

sinn ein, bis das Ventil schließt. Es ist hierbei kein "harter Anschlag" spürbar.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

Page 17

Prüfpumpe

CPP30

Pumpen Sie an der Handpumpe (5), bis der gewünschte Druck in

etwa erreicht ist, in der Regel jedoch nicht mehr als 20 - 25 bar.

Drehen Sie das Feinregulierventil (2) im Uhrzeigersinn, um den

Druck zu erhöhen, oder entgegen dem Uhrzeigersinn, um den

Druck zu verringern, bis der gewünschte Prüfdruck genau

erreicht ist (abzulesen am Referenz-Messgerät).

Wenn Sie mit den Handgriffen (5) einen Vordruck von ca. 20 bar

erreicht haben, können Sie mit dem Feinregulierventil den Druck

bis 35 bar erhöhen (abhängig vom Volumen des Messkreises bis

über 40 bar).

Nach Erhöhung des Druckes kann die Anzeige für etwa 30 Sekunden wieder leicht absinken. Thermodynamische Effekte, die

Schlauchverbindung und die Dichtungen sind hierfür die Ursache.

Regeln sie den Prüfdruck mit dem Feinregulierventil (2) entsprechend nach. Kommt der Druckabfall nicht zum Stillstand, ist der

Messkreis auf Dichtheit zu prüfen.

Aufgrund des geringen Hubes der Handprüfpumpe sollten nur

Prüflinge mit kleinem Volumen gestestet werden.

D

Eine Druckreduzierung erreichen Sie zunächst durch Drehen

Betätigen Sie das Umschaltventil niemals wenn die Handprüfpumpe unter Druck oder Vakuum steht! Schalten Sie nur bei

geöffnetem Ablassventil um.

Demontieren Sie das Referenz-Messgerät oder den Prüfling

erst, wenn das Ablassventil geöffnet ist und sich dadurch kein

Druck mehr in der Handprüfpumpe befindet.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

des Feinregulierventils (2) entgegen dem Uhrzeigersinn und

dann durch vorsichtiges Drehen am Ablassventil (3).

17

Page 18

Prüfpumpe

CPP30

4.2 Vakuumerzeugung

D

Vor einer Vakuumerzeugung muss ggf. das Umschaltventil (4)

betätigt werden (siehe Aufkleber an der Pumpe). Verwenden Sie

hierzu einen Stift oder einen kleinen Schraubendreher. Die Umhüllung des Umschalters soll unbeabsichtigte Betätigung vermeiden helfen.

Betätigen Sie das Umschaltventil (4) niemals wenn die Handprüfpumpe unter Druck oder Vakuum steht! Schalten Sie nur

bei geöffnetem Ablassventil (3) um.

Vergewissern Sie sich, dass das Ablassventil (3) nicht ganz

geschlossen ist.

Drehen Sie das Feinregulierventil (2) durch Drehen im Uhrzeiger-

sinn fast ganz hinein, bis ein leichter Anschlag zu spüren ist.

Vergewissern Sie sich, dass Rändel- und Kontermutter (6) so ein-

gestellt sind, dass bei zusammengedrückten Handgriffen (5) die

oberhalb von (6) sichtbare Feder gerade noch etwas Spiel hat.

Drehen Sie das Ablassventil (3) vorsichtig im Uhrzeigersinn ein,

bis das Ventil schließt (dabei ist kein “harter Anschlag” zu

spüren).

18

Pumpen Sie vorsichtig und langsam an der Handpumpe (5),

max. bis etwa -0,9 bar Vakuum erreicht sind.

Drehen Sie das Feinregulierventil (2) entgegen dem Uhrzeiger-

sinn heraus, hierdurch können Sie das erzeugte Vakuum auf

-0,95 bar erhöhen bzw. punktgenau einstellen.

Nach Erhöhung des Vakuums kann die Anzeige für etwa 30 Sekunden wieder leicht ansteigen. Thermodynamische Effekte, die

Schlauchverbindung und die Dichtungen sind hierfür die Ursache.

Regeln Sie den Prüfdruck mit der Handpumpe (5) entsprechend

vorsichtig und langsam nach. Kommt der Druckanstieg nicht zum

Stillstand, so ist der Messkreis auf Dichtheit zu prüfen.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

Page 19

Prüfpumpe

CPP30

Aufgrund des geringen Hubes der Kalibrier-Handprüfpumpe sollten

nur Prüflinge mit kleinem Volumen getestet werden.

Eine Vakuumreduzierung erreichen Sie durch vorsichtiges und

feinfühliges Öffnen des Ablassventils (3).

Betätigen Sie das Umschaltventil niemals wenn die Handprüfpumpe unter Druck oder Vakuum steht! Schalten Sie nur bei

geöffnetem Ablassventil um.

Demontieren Sie das Referenz-Messgerät oder den Prüfling

erst, wenn das Ablassventil geöffnet ist und sich dadurch kein

Vakuum mehr in der Handprüfpumpe befindet.

Um einen maximalen Wirkungsgrad zu erreichen, sollte

die Feder oberhalb der Rändelmutter mit Kontermutter (6)

gerade etwas Luft ("Spiel")

haben. Wenn Sie Prüflinge bzw.

Referenzen mit kleinen

Messbereichen prüfen, können

Sie durch Drehen von Rändelmutter und Kontermutter (6)

nach oben den Hubweg

verkürzen, dadurch wird

weniger Druck bzw. Vakuum je

Zusammendrücken der Handgriffe erreicht und die Gefahr

eines versehentlichen

Überdruck-Schutzeinrichtung

Überdrückens minimiert.

Stellen Sie hinterher Rändelmutter und Kontermutter (6)

wieder auf den optimalen

Wirkungsgrad ein.

D

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

19

Page 20

Prüfpumpe

CPP30

5. Wartungshinweis

D

Vor dem Adaptieren von Referenz-Gerät und Prüfling sollten die

Dichtungen in den beiden Anschlüssen auf richtigen Sitz und

Verschleiß überprüft und bei Bedarf ausgetauscht werden.

Ein Wartungssatz bestehend aus O-Ringen und Dichtungen ist als

Zubehör erhältlich.

Die Handprüfpumpe darf nicht verschmutzt werden und vor allem

nicht mit feuchten, flüssigen oder gar aggressiven Medien in

Berührung kommen.

6. Fehlerursachen

Wenn kein Druck oder Vakuum richtig aufgebaut werden kann

oder wenn der eingestellte Druck oder Vakuum nicht stabil

bleibt, so liegt die Ursache zumeist bei nicht richtig eingesetzten oder falsch ausgewählten Dichtungen. Prüfen Sie auch, ob

eventuell verwendete Adapter an der Prüflingsseite fest

angezogen sind.

Bevor Sie eine Undichtigkeit in der Handprüfpumpe vermuten:

Prüfen Sie bitte zunächst, ob das Ablassventil geschlossen ist

und ob der Druck-/Vakuum-Umschalter eindeutig geschaltet ist

und sich nicht ein einer "Mittelstellung" befindet. (Umschaltknopfoberfläche und Innenhülse befinden sich auf gleicher

Höhe und bilden eine sichtbar plane Fläche.)

20

Wenn die Handprüfpumpe längere Zeit nicht benutzt wurde,

kann der erste Hub etwas schwergängig sein. Dieser Effekt ist

danach bei weiterem Betrieb wieder verschwunden.

Vermeiden Sie unbedingt jegliche Gewalteinwirkung auf die

Bedienungselemente der Handprüfpumpe.

Schließen Sie niemals eine externe Druckversorgung an die

Prüfpumpe an.

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

Page 21

Prüfpumpe

CPP30

7. Technische Daten

Druckbereich -0,95 ... +35,0 bar

Medium Luft

Druckanschlüsse G ½“ Innengewinde freilaufend für

Referenz

G ¼“ Innengewinde für Prüfling

am Schlauch

Druckfeineinstellung Feinregulierventil

Überdruckschutz mittels Rändelmutter einstellbar

Material Messing verchromt, anodisiertes

Aluminium, ABS

Abmessungen 220 (L) x 105 (B) x 63 (T) mm

Masse 0,51 kg

Standardzubehör Prüflinganschlussschlauch mit

G ¼“ Anschluss, 1 m

8. Bestelldaten / Zubehör

Handprüfpumpe CPP30 Best.-Nr.: 12139671

Kunststoffkoffer inkl. Schaumstoffein- Best.-Nr.: 12139573

lage mit Aussparungen für CPP30

Abmessungen in mm: (B/H/T) 395 x 295

x 106

Adapter- und Dichtungssatz für CPP30 Best.-Nr.: 12139689

Prüflingsschlauch G ¼“ außen auf

G E“, G F“ und G ½“ innen

Adapter- und Dichtungssatz für CPP30 Best.-Nr.: 12140422

Prüflingsschlauch G ¼“ außen auf

M 12 x 1,5, M 20 x 1,5 und Minimess

®

Adapter- und Dichtungssatz für CPP30 Best.-Nr.: 12139701

Prüflingsschl. G ¼“ außen auf E“ NPT,

¼“ NPT, F“ NPT und ½“ NPT innen

Wartungssatz für CPP30 mit ver- Best.-Nr.: 12139786

schiedenen O-Ringen und Dichtungen

D

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

21

Page 22

Prüfpumpe

CPP30

Für Ihre Notizen

D

WIKA Betriebsanleitung Prüfpumpe22

11044608.02 07/2006 D/GB

Page 23

WIKA Global

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Phone: (+54-11) 4730 18 00

Fax: (+54-11) 4761 00 50

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Phone: (+55) 15-3266 16 55

Fax: (+55) 15-3266 16 50

E-mail: marketing@wika.com.br

www.wika.com.br

Africa/Middle East

Egypt

WIKA Alexander Wiegand GmbH &

Co. KG

Makram Ebaid

Nasr City, Cairo

Phone: (+20) 2 - 273 31 40

Fax: (+20) 2 - 273 31 40

E-mail: ahmed.azab@wika.de

Iran

WIKA Instrumentation Pars (KFZ)

Ltd.

Anahita Tower, Tehran

Phone: (+98-21) 8878 3514-17

Fax: (+98-21) 8887 8593

E-mail: info@wika.ir

www.wika.ir

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview, Johannesburg 2047

Phone: (+27) 11-621 00 00

Fax: (+27) 11-621 00 59

E-mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Phone: (+971) 4 - 883 90 90

Fax: (+971) 4 - 883 91 98

E-mail: wikame@emirates.net.ae

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Phone: (+86) 21 - 53 85 25 73

Fax: (+86) 21 - 53 85 25 75

E-mail: wikash@online.sh.cn

www.wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Phone: (+91) 20 - 27 05 29 01

Fax: (+91) 20 - 27 05 19 25

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Phone: (+81) 3-54 39 66 73

Fax: (+81) 3-54 39 66 74

E-mail: t-shimane@wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Phone: (+7) 32 72 33 08 48

Fax: (+7) 32 72 78 99 05

E-mail:

wika-kazakhstan@nursat.kz

Korea

WIKA Korea Ltd.

Seoul 153-023

Phone: (+82) 2 - 8 69 05 05

Fax: (+82) 2 - 8 69 05 25

E-mail: info@wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn. Bhd.

Selangor Darul Ehsan

Phone: (+60) 3 - 56 36 88 58

Fax: (+60) 3 - 56 36 90 72

E-mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Phone: (+65) 68 44 55 06

Fax: (+65) 68 44 55 07

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Phone: (+886) 034 20 60 52

Fax: (+886) 034 90 00 80

E-mail: info@wika.com.tw

www.wika.com.tw

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Phone: (+61) 2 - 88 45 52 22

Fax: (+61) 2 - 96 84 47 67

E-mail: sales@wika.com.au

www.wika.com.au

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

23

Page 24

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Wien

Phone: (+43) 1-86 91 631

Fax: (+43) 1-86 91 634

E-mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX ECHT

Phone: (+31) 475-535 500

Fax: (+31) 475-535 446

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

1309 Sofia

Phone: (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-mail: t.antonov@wika.bg

Finland

WIKA Finland Oy

00210 Helsinki

Phone: (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-mail: info@wika.fi

www.wika.fi

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Phone: (+33) 1-34 30 84 84

Fax: (+33) 1-34 30 84 94

E-mail: info@wika.fr

www.wika.fr

Italy

WIKA Italiana SRL

20020 Arese (Milano)

Phone: (+39) 02-93 86 11

Fax: (+39) 02-93 86 174

E-mail: info@wika.it

www.wika.it

Poland

Kujawska Fabryka Manometrow

-KFM S.A.

87-800 Wloclawek

Phone: (+48) 542 30 11 00

Fax: (+48) 542 30 11 01

E-mail: info@manometry.com.pl

www.manometry.com.pl

Romania

WIKA Instruments S.R.L.

Bucuresti, Sector 5

Phone: (+40) 21-456 31 38

Fax: (+40) 21-456 31 37

E-mail: m.anghel@wika.ro

Russia

ZAO „WIKA MERA“

127015 Moscow

Phone: (+7) 495-786 21 25

Fax: (+7) 495-786 21 23

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

11060 Belgrad

Phone: (+381) 11 27 63 722

Fax: (+381) 11 75 36 74

E-mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

08280 Sabadell (Barcelona)

Phone: (+34) 90-290 25 77

Fax: (+34) 93-393 86 66

E-mail: info@wika.es

www.wika.es

Switzerland

MANOMETER AG

6285 Hitzkirch

Phone: (+41) 41-919 72 72

Fax: (+41) 41-919 72 73

E-mail: info@manometer.ch

www.manometer.ch

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Phone: (+38) 062 345 34 16

Fax: (+38) 062 345 34 16

E-mail: info@wika.donetsk.ua

www.wika.donetsk.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Phone: (+44) 17 37 64 40 08

Fax: (+44) 17 37 64 44 03

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Office

Edmonton, Alberta, T6N 1C8

Phone: (+1) 780-463 70 35

Fax: (+1) 780-462 00 17

E-mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.

01219 Mexico D.F.

Phone: (+52) 555 020 53 00

Fax: (+52) 555 020 53 01

E-Mail ventas@wika.com.mx

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Phone: (+1) 770-513 82 00

Fax: (+1) 770-338 51 18

E-mail: info@wika.com

www.wika.com

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg / Germany

Phone (+49) 93 72/132-9986

Fax (+49) 93 72/132-217

E-Mail testequip@wika.de

www.wika.de

11044608.02 07/2006 D/GB

WIKA Betriebsanleitung Prüfpumpe

Loading...

Loading...