Page 1

Operating instructions

Betriebsanleitung

Portable process calibrator, model CPH7000

Portabler Prozesskalibrator, Typ CPH7000

EN

DE

Portable process calibrator model CPH7000 with optional hand pump

Page 2

ENDEOperating instructions model CPH7000 Page 3 - 64

Betriebsanleitung Typ CPH7000 Seite 65 - 125

Further languages can be found at www.wika.com.

© 02/2017 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 3

Contents

Contents

1. General information 6

1.1 Software licence agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Short overview 7

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Product passport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Safety 8

3.1 Explanation of symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Responsibility of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Personnel qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Labelling, safety marks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

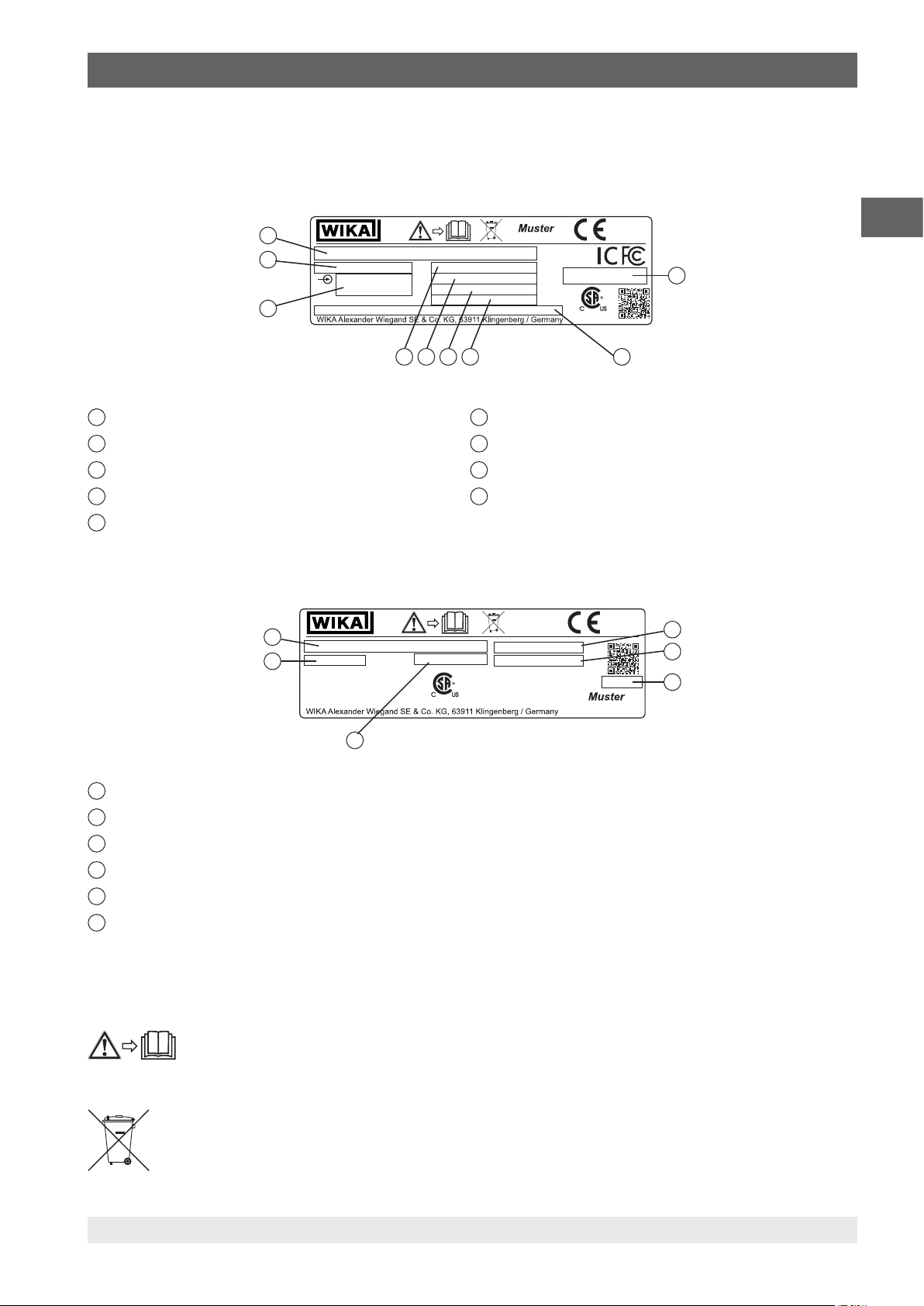

3.6.1 Product label for process calibrator model CPH7000 . . . . . . . . . . . . . . . . . . . 11

3.6.2 Product label for reference pressure sensor model CPT7000 . . . . . . . . . . . . . . 11

4. Design and function 12

4.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Functions and data transfer with the WIKA-Cal calibration software . . . . . . . . . . . . . 12

4.2.1 WIKA-Cal configuration (also possible with the demo version) . . . . . . . . . . . . . . 13

4.2.2 WIKA-Cal - Cal-Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.3 WIKA-Cal - Log-Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.4 WIKA-Cal - switch test template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.1 Rechargeable battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.2 Using the power supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.3 During charging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Mechanical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.7 Barometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.8 Reference pressure sensor model CPT7000. . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.8.1 Connection of the model CPT7000 reference pressure sensor. . . . . . . . . . . . . . 21

4.8.2 Electrical connection of the CPT7000 reference pressure sensor to the CPH7000 . . . 21

4.9 Carrying system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.10 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.10.1 Applications (apps). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.10.2 Symbols of the status bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.10.3 Battery symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5. Transport, packaging and storage 24

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Packaging and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Rechargeable battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EN

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 3

Page 4

EN

Contents

6. Commissioning, operation 26

6.1 Electrical mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.1 ON/OFF key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.1.1 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.1.2 Locking the screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.1.3 Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.2 Application [Settings]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.3 Application [Info] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.4 Application [Remote] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.5 Application [Service] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.6 Further settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.6.1 Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.6.2 Rechargeable battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.6.3 Changing the application task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1 Configuration of the “Measure” function . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1.1 Setting test item 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1.2 Setting test item 2 and 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.2 Functions with symbol and meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.3 Measuring the external reference pressure sensor on channel 1 or on channel 2 . . . 34

6.3.4 Measuring the external temperature probe. . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.5 Measuring current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.6 Measuring current with simultaneous DC 24 V voltage supply . . . . . . . . . . . . . . 36

6.3.7 Measuring voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.8 Measuring voltage with simultaneous DC 24 V voltage supply . . . . . . . . . . . . . . 37

6.3.9 Simulating current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.10 Simulating current with simultaneous DC 24 V voltage supply . . . . . . . . . . . . . . 38

6.3.11 Manual pressure value acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.1 Preparing the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.1.1 Selecting the test item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.1.2 Selecting the reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.1.3 Determining calibration points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.2 Carrying out the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.3 Completing the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.4 Representation of the calibration results . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.5 Repeating a calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.6 Deleting a calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5.1 Preparing a logger process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5.1.1 Setting test item 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5.1.2 Setting test item 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.5.1.3 Setting test item 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.5.1.4 Setting logger parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.5.2 Representation of logger results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5.3 Analysing or repeating a logger process . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5.4 Deleting logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

14204467.02 03/2019 EN/DE

4 WIKA operating instructions portable process calibrator, model CPH7000

Page 5

Contents

6.6 Switch test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.6.1 Switch test with external voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.6.2 Switch test with DC 24 V voltage supply by means of CPH7000 . . . . . . . . . . . . . 48

6.6.3 Preparing the switch test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.6.3.1 Selecting the test item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.6.3.2 Selecting the reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.4 Carrying out and completing the switch test . . . . . . . . . . . . . . . . . . . . . . . . 51

6.6.5 Analysing or repeating a switch test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.6.6 Delete switch test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7. Faults 52

8. Maintenance, cleaning and recalibration 53

8.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.3 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9. Return and disposal 54

9.1 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10. Specifications 55

10.1 Digital process calibrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.2 Temperature probe Pt100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.3 Atmospheric module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.4 WIKA-Wireless . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.5 Reference pressure sensor model CPT7000. . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.6 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.7 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.8 Patents, property rights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.9 Dimensions in mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11. Accessories 62

EN

Appendix: EU declaration of conformity model CPH7000 126

Appendix: EU declaration of conformity model CPT7000 127

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 5

Page 6

EN

1. General information

1. General information

■

The process calibrator model CPH7000 described in the operating instructions has been designed and manufactured using

state-of-the-art technology. All components are subject to stringent quality and environmental criteria during production. Our

management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all

safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate vicinity of the instrument and

readily accessible to skilled personnel at any time. Pass the operating instructions on to the next operator or owner of the

instrument.

■

Skilled personnel must have carefully read and understood the operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 15.51

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

1.1 Software licence agreement

This product contains intellectual property, i.e. software programs which are licensed to be used by the end user/client

(hereinafter referred to as “end user”).

The license does not include the sale of the intellectual property.

The end user shall neither copy nor disassemble or recompile the software program.

The software program will be provided to the end user “as it is” without any guarantees, either expressly or

implicitly, including but not limited to warranties of marketability and fitness for purpose. The end user has to bear

the entire quality and performance risk related to the software program.

Both WIKA and its suppliers are not liable for any damage to the end user (including but not limited to general,

special, consequential or incidental damage, including loss of business profits, business interruption, loss of

business information, and the like) resulting from or relating to the delivery, use or performance of the software

program.

The software included in this product contains copyrighted software that is licensed under the GPL/LGPL. A copy of the

license texts is included in the packaging of this product. You may obtain the complete Corresponding Source code from

us for a period of three years after our last shipment of this product and/or spare parts therefor, which will be no earlier than

01/01/2030, for a fee of 10 €. Please use our contact form at CTServiceteam@wika.com and write „Corresponding Source for

CPH7000“ in the memo line. This offer is valid to anyone in receipt of this information.

6 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 7

1. General information / 2. Short overview

WARNING!

Installing modified versions of open source software components on the product will result in the loss of warranty.

Also support service and software updates will be refused.

Make sure to follow the safety precautions in the operating instructions. Improper access to the instrument is likely

to result in its damaging.

2. Short overview

2.1 Overview

1 2 3

15

14

13

4

5

1

2

3

4

5

6

EN

Connection for external pressure sensor - channel 1

(only CPT7000)

Internal sensor for test item

(optional, available only in conjunction with the

mechanical hand pump)

Connection for external pressure sensor - channel 2

(only CPT7000)

Sockets for 4 mm plugs for measuring and simulating

current (DC)

Connection for atmospheric module or temperature

probe Pt100

Display

7

LED charging indicator

6

8

Home button

9

Mechanical hand pump (optional)

10

Fine adjustment valve

(optional, available only in conjunction with the

7

8

mechanical hand pump)

11

Vent valve

(optional, available only in conjunction with the

mechanical hand pump)

12

12

Switch to switch between pressure build-up or vacuum

(optional, available only in conjunction with the

mechanical hand pump)

13

Connection for power supply unit

14

ON/OFF key

15

Sockets for 4 mm plugs for measuring and simulating

voltages (DC)

11 10

9

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 7

Page 8

2. Short overview / 3. Safety

2.2 Description

The model CPH7000 process calibrator is a battery-powered, precise, portable calibrator for the on-site calibration and

checking of analogue pressure measuring instruments, pressure transmitters and process transmitters. Furthermore, pressure

switches can be checked and the switch point determined. With the CPH7000, not only can transmitters be checked, but also

simulated and tested.

EN

The integrated hand pump (optional) enables you to generate a pressure of up to 25 bar (360 psi). This pressure can be

measured by means of an integrated pressure sensor (optional, available only in conjunction with the pump).

For pressure ranges of -1 ... 10,000 bar (-14.5 ... 145,000 psi), the model CPT7000 external precision pressure transmitter is

available. In conjunction with the data logger, it is also possible to carry out a leakage test in a very simple manner.

2.3 Scope of delivery

■

Process calibrator model CPH7000

■

Power supply unit

■

Operating instructions

■

Service case with 2 connection cables (4 mm plugs)

■

Calibration certificate

Cross-check scope of delivery with delivery note.

2.4 Product passport

The product passport can be retrieved from the product page or directly from the corresponding web application (https://portal.

wika.com/serial/).

3. Safety

3.1 Explanation of symbols

DANGER!

... indicates a directly dangerous situation resulting in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage to property or the

environment, if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety instructions not be observed, there is a risk of

serious or fatal injury.

Information

... points out useful tips, recommendations and information for efficient and trouble-free operation.

8 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 9

3. Safety

3.2 Intended use

The model CPH7000 process calibrator is a portable multi-function calibrator for the calibration of a variety of measuring

instruments. An integrated mechanical hand pump (optional) enables you to generate pressures up to 25 bar (360 psi); an

integrated electrical module also enables you to supply transmitters or sensors with a current of max. 30 mA (voltage (idling) =

DC 24 V), in addition to the typical measurement of current and voltage signals.

The process calibrator can be used to carry out and document a complete calibration process. In addition to the functions

of displaying, measuring and calibrating, the functions logging and switch test are also available. The use of the WIKA-Cal

software also allows a complete documentation.

The instrument has been designed and built solely for the intended use described here, and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed. Improper handling or operation of the

instrument outside of its technical specifications requires the instrument to be taken out of service immediately and inspected

by an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from humidity, impacts, strong magnetic

fields, static electricity and extreme temperatures, do not insert any objects into the instrument or its openings). Plugs and

sockets must be protected from contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended use.

EN

3.3 Improper use

DANGER!

Danger to life from explosion!

Improper use of the process calibrator causes a risk of explosion that can result in death.

WARNING!

Injuries, material and environmental damage due to an improper use of the process calibrator!

Improper use of the process calibrator causes a direct danger to life.

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

14204467.02 03/2019 EN/DE

▶

The process calibrator should not be thrown into fire, since the built-in battery can explode.

▶

Do not throw the process calibrator into water → this can result in the destruction of the safety circuit, in heat

generation, in inflammation, in the formation of oxyhydrogen or corrosion and in the generation of electrolytes.

▶

Overcharging, reverse charging and too high charging currents can result in fire or excessive gas formation.

▶

The use of incorrect, unsuitable power supply units can lead to overheating, fire and to the destruction of the

rechargeable battery.

▶

Crushing due to mechanical damage may result in the escape of electrolytes, in an internal short circuit, in

heating or fire.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

▶

There must be no external pressure acting on the CPH7000.

▶

Do not use the CPT7000 with abrasive or viscous media.

▶

Only dry, clean air can be used as medium for the CPH7000.

▶

It is forbidden to open the instrument.

▶

Do not open the service flap on the rear. Only the manufacturer is allowed to open it.

▶

Do not apply a voltage greater than the specified voltage to the instrument. See chapter 10 “Specifications”.

▶

Make sure that the test probes never contact a voltage source while the test leads are connected to the

terminals.

▶

Do not use the CPH7000 if it is damaged. Before using the process calibrator, check that there are no cracks

or missing plastic parts on the case. Pay particular attention to the insulation of the connectors.

▶

Select the proper function and correct measuring range for the measurement.

WIKA operating instructions portable process calibrator, model CPH7000 9

Page 10

EN

3. Safety

▶

When using the electrical module, set the measurement type first and then connect the connection cables.

▶

Only tighten the vent valve by hand, as it is a needle valve. Tightening with excessive force can result in a

damage of the needle valve or the sealing.

▶

Inspect the test leads for damaged insulation or exposed metal. Check the continuity of the leads. Damaged

test leads should be replaced before using the process calibrator.

▶

When using test probes, keep fingers away from the test probe contacts. Keep your fingers behind the test

probes' finger guards.

▶

First connect the common lead, and then the live lead. When disconnecting, remove the live test lead first.

▶

Disconnect test leads before changing to another measurement or source function.

▶

When the battery indicator lights up red, load the rechargeable battery of the CPH7000, in order to avoid an

incorrect display or a data loss.

▶

To avoid any damage to the process calibrator or to the inspection equipment, always use the proper

connection cable, function and area for the respective measuring application.

▶

The switch valve can be switched from positive pressure to vacuum or from vacuum to positive pressure only

in depressurized state.

▶

Only use the accessories specified and authorized by WIKA.

▶

If pressure is applied over a long period of time, the pump can be damaged.

▶

Only use pressure sensors model CPT7000! The use of other pressure sensors can result in the destruction of

the measuring instrument and of the pressure sensor.

▶

Make sure that the internal sensor is not overloaded by the pump.

The electrical module can generate max. 30 mA and DC 24 V and measure max. 30 mA and DC 30 V.

With the integrated pump, pressures from -0.85 ... +25 bar (-12.3 ... +360 psi) can be generated.

Any use beyond or different to the intended use is considered as improper use.

3.4 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore responsible for legal obligations regarding safety at

work.

The safety instructions within these operating instructions, as well as the safety, accident prevention and environmental

protection regulations for the application area must be maintained.

The operator is obliged to maintain the product label in a legible condition.

3.5 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be carried out by skilled personnel who have

the qualifications described below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of country-specific regulations,

current standards and directives, are capable of carrying out the work described and independently recognising potential

hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

10 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 11

3. Safety

3.6 Labelling, safety marks

3.6.1 Product label for process calibrator model CPH7000

The product label is located on the rear, in the upper part.

9

8

7

1

Approval-related data for radio approval

2

Safety instructions for radio approval

3

Permissible ambient temperature

4

Serial number

5

Date of manufacture (month-year)

6

Accuracy

7

Input signals

8

Pressure measuring range

9

Model

3.6.2 Product label for reference pressure sensor model CPT7000

6

5

EN

1

256 4 3

1

2

3

1

Serial number

2

Serial number external sensor

3

Date of manufacture (month-year)

4

Accuracy

5

Pressure measuring range

6

Model

Symbols

Do not dispose of with household waste. Ensure a proper disposal in accordance with national regulations.

14204467.02 03/2019 EN/DE

4

Before mounting and commissioning the instrument, ensure you read the operating instructions!

WIKA operating instructions portable process calibrator, model CPH7000 11

Page 12

4. Design and function

4. Design and function

The model CPH7000 process calibrator is a battery-powered, precise, portable calibrator for the on-site calibration and

checking of analogue pressure measuring instruments, pressure transmitters and process transmitters. Furthermore, pressure

switches can be checked and the switch point determined. With the CPH7000, not only can transmitters be checked, but also

EN

simulated and tested.

The CPH7000 can be operated by means of a clearly structured touchscreen. The integrated rechargeable battery allows the

CPH7000 to be used daily in the field.

4.1 Design

The CPH7000 can optionally be equipped with an integrated reference pressure sensor as well as an integrated manual

pressure generation (pressure sensor only available in conjunction with pressure generation), with which pressures from

-0.85 ... +25 bar (-12.3 ... +360 psi) can be generated.

A pressure connection enables a calibration item (test item) to be connected to the reference pressure sensor as well as to

the integrated pressure generation of the CPH7000. The integrated pump (optional) allows you to generate different pressure

ratings and thus to carry out a calibration.

An external separate pressure generation up to 25 bar (360 psi) is thus not necessary.

Transmitter output signals can simultaneously be measured via an electrical module, thus enabling the simultaneous display

of the reference and test item value on the screen. This allows a complete transmitter calibration to be carried out with just the

CPH7000.

In addition to the integrated sensor, it is also possible to connect up to two external reference pressure sensors to the

CPH7000, thus enabling the measurement of pressure also in other pressure ranges or differential pressure. Communication

between CPH7000 and pressure sensors is digital.

The ambient atmospheric pressure is measured via an integrated barometric reference which can optionally be integrated

in the case. This also enables gauge pressure sensors to be converted into absolute pressure. The ambient conditions

(temperature and humidity) can be measured by means of an additional external atmospheric module. To the connection for

the atmospheric module, it is also possible to connect a temperature probe Pt100.

4.2 Functions and data transfer with the WIKA-Cal calibration software

The calibrator offers the possibility to create calibration routines quickly and easily, but also to carry out preconfigured

calibration routines. An integrated memory allows the recording of logger cycles as well as calibrations on site.

The completed calibration processes can be transmitted to a PC via WIKA-Wireless.

As soon as a connection exists over WIKA-Wireless, it can communicate with the WIKA-Cal calibration software from version

1.0.66. Data can also be transferred using Windows Explorer.

A complete paperless transmitter calibration can be carried out using the CPH7000 and WIKA-Cal.

As the CPH7000 features an electrical module, the hand-held also has to be set up as a multimeter.

Compatibility between the CPH7000 process calibrator and the WIKA-Cal evaluation software is only possible

with the following firmware versions and higher.

CPH7000: 1.1.4 or higher

WIKA-Cal: 1.0.82 or higher

12 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 13

4. Design and function

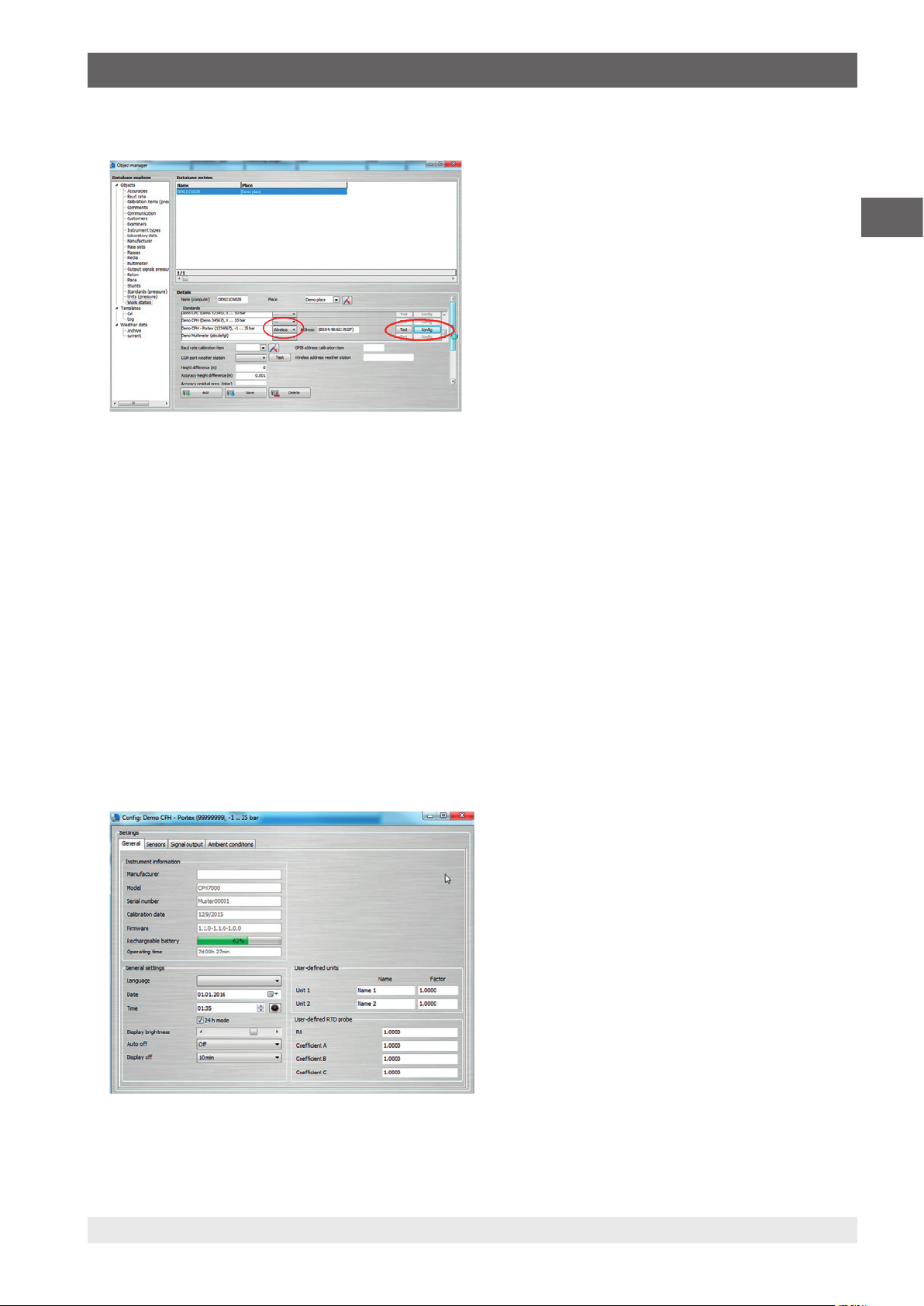

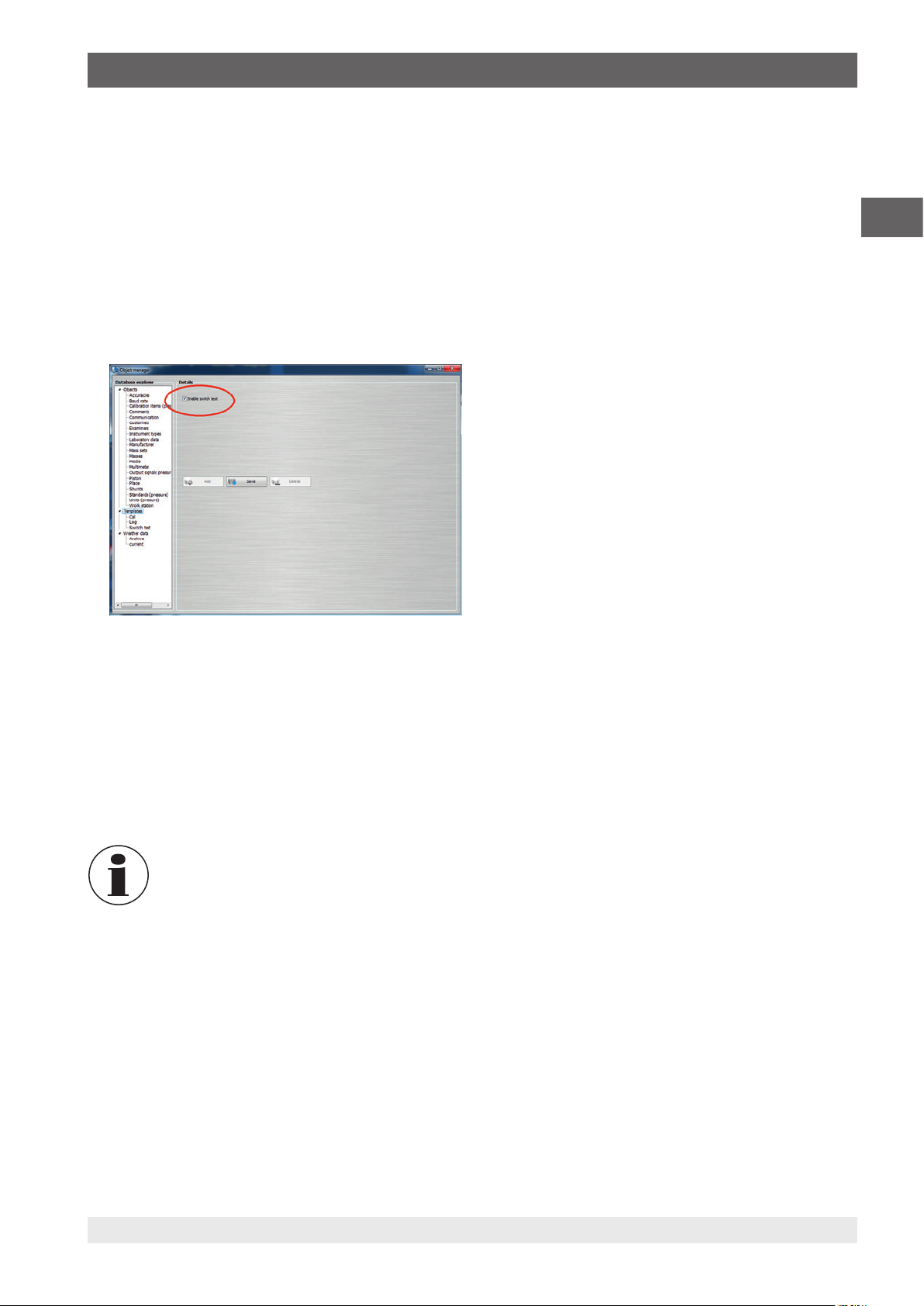

4.2.1 WIKA-Cal configuration (also possible with the demo version)

1. In WIKA-Cal, in the “Object manager”, open the menu item “Workplace”.

The CPH7000 must first be defined as a standard and assigned to the workplace.

⇒

2. Call up the Wireless function.

The Wireless monitor will open.

⇒

3. Click into the address field.

The address will be displayed automatically. If required, correct this.

⇒

The communication is working properly if the pressure value displayed on the instrument is shown after pressing the

⇒

[Test] button.

4. Via [Config], the configuration dialogue for the instrument can be called up.

EN

In the configuration window, the four functions “General information”, “Sensors”, “Signal output” and “Ambient

conditions” are available.

General information

Here are all the general parameters of the CPH7000 used.

Specific pressure units with the associated factor can be set or also specific temperature coefficients entered for the Pt100

probe.

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 13

Page 14

4. Design and function

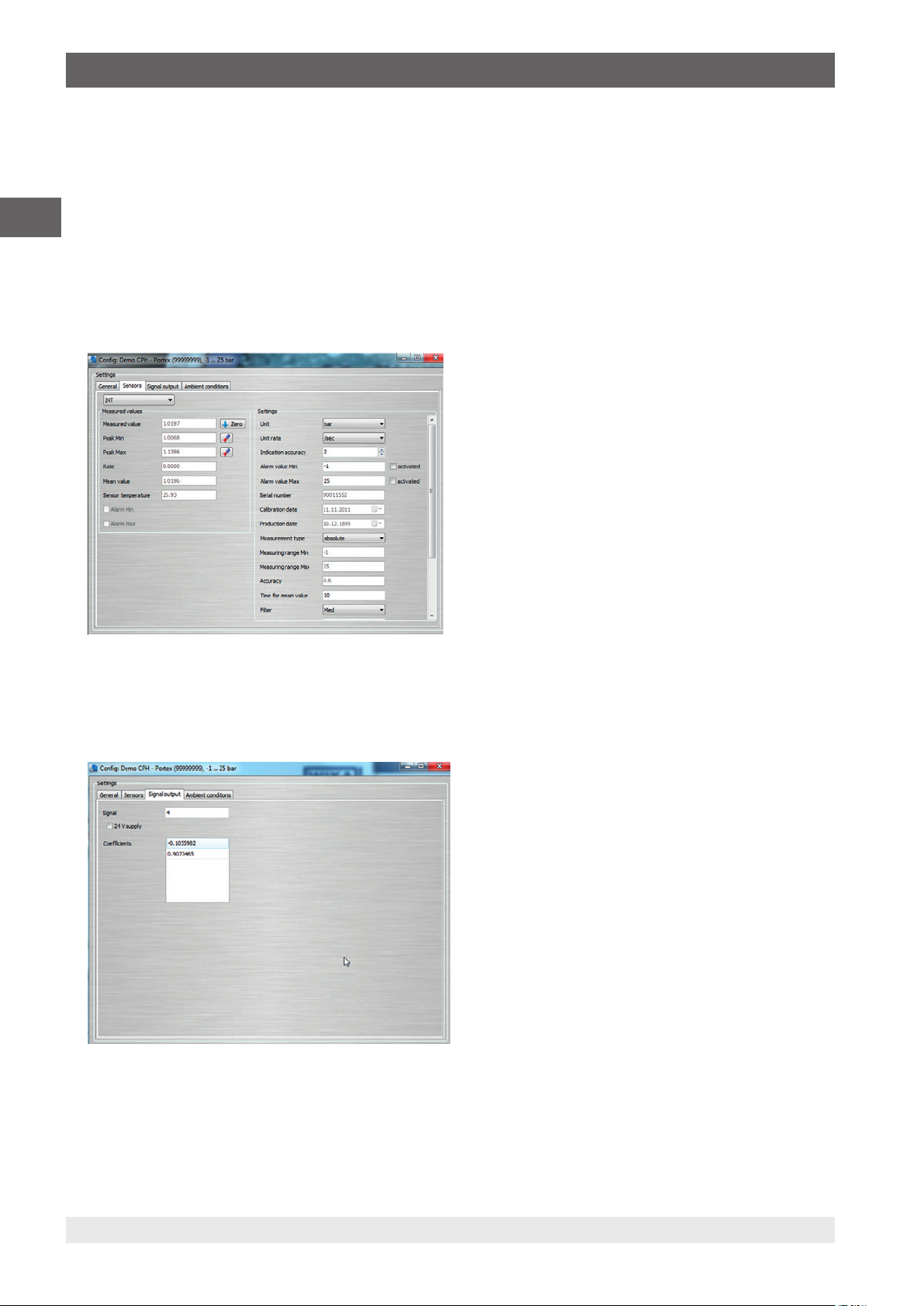

Sensors

The following sensors can be selected:

INT = Internal reference pressure sensor

EN

EXT1 = External CPT7000 reference pressure sensor to channel 1

EXT2 = External CPT7000 reference pressure sensor to channel 2

RTD = External Pt100 temperature probe

IN = Integrated electrical module

EXT1, EXT2 and RTD are only displayed when these are also connected.

Signal output

Here, the current and voltage values can be read in and overwritten. The prerequisite for this is that under “Measure”, a

current or voltage channel has also been selected.

14 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 15

4. Design and function

Ambient conditions

Here, the measured values from the atmospheric module and barometer are displayed.

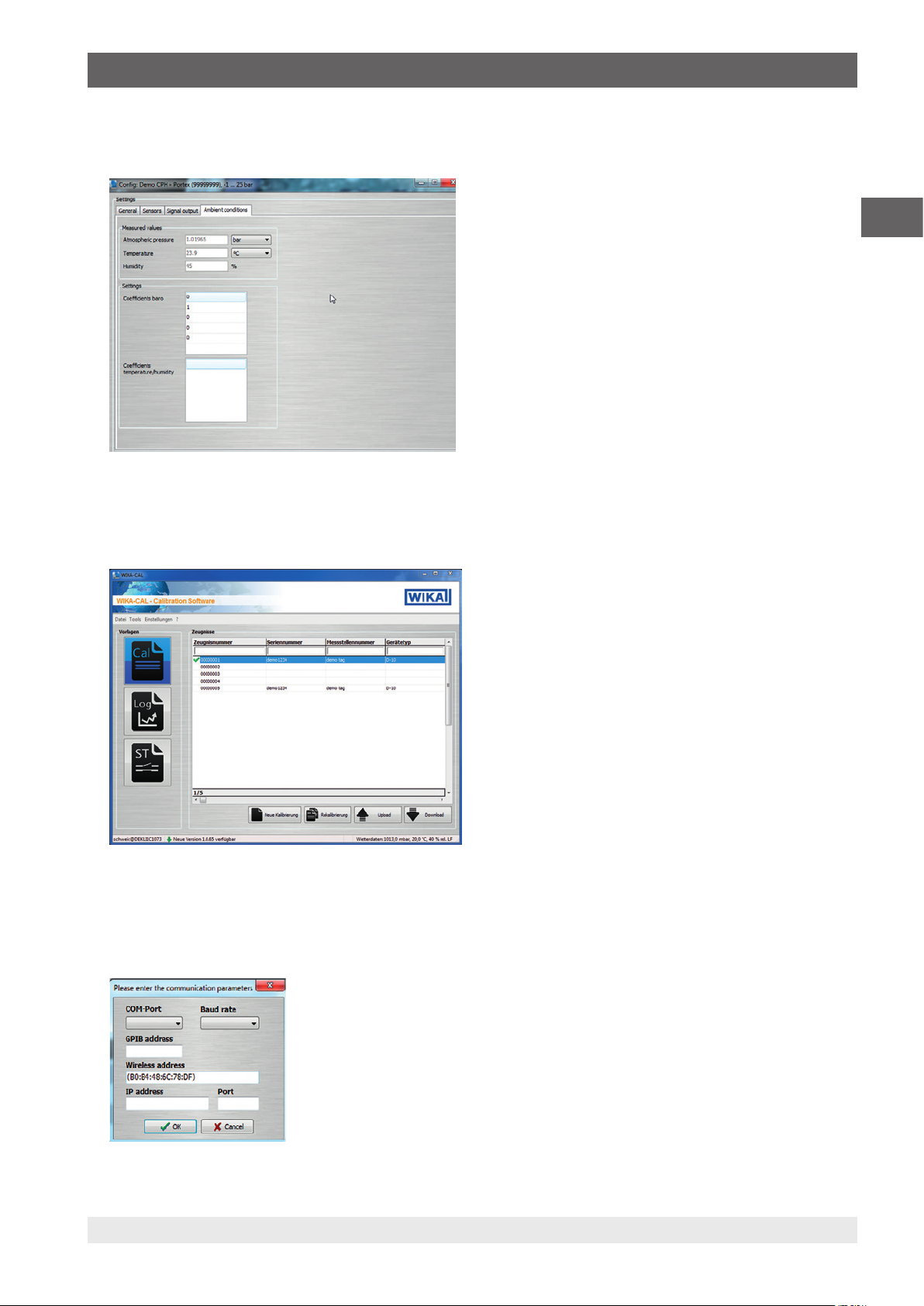

4.2.2 WIKA-Cal - Cal-Template

The following options are available with the “Cal-Template”:

“New calibration”, “Recalibration”, “Upload” and “Download”

EN

New calibration

A new calibration certificate will be created. All parameters from the calibration item and reference instrument must be

entered, and then the calibration can start. By pressing on the “Measuring results” table, a new window opens in which the

communication parameters are requested. Here, the CPH7000 used must be selected, then the measurement starts.

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 15

Page 16

4. Design and function

Recalibration

Select the required certificate from the database. Only completed certificates (marked with a green tick) can be recalibrated. A

copy of the certificate will be created and opened, and when the [Measuring results] table is pressed, the measurement can

be restarted.

EN

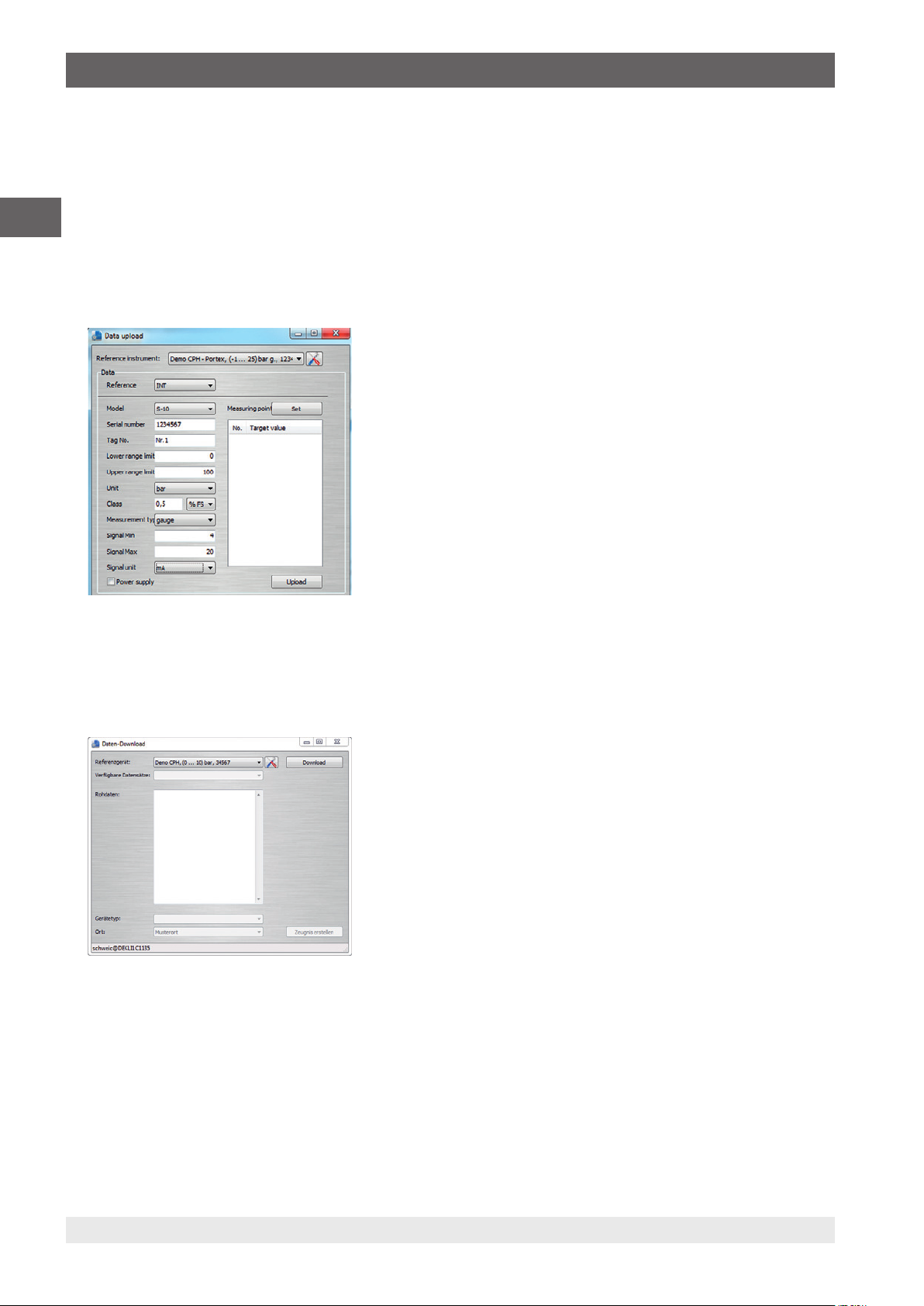

Upload

With “Upload”, a calibration routine can be defined and installed on the CPH7000.

All parameters must be entered. The measuring points and measurement series can be specified by default. With upload, the

calibration routine will be created and uploaded to the CPH7000.

Download

The calibrations stored on the CPH7000 can be downloaded and archived using “Download”.

▶

Select reference instrument and click on “Download”.

Then the available data sets are shown in the selection window.

⇒

4.2.3 WIKA-Cal - Log-Template

The following options are available with the “Log-Template”:

New log

The “New Log” function opens a new logger protocol.

Following the input of all parameters, the “Wireless address” line must be pressed in the communication window. Select the

CPH7000 used and confirm.

By pressing the [Measuring results] graphic, the logger process is started.

14204467.02 03/2019 EN/DE

16 WIKA operating instructions portable process calibrator, model CPH7000

Page 17

4. Design and function

Repeat logging

Similar to “Recalibration”, it is possible to repeat logger sequences.

Download

The logger sequences stored on the CPH7000 can be downloaded and archived using “Download”.

4.2.4 WIKA-Cal - switch test template

Here, only the option “Download” is available:

The switch test procedures stored on the CPH7000 can be downloaded and archived using “Download”.

The switch test function in the WIKA-Cal software has to be activated under “Object manager / Templates”.

EN

When this box is checked, the template for the switch test will appear in the main menu window (see chapter

4.2.2 “WIKA-Cal - Cal-Template”).

4.3 Voltage supply

The internal Lithium-Ion battery, which can be easily charged with the battery charger supplied with the equipment, serves as

the voltage supply for the instrument.

To charge the CPH7000 rechargeable batteries, the mains plug of the power supply unit must always be plugged in to a mains

socket and accessible, so that one can always remove it from the mains socket without difficulty.

When using the electrical module, better results are achieved if the battery is not charged during the

measurement.

To avoid incorrect measurements, recharge the battery as soon as the battery indicator flashes. If the battery discharges too

much, the CPH7000 will automatically turn off.

The battery life is up to 8 hours in continuous operation (without backlighting, WIKA-Wireless is not active and the electrical

module does not supply voltage/current).

In the upper right corner of the display there is a symbol for the battery capacity. For instructions on batteries see chapter

4.10.3 “Battery symbol”).

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 17

Page 18

4. Design and function

4.3.1 Rechargeable battery

The integrated lithium-ion battery is subject to the requirements of the Dangerous Goods Directive. Special

requirements for packaging and labelling must be observed when shipping. A dangerous goods expert must be

consulted when preparing the package.

EN

The rechargeable battery is permanently installed in the model CPH7000 process calibrator.

The battery can be charged only using the power supply unit included in the scope of delivery.

4.3.2 Using the power supply unit

Do not ship the CPH7000 if the rechargeable battery is damaged or defective.

Observe the different dangerous goods requirements relative to the respective modes of transport and any other

national regulations.

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

▶

Only use the power supply unit from WIKA supplied with the instrument!

▶

If there is any visible damage to the case or the wiring, do not use the power supply unit!

▶

Never install nor store the power supply unit in the following locations, as this can lead to a failure in operation:

■

Places where there is strong humidity or condensation

■

Outdoors

▶

Disconnect the power supply unit from the mains supply when it won’t be used for a longer period of time.

▶

The power supply unit is maintenance-free. It must not be opened (danger of electrical shock).

▶

Before cleaning, disconnect the power supply unit from the mains supply. Do not clean with chemical cleaning

agents. Only clean with a dry cloth.

▶

The power supply unit may only be used at an ambient temperature of 0 ... 40 °C (32 ... 104 °F) (humidity: up to

90 % relative humidity, non-condensing).

To avoid measurement uncertainties, use the CPH7000 only without a connected power supply unit.

The instrument is delivered with a charge level of 25 ... 50 % and should be fully charged once before being used.

The battery capacity status (charge state in %) is displayed shortly after the instrument is switched on.

When the power supply unit is connected to the CPH7000, the battery will be charged, even if the CPH7000 is

switched off.

The typical charging time of the rechargeable battery is < 5 h.

■

When the power supply unit is no longer being used, the mains plug should be disconnected from the mains socket. Do not

leave the rechargeable battery connected to the power supply unit for longer than one day, since overcharging can shorten

its service life.

■

Should the rechargeable battery still not be fully charged after 24 hours, contact the manufacturer. When not being used, a

fully charged battery will lose its charge over time.

■

Extreme temperatures have an adverse effect on battery charging. As a result, the battery may first need to be either cooled

or warmed, as appropriate.

■

When the battery is almost completely discharged, the message “low BAT” appears in the display. To avoid a data loss, the

instrument must be charged immediately.

18 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 19

4. Design and function

4.3.3 During charging

WARNING!

Physical injuries and damage to property and the environment

The temperature range over which the Lithium-Ion battery can be charged is 0 ... 40 °C (32 ... 104 °F).

▶

Do not charge the lithium-ion battery outside this temperature range. This may result in heating or demolition.

In addition, the performance of the Lithium-Ion battery can be affected and the service life reduced.

4.4 Electrical connections

3

EN

2

1

5 6 7 8

4

1

Connection for external pressure sensor model CPT7000 to channel 1 (EXT 1)

2

Connection for external pressure sensor model CPT7000 to channel 2 (EXT 2)

3

Connection for atmospheric module (AMB) or temperature probe Pt100 (RTD)

4

Connection for power supply unit

5

V

- Sockets for 4 mm plugs: Connection for DC 24 V supply

out

6

V

- Sockets for 4 mm plugs: Connection for measuring voltages (DC 30 V) (V_IN)

in

7

mA - Sockets for 4 mm plugs: Connection for measuring and simulating current (30 mA) (mA)

8

GND - Ground connection (GND)

Any external circuit connected to this instrument must be protected against electrical shock by additional

insulation or insulation enhanced against potentially dangerous active voltages.

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 19

Page 20

4. Design and function

4.5 Mechanical connection

EN

9

G 1/8 female thread

9

Optionally, it can be used only in conjunction with the hand pump (INT).

10

Pumping unit

In order not to put a strain on the case, it is recommended to hold the pressure connection on the CPH7000 by

means of an open-ended spanner.

The connections of the CPH7000 without pumping unit are provided with plugs. In order to maintain the IP

protection class, these plugs should not be removed.

4.6 Pump

10

CAUTION!

Physical injuries and damage to property and the environment

Improper handling of the pump can damage the process calibrator.

▶

Do not use the pump when switched off.

The pump is a consumable. Regular maintenance is recommended after 100,000 pump cycles at the latest. Under normal use

conditions, this corresponds to a service life of 2 years.

Recommended procedure in vacuum range

1. Always pull out the piston rod until it stops.

2. Wait 5 seconds.

3. Carry out another pumping stroke until the desired pressure is reached.

4.7 Barometer

The barometric sensor is a very stable, high-accuracy absolute pressure sensor designed to measure the daily atmospheric

pressure.

It can be used to emulate gauge pressure using an absolute pressure sensor or to emulate absolute pressure using a gauge

pressure sensor. For a seamless absolute pressure emulation, a bi-directional measuring range with a start of measuring

range of -1 bar (-14.5 psi) is recommended.

4.8 Reference pressure sensor model CPT7000

For the CPH7000 process calibrator, a variety of reference pressure sensors with measuring ranges from 250 mbar (4 psi) up

to 10,000 bar (145,000 psi) and vacuum pressure sensors with an accuracy of 0.025 % FS are available. These sensors can

be replaced on the instrument very quickly and without using any tools.

When the process calibrator is switched on, the connected reference pressure sensor will be automatically detected.

14204467.02 03/2019 EN/DE

20 WIKA operating instructions portable process calibrator, model CPH7000

Page 21

4. Design and function

4.8.1 Connection of the model CPT7000 reference pressure sensor

CAUTION!

Physical injuries and damage to property and the environment

If third-party reference pressure sensors are used, they can damage the process calibrator and the reference

pressure sensor.

▶

Only use reference pressure sensors of model CPT7000!

▶

When the CPH7000 is switched on, the model CPT7000 reference pressure sensor must be mounted in the

position in which the measurements will be made and must not be under pressure, but rather should be at

atmospheric pressure.

▶

Only ever use the original WIKA connection cable in the operation of CPT7000 reference pressure sensors.

4.8.2 Electrical connection of the CPT7000 reference pressure sensor to the CPH7000

To electrically connect a model CPT7000 reference pressure sensor, the corresponding plug connection of the cable at the

sensor must be plugged in.

To disconnect the sensor, do not pull on the cable, but rather only on the connector sleeve.

To connect it to the CPH7000, the other end of the cable must also be plugged in. To disconnect the CPH7000, do not pull on

the cable, but rather only on the connector sleeve.

EN

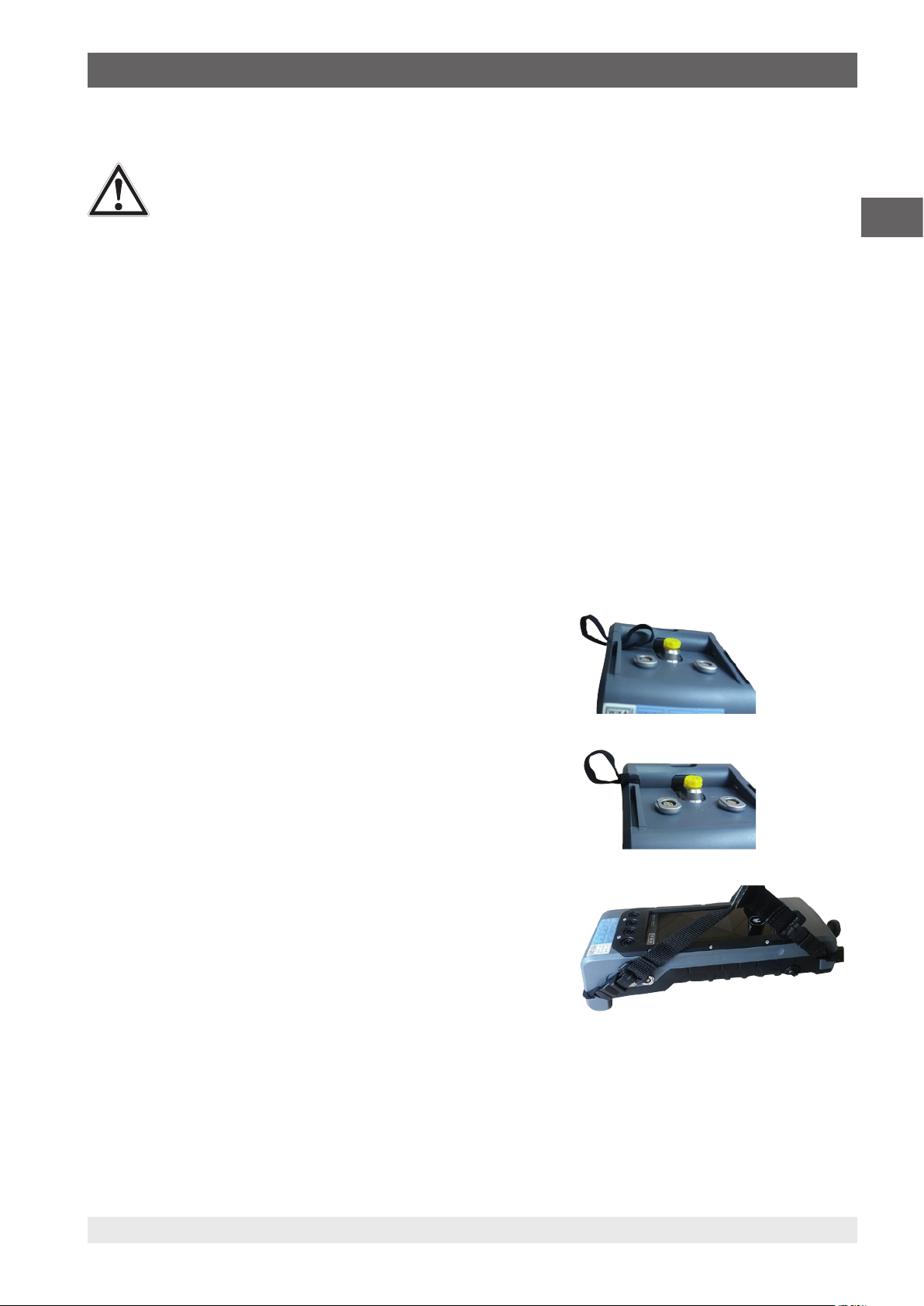

4.9 Carrying system

For safely carrying the CPH7000, the associated shoulder strap can be put on.

Recommended procedure for putting on the shoulder strap:

1. Pull the enclosed loops through the eyelets of the CPH7000, see figure 1.

2. Thread the loop, see figure 2.

3. Fasten the hooks of the shoulder strap, see figure 3.

Recommendation:

Fasten the long belt to the top corners of the CPH7000 and the short belt to

the bottom ones.

Figure 1

Figure 2

Figure 3

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 21

Page 22

EN

4. Design and function

4.10 Display

11

18

27

10

6

3

4

5

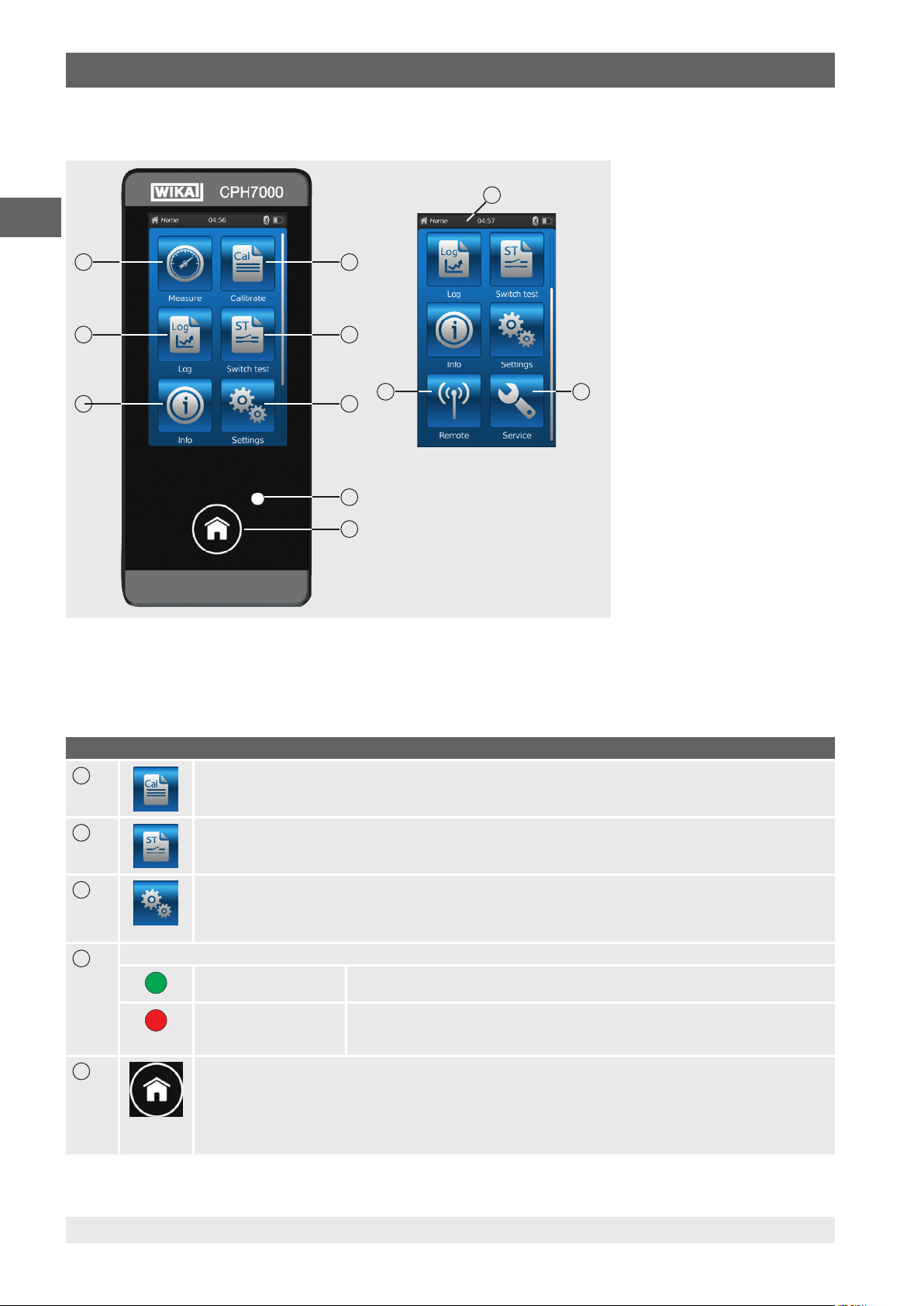

4.10.1 Applications (apps)

Eight applications are available on the start page:

Measure, Calibrate, Logger, Switch test, Info, Settings, Remote and Service.

Pos. Symbol

1

2

Calibration

Opens the [Calibrate] application, see chapter 6.4 “Calibrate”

Switch test

Opens the [Switch test] application, see chapter 6.6 “Switch test”

9

3

Settings

Setting or changing of all instrument parameters, such as: Language, date, time, display brightness, pressure units

and temperature probes

For more information please refer to chapter 6.2.2 “Application [Settings]”.

4

LED display

■

LED lights up green:

■

LED flashes green:

■

LED lights up red:

■

LED flashes red:

The rechargeable battery is fully charged

CPH7000 in start mode

The rechargeable battery is being charged

Charging error

⇒ Remove the charging cable and reconnect it to the CPH7000

5

Home

Use the [Home] button to go to the start page.

If the [Home] button is held pressed for more than 2.5 seconds, a screenshot with the file name “YYYYMMDD_

hhmmss-Screenshot.png” 1) will be created. This file can be readout via WIKA-Wireless.

The CPH7000 can store a maximum of 50 screenshots; if more than 50 screenshots are created, the first ones will

be overwritten.

1) An instructions for downloading the screenshots are available on request.

22 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 23

4. Design and function

Pos. Symbol

6

7

Info

To call all information on the CPH7000, including all connected internal and external sensors, see chapter

6.2.3 “Application [Info]”.

Logger

Opens the [Logger] application, see chapter 6.5 “Logger”.

EN

8

9

10

Measure

Opens the [Measure] application. Three channels can be simultaneously selected and displayed. See chapter

6.3 “Measure”.

Service

Display of all service-relevant data of the connected sensors and of current error messages, see chapter

6.2.5 “Application [Service]”.

Remote

Display of the communication commands and parameters

Switching on or off the WIKA-Wireless interface, see chapter 6.2.4 “Application [Remote]”.

Further definitions

“XXX” Menu XXX will be selected

[XXX] Press button XXX

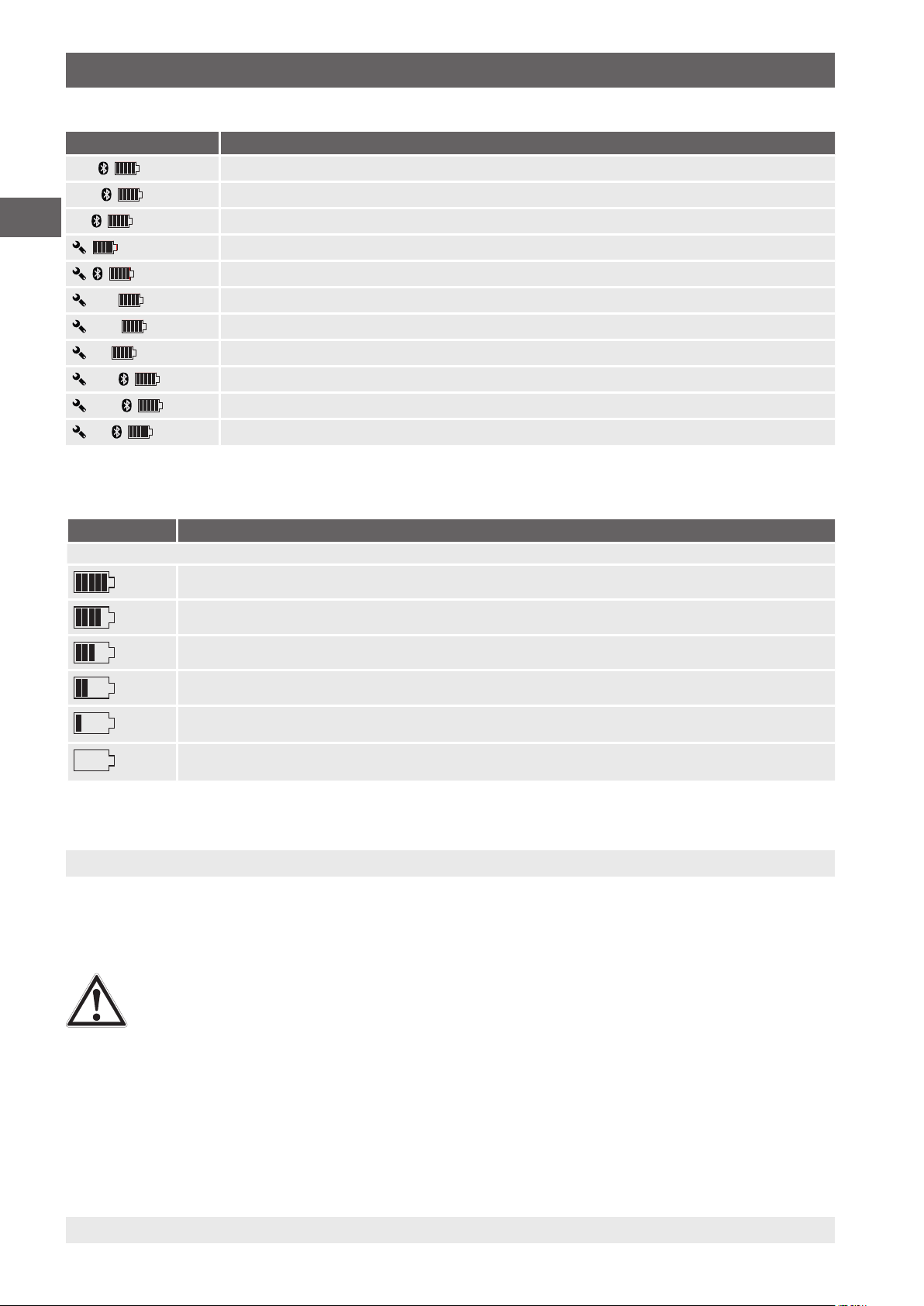

4.10.2 Symbols of the status bar

Pos. Symbol

11

The status bar is located at the top of the screen.

■

Left: Display of the selected function page

■

Middle: Display of the currently set time

■

Right: Display of the activated function and battery status

Symbol The symbol lights up on:

Home

Measure

Calibrate

Logger

Switch test

Info

Settings

Remote

Service

Cal

Log

St

14204467.02 03/2019 EN/DE

Start screen activated

Application [Measure] activated

Application [Calibrate] activated

Application [Logger] activated

Application [Switch test] activated

Application [Info] activated

Application [Settings] activated

Application [Remote] activated

Application [Service] activated

WIKA-Wireless switched on

Calibration switched on

Logger switched on

Switch test switched on

WIKA operating instructions portable process calibrator, model CPH7000 23

Page 24

4. Design and function / 5. Transport, packaging and storage

Symbol The symbol lights up on:

Cal

Log

EN

St

Cal

Log

St

Cal

Log

St

4.10.3 Battery symbol

Calibration started and WIKA-Wireless active

Logger started and WIKA-Wireless active

Switch test started and WIKA-Wireless active

Request: Open the [Service] app

Request: Open the [Service] app and WIKA-Wireless active

Request: Open the [Service] app and calibration active

Request: Open the [Service] app and logger active

Request: Open the [Service] app and switch test active

Request: Open the [Service] app, calibration and WIKA-Wireless active

Request: Open the [Service] app, logger and WIKA-Wireless active

Request: Open the [Service] app, switch test and WIKA-Wireless active

Symbol The symbol lights up on:

The battery symbol is lit continuously and is dependent upon the current battery status.

Battery status 100 %

Battery status 80 %

Battery status 60 %

Battery status 40 %

Battery status 20 %

Charge the battery

⇒

Battery status 0 %

Charge the battery immediately

⇒

5. Transport, packaging and storage

5.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal transport, proceed carefully and

observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter 5.2 “Packaging and storage”.

If the instrument is transported from a cold into a warm environment, the formation of condensation may result in instrument

malfunction. Before putting it back into operation, wait for the instrument temperature and the room temperature to equalise.

24 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 25

5. Transport, packaging and storage

5.2 Packaging and storage

The process calibrator CPH7000 is delivered in a plastic case. This will provide optimum protection during transport (e.g.

change in installation site, recalibration).

Permissible conditions at the place of storage:

Process calibrator

model CPH7000

Storage temperature -20 ... +60 °C (-4 ... +140 °F) -20 ... +80 °C (-4 ... +176 °F) -40 ... +70 °C (-40 ... +158 °F)

Humidity 35 ... 85 % relative humidity

(non-condensing)

Reference pressure sensor

model CPT7000

0 ... 95 % relative humidity

(non-condensing)

Power supply unit

model FW7530

20 ... 80 % relative humidity

(non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the process calibrator in the supplied plastic case in a location that fulfils the conditions listed above.

Fully charge the CPH7000 (to avoid deep discharge of the rechargeable battery)

5.3 Rechargeable battery

The integrated lithium-ion battery is subject to the requirements of the Dangerous Goods Directive. Special

requirements for packaging and labelling must be observed when shipping. A dangerous goods expert must be

consulted when preparing the package.

Do not ship the CPH7000 if the rechargeable battery is damaged or defective.

Observe the different dangerous goods requirements relative to the respective modes of transport and any other

national regulations.

EN

The rechargeable battery is permanently installed in the model CPH7000 process calibrator. In case the battery in the process

calibrator stops working, contact the manufacturer.

For contact details see chapter 1 “General information” or the back page of the operating instructions.

▶

Do not throw the instrument into fire.

If the CPH7000 is thrown into fire, the built-in rechargeable battery can explode.

▶

Do not throw the instrument into water.

If the CPH7000 is thrown into water, this can result in the destruction of the safety circuit, in heat generation, in

inflammation, in the formation of oxyhydrogen or corrosion and in the generation of electrolytes.

▶

Overcharging, reverse charging, too high charging currents

Overcharging, reverse charging, too high charging currents and the use of incorrect, unsuitable chargers can lead to

overheating, fire, excessive gas formation and to the destruction of the rechargeable battery.

▶

Crushing, mechanical damage

Crushing can cause the rechargeable battery to be damaged, for example by means of mechanical pressure. This may

result in the escape of electrolytes, in an internal short circuit, and in heating and fire.

▶

Before storing the instrument for a longer time, fully charge the CPH7000, in order to avoid deep discharge of the

rechargeable battery.

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 25

Page 26

6. Commissioning, operation

6. Commissioning, operation

Personnel: Skilled personnel

Only use original parts (see chapter 11 “Accessories”).

EN

Prior to commissioning, check the CPH7000 process calibrator as well as the CPT7000 external pressure transmitter for

integrity.

Only use the calibrator and the reference pressure sensors if they are in perfect condition with respect to safety.

6.1 Electrical mounting

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

▶

Operation using a defective power supply unit (e.g. short circuit from the mains voltage to the output voltage)

can result in life-threatening voltages at the instrument!

▶

Only use the power supply unit from WIKA supplied with the instrument!

6.2 Operation

The On/Off key is located on the left side of the case. To switch on the instrument, the key must be pressed for approx. 2.5 s

until the LED starts to flash green. As soon as the process calibrator is turned on, it will go through a short self-test routine.

Then the main screen appears. The calibrator requires a warm-up period of about 5 minutes to reach its specified accuracy.

Large changes in ambient temperature may make a longer warm-up period necessary. The pressure sensors should be zeroed

each time the calibrator is started.

6.2.1 ON/OFF key

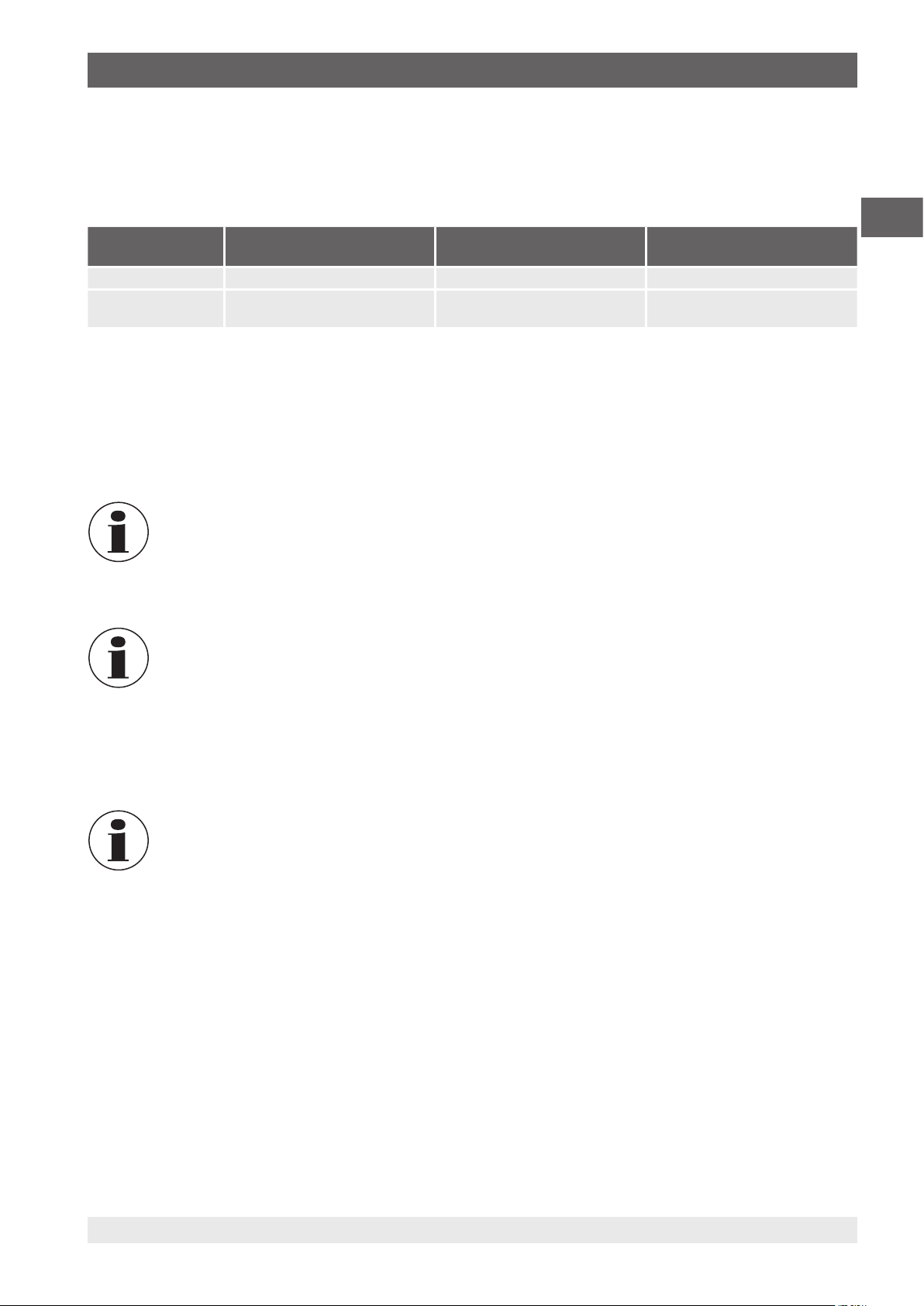

6.2.1.1 Switching on

1. To switch on the instrument, the On/Off key must be pressed for approx. 2.5 s.

The main screen appears.

⇒

The desired applications can now be started.

⇒

6.2.1.2 Locking the screen

1. To lock the screen, the On/Off key must be pressed briefly.

The locking dialog appears.

⇒

The process calibrator is locked for further entries.

⇒

2. To unlock the screen, press the On/Off key.

Return to the main screen.

⇒

26 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 27

6. Commissioning, operation

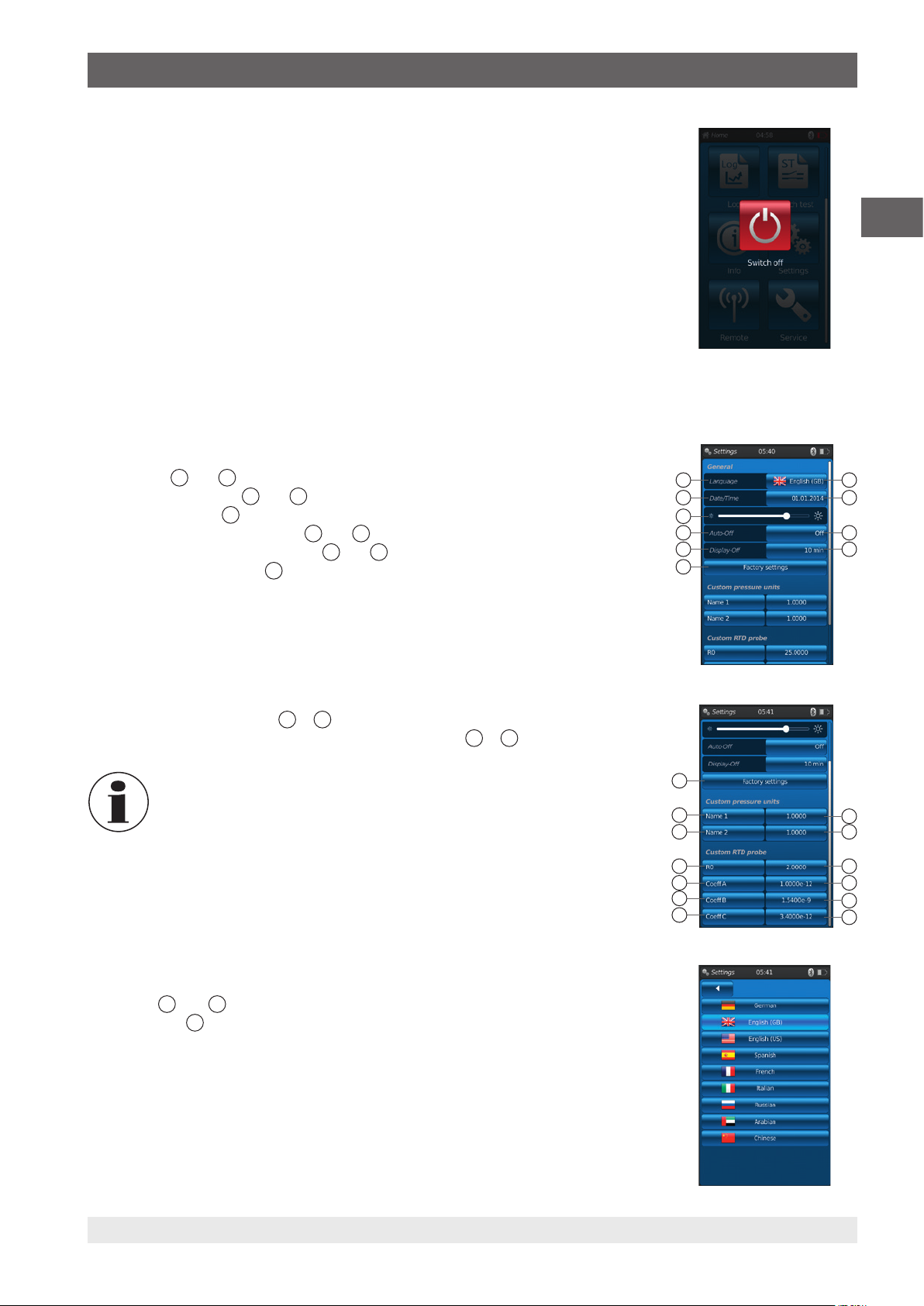

6.2.1.3 Switching off

1. To switch off the instrument, press the On/Off key for approx. 2.5 s.

The switching off dialog appears.

⇒

■

Confirm the dialog or press the On/Off key again.

The process calibrator is switched off.

⇒

■

To cancel, press [Home].

Return to the main screen.

⇒

2. To directly switch off the instrument, press the On/Off key for more than 10 s.

The process calibrator is switched off.

⇒

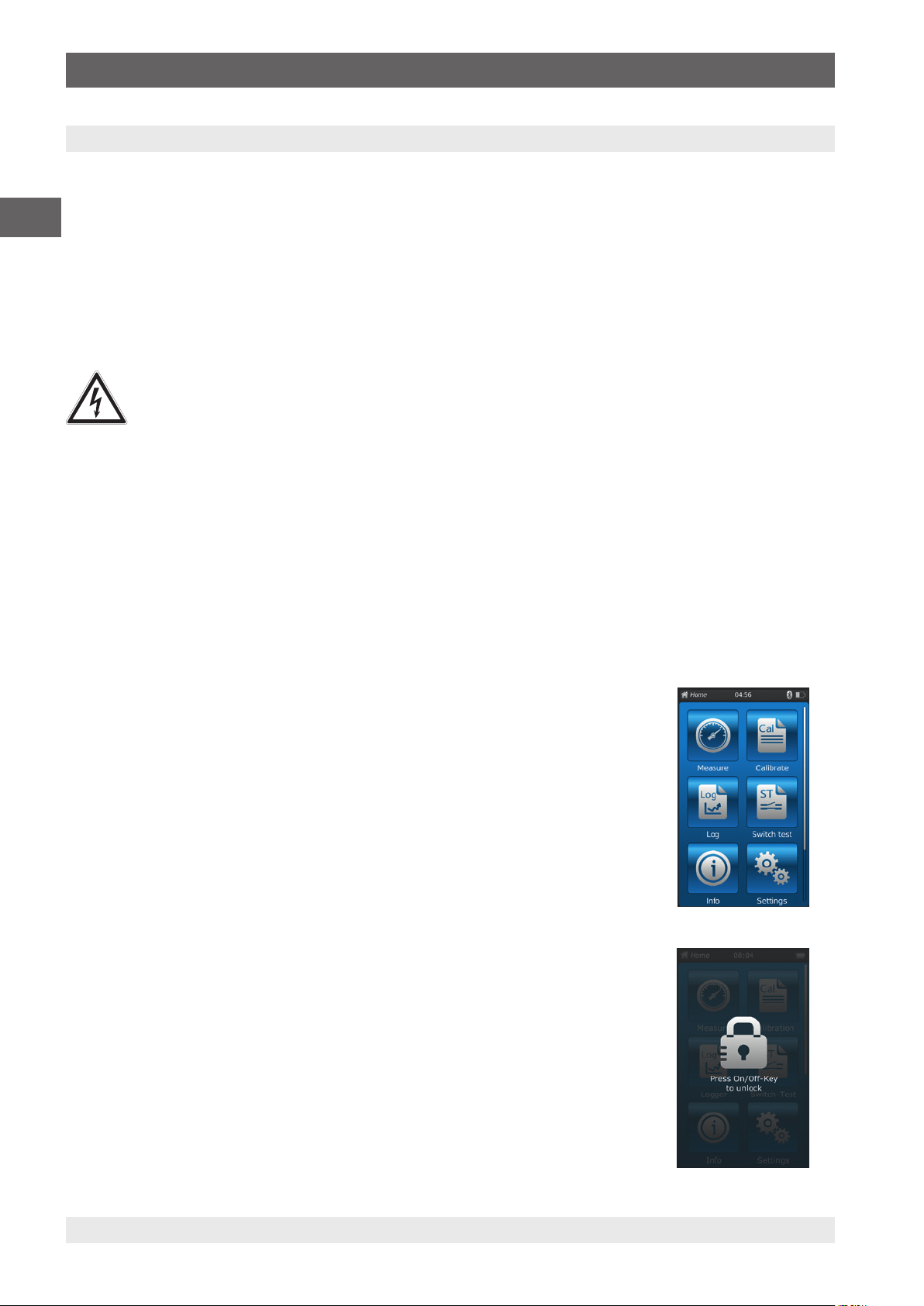

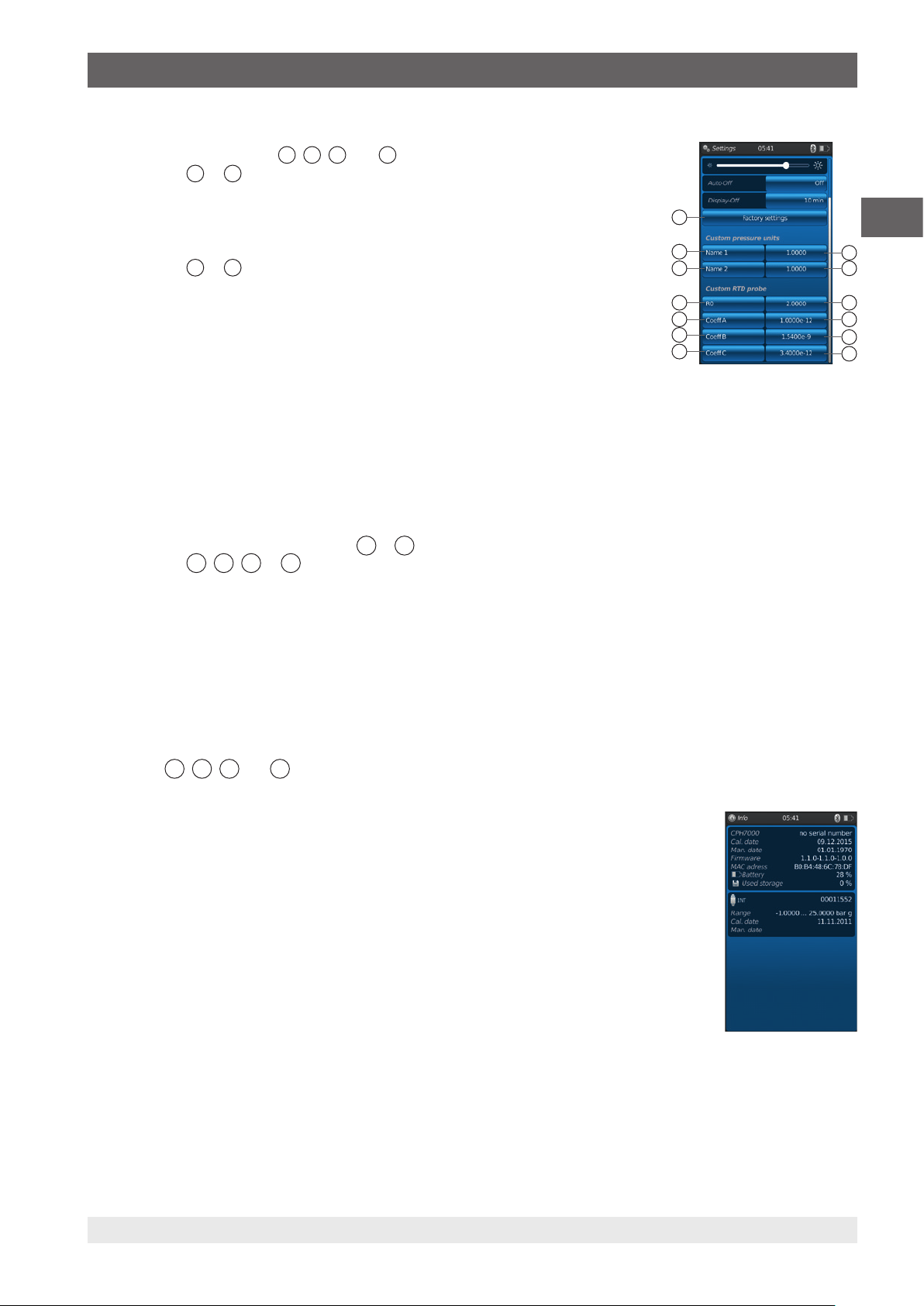

6.2.2 Application [Settings]

Press the [Settings] app to go to the instrument settings level.

The following information can be entered or changed:

■

Language 1 and

■

Current time and date 3 and

■

Display brightness

■

Setting of the “Auto-Off function” 6 and

■

Setting of the “Display-Off function” 8 and

■

Reset to “factory settings”

2

4

5

7

9

10

EN

21

43

5

76

98

10

■

User-defined pressure units 11 ...

■

User-defined temperature probes, including all coefficients 15 ...

14

The limits of the temperature coefficients are 0.0000 ... 999.0000.

Very small coefficient values can be entered via the exponential function. Here,

the [ . ](point) button must be pressed twice (e.g.: 1e-5 for 0.00001, 1e-6 for

0.000001 etc.).

Setting and/or changing:

Language

1. Press button

1

and 2:

2

.

2. Click on the country flag to select the language.

The desired operating language is set.

⇒

Return to the menu screen.

⇒

Press [◀] to cancel and return to the “Settings” menu screen.

22

10

11

13

15

17

19

21

12

14

16

18

20

22

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 27

Page 28

6. Commissioning, operation

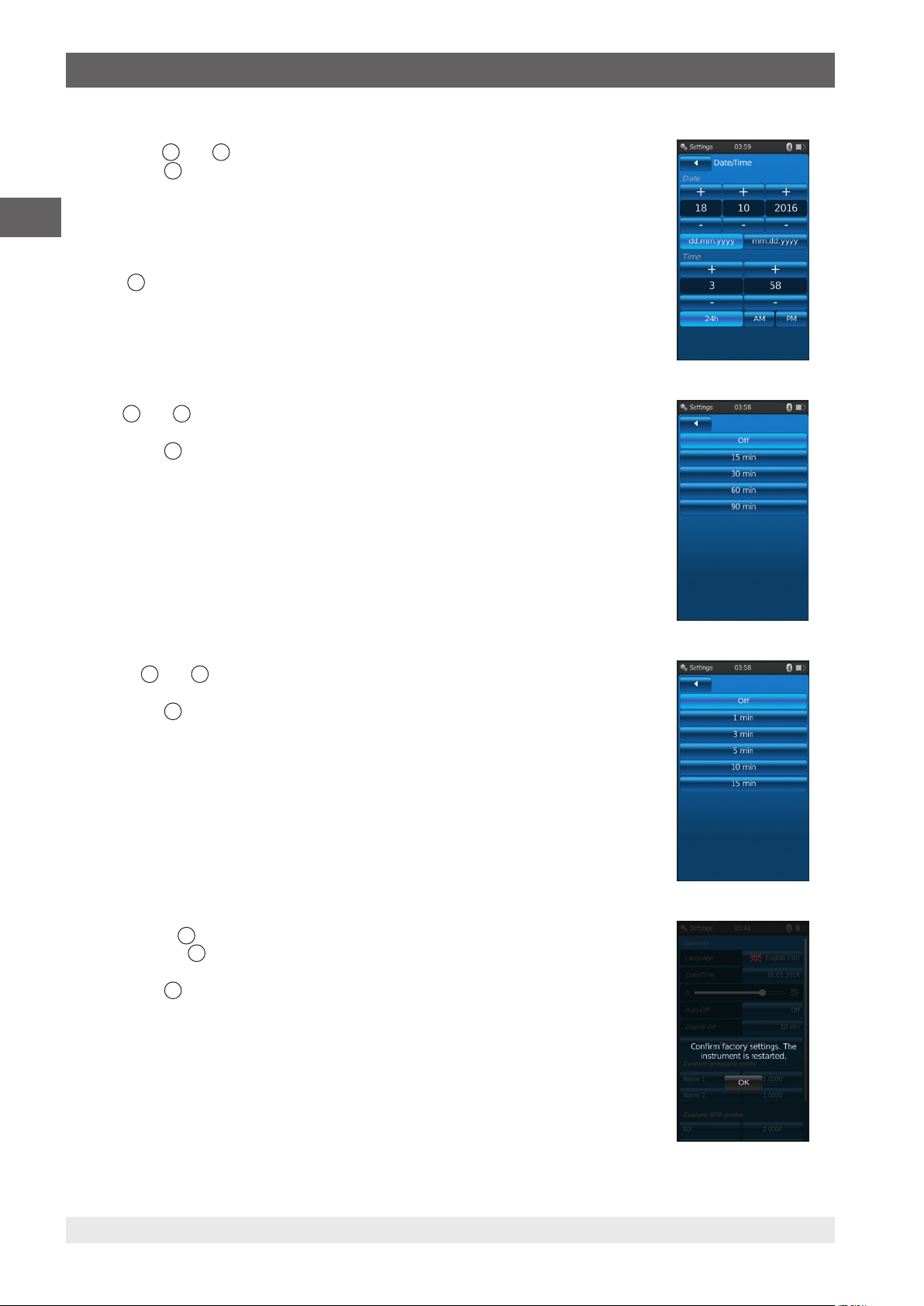

Date and time 3 and 4:

1. Press button

The date and time can be entered using the [+] and [-] buttons.

⇒

The [dd.mm.yyyy] and [mm.dd.yyyy] buttons are used to select the date format.

EN

⇒

The time display can be selected using the [24h], [AM] and [PM] buttons.

⇒

2. Press [◀] to return to the “Settings” menu screen and to save the settings.

Contrast 5:

The contrast or the brightness is adjusted via a scroll bar.

4

.

Auto off

Automatic switching off the process calibrator after a prescribed time

1. Press button

2. Select setting.

Display off

Automatic switching off the display after a prescribed time

1. Press button

2. Select setting.

6

and 7:

7

.

The following can be selected: Off, 15 min, 30 min, 60 min and 90 min

⇒

The desired time is set.

⇒

Return to the menu screen.

⇒

8

and 9:

9

.

The following can be selected: Off, 1 min, 3 min, 5 min, 10 min and 15 min

⇒

The desired time is set.

⇒

Return to the menu screen.

⇒

10

Factory settings

Pressing the button

1. Press button

Press [OK] to restore the settings and restart the instrument.

To cancel, press [Home].

Return to the main screen.

⇒

28 WIKA operating instructions portable process calibrator, model CPH7000

:

10

restores the process calibrator to factory settings.

10

.

14204467.02 03/2019 EN/DE

Page 29

6. Commissioning, operation

User-defined pressure units 11, 12, 13 and 14:

1. Press button

An alphanumerical keyboard will be displayed.

⇒

2. Enter the name of the user-defined pressure unit.

3. Confirm with [OK].

Return to the menu screen.

⇒

4. Press button

A numeric keypad will be displayed.

⇒

5. Enter the multiplication factor of the user-defined pressure unit.

The basic unit is “bar”.

⇒

6. Confirm with [OK].

Return to the menu screen.

⇒

Press [Delete] to delete the entire entry.

Press [] to delete the last entry step.

To cancel, press [Home].

Return to the menu screen.

⇒

The values will not be saved.

⇒

A maximum of two user-defined pressure units can be defined.

11

12

or 13.

or 14.

10

11

13

15

17

19

21

EN

12

14

16

18

20

22

15

User-defined temperature probes (RTD)

1. Press button

A numeric keypad will be displayed.

⇒

16, 18, 20

or 22.

... 22:

2. Enter numerical values.

3. Confirm with [OK].

Return to the menu screen.

⇒

Press [Delete] to delete the entire entry.

Press [] to delete the last entry step.

To cancel, press [Home].

Return to the menu screen.

⇒

The buttons

15, 17, 19

and 21 cannot be changed.

6.2.3 Application [Info]

Pressing the [Info] app displays all information about the CPH7000, including all internal and external

sensors connected.

The following information is displayed:

■

For the process calibrator:

Serial number, calibration date, date of manufacture, firmware, MAC address, battery status,

memory used

■

For a connected internal (int) or external sensor (EXT1, EXT2), a temperature probe Pt100 (RTD) or

the atmospheric module (AMB):

Measuring range, calibration date, date of manufacture

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 29

Page 30

6. Commissioning, operation

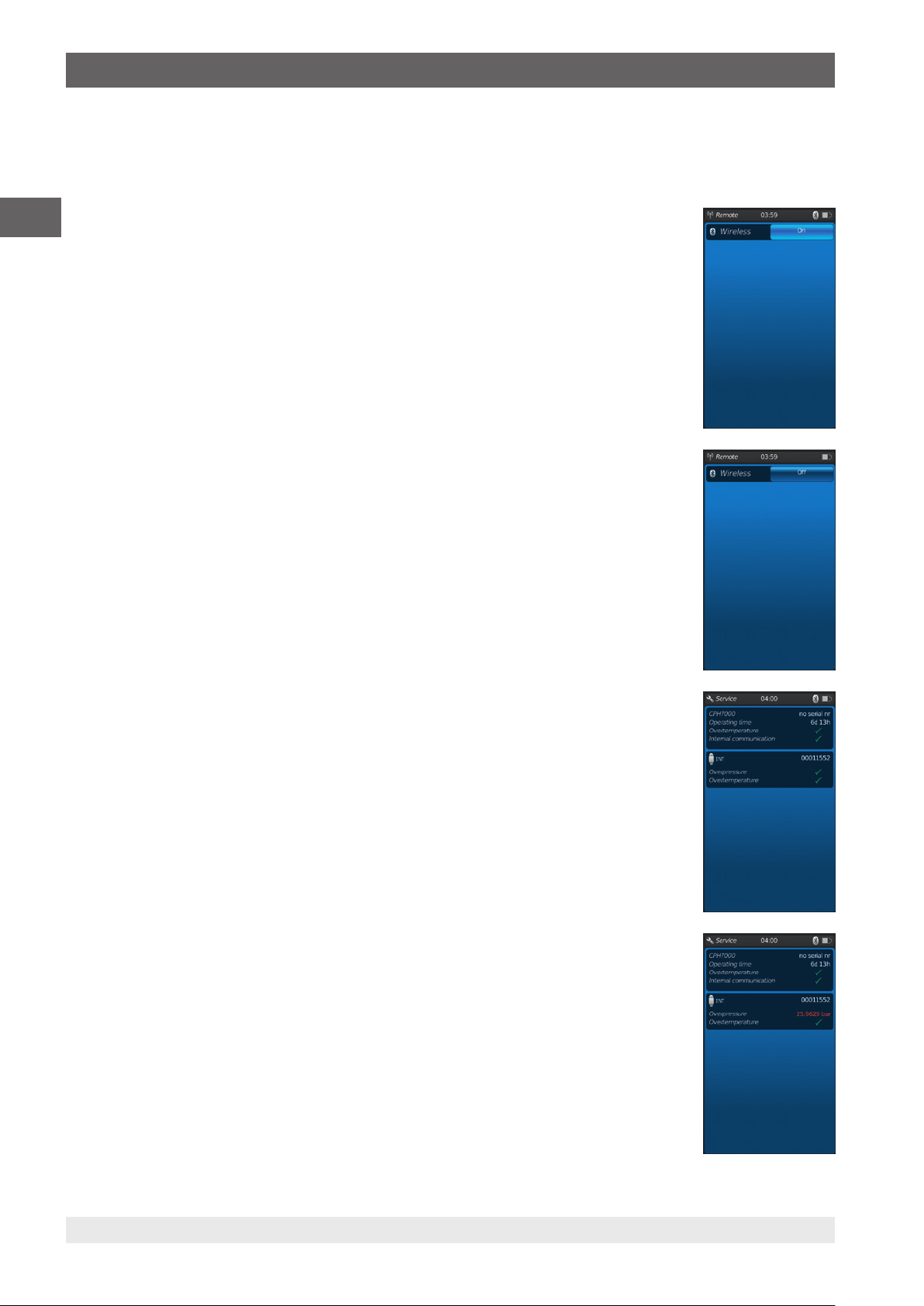

6.2.4 Application [Remote]

Press the [Remote] app to go to the data transfer level.

This is where the WIKA-Wireless interface is switched on or off and the CPH7000 can be connected to a computer via this

interface.

EN

Switching on or off the WIKA-Wireless interface:

1. Press app [Remote].

2. Press button [Off] or [On]

During activation, the wireless sign will be displayed next to the battery icon.

⇒

During deactivation, it will not be displayed.

⇒

6.2.5 Application [Service]

All service-relevant information is listed in the [Service] application. A green check mark indicates that

the instrument is functioning correctly. A red X or the maximum sensor value shows an error.

The warning “Spanner” in the status bar is only acknowledged when, after an error, the service window

is opened.

▶

Press button [Home].

Return to the main screen.

⇒

Error message is no longer displayed.

⇒

30 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 31

6. Commissioning, operation

6.2.6 Further settings

6.2.6.1 Memory

If more than 90 % of the internal memory (1 GB RAM and 4 GB Flash) has been written, this message

appears.

To avoid data loss, transfer the data to an external storage medium and delete the data on the

CPH7000.

The connection to data transfer is WIKA-Wireless.

WIKA-Cal is the software for further analysis.

6.2.6.2 Rechargeable battery

If the battery capacity is below 10 %, this warning message appears.

The CPH7000 is to be charged immediately using the power supply unit provided, otherwise data loss

may occur.

EN

6.2.6.3 Changing the application task

If a data recording (e.g.: a logger process) is running in the background and a new measuring

application (e.g: measure) is started at the same time, a warning message appears (e.g.: logger is

active. Would you like to start the measurement anyway?).

■

Confirm with [OK].

The new measuring application is started

⇒

The old application is terminated; this logger process can be saved the next time you

open the app. It is not possible to continue the finished measurement.

■

To cancel, press [Home].

Return to the main screen.

⇒

Data continue to be recorded in the background.

⇒

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 31

Page 32

6. Commissioning, operation

6.3 Measure

When using the electrical module, better results are achieved if the battery is not charged during the

measurement.

EN

6.3.1 Configuration of the “Measure” function

Press the [Measure] app to go to the “Measure” function.

In this function all measuring channels are displayed simultaneously.

One measuring channel consists of several segments.

The following parameters can be set:

■

Type of test item

■

INT, EXT1 1), EXT2 1), mAIN, mAIN24V, VIN, VIN24V, mA

1)

AMB

, RTD

■

Pin assignment

■

Shows that the CPH7000 is in the setting mode

■

Type of pressure (rel. or abs.)

■

If a barometric reference is installed in the CPH7000, it is possible to switch between rel.

and abs. The CPH7000 calculates the respective pressure value from the values of the barometer.

5

■

Unit

■

Zero point setting

1

1)

switch test, switch test

2

4

6

24V

, [---]

3

Out

, mA

24V, GAU 1), DIFF,

Out

Channel 1

Channel 2

Channel 3

6.3.1.1 Setting test item 1

1 2 3

By directly pressing one of the measuring channels, you go to the setting screen of the

measurands.

Out

1

.

, mA

24V, GAU 1), DIFF, AMB 1), RTD

Out

1)

switch test, switch test

24V

, [---]

1. Press button

The selection window of the possible methods of measurements is displayed.

⇒

You can choose between: INT, EXT1 1), EXT2 1), mAIN, mAIN24V, VIN, VIN24V,

⇒

mA

2. Select type of test item.

Return to the menu screen.

⇒

Selecting the type of pressure

4

3. Press button 4.

4. Select type of pressure (rel. or abs.)

If a barometric reference is installed in the CPH7000, it is possible to switch between rel. and abs. The CPH7000

⇒

calculates the respective pressure value from the values of the barometer.

Selecting the pressure unit

5

5. Press button 5.

The selection window of the possible pressure units is displayed.

⇒

6. Select pressure unit.

Return to the menu screen.

⇒

Zero point setting

6

7. Press button 6.

A numeric keypad will be displayed.

⇒

8. Adjust the zero point

9. Confirm with [OK].

Return to the menu screen.

⇒

456

32 WIKA operating instructions portable process calibrator, model CPH7000

14204467.02 03/2019 EN/DE

Page 33

6. Commissioning, operation

Pin assignment

1. Press button 2.

The selection window of the possible pin assignments is displayed.

⇒

You can choose between: INT, EXT1 1), EXT2 1), mAIN, mAIN24V, VIN, VIN24V, mA

⇒

GAU

2. Select pin assignment.

Return to the menu screen.

⇒

1) Displayed only if an external sensor is connected.

6.3.1.2 Setting test item 2 and 3

Test items 2 and 3 are programmed in the same way as test item 1.

If only 1 test item is measured, the type of test item [---] is selected in the selection window of test items 2 and 3.

6.3.2 Functions with symbol and meaning

Function Symbol Meaning

INT

EXT1

EXT2

RTD

INmA

INmA24V

INV Measuring voltage

INV24V

OUTmA

2

1)

, DIFF, AMB 1), RTD

, mA

1)

switch test, switch test

Internal reference pressure sensor

The current pressure value of the internal reference pressure sensor is displayed.

External reference pressure sensor to channel 1

The current pressure value of the external reference pressure sensor on channel 1 is

displayed.

This function can only be selected if also an external sensor is connected to channel 1.

External reference pressure sensor to channel 2

The current pressure value of the external reference pressure sensor on channel 2 is

displayed.

This function can only be selected if also an external sensor is connected to channel 2.

External temperature probe

The current temperature value of the external temperature probe is displayed.

This function can only be selected if also an external temperature probe is connected.

Measuring current

Activates the integrated electrical module for current measurement (0 ... 30 mA).

▶

Observe the electrical pin assignment, see chapter 6.3.5 “Measuring current”.

Measuring current with DC 24 V voltage supply

Activates the integrated electrical module for current measurement with simultaneous

DC 24 V (0 ... 30 mA) voltage supply by means of the CPH7000.

▶

Observe the electrical pin assignment, see chapter 6.3.6 “Measuring current with

simultaneous DC 24 V voltage supply”.

Activates the integrated electrical module for voltage measurement (DC 0 ... 30 V).

▶

Observe the electrical pin assignment, see chapter 6.3.7 “Measuring voltage”.

Measuring voltage with DC 24 V voltage supply

The measurement of the voltage value is accurate to 3 decimal places.

Activates the integrated electrical module for voltage measurement with simultaneous

DC 24 V (DC 0 ... 30 V) voltage supply by means of the CPH7000.

▶

Observe the electrical pin assignment, see chapter 6.3.8 “Measuring voltage with

simultaneous DC 24 V voltage supply”.

Simulating current

Current (mA) is generated from the integrated current source.

▶

Observe the electrical pin assignment, see chapter 6.3.9 “Simulating current”.

24V

, [---]

Out

Out

24V,

EN

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 33

Page 34

EN

6. Commissioning, operation

Function Symbol Meaning

OUTmA24V

GAU

DIFF

Switch test

Switch test

24V

AMB

Simulating current with DC 24 V voltage supply

Current (mA) is generated from the integrated current source. The internal voltage supply is

constant (DC 24 V).

▶

Observe the electrical pin assignment, see chapter 6.3.10 “Simulating current with

simultaneous DC 24 V voltage supply”.

Manual pressure value acquisition

Allows a value to be manually entered (e.g.: of a pressure gauge).

▶

Observe the electrical pin assignment, see chapter 6.3.11 “Manual pressure value

acquisition”.

Displaying the difference value

Displays the difference value of two selected connections. For the subtraction (upper - lower

display) the significant figure rule applies.

Switch test

If no reference has been selected, the switch test cannot be selected as well.

The internal or an external sensor can be used as reference.

▶

Observe the electrical pin assignment, see chapter 6.6 “Switch test”.

Switch test with DC 24 V voltage supply

The switch is supplied by the CPH7000 with DC 24 V.

The internal or an external sensor can be used as reference.

▶

Observe the electrical pin assignment, see chapter 6.6 “Switch test”.

Displaying environmental parameters

Displays the values of the existing atmospheric module and of the integrated barometer. If

the atmospheric module is not connected, only dashes (-.---) are displayed for the measured

values temperature and humidity.

The “AMB” function can only be selected if the external atmospheric module or the barometer

is also connected. If the barometer is connected, the atmospheric pressure data can be

readout by the “AMB” function.

6.3.3 Measuring the external reference pressure sensor on channel 1 or on channel 2

“EXT1” and “EXT2” functions, buttons

Pin assignment channel 1

and

Process connection

may vary

14204467.02 03/2019 EN/DE

34 WIKA operating instructions portable process calibrator, model CPH7000

Page 35

6. Commissioning, operation

Pin assignment channel 2

The connection can also be made with the CPH7000 switched on.

Both ports can be used simultaneously.

6.3.4 Measuring the external temperature probe

EN

Process connection

may vary

“RTD” function,

Pin assignment

The connection point for the Pt100 probe is located on the CPH7000 on the right side of the case.

To carry out a temperature measurement, the [Measure] application has to be opened and the “RTD” function selected (in

one of the 3 channels).

The “RTD” function can only be selected when the temperature probe is connected.

button

14204467.02 03/2019 EN/DE

WIKA operating instructions portable process calibrator, model CPH7000 35

Page 36

6. Commissioning, operation

6.3.5 Measuring current

“INmA” function,

Pin assignment

EN

button

+

0 ... 30 mA

Current source

-

V

outVin

mA GND

To measure current, the [Measure] application has to be opened and the “INmA” function selected (in one of the 3 windows).

First, enter all settings in the CPH7000, then make the electrical connection.

6.3.6 Measuring current with simultaneous DC 24 V voltage supply

“INmA24V” function, button

Pin assignment

Pressure

Test

item

Reference

+ -

External/internal

pressure supply

V

outVin

mA GND

To measure current, the [Measure] application has to be opened and the “INmA24V” function selected (in one of the 3

windows).