Page 1

Operating instructions

Betriebsanleitung

Portable pressure calibrator, model CPH7650

Tragbarer Druckkalibrator, Typ CPH7650

EN

DE

Portable pressure calibrator, model CPH7650

Page 2

EN

Operating instructions model CPH7650 Page 3 - 58

DE

Betriebsanleitung Typ CPH7650 Seite 59 - 113

Further languages can be found at www.wika.com.

© 03/2018 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2

WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 3

Contents

Contents

1. General information 5

2. Safety 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Personnel qualification . . . . . . . . . . . . . . . . . . . 8

2.3 Special hazards . . . . . . . . . . . . . . . . . . . . . 8

2.4 Use of Lithium-Ion rechargeable batteries . . . . . . . . . . . .10

2.5 Labelling, safety marks . . . . . . . . . . . . . . . . . . .12

3. Specifications 13

4. Design and function 15

4.1 Description . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Front . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . .17

4.4 Voltage supply . . . . . . . . . . . . . . . . . . . . . .17

4.5 User interface . . . . . . . . . . . . . . . . . . . . . . 18

4.5.1 Requirements for test assemblies with the CPH7650 . . . . . . . 19

4.5.2 Important instrument settings for calibration using calibration mode . . 19

4.5.3 Zero point setting and offset correction . . . . . . . . . . . .20

4.5.4 Reference pressure sensor CPT6000 . . . . . . . . . . . . 20

5. Transport, packaging and storage 22

5.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Packaging . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . 22

6. Commissioning, operation 23

6.1 Menu structure (operating modes) . . . . . . . . . . . . . . . 24

6.2 Explanation of the display . . . . . . . . . . . . . . . . . . 25

6.2.1 Instrument status messages shortly after switching on the CPH7650 . .25

6.2.2 Switching the pressure calibrator off . . . . . . . . . . . . .26

6.2.3 Display contents of the operating modes . . . . . . . . . . . 26

6.2.4 Content of the SETUP menu . . . . . . . . . . . . . . .29

6.3 Operating modes . . . . . . . . . . . . . . . . . . . . .32

6.3.1 MEASURING mode . . . . . . . . . . . . . . . . . . 32

6.3.2 MEASURING mode (with test item) . . . . . . . . . . . . . 34

6.3.3 Mode CALIBRATION . . . . . . . . . . . . . . . . . . 36

6.3.4 CALIBRATION mode (preparing the test points of a calibration). . . . 38

6.3.5 CALIBRATION mode (calibration of a pressure transmitter) . . . . . 41

6.3.6 CALIBRATION mode (calibration of a pressure gauge) . . . . . . 42

6.3.7 SWITCH TEST mode . . . . . . . . . . . . . . . . . . 43

6.4 SETUP additional menu items . . . . . . . . . . . . . . . . 45

14261987.01 03/2018 EN/DE

EN

3WIKA operating instructions, model CPH7650

Page 4

Contents

6.4.1 SETUP additional menu items: Functions . . . . . . . . . . . 45

6.4.2 SETUP additional menu items: CPH info . . . . . . . . . . . 46

6.4.3 SETUP additional menu items: Reference sensor . . . . . . . . 47

EN

6.4.4 SETUP additional menu items: Reference sensor list . . . . . . . 48

6.4.5 SETUP additional menu items: CPH configuration . . . . . . . .49

6.4.6 SETUP additional menu items: Interface . . . . . . . . . . . 50

6.4.7 SETUP additional menu items: CLEAR CalProg . . . . . . . . .50

6.5 Connection of the model CPT6000 reference pressure sensor . . . . . 51

6.6 Voltage supply . . . . . . . . . . . . . . . . . . . . . .51

6.7 Charging/discharging the Lithium-Ion rechargeable batteries . . . . . .52

6.8 Pressure measurement . . . . . . . . . . . . . . . . . . .53

6.9 Measuring and sourcing current (4 ... 20 mA) . . . . . . . . . . . 53

7. Maintenance, cleaning and recalibration 54

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . 54

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . .54

7.3 Recalibration . . . . . . . . . . . . . . . . . . . . . .54

8. Faults 55

9. Dismounting, return and disposal 56

9.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . 56

9.2 Return. . . . . . . . . . . . . . . . . . . . . . . . . 56

9.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . .56

10. Accessories 57

Declarations of conformity can be found online at www.wika.com.

4 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 5

1. General information

1. General information

■

The portable pressure calibrator described in the operating instructions has been

manufactured using state-of-the-art technology. All components are subject to

stringent quality and environmental criteria during production. Our management

systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insufficiently qualified skilled personnel or unauthorised modifications to

the instrument.

EN

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 17.02

- Application consultant:

Tel.: +49 9372 132-9986

Fax: +49 9372 132-8767

info@wika.com

14261987.01 03/2018 EN/DE

5WIKA operating instructions, model CPH7650

Page 6

1. General information / 2. Safety

Explanation of symbols

WARNING!

EN

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to property or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

DANGER!

... identifies hazards caused by electrical power. Should the safety

instructions not be observed, there is a risk of serious or fatal injury.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate reference pressure sensor has been selected in terms of

measuring range, design and specific measuring conditions.

Non-observance can result in serious injury and/or damage to the

equipment.

Further important safety instructions can be found in the individual chapters

of these operating instructions.

6 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 7

2. Safety

2.1 Intended use

This portable pressure calibrator serves as a calibration instrument for the widest variety

of pressure measuring instruments and has been designed for mobile use as well as for

stationary workshop and laboratory testing. Through the combination of the integrated

electrical pump and the electrical modules, in addition to the traditional measurement of

current and voltage signals it also enables you to supply transmitters or sensors with a

max. of 30 mA (voltage (idling) = DC 24 V). The pressure calibrator can be used to carry

out and document a complete calibration process.

WARNING!

■

Only use model CPT6000 reference pressure sensors!

■

Using other sensors could damage both the pressure calibrator and the

reference pressure sensor.

■

To change the sensor, switch off the pressure calibrator and make sure

the system is vented. Before switching the instrument on, connect the

sensor, otherwise it may not be correctly identified by the instrument.

■

When the CPH7650 is switched on, the CPT6000 reference pressure

sensor must not be under pressure, but rather should be at atmospheric

pressure. For overpressure or gauge pressure sensors, there is a

pressure compensation vent in the top of the sensor under the plastic

fitting. This vent (with integrated diaphragm) must always remain clear!

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

EN

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specifications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic fields, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

14261987.01 03/2018 EN/DE

7WIKA operating instructions, model CPH7650

Page 8

2. Safety

2.2 Personnel qualification

WARNING!

EN

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specific regulations, current standards and directives, are capable

of carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Special hazards

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury and damage to

equipment.

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualifications described below.

WARNING!

■

Do not apply a voltage greater than the specified voltage to the

instrument (see chapter 3 „Specifications“).

■

Do not apply any external pressure to the CPH7650.

■

Make sure that the test probes never contact a voltage source while the

test cables are connected to the current terminals.

■

Do not use the calibrator if it is damaged. Before using the instrument,

check that there are no cracks on the case or any missing plastic parts.

Pay particular attention to the insulation of the connectors.

■

Select the proper function and correct measuring range for the

measurement.

■

Observe the operating parameters in accordance with chapter

3 “Specifications”.

■

Always operate the pressure calibrator within the defined pressure range.

■

To ensure problem-free operation, only operate the instrument on battery

power. Only use the power supply unit for charging the instrument's

batteries.

■

Inspect the test cables for damaged insulation or exposed metal. Check

the continuity of the leads. Damaged test leads should be replaced before

using the instrument.

■

When using test probes, keep fingers away from the test probe contacts.

Keep your fingers behind the test probes' finger guards.

■

First connect the common lead, and then the live lead. When

disconnecting, remove the live test lead first.

14261987.01 03/2018 EN/DE

8 WIKA operating instructions, model CPH7650

Page 9

2. Safety

■

Do not use the instrument if it is not working properly. The instrument

protection might be compromised. If in doubt, have the instrument

checked.

■

Do not operate the instrument in areas with explosive gases, vapours or

dust.

■

When measuring pressure, make sure that the pressure calibrator has

been switched to a depressurised state before the reference sensor or

the test item is connected or disconnected.

■

Disconnect test leads before changing to another measurement or source

function.

■

The switching valve (+/- pressure) should only ever be actuated when in a

depressurised state.

WARNING!

■

To avoid false indications, which could lead to possible electric shock or

injuries, charge the rechargeable battery as soon as the battery indicator

appears.

■

In order to avoid any possible damage to the instrument or the test

equipment, use the correct leads, the correct function and the correct

range for the measuring application.

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

■

Charging using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) can result in life-threatening voltages

at the instrument!

■

Only use the power supply unit permitted by WIKA for the model

CPH7650 portable pressure calibrator.

■

Only use a charger that is fully functional or undamaged.

EN

The safety of the operator may be endangered if, for example

■

there is visible damage to the instrument.

■

the instrument is no longer working as specified.

■

the instrument has been stored under unsuitable conditions for an extended period of

time.

If there is any doubt, please return the instrument to the manufacturer for repair or

maintenance.

14261987.01 03/2018 EN/DE

9WIKA operating instructions, model CPH7650

Page 10

2. Safety

2.4 Use of Lithium-Ion rechargeable batteries

WARNING!

EN

Misusing Lithium-Ion batteries can lead to heating, explosion or ignition and

result in serious injury. Follow the safety instructions listed below:

■

Do not solder directly to the Lithium-Ion batteries.

■

Do not incinerate or heat the Lithium-Ion batteries.

■

The Lithium-Ion batteries must only ever be connected with the correct

polarity.

■

Never connect the positive terminal and the negative terminal of the

Lithium-Ion batteries to each other with any metallic object (such as wire).

■

Never carry or store the Lithium-Ion batteries together with necklaces,

hairpins, or other metal objects.

WARNING!

■

Lithium-Ion batteries should never be punctured with nails nor hit with a

hammer. In addition, Lithium-Ion batteries must never be trodden on or

exposed to other strong shocks or vibrations.

■

Lithium-Ion batteries must never come into contact with water or salt

water. Moreover, they must never get wet.

WARNING!

Never take the Lithium-Ion battery apart nor alter it in any way. It contains

safety and protection devices which, if damaged, may cause it to generate

heat, explode or ignite.

WARNING!

Never place the Lithium-Ion batteries close to fires, ovens or other

high-temperature locations. Never leave the Lithium-Ion batteries in direct

sunshine or use or store them inside cars in hot weather. Doing so may

cause the Lithium-Ion batteries to generate heat, explode or ignite. Using the

Lithium-Ion batteries in this manner may also result in a loss of performance

and a shortened service life.

Never fit the Lithium-Ion batteries into equipment designed to be

hermetically sealed. In some cases hydrogen or oxygen may be discharged

from the Lithium-Ion batteries, which may result in rupture, fire or explosion.

10 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 11

2. Safety

WARNING!

The Lithium-Ion batteries must, without fail, no longer be used if, during

operation, charging or storing they give off an unusual smell, feel hot,

change colour, change shape, or appear abnormal in any other way. Contact

your sales partner if any of these problems are observed.

Never put the Lithium-Ion batteries in microwave ovens, high-pressure

containers nor on induction cookers.

Should the Lithium-Ion batteries ever leak and the fluid come into contact

with the eyes, do not under any circumstances rub the eyes. Rinse the eyes

thoroughly with water and seek immediate medical attention. If the eyes are

left untreated, damage to the eyes could occur.

CAUTION!

When the Lithium-Ion batteries wear out, insulate the terminals with

adhesive tape or similar materials before disposal.

WARNING!

Follow the instructions listed below for charging the Lithium-Ion batteries.

Failure to do so may cause the Lithium-Ion batteries to become hot, explode

or ignite and result in serious injury.

■

To charge the Lithium-Ion batteries, only ever use the specified WIKA

battery charger.

■

Never connect the Lithium-Ion batteries directly to a mains plug or to a

car's cigarette lighter.

■

Never leave the Lithium-Ion batteries in or near fire, nor in direct sunlight.

If the Lithium-Ion batteries become hot, the built-in safety device is

activated and overcharging prevented. Heating the Lithium-Ion batteries

can damage the safety device and can thus lead them to heat up further,

to cease to work or to ignite.

EN

WARNING!

Never continue to charge the Lithium-Ion batteries if they do not fully

recharge within the specified time. Doing so may cause the Lithium-Ion

batteries to become hot, explode or ignite.

14261987.01 03/2018 EN/DE

11WIKA operating instructions, model CPH7650

Page 12

2. Safety

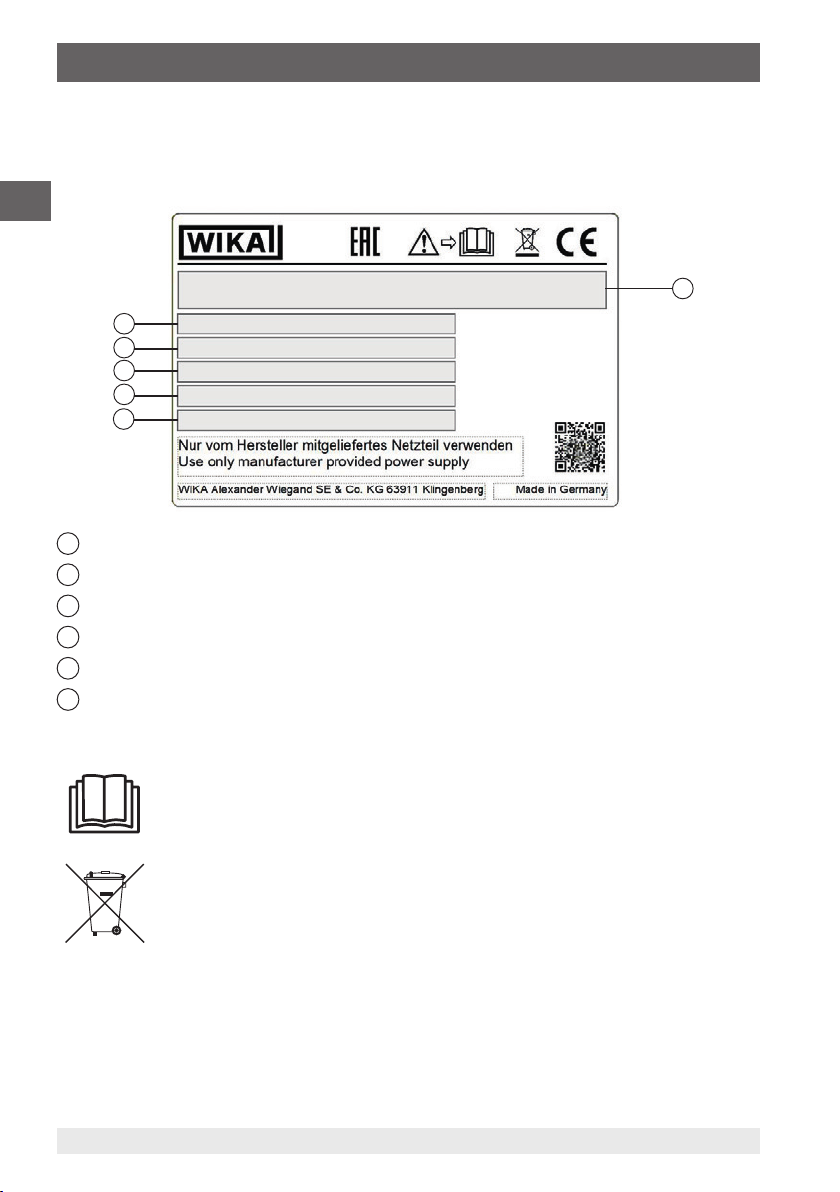

2.5 Labelling, safety marks

Product label

EN

6

5

4

3

2

1

Product name

2

Date of manufacture (month/year)

3

Serial number

4

Output signal, power supply

5

Input signal

6

Pressure range

1

Symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

This marking on the instruments indicates that they must not be disposed of

in domestic waste. The disposal is carried out by return to the manufacturer

or by the corresponding municipal authorities.

12 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 13

3. Specifications

3. Specifications

Measuring ranges

Pressure

Gauge pressure -1 … +20 bar, -1 … +10 bar, 0 … 20 bar, 0 … 10 bar

Absolute pressure 0 … 10 bar abs., 0 … 20 bar abs.

Overpressure limit

Accuracy 0.025 % FS

Resolution 5-digit

Temperature compensation 15 … 35 °C (59 ... 95 °F)

Temperature coefficient 0.002 % of span/°C outside of 15 ... 35 °C (59 ... 95 °F)

Current

Measuring range 0 … 24 mA (max. load 1,000 Ω)

Resolution 1 µA

Accuracy 0.015 % of reading ±2 µA (simulation and measurement)

Voltage

Measuring range DC 0 … 30 V

Resolution 1 mV

Accuracy 0.015 % of reading ±2 mV (measurement)

1) Via exchangeable model CPT6000 reference pressure sensors

2) The electrical pump can generate -0.85 … +20 bar (-12 … 290 psi).

1)

2)

3 times

EN

Base instrument

Pressure supply -0.85 ... +20 bar (-12 ... +290 psi), via integrated electric pump

Pressure connection for test

item

Permissible media For dry, clean and non-aggressive gases

Output

Voltage supply DC 24 V

Power supply

Battery type Lithium-Ion rechargeable battery

Permissible ambient conditions

Operating temperature -10 … +50 °C (14 ... 122 °F)

Storage temperature -20 … +60 °C (-4 ... +140 °F)

Relative humidity 35 ... 85 % r. h. (non-condensing)

Communication

Interface USB via special interface cable

14261987.01 03/2018 EN/DE

G ½" female thread

13WIKA operating instructions, model CPH7650

Page 14

3. Specifications

Base instrument

Case

EN

Case NK-7TM resin

Front panel Aluminium

Ingress protection IP67 (case closed)

IP40 (case opened)

Dimensions 387.4 x 304.8 x 177.8 mm (15.25 x 12 x 7 in)

Weight approx. 7 kg (15.5 lbs.)

Certificates

Certificate

Calibration Standard: 3.1 calibration certificate per DIN EN 10204

Option: DKD/DAkkS calibration certificate

Recommended recalibration

1 year (dependent on conditions of use)

interval

Approvals and certificates, see website

Available pressure range and resolution

Pressure range and factors

Gauge pressure -1 ... +20 bar (-14.5 ... +290 psi)

Overpressure limit 40 bar (580 psi)

Unit Conversion factor

psi 1 300.00

bar 0.06894757 20.684

mbar 68.94757 20,684

kPa 6.894757 2,068.4

MPa 0.00689476 2.0684

kg/cm² 0.07030697 21.092

O (4 °C) 70.3089 21,093

cmH

2

O (20 °C) 70.4336 21,130

cmH

2

O (4 °C) 27.68067 8,304.2

inH

2

O (20 °C) 27.72977 8,318.9

inH

2

O (60 °F) 27.70759 8,312.3

inH

2

mmHg (0 °C) 51.71508 15,515

inHg (0 °C) 2.03602 610.81

3) Electrical pump: -0.85 … +20 bar (-12 … 290 psi)

14261987.01 03/2018 EN/DE

14 WIKA operating instructions, model CPH7650

Page 15

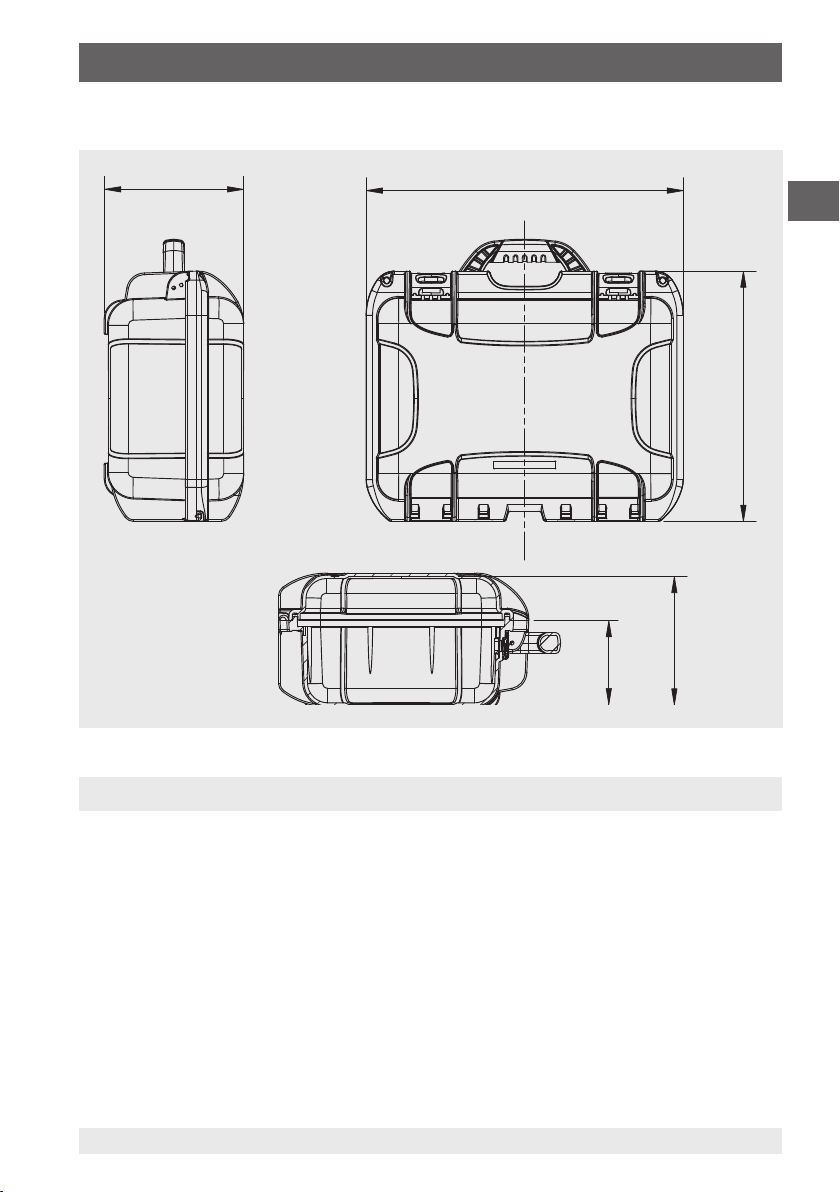

3. Specifications / 4. Design and function

104 (4,11)

158 (6,22)

Dimensions in mm (in)

172 (6,76)

390 (15,36)

EN

308 (12,13)

4. Design and function

4.1 Description

The CPH7650 is a compact, portable pressure calibrator, which has been designed

for mobile use as well as for stationary workshop and laboratory testing. An integrated

electrical pump enables you to generate pressures up to 20 bar (300 psi) and an

integrated electrical module also enables you to supply transmitters or sensors with

a current of max. 30 mA (voltage (idling) = DC 24 V), in addition to the traditional

measurement of current and voltage signals.

The pressure calibrator can be used to carry out and document a complete calibration

process. In addition to the features of displaying or measuring and calibration, there

is also a switch test. The use of the WIKA-Cal software also allows a complete

documentation.

14261987.01 03/2018 EN/DE

15WIKA operating instructions, model CPH7650

Page 16

4. Design and function

4.2 Front

EN

1

Test item

2

Overview of the electrical connection

1

2

3 4

5

6

7

8

9

10111213

3

Electrical connection to the model CPT6000 reference sensor

4

Reference sensor CPT6000

5

Connecion of the power supply unit

6

WIKA-Cal connection

7

Fine adjustment / drain valve

8

Switch for pressure / vacuum

9

Pump speed controller

10

Operation

11

Electrical module

12

Display

13

Numeric keypad

16 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 17

4. Design and function

4.3 Scope of delivery

■

Portable pressure calibrator model CPH7650

■

Operating instructions

■

Test cables

■

Battery charger

■

3.1 calibration certificate per DIN EN 10204

Cross-check scope of delivery with delivery note.

4.4 Voltage supply

Charging the battery

In order to avoid false measurements, charge the battery as soon as the battery indicator

is displayed. If the battery has run down too far, the instrument will switch itself off

automatically.

Only ever use the power supply unit permitted by WIKA for the model CPH7650 portable

pressure calibrator.

To avoid measurement uncertainties, only use the CPH7650 without the mains supply

connected. The full pump performance can only be guaranteed with the battery fully

charged and without the power supply unit connected.

The instrument should be fully charged before being put into operation.

The battery capacity status (charge state in %) is displayed shortly after the instrument is

switched on. When the power supply unit is connected, the rechargeable battery will be

charged, even if the CPH7650 is switched off.

EN

The typical charging time of the rechargeable battery is < 5 hours.

WARNING!

■

When the power supply unit is no longer being used, the mains plug

should be disconnected from the mains socket. Do not leave the

rechargeable battery connected to the power supply unit for longer than

one day, since overcharging can shorten its service life.

■

Should the rechargeable battery still not be fully charged after 24 hours,

contact the manufacturer. When not being used, a fully charged battery

will lose its charge over time.

■

Extreme temperatures have an adverse effect on battery charging. As

a result, the battery may first need to be either cooled or warmed, as

appropriate.

■

When the battery is almost completely discharged, the message “low

BAT” appears in the display. To avoid a data loss, the instrument must be

charged immediately

14261987.01 03/2018 EN/DE

17WIKA operating instructions, model CPH7650

Page 18

4. Design and function

4.5 User interface

EN

6

5

1

SETUP menu

2

Selection and entry confirmation

3

Return to previous level

4

Clear entry

5

Input confirmation

6

Numeric keypad

Switch on via pressing any button

Switch off via menu item in main menu

1

2

3

4

18 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 19

4. Design and function

4.5.1 Requirements for test assemblies with the CPH7650

■

Before starting any task, the instrument should be switched on briefly to determine

that there is sufficient charge in the battery (rechargeable battery capacity in %). The

battery capacity is indicated briefly in an instrument status message after switching

on (see chapter 6.2.1 “Instrument status messages shortly after switching on the

CPH7650”).

■

Initially, the test assembly must be physically assembled and, if necessary, connected

electrically (see chapter 4.5.4.1 “Connection of the model CPT6000 reference

pressure sensor”).

■

Before switching the CPH7650 on, ensure that the test assembly is not pressurised

(system is vented to atmosphere) and that the equipment is correctly assembled and

in the correct mounting position.

■

Only connect test and calibration installations once the system has been

depressurised!

Compensation for height differences

If a significant elevation difference exists between the CPT6000 reference pressure

sensor and the test item, then the pressure difference, based on a medium column, can

be compensated automatically via the menu (see chapter 6.4.5 “SETUP additional menu

items: CPH configuration”).

4.5.2 Important instrument settings for calibration using calibration mode

EN

Calibration date

The instrument has an integral real-time clock with date. The current date of a calibration

is stated later in the calibration certificate. Before starting a calibration, you must ensure

that the internal date of the CPH7650 is correct (see

chapter 6.4.5 “SETUP additional menu items: CPH configuration”).

Unit and resolution

After selecting one of the main menu items (e.g.: MEASURING, CALIBRATION or

SWITCH TEST) from the SETUP menu (press SETUP key), using the menu item “Unit”,

and its associated submenu respectively (move the cursor to “Unit” and press the right

or left arrow), you can set the unit and adjust its resolution (see chapter 6.3 “Operating

modes”).

14261987.01 03/2018 EN/DE

19WIKA operating instructions, model CPH7650

Page 20

4. Design and function

Available units, including their conversion factors in relation to the unit bar

bar 1.00000E+00

mbar 1.00000E-03

hPa 1.00000E-03

EN

psi 6.89475E-02

inHg (0 °C) 3.37690E-02

cmHG (0 °C) 1.33322E-02

MPa 1.00000E+01

kPa 1.00000E-02

Pa 1.00000E-05

O (4 °C) 9.80670E-02

mH

2

O (4 °C) 9.80670E-04

cmH

2

O (4 °C) 9.80670E-05

mmH

2

2

kg/cm

O (60 °C) 2.48800E-03

inH

2

O (0 °C) 1.33322E-03

mmH

2

4.5.3 Zero point setting and offset correction

Zero point setting for overpressure sensors

If the measured value shown on the CPH7650, with an overpressure sensor connected

and the test assembly vented to atmosphere, is not equal to zero, then by pressing the

CLEAR button twice (within five seconds), the zero point can be corrected (maximum

allowable correction value is twice the magnitude of the class accuracy).

9.80665E-01

Offset correction for absolute pressure sensors

For absolute pressure sensors, an offset correction can be made via the menu (see

chapter 6.4.3 “SETUP additional menu items: Reference sensor”).

4.5.4 Reference pressure sensor CPT6000

For the model CPH7650 pressure calibrator, there are many reference pressure sensors

to choose from, with accuracies of 0.025 % which can be interchanged quickly and

without tools. When the pressure calibrator is switched on, the reference pressure sensor

attached is recognised automatically, so that no further configuration of the sensor is

needed.

20 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 21

4. Design and function

4.5.4.1 Connection of the model CPT6000 reference pressure sensor

WARNING!

■

Only use model CPT6000 reference pressure sensors!

■

Using other sensors could damage both the pressure calibrator and the

reference pressure sensor.

■

To change the sensor, switch off the pressure calibrator and make sure

the system is vented. Before switching the instrument on, connect the

sensor, otherwise it may not be correctly identified by the instrument.

■

When the CPH7650 is switched on, the CPT6000 reference pressure

sensor must not be under pressure, but rather should be at atmospheric

pressure. For overpressure or gauge pressure sensors, there is a

pressure compensation vent in the top of the sensor under the plastic

fitting. This vent (with integrated diaphragm) must always remain clear!

CAUTION!

Only ever use the original WIKA sensor connection cable in the operation of

CPT6000 reference pressure sensors.

WARNING!

The pump performance is independent of the pressure range of the selected

reference sensor. The operator must ensure that the CPT6000 reference

sensor is not over-pressured.

EN

4.5.4.2 Electrical connection of the CPT6000 reference pressure sensor to the

CPH7650

The calibrator and the reference pressure sensor are connected to each other electrically

using a separate connection cable. To electrically connect a model CPT6000 reference

pressure sensor, the corresponding cable connector must be plugged in at the sensor in

accordance with the orientation guide. To disconnect the sensor, do not pull on the cable,

but rather only on the connector sleeve.

To connect it to the CPH7650, the other end of the cable must also be plugged in in

accordance with the orientation guide.

4.5.4.3 Mechanical connection of the CPT6000 reference pressure sensor to the

CPH7650

To make the mechanical connection of the CPT6000 reference pressure sensor, it must

be placed, connection thread first, in the sensor bracket of the instrument. Then, the

sensor must be tightened again.

(Tighten = turn clockwise; release = turn anti-clockwise)

No further tools are required for this.

14261987.01 03/2018 EN/DE

21WIKA operating instructions, model CPH7650

Page 22

5. Transport, packaging, storage

5. Transport, packaging and storage

5.1 Transport

Check the portable pressure calibrator for any damage that may have been caused by

EN

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +60 °C

■

Relative humidity: 0 ... 85 % r. h. (non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the portable pressure calibrator in its original packaging in a location that fulfils

the conditions listed above. If the original packaging is not available, pack and store the

instrument as described below:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to health,

e.g. caustic, toxic, carcinogenic, radioactive, etc.

22 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 23

6. Commissioning, operation

6. Commissioning, operation

By pressing any key, the model CPH7650 portable pressure calibrator will be switched

on. The calibrator requires a warm-up for a few minutes (max. 5 minutes) to reach its

specified accuracy. Large changes in ambient temperature may make a longer warm-up

period necessary. The pressure display of the calibrator should be zeroed before starting

the pressure calibration.

Instrument features

The instrument features 3 operating modes: MEASURING / CALIBRATION / SWITCH

TEST, which offer the user maximum convenience according to its application. For

supplying the test items and to read their measuring signals, there are electrical inputs

and outputs available.

In the MEASURING (with test item) and CALIBRATION operating modes, the measured

values of both the reference pressure sensor and the test item, as well as their deviation,

are displayed in both current pressure units and in %. In this way the operator is

immediately informed online whether the test item meets the class accuracy or not.

The difference between these two modes is that the calibration data in CALIBRATION

mode are stored internally and can later be transferred onto printable certificates through

software (WIKA-Cal).

With respect to the transfer of data to a PC, the model CPH7650 pressure calibrator has a

USB interface, selectable via menu.

SETUP menu

Using the SETUP key, one can access the SETUP menu, where the required operating

mode (MEASURING / CALIBRATION / SWITCH TEST) can be selected and configured,

a stored function can be recalled or a general instrument setting (such as the menu

language) can be changed.

EN

14261987.01 03/2018 EN/DE

23WIKA operating instructions, model CPH7650

Page 24

6. Commissioning, operation

6.1 Menu structure (operating modes)

Through the SETUP menu, the required operating mode can be easily selected (see

drawing below).

EN

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

SELECTSELECT SELECT

SELECT SELECTSELECT

optional

Operating modes Configuration SETUP menu

It is possible to change the test item display (pressure ↔ electrical signal) via

24 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 25

6. Commissioning, operation

6.2 Explanation of the display

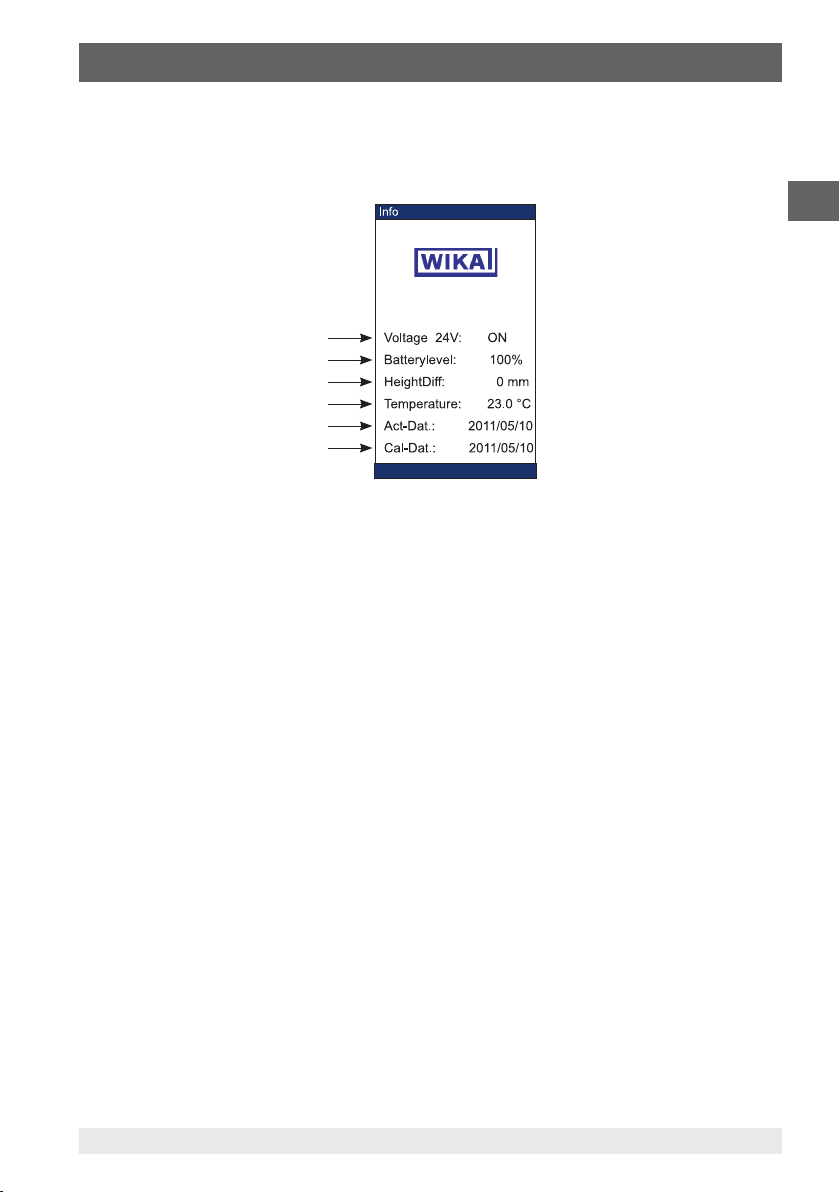

6.2.1 Instrument status messages shortly after switching on the CPH7650

Directly after the instrument is switched on, the following status messages are displayed

briefly:

CPH7650

a

b

c

d

e

f

a) The voltage supply of 24 V (available at the upper end of instrument) can, during the

configuration of each operating mode, be switched on or off. If it is not needed for a

measurement, then it should be switched off, in order to conserve energy.

b) Current battery capacity (see chapter 6.4.5 “SETUP additional menu items: CPH

configuration”)

c) Height difference in mm

In the “SETUP\CPH configuration” menu, set the height difference between the test

item and the CPT6000 reference pressure sensor. This value influences an automatic

correction calculation in order to eliminate any pressure difference based on a

medium column. This value must be correct for the following measuring procedure

and/or be adjusted accordingly in the “SETUP/CPH configuration” menu (see chapter

6.4.5 “SETUP additional menu items: CPH configuration”).

d) Temperature in [°C]

In the “SETUP\CPH configuration” menu, the temperature (ambient temperature) is

entered. This value can be adjusted accordingly in the “SETUP\CPH configuration”

menu (see chapter 6.4.5 “SETUP additional menu items: CPH configuration”).

e) Current date of the integrated real-time clock

In the “SETUP\CPH configuration” menu, the date of the real-time clock is set, which is

later marked on the calibration certificate. This value must be correct for the following

measuring procedure in calibration mode and/or be adjusted accordingly in the

“SETUP/CPH configuration” menu (see chapter 6.4.5 “SETUP additional menu items:

CPH configuration”).

f) Calibration date for the electrical measuring inputs of the CPH7650 (Year/Month/Day)

Following the status messages, the display returns to the screen for the last-selected

operating mode (see following chapter 6.2.3 “Display contents of the operating

modes”).

EN

14261987.01 03/2018 EN/DE

25WIKA operating instructions, model CPH7650

Page 26

6. Commissioning, operation

6.2.2 Switching the pressure calibrator off

The instrument is switched off using the “Switch off CPH” menu item in the first submenu.

For this, press the SETUP key, select the “Switch off CPH” menu item and confirm using

the SELECT button. Switch off the CPH7650.

EN

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

Switching off

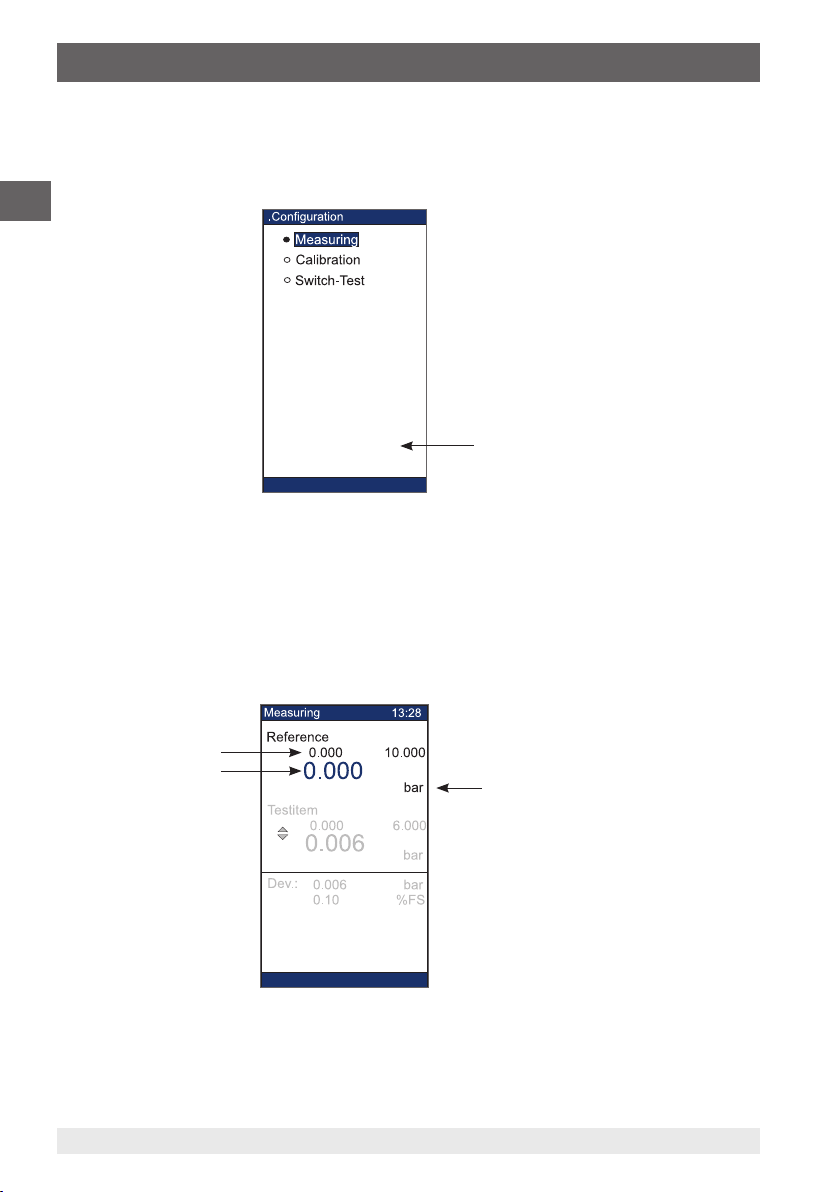

6.2.3 Display contents of the operating modes

Operating mode: MEASURING

When a CPH7650 with a CPT6000 reference pressure sensor connected to it is first

switched on, the instrument (after displaying a brief status message) switches to

MEASURING mode (see following figure)

Display: MEASURING with reference pressure sensor only (without test item)

a

b

c

a) Measuring range of the CPT6000 reference pressure sensor (which is currently

connected)

b) Current measured value of the reference pressure sensor

c) Pressure unit (adjustable via menu)

14261987.01 03/2018 EN/DE

26 WIKA operating instructions, model CPH7650

Page 27

6. Commissioning, operation

In MEASURING mode, at the same time as the reference-pressure value, a test item can

also be displayed on the screen (see following figure). With respect to the configuration,

see chapters 6.3.1 “MEASURING mode” and 6.3.2 “MEASURING mode (with test item)”.

Display: MEASURING with test item

d

a

b

c

P I/U

switchable

e

f

Pressure signal (test item) Electrical signal (test item)

a) Measuring range of the test item

b) Current measured value of the test item

c) Deviation/difference between reference and test item in the current pressure units and

in % of the measuring span (% FS) or % of reading (% rd)

d) Pressure unit (of the test item)

e) Original output signal of the test item

f) Current value of the output signal of the test item

EN

14261987.01 03/2018 EN/DE

27WIKA operating instructions, model CPH7650

Page 28

6. Commissioning, operation

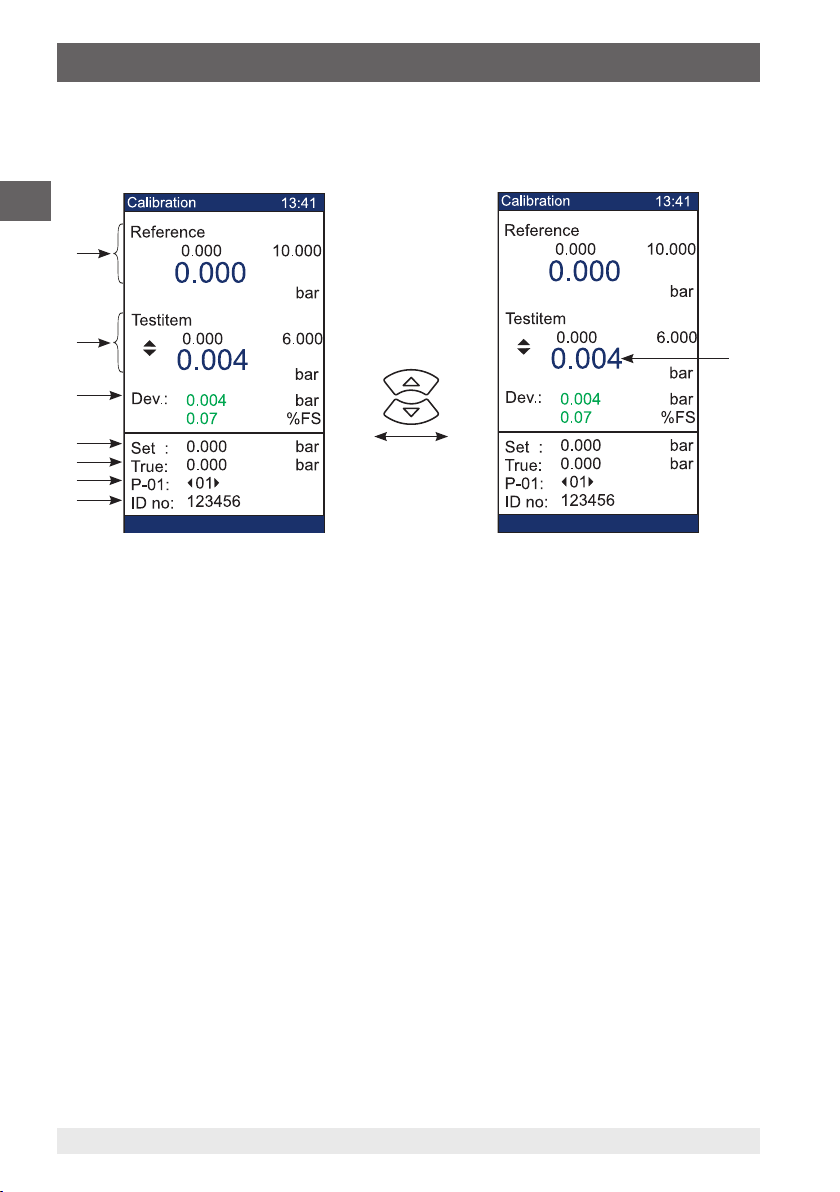

Operating mode: CALIBRATION

In the CALIBRATION mode the data shown above the dashed dividing line is the same

as in the “MEASURING with test item” mode.

EN

a

b

c

d

e

P I/U

switchable

f

g

Pressure signal (test item) Electrical signal (test item)

a) Current measured value of the CPT6000 reference pressure sensor

b) Current measured value of the test item

c) Deviation between the test item and reference

d) Set point of the calibration

e) Actual value of the calibration

f) P - 01: Test item No. 1

<01>: Test step No. 1

g) IDENT number of the test item

h) Current value of the output signal of the test item

h

28 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 29

6. Commissioning, operation

Operating mode: SWITCH TEST

In the SWITCH TEST mode, along with the reference pressure sensor data (see

MEASURING mode), the status and switch points of the pressure switch are also

displayed.

a

f

b

c

d

e

a) Current measured value of the CPT6000 reference pressure sensor

b) Current switching status/status of the pressure switch

c) Opening switch point

d) Closing switch point

e) Hysteresis/separation between opening and closing of the switch

f) Pressure unit (adjustable via menu)

EN

6.2.4 Content of the SETUP menu

a

b

c

d

e

f

g

h

i

y

k

14261987.01 03/2018 EN/DE

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

29WIKA operating instructions, model CPH7650

Page 30

6. Commissioning, operation

a) Operating mode MEASURING

■

To measure working or process pressures

■

For comparative measurements and/or calibrations (without data recording) of

EN

mechanical* and electrical pressure measuring instruments (supply and display of

the test item through the CPH7650)

→ For further information, see chapter 6.3.1 “MEASURING mode” and

6.3.2 “MEASURING mode (with test item)”

b) Operating mode CALIBRATION

■

For on-site calibration of mechanical 1) and electrical pressure measuring

instruments (without PC). In this case the data sets (for up to 16 test items, each

with up to 32 test steps including date and time) are recorded within the CPH7650.

1) For mechanical dial instruments, the test item's measured value must be entered via the numeric keypad.

→ For more information please refer to chapter 6.3.3 “Mode CALIBRATION”

c) Operating mode SWITCH TEST

■

For the easy checking of pressure switches, including automatic calculation of the

switch hysteresis.

→ For more information please refer to chapter 6.3.7 “SWITCH TEST mode”

d) Operating functions

■

Tare: Offset correction of the reference pressure value

■

Min/Max: Minimum/Maximum memory

■

Alarm: Min/Max alarm (visual and audible)

■

Filter: Damping/smoothing of the reference sensor signal

→ For further information see chapter 6.4.1 „SETUP additional menu items: Functions“

e) General CPH7650 instrument data

■

Calibration data for the electrical measuring inputs

■

Firmware number

■

Serial number of the instrument

→ For more information please refer to chapter 6.4.2 “SETUP additional menu items:

CPH info”

30 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 31

6. Commissioning, operation

f) Data for the currently connected reference pressure sensor

■

Measuring range

■

Accuracy class

■

Pressure type of the sensor

■

Information in the event of reference sensor overpressure

■

Calibration data for the reference sensor

→ For more information please refer to chapter 6.4.3 “SETUP additional menu items:

Reference sensor”

g) Reference sensor list

■

List of the stored reference sensors that can be attached and are calibrated.

→ For more information please refer to chapter 6.4.4 “SETUP additional menu items:

Reference sensor list”

h) CPH configuration

■

Info: On battery capacity

■

Setting options from: Menu language, system time/system clock, display brightness,

Powersave function (automatic energy saving mode; see chapter 6.4.5 “SETUP

additional menu items: CPH configuration”)

■

Input options:

- Ambient temperature during the calibration

- Height difference existing between the reference pressure sensor and test item

(see chapter 4.5.1 “Requirements for test assemblies with the CPH7650”).

EN

→ For more information please refer to chapter 6.4.5 “SETUP additional menu items:

CPH configuration”

i) Interface

■

USB interface, incl. setting of the baud rate

→ For more information please refer to chapter 6.4.6 “SETUP additional menu items:

Interface”

j) CLEAR CalProg

■

Delete all stored calibration data (clear and reset all memory space)

→ For more information please refer to chapter 6.4.7 “SETUP additional menu items:

CLEAR CalProg”

k) Switching off the model CPH7650 pressure calibrator

→ For more information please refer to chapter 6.2.2 “Switching the pressure calibrator

off”

14261987.01 03/2018 EN/DE

31WIKA operating instructions, model CPH7650

Page 32

6. Commissioning, operation

6.3 Operating modes

6.3.1 MEASURING mode

1. Access SETUP menu

EN

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

Press

(SETUP key)

Selection

(Menu item)

2. Preparing for MEASURING

..Measuring

a

b

c

d

e

f

g

3. Mode: MEASURING

Pressure unit

(adjustable via

menu)

SELECT

SELECT

Confirmation

(of the selection)

Selection

(Menu item);

configuration, see

next page

Confirmation

(of the input)

32 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 33

6. Commissioning, operation

In order to switch the instrument into MEASURING mode, follow the instructions on the

previous page.

The following is a more detailed explanation of point 2 “Preparation for MEASURING”:

a) Test item type and test item measuring signal: [----] For measurement without test item

b) Start of measuring range and end of measuring range of the test item currently to be

calibrated

c) Unit and resolution (submenu)

Select and confirm (standard units) via

Customer-specific unit; with respect to bar

(input via numeric keypad)

Display resolution in operating mode via

(back with )

d) Measurement uncertainty of the test item in % FS (i.e. of the span) or % rd (i.e. of

reading)

e) Measurement type for the test item (gauge or absolute)

f) Test medium (pneumatic → gas or hydraulic → oil)

g) Voltage supply for test item (on/off)

If no external supply is required for the test item, “OFF” should be selected to conserve

energy.

EN

XXX

◁▷ ◀▶

0.00 Parameter input via numeric keypad

ENTER

Short info:

14261987.01 03/2018 EN/DE

Current cursor position; Alter via

Parameter selection from list or menu via

Input confirmation

CLEAR

Clear entry

33WIKA operating instructions, model CPH7650

Page 34

6. Commissioning, operation

6.3.2 MEASURING mode (with test item)

1. Access SETUP menu

EN

2. Prepare MEASUREMENT

a

b

c

d

e

f

g

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

SELECT

Press

(SETUP key)

Selection

(Menu item)

Confirmation

(of the selection)

Selection

(Menu item);

configuration, see

next page

Confirmation

(of the input)

3. Mode: MEASURING

Deviation

SELECT

P I/U

switchable

Pressure signal (test item) Electrical signal (test item)

34 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 35

6. Commissioning, operation

Should the instrument be switched into “MEASURING” mode (with test item = display

of the test signal as an electrical signal or as a pressure), in order to carry out a

comparative measurement or calibration without measured-value recording, then follow

the instructions on the previous page.

The following is a more detailed explanation of point 2 “Preparation for MEASURING”

a) Test item type and test item measuring signal

0 ... 20 mA / 4 ... 20 mA / 0 ... 1 V / 0 ... 2 V / 0 ... 5 V / 0 ... 10 V / or mechanical for dial

pressure gauge

If a comparative measurement with a mechanical dial instrument (test item) is being

made, then the gauge’s measured value should be entered via the numeric keypad and

confirmed with the ENTER key.

b) Start of measuring range and end of measuring range of the test item currently to be

calibrated

c) Unit and resolution (submenu)

Select and confirm (standard units) via

Customer-specific unit; with respect to bar

(input via numeric keypad)

EN

Display resolution in operating mode via

(back with )

d) Measurement uncertainty of the test item in % FS (i.e. of the span) or % rd (i.e. of

reading)

e) Measurement type for the test item (gauge or absolute)

f) Test medium (pneumatic → gas or hydraulic → oil)

g) Voltage supply for test item (on/off)

If no external supply is required for the test item, “OFF” should be selected to conserve

energy.

XXX

◁▷ ◀▶

0.00 Parameter input via numeric keypad

ENTER

Short info:

14261987.01 03/2018 EN/DE

Current cursor position; Alter via

Parameter selection from list or menu via

Input confirmation

CLEAR

Clear entry

35WIKA operating instructions, model CPH7650

Page 36

6. Commissioning, operation

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

6.3.3 Mode CALIBRATION

1. Access SETUP menu

EN

2. Preparation for CALIBRATION

a

b

c

d

e

f

g

h

i

y

k

l

m

n

SELECT

Press

(SETUP key)

Selection

(Menu item)

Confirmation

(of the selection)

Selection

(Menu item);

configuration, see

next page

SELECT

Confirmation

(of the input)

3. Mode: Calibration

Deviation

36 WIKA operating instructions, model CPH7650

Pressure signal (test item) Electrical signal (test item)

P I/U

switchable

14261987.01 03/2018 EN/DE

Page 37

6. Commissioning, operation

In order to put the instrument into CALIBRATION mode, the procedure on the previous

page should be followed.

The following is a more detailed explanation of point 2 “Preparation for CALIBRATION”

a) Number of the calibration and therefore the test item (up to 16 calibrations, each with

up to 32 test steps, can be predefined and then recorded)

b) Test item type and test item measuring signal

0 ... 20 mA / 4 ... 20 mA / 0 ... 1 V / 0 ... 2 V / 0 ... 5 V / 0 ... 10 V / or mechanical for dial

pressure gauge

c) IDENT number of the test item

d) Measuring point number of the test item

e) Start of measuring range and end of measuring range of the test item currently to be

calibrated

f) Unit and resolution (submenu)

Select and confirm (standard units) via

Customer-specific unit; with respect to bar

(input via numeric keypad)

Display resolution in operating mode via

(back using )

g) Measurement uncertainty of the test item in % FS (i.e. of the span) or % rd (i.e. of

reading)

h) Measurement type for the test item (gauge or absolute)

i) Test medium (pneumatic → gas or hydraulic → oil)

j) Voltage supply for test item (on/off) [If no external supply is required for the test item,

“OFF” should be selected to conserve energy]

k) Number of the test point x

l) Optional delay time [sec] (see chapter 6.3.4 “CALIBRATION mode (preparing the test

points of a calibration)”)

m) Value of the test point x (input via numeric keypad)

(Test point x+1 and x-1 accessible via

)

n) True value of the test item (will be recorded during the calibration)

EN

14261987.01 03/2018 EN/DE

37WIKA operating instructions, model CPH7650

Page 38

6. Commissioning, operation

6.3.4 CALIBRATION mode (preparing the test points of a calibration)

1. Test point

(define)

EN

1. Test point

(defined)

ENTER

Calibration/test item No. 1

Select from menu item: “Set

point”

No. of the test point

Set point of the test point

Entry of the test point (e.g.

0 bar) via numeric keypad and

confirmation with

←

Test point No. 1 = 0 bar

2. Test point

(define)

← 2. Call up test point

(with

back to previous test

point)

x. Test point

(define)

38 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 39

6. Commissioning, operation

With this example, the definition of individual test points/pressure steps for a calibration is

clarified. It is possible to prepare up to 16 calibrations, each with up to 32 test steps.

Accessing the menu item

Via

and selection of the menu item: CALIBRATION (or see chapter 6.3.3 “Mode

CALIBRATION”)

Enter the desired test points in the way described on the previous page.

With the calibration of pressure measuring instruments with electrical output signals

(pressure transmitters/transmitters) the reference is calibrated to the display (i.e. the

pressure is always adjusted so that the reference value matches the set point exactly).

As an exact setting of the pressure is not always possible under certain circumstances,

the true reference value is also recorded along with the actual value (test item value)

and the set point (reference value). With the WIKA-Cal software, this can be listed in the

calibration certificate.

If the calibration is to follow DKD/DAkkS guidelines, then the measured

value for each subsequent test point should not be recorded until a defined

time has passed (for example 30 seconds), consisting of a load change time

and settling time (see figure A: Calibration cycle to DKD/DAkkS guideline 6

- 1 for measurement uncertainty > 0.6 % of measuring span).

Z

M1

M2

2 Minutes

30 s 30 s

For Bourdon tube

pressure gauges:

5 minutes

Readings

EN

14261987.01 03/2018 EN/DE

Figure A

39WIKA operating instructions, model CPH7650

Page 40

6. Commissioning, operation

EN

optional delay time [sec]

Input via numeric input keypad and confirmation

ENTER

with

With the entry of such a delay time, the acceptance/recording of the test point is blocked

for this duration. (In the above example, after the first test point has been recorded,

30 seconds must pass before the second test point can be recorded.)

Should all test points need to be cleared or reset, since the new calibration

consists of fewer test points than the previous test series, the CLEAR button

simply needs to be pressed. This will clear and reset the current and all

subsequent test points.

(This process can take several seconds.)

Should all saved calibration data for all calibrations need to be cleared at

a single time, see chapter 6.4.7 “SETUP additional menu items: CLEAR

CalProg”.

40 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 41

6. Commissioning, operation

6.3.5 CALIBRATION mode (calibration of a pressure transmitter)

1. Test point

(e.g. 0 bar)

Deviation

No. of test item

and No. of test

point

2. Test point

(e.g. 1 bar)

ENTER

Generate the specified set

point in accordance with the

reference display (establish

a pressure-free condition/

atmosphere) and with

←

Record the measured values of

the test point

EN

Deviation

No. of test item

and No. of test

point

2. Test point

Deviation

No. of test item

and No. of test

x. Test point

14261987.01 03/2018 EN/DE

point

ENTER

Generate the specified set

point in accordance with the

reference display using the

pressure generator

Record the measured values of

the test point

(with

test point)

back to previous

41WIKA operating instructions, model CPH7650

Page 42

6. Commissioning, operation

6.3.6 CALIBRATION mode (calibration of a pressure gauge)

1. Test point

(e.g. 0 bar)

EN

Deviation

Generate the specified set point

in accordance with the test

item display using the pressure

generator

No. of test item

and No. of test

2. Test point

(e.g. 1 bar)

Deviation

No. of test item

and No. of test

2. Test point

point

point

ENTER

If the set point = 0 bar, the

calibration assembly must

be brought to a pressure-free

condition/vented to atmosphere

(test item must indicate 0 bar;

if necessary, make a zero point

setting) and with

←

Record the measured values of

the test point

Generate the specified set point

in accordance with the test

item display using the pressure

generator

Deviation

No. of test item

and No. of test

x. Test point

ENTER

point

Record the measured values of

the test point

(with

test point)

back to previous

42 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 43

6. Commissioning, operation

Functions

CPH-Info

ReferenceSensor

Ref. Sensor-list

CPH-Configuration

Interface

CLEAR CalData

CPH switch off

6.3.7 SWITCH TEST mode

1. Access SETUP MENU

2. Preparing the SWITCH

TEST

a

b

SELECT

Press

(SETUP key)

EN

Selection

(Menu item)

Confirmation

(of the selection)

Selection

(Menu item);

configuration, see

next page

3. Mode: SWITCH TEST

switching status

Switch points

14261987.01 03/2018 EN/DE

Current

Hysteresis

SELECT

Confirmation

(of the input)

Before the pressure switch test After the pressure switch test

43WIKA operating instructions, model CPH7650

Page 44

6. Commissioning, operation

In order to put the instrument into SWITCH TEST mode, the procedure on the previous

page should be followed.

EN

The switch test is not suitable for electronic switches (e.g. PNP- or NPN

switches), but is only for mechanical, potential-free switches.

The following is a more detailed explanation of point 2 “Preparation for SWITCH TEST”

a) Voltage supply for test item (on/off) [If no external supply is required for the test item,

“OFF” should be selected to conserve energy]

b)Unit and resolution (submenu)

Select and confirm (standard unit) via

Customer-specific unit; with respect to bar

(input via numeric keypad)

Display resolution in operating mode via

(back with )

The calculated measured values of the two switch points and the hysteresis

can be reset by pressing the “0” key.

44 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 45

6. Commissioning, operation

6.4 SETUP additional menu items

6.4.1 SETUP additional menu items: Functions

a

b

c

d

e

a) Current measured value of the connected CPT6000 reference pressure sensor

b) Offset function that influences the current measured value. The value entered is added

to the current measured value.

c) (e.g. Ref. 0.000 and Tare: 1.000 → [new] Ref. 1.000)

d) Minimum and maximum value memory

The memory is reset by highlighting the value with the cursor (via

CLEAR button.

d) Audible and visible alarm function

upper alarm limit: ≥ bar

lower alarm limit: ≤ bar

If the current measured value goes outside the set alarm limits, an intermittent alarm

tone sounds and the lower status line blinks.

Activation via:

Move the cursor to the field next to the word Alarm that reads <OFF> and via

change it to <ON>.

Deactivation via:

set back to <OFF>

e) Filter [1-5]:

Damping/smoothing of the reference sensor signal

Definition of the numbers:

1 = no additional smoothing ... 5 = strong smoothing

..Functions

0.000

Ref.:

0.000

Tare:

0.000

Min:

0.000

Max:

Alarm:

Filter:

Ref. = rel. Pressure

Offset pressure

ON

10.00

≥

-1.00

≤

0

bar

bar

bar

bar

bar

bar

ENTER

Select menu item

Input via numeric keypad

Confirmation of input

(Clear deletes the input, or

resets the MIN/MAX memory)

) and pressing the

EN

14261987.01 03/2018 EN/DE

45WIKA operating instructions, model CPH7650

Page 46

6. Commissioning, operation

6.4.2 SETUP additional menu items: CPH info

EN

Info

CPH7650

CPH6000

a

b

c

Cal-Dat.: 2011/05/10

Firmware: 20.05

Serial No: 6000.001

In this menu item general data are listed, such as:

a) Calibration date for the calibration of the electrical measuring inputs of the CPH7650

(Year/Month/Day)

b) Firmware version of the CPH7650

c) Serial number of the CPH7650

46 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 47

6. Commissioning, operation

6.4.3 SETUP additional menu items: Reference sensor

..ReferenceSensor

a

b

c

d

e

f

Sensor no:

R.-Start:

Range-End:

Unit:

Class:

%FS

Pressuretype:

Overload:

Read

362A

0.00

10.00

bar

0.025

0 sec

EN

rel

g

h

i

Ref-Value:

Offset:

Cal-Dat.:

Reference sensor

0.001

0.000

2011/05/10

a) Sensor number of the currently connected CPT6000 reference pressure sensor

b) Start of measuring range and end of measuring range for the currently connected

CPT6000 reference pressure sensor

c) Basic pressure unit of the CPT6000 reference pressure sensor

d) Accuracy of the measuring chain of the CPH7650 with connected CPT6000 reference

pressure sensor

e) Pressure type of the currently connected CPT6000 reference pressure sensor

(overpressure (gauge pressure) or absolute pressure)

f) Length of time for which the CPT6000 reference pressure sensor was unacceptably

overloaded.

If the value here is not equal to zero, then it is highly probable that the

instrument no longer meets its specified class accuracy. The only solution

for this is an immediate recalibration. (For absolute pressure sensors < 1 bar

this function is deactivated, since for this measuring range atmospheric

pressure already represents an overload)

g) Current measured value of the connected CPT6000 reference pressure sensor

h) This menu option only appears if the CPH7650’s reference pressure sensor is an

absolute pressure sensor.

Through this menu option the measured value of the reference pressure sensor can be

adjusted. This should only be used, however, as close as possible to the absolute zero,

and using a reference that is at least 4 times more accurate.

i) Calibration date of the CPT6000 reference pressure sensor (Year/Month/Day)

14261987.01 03/2018 EN/DE

47WIKA operating instructions, model CPH7650

Page 48

6. Commissioning, operation

6.4.4 SETUP additional menu items: Reference sensor list

..Ref. Sensor-list

362A

Rp52

Kd35

Rp56

----

362A

06

07

08

09

10

10.000

2011/05/10

----

----

----

----

----

0.000

bar

0.025

Selection

of a listed sensor with

EN

a

Current

01

02

b

03

04

05

R.-Start:

Range-End:

c

Unit:

Cal-Dat.:

Class:

The CPH7650 pressure calibrator supports up to 10 CPT6000 reference pressure

sensors.

These are listed in this menu.

a) Currently connected CPT6000 reference pressure sensor

b) Sensor list of the supported CPT6000 reference pressure sensors (calibrated with the

instrument)

c) Data of the sensor which has been selected using the cursor

(calibration date: Year/Month/Day)

48 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 49

6. Commissioning, operation

6.4.5 SETUP additional menu items: CPH configuration

a

b

c

d

e

ENTER

f

g

h

Selection of menu item

Input via numeric keypad

Confirmation of input

(Clear deletes the input)

This menu section lists general instrument settings, such as:

a) Input possibility for an ambient temperature

b) Input possibility for a height difference between reference pressure sensor and test

item, used in the automatic correction (deduction of a medium column)

c) Selection of the menu language (German/English/French/Spanish/Italian)

d) Date of the system clock (Year/Month/Day)

e) Time of the system clock (Hours/Minutes/Seconds)

f) Brightness of the backlighting of the display

g) Powersave function (automatic switch-off time for backlighting and internal 24 V test

item power supply).

If the instrument is idle for the set switch-off time (no buttons pressed and no interface

communication), then the backlighting and the 24 V test item power supply will

be switched off, until any button is pressed (except ON/OFF) or the instrument is

addressed over the interface.

h) Current battery capacity

At 10 % the low battery charge warning, “low BAT” is shown in the display.

EN

14261987.01 03/2018 EN/DE

49WIKA operating instructions, model CPH7650

Page 50

6. Commissioning, operation

6.4.6 SETUP additional menu items: Interface

..Interface

USB

EN

RS232

(8N1)

The USB interface can be switched on and off. In order to extend the battery life, the USB

interface should be deactivated when not in use.

ON

9600

SELECT

Select serial interface

Confirm selection

Change between interface type

and baud rate

6.4.7 SETUP additional menu items: CLEAR CalProg

If the SETUP menu item CLEAR CalData is selected with the cursor and then the

SELECT button pressed 2 x, then all stored calibration data will be deleted or reset.

The status of the deletion process is shown at the left of the lower info

screen.

50 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 51

6. Commissioning, operation

6.5 Connection of the model CPT6000 reference pressure sensor

WARNING!

■

Only use model CPT6000 reference pressure sensors!

■

Using other sensors could damage both the pressure calibrator and the

reference pressure sensor.

■

To change the sensor, switch off the pressure calibrator and make sure

the system is vented. Before switching the instrument on, connect the

sensor, otherwise it may not be correctly identified by the instrument.

■

When the CPH7650 is switched on, the CPT6000 reference pressure

sensor must not be under pressure, but rather should be at atmospheric

pressure. For overpressure or gauge pressure sensors, there is a

pressure compensation vent in the top of the sensor under the plastic

fitting. This vent (with integrated diaphragm) must always remain clear!

CAUTION!

Only ever use the original WIKA sensor connection cable in the operation of

CPT6000 reference pressure sensors.

6.6 Voltage supply

The internal Lithium-Ion battery, which can be easily charged with the battery charger

supplied with the equipment, serves as the voltage supply for the instrument. To charge

the CPH7650 rechargeable batteries, the mains plug of the charger/power supply unit

must always be plugged into a mains socket and accessible, so that one can always

remove it from the mains socket without difficulty.

EN

CAUTION!

For EMC reasons, never use the CPH7650 with a power supply unit

connected.

The instrument should be fully charged before being put into operation.

The battery capacity status (charge state in %) is displayed shortly after the instrument

is switched on and can be learnt about in chapter 6.4.5 “SETUP additional menu items:

CPH configuration”.

When the mains lead is connected to the CPH7650, the battery will be

charged, even if the CPH7650 is switched off

14261987.01 03/2018 EN/DE

51WIKA operating instructions, model CPH7650

Page 52

6. Commissioning, operation

■

When the battery charger is no longer being used, the mains plug should be

disconnected from the mains socket. Do not leave the battery charger connected to

the rechargeable battery for longer than one day, since overloading can shorten its

EN

service life.

■

Should the rechargeable battery still not be fully charged after 24 hours, contact the

manufacturer. When not being used, a fully charged battery will lose its charge over

time.

■

Extreme temperatures have an adverse effect on battery charging. As a result, the

battery may first need to be either cooled or warmed, as appropriate.

6.7 Charging/discharging the Lithium-Ion rechargeable batteries

CAUTION!

The temperature range over which the Lithium-Ion battery can be charged is

10 ... 45 °C. Charging the Lithium-Ion battery at temperatures outside of this

range may lead to heating or damage. In addition, the performance of the

Lithium-Ion battery can be affected and the service life reduced.

WARNING!

In order to charge the Lithium-Ion battery, never use any instrument other

than that specified by WIKA. When the Lithium-Ion battery is used in

instruments other than the instruments specified by WIKA, the performance

and service life of the Lithium-Ion battery may be reduced, and, should the

instrument cause an abnormal current to flow, it can cause the Lithium-Ion

battery to become hot, explode or ignite and result in serious injury.

CAUTION!

The temperature range over which the Lithium-Ion battery can be

discharged is -10 ... +60 °C. Use of the Lithium-Ion battery outside of this

temperature range may affect the performance of the battery or may reduce

its service life.

52 WIKA operating instructions, model CPH7650

14261987.01 03/2018 EN/DE

Page 53

6. Commissioning, operation

6.8 Pressure measurement

For pressure calibration, connect the test item to the test item connection. Choose a

reference sensor that is suitable for the pressure range and accuracy.

CAUTION!

Pressure sensors may be damaged and/or injuries may occur to

the personnel due to improper application of pressure. For a better

understanding with respect to overpressure and burst pressure, follow

the specifications laid down in these operating instructions (see chapter

3 “Specifications”).

The calibrator display will indicate “OL” when an inappropriate pressure is

applied. As soon as “OL” is observed on any pressure display, the pressure

should be reduced immediately to prevent damage or possible physical

injury. “OL” is displayed if the pressure exceeds the nominal range by 110 %.

Use the ZERO button to zero the pressure sensor once it is vented to

atmospheric pressure.

Media compatibility

CAUTION!

The calibrator should only be used with clean, dry air! To prevent

contamination by the test items, the use of a dirt trap is recommended (see

chapter 10 “Accessories”)!

6.9 Measuring and sourcing current (4 ... 20 mA)

To measure current, use the input terminals via the display on the calibrator and select

the mA function. Current is measured in mA and percentage of the measuring range. The

measuring range of the calibrator is set to 0 % at 4 mA and 100 % at 20 mA.

EN

14261987.01 03/2018 EN/DE

53WIKA operating instructions, model CPH7650

Page 54

7. Maintenance, cleaning and recalibration

7. Maintenance, cleaning and recalibration

7.1 Maintenance