Page 1

Operating instructions

Betriebsanleitung

Intrinsically-safe hand-held pressure calibrator, model CPH65I0

Eigensicherer Hand-Held Druckkalibrator, Typ CPH65I0

GB

D

Intrinsically-safe hand-held pressure calibrator,

model CPH65I0-S2

Page 2

Operating instructions model CPH65I0 Page 3 - 50

GB

Betriebsanleitung Typ CPH65I0 Seite 51 - 97

D

© 2013 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2

WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 3

Contents

Contents

1. General information 4

2. Safety 5

Intended use

2.1

Personnel qualication

2.2

Additional safety instructions for instruments per ATEX

2.3

Special hazards

2.4

Labelling, safety marks

2.5

3. Specications 12

4. Design and function 17

Description

4.1

Scope of delivery

4.2

Pressure and electrical connections

4.3

Keypad

4.4

5. Transport, packaging and storage 20

6. Commissioning, operation 21

Calibrator display

6.1

Using the backlighting

6.2

Using of the "ZERO" function

6.3

Further menu controlled functions

6.4

Factory settings

6.5

Menu structure

6.6

Measuring pressure

6.8

Measuring current

6.8

Measuring temperature with a resistance thermometer

6.9

Performing a pressure switch test

6.10

Calibrating transmitters

6.11

MIN/MAX memory

6.12

7. Maintenance, cleaning and recalibration 44

8. Faults 46

9. Dismounting, return and disposal 47

10. Accessories 48

Appendix: EC Declaration of Conformity for model CPH65I0 49

11

17

17

18

19

21

23

23

25

29

32

34

35

36

37

39

44

GB

6

6

7

9

Declarations of conformity can be found online at www.wika.com.

14061681.02 03/2013 GB/D

3WIKA operating instructions, model CPH65I0

Page 4

1. General information

1. General information

■

The model CPH65I0 hand-held pressure calibrator described in the operating

GB

instructions has been manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the

instrument. Working safely requires that all safety instructions and work instructions

are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using

the product contrary to its intended use, non-compliance with these operating

instructions, assignment of insuciently qualied skilled personnel or unauthorised

modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 14.51

- Application consultant:

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.com

4 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 5

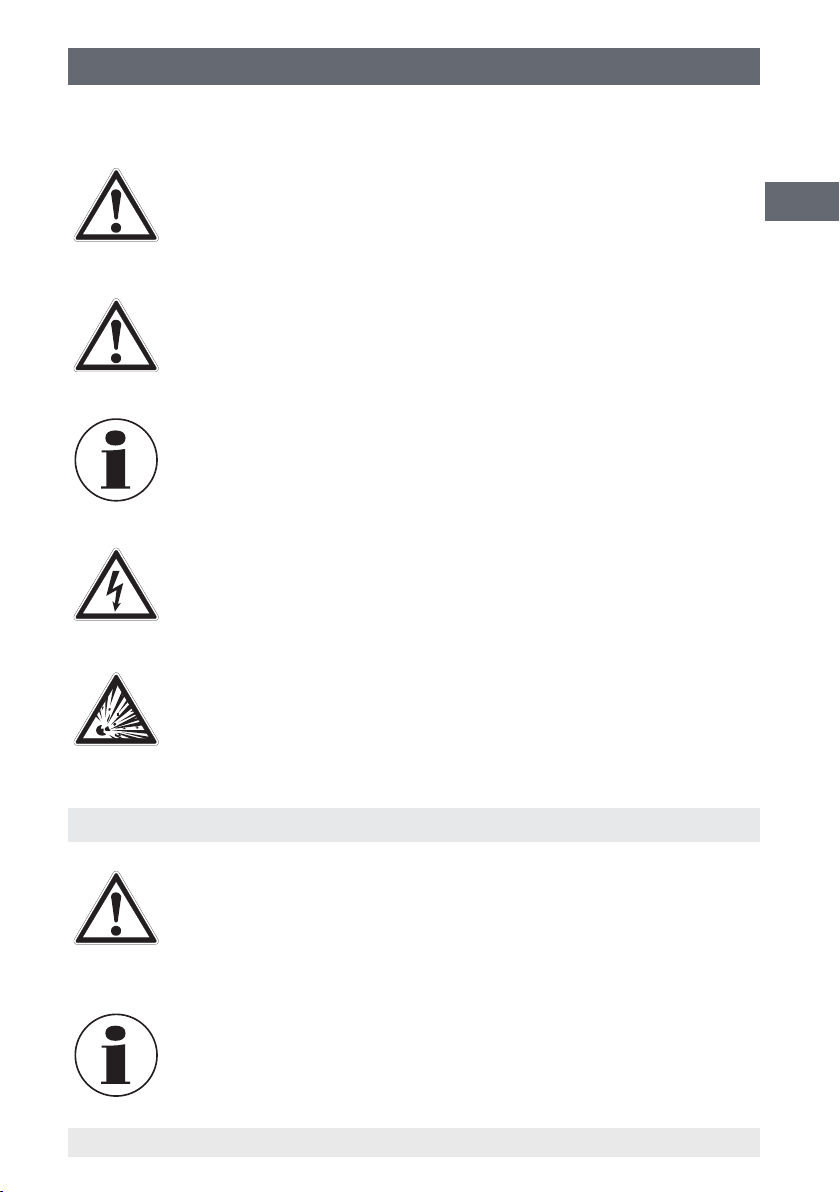

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light

injuries or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient

and trouble-free operation.

DANGER!

...identies hazards caused by electric power. Should the safety

instructions not be observed, there is a risk of serious or fatal injury.

GB

WARNING!

... indicates a potentially dangerous situation in the hazardous area that

can result in serious injury or death, if not avoided.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate hand-held pressure calibrator has been selected in terms of

measuring range, design and specic measuring conditions.

Non-observance can result in serious injury and/or damage to the

equipment.

Further important safety instructions can be found in the individual

chapters of these operating instructions.

14061681.02 03/2013 GB/D

5WIKA operating instructions, model CPH65I0

Page 6

2. Safety

2.1 Intended use

The model CPH65I0 intrinsically-safe hand-held calibrator can be used as a calibration

reference or in any application requiring high-accuracy pressure measurement.

GB

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to

equipment.

■

The activities described in these operating instructions may only

be carried out by skilled personnel who have the qualications

described below.

■

Keep unqualied personnel away from hazardous areas.

6 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 7

2. Safety

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specic regulations, current standards and directives, are capable

of carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Additional safety instructions for instruments per ATEX

WARNING!

Non-observance of these instructions and their contents may result in

the loss of explosion protection.

Battery operation:

■

Use AA alkaline batteries only!

■

Only replace the batteries outside the hazardous area!

■

Only use permitted size AA alkaline batteries as described in the

following table.

GB

Permitted batteries

Battery manufacturer

(alkaline batteries - AA 1.5 V)

Duracell MN1500

Rayovac 815

Energizer E91

Panasonic AM3*

*model AM3 has been replaced by model LR6XWA

Temperature range:

■

14061681.02 03/2013 GB/D

Model

Permissible ambient temperature range: -10 ... +45 °C

7WIKA operating instructions, model CPH65I0

Page 8

GB

2. Safety

Connection values

Max. voltage Uo = DC 7.14 V

Max. current Io = 1.12 mA

Max. power Po = 2 mW

Max. eective internal capacitance Co = 240 µF

Max. eective internal inductance Lo = 1 H

Power supply circuit

Max. voltage Ui = DC 30 V

Max. current Ii = 80 mA

Max. power Pi = 750 mW

Max. eective internal capacitance Ci = 0 nF

Max. eective internal inductance Li = 0 mH

WARNING!

Further hazardous area safety instructions:

Observe the operating information and the relevant state regulations

concerning use in hazardous areas (e.g. EN IEC 60079-14).

The model CPH65I0 intrinsically-safe hand-held pressure calibrator has

been designed for use in hazardous areas. In these areas there is the

possibility of inammable or explosive gases being present.

The model CPH65I0 intrinsically-safe hand-held pressure calibrator has

been designed to be intrinsically safe. This means that connection with

other equipment that is in an intrinsically-safe circuit will not lead to arcs

capable of causing ignition, so long as the parameters are complied with.

Information/Approval for hazardous locations

WARNING!

Hazardous Areas

A hazardous area, as used in these operating instructions, refers to

an area made hazardous by the potential presence of ammable or

explosive vapours. These areas are also referred to as hazardous

locations.

8 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 9

2. Safety

WARNING!

The replacement of components may compromise the explosion

protection. Service and repair must be carried out by the manufacturer.

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination

certicate and the relevant country-specic regulations for installation

and use in hazardous areas (e.g. IEC 60079-14, NEC, CEC).

Non-observance can result in serious injury and/or damage to

equipment.

For additional important safety instructions for instruments with ATEX

approval see chapter 2.3 "Additional safety instructions for instruments

per ATEX".

II 2 G Ex ia IIB T3 Gb (Ta = -10…+45 °C)

DEKRA 12ATEX 0146 X

Ex ia IIB T3 Gb (Ta = -10…+45 °C)

IECEx CSA 11.0019X

GB

WARNING!

■

■

■

■

■

■

■

■

14061681.02 03/2013 GB/D

Pressure sensors should only be mounted or dismounted when the

system is free from pressure.

Observe the working conditions in accordance with chapter

3 "Specications".

Always operate the pressure calibrator within its overload limits. See

chapter 3 "Specications".

Do not apply a voltage greater than the specied voltage to the

instrument. See chapter 3 "Specications".

Residual media on the dismounted calibrator and/or sensors can

result in a risk to persons, the environment and the equipment. Take

sucient precautionary measures.

Only use those accessories available from WIKA for the calibrator.

Make sure that the test probes never contact a voltage source while

the test cables are connected to the current terminals.

The measurement signal of the reference (or test sample) can be

inuenced by large electromagnetic eects and the display of the

signal may be lost completely.

9WIKA operating instructions, model CPH65I0

Page 10

GB

2. Safety

WARNING!

■

Do not use the calibrator if it is damaged. Before using the

instrument, check that there are no cracks or missing plastic parts on

the case. Pay particular attention to the insulation of the connectors.

■

The battery cover must be closed and locked in place before the

instrument is operated.

■

Remove the test cables from the instrument before opening the

battery compartment.

■

Inspect the test cables for damaged insulation or exposed metal.

Check the continuity of the leads. Damaged test leads should be

replaced before using the instrument.

■

When using test probes, keep ngers away from the test probe

contacts. Place ngers behind the nger guards on the test probes.

■

Do not use the instrument if it is not working properly. The instrument

protection might be compromised. If in doubt, have the instrument

checked.

■

Only use the instrument in classied areas for which the calibrator is

approved.

■

Disconnect test leads before changing to another measurement or

generation function.

■

To avoid false readings, replace the battery as soon as the battery

indicator appears.

■

Use the correct connection, the proper function and the correct

measuring range for measurements.

■

When screwing an adaptor onto the NPT thread of the calibrator, a

sealing material must also be used (e.g. PTFE tape).

■

When screwing on, use a spanner on the pressure connection for

xing to the calibrator, in order to avoid unnecessary stress on the

case.

10 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 11

2. Safety

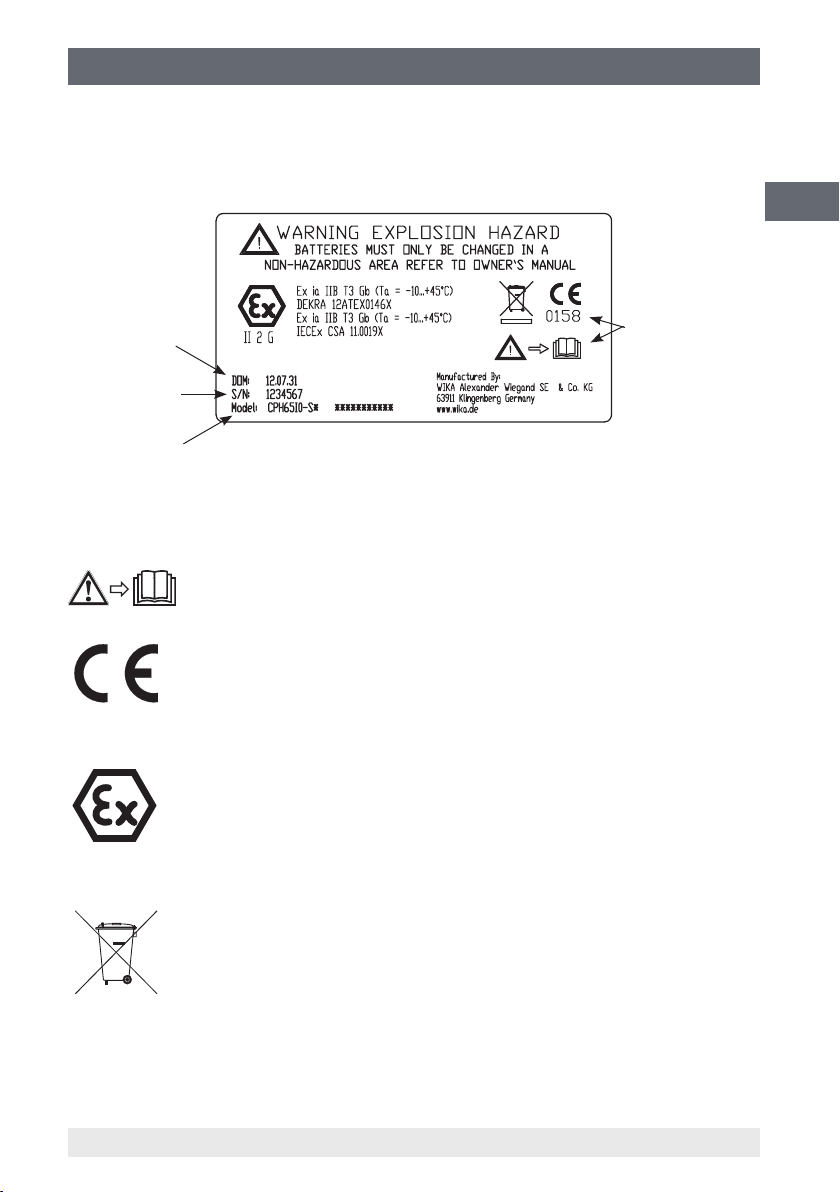

2.5 Labelling, safety marks

Product label

GB

Date of

manufacture

Serial number

1- or 2-channel

version

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the requirements of the

European directive 94/9/EC (ATEX) on explosion protection.

For an explanation

of symbols, see

below

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities (see

directive 2002/96/EC).

14061681.02 03/2013 GB/D

11WIKA operating instructions, model CPH65I0

Page 12

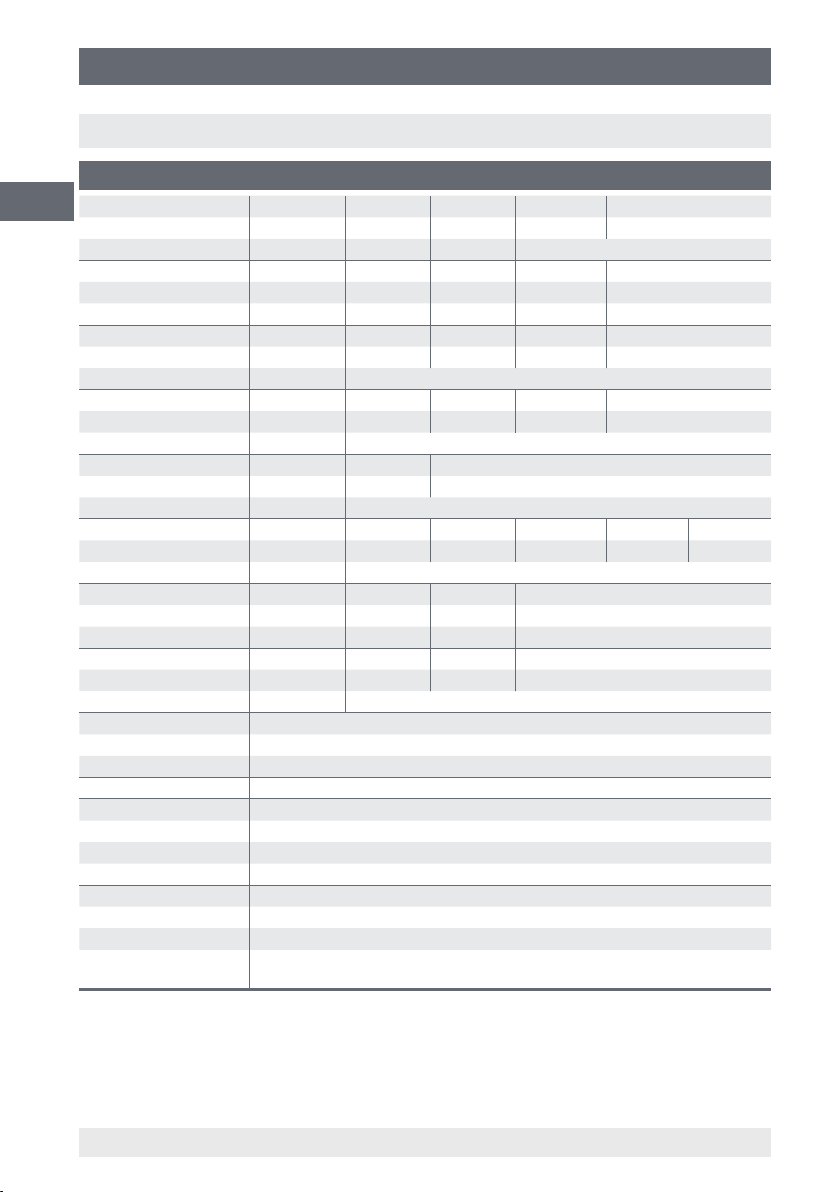

3. Specications

3. Specications

Sensor technology

GB

Measuring range mbar

Overpressure limit mbar 70 200 700 1,000

Accuracy % FS 0.1 0.05 0.035

Measuring range bar -1 ... +1

Overpressure limit bar 2 4 2 4

Accuracy % FS 0.025

Measuring range bar 0 ... 3.5

Overpressure limit bar 13 13 13 40

Accuracy % FS 0.025

Measuring range bar 0 ... 35

Overpressure limit bar 70 200 200 400

Accuracy % FS 0.025

Measuring range bar 0 ... 350 0 ... 700

Overpressure limit bar 700 1,000

Accuracy % FS 0.035

Measuring range bar abs. 0 ... 1 0 ... 2 0 ... 7 0 ... 10 0 ... 20

Overpressure limit bar abs. 2 4 13 13 40

Accuracy % FS 0.025

Measuring range

Overpressure limit mbar di. 70 200 700

Accuracy % FS 0.1 0.05 0.035

Measuring range

Overpressure limit mbar di. 4,000 7,000 10,000

Accuracy % FS 0.025

Type of pressure Relative pressure, absolute pressure, vacuum and dierential pressure

Pressure connection ⅛ NPT female (incl. adapter ⅛ NPT male to G ½ B male)

Pressure medium all liquids and gases which are compatible with 316 SS stainless steel

Resolution 5-digit

Current

Measuring range 0 … 24 mA

Resolution 1 µA

Accuracy 0.015 % of measured value ±2 µA

Temperature

Measuring range -40 … +150 °C

Resolution 0.01 °C

Accuracy 0.015 % of measured value ±20 mΩ, or 0.2 °C for complete measuring chain

1) Non isolated: Only use the pressure measuring ranges marked in this way with clean and non-corrosive gases.

2) Pressure measurement possible in vacuum range to -1 bar.

3) For dierential pressure sensors with a measuring range of 25 mbar, the maximum static pressure is limited to 70 mbar. For the

measuring ranges 70, 350, 2,000, 3,500 and 7,000 mbar the static pressure is limited to a maximum of 10 bar.

4) The dierential pressure sensor is only possible with the CPH65I0-S1 (1-channel version). Both pressure connections for the

dierential pressure measurement are located at the bottom of the calibrator.

5) Adapter not included in delivery for North America.

1)

mbar di.

mbar di.

-25 ... +25 -70 … +70

1)

-1 ... +2 1)0 … 1

2)

0 ... 7

2)

0 ... 70 0 ... 100 0 ... 200

1) 3)

0 ... 25 0 ... 70 0 ... 350

1) 3)

0 ... 2,000 0 ... 3,500 0 ... 7,000

2)

-350 ... +350

0 ... 10

(Pt100 resistance thermometer and CPH65I0)

1)

2)

-500 … +500

1)

0 ... 2

0 ... 20

5)

2)

4)

1)

12 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 13

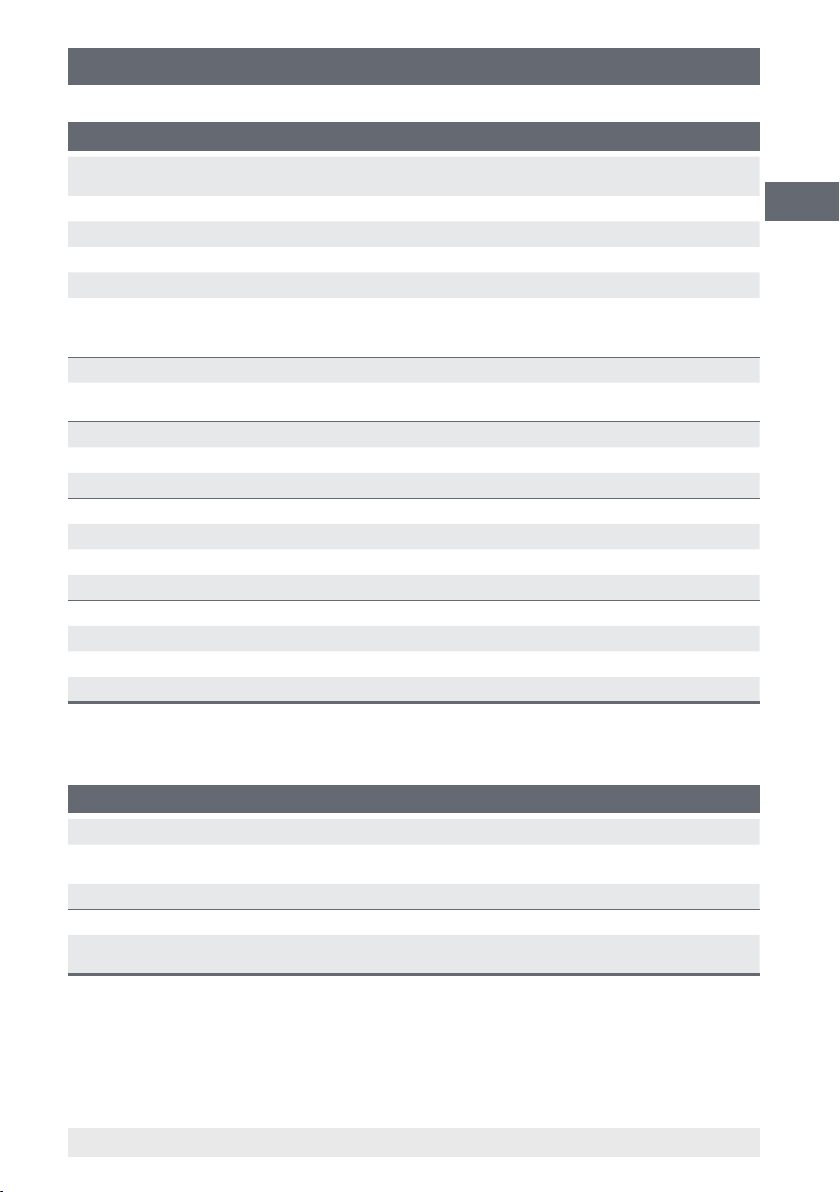

3. Specications

Base instrument

Measuring inputs 1 input for CPH65I0-S1

Pressure connection ⅛ NPT female thread

Pressure medium

Temperature compensation 15 … 35 °C

Temperature coecient 0.002 % of the span/°C outside of the 15 ... 35 °C temperature range

Pressure units psi, bar, mbar, kPa, MPa, kg/cm², mmH

Indicator

Display 5-digit display; large backlit screen for the display of up to three

Voltage supply

Power supply DC 6 V, 4 x 1.5 V AA alkaline batteries

Battery life > 35 hours

Permissible ambient conditions

Operating temperature -10 ... +45 °C

Storage temperature -20 ... +60 °C

Relative humidity 5 ... 95 % r. h. (non-condensing)

Case

Material stainless steel and plastic

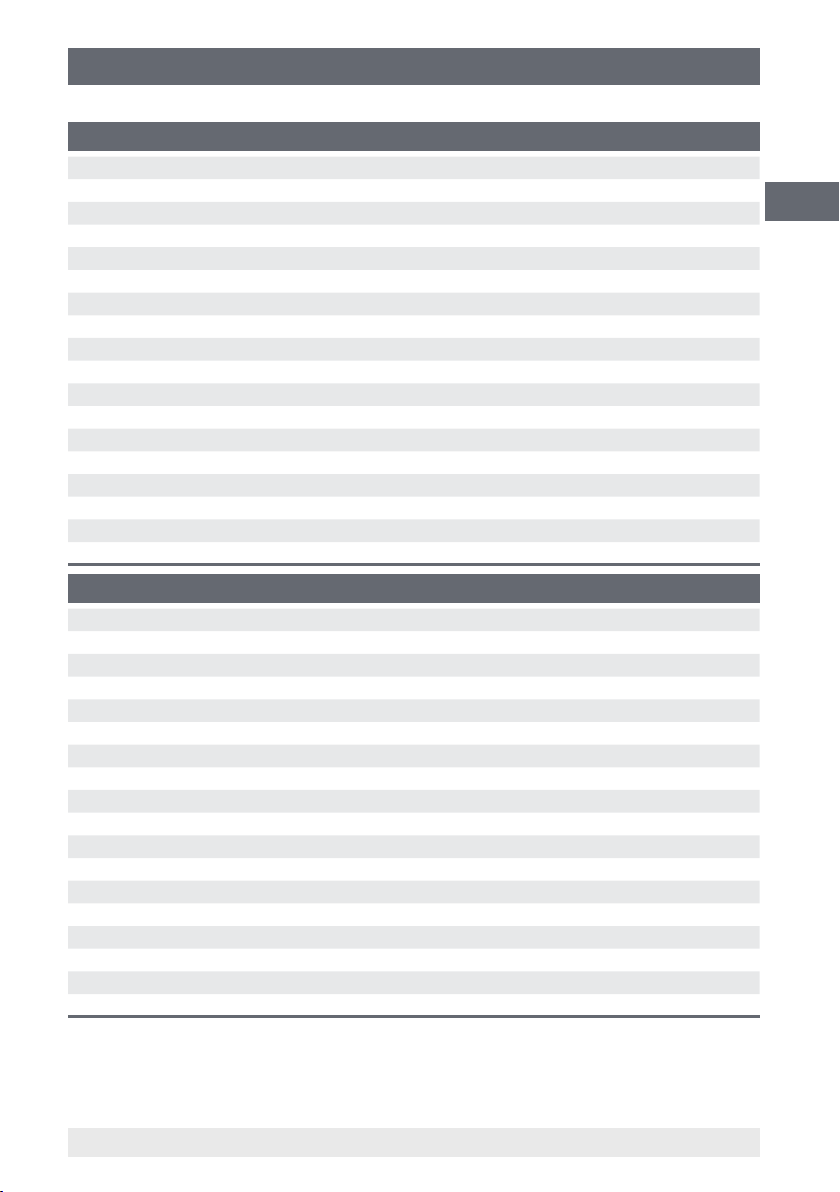

Dimensions see technical drawing

Weight approx. 570 g

Non isolated: Only use the pressure measuring ranges marked in this way with clean and non-corrosive gases. (See sensor

1)

table)

2 inputs for CPH65I0-S2

all liquids and gases which are compatible with 316 SS stainless steel

O (4 °C), mmH2O (20 °C),

cmH

O (4 °C), cmH2O (20 °C), inH2O (4 °C), inH2O (20 °C),

2

inH

O (60 °F), mmHg (0 °C), inHg (0 °C), ft H2O (60 °F)

2

measurement parameters

2

GB

1)

Approvals and certicates

CE conformity

EMC directive 2004/108/EC, EN 61326 emission (group 1, class B) and interference

immunity (portable measurement equipment)

ATEX directive 94/9/EC, category 2G, ignition protection type Ex ia IIB T3 Gb

Certicate

Calibration Standard: 3.1 calibration certicate per EN 10204

Option: DKD/DAkkS calibration certicate

Approvals and certicates, see website

14061681.02 03/2013 GB/D

13WIKA operating instructions, model CPH65I0

Page 14

3. Specications

Types of explosion protection

ATEX directive 94/9/EC, category 2G, ignition protection type Ex ia IIB T3 Gb

GB

IECEx Ex ia IIB T3 Gb (Ta = -10…+45 °C)

Connection values

Max. voltage Uo = DC 7.14 V

Max. current Io = 1.12 mA

Max. power Po = 2 mW

Max. eective internal capacitance Co = 240 µF

Max. eective internal inductance Lo = 1 H

Power supply circuit

Max. voltage Ui = DC 30 V

Max. current Ii = 80 mA

Max. power Pi = 750 mW

Max. eective internal capacitance Ci = 0 nF

Max. eective internal inductance Li = 0 mH

LEMO plug connector only for use with LTP100A RTD sensor

For further specications see WIKA data sheet CT 14.51 and the order documentation.

Available measuring ranges and resolutions

II 2 G Ex ia IIB T3 Gb (Ta = -10…+45 °C)

DEKRA 12ATEX 0146 X

IECEx CSA 11.0019X

Measuring ranges and factors

Measuring range in bar

Unit Conversion factor

psi 1 0.4000 1.0000 5.0000 7.2000 15.000 30.000

bar 0.06894757 0.0276 0.0689 0.3447 0.4964 1.0342 2.0684

mbar 68.94757 27.579 68.948 344.74 496.42 1,034.2 2,068.4

kPa 6.894757 2.7579 6.8948 34.474 49.642 103.42 206.84

Mpa 0.00689476 0.0028 0.0069 0.0345 0.0496 0.1034 0.2068

kg/cm² 0.07030697 0.0281 0.0703 0.3515 0.5062 1.0546 2.1092

mmHg (0 °C) 51.71507 20.686 51.715 258.58 372.35 775.73 1,551.5

inHg (0 °C) 2.03603 0.8144 2.0360 10.180 14.659 30.540 61.081

O (4 °C) 70.3089 28.124 70.309 351.54 506.22 1,054.6 2,109.3

cmH

2

O (20 °C) 70.4336 28.173 70.434 352.17 507.12 1,056.5 2,113.0

cmH

2

O (4 °C) 703.089 281.24 703.09 3,515.4 5,062.2 10,546 21,093

mmH

2

O (20 °C) 704.336 281.73 704.34 3,521.7 5,071.2 10,565 21,130

mmH

2

O (4 °C) 27.68067 11.072 27.681 138.40 199.30 415.21 830.42

inH

2

O (20 °C) 27.72977 11.092 27.730 138.65 199.65 415.95 831.89

inH

2

O (60 °F) 27.70759 11.083 27.708 138.54 199.49 415.61 831.23

inH

2

O (60 °F) 2.308966 0.9236 2.3090 11.545 16.625 34.634 69.269

ftH

2

14 WIKA operating instructions, model CPH65I0

0 ... 0.025 0 ... 0.07 0 ... 0.35 0 ... 0.5 0 ... 1 1)0 ... 2

2)

14061681.02 03/2013 GB/D

Page 15

3. Specications

Measuring ranges and factors

Measuring range in bar

0 ... 3.5 0 ... 7

Unit Conversion factor

psi 1 50.000 100.00 150.00 300.00 500.00

bar 0.06894757 3.4474 6.8948 10.342 20.684 34.474

mbar 68.94757 3,447.4 6,894.8 10,342 20,684 34,474

kPa 6.894757 344.74 689.48 1,034.2 2,068.4 3,447.4

Mpa 0.00689476 0.3447 0.6895 1.0342 2.0684 3.4474

kg/cm² 0.07030697 3.5153 7.0307 10.546 21.092 35.153

mmHg (0 °C) 51.71507 2,585.8 5,171.5 7,757.3 15,515 25,858

inHg (0 °C) 2.03603 101.80 203.60 305.40 610.81 1,018.0

O (4 °C) 70.3089 3,515.4 7,030.9 10,546 21,093 35,154

cmH

2

O (20 °C) 70.4336 3,521.7 7,043.4 10,565 21,130 35,217

cmH

2

O (4 °C) 703.089 35,154 70,309 --

mmH

2

mmH2O (20 °C) 704.336 35,217 70,434 -inH2O (4 °C) 27.68067 1,384.0 2,768.1 4,152.1 8,304.2 13,840

O (20 °C) 27.72977 1,386.5 2,773.0 4,159.5 8,318.9 13,865

inH

2

O (60 °F) 27.70759 1,385.4 2,770.8 4,156.1 8,312.3 13,854

inH

2

O (60 °F) 2.308966 115.45 230.90 346.34 692.69 1,154.5

ftH

2

Measuring ranges and factors

Measuring range in bar

Unit Conversion factor

psi 1 1,000.0 1,500.0 3,000.0 5,000.0 10,000

bar 0.06894757 68.948 103.42 206.84 344.74 689.48

mbar 68.94757 68,948 -kPa 6.894757 6,894.8 10,342 20,684 34,474 68,948

Mpa 0.00689476 6.8948 10.342 20.684 34.474 68.948

kg/cm² 0.07030697 70.307 105.46 210.92 351.53 703.07

mmHg (0 °C) 51.71507 51,715 77,573 -inHg (0 °C) 2.03603 2,036.0 3,054.0 6,108.1 10,180 20,360

O (4 °C) 70.3089 70,309 --

cmH

2

cmH2O (20 °C) 70.4336 70,434 -mmH2O (4 °C) 703.089 -mmH2O (20 °C) 704.336 -inH2O (4 °C) 27.68067 27,681 41,521 83,042 -inH2O (20 °C) 27.72977 27,730 41,595 83,189 -inH2O (60 °F) 27.70759 27,708 41,561 83,123 -ftH2O (60 °F) 2.308966 2,309.0 3,463.4 6,926.9 11,545 23,090

1) This data is also valid for the measuring ranges -1 ... +1 bar and 0 ... 1 bar abs.

2) This data is also valid for the measuring ranges -1 ... +2 bar and 0 ... 2 bar abs.

3) This data is also valid for the measuring ranges 0 ... 7 bar abs., 0 ... 10 bar abs. and 0 ... 20 bar abs.

4) Due to the limited screen resolution, no values can be displayed here. The resolution is limited to 5 digits.

0 ... 70 0 ... 100 0 ... 200 0 ... 350 0 ... 700

4)

4)

3)

0 ... 10 3)0 ... 20 3)0 ... 35

4)

4)

4)

4)

4)

4)

--

4)

--

4)

--

4)

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

4)

4)

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

4)

--

GB

14061681.02 03/2013 GB/D

15WIKA operating instructions, model CPH65I0

Page 16

3. Specications

Dimensions in mm

GB

Front view Side view, right

16 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 17

4. Design and function

4. Design and function

4.1 Description

The model CPH65I0-S1/S2 intrinsically-safe hand-held pressure calibrator has been

designed so that it is simple to handle, but is also a very versatile pressure calibrator.

The two internal reference pressure sensors, combined with current input, pressure

switch function and a resistance thermometer, enable the CPH65I0-S1/S2 to calibrate

practically any pressure instrument.

The model CPH65I0-S1 intrinsically-safe hand-held pressure calibrator has a single

integrated pressure sensor; the model CPH65I0-S2 intrinsically-safe hand-held

pressure calibrator has two integrated pressure sensors. The CPH65I0-S1 uses

connection P1 for all pressure measurements. Connection P2 is only used in the

CPH65I0-S2. Thus, the pressure-related menu selection for the CPH65I0-S1 is limited

to connection P1 only. All other CPH65I0-S1 features and functions are identical to the

CPH65I0-S2.

4.2 Scope of delivery

■

Model CPH65I0-S1/S2 intrinsically-safe hand-held pressure calibrator

■

Operating instructions

■

Test cables

■

4 AA alkaline batteries

■

1 x adapter 1/8 NPT male to G 1/2 B male per pressure connection

■

1x PTFE tape

■

3.1 calibration certicate per DIN EN 10204

1)

GB

1) Adapter not included in delivery for North America

Cross-check scope of delivery with delivery note.

14061681.02 03/2013 GB/D

17WIKA operating instructions, model CPH65I0

Page 18

4. Design and function

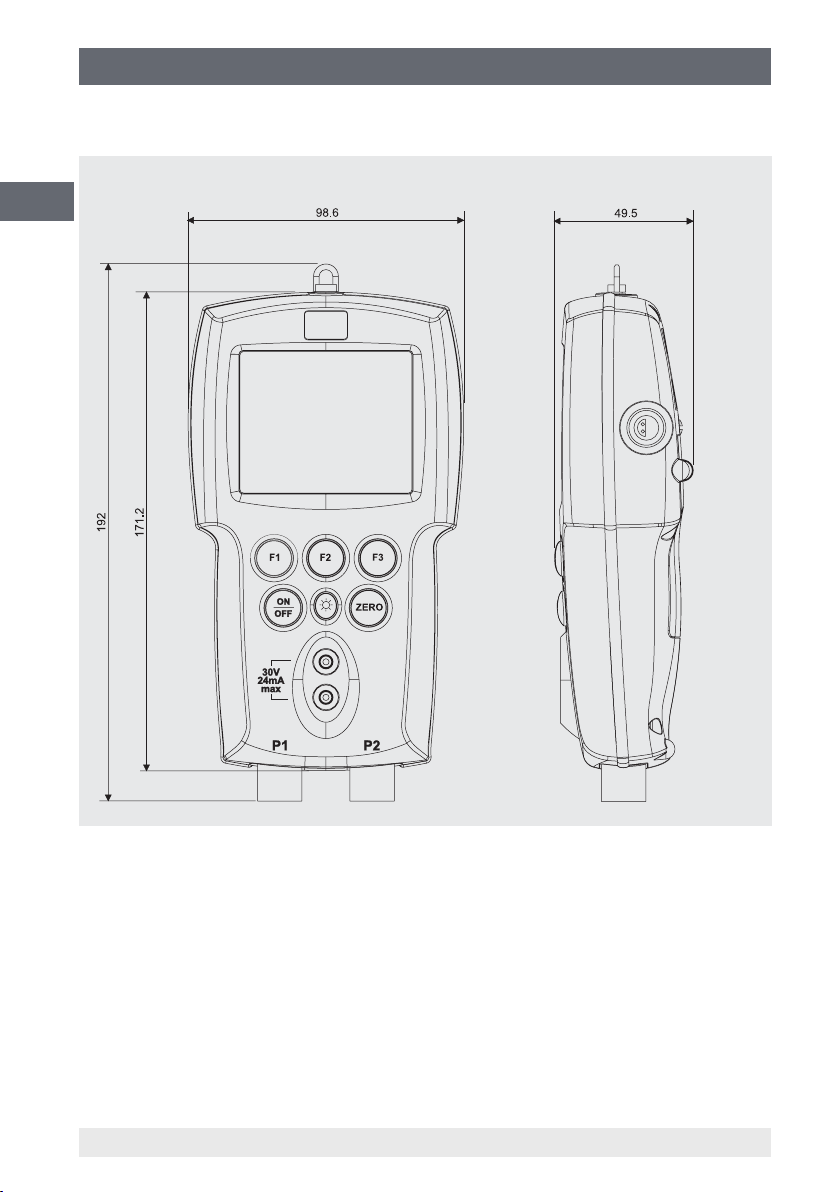

4.3 Pressure and electrical connections

Front view Side view, right

GB

CPH65I0

[P1]

mA -25.00%

RTD

72.50 °F

CONF

UPPER

F1 F2 F3

psi

0.000

0.000 mA

MORE

4

ON

OFF

30V

3

24mA

max

P1 P2

ZERO

1 2

1) P1 pressure connection

Connection for internal sensor, P1

2) P2 pressure connection

Connection for internal sensor, P2

3) Input connection

Electrical connections for current and switch test

4) Resistance thermometer

Connection for external resistance thermometer

18 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 19

4. Design and function

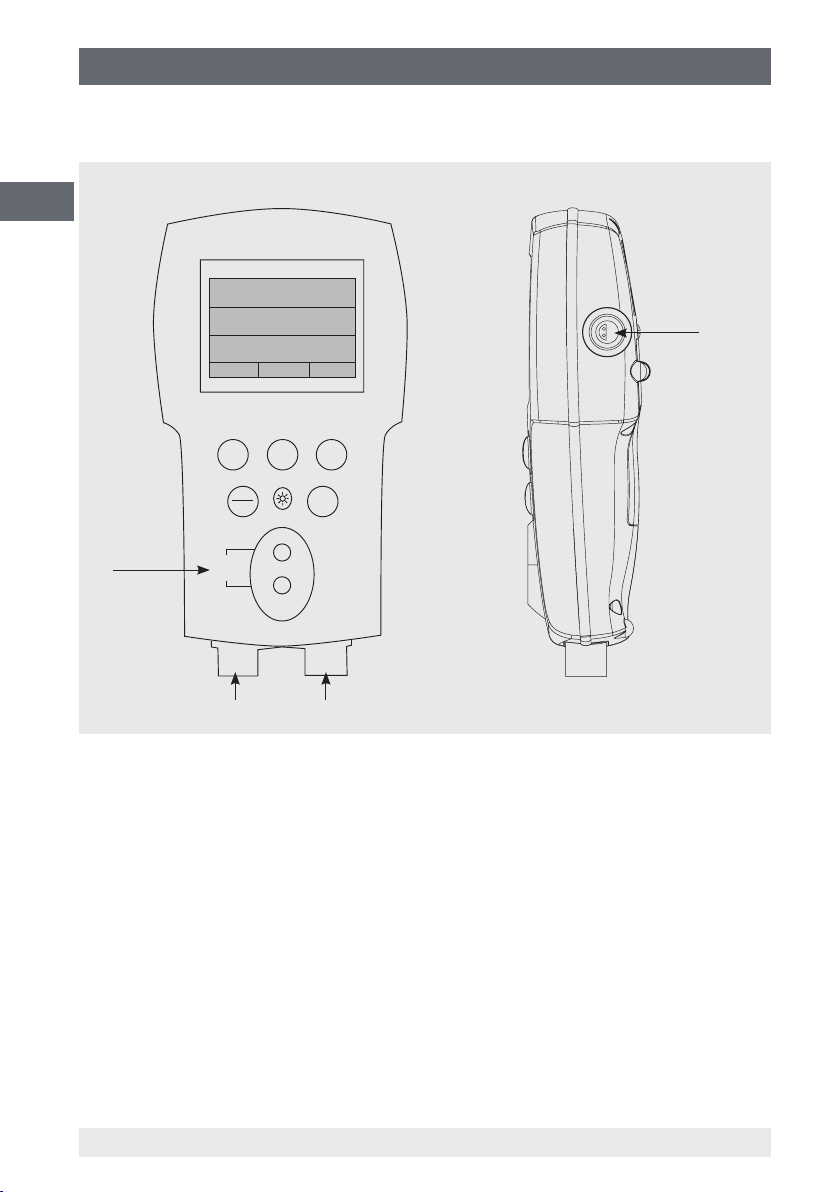

4.4 Keypad

F1 F2 F3

1

GB

ON

OFF

2 4

1) Function keys

Conguration of the instruments

2) ON/OFF button

Turning the instrument on and o

3) Backlighting

Turning the backlighting on and o

4) ZERO key

Zeroing of the pressure measurement

3

ZERO

14061681.02 03/2013 GB/D

19WIKA operating instructions, model CPH65I0

Page 20

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

GB

Check hand-held pressure calibrator for any damage that may have been caused by

transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +60 °C

■

Relative humidity: 5 ... 95 % r. h. (non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the hand-held pressure calibrator in its original packaging in a location that fulls

the conditions listed above. If the original packaging is not available, pack and store the

instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to

health, e.g. caustic, toxic, carcinogenic, radioactive, etc.

20 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 21

6. Commissioning, operation

6. Commissioning, operation

As soon as the model CPH65I0 hand-held pressure calibrator is turned on, by pressing

the ON/OFF key, it will go through a short self-test routine. During this routine, the

display shows the current rmware version, auto-shutdown status and the measuring

range of the internal pressure sensor. The calibrator requires a maximum of 5 minutes

warm-up to reach its specied accuracy. Large changes in ambient temperature may

make a longer warm-up period necessary. The pressure display of the calibrator should

be zeroed before starting the pressure calibration. See chapter 6.3 "Use of the "ZERO"

function".

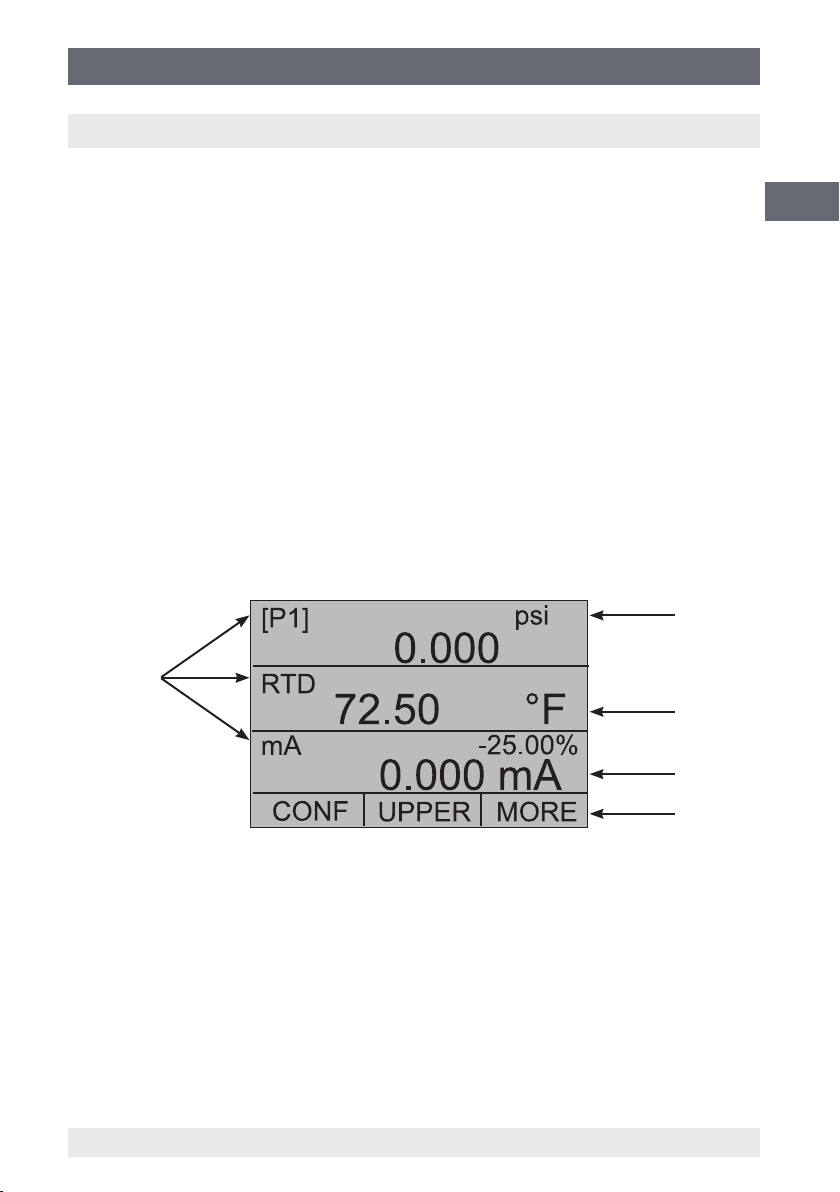

6.1 Calibrator display

The calibrator's display consists of two sectors: The menu bar (located along the

bottom of the screen) is used to access the menu system. The main display (the rest of

the display) consists of up to three sub-sectors for the measurement activities. These

sub-sectors will be referred to as the UPPER, MIDDLE and LOWER displays in this

document.

Figure 1 shows the location of the dierent display elds, which are described in the

following table.

1

GB

5

Figure 1: Display

1) Pressure units

Indication of the pressure unit (selectable from 16 pressure units)

2) Units

Indication of the measuring unit

3) Display of the span

Indication of 4 ... 20 mA span (only with mA measurement)

4) Menu list

5) Primary parameters

Indication of the current measured parameters

14061681.02 03/2013 GB/D

2

3

4

21WIKA operating instructions, model CPH65I0

Page 22

6. Commissioning, operation

6.1.1 Main menu Functionality

There are three options in this menu: "CONFIG", {active display} and "MORE". The

main menu is the home menu for the menu display.

GB

6.1.1.1 Setting the {active display} parameters

The {active display} is displayed via the middle option in the menu in the main display.

Pressing the F2 key switches between the {active display}.

6.1.1.2 Setting the {active display} parameters

In order to set the {active display} parameters, select the "CONFIG" option and open

the conguration menu.

The "SELECT" option switches between the available choices for each parameter.

Since voltage, current and switch-test modes all use the same leads, two of these

functions cannot be used concurrently. The ability to select certain functions is limited

and dependent upon what is already selected in the other display sector. The "NEXT"

option is used to switch to the second parameter.

Only the resistance thermometer and pressure modes have a second parameter.

Resistance thermometers can be displayed in Celsius or Fahrenheit and for pressure

there are 16 dierent units.

Within any single display sector, the following modes are available:

P[1] = left integrated pressure sensor

P[2] = right integrated pressure sensor (only for CPH65I0-S2)

P[1] ST = switch test with left integrated sensor.

P[2] ST = switch test with right integrated sensor (only for CPH65I0-S2)

mA measurement = current measurement

RTD = resistance thermometer (in the event a resistance thermometer

is connected)

22 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 23

6. Commissioning, operation

The following table shows which functions are available concurrently.

An "--" in a column indicates that the mode in the active display will not be available for

selection if the mode in that row is in use in any other display sector.

Active display

P[1] P[2] P[1] ST P[2] ST mA RTD

P[1]

P[2]

P[1] ST

P[2] ST

mA

Other displays

RTD

6.1.1.3 Accessing other menus

In order to access further menus, select the "MORE" option in the main menu. See

chapter 6.6 "Menu structure".

6.2 Using the backlighting

The backlight has its own dedicated button. The light is toggled on and o when the

button is pressed.

-- -- --

-- -- --

-- --

GB

6.3 Using the "ZERO" function

When the ZERO key is pressed, the calibrator will zero the {active display}, as long as

a pressure mode is selected and the pressure is within the zero limit. The zero limits are

within 5 % of the full scale range of the selected sensor. If the display indicates "OL" the

zero function will not operate.

The ZERO key is only used for pressure.

14061681.02 03/2013 GB/D

23WIKA operating instructions, model CPH65I0

Page 24

6. Commissioning, operation

6.3.1 Internal relative pressure sensor

When a relative pressure sensor is selected in the {active display} and the ZERO key

is pressed, the calibrator subtracts the current displayed reading from the output value.

The zero limits are within 5 % of the full scale range of the selected sensor. If the display

GB

indicates "OL" the zero function will not operate.

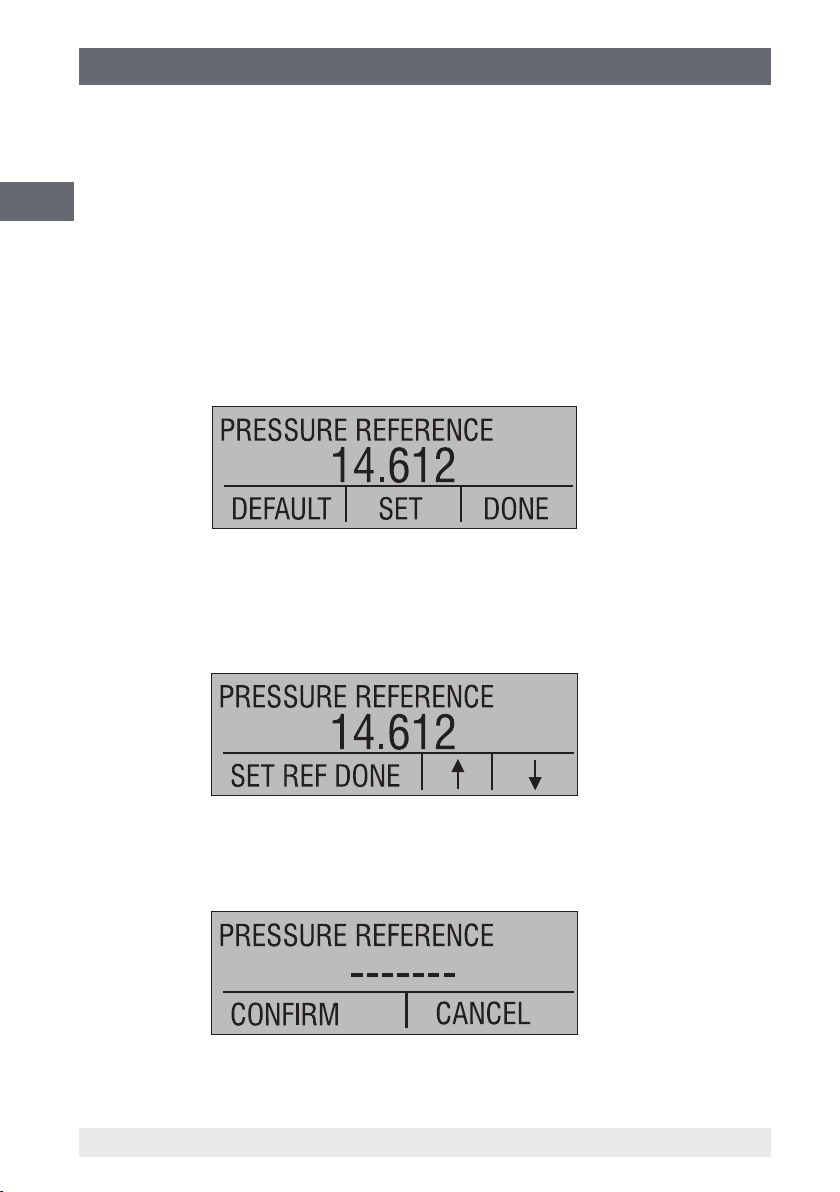

6.3.2 Internal absolute pressure sensor

If an absolute pressure sensor is selected in the {active display} and the ZERO button

is pressed, the calibrator instructs the user to enter the reference pressure value with

"SET" or to reset with "DEFAULT". The reference instrument should be at least four

times as accurate as the absolute pressure sensor of the CPH65I0.

If "SET" is selected, the calibrator prompts the user to enter the barometric reference

pressure. The arrow keys, F2 and F3, can be used for this. The sensor connection

should be open (vented) to atmosphere while performing this procedure.

If, alternatively, "DEFAULT" is selected, the reversion to the factory setting must be

accepted with "CONFIRM" or the action aborted with "CANCEL".

24 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 25

6. Commissioning, operation

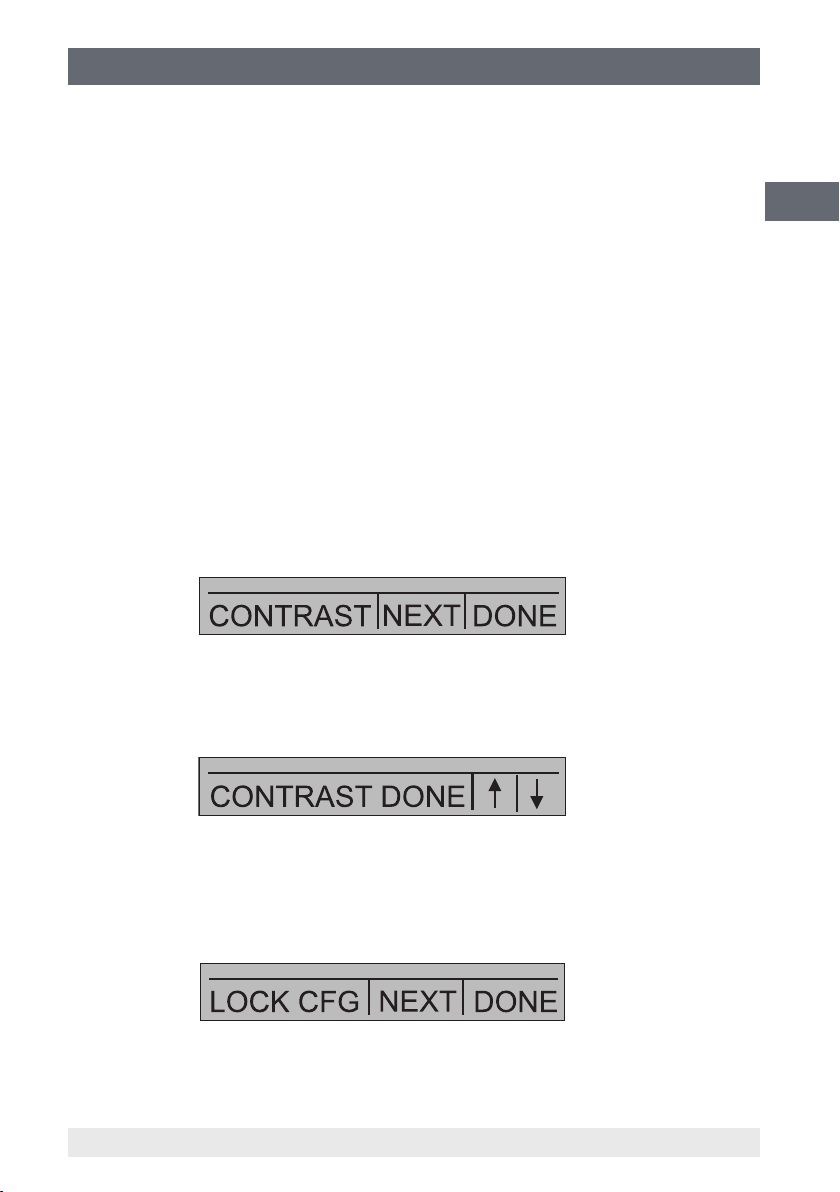

6.4 Further menu controlled functions

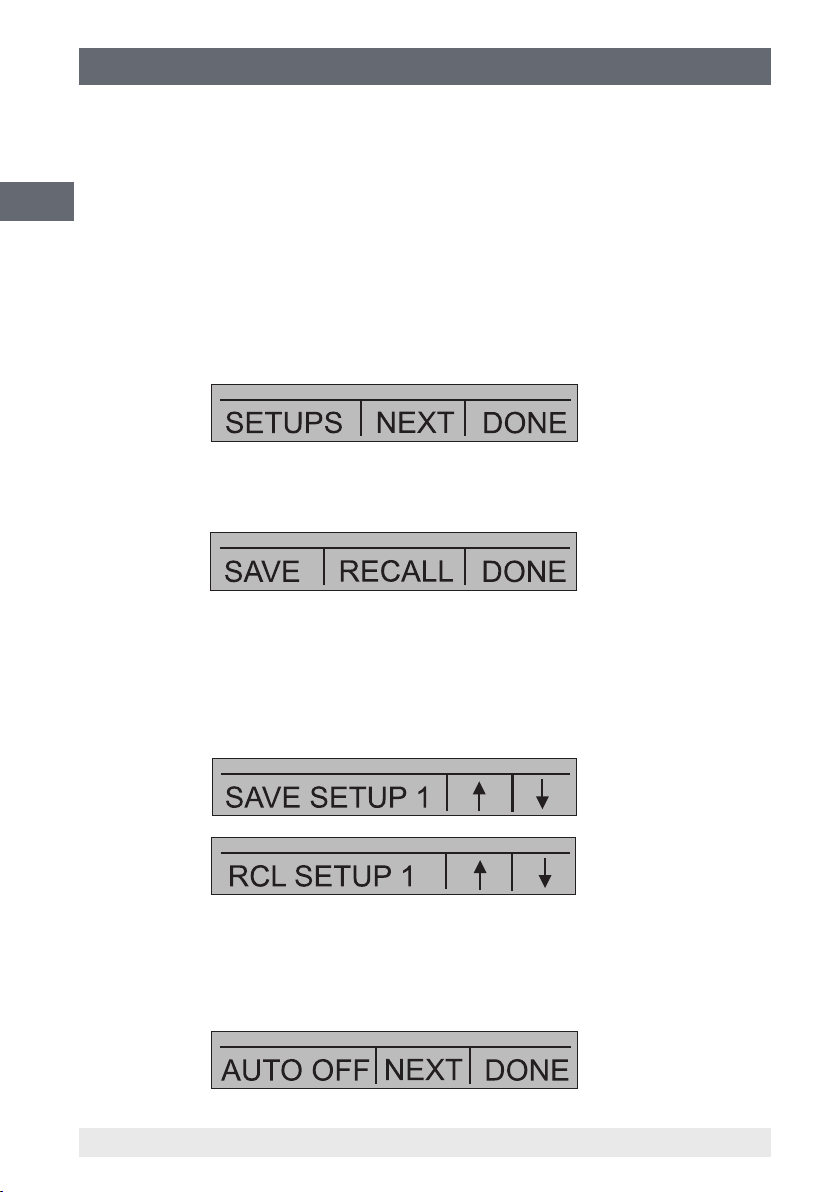

There are ten submenus that can be accessed through the "MORE" option of the main

menu. A submenu contains three options. The rst option is unique to this function. The

second and third options of a submenu are always the same.

The "NEXT" option leads to the next submenu and the "DONE" option returns one to

the home menu.

With the last submenu the "NEXT" option returns to the home menu. The detailed menu

structure can be seen in 6.6 "Menu structure".

Note on naming:

If a 'Submenu' has further subdivisions, from now on it will be referred to as {function}

main menu. The "CONTRAST" submenu, for example, will be referred to as the

"CONTRAST" main menu. Otherwise it will be referred to as the {function} menu.

6.4.1 Setting the contrast

From the CONTRAST main menu, choose the "CONTRAST" option in order to access

the "Setting the contrast" menu.

GB

Use the F2 and F3 keys to set the display contrast to the desired strength and then use

the "DONE" option to return to the home menu.

6.4.2 Locking and unlocking congurations

Use the "LOCK CFG" or "UNLOCK CFG" option of the conguration lock menu

respectively to lock or unlock the display conguration.

14061681.02 03/2013 GB/D

25WIKA operating instructions, model CPH65I0

Page 26

6. Commissioning, operation

When the "LOCK CFG" option is chosen, the menu display returns home and the

"CONFIG" option on the main menu indicates that it is locked. Also, all other menus are

locked with the exception of the "CONTRAST" and "UNLOCK CFG" menus. When the

"UNLOCK CFG" option is chosen, the conguration is unlocked and the menu display

GB

continues to the next submenu.

6.4.3 Saving and recalling settings

The calibrator automatically saves the current setting for recall on power-up. In addition,

ve settings can be accessed through the "SETUPS" menu. Select the "SETUPS"

option from the submenu.

"SAVE" to save the setting, "RECALL" to recall the setting or "DONE" to return home.

If "SAVE" or "RECALL" is selected, use the arrow keys to select the setting location.

Then use the "SAVE" option to store the current setting into the selected location or the

"RECALL" option to recall the setting stored in the selected location. The display menu

will automatically return home.

6.4.4 Setting auto shut-o parameters

The calibrator will switch itself o after a specied time; this function can also be

deactivated. Use the "AUTO OFF" option to set the auto shut-o parameters.

26 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 27

6. Commissioning, operation

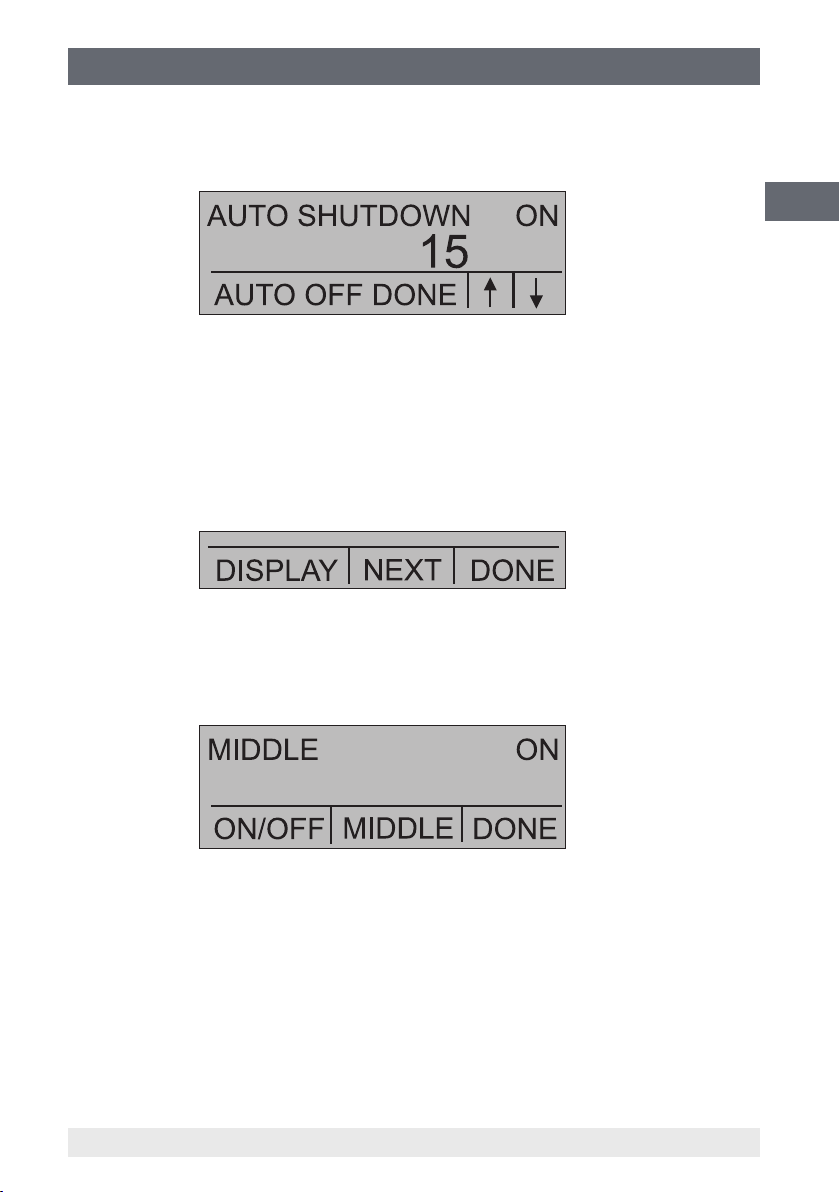

Use the F2 and F3 keys to select the time after which the calibrator will turn itself o, or

disable the auto shut-o by scrolling down to "0".

Use the "AUTO OFF DONE" option to set the parameters and return home. The auto

shut-o time is reset whenever a key is pressed.

6.4.5 Activating and deactivating a display

Use the "DISPLAY" option on the 'Display selection' main menu to access the display

activation menu.

The F2 key can be used to select the desired display. The "ON/OFF" option switches

the selected display on or o. The selected display and the current status "ON/OFF" are

shown in the lower display.

GB

Select the "DONE" option to save the changes and return home. When a display

is deactivated its conguration is retained. As soon as the display is activated, the

conguration is checked against the congurations of the other currently-active displays.

If there is any conict between congurations, the recalled display’s conguration is

modied to avoid the conict. If all three displays are deactivated the lower display will

switch on automatically.

14061681.02 03/2013 GB/D

27WIKA operating instructions, model CPH65I0

Page 28

6. Commissioning, operation

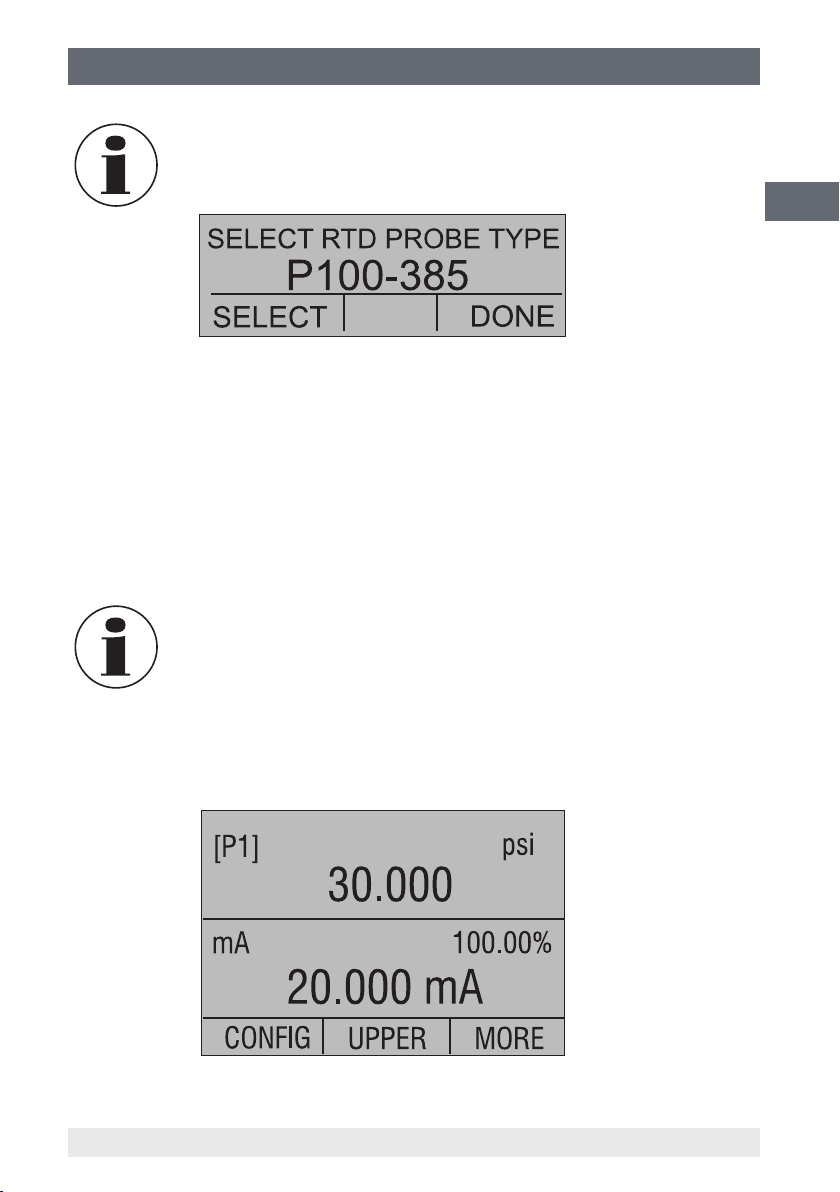

6.4.6 Reduced screen resolution

Due to the high accuracy of the CPH65I0, the measured value is displayed with a higher

resolution. In some cases, this is a disadvantage. For this, the CPH65I0 has a function

for lowering the display resolution. This function removes the last digit.

GB

In order to switch the function on or o, perform the following:

With the calibrator switched on, press the F3 key in order to activate the "MORE"

option. Press the "NEXT" key until "RESOLUTION" appears in the left-hand text eld.

Then press the F1 key to activate the function.

Select "ON" or "OFF" in order to switch the lower display resolution on or o.

Use "DONE" in order to return to the home menu.

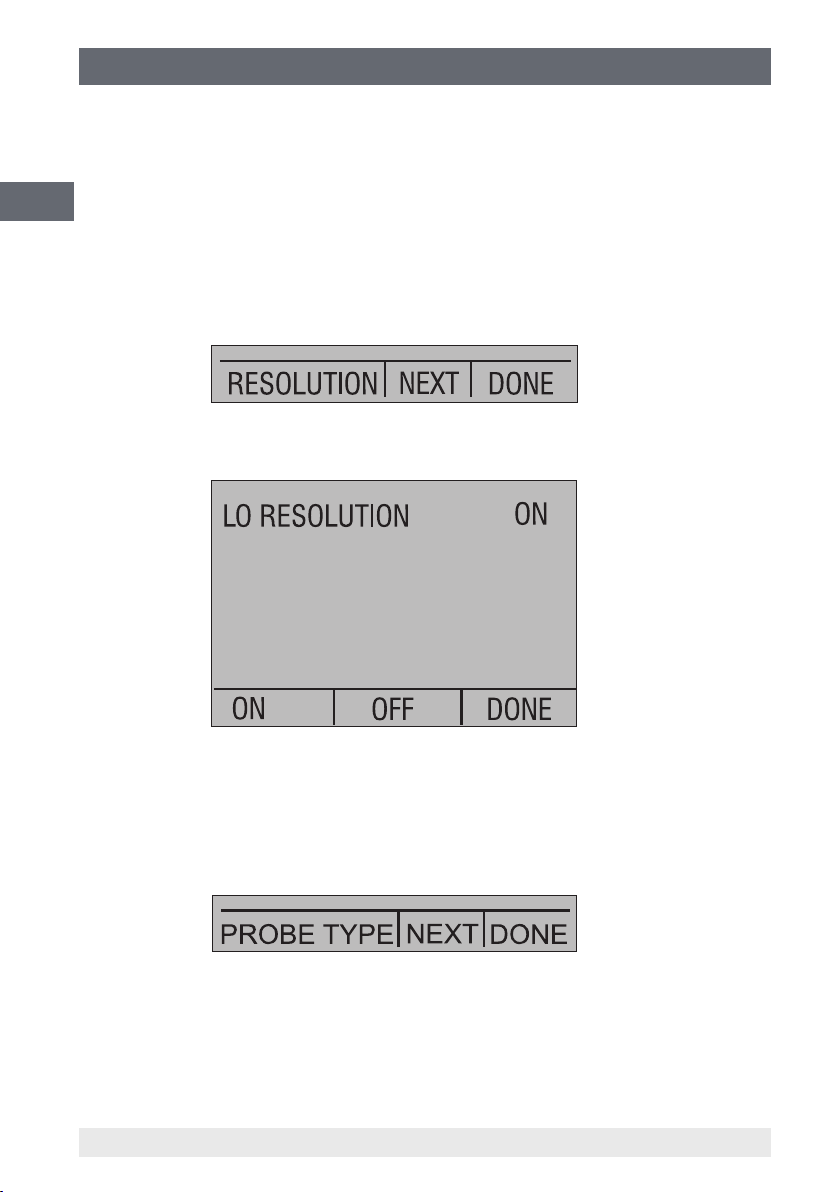

6.4.7 Setting the resistance thermometer probe

Use the "PROBE TYPE" option of the 'RTD Probe Type' main menu to access the

menu for resistance thermometer probe selection.

There are four types of resistance thermometers: "P100-385", "P100-392",

"P100-JIS" and "CUSTOM". With "CUSTOM", custom resistance thermometers

can be selected. Use the "SELECT" option to select the desired probe type and the

"DONE" option to store the change and return home.

28 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 29

6. Commissioning, operation

The default resistance thermometer type is "PT100-385" (Pt100-385).

6.4.8 Damping

Damping can be turned ON or OFF using the "DAMPING" menu selection. As soon as

the damping function is switched ON, the calibrator displays the running average of the

last ten measurements. The calibrator makes approximately three readings per second.

6.5 Factory settings

The calibrator is delivered with ve commonly-used factory settings. These settings are

shown below.

Any of these settings can be changed and saved by the user.

GB

Setting 1:

The upper display is set to [P1] mode and the middle is set to "mA"; the lower is o.

14061681.02 03/2013 GB/D

29WIKA operating instructions, model CPH65I0

Page 30

6. Commissioning, operation

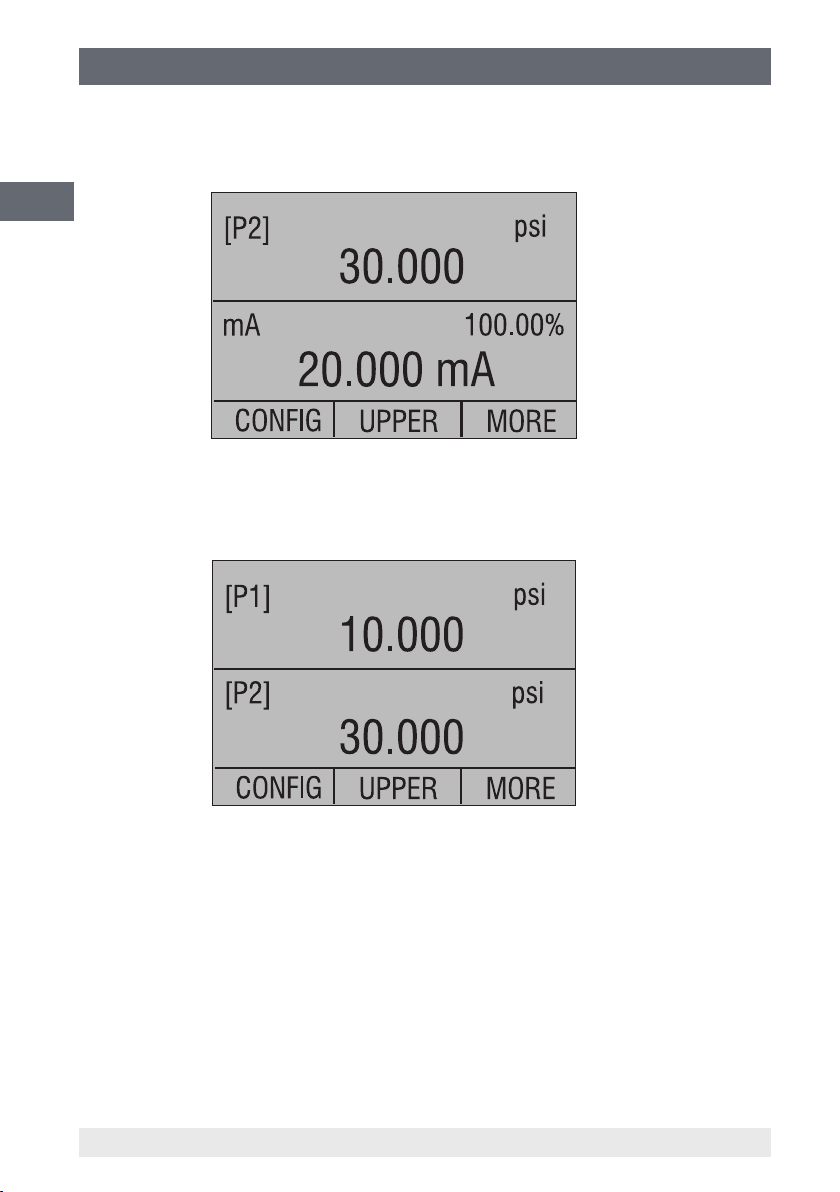

Setting 2:

The upper display is set to [P2] mode and the middle is set to "mA"; the lower is o.

GB

Setting 3:

The upper display is set to [P1] mode and the middle is set to [P2]; the lower is o.

30 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 31

6. Commissioning, operation

Setting 4:

The upper display is set to [P1] "SWITCH TEST" all other displays are o.

Setting 5:

The upper display is set to [P1], the middle display is set to [P2] and the lower display is

set to "RTD".

GB

14061681.02 03/2013 GB/D

31WIKA operating instructions, model CPH65I0

Page 32

6. Commissioning, operation

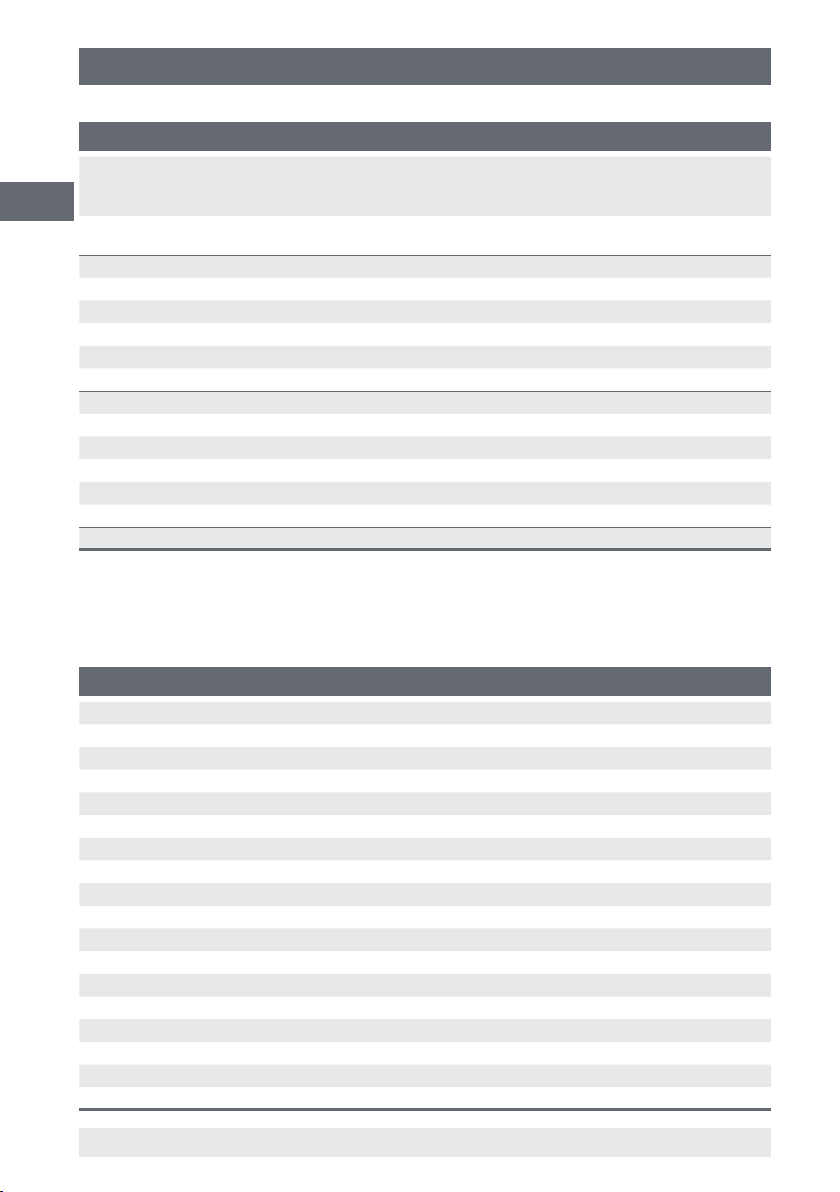

6.6 Menu structure

GB

32 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 33

6. Commissioning, operation

GB

14061681.02 03/2013 GB/D

33WIKA operating instructions, model CPH65I0

Page 34

6. Commissioning, operation

6.7 Measuring pressure

For pressure calibration, connect the calibrator with an appropriate adapter. Select the

pressure setting for the display being used. The calibrator is equipped with one or two

internal reference pressure sensors.

GB

Choose a sensor that is suitable for the pressure range and accuracy.

CAUTION!

Pressure sensors may be damaged and/or injuries may occur to

the personnel due to improper application of pressure. For a better

understanding with respect to overpressure and burst pressure, follow

the specications laid down in these operating instructions (see chapter

3 "Specications"). Vacuum should not be applied to any gauge pressure

sensor.

The calibrator display will indicate "OL" when an inappropriate pressure

is applied. As soon as "OL" is observed on any pressure display, the

pressure should be reduced immediately to prevent damage or possible

physical injury. "OL" is displayed if the pressure exceeds 110 % of the

nominal range of the sensor or if a vacuum in excess of 140 mbar (2 psi)

is applied on a gauge pressure sensor.

Valve

Figure 2: Pressure measurement

34 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 35

6. Commissioning, operation

In order to protect the sensor from damage, the calibrator displays "OL"

[Overload] as soon as the applied pressure exceeds 120 % of the

complete measuring range.

In order to ensure the accuracy of the calibrator, it is necessary to reset

the calibrator to zero before a calibration.

6.7.1 Media compatibility

Most of the calibrator measuring ranges include a sensor that is isolated from the

medium in order to eliminate any contamination (observe chapter 3 "Specications").

If possible, use clean dry air. As this is not always possible, it must be ensured that the

medium is compatible with nickel-plated brass and stainless steel.

6.8 Measuring current

WARNING!

Observe the connection parameters prior to making a connection to the

instrument.

To measure current, use the input terminals on the front of the calibrator. Select the

mA function on the lower display. Current is measured in mA and percentage of the

measuring range. The measuring range on the calibrator is set to 0 % at 4 mA and

100 % at 20 mA.

GB

Example:

If the current measured is displayed as 75 %, then the value is 16 mA.

The display will indicate "OL" when the measured current exceeds the

nominal range of current measurement (24 mA).

4 ... 20 mA

14061681.02 03/2013 GB/D

Test item

35WIKA operating instructions, model CPH65I0

Page 36

6. Commissioning, operation

6.9 Measuring temperature with a resistance thermometer

For temperature measurement, select the function "RTD" on one of the displays.

The correct resistance thermometer must be used. There are four types of resistance

thermometer supported: "P100-385", "P100-392", "P100-JIS" and "CUSTOM".

GB

The factory default type is "P100-385", so if the CPH65I0 is being used

with a WIKA Pt100 you do not have to reset the resistance thermometer

type.

The WIKA Pt100 needs only to be connected to the CPH65I0 and the measured

temperature will immediately be displayed.

The display will indicate "OL" if the measured temperature is outside

the nominal measurement range of the resistance thermometer (below

-40 °C or above +150 °C).

CAUTION!

Only specic thermometer types are permitted (as dened in

chapter 2.3). It is recommended that those accessories available from

WIKA are used.

Figure 3: CPH65I0 with a resistance thermometer

36 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 37

6. Commissioning, operation

6.10 Performing a pressure switch test

WARNING!

Observe the connection parameters prior to making a connection to the

instrument.

GB

[P1] ST CLOSE

CPH65I0

psi

0.000

CONFIG

LOWER

MORE

F1 F2 F3

ON

ZERO

OFF

30V

24mA

max

P1 P2

Figure 4: CPH65I0 with a pressure switch

To perform a switch test, the following steps must be taken:

1. Switch to SETUP 4 (standard switch test).

SETUP 4: The upper display is set to [P1] ST, all other displays are switched o.

Pressure

switches

The pressure switch test can be performed with the following functions

[P1] ST or [P2] ST.

2. Connect the calibrator to the pressure switch using the switch terminals. The polarity

of the terminals is not important. Then connect the calibrator and the pump to the

pressure switch.

14061681.02 03/2013 GB/D

37WIKA operating instructions, model CPH65I0

Page 38

6. Commissioning, operation

3. Open the vent key on the pump and zero the calibrator. Then close the vent after

resetting the calibrator.

4. The top of the display will indicate "CLOSE".

GB

5. Apply pressure to the pump slowly until the pressure switch opens.

In the switch test mode the display update rate is increased to help

capture changing pressure inputs. Even with this enhanced sample rate

the device under test should be pressurized slowly in order to ensure

accurate readings.

6. Once the switch is open, "OPEN" will be displayed; bleed the pump slowly until the

pressure switch closes.

7. In the top display it will now read "SW OPENED AT" and give you the pressure at

which the switch opened is displayed.

38 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 39

6. Commissioning, operation

8. Select the "NEXT" option to display the pressure at which the switch closed and the

hysteresis "SW DEADBAND" .

9. Select the "NEW TEST" option to clear the data and perform another test.

10. Select the "DONE" option to end the test and return to the standard pressure

setting.

The previous example uses a normally closed switch. The basic

procedure is eectively the same for a normally open switch, the display

will simply read "OPEN" instead of "CLOSE".

6.11 Calibrating transmitters

GB

6.11.1 Using the mA measurement function

WARNING!

Observe the connection parameters prior to making a connection to the

instrument.

The mA function enables to read out the 4 ... 20 mA output from the instrument being

calibrated. This is achieved passively - meaning the test item generates the 4 ... 20 mA

directly. This value is read by the calibrator.

14061681.02 03/2013 GB/D

39WIKA operating instructions, model CPH65I0

Page 40

6. Commissioning, operation

6.11.2 Calibrating a pressure-to-current transmitter

WARNING!

GB

To calibrate a pressure-to-current transmitter (P/I), perform the following:

1. Connect the calibrator and the pump to the transmitter.

2. Apply pressure with the pump.

3. Measure the current output of the transmitter.

4. Ensure that the read value is correct. If it isn't, the transmitter must be adjusted.

Observe the connection parameters prior to making a connection to the

instrument.

Figure 5: CPH65I0 with a pressure transmitter

40 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 41

6. Commissioning, operation

6.11.3 %-Error function

WARNING!

Observe the connection parameters prior to making a connection to the

instrument.

The calibrator features a special function which can calculate the error in the pressure

value from the mA value as a percentage of the 4 ... 20 mA span. The %-Error mode

uses all three screens and has a special menu structure. It displays pressure, mA and

%-error simultaneously.

CPH65I0

0.00

4.000 mA

0.00 %

LOWER

MORE

ZERO

psi

SIGNAL

+

–

TEST

[P1]

mA 0.00%

% ERROR

CONFIG

F1 F2 F3

ON

OFF

30V

24mA

max

GB

P1 P2

Figure 6: CPH65I0 with a pressure transmitter with %-Error function

Example:

Suppose a pressure transmitter under test has a full scale range of 0 ... 20 bar and gives

a corresponding 4 ... 20 mA output signal. The user can programme in a 0 ... 20 bar

14061681.02 03/2013 GB/D

41WIKA operating instructions, model CPH65I0

Page 42

6. Commissioning, operation

pressure span into the calibrator and the calibrator will then calculate and display the

deviation or %-Error value from the 4 ... 20 mA output. This then eliminates manual

calculations of the test item deviation.

GB

To use the "%-ERROR" function, perform the following:

1. Once the calibrator is switched on and operating, press the F3 key to activate the

"MORE" menu option. Then press the F1 key to activate the "%-ERROR" option.

In this function the specication of the test item (such as unit, lower limit of the

measuring range, upper limit of the measuring range) must be entered into the

CPH65I0.

2. Press the F1 key to select the "CONFIG" option.

3. The rst option is the connection setting. Use the "SELECT" option to scroll through

the choice of ports (pressure connections). Once this is completed, select the

"NEXT" option.

4. Use "SELECT" to scroll through the "UNIT" options and select "NEXT" to move on.

42 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 43

6. Commissioning, operation

5. Use the arrow keys to set the upper limit of the measuring range; select

"DONE SET" when nished.

6. Use the arrow keys to set the lower limit of the measuring range and select

"DONE SET" when nished, the "%-ERROR" mode will be ready to use.

GB

The lower and upper limit of the measuring range will be saved in

non-volatile memory.

14061681.02 03/2013 GB/D

43WIKA operating instructions, model CPH65I0

Page 44

6. Commissioning, operation / 7. Maintenance, cleaning, ...

6.12 MIN/MAX memory

The CPH65I0 has a MIN/MAX function for capturing the minimum and maximum values

of any displayed parameter.

The MIN/MAX function can be set by stepping through the menu options until "MIN/

GB

MAX" is shown on the display above the F1 key. At this point, pressing the F1 key

will scroll the display through the MIN/MAX values that are stored in the "MIN/MAX"

registers. These readings are live so new MIN/MAX values will be recorded while in this

mode.

To clear the "MIN/MAX" registers, simply press the "CLEAR" key. These registers are

also cleared on power-up or when the conguration is changed.

7. Maintenance, cleaning, and recalibration

7.1 Maintenance

The model CPH65I0 hand-held pressure calibrator is maintenance-free.

Repairs must only be carried out by the manufacturer.

This does not apply to the battery replacement.

7.2 Replacing the batteries

To avoid false measurements, replace the batteries as soon as the battery indicator

comes on. If the batteries run too low the CPH65I0 will automatically shut down to avoid

the batteries leaking.

WARNING!

■

Only use permitted size AA alkaline batteries as described in the

following table.

■

Only replace the batteries outside the hazardous area.

44 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 45

7. Maintenance, cleaning, and recalibration

Permitted batteries

Battery manufacturer

(alkaline batteries - AA 1.5 V)

Duracell MN1500

Rayovac 815

Energizer E91

Panasonic AM3*

*model AM3 has been replaced by model LR6XWA

CAUTION!

To avoid personal injury or damage to the calibrator, only use

accessories supplied by WIKA and ensure that no water nds its way into

the case.

Model

GB

14061681.02 03/2013 GB/D

Figure 7: Replacing the batteries

45WIKA operating instructions, model CPH65I0

Page 46

7. Maintenance, cleaning, and recalibration / 8. Faults

7.3 Cleaning

CAUTION!

■

GB

7.4 Recalibration

DKD/DAkkS certicate - Ocial certicates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. The basic settings will be corrected if necessary.

Before cleaning the hand-held pressure calibrator, vent it correctly,

disconnect it from the pressure supply and switch it o.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Residual media in the dismounted hand-held pressure calibrator can

result in a risk to personnel, the environment and equipment. Take

sucient precautionary measures.

■

In order to prevent physical injury or damage to the instrument,

ensure that no water nds its way into the housing.

■

In order not to damage the display or case, do not use any solvent or

scouring agents for cleaning.

For information on returning the instrument see chapter 9.2 "Return".

8. Faults

Display Cause Measures

Low battery power, functioning

is only guaranteed for a short

period of time

OL

-OL

46 WIKA operating instructions, model CPH65I0

Reading is signicantly above or

below the measuring range

Insert new batteries

Check: is the pressure within the

permissible measuring range of

the sensor?

--> Reduce the applied pressure

14061681.02 03/2013 GB/D

Page 47

8. Faults / 9. Dismounting, return and disposal

Display Cause Measures

No display or

undenable

characters,

instrument is not

responding to

key press

Battery at Insert new batteries

System error Switch o the instrument, wait

Technical fault Send in for repair

CAUTION!

If faults cannot be eliminated by means of the measures listed above,

the hand-held pressure calibrator must be shut down immediately, and it

must be ensured that pressure and/or signal are no longer present, and it

must be prevented from being inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

9.2 "Return".

9. Dismounting, return and disposal

WARNING!

Residual media on the hand-held pressure calibrator can result in

a risk to persons, the environment and equipment. Take sucient

precautionary measures.

GB

for a short period of time, switch

on again

9.1 Dismounting

Only disconnect the instrument once the system has been depressurised!

9.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of

hazardous substances (acids, bases, solutions etc.).

When returning the instrument, use the original packaging or a suitable transport

package.

14061681.02 03/2013 GB/D

47WIKA operating instructions, model CPH65I0

Page 48

9. Dismounting, return and disposal / 10. Accessories

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in the packaging.

GB

Place shock-absorbent material evenly on all sides of the transport packaging.

3. Label the shipment as transport of a highly sensitive measuring instrument.

Information on returns can be found under the heading "Service" on our

local website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities (see EU

directive 2002/96/EC).

10. Accessories

Voltage supply

■

Four AA alkaline batteries

Connection adapters

■

Various pressure adapters

Temperature measurement

■

Pt100 resistance thermometer

Miscellaneous

■

DKD/DAkkS certied accuracy

48 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 49

Appendix: EC Declaration of Conformity for model CPH65I0

GB

14061681.02 03/2013 GB/D

49WIKA operating instructions, model CPH65I0

Page 50

GB

50 WIKA operating instructions, model CPH65I0

14061681.02 03/2013 GB/D

Page 51

Inhalt

Inhalt

1. Allgemeines 52

2. Sicherheit 53

Bestimmungsgemäße Verwendung

2.1

Personalqualikation

2.2

Zusätzliche Sicherheitshinweise für Geräte nach ATEX

2.3

Besondere Gefahren

2.4

Beschilderung, Sicherheitskennzeichnungen

2.5

3. Technische Daten 60

4. Aufbau und Funktion 65

Beschreibung

4.1

Lieferumfang

4.2

Druck- und elektrische Anschlüsse

4.3

Tastenfeld

4.4

5. Transport, Verpackung und Lagerung 68

6. Inbetriebnahme, Betrieb 69

Display des Kalibrators

6.1

Verwendung der Hintergrundbeleuchtung

6.2

Verwendung der "ZERO"-Funktion

6.3

Weitere menügesteuerte Funktionen

6.4

Werkseinstellungen

6.5

Menüstruktur

6.6

Druckmessung

6.7

Strom messen

6.8

Temperaturmessung mit einem Widerstandsthermometer

6.9

Druckschaltertest durchführen

6.10

Messumformer kalibrieren

6.11

MIN-/MAX-Wert-Speicher

6.12

7. Wartung, Reinigung und Rekalibrierung 92

8. Störungen 94

9. Demontage, Rücksendung und Entsorgung 95

10. Zubehör 96

Anlage: EG-Konformitätserklärung Typ CPH65I0 97

54

54

55

57

59

65

65

66

67

69

71

71

73

77

80

82

83

84

85

87

92

D

Konformitätserklärungen nden Sie online unter www.wika.de.

14061681.02 03/2013 GB/D

51WIKA Betriebsanleitung, Typ CPH65I0

Page 52

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Hand-Held Druckkalibrator Typ CPH65I0

wird nach dem aktuellen Stand der Technik gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

D

zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD-/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: CT 14.51

- Anwendungsberater:

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

52 WIKA Betriebsanleitung, Typ CPH65I0

14061681.02 03/2013 GB/D

Page 53

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden

führen kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder

tödlicher Verletzungen.

D

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen

führen kann, wenn sie nicht gemieden wird.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der richtige Hand-Held Druckkalibrator hinsichtlich Messbereich, Ausführung und

spezischen Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

14061681.02 03/2013 GB/D

53WIKA Betriebsanleitung, Typ CPH65I0

Page 54

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Der Eigensichere Hand-Held Druckkalibrator Typ CPH65I0 kann als Kalibriergerät sowie

für jede Anwendung, bei der eine hochgenaue Druckmessung erforderlich ist, verwendet werden.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

D

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statischer Elektrizität und extremen Temperaturen

schützen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und

Buchsen vor Verschmutzung schützen.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

54 WIKA Betriebsanleitung, Typ CPH65I0

14061681.02 03/2013 GB/D

Page 55

2. Sicherheit

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen

Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Zusätzliche Sicherheitshinweise für Geräte nach ATEX

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust

des Explosionsschutzes führen.

Batteriebetrieb:

■

Nur Alkalibatterien Typ AA verwenden!

■

Den Batterietausch nur außerhalb des explosionsgefährdeten

Bereiches durchführen!

■

Nur zugelassene Alkalibatterien der Größe AA, wie in der folgenden

Tabelle beschrieben, verwenden.

D

Zugelassene Batterien

Batteriehersteller

(Alkalibatterien - AA 1,5 V)

Duracell MN1500

Rayovac 815

Energizer E91

Panasonic AM3*

*Typ AM3 ist ersetzt durch Typ LR6XWA

Temperaturbereich:

■

14061681.02 03/2013 GB/D

Typ

Zulässige Umgebungstemperatur: -10 ... +45 °C.

55WIKA Betriebsanleitung, Typ CPH65I0

Page 56

2. Sicherheit

D

Anschlusswerte

Max. Spannung Uo = DC 7,14 V

Max. Stromstärke Io = 1,12 mA

Max. Leistung Po = 2 mW

Max. innere wirksame Kapazität Co = 240 µF

Max. innere wirksame Induktivität Lo = 1 H

Versorgungsstromkreis

Max. Spannung Ui = DC 30 V

Max. Stromstärke Ii = 80 mA

Max. Leistung Pi = 750 mW

Max. innere wirksame Kapazität Ci = 0 nF

Max. innere wirksame Induktivität Li = 0 mH

Zusätzliche Ex-Sicherheitshinweise:

Die Betriebshinweise sowie die jeweiligen Landesvorschriften bezüglich

Ex-Einsatz (e.g. EN IEC 60079-14) beachten.

Der eigensichere Hand-Held Druckkalibrator Typ CPH65I0 wurde für die

Verwendung in explosionsgefährdeten Bereichen konstruiert. In diesen

Bereichen können möglicherweise entzündliche oder explosive Gase

auftreten.

Der

eigensichere

konstruiert. Dies bedeutet, dass das Verbinden mit Ausrüstungsteilen,

welche sich in eigensicheren Schaltkreisen benden, keinen

entzündungsfähigen Lichtbogen verursachen solange die Parameter

eingehalten werden.

Information/Zulassung für explosionsgefährdete Räume

WARNUNG!

Explosionsgefährdete Bereiche

Explosionsgefährdete Bereiche, wie in dieser Betriebsanleitung erwähnt,

bezeichnen einen Bereich, der durch das mögliche Vorhandensein von

entzündlichen oder explosiven Dämpfen explosionsgefährdet ist. Diese

Bereiche werden auch als explosionsgefährdete Räume bezeichnet.

56 WIKA Betriebsanleitung, Typ CPH65I0

Hand-Held Druckkalibrator Typ CPH65I0 ist eigensicher

14061681.02 03/2013 GB/D

Page 57

2. Sicherheit

II 2 G Ex ia IIB T3 Gb (Ta = -10…+45 °C)

DEKRA 12ATEX 0146 X

Ex ia IIB T3 Gb (Ta = -10…+45 °C)

IECEx CSA 11.0019X

WARNUNG!

Der Austausch von Bauteilen kann den Explosionsschutz beeinträchtigen.

Service und Reparaturen sind vom Hersteller durchzuführen.

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die

jeweiligen landesspezischen Vorschriften zur Installation und Einsatz

in explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC)

einhalten. Bei Nichtbeachten können schwere Körperverletzungen und/

oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit ATEX-Zulassung

siehe Kapitel 2.3 „Zusätzliche Sicherheitshinweise für Geräte nach

ATEX“.

WARNUNG!

■

Drucksensor nur im drucklosen Zustand montieren bzw. demontieren.

■

Betriebsparameter gemäß Kapitel 3 „Technische Daten“ beachten.

■

Druckkalibrator immer innerhalb des Überlastgrenzbereiches

betreiben. Siehe Kapitel 3 „Technischen Daten“.

■

Keine größere Spannung als angegeben an das Gerät anlegen.

Siehe Kapitel 3 „Technischen Daten“.

■

Messstoreste an ausgebauten Kalibratoren und/oder den Sensoren

können zur Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

■

Nur das von WIKA erhältliche Zubehör für den Kalibratoren verwenden

■

Darauf achten, dass die Prüfspitzen nie mit einer Spannungsquelle

in Kontakt kommen, wenn die Prüfkabel an die Stromklemmen

angeschlossen sind.

■

Das Messsignal der Referenz (bzw. des Prüings) kann durch

massive elektromagnetische Einstrahlung beeinusst werden bzw.

die Anzeige des Signals ganz ausbleiben.

D

14061681.02 03/2013 GB/D

57WIKA Betriebsanleitung, Typ CPH65I0

Page 58

2. Sicherheit

D

WARNUNG!

■

Den Kalibrator nicht in beschädigtem Zustand verwenden. Vor dem

verwenden des Gerätes prüfen, ob das Gehäuse Risse oder fehlende

Kunststoteile aufweist. Besonders auf die Isolierung der Stecker

achten.

■

Die Batterieabdeckung muss geschlossen und eingerastet sein,

bevor das Gerät verwendet wird.

■

Die Prüfkabel vom Gerät abnehmen, bevor das Batteriefach geönet

wird.

■

Die Prüfkabel auf eine beschädigte Isolierung oder blankes

Metall prüfen. Die Durchgängigkeit der Kabel prüfen. Beschädigte

Prüeitungen austauschen bevor das Gerät verwendet wird.

■

Bei Verwendung von Prüfspitzen die Finger von den

Prüfspitzenkontakten fernhalten. Die Finger hinter den Fingerschutz

an den Prüfspitzen anlegen.

■

Das Gerät nicht verwenden, wenn es nicht normal funktioniert. Der

Geräteschutz kann beeinträchtigt sein. Im Zweifelsfall das Gerät

überprüfen lassen.

■

Das Gerät nur in klassizierten Bereichen verwenden, für die der

Kalibrator zugelassen ist.

■

Die Prüeitungen lösen, bevor in eine andere Mess- oder Quellfunktion

gewechselt wird.

■

Zur Vermeidung einer falschen Anzeige die Batterie ersetzen, sobald

die Batterieanzeige erscheint.

■

Für Messungen die richtigen Anschlüsse, die richtige Funktion und

den richtigen Messbereich verwenden.

■

Beim Anschrauben eines Adapters an das NPT-Gewinde des Kalibrators ist zusätzlich die Verwendung eines Dichtmittels (z. B. PTFEBand) notwendig.

■

Beim Anschrauben einen Schraubenschlüssel am Druckanschluss

zum Fixieren des Kalibrators verwenden, um unnötige Spannungen

am Gehäuse zu vermeiden.

58 WIKA Betriebsanleitung, Typ CPH65I0

14061681.02 03/2013 GB/D

Page 59

2. Sicherheit

2.5 Beschilderung, Sicherheitskennzeichnungen

Typenschild

D

Herstellungsdatum

Seriennummer

1- oder 2-KanalVersion

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = EX)

Geräte mit dieser Kennzeichnung stimmen überein mit den Anforderungen der europäischen Richtlinie 94/9/EG (ATEX) zum Explosionsschutz.

Symbolerklärung

siehe unten

Bei Geräten mit dieser Kennzeichnung wird darauf hingewiesen, dass

diese nicht in den Hausmüll entsorgt werden dürfen. Die Entsorgung

erfolgt durch Rücknahme bzw. durch entsprechende kommunale Stellen

(siehe EU-Richtlinie 2002/96/EC).

14061681.02 03/2013 GB/D

59WIKA Betriebsanleitung, Typ CPH65I0

Page 60

3. Technische Daten

3. Technische Daten

Sensorik

Messbereich mbar

Überlast-Druckgrenze mbar 70 200 700 1.000

Genauigkeit % FS 0,1 0,05 0,035

D

Messbereich bar -1 ... +1

Überlast-Druckgrenze bar 2 4 2 4

Genauigkeit % FS 0,025

Messbereich bar 0 ... 3,5

Überlast-Druckgrenze bar 13 13 13 40

Genauigkeit % FS 0,025

Messbereich bar 0 ... 35

Überlast-Druckgrenze bar 70 200 200 400

Genauigkeit % FS 0,025

Messbereich bar 0 ... 350 0 ... 700

Überlast-Druckgrenze bar 700 1.000

Genauigkeit % FS 0,035

Messbereich bar abs. 0 ... 1 0 ... 2 0 ... 7 0 ... 10 0 ... 20

Überlast-Druckgrenze bar abs. 2 4 13 13 40

Genauigkeit % FS 0,025

Messbereich

Überlast-Druckgrenze mbar di. 70 200 700

Genauigkeit % FS 0,1 0,05 0,035

Messbereich

Überlast-Druckgrenze mbar di. 4.000 7.000 10.000

Genauigkeit % FS 0,025

Druckart Relativdruck, Absolutdruck, Vakuumdruck und Dierenzdruck

Druckanschluss ⅛ NPT innen (inkl. Adapter ⅛ NPT außen auf G ½ B außen)

Druckmedium alle Flüssigkeiten und Gase, die mit CrNi-Stahl 316 SS kompatibel sind

Auösung 5-stellig

Strom

Messbereich 0 … 24 mA

Auösung 1 µA

Genauigkeit 0,015 % vom Messwert ±2 µA

Temperatur

Messbereich -40 … +150 °C

Auösung 0,01 °C

Genauigkeit 0,015 % vom Messwert ±20 mΩ, bzw. 0,2 °C für komplette Messkette

1) Nicht isoliert: Die so markierten Druckmessbereiche dürfen ausschließlich mit sauberen und nicht-korrosiven Gasen verwendet

werden.

2) Druckmessung im Vakuumbereich bis -1 bar möglich.

3) Bei Dierenzdrucksensoren mit einem Messbereich von 25 mbar ist der maximale statische Druck auf max. 70 mbar begrenzt.

Für die Messbereiche 70, 350, 2.000, 3.500 und 7.000 mbar ist der maximale statische Druck auf max. 10 bar begrenzt.

4) Dierenzdrucksensor nur möglich bei CPH65I0-S1 (1-Kanal-Version). Beide Druckanschlüsse für die Dierenzdruckmessung

benden sich an der Unterseite des Kalibrators.

5) Adapter nicht im Lieferumfang für Nordamerika.

60 WIKA Betriebsanleitung, Typ CPH65I0

1)

mbar di.

mbar di.

-25 ... +25 -70 … +70

1)

-1 ... +2 1)0 … 1

2)