Page 1

Calibration technology

Hydraulic test pumps

Models CPP1000-M, CPP1000-L, hand spindle pump

Models CPP1000-X, CPP1600-X, CPP7000-X, comparison test pump

WIKA data sheet CT 91.05

Applications

■

Simple test pressure generation on site, in the laboratory

or in the workshop

■

For the testing, adjustment and calibration of all types of

pressure measuring instruments

■

Hydraulic pressure generation up to 7,000 bar

(100,000 psi)

Special features

■

Ergonomic handling through the smooth-running,

internally operating, precision spindle

■

Integrated oil reservoir

■

Removable star handle

■

Freely rotating test connections (i.e. measuring

instruments can be aligned)

■

Proven technology of the model CPB5800 pressure

balance

Description

Application areas

Test pumps serve as pressure generators for the testing,

adjustment and calibration of mechanical and electronic

pressure measuring instruments through comparative

measurements. These pressure tests can take place in the

laboratory or workshop, or on site at the measuring point.

Easy operation

If one connects the test item and a suciently accurate

reference measuring instrument to the test pump, on

actuating the pump, the same pressure will act on both

instruments. By comparison of the two measured values at

any given pressure value, a check of the accuracy and/or

adjustment of the pressure measuring instrument under test

can be carried out.

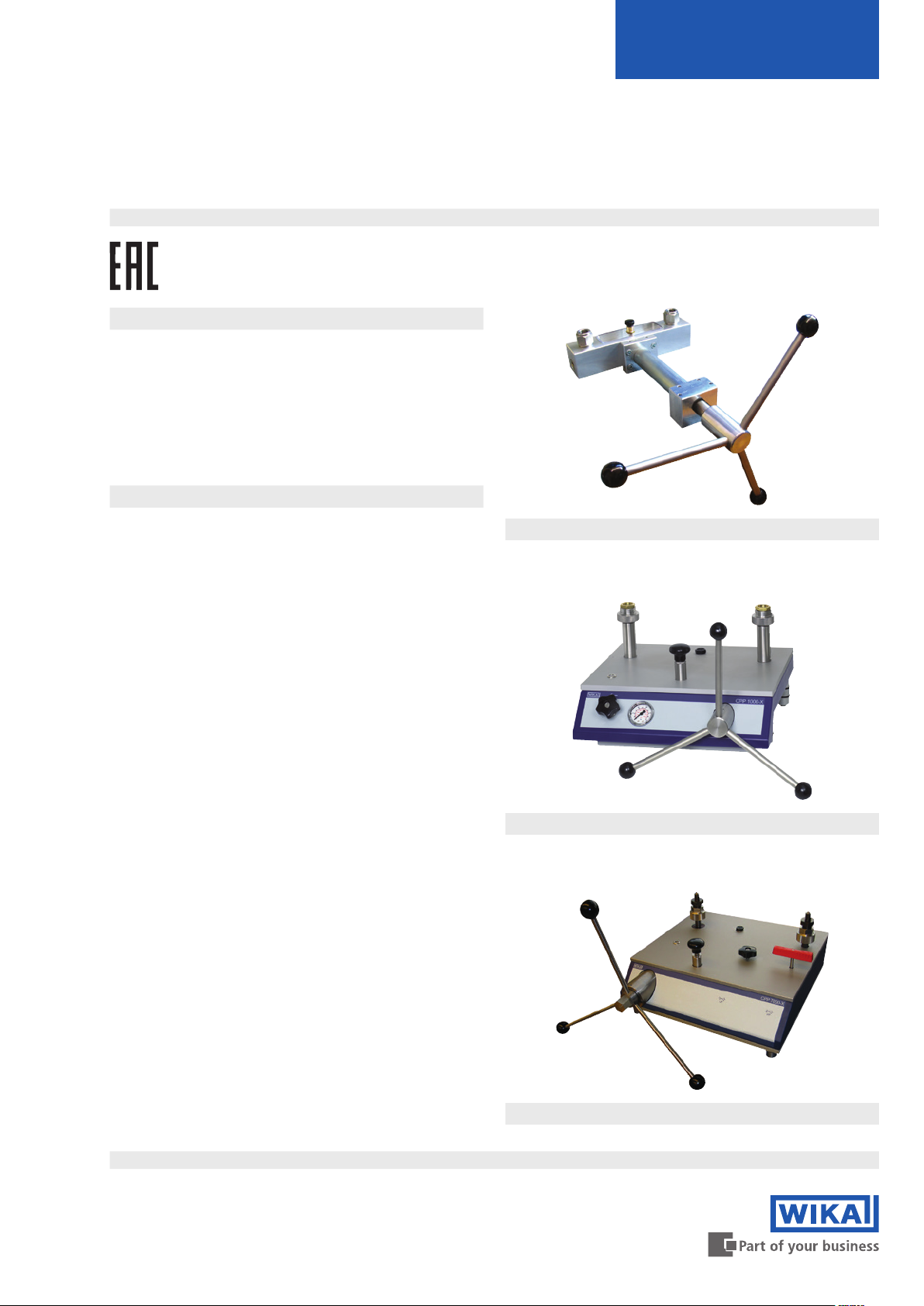

Hand spindle pump, model CPP1000-M

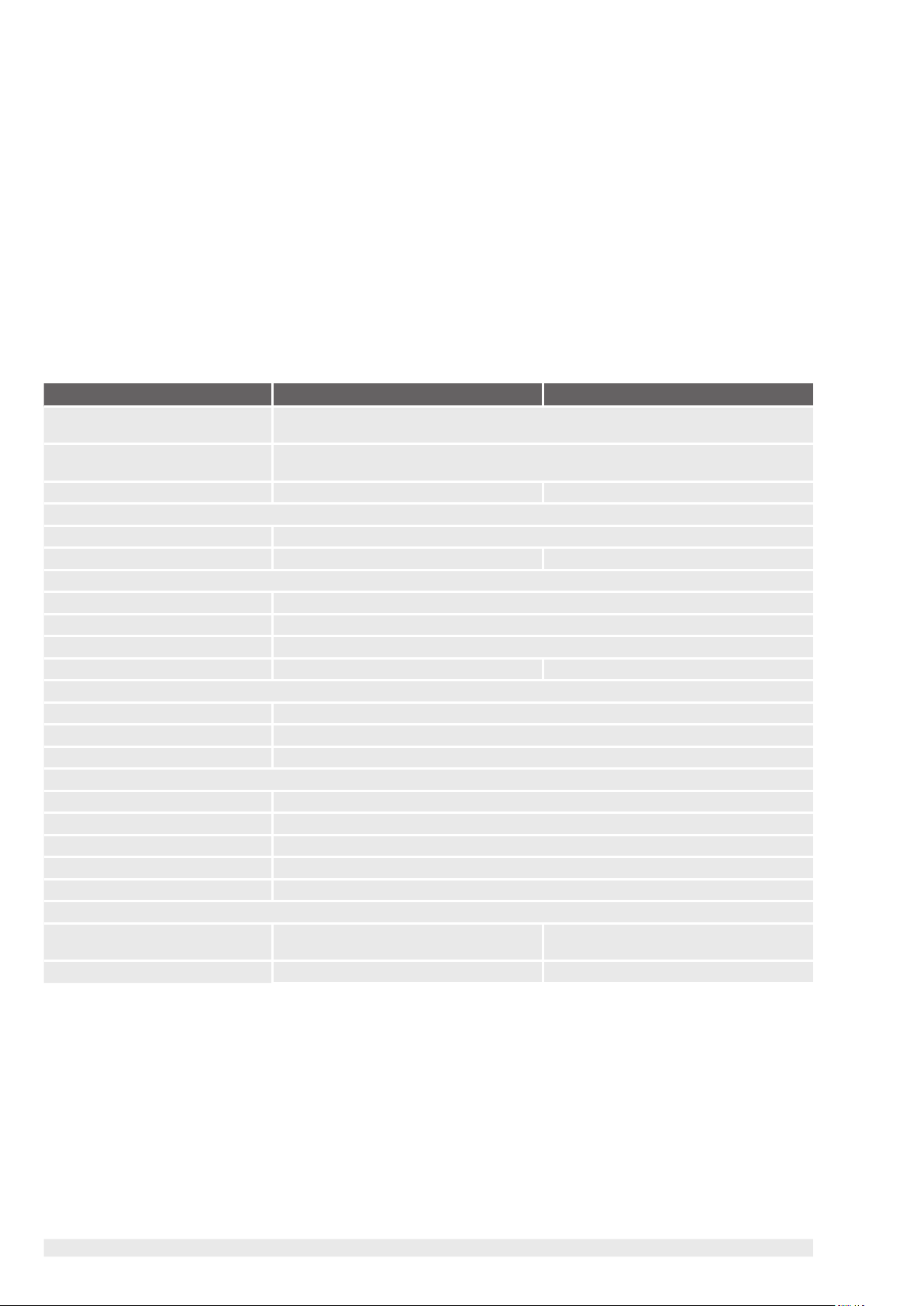

Comparison test pump, model CPP1000-X

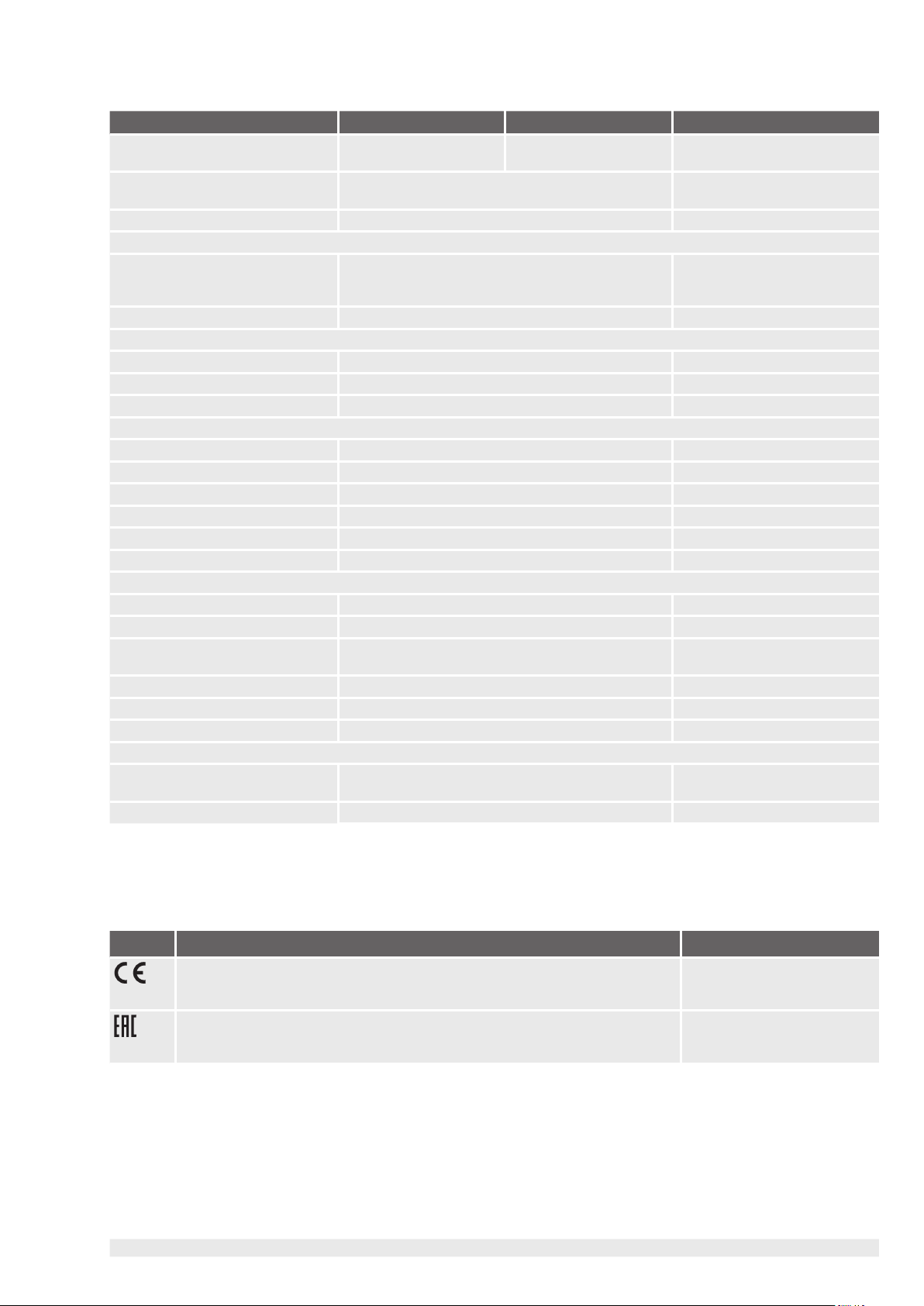

Comparison test pump, model CPP7000-X

WIKA data sheet CT 91.05

Data sheets showing similar instruments:

Test pump, pneumatic; model CPP30; see data sheet CT 91.06

Test pump, hydraulic; CPP700-H and CPP1000-H; see data sheet CT 91.07

Hand-held pressure indicator; CPH6300; see data sheet CT 12.01

ProcessCalibrator; CPH6000; see data sheet CT 15.01

Calibration software; WIKA-CAL; see data sheet CT 95.10

∙ 03/2016

Page 1 of 10

Page 2

CPP-X series oers exceptional ease-of-use

For a precise approach to the measuring points, the test

pumps are tted with a spindle for ne control. In particular,

the smooth running of the hand spindle enables this, even at

very high pressures. Furthermore, the spindles for this model

range only run within the pump body.

With the integrated priming pump, large test volumes can be

easily lled and primed for the models CPP-X.

Due to the design of the base, the CPP-X models have a high

durability and oer the highest ease-of-use with the proven

technology of the model CPB5800 pressure balance.

This eliminates any harmful bending moment from an

externally running spindle and, especially for eld operation,

there is the advantage that dimensions of these pumps do

not alter during operation through the rotation of the spindle.

Specications

Hand spindle pump

CPP1000-M CPP1000-L

Pressure range 0 ... 1,000 bar

(0 ... 14,500 psi)

Pressure transmission medium Hydraulic uid based on mineral oil or single distilled water

Reservoir 110 cm³ 55 cm³

Pressure connections

Test connection 2 x G ½ female thread, freely rotating, with O-ring

Distance between test connections 200 mm (7.9 in) 115 mm (4.5 in)

Piston of spindle pump

Piston diameter 8 mm (0.3 in)

Swept volume per revolution approx. 0.1 cm³

Overall swept volume approx. 3.9 cm³

Fine pressure adjustment optional, see accessories Fine adjustment valve on the side

Required force at

250 bar (3,600 psi) 2.0 Nm

500 bar (7,200 psi) 4.0 Nm

1,000 bar (14,500 psi) 8.0 Nm

Material

Cylinder Brass

Piston Stainless steel

Rear ange Aluminium

Sealings FKM, NBR (standard), optional EPDM

Stationary mounting 2 x Ø 6.4 mm (0.25 in) through-bores in the front ange

Instrument base

Dimensions (L x W x H) 420 x 280 x 103 mm

Weight 6.3 kg (13.89 lbs.) 5.6 kg (12.35 lbs.)

1) Other pressure transmission media on request.

2) Using the EPDM variant (for aggressive media), Skydrol

(water-based hydraulic uids are not suitable)

2)

(16.5 x 11.0 x 4.1 in)

®

or brake uid is permissible as pressure transmission medium.

420 x 240 x 103 mm

(16.5 x 9.5 x 4.1 in)

1)

Page 2 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Page 3

Comparison test pump

CPP1000-X CPP1600-X CPP7000-X

Pressure range 0 ... 1,000 bar

(0 ... 14,500 psi)

Pressure transmission medium Hydraulic uid based on mineral oil / clean water, free of

calcium-carbonate

1)

Reservoir 250 cm³ 250 cm³

Pressure connections

Test connection 2 x G ½ female threaded quick-connectors, freely rotating,

exchangeable, with O-ring

Distance between test connections 300 mm (11.8 in) 346 mm (13.6 in)

Piston of the comparison test pump

Piston diameter 8 mm (0.3 in) 7.5 mm (0.3 in)

Swept volume per revolution approx. 0.1 cm³ approx. 0.08 cm³

Overall swept volume approx. 3.9 cm³ approx. 2.5 cm³

Required force at

250 bar (3,600 psi) 2.0 Nm 1.5 Nm

500 bar (7,200 psi) 4.0 Nm 3.0 Nm

1,000 bar (14,500 psi) 8.0 Nm 6.0 Nm

3,000 bar (43,500 psi) -- 18 Nm

5,000 bar (72,500 psi) -- 30 Nm

7,000 bar (100,000 psi) -- 42 Nm

Material

Cylinder Brass Stainless steel

Piston Stainless steel hardened stainless steel

Piping 1.4404 stainless steel, 6 x 2 mm (0.2 x 0.1 in) 1.4404 stainless steel, 6 x 2 mm

Rear ange Aluminium --

Sealings FKM, NBR (standard), optional EPDM

Stationary mounting Stable base Stable base

Instrument base

Dimensions (L x W x H) 400 x 375 x 265 mm

(15.8 x 14.8 x 10.4 in)

Weight 20 kg (44.1 lbs.) 32,5 kg (71.7 lbs.)

1) Other pressure transmission media on request.

2) Using the EPDM variant (for aggressive media), Skydrol

®

or brake uid is permissible as pressure transmission medium.

0 ... 1,600 bar

(0 ... 23,200 psi)

2)

0 ... 7,000 bar

(0 ... 100,000 psi)

Sebacate oil

2 x M16 x 1.5 male thread, freely

rotating, exchangeable, with

sealing cone

(0.2 x 0.1 in)

NBR

460 x 445 x 265 mm

(18.1 x 17.5 x 10.4 in)

Approvals

Logo Description Country

EC declaration of conformity for model CPP1600-X

Pressure equipment directive

(PS > 1,000 bar; module A, pressure accessory

EAC

■

Pressure equipment directive

■

Machinery directive

Approvals and certicates, see website

WIKA data sheet CT 91.05 ∙ 03/2016 Page 3 of 10

European Community

Eurasian Economic Community

Page 4

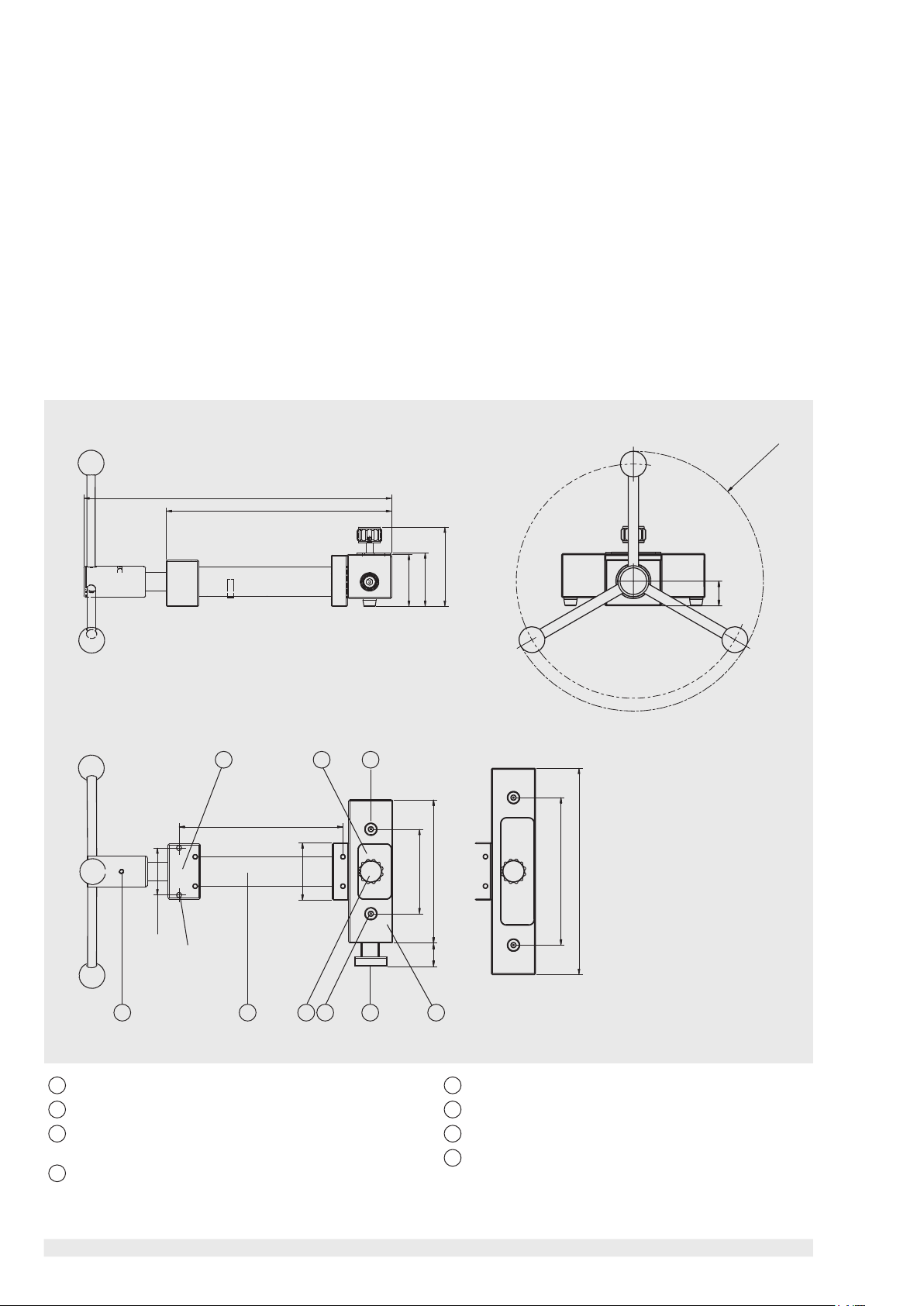

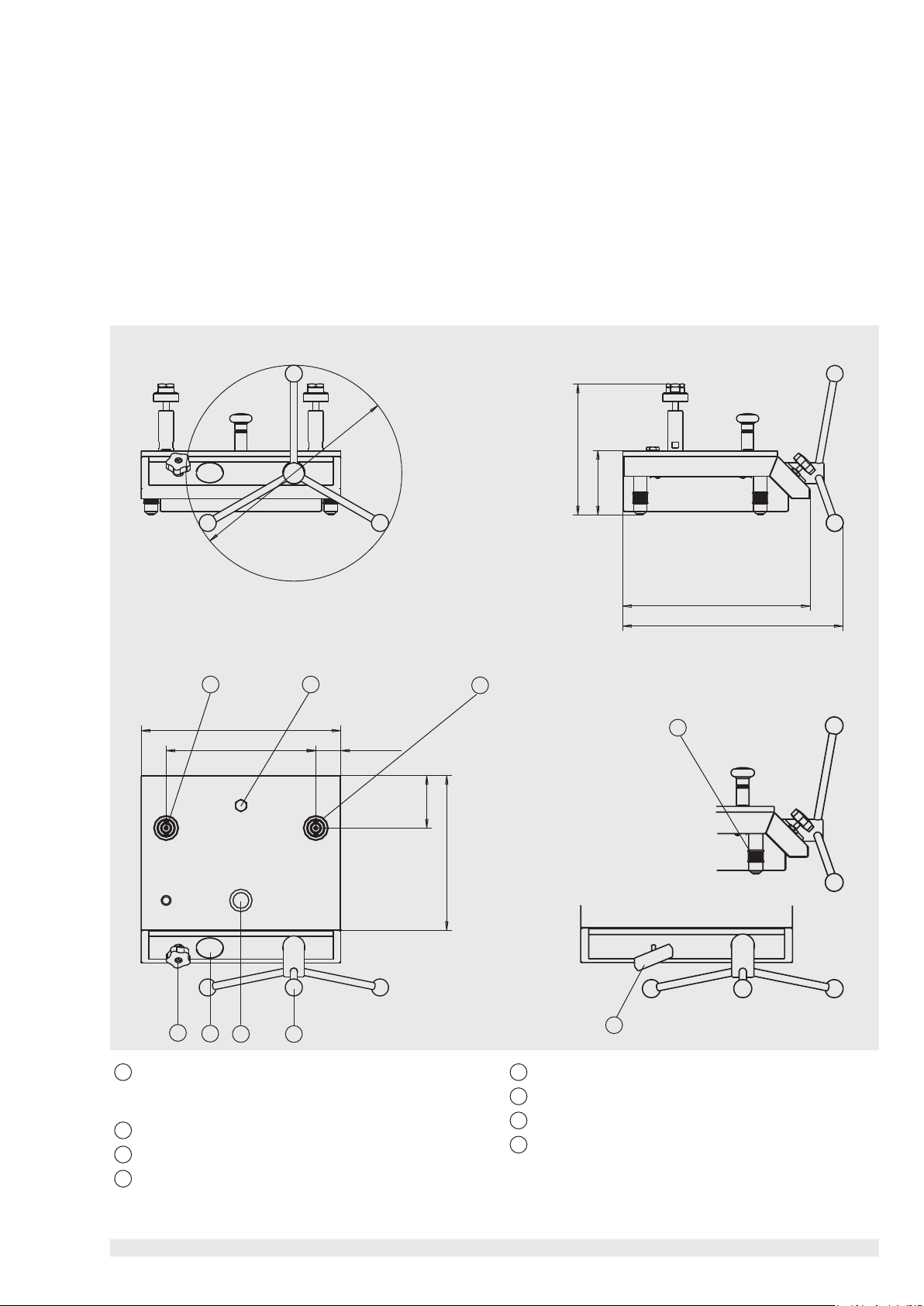

)

Hand spindle pump model CPP1000 version M and L, up to 1,000 bar (14,500 psi),

hydraulic

The model CPP1000-M and CPP1000-L hand spindle

pumps, with their compact size and low weight, are the basic

versions in the CPP series of test pumps.

They have been designed primarily for the test and

calibration of pressure measuring instruments with small

volumes. Test items and reference instruments with larger

volumes should either be pre-lled oine from the test pump

or also simply and conveniently lled directly from the hand

spindle pump, using the shut-o valves available as an

accessory for the test connections.

The CPP1000-L is the case version with a narrow rear ange,

sealed reservoir and a ne adjustment valve built-in as

standard.

For the CPP1000-M, the ne adjustment valve is available as

an accessory and can be tted as an option. When using the

ne adjustment valve, only one shut-o valve can be tted for

one test connection.

The test connections are G ½ female. Corresponding thread

adapters are available for the calibration of instruments with

dierent connection threads.

Dimensions in mm (in)

Side view (right) Front view

418 (16.46)

306 (12.05)

~ 108 (~ 4.25)

73 (2.87)

71 (2.80)

Ø 354 (13.94

33.5

(1.32)

Top view

1 2 3

223 (8.78)

78

(3.07)

64 (2.52)

2 x Ø 6.4 (0.3 in)

1

Front ange with 2 xing bores, Ø 6.4 mm (0,3 in)

2

Medium reservoir

3

Test connection, G ½ female thread, freely rotating,

with O-ring

4

Rear ange

115 (4.53)

45

195 (7.38)

(1.77)

453678

CPP1000-MCPP1000-L

5

Fine adjustment valve (at CPP1000-M as an option)

6

Shut-o valve for reservoir (optional)

7

Cylinder with spindle and piston

8

Star handle with spring-loaded thrust pad

200 (7.87)

280 (11.02)

Page 4 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Page 5

Comparison test pumps models CPP1000-X and CPP1600-X, up to 1,000 bar (14,500 psi)

or 1,600 bar (23,200 psi), hydraulic

The model CPP1000-X and CPP1600-X comparison test

pumps have been designed around a solid base and, with

the proven technology of the CPB5800 pressure balance,

oer exceptional ease-of-use. With the integrated priming

pump and the 250 ml tank, large test volumes can also be

easily lled and primed.

Dimensions in mm (in)

Front view

Ø 432.5

(17.03)

Both test connections on both pump models are tted

with quick-release connectors with knurled nuts and

exchangeable threaded inserts (as standard G ½ female

thread). Corresponding threaded inserts are available for the

calibration of instruments with dierent connection threads.

Side view (left)

262 (10.31)

129 (5.08)

Top view

1 2

400 (15.75)

300 (11.81)

6

5

375 (14.76)

441 (17.36)

1

50 (1.97)

150

(5.91)

4

3

Detailed section view model

CPP1600-X

- with high-pressure shut-o valve

- without pressure gauge

Dimensions are identical.

310 (12.20)

8

7

1

Test connections (quick-release connector with G ½

female thread, exchangeable, freely rotating, with

O-ring)

2

Plug screw for medium reservoir

3

Spindle pump with star handle

4

Priming pump

WIKA data sheet CT 91.05 ∙ 03/2016 Page 5 of 10

5

Test pressure gauge

6

Shut-o valve 1,000 bar (14,500 psi)

7

Rotatable feet

8

High-pressure shut-o valve 1,600 bar (23,200 psi)

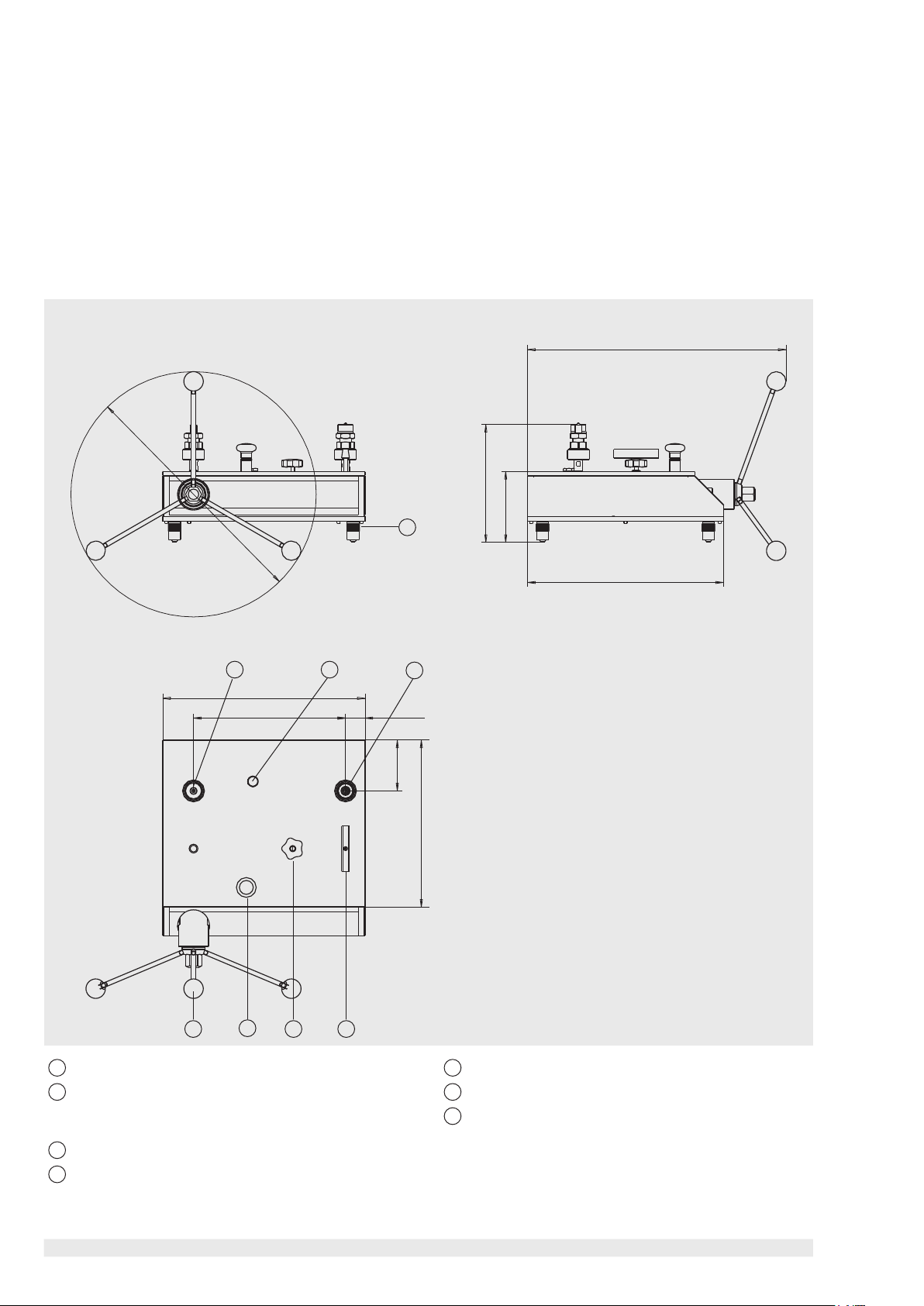

Page 6

587 (23.11)

Comparison test pump model CPP7000-X, up to 7,000 bar (100,000 psi), hydraulic

The model CPP7000-X comparison test pump has been

designed around a solid base and, with the proven

technology of the CPB5000HP high-pressure pressure

balance, oers exceptional ease-of-use. With the integrated

priming pump and the 250 ml tank, large test volumes can

also be easily lled and primed.

Dimensions in mm (in)

Ø 558 (21.97)

Both test connections are tted with knurled nuts and

exchangeable thread adapters with sealing cones (as

standard M16 x 1.5 male threads). Corresponding thread

adapters are available as accessories for the calibration of

instruments with other connection threads.

Side view (left)Front view

268 (10.55)

1

161.5 (6.36)

Top view

460 (18.11)

345.5 (13.60)

445 (17.52)

32

44.5 (1.75)

115.5

(4.55)

2

280 (14.96)

7

1

Rotatable feet

2

Test connections (knurled nut with M16 x 1.5 male

6

thread adapter, exchangeable, freely rotating, with

45

5

Low-pressure shut-o valve (LP)

6

Priming pump

7

Spindle pump with star handle

sealing cone)

3

Plug screw for medium reservoir

4

High-pressure shut-o valve (HP)

Page 6 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Page 7

Recommended reference pressure measuring instruments:

Precision digital pressure gauge model CPG1000

Measuring ranges: up to 700 bar (10.000 psi)

Accuracy: 0.05 % of span

For further specications see data sheet CT 10.01

Hand-held pressure indicator model CPH6300

Measuring ranges: up to 1,000 bar (14,500 psi)

Accuracy: 0.2 % of span

For further specications see data sheet CT 12.01

Precision hand-held pressure indicator model CPH6400

Measuring ranges: up to 6,000 bar (85,000 psi)

Accuracy: up to 0.025 % of span

For further specications see data sheet CT 14.01

ProcessCalibrator model CPH6000

Measuring ranges: up to 8,000 bar (115,000 psi)

Accuracy: up to 0.025 % of span

For further specications see data sheet CT 15.01

Calibration software

WIKA-CAL calibration software for creating calibration

certicates or logger protocols

For specications see data sheet CT 95.10

WIKA data sheet CT 91.05 ∙ 03/2016 Page 7 of 10

Page 8

Complete test and service cases with pressure generation

Calibration case with model CPH6000

ProcessCalibrator and model CPP1000-L hand spindle

pump for pressures up to 1,000 bar (14.500 psi)

consisting of:

■

Transport case with model CPH6000 ProcessCalibrator

■

Hydraulic hand spindle pump model CPP1000-L up to

1,000 bar (14.500 psi)

■

Sensor cable for external operation of sensor

■

Test cable set with connection terminals

■

Charger

■

Interface cable

■

Sealing set

■

Spaces for several CPT6000 reference pressure sensors

Basic version incl. hydraulic pressure generation

Basic version incl. hydraulic pressure generation

For further specications see data sheet CT 15.01.

Calibration case with model CPG1000 precision digital

pressure gauge and model CPP700-H hand test pump,

for pressures 0 ... 700 bar (0 ... 10.000 psi), consisting

of:

■

Plastic service case with foam insert

■

Precision digital pressure gauge model CPG1000

■

Hydraulic hand test pump model CPP700-H; 0 … 700 bar

(0 ... 10.000 psi)

For further specications see data sheet CT 10.01 or

CT 91.07

Calibration case with model CPH6400 precision

hand-held pressure indicator and model CPP30

hand test pump for pressures of -0.95 ... +35 bar

(-13,8 ... +500 psi), consisting of:

■

Service case with foam insert

■

Precision hand-held pressure indicator model CPH6400

■

Pneumatic hand test pump model CPP30,

-0.95 ... +35 bar (-13,8 ... +500 psi)

■

Sensor cable for external operation of sensor

■

Charger

■

Spaces for several CPT6400 reference pressure sensors

For further specications see data sheet CT 91.06 or

Basic version incl. pneumatic pressure generation

Page 8 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

CT 14.01

Page 9

Hand spindle pumps models CPP1000-M and CPP1000-L

Scope of delivery

■

Spindle pump for lling, pressure generation and ne

pressure adjustment

■

Star handle

■

Two test connections with G ½ female thread, loose union

connection, with O-ring

■

Fine adjustment valve and/or shut-o valve for model

CPP1000-M as an option

■

Shut-o valve for model CPP1000-L as an option (ne

adjustment valve is a standard)

■

Operating instructions

Accessories

Adapters

■

Connection adapter, G ½ male to G ⅛ female,

max. 250 bar (3,600 psi), mat.: brass

■

Connection adapter, G ½ male to G ⅜ female,

max. 600 bar (8,700 psi), mat.: brass

■

Connection adapter, G ½ male to G ¼ female,

max. 1,000 bar (14,500 psi), mat.: 1.4571

■

Connection adapter, G ½ male to M20 x 1.5 female,

max. 1,000 bar (14,500 psi), mat.: 1.4571

■

Connection adapter, G ½ male to ¼ NPT female,

max. 1,000 bar (14,500 psi), mat.: 1.4571

■

Connection adapter, G ½ male to ½ NPT female,

max. 1,000 bar (14,500 psi), mat.: 1.4571

■

Blind plug, G ½ male, mat.: brass

Valves

■

Shut-o valve for test connection, enabling the easy lling

of instruments with large volumes with lling medium,

directly from the hand spindle pump. Max. permissible

pressure: 1,000 bar (14,500 psi). For test items and

reference instruments with a large volumes, two shut-o

valves are recommended.

- Shut-o valve (recommended for connected volumes

> 4 cm³), standard version

- Shut-o valve (recommended for connected volumes

> 4 cm³), EPDM version

■

Fine adjustment valve for retrotting to the CPP1000-M;

enables precise approach to the measuring points

- Fine adjustment valve, standard version

- Fine adjustment valve, EPDM version

Pressure transmission medium

■

Hydraulic uid based on VG22 mineral oil in plastic bottle,

content 1 litre

Other

■

Set of O-rings, consisting of 10 seals for the test

connections, mat.: FKM/FPM, standard version

■

Set of O-rings, consisting of 10 seals for the test

connections, mat.: EPDM

■

90° angle connection for test items with back mounting

connection, standard version

■

90° angle connection, for test items with back mounting

connection, NBR sealing

■

Replacement tank cover incl. shut-o valve, standard

version

■

Replacement tank cover incl. shut-o valve, EPDM version

■

Replacement seal for tank cover

Tools

■

Maintenance set for hydraulic hand spindle pumps,

standard version

■

Maintenance set for hydraulic hand spindle pumps, EPDM

version

Comparison test pump of model CPP1000-X and CPP1600-X

Scope of delivery

■

Priming pump for lling, spindle pump for pressure

generation and ne pressure adjustment

■

Two test connections with G ½ female thread, loose union

connection, with O-ring

■

Operating instructions

Accessories

Adapters

■

Adapter set for quick-release connector in case with G ¼,

G ⅜, ½ NPT, ¼ NPT and M20 x 1.5 female, mat.: stainless

steel

■

“NPT” adapter set for quick-release connector in case with

⅛ NPT, ¼ NPT, ⅜ NPT und ½ NPT female, mat.: stainless

steel

■

Adapter for connection column, G ½ male to M16 x 1.5

male with sealing cone, mat.: stainless steel

Pressure transmission medium

■

Hydraulic uid based on VG22 mineral oil in plastic bottle,

content 1 litre

Other

■

Set of O-rings, consisting of 10 replacement seals (8 x 2)

for the test connections, mat.: NBR

■

Set of O-rings, consisting of 10 replacement seals (8 x 2)

for the test connections, mat.: EPDM

■

90° angle connection for test items with back mounting

connection, standard version

■

90° angle connection, for test items with back mounting

connection, NBR sealing

■

Replacement seal set for needle valve, standard version

■

Replacement seal set for needle valve, EPDM version

Tools

■

Maintenance set for hydraulic volume adjuster, standard

version

■

Maintenance set for hydraulic volume adjuster, EPDM

version

■

Sealing and maintenance set for instrument base (without

volume adjuster), standard version

■

Sealing and maintenance set for instrument base (without

volume adjuster), EPDM version

WIKA data sheet CT 91.05 ∙ 03/2016 Page 9 of 10

Page 10

Comparison test pump model CPP7000-X

Scope of delivery

■

Priming pump for lling, spindle pump for pressure

generation and ne pressure adjustment

■

Two test connections with M16 x 1.5 male thread, loose

union connection, with sealing cone

■

Operating instructions

Accessories

Adapters

■

Adapter for connection column, M16 x 1.5 male with

sealing cone, mat.: hardened stainless steel

■

Adapter for connection column, M20 x 1.5 male with

sealing cone, mat.: hardened stainless steel

■

Adapter for connection column, 9/16-18 UNF male with

sealing cone, mat.: hardened stainless steel

■

Adapter for connection column, G ½ female with O-ring,

max. 1,600 bar (23,200 psi), mat.: 1.4571

Pressure transmission medium

■

Sebacate oil in plastic bottle, content 0.5 litre

Ordering information

CPP1000-M / Package / Version / Operating uid / Left valve / Right valve / Valve mounting / Accessories / Additional ordering

information

CPP1000-L / Package / Operating uid / Left valve / Valve mounting / Accessories / Additional ordering information

CPP1000-X / Package / Medium / Adapter set / Angle connection / Accessories / Additional ordering information

CPP1600-X / Package / Medium / Adapter set / Angle connection / Accessories / Additional ordering information

CPP7000-X / Package / Additional adapter / Accessories / Additional ordering information

© 2006 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

Page 10 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

03/2016 EN

Loading...

Loading...