Page 1

Portable pressure calibrator

Model CPH7600

Applications

■

Calibration service companies and service industry

■

Measurement and control laboratories

■

Quality assurance

Special features

■

Measurement and electrical pressure generation at the

touch of a button with integrated pump, from -0.8 ... +20 bar

■

Accuracy: 0.025 % of reading ±0.01 % FS (incl. calibration

certicate)

■

Generation/measurement of 4 ... 20 mA, and DC 24 V

voltage supply to power transmitters

■

Pressure supply via external compressed air line

■

Robust case design, IP 67

Calibration technology

WIKA data sheet CT 17.01

Wally Box III

Wally Box III, model CPH7600

Description

General information

With the model CPH7600, Wally Box III, WIKA oers a further

development of the well-known Wally Box I and Wally Box II.

The Wally Box III is a compact, portable pressure calibrator, which has been designed for mobile use as well as for

stationary workshop and laboratory testing. A special feature

of this test instrument is that it is tted with two independently-operating pressure systems.

One pneumatic system is designed to be supplied from an

external pressure supply, while the supply pressure of the

second system is generated by the integrated electrical

pressure generation. This enables the user to perform dierent measurement tasks or calibrations, regardless of external

pressure and power supplies.

Accuracy

The Wally Box III provides an accuracy of 0.025 % of reading

±0.01 % FS for the built-in pressure sensor. The temperature

compensation of the built-in sensor safeguards the accuracy

for applications in the eld. Readings can be displayed in one

of 13 standard units.

Features

With the Wally Box III, not only accurate pressure measurements are possible, but also exact current and voltage

measurements, as well as a DC 24 V supply for test items.

Pressure values and electrical measured values are simultaneously shown in the display.

The calibrator is integrated into a robust, as well as dust and

watertight transport case. Thus the mobile pressure calibrator

is particularly suited to use in harsh industrial environments.

A ow diagram on the front panel gives information on the

connection of the individual pneumatic components.

With the built-in NiMH rechargeable battery, a battery life of

50 hours or 125 pump cycles up to 20 bar is guaranteed. The

external universal power supply is designed for an operating

voltage of AC 100 ... 240 V.

Page 1 of 9WIKA data sheet CT 17.01 ∙ 05/2014

Data sheets showing similar products:

ProcessCalibrator; model CPH6000; see data sheet CT 15.01

Precision hand-held pressure indicator; model CPH6400; see data sheet CT 14.01

Hand-held pressure indicator; model CPH6300; see data sheet CT 12.01

Model CPH6600 hand-held pressure calibrator with integrated pump; see data sheet CT 16.01

Calibration software; WIKA-CAL; see data sheet CT 95.10

Page 2

Software

The WIKA-CAL calibration software is available for online

calibration in combination with a PC. Using this software, the

data is automatically transferred into a printable calibration

certicate. Furthermore, WIKA-CAL also oers, over and

Certied accuracy

For the CPH7600, the accuracy is certied by a factory

calibration certicate which accompanies the instrument. On

request, we can provide a DKD/DAkkS calibration certicate

for this instrument.

above PC-supported calibration, the management of the

calibration and instrument data in an SQL database. For data

transfer, an RS-232 interface is available.

Specications

Model CPH7600

Measuring ranges

Pressure

Relative pressure -0.8 ... +20 bar

Overpressure limit 40 bar

Burst pressure 135 bar

Accuracy 0.025 % of reading ±0.01 % FS

Resolution 5-digit

Temperature compensation 15 ... 35 °C

Temperature coecient 0.002 % of the span/°C beyond the 15 ... 35 °C

Current

Measuring range 0 ... 24 mA (max. load 1,000 Ω)

Resolution 1 µA

Accuracy 0.015 % of reading ±2 µA (simulation and measurement)

Voltage

Measuring range DC 0 ... 30 V

Resolution 1 mV

Accuracy 0.015 % of reading ±2 mV (measurement)

1) Maximum pressure for the integrated lines: 40 bar

1)

1)

Base instrument

Pressure supply maximum pressure for the integrated pressure generation: 20 bar

maximum pressure via external pressure supply: 7 bar

Pressure connection ⅛ NPT (female)

Permissible media clean, dry, non-corrosive gases, compatible with silicon, Pyrex, RTV, gold, ceramic, nickel and

aluminium

Output

Voltage supply DC 24 V

Power supply

Battery type DC 16 V, NiMH rechargeable battery

Battery life (fully-charged) approx. 50 hours (only measurement or with external pressure supply)

125 pump cycles to 20 bar

300 pump cycles to 10 bar

1,000 pump cycles to 2 bar

Permissible ambient conditions

Operating temperature -10 ... +50 °C

Storage temperature -20 ... +60 °C

Relative humidity 35 ... 85 % r. h. (no condensation)

Communication

Interface RS-232 via special interface cable

Page 2 of 9 WIKA data sheet CT 17.01 ∙ 05/2014

Page 3

Case

Material

Case NK-7TM Resin

Front panel Aluminium

Ingress protection IP 67 (case closed)

IP 40 (case opened)

Dimensions 387.4 x 304.8 x 177.8 mm (15.25 x 12 x 7")

Weight approx. 7 kg (15.5 lbs.)

EC conformity, Approvals and certicates

EC conformity

EMC directive

Approvals

GOST-R Import certicate, Russia

Certication

Calibration Standard: 3.1 calibration certicate per DIN EN 10204

Recommended calibration interval 1 year (dependent on conditions of use)

Approvals and certicates, see website

2004/108/EC, EN 61326 emission (group 1, class B) and interference immunity (portable equipment)

Option: DKD/DAkkS calibration certicate

Available pressure range and resolution

Pressure range and factors

Relative pressure -0.8 ... +20 bar

Overpressure limit 40 bar

Burst pressure 135 bar

Unit Conversion factor

psi 1 300.00

bar 0.06894757 20.684

mbar 68.94757 20,684

kPa 6.894757 2,068.4

MPa 0.00689476 2.0684

kg/cm² 0.07030697 21.092

O (4 °C) 70.3089 21,093

cmH

2

O (20 °C) 70.4336 21,130

cmH

2

O (4 °C) 27.68067 8,304.2

inH

2

O (20 °C) 27.72977 8,318.9

inH

2

O (60 °F) 27.70759 8,312.3

inH

2

mmHg (0 °C) 51.71508 15,515

inHg (0 °C) 2.03602 610.81

Page 3 of 9WIKA data sheet CT 17.01 ∙ 05/2014

Page 4

Features

Pressure supply

The Wally Box III enables the supply of pressure in two

dierent ways. The rst is an integrated electric pump from

-0.8 ... +20 bar. The second possibility is the connection of

compressed air up to 8 bar, which allows the user to control

pressures up to 7 bar via a ne adjustment.

The advantage for the user of these two dierent pressure

supplies is that the compressed air supply of a workshop can

be used, but also, for applications in the eld, the air supply is

ensured via the integrated electrical pressure generation.

Current and voltage

In addition to pressure, the Wally Box III measures and

simulates also a 4 ... 20 mA current loop signals, can

measure up to DC 30 V and comes with an internal DC 24 V

voltage supply to power the transmitter being calibrated. The

DC 24 V voltage supply is switchable for transmitters with mA

as well as V output signal.

Display

The Wally Box III can display up to three calibration values

simultaneously. This means that the internal pressure sensor,

an external pressure sensor and electrical values (mA or V)

can be displayed simultaneously. The instrument has a large

graphic LCD display with backlighting.

Pressure ranges

The Wally Box III features an integrated reference pressure

sensor with a measuring range of -0.8 ... +20 bar. Since the

accuracy is specied in % of reading, the Wally Box III lends

itself to the calibration of test items with dierent measuring

ranges up to 20 bar.

Each pressure range can be accurately generated with the

integrated electric pump at the touch of a button, or accurately controlled with external compressed air. The ne adjustment is made with the integrated volume slide.

Functions

The Wally Box III has a complete range of useful functions.

Switch tests can be performed via the internal or external

pressure input. The deviation of the test item is directly calculated and indicated on the display. A damping function is

available. Up to ve frequently-used instrument settings can

be stored and retrieved with the touch of a key.

Similarly, high-accuracy model CPT6100 external pressure

sensors can be connected via a sensor cable. This allows

accuracies of up to 0.01 % to be achieved.

Robustness

The Wally Box III consists of a calibrator, which is built into

a rugged service case. With this design, the Wally Box III is

suited to extremely harsh operating conditions.

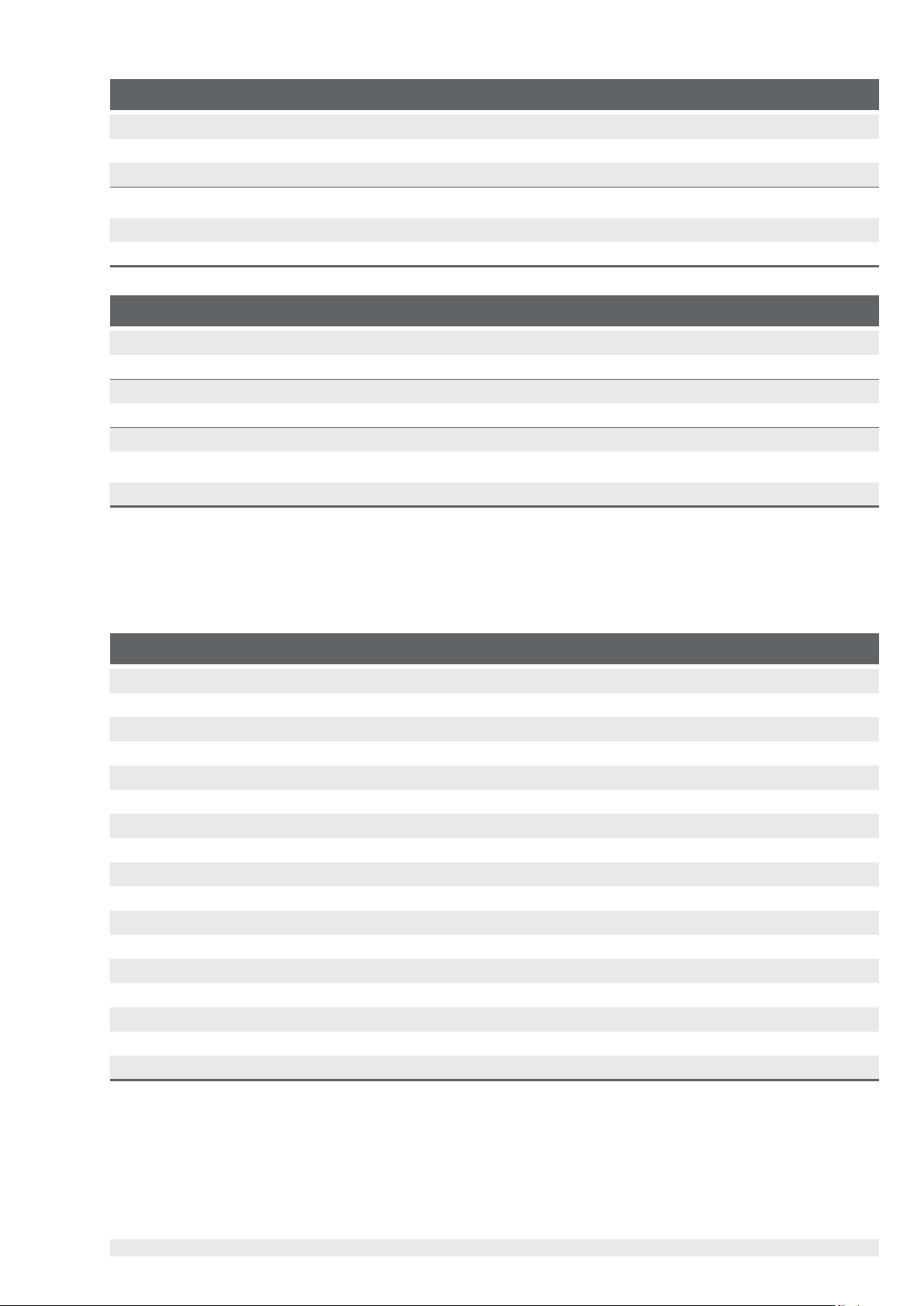

Display layout

3

Keypad

1) Pressure units

1

2

1

2

3

46

5

Indication of the pressure unit (selectable from

13 pressure units)

2) Display of the span

Indication of 4 ... 20 mA span (only for the functions mA

and mA current loop)

3) Primary parameters

Indication of the current measured parameters

1) Function keys

Conguration of the calibrator

2) HOME key

Return to main menu

3) Arrow keys

Control of the current source/current simulation and adjust-

ment of the pump limit and the %-error limit

4) ZERO key

Zeroing of the pressure measurement

5) PUMP key

Start-up of the pump operating

6) ON/OFF key

Turning the calibrator on and o

Page 4 of 9 WIKA data sheet CT 17.01 ∙ 05/2014

Page 5

Dimensions in mm (inch)

253.4 mm (9.98")

368.5 mm (14.51")

390 mm (15.36")172 mm (6.76")

308 mm (12.13")

(4.11")

104 mm

158 mm (6.22")

Page 5 of 9WIKA data sheet CT 17.01 ∙ 05/2014

Page 6

Special operating modes

Operating mode: Pressure switch test

Pressure switch test

With the pressure switch function, the Wally Box III can

In the switch test mode the display update rate is increased

to capture changing pressure inputs quickly.

indicate the pressures at which the switch closes or opens. In

addition, the hysteresis can be calculated.

Operating mode: Calibrating transmitters and %-error function

Use small-volume hose lines, as far

as possible

Pressure switch

Calibrating transmitters

With the mA/V measuring function, 4 ... 20 mA output and

0 ... 30 V output can be read from the test item. This can be

done in two ways.

1) Passively – the test item generates 4 ... 20 mA or

0 ... 30 V directly. The value is read by the calibrator.

2) Actively – the calibrator supplies a voltage of DC 24 V

to the test item whilst reading the resulting 4 ... 20 mA or

0 ... 30 V signal.

The calibrator features a special function which can calculate the error in the pressure value from the mA value as a

percentage of the 4 ... 20 mA span. The %-error mode uses

all three screens and has a special menu structure. It displays

pressure, mA and %-error simultaneously.

Example:

A transmitter to be tested has a measuring range of 20 bar

and outputs a corresponding 4 ... 20 mA signal. The user can

program in a 0 ... 20 bar pressure span into the calibrator

and the calibrator will then calculate and display the devia-

tion or error in a percentage value of the 4 ... 20 mA output.

This is produced without the need for any manual calculation,

which is also an advantage if it is dicult to set an accurate

pressure using an external pump.

Use small-volume hose lines, as far

as possible

Page 6 of 9 WIKA data sheet CT 17.01 ∙ 05/2014

Page 7

Dirt trap

The Wally Box III should only be used with dry and clean test

items. Soiling of the integrated pump, for example, through

contaminated test items, can lead to faults on the pump or

require the pump to be cleaned.

By using the dirt trap specically developed for the

Wally Box III, contamination of the integrated pump can be

prevented.

Using the dirt trap

The dirt trap is attached, hand-tight, at the pressure connec-

tion of the calibrator. Sealing is achieved via the O-ring tted

on the ⅛ NPT male thread of the dirt trap. The maximum

working pressure is limited to 35 bar.

The test item is mounted to the upper connection of the dirt

trap, using a suitable sealing method. The connection to the

test item is usable universally as ⅛ NPT female or ⅛ BSP

female. Use a ⅞" or 23 mm spanner on the hex of the upper

pressure port to connect the test item with the dirt trap.

As soon as either moisture or dirt can be seen in the

transparent chamber, the dirt trap should be removed and

cleaned.

Once the upper dirt trap connection has been unscrewed, the

transparent acrylic chamber and the O-rings can be removed

and cleaned with a clean cloth.

Wally Box III, model CPH7600 with mounted dirt trap

Dirt trap

Output to calibrator

⅞" or 23 mm spanner

Input

Page 7 of 9WIKA data sheet CT 17.01 ∙ 05/2014

Page 8

WIKA-CAL calibration software

Easy and fast creation of a high-quality calibration

certicate

The WIKA-CAL calibration software is used for generating

calibration certicates or logger protocols for pressure

measuring instruments and is available as a demo version for

a cost-free download.

A template helps the user and guides him through the

creation process of a document.

In order to switch from the demo version to a full version of

the respective template, a USB key with the template has to

be purchased.

The pre-installed demo version automatically changes to

the selected full version when the USB key is inserted and

is available as long as the USB key is connected to the

computer.

■

Creation of calibration certicates for mechanical and

electronic pressure measuring instruments

■

A calibration assistant guides you through the calibration

■

Automatic generation of the calibration steps

■

Generation of 3.1 certicates in accordance with

DIN EN 10204

■

Creation of logger protocols

■

User-friendly interface

■

Languages: German, English, Italian and more due with

software updates

For further information see data sheet CT 95.10

Calibration certicates can be created with the Cal-Template and logger protocols can be created with the Log-Template.

Cal Demo

Generation of calibration certicates limited to 2 measuring

points, with automatic initiation of pressures via a pressure

controller.

Cal Light

Generation of calibration certicates with no limitations on

measuring points, without automatic initiation of pressures

via a pressure controller.

Log Demo

Creation of data logger test reports, limited to 5 measured

values.

Log

Creation of data logger test reports without limiting the

measured values.

Page 8 of 9 WIKA data sheet CT 17.01 ∙ 05/2014

Page 9

Scope of delivery

■

Wally Box III, model CPH7600 (Order no. 14049201)

■

Operating instructions

■

Test cables

■

Calibration hose with ⅛ NPT male thread connections

■

Adapter set consisting of:

- ⅛ NPT female to ¼ NPT female

- ⅛ NPT female to ¼ BSP female

- ⅛ NPT female to G ½ female

■

PTFE thread seal tape

■

Battery charger

■

3.1 calibration certicate per DIN EN 10204

Option

■

DKD/DAkkS certied accuracy

Accessories

Connection adapters

■

Various pressure adapters

Dirt trap

■

Dirt trap (Order no. 13477103)

Connection cables

■

RS-232 interface cable (Order no. 14006096)

Software

■

WIKA-CAL calibration software

Ordering information

To order the described product the given order number is sucient. Other options require additional specication.

05/2014 GB

© 2012 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

Page 9 of 9WIKA data sheet CT 17.01 ∙ 05/2014

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Loading...

Loading...