Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Intrinsically safe hand-held pressure indicator,

model CPH62I0-S1/CPH62I0-S2

Eigensicheres Hand-Held Druckmessgerät,

Typ CPH62I0-S1/CPH62I0-S2

Indicateur de pression portable à sécurité intrinsèque,

type CPH62I0-S1/CPH62I0-S2

Manómetro portátil de seguridad intrínseca,

modelo CPH62I0-S1/CPH62I0-S2

GB

D

F

E

Intrinsically safe hand-held pressure indicator,

model CPH62I0-S1/CPH62I0-S2

Page 2

Operating instructions

GB

model CPH62I0-S1/CPH62I0-S2

Betriebsanleitung

D

Typ CPH62I0-S1/CPH62I0-S2

Mode d'emploi

F

type CPH62I0-S1/CPH62I0-S2

Manual de instrucciones

E

modelos CPH62I0-S1/CPH62I0-S2

© 2005 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Page 3 - 44

Seite 45 - 86

Page 87 - 122

Página 123 - 158

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 11

4. Design and function 14

5. Transport, packaging and storage 17

6. Commissioning, operation 18

7. Maintenance, cleaning and servicing (recalibration) 31

8. Faults 32

9. Dismounting, return and disposal 34

10. Accessories 35

GB

Appendix 1: EC Declaration of Conformity for model

CPH62I0

Appendix 2: EC Declaration of Conformity for model

CPT62I0

Appendix 3: EC-type examination certicate for model

CPH62I0 (only in German)

Appendix 4: EC-type examination certicate for model

CPT62I0

Declarations of conformity can be found online at www.wika.com.

11221801.02 02/2011 GB/D/F/E

36

37

38

41

3WIKA operating instructions, model CPH62I0

Page 4

1. General information

1. General information

■

GB

The hand-held pressure indicator described in the operating instructions has been

designed and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the handheld pressure indicator. Working safely requires that all safety instructions and work

instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the hand-held pressure indicator’s range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity of the hand-held pressure indicator and readily accessible to skilled

personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions, prior to beginning any work.

■

The manufacturer’s liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the hand-held pressure indicator.

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 11.02

- Application consultant:

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

4 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 5

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light

injuries or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient

and trouble-free operation.

DANGER!

...identies hazards caused by electric power. Should the safety instructions not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation in the hazardous area,

which can result in serious injury or death, if not avoided.

GB

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate hand-held pressure indicator and the appropriate pressure

sensor has been selected in terms of measuring range, design and

specic measuring conditions.

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual

chapters of these operating instructions.

11221801.02 02/2011 GB/D/F/E

5WIKA operating instructions, model CPH62I0

Page 6

2. Safety

2.1 Intended use

The CPH62I0 hand-held pressure indicator can be used as a calibrator, and for any

application where an accurate pressure measurement is required, within hazardous

GB

areas.

The hand-held pressure indicator has been designed and built solely for the intended

use described here, and may only be used accordingly.

The technical specications contained in these operating instructions must be

observed. Should the hand-held pressure indicator be improperly handled or operated

outside of its technical specications, it has to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the hand-held pressure indicator is transported from a cold into a warm environment,

the formation of condensation may result in the instrument malfunctioning. Before

putting it back into operation, wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to

equipment.

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualications described

below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

6 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 7

2. Safety

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

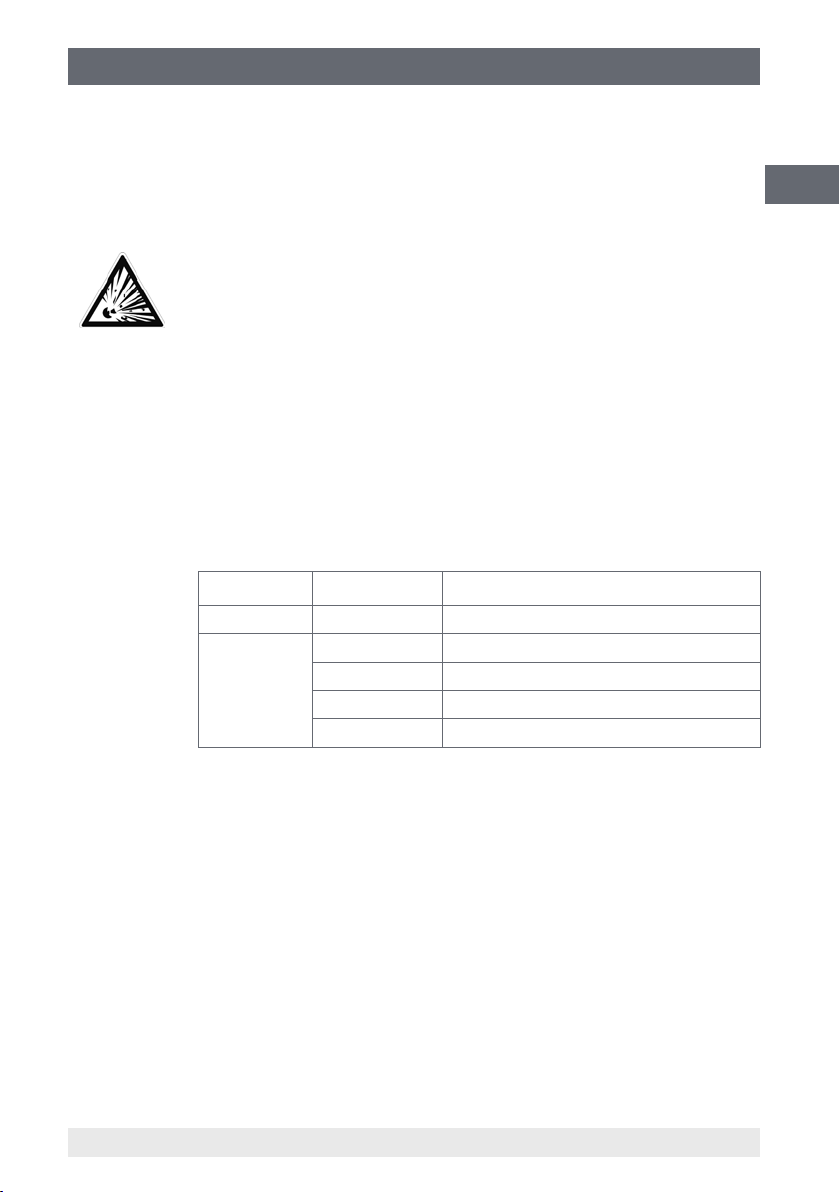

2.3 Additional safety instructions for instruments with ATEX approval

WARNING!

Non-observance of these instructions and their contents may result in

the loss of explosion protection.

The CPH62I0 hand-held pressure indicator is used for measuring

absolute and/or gauge pressures. In addition, the 2-channel version

can be used to measure dierential pressure. The measurement is

carried out by an external pressure sensor.

■

Battery operation:

Only the usage of approved 9 V batteries allowed!

Batteries may only be changed outside of the hazardous area!

Approved batteries are:

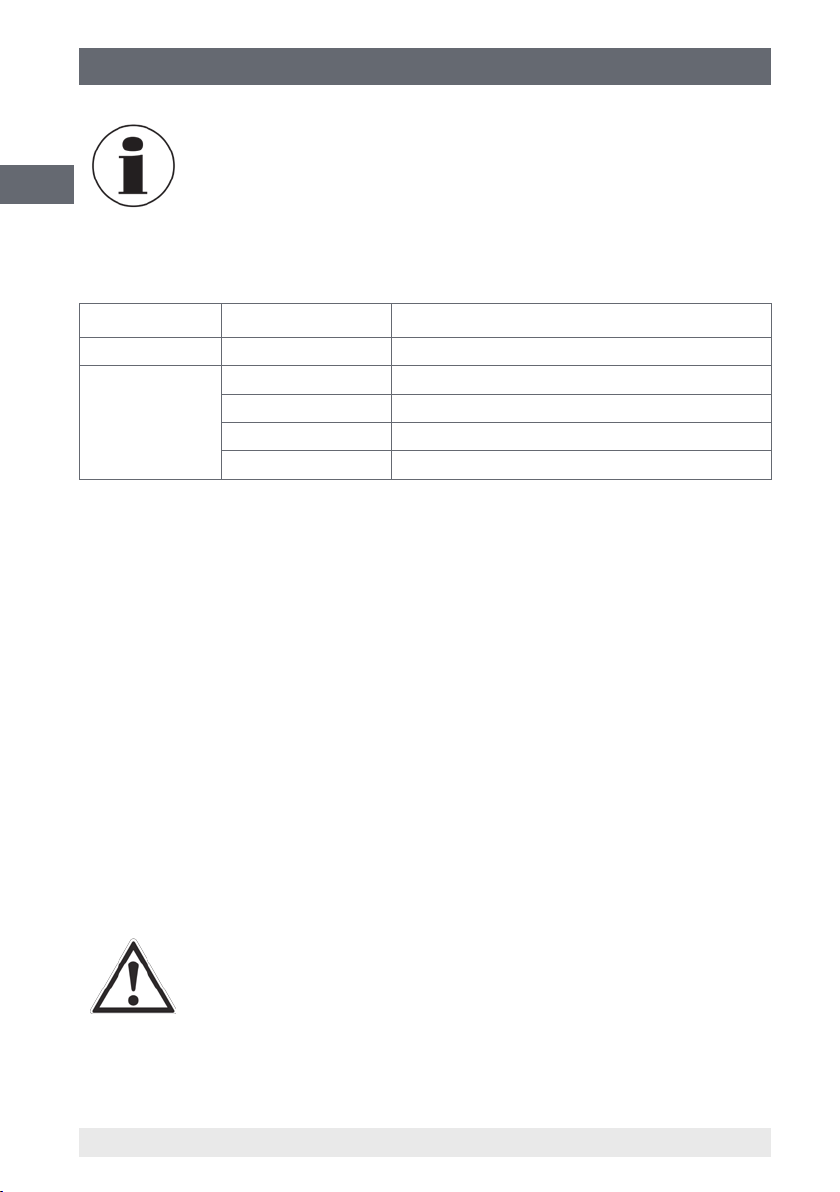

Battery type Manufacturer Battery name

6F22 GB GREENCELL, 9 V (1604G)

6LF22

or

6LR61

GP SUPER Alkaline, 9 V (1604A)

Duracell DURACELL PLUS, Alkaline, 9 V

Varta powerone alkaline, 9 V (No. 4122)

Varta INDUSTRIAL, Alkaline, 9V (No. 4022)

GB

11221801.02 02/2011 GB/D/F/E

■

Ex-Zone operation:

Within Ex-Zones the accompanying leather case must be used!

■

Serial interface:

The serial interface may not be used within hazardous areas.

Connection and operation are only permitted to be used outside of

hazardous areas!

Only the WIKA interface converter may be used!

■

Pressure sensor:

You must only use model CPT62I0 pressure sensors! Usage of

other sensors may result in damage to the sensor and instrument.

When operating with two model CPT62I0 pressure sensors, be

careful that the sensors are not screwed into, nor are in contact

with, surfaces with diering electrical potentials.

7WIKA operating instructions, model CPH62I0

Page 8

GB

2. Safety

Only use the original WIKA connecting cable, which is provided

specically for connecting the CPT62I0 pressure sensor to the

CPH62I0 hand-held pressure indicator. The same applies to the

extension cable, which may be used to a maximum permissible

length of 5 m.

■

Temperature range:

Do not operate below -10 °C. Permissible ambient temperature

range: -10 ... +50 °C

■

Mains operation:

Only use WIKA power supplies! Operation with the external power

supply is not permitted in hazardous areas!

■

Analogue output:

The analogue output must not be used in hazardous areas!

Only use the analogue output with a passive voltmeter.

■

Equipotential bonding:

Do not apply dierent potentials to the components connected to

the instrument (pressure sensor, power supply, interface) and do

not connect them by means of an equipotential bonding.

Only connect pressure sensors for operation in hazardous areas!

If two pressure sensors are connected, make sure that they are

connected to the same electrical potential or have an equipotential

bonding.

■

Ambient conditions:

Take care that the device is not exposed to environments that

enable the ingress of humidity, water, conducting liquids or dust.

■

Non intrinsically-safe use:

The hand-held pressure indicator can also be used as non intrinsically-safe device for connection to non intrinsically-safe devices (i.e.

power supply unit, interface converter, etc.).

Likewise, only approved accessories may be used in this operating

mode!

Before the hand-held pressure indicator is once again used as an

intrinsically-safe device, it must be checked for visible damage and

correct functioning before it is returned to its leather case!

8 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 9

2. Safety

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination

certicate and the relevant country-specic regulations for installation

and use in hazardous areas (e.g.

VDE 0165,

IEC 60079-14, NEC, CEC).

Non-observance can result in serious injury and/or damage to equipment.

For additional important safety instructions for insturments with ATEX

approval see chapter “2.3 Additional safety instructions for instruments

with ATEX approval”.

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic

gases or liquids, and refrigeration plants, compressors, etc., in addition

to all standard regulations, the appropriate existing codes or regulations must also be followed.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

Operation using a defective power supply unit (e.g. short circuit from

the mains voltage to the output voltage) can result in life-threatening

voltages on the hand-held pressure indicator!

WARNING!

Residual media in dismounted hand-held pressure indicator or

pressure sensor can result in a risk to persons, the environment and

the equipment.

Take sucient precautionary measures.

Should a failure occur, aggressive media with extremely high temperature and under high pressure or vacuum may be present at the

handheld pressure indicator’s sensors.

GB

If there is a possibility that the instrument can no longer be used safely, the instrument

must be switched o immediately and marked accordingly to prevent re-use.

The safety of the operator may be endangered if, for example:

■

there is visible damage to the instrument.

■

the instrument is not working as specied.

■

the instrument has been stored under unsuitable conditions for an extended period of

time.

If there is any doubt, please return the instrument to the manufacturer for repair or

maintenance.

11221801.02 02/2011 GB/D/F/E

9WIKA operating instructions, model CPH62I0

Page 10

2. Safety

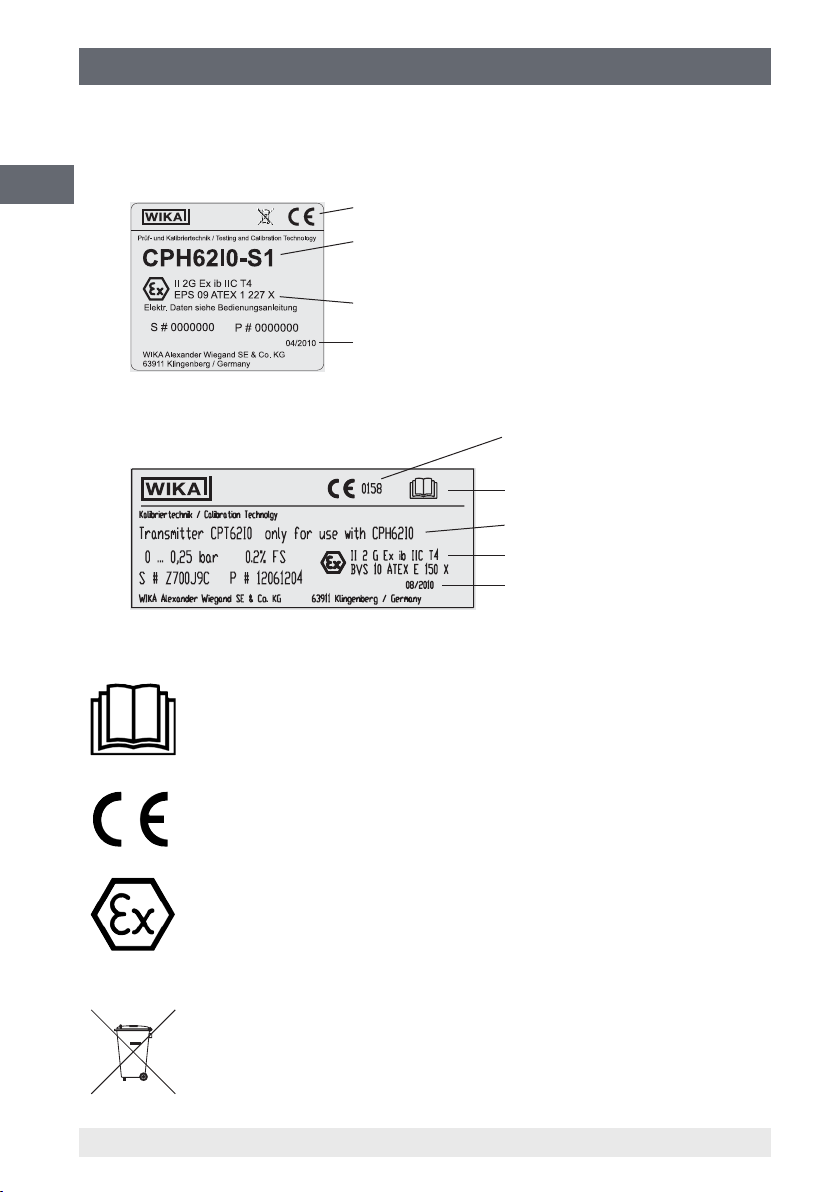

2.5 Labelling / Safety marks

5.2.1 Product label for hand-held pressure indicator

GB

For an explanation of symbols, see below

Model:

1-channel version: CPH62I0-S1

2-channel version: CPH62I0-S2

Approval number

Date of manufacture (year/month)

2.5.2 Product label for pressure sensor

Explanation of symbols

Before mounting and commissioning the hand-held pressure indicator,

ensure you read the operating instructions!

CE, Communauté Européenne

Hand-held pressure indicators bearing this mark comply with the

relevant European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = Ex)

Hand-held pressure indicators bearing this mark comply with the

requirements of the European Directive 94/9/EC (ATEX) on explosion

protection.

Code of the notied body monitoring

the quality assurance system for the

production

For an explanation of symbols, see below

Model

Approval number

Date of manufacture (year/month)

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities. See EU

Directive 2002/96/EC.

10 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 11

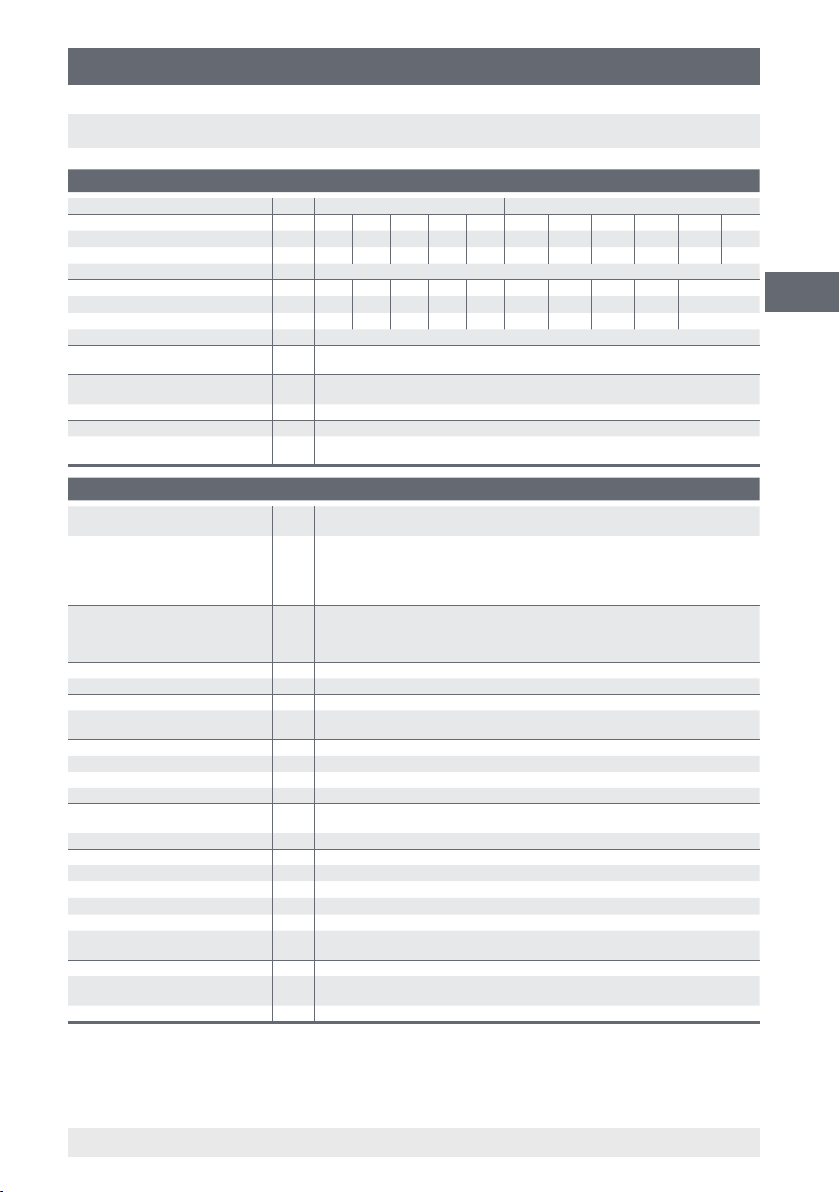

3. Specications

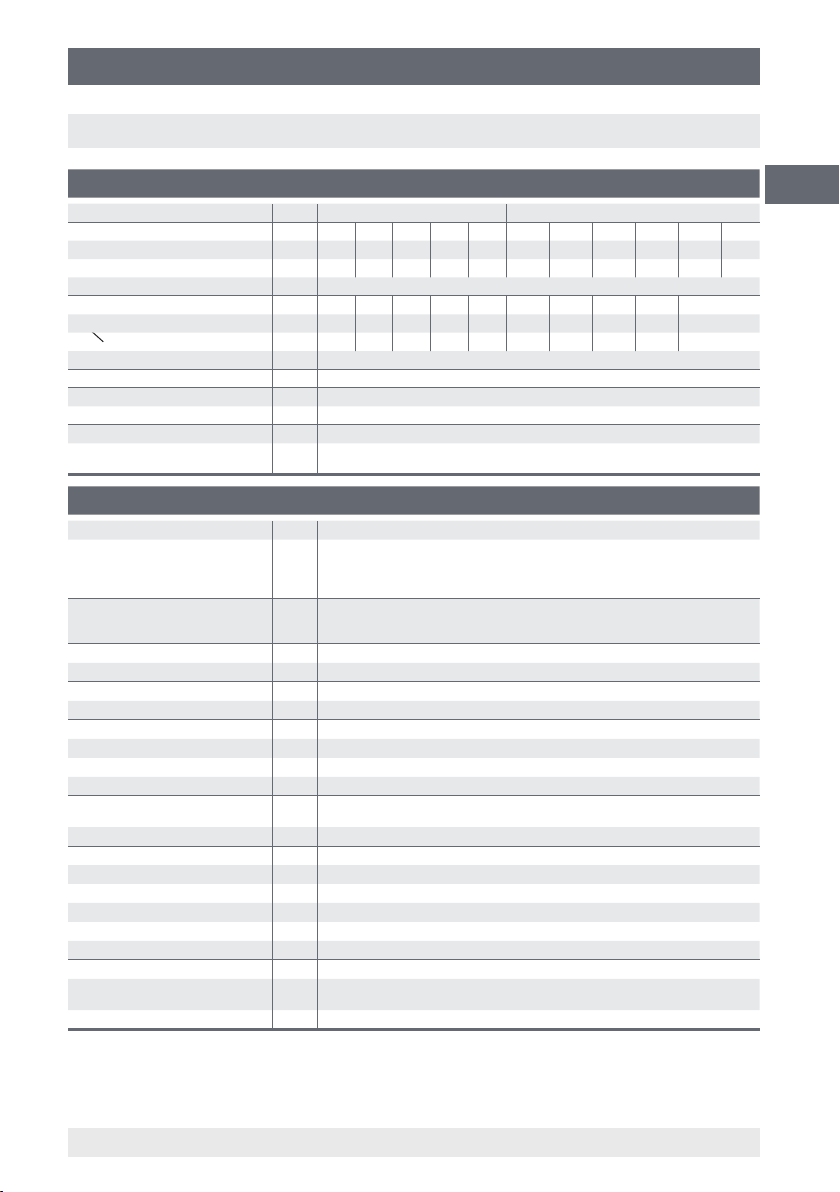

3. Specications

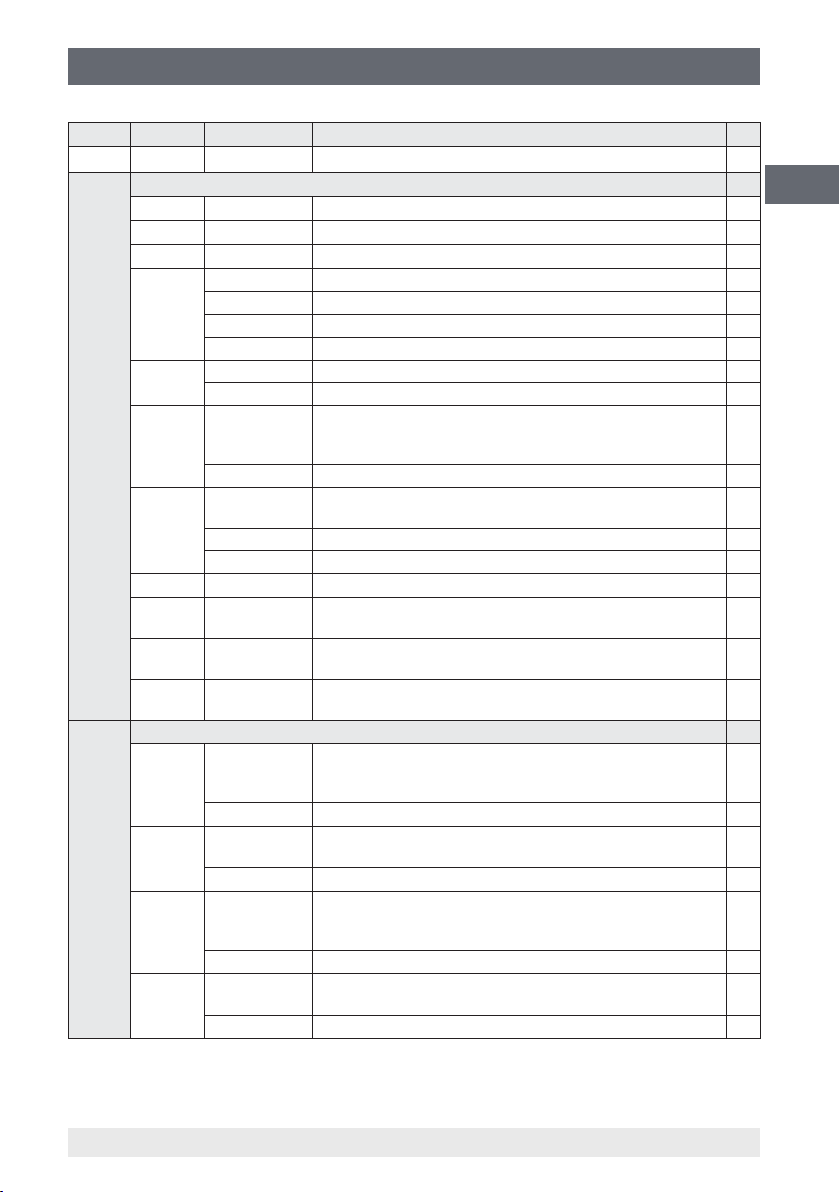

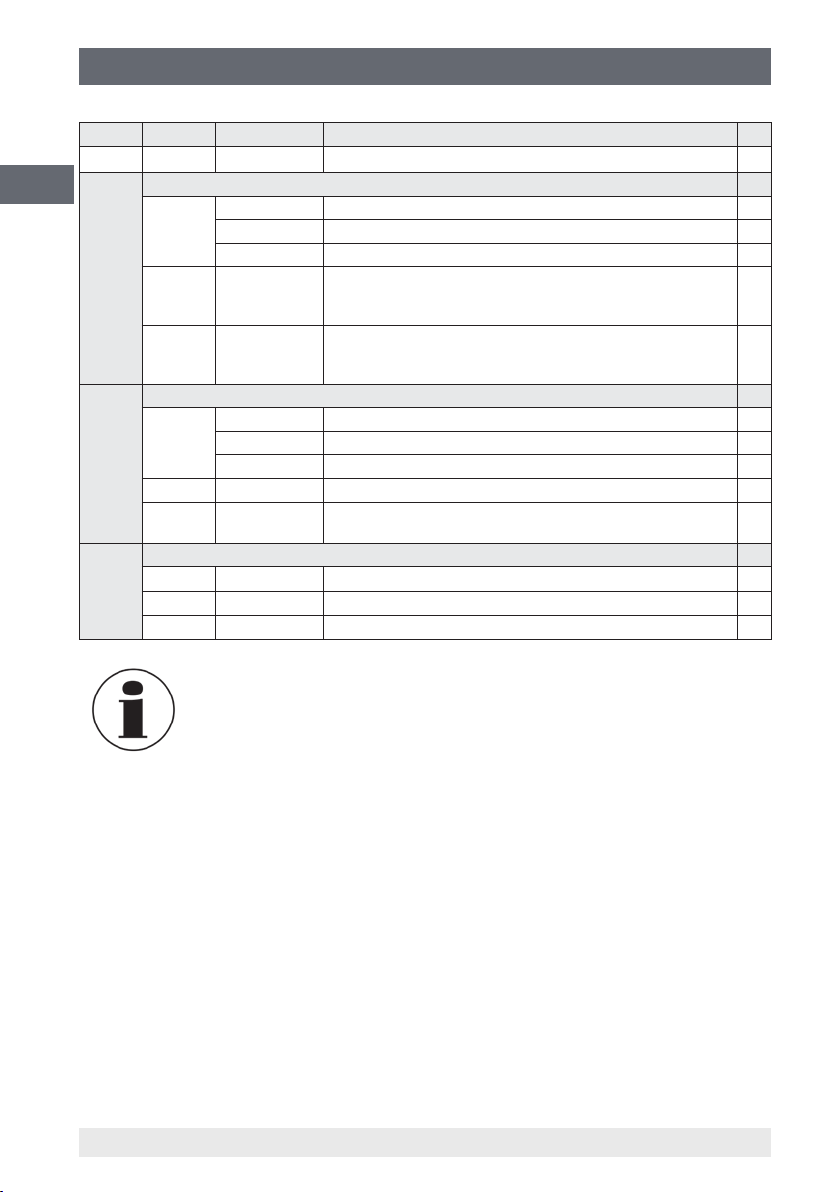

Specications

Input 1 input for CPH62I0-S1 2 inputs for CPH62I0-S2

Pressure range

Over pressure safety bar 1 1.5 2 2 4 5 10 10 17 35 35

Burst pressure bar 2 2 2.4 2.4 4.8 6 12 12 20.5 42 42

Resolution (max.) depending on pressure range

Pressure range

Over pressure safety bar 80 50 80 120 200 320 500 800 1200 1500

Burst pressure bar 96 250 400 550 800 1000 1200 1700 2400 3000

Resolution (max.) depending on pressure range

Type of pressure gauge {absolute 0.25 up to 16 bar & vacuum on request}

Accuracy (measurement chain)

Display Large LCD display for display of 2 values and additional information

Range of display max. -19999 up to 19999, depending on sensors used

Units can be selected: bar, mbar, psi, Pa, kPa, MPa, mmHg and inHg (dependent on

1)

1)

CPH62I0 hand-held indicator (complete measuring chain)

bar 0.1 0.16 0.25 0.4 0.6 1.0 1.6 2.5 4.0 6.0 10

bar 16 25 40 60 100 160 250 400 600 1000

0.2 % FS ± 1 digit at reference temperature of 20 °C; optional: 0.1 %

range)

Specications CPH62I0 digital instrument

Functions via key press Min-, Max-memory, Hold, Tare, Oset-correction, Logger (Start/Stop)

Functions via Menu

Data logger - discrete value logger: up to 99 recordings incl. time via key press

Interface (serial)

Analogue output

Power supply 9 V-zinc-carbon battery, alternative: 9 V rechargeable battery or mains supply

Power consumption cycle time slow: < 1.6 mA, fast: < 7.0 mA, Low-Power-Logger-Fct.: < 0.3 mA

Permissible

■

Working temperature °C -10 ... +50

■

Air humidity % r. H. 0 ... 95 relative humidity without moisture condensation

■

Storage temperature °C -20 ... +70

Housing

Weight g approx. 160

Connection values

■

Max. voltage DC V Uo = 10,38

■

Max. strength of current mA Io = 93

■

Max. power mW Po = 240

■

Max. eective internal capacitance nF Co = 1240

■

Max. eective internal inductance Lo negligible

CE conformity

■

EMC directive

■

ATEX directive 94/9/EC, Category 2G, Ignition protection type Ex ib IIC T4

1) In an oxygen version, a ush diaphragm model is not available. In an oxygen version model CPT62I0 is only available in gauge pressure ranges ≥ 0.25

bar with media temperatures between -10 … +50 °C and using stainless steel or Elgiloy® wetted parts.

2) For the intrinsically safe version, the use of the interface and analogue output is not permitted within an explosive atmosphere.

3) O-ring made of FKM/FPM or EPDM for ush diaphragm with integrated cooling element.

{} Items in curved brackets are optional extras for additional price.

11221801.02 02/2011 GB/D/F/E

2)

2)

Min-, Max-alarm (visual), Sealevel (barom. air pressure), Power-O-Function,

measurement rate: 4/sec (“slow“); > 1000/sec (“fast“); > 1000/sec unltered (“peakdetect“) [via “peak-detect“ and min-/max-memory: pressure peaks of 1.5 msec can

be detected]

- cyclic logger: automatic recording up to 10,000 values incl. time

- cycle time: selectable from 1 ... 3600 seconds

USB or RS-232 interface via special interface cable

0 ... 1 V; congurable (alternative instead of serial interface, selectable via menu)

Impact-resistant ABS, membrane keyboard, transparent panels with protective leather

case

2004/108/EC, EN 61326 Emission (Group 1, Class B) and Immunity (portable

equipment)

GB

11WIKA operating instructions, model CPH62I0

Page 12

3. Specications

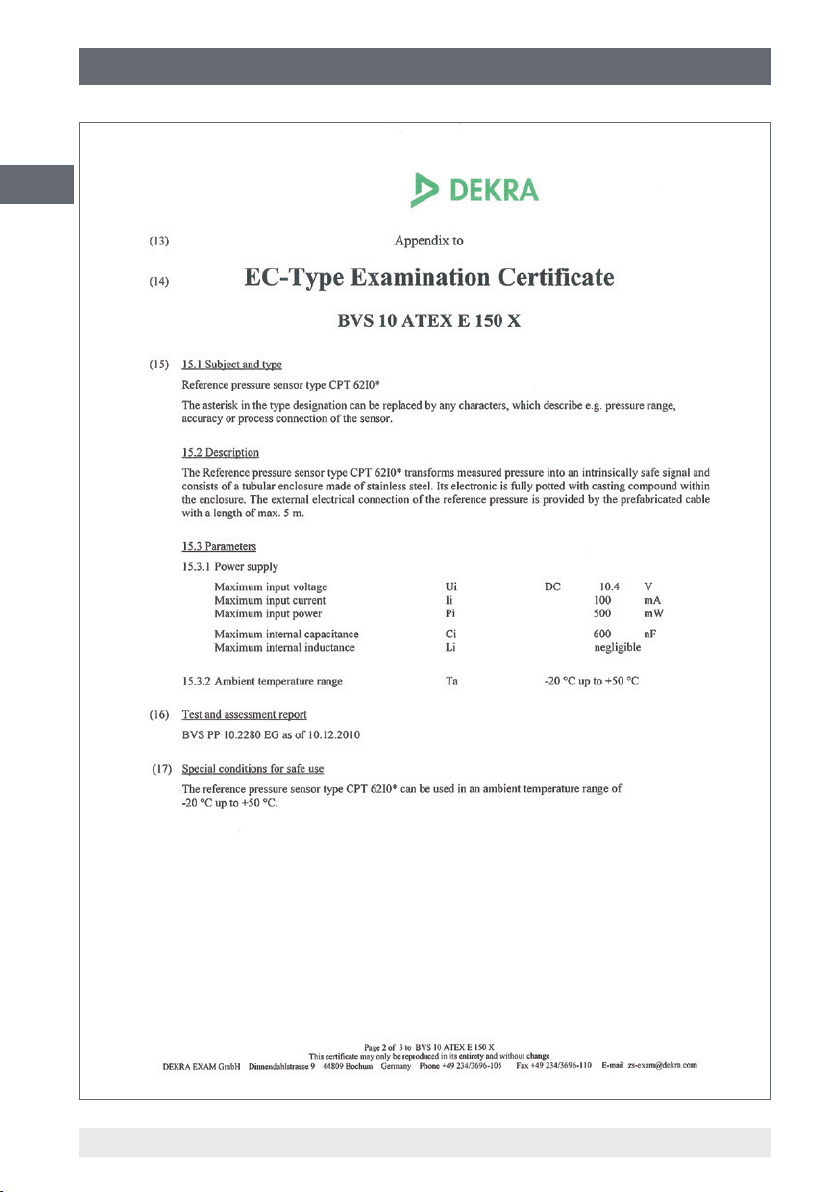

Specications CPT62I0 reference pressure sensor

Pressure connection

GB

Material

■

Wetted parts Stainless steel or Elgiloy®, (> 25 bar with NBR seal)

■

Internal transmission uid Synthetic oil, (only for pressure ranges up to 16 bar or ush diaphragm)

One year stability 0.2 % of span at reference conditions

Permissible

■

Medium temperature

■

Ambient temperature °C -20 ... +50 (T4)

■

Storage temperature °C -40 ... +80

Protection class IP 67 (Sensor) / IP 54 (Plug)

Compensated range °C 0 ... 70

Temperature coecients

■

Mean TC of zero signal 0.2 % / 10 K (< 0.4 for pressure ranges < 250 mbar)

■

Mean TC of span 0.2 % / 10 K

Supply circiut

■

Max. voltage DC V Ui = 10,4

■

Max. strength of current mA Ii = 93

■

Max. power mW Pi = 500

■

Max. eective internal capacitance nF Ci = 600

■

Max. eective internal inductance Li negligible

CE conformity

■

Pressure equipment directive 97/23/EC

■

EMC directive 2004/108/EC, EN 61326 Emission (Group 1, Class B) and Immunity (portable

■

ATEX directive 94/9/EC, Category 2G, Ignition protection type Ex ib IIC T4

Connection to CPH62I0 via 1 m cable (plug & play); on request: up to 5 m

Weight g approx. 220

1) In an oxygen version, a ush diaphragm model is not available. In an oxygen version model CPT62I0 is only available in gauge pressure ranges ≥ 0.25

bar with media temperatures between -10 … +50 °C and using stainless steel or Elgiloy® wetted parts.

2) For the intrinsically safe version, the use of the interface and analogue output is not permitted within an explosive atmosphere.

3) O-ring made of FKM/FPM or EPDM for ush diaphragm with integrated cooling element.

{} Items in curved brackets are optional extras for additional price.

1)

1)

G½ B; {ush diaphragm (G1 for 0.1 up to 1.6 bar) or various connection adapters

on request}

ush diaphragm version: stainless steel {Hastelloy C4}; O-Ring: NBR

or EPDM}

{Halocarbon oil for oxygen applications}; {Listed by FDA for food industry}

°C -20 ... +50 (T4)

equipment)

3)

{FKM/FPM

For further specications see WIKA data sheet

CT 11.02

and the order documentation.

WARNING!

For further important safety instructions for the operation in hazardous

areas see chapter “2.3 Additional safety instructions for instruments

with ATEX approval”.

12 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 13

3. Specications

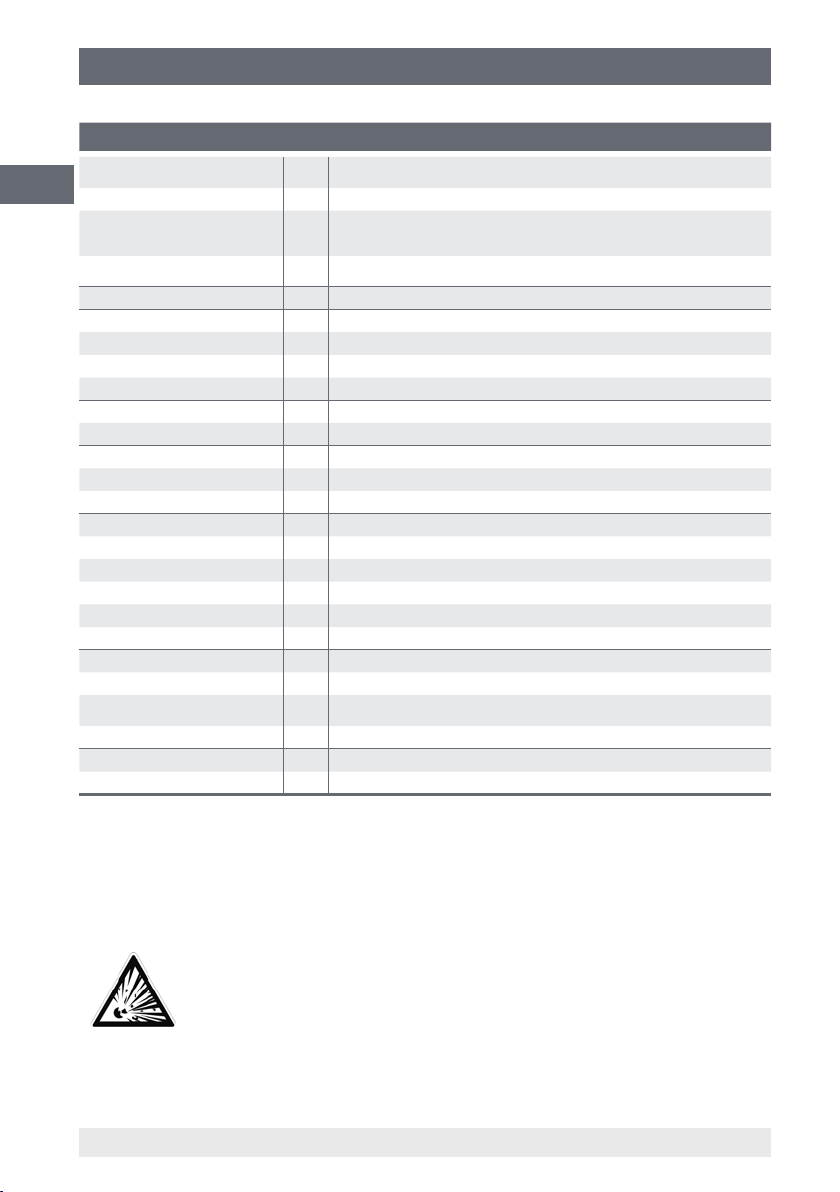

Dimensions in mm

Pressure sensor CPT62I0Digital instrument CPH62I0

Note: The intrinsically safe version CPH62I0 in a protective leather case has no rubber base on the back.

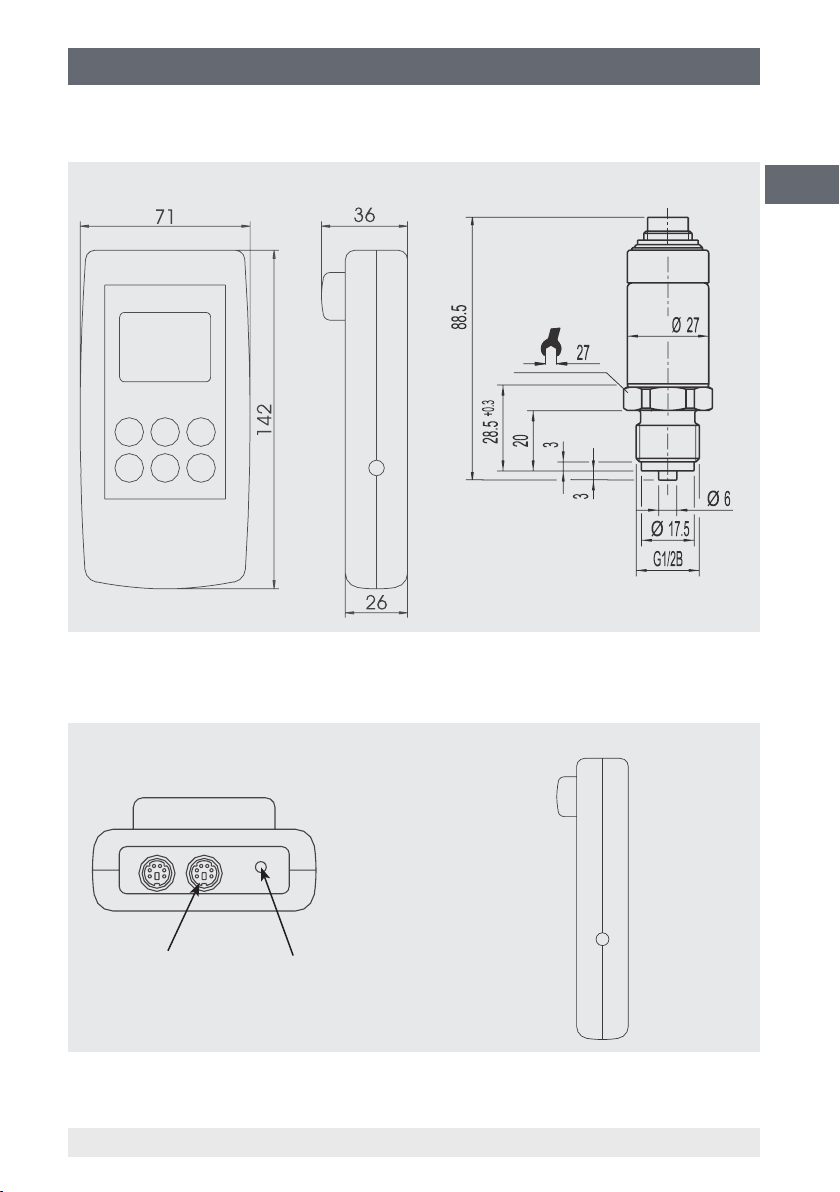

Electrical connections to the digital instrument

Top view Side view (left)

GB

Option: 2-channel versions

1) For the intrinsically safe version CPH62I0 the use of the interface and power supply unit is not permitted within an explosive

atmosphere.

11221801.02 02/2011 GB/D/F/E

Connection for interface adapter

(under the Ex-protective leather

case)

1)

13WIKA operating instructions, model CPH62I0

Page 14

4. Design and function

4. Design and function

4.1 Short description / Description

GB

The CPH62I0 hand-held pressure indicator can be used as a calibrator and for any

application where an accurate pressure measurement is required, within hazardous

areas.

Pressure sensors with ranges up to 1,000 bar are available for the CPH62I0 handheld pressure indicator. This hand-held pressure indicator recognises the range of the

connected pressure sensor automatically and guarantees high precision.

Both gauge and absolute pressure ranges can be measured, and by using the

CPH62I0-S2 with two connected pressure sensors, it is also possible to measure dierential pressure. Via menu selection, pressures can be displayed in bar, mbar, psi, Pa,

kPa, MPa, mmHg or inHg.

An integrated data logger and various other functions (such as Min, Max, Hold, Tare,

Oset correction, Alarm, Power-o, 3 Sample rates, Sealevel etc.) ensure that the

instrument can be used for many dierent applications.

4.2 Scope of delivery

■

CPH62I0-S1 or CPH62I0-S2: Intrinsically safe version EX ib IIC T4 or ATEX directive

94/9/EC incl. 9 V battery

■

One sensor connection cable per channel

■

Calibration certicate 3.1 per DIN EN 10204

■

Choice of sensors

Cross-check scope of delivery with delivery note.

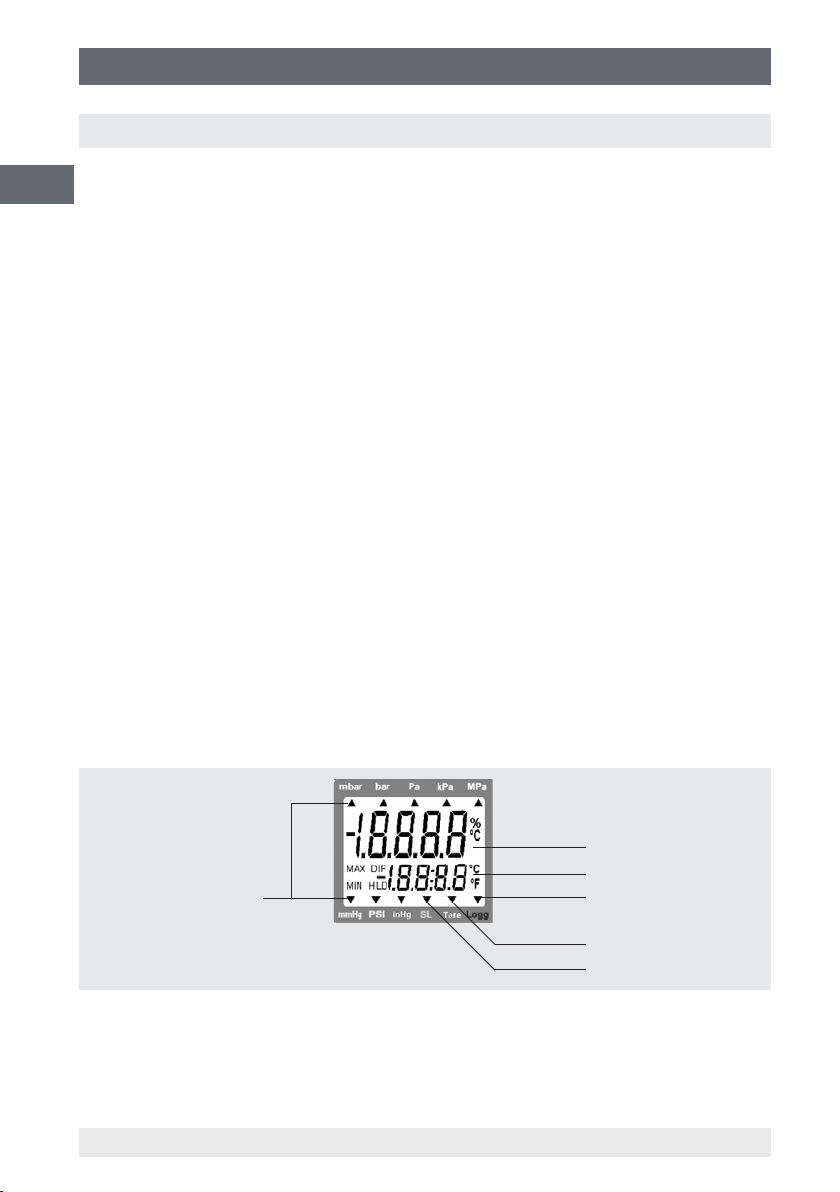

4.3 Display

1

2

6

3

4

5

1. Main display: shows the current measured value of CH1.

2.

Lower display: For the 2-channel version, shows the measured value of CH2 or DIF

(CH1-CH2). For the 1 channel version, it displays the min, max or hold function values.

3. Logg: shown if logger function is selected, ashes if cyclic logger is running.

14 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 15

4. Design and function

4. Tare: indicates that the tare function is activated.

5. SL: indicates, that the sea level function is activated.

6. Measuring unit: an arrow points to the chosen measuring unit.

4.4 Electrical connections

On the upper edge of the device are located the connector sockets for attaching the

CPH series pressure sensors, CH1 and CH2 (CH2 only with the 2-channel version),

(see chapter “6.6 Available pressure sensors”), as is the socket for the WIKA interface

cable (see chapter “6.5 The serial interface”).

Connection for WIKA interface

cable (RS-232/USB) or optional

analogue output

GB

CH1

On the left side of the device the mains adapter socket for connecting the power

supply unit is located (see current CPH62I0 price list).

4.5 Power supply

Battery operation status

If ´bAt´ are shown in the lower display the battery is low and needs to be replaced. The

device will, however, work normally for a limited period. If ´bAt´ is shown in the upper

display the voltage is too low to operate the device; the battery will be completely at.

11221801.02 02/2011 GB/D/F/E

CH2 (only for 2-channel version:

CPH62I0-S2)

WARNING!

Operation as analogue output:

Connection via suitable cable.

Attention: The output mode must be congured via menu and inu-

ences battery life!

15WIKA operating instructions, model CPH62I0

Page 16

4. Design and function

If the device will not be used for some time, we advise that the battery

is removed. The real time clock has to be set again once the battery

GB

Only the usage of approved batteries is allowed!

Approved batteries are:

Battery type Manufacturer Battery name

6F22 GB GREENCELL, 9 V (1604G)

6LF22

or

6LR61

4.6 Pressure sensors

Connecting/Changing pressure sensors

Only use model CPT62I0 pressure sensors. Using other pressure sensors can damage

the instrument! Switch o the device before changing the pressure sensor, and connect

the pressure sensor before turning the device back on, otherwise the pressure sensor

might not be identied correctly.

has been reconnected.

GP SUPER Alkaline, 9 V (1604A)

Duracell DURACELL PLUS, Alkaline, 9 V

Varta powerone alkaline, 9 V (No. 4122)

Varta INDUSTRIAL, Alkaline, 9V (No. 4022)

The hand-held pressure indicator and the pressure sensor are connected using a

discrete connecting cable. When changing the pressure sensor, always connect and

disconnect at the pressure sensor end of the cable.

To connect the pressure sensor, rotate the plug till it locates in the guide slot, allowing it

to plug in. Then tighten the safety collar (by screwing it lightly in a clockwise direction).

When connecting the cable to the pressure indicator, the connector might not locate

properly in the socket. In this event you should try holding the plug by the cable strain

relief, rather than by the connector housing. If the plug is correctly located, it will slide in

smoothly. To disconnect the pressure sensor hold it by the plug to release the connector

lock. Do not pull the cable to release it.

WARNING!

For gauge sensors, the pressure compensation vent hole is found at

the top of the sensor housing. This vent (with integral membrane seal)

must be kept clear without fail!

16 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 17

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check hand-held pressure indicator for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +70 °C

■

Humidity: 0 ... 95 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the hand-held pressure indicator in its original packaging in a location that fulls

the conditions listed above. If the original packaging is not available, pack and store the

hand-held pressure indicator as described below:

1. Wrap the hand-held pressure indicator in an antistatic plastic lm.

2. Place the hand-held pressure indicator, along with shock-absorbent material, in the

packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

GB

WARNING!

Before storing the hand-held pressure indicator (following operation),

remove any residual media. This is of particular importance if the

medium is

tive, etc.

11221801.02 02/2011 GB/D/F/E

hazardous to health, e.g. caustic, toxic, carcinogenic, radioac-

17WIKA operating instructions, model CPH62I0

Page 18

6. Commissioning, operation

6. Commissioning, operation

6.1 Operator panel and basic operation

GB

On turning the device on, if the logger function is selected, the integrated clock‘s time

will be displayed briey. If a zero point adjustment has been carried out, the display will

indicate this by showing “nuLL-Corr”.

After changing the battery the menu for setting the clock is activated automatically

(‘CLOC’). Check the clock and adjust if necessary (see chapter “6.3.11 (CLOC) Real

time clock“).

5

1

2

5

1. ON/OFF

2. SET/MENU: Enter conguration menu

3. TARA: Activate tare function, zero point adjustment

4. STORE/QUIT: Activate hold function or logger function

(see chapter “6.4 Operation of logger”)

5. MIN/MAX: Display the respective min-/max-memory value

Max-Function: Pressing ´MAX´ shows the maximum measured value recorded.

Pressing it again hides it. To clear the max-memory press the ´MAX´

key for > 2 seconds.

Min-Function: Pressing ´MIN´ shows the minimum measured value recorded. Press-

ing it again hides it. To clear the min-memory press the ´MIN´ key for >

2 seconds.

Hold-Function: By pressing ´STORE/QUIT´ the instantaneous measured value will

be shown in the lower display. Pressing it again hides it. (Only when

logger = ‘o‘ is selected in the main menu).

Logger-Functions: Activated by the ´STORE/QUIT´ key, only if the logger has been

selected via the main menu (see chapter “6.4 Operation of logger”).

Tare-Function: By pressing ´TARA´, the display will be set to 0. All measurements

from then on will be displayed relative to the set tare value. When the

tare function is activated, the arrow ´TARA´ appears in the display. To

deactivate the tare function press ´TARA´ for > 2 seconds.

3

4

18 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 19

6. Commissioning, operation

Activating/deactivating ´TARA´ clears the max- and min-memories.

Zero-Point Adjust: (for gauge pressure sensors only) If there is no pressure applied

to the pressure ports the device should display 0. If there is a perma-

nent oset (and the device is being used under steady conditions),

a permanent zero point adjustment can be carried out. To carry out

the adjustment, press ´TARA´ for approx. 5 seconds. (Please note: A

zeropoint adjustment can only be made if the dierence between the

display value and the factory calibration value is less than 2 %! E.g.

for a measuring range of 0 ... 25 bar, => zeropoint adjustment up to

0.5 bar is possible). To revert to the factory calibration, press ´TARA´ for

approx. 15 seconds.

A zero-point adjustment can only be carried out if the dierence

between the value on display is less than 500 digits!

If a zero-point adjustment has been made, this will be signalled by the

message “nuLL-Corr“ being displayed briey as the device is turned on.

Dierential pressure: Pressing ´SET/MENU´ shows the dierence between the

measured values of Channel 1 and Channel 2 (DIF=CH1-CH2) in the

lower display. Pressing it again will hide it (only with the 2-channel

version and when 2 pressure sensors are connected).

GB

11221801.02 02/2011 GB/D/F/E

19WIKA operating instructions, model CPH62I0

Page 20

6. Commissioning, operation

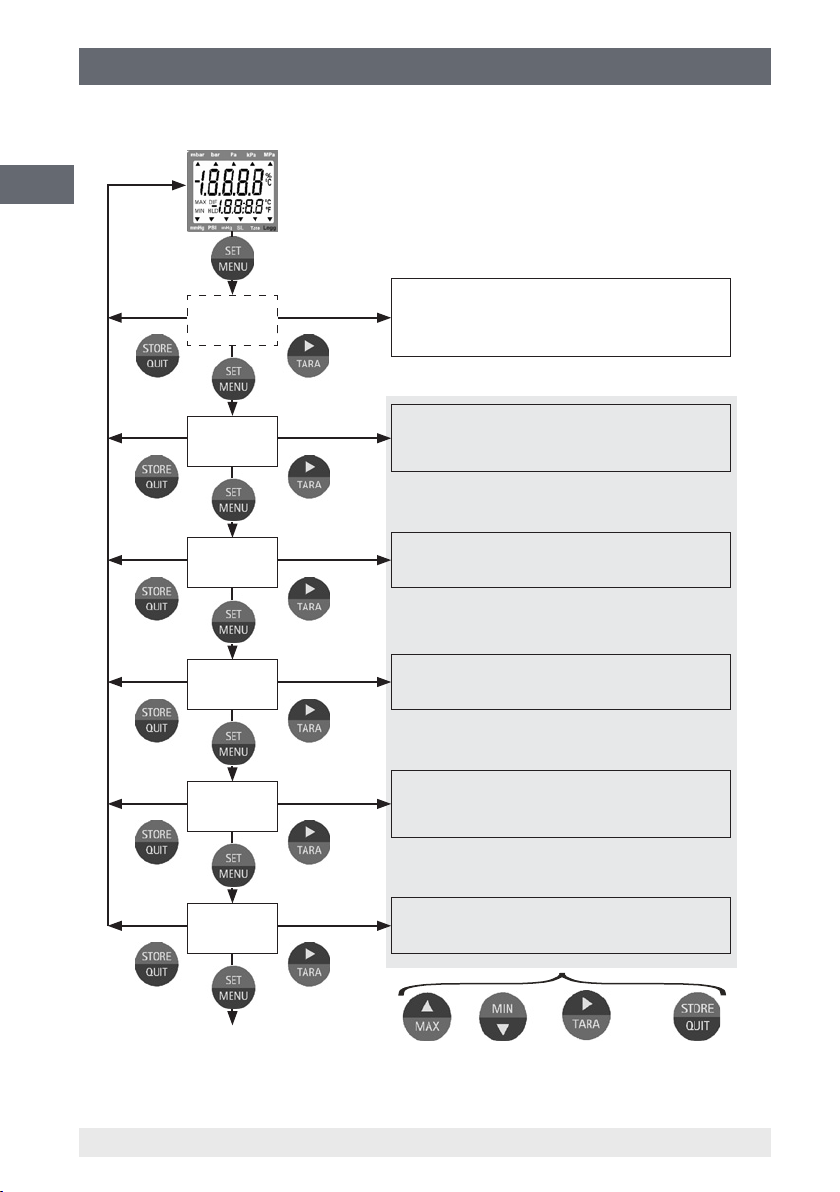

6.2 Main menu

GB

Read*

Logg

(2 sec)

Stored data*

Recall of individually logged data and respective

time stamp (´Func-STOR´ conguration (see

chapter “6.4 Operation of logger”).

Set

Conf

Set

CAL

Set

AL

Set**

Logg

Set

Cloc

Conguration

Unit** / Sea-Level** / Measuring rate** /

Power-o / interface-address

Calibration

Adjustment of zero and span

Alarm

Min/Max alarm visual

Logger**

Switch from simple ‘Hold’ to ‘Logger’ function:

Single-point values (STOR) or Cyclic (CYCL)

System-clock

time / day & month / year

(ring - shift)

set parameter next parameter store & quit

* appears only if data (Func-STOR) is in the logger memory.

** appears only if the logger memory is empty (see chapter “6.4 Operation of logger”).

20 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 21

6. Commissioning, operation

Menu Param. Setting Meaning

´MENU´

SEt

ConF

SEt

CAL

▶ ▲ or ▼

Set Conguration: Generic settings

Unit

SL

Alti

rAtE

t.AVG

P.oFF

Out

Adr.

dAC.

dAC.0

dAC.1

Set Calibration: Adjustment of sensors

OFS.1

SCL.1

OFS.2

SCL.2

mbar, bar, ... Unit: Unit of display *, **

oFF / on Sea-level correction: on or o *, **

-200 ... +9999

Slo Slow: Measuring rate (4 Hz ltered, low power consumption) *

FASt Fast: Measuring rate, ltered (> 1000 Hz) *

P.dEt Peak detection: fast measuring rate, unldered (> 1000 Hz) *

1 ... 120 Averaging interval in seconds, used by the averaging function o

oFF Averaging function deactivated

1 ... 120 Auto Power-O delay in minutes. Device will automatically switch

oFF Auto Power-O function inactive (continuous operation)

oFF Function of the output: No output function, lowest power consump-

SEr Output is serial interface

dAC Output is analogue output 0 ... 1 V

01, 11 ... 91 Communications address of the interface

CH1, CH2 or

CH DIF

eg. -5.00 ...

+5.00 mbar

eg. -5.00 ...

+5.00 mbar

Sensordep.,

e.g. -5.00 ...

+5.00 mbar

OFF Zero displacement inactive (=0.0 °)

eg. -5.00 ...

+5.00 mbar

OFF Scale correction factor inactive (=0.000)

Sensordep.,

e.g. -5.00 ...

+5.00 mbar

OFF Zero dispacement deactive (=0.0°)

eg. -5.00 ...

+5.00 mbar

OFF Scale correction factor inactive (=0.000)

Altitude: Input of altitude above sea-level [m] (only if on) *, **

Rate: Measuring rate (see chapter 6.3.3) *

itself o if, during this interval, no key is pressed, or there is no

serial communication.

tion

Choice of the input to be the source for the analogue output (if Out

= dAC)

Enter desired value at which the analogue output potential should

be 0 V (if Out = dAC)

Enter desired value at which the analogue output potential should

be 1 V (if Out = dAC)

The offset of sensor 1 will be displaced by this value to compensate for deviations in the probe or in the measuring device.

The measuring scale of sensor 1 will be changed by this factor

[%] to compensate deviations of probe or measuring device.

The offset of sensor 2 will be displaced by this value to compensate for deviations in the probe or in the measuring device.

The measuring scale of sensor 2 will be changed by this factor

[%] to compensate deviations of probe or measuring device.

GB

11221801.02 02/2011 GB/D/F/E

21WIKA operating instructions, model CPH62I0

Page 22

6. Commissioning, operation

Menu Param. Setting Meaning

GB

´MENU´

SEt

AL.

SEt

LoGG

SEt

CLOC

▶ ▲ or ▼

Set Alarm: Alarm function conguration

AL.

[1,2,DIF]

AL.Lo

[1,2,DIF]

AL.Hi

[1,2,DIF]

Set Logger: Logger function conguration

Func

CYCL

Lo.Po

Set Clock: Setting of real time clock

CLOC

dAtE

YEAr

on Alarm function on

no. So Alarm function on

oFF No alarm function

Min-Range ...

... AL.Hi

AL.Lo ...

... Max-Range

CYCL Cyclic: logger function ‘cyclic logger’

Stor Store: logger function ‘discrete value logger’

oFF No logger function

1 ... 3600 Cycle time for cyclic logger [seconds]

on / oFF Low-power logger with very low power consumption (only if cyclic

HH:MM Clock: set time hours:minutes

TT.MM Date: set time day.month

YYYY Year: set time year

Min alarm limit

(not when AL.oFF, Min-Range is the lower display range of the

connected sensor)

Max alarm limit

(not when AL.oFF, Max-Range is the upper display range of the

connected sensor)

*

*

*

*

logger with slow measuring rate)

* If there is existing data in the logger memory, the menus/param-

eters cannot be accessed! If these need to be adjusted, the logger

memory must rst be cleared! (see chapter “6.4 Operation of

logger”.)

** This menu can only be invoked if an appropriate sensor is connect-

ed to connection 1. When using a second sensor on connection 2

then settings are adopted.

6.3 Conguration

To change device settings, press the ´SET/MENU´ key for 2 seconds. This will access

the conguration menu (main display: ´SEt´).

Pressing the ´SET/MENU´ key again scrolls down the menus, pressing the ´TARA´

key scrolls across to the associated parameters, which can then be selected with the

´TARA´ key.

The parameters can be altered using the ´MIN´ or ´MAX´ keys. Pressing the ´SET/

MENU´ key again saves the settings and returns you to the main conguration menu.

The ´STORE/QUIT´ key exits the conguration and returns you to standard measuring

mode.

22 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 23

6. Commissioning, operation

6.3.1 (Unit) Choice of pressure units

Depending on the pressure range, the pressure value can be displayed in any one of the

following units: mbar, bar, Pa, kPa, MPa, mmHg, inHg or psi.

6.3.2 (SL) Sea-level correction for absolute pressure sensors

If an absolute pressure sensor is connected to the instrument, then the device displays

the true absolute pressure measured by the sensor. This does not necessarily equate to

the values given by weather stations, which give the pressure at sea-level. Usually the

sensor is situated above sea-level and therefore, if the value at sea-level (zero) is to be

measured, the pressure loss resulting from the elevation above sea-level must be consid-

ered! To correct the displayed value activate the “Sea-Level-Function“ (SL). (Setting is

only possible, if an abs. pressure sensor is connected to sensor connection 1.)

Then enter the sensor‘s height above sea-level in metres (Alti). When activated, the

display shows the SL-arrow and the device displays the absolute pressure value relative

to sea-level.

When two absolute pressure sensors are connected, the sea level

function for both corresponds to the setting of pressure sensor 1.

6.3.3 (rAtE) Choice of measuring rates: “rAtE-Slo, -P.dEt, -FASt“

Three options of measuring rate are supported. Two of them work with high measuring frequencies of over 1000 measurements per second. Whichever one of these was

selected during conguration (see above), this will be displayed in the lower display:

“P.dEt“ or “FASt“.

GB

6.3.3.1 rAtE-Slo = standard measuring

Measuring rate 4 Hz, averaging and lter functions are active.

Application: Measurement of slowly changing or static pressures, e.g. leak testing,

atmospheric pressure, highest accuracy, high noise immunity (EMI and unstable

measuring signals), low power consumption.

6.3.3.2 rAtE-P.dEt: Peak detection

Measuring rate > 1000 Hz, the value is displayed unltered.

Application with logger function: Measurement of pressure spikes or uctuating

pressures with a resolution of < 1 ms. The cyclic logger function records the arithmetic

mean value, the highest and the lowest peak during the chosen time interval.

Higher power consumption, measuring is sensitive to noise (EMI,..).

11221801.02 02/2011 GB/D/F/E

23WIKA operating instructions, model CPH62I0

Page 24

6. Commissioning, operation

6.3.3.3 rAtE-FASt: fast ltered measuring

Measuring rate > 1000 Hz, but the value is ltered slightly (higher noise immunity than

P.dEt, small peaks will be ltered out), apart from that, identical behaviour to P.dEt.

GB

6.3.4 Averaging function

The averaging function acts on the displayed values (LCD and serial interface). It

is completely independent of the averaging within the logger function, please don‘t

confuse them!

The averaging integrates the measured values during a chosen time interval and then

calculates the average display value. It is independent of the selected measuring rate

(slow, fast, peak detect).

Until sucient values to calculate an average value have been collected (dependant

on selected averaging time), the upper display shows “----“, the lower display shows a

´countdown´.

During an active low-power-logging procedure the average is always deactivated.

Operation of min/max-value memory in conjunction with the averaging function:

■

If averaging is activated and ‘slow’ measuring rate is selected (rAtE-Slo), the min-/

max-memory value relates to the average display value.

■

If averaging is activated and ‘fast’ measuring rate is selected (rAtE-FASt or P.dEt), the

min-/max-memory value relates to the internal measured values (pressure spikes can

be detected).

6.3.5 Zero correction sensor 1 (OFS.1) and sensor 2 (OFS.2)

A zero displacement can be carried out for the measured value:

displayed value = measured value - oset

Standard setting: ‘o‘ = 0.00, i.e. no zero oset will be carried out. Together with the

scale correction (see below) this factor is mainly used to compensate for sensor devia-

tions. Input is in the display unit.

6.3.6 Span correction sensor 1 (SCL.1) and sensor 2 (SCL.2)

The scale of the measurement can be inuenced by this setting (factor is in %):

displayed value = (measured value - oset) * (1+Scal/100)

Standard setting: ‘o‘ = 0.000, i.e. value is not corrected. Together with the zero oset

(see above) this factor is mainly used to compensate for sensor deviations.

24 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 25

6. Commissioning, operation

6.3.7 (P.oFF) Power o function

If no key is pressed, and no serial communication occurs during the interval set in

conguration (P.o), the device will automatically switch itself o to save battery power.

If P.oFF = oFF then the automatic power o is deactivated.

6.3.8 (Out) Output

The output can be used as a serial interface (RS-232 or USB) or as an analogue output

(0 ... 1 V).

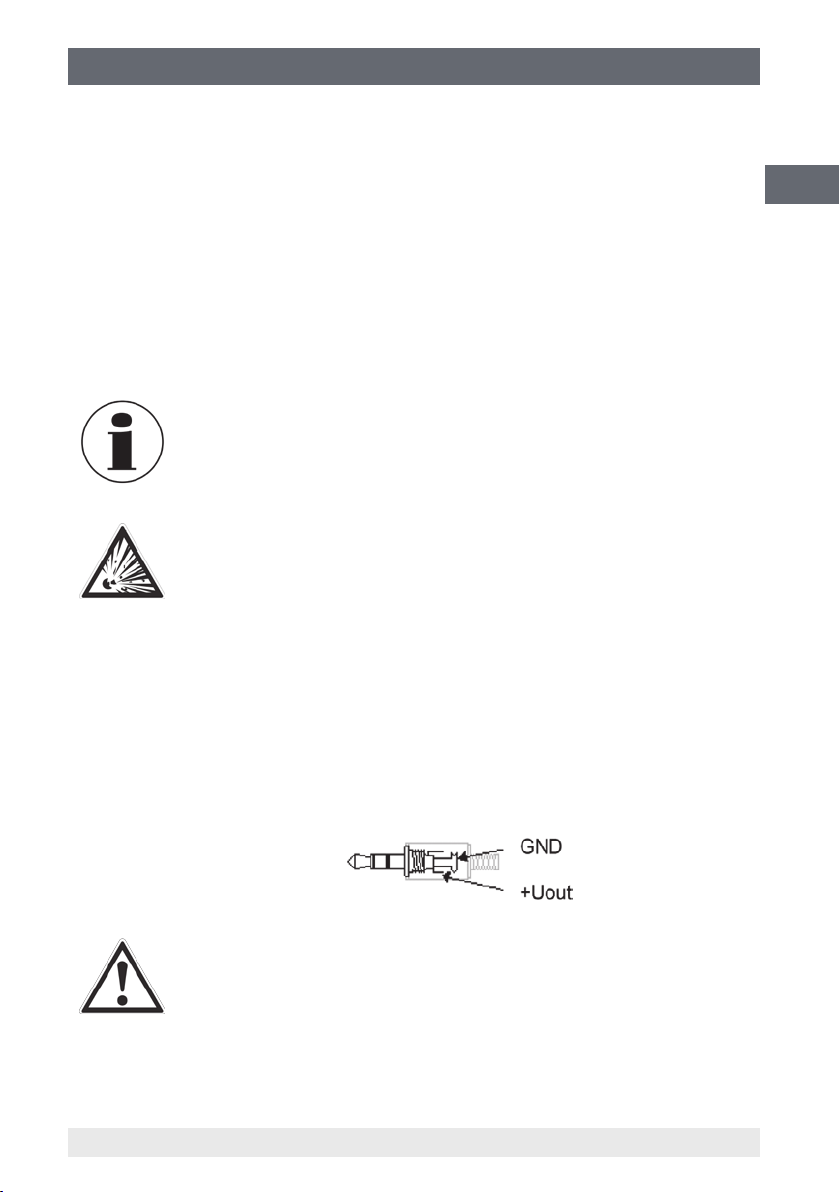

6.3.9 (dAC.) Analogue output – scaling with (dAC.0) and (dAC.1)

Analogue output cannot be used during logger recordings.

WARNING!

Only use the analogue output with a passive voltmeter.

GB

With dAC.0 and dAC.1 the analogue output can be easily scaled.

It should be ensured that the analogue output is not overloaded, otherwise the output

value could be incorrect and battery life can be reduced. Loads up to approx. 10 kΩ are

not critical. If the display exceeds the value set by dAC.1, then the device will apply 1 V

to the output. If the display falls below the value set by dAC.0, then the device will apply

0 V to the output. In the event of an error (Err.1, Err.2, no sensor, etc.) the device will

apply slightly above 1 V to the output.

Plug wiring:

WARNING!

The 3rd contact must be left oating! Only stereo plugs are permitted!

11221801.02 02/2011 GB/D/F/E

25WIKA operating instructions, model CPH62I0

Page 26

6. Commissioning, operation

6.3.10 (AL.) Alarm

There are three possible settings: Alarm o (AL.oFF), on (AL.on), on (AL.no.So).

The following conditions will prompt an alarm to be displayed, if the alarm function is

GB

activated (on or no.So):

■

Value is below lower alarm limit (AL.Lo) or above upper alarm limit (AL.Hi).

■

Sensor error (Sens-Erro)

■

Low battery (bAt)

■

Fe 7: System error

When an alarm occurs, the alarm arrow ashes, and, during serial communication, the

‘PRIO’-ag is set within the transmitted message.

6.3.11 (CLOC) Real time clock

The real time clock is needed for time-stamping each data point recorded within the

logger function. As a result, the clock settings should be checked regularly. If the battery

has been replaced the appropriate menu ‘CLOC’ will be accessed automatically.

6.4 Operation of logger

The device supports two dierent logger functions:

"Func-STOR":

Each time the ´STORE/QUIT´ key is pressed a data point will be recorded.

"Func-CYCL": Measurements will automatically be recorded at a dened interval, set

within the logger menu ‘CYCL‘ until the logger is stopped or the logger

memory becomes full. Logging is started by pressing the ´STORE/

QUIT´ key for 2 seconds.

The logger records up to 3 measurement values for each interval:

■

Current or mean value (depending on logger setting, see below), Min-Peak and

Max-Peak. (Sensor 1, Sensor 2, dierence)

To evaluate the data, WIKA’s Data logger evaluation software GSoft (V 2.3 or higher)

must be used. The software also allows easy conguration and operation of the logger.

If the logger is selected (Func-STOR or Func-CYCL) the hold function is deactivated; the

´STORE/QUIT´ key is then used solely for the operation of the logger functions.

Min- and Max-Peak are, respectively, the minimum and the maximum measured values

during the last measurement interval. Therefore both the instantaneous pressure values

and the measured uctuations can be better analysed.

26 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 27

6. Commissioning, operation

6.4.1 “Func-Stor“: Storing discrete measurements

In this mode, each time the ´Store/Quit´ key is pressed a measurement and its time

stamp will be recorded. The data recorded can be viewed either on the display (an

additional menu item “REAd-LoGG“ is displayed when scrolling through the conguration menu) or through the serial interface and a PC running the GSoft software.

Max. number of measurements: 99

The data recorded includes the following values:

■

Sensor 1: instantaneous value at that data point

■

Sensor 1: Min-Peak, Max-Peak since last data point

■

Sensor 2*: instantaneous value at that data point

■

Sensor 2*: Min-Peak, Max-Peak since last data point

■

Instantaneous dierence (Sensor 1 - Sensor 2)*: at that data point

■

Min-Peak, Max-Peak of the dierence (Sensor 1 - Sensor 2)*: Min-Peak, Max-Peak

since last data point

■

Time and date stamp of that data point

* Only for 2-channel version CPH62I0-S2

After each recording “St. XX“ will be displayed for a short time. XX represents the

number of the data point.

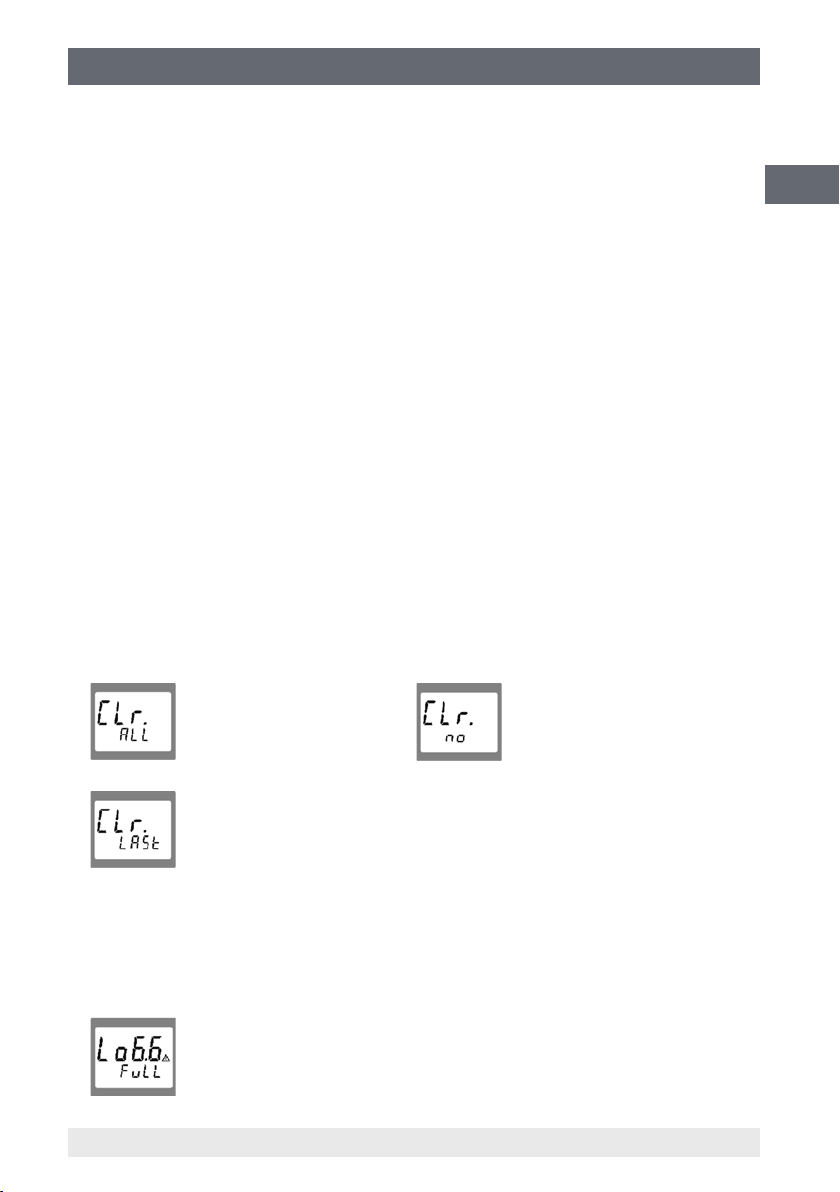

If the logger memory already contains data:

When the ´STORE/QUIT´ key is pressed for 2 seconds, the option to clear the logger

memory will be displayed:

GB

clear all data points clear nothing (cancel menu)

clear the last data point

Use the ´MIN´ or the ´MAX´ key to display the required option. The ´STORE/QUIT´ key

selects that choice.

If the logger memory is full, the display will show:

11221801.02 02/2011 GB/D/F/E

27WIKA operating instructions, model CPH62I0

Page 28

6. Commissioning, operation

Viewing Recorded Measurements

Within the “LoGG-Stor“ function the measurements can be viewed directly on the

instrument display as well as through a computer (“Func-CYCL“ only allows for the data

GB

to be viewed on computer). Press the ´SET/MENU´ key for 2 seconds: The rst menu

displayed is now “rEAd-LoGG“ (read logger data). By then pressing the ´TARA´ key, the

last measurement recorded will be displayed; pressing the ´TARA´ key again scrolls

between the dierent values related to this data point. Pressing the ´MIN´ key or ´MAX´

key selects dierent data points.

6.4.2 “Func-CYCL“: Automatic datalogging with adjustable cycle-time

The Logger cycle-time is adjustable (see Conguration). For example, setting “CYCL“ =

60: A measurement is made every 60 seconds.

When the slow measurement “rAtE-Slo“ is chosen, additionally a low power function is

available: “Lo.Po“. If “Lo.Po“ is on, the device only will take a measurement at the point

of time of the recording. In between the recordings the measuring is not active. This

decreases the power consumption enormously and therefore is recommended for long

time recordings where no mains adapter is available.

Max. number of measurements: CPH62I0-S1: 10,000

CPH62I0-S2: 4,000

(at max. 64 recording sequences)

Cycle-time: 1 ... 3,600 seconds (=1 h),

selectable from the conguration menu

A measurement contains:

■

Slow measuring rate (rAtE-SLo):

- Sensor 1: current value at that data point

- Sensor 1: Min-Peak, Max-Peak since last data point

- Sensor 2*: instantaneous value at that data point

- Sensor 2*: Min-Peak, Max-Peak since last data point

- Instantaneous dierence (Sensor 1 - Sensor 2)*: at that data point

- Min-Peak, Max-Peak of dierence (Sensor 1 - Sensor 2)*: Min-Peak, Max-Peak

since last data point

■

Fast measuring rate (rAtE-FASt, -P.dEt):

- Sensor 1: average since last data point

- Sensor 1: Min-Peak, Max-Peak since last data point

- Sensor 2*: average since last data point

- Sensor 2*: Min-Peak, Max-Peak since last data point

- Average dierence (Sensor 1 - Sensor 2)*: since last data point

- Min-Peak, Max-Peak of dierence (Sensor 1 - Sensor 2)*: Min-Peak, Max-Peak

since last data point

* Only for 2-channel version CPH62I0-S2

28 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 29

6. Commissioning, operation

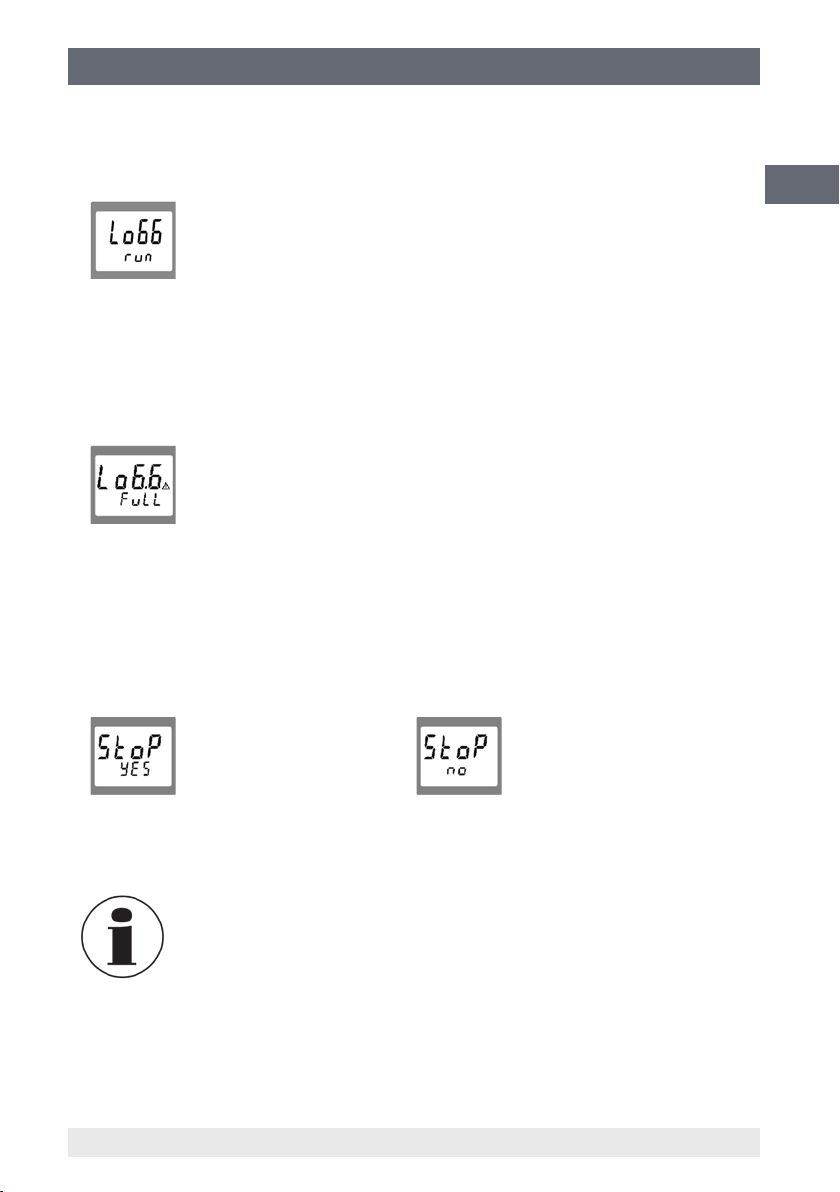

Starting logging:

By pressing ´STORE/QUIT´ for 2 seconds the logger operation will be selected. The

display will show:

By pressing ´STORE/QUIT´ again briey, the recording will be initiated.

After that the display shows ‘St.XXXX‘ for a short time whenever a measurement is

recorded. XXXX is the number of the measuring 1 ... 4000 or 10000.

If the logger memory is full, the display will show:

The recording will be stopped automatically.

If the Low-Power-Logger-function is selected "Lo.Po = on" the device switches itself o

as soon as the memory becomes full.

Stopping the logging manually:

By pressing the ´STORE/QUIT´ key, recording can be manually interrupted. The follow-

ing choice then appears:

GB

Stop recording Do not stop recording

The selection can be made with the ´MAX´ key and ´MIN´ key. The ´STORE/QUIT´ key

conrms the selection.

If you try to switch o the instrument during a logging cycle, you will

also be asked if you wish to stop recording. The device can only be

switched o after the recording has been stopped!

The Auto-Power-O-function is deactivated during logging!

11221801.02 02/2011 GB/D/F/E

29WIKA operating instructions, model CPH62I0

Page 30

6. Commissioning, operation

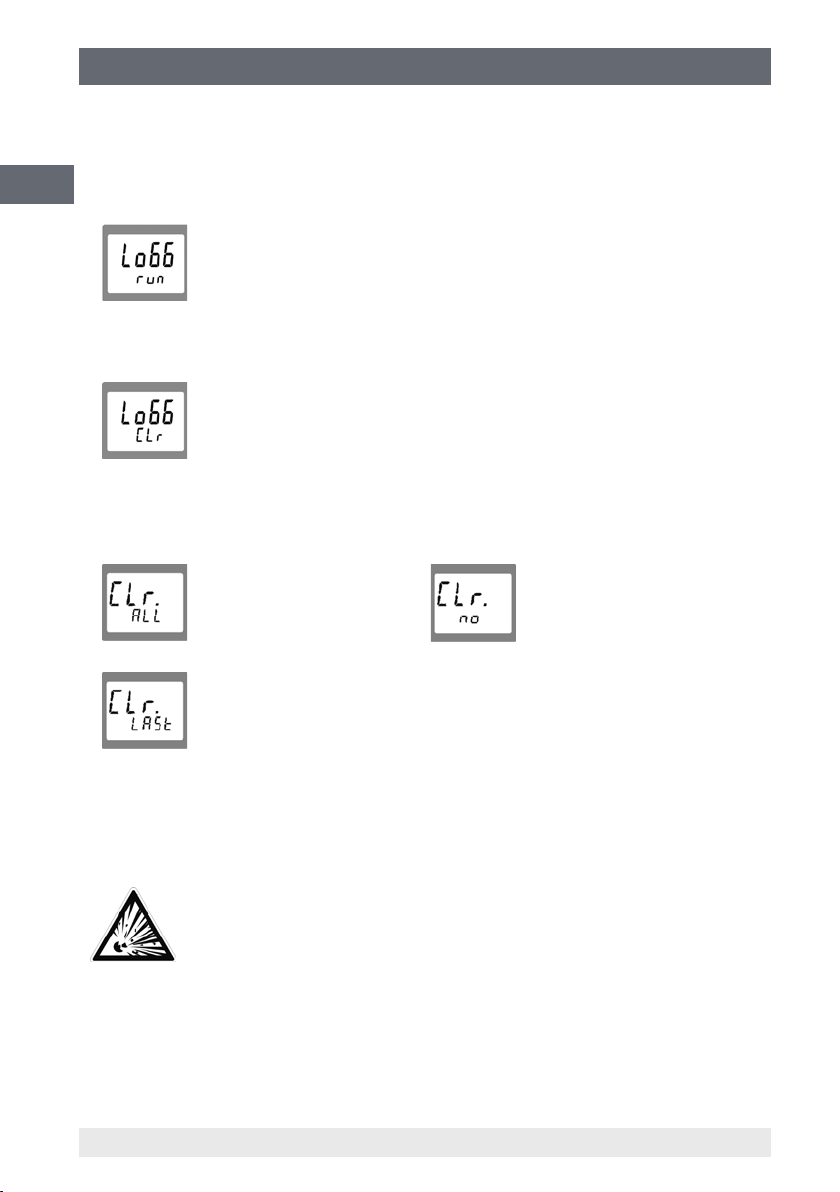

Clearing data:

When the ´STORE/QUIT´ key is pressed for 2 seconds, the logger operation will be

selected.

GB

The display will show:

By briey pressing the ´MAX´ key or ´MIN´ key, the display will change to:

When ´STORE/QUIT´ is pressed, the choice for clearing the logger memory will be

displayed:

clear all recordings clear nothing

(cancel menu)

clear the last recording

sequence

The selection can be made with the ´MAX´ key and ´MIN´ key. The ´STORE/QUIT´ key

conrms the selection.

6.5 The serial interface

WARNING!

The serial interface is not allowed to be operated in hazardous areas.

For data transfer to a computer there are two electrically-isolated interface adapters

available (see price list calibration technology) for connection to a RS-232 or USB interface (USB-driver necessary).

(See calibration technology price list: Data logger evaluation software GSoft.)

30 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 31

6. Commissioning, operation / 7. Maintenance, cleaning ...

6.6 Available pressure sensors

The instrument has been designed so that all model CPT62I0 pressure sensors can be

connected without the need for any conguration or recalibration. A wide range of interchangeable sensors is therefore available, with ranges of up to 1000 bar (see current

price list for model CPT62I0 pressure sensors).

7. Maintenance, cleaning and servicing (recalibration)

7.1 Maintenance

The hand-held pressure indicator CPH62I0 is maintenance-free.

Repairs must only be carried out by the manufacturer. This does not apply to the battery

replacement.

The safety of the operator may be endangered if, for example:

■

there is visible damage to the instrument.

■

the instrument is not working as specied.

■

the instrument has been stored under unsuitable conditions for an extended period of

time.

If there is any doubt, please return the instrument to the manufacturer for repair or

maintenance.

GB

7.2 Cleaning

CAUTION!

For information on returning the hand-held pressure indicator see

chapter “9.2 Return”.

11221801.02 02/2011 GB/D/F/E

■

Before cleaning, correctly disconnect the hand-held pressure

indicator from the pressure supply, switch it o and disconnect it

from the mains.

■

Clean the hand-held pressure indicator with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted hand-held pressure indicator or

pressure sensor before returning it, in order to protect persons and

the environment from exposure to residual media.

■

Residual media in dismounted hand-held pressure indicators or

pressure sensor can result in a risk to persons, the environment and

equipment. Take sucient precautionary measures.

31WIKA operating instructions, model CPH62I0

Page 32

7. Maintenance, cleaning and servicing (recalibration) / 8. Faults

7.3 Recalibration

DKD/DAkkS certicate - Certicates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

GB

time intervals of approx. 12 months. Every factory recalibration includes, additionally, an

extensive free-of-charge check of all system parameters with respect to their compli-

ance with the specication. The basic settings will be corrected if necessary.

8. Faults

Display Meaning Measures

Low battery power, device will only

work for a short while longer

Battery at Replace battery

Replace battery

SEnS

Erro

or Err.9

- - - -

- - - -

No display or

strange symbols, device is

not responding to input

Mains operation without battery:

incorrect voltage

No sensor connected Switch o device and connect

Connected sensor or device faulty If second sensor available, check

Value signicantly out of measuring

range

Logger data is being read by the

serial interface

Battery at Replace battery

Mains operation without battery:

incorrect voltage or polarity

System error Disconnect battery or power supply,

Instrument faulty Return to manufacturer for repair

Check power supply, change it if

necessary

sensor

if device is ok. Return defective

device/sensor to manufacturer for

repair

Check: pressure not within sensor

range?

When the data transfer is complete

the device will automatically return

to normal measuring display, no

remedy necessary

Check power supply, change it if

necessary

wait a while, re-connect

32 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 33

8. Faults

Display Meaning Measures

Err.1

Measured value above allowable

range

Sensor faulty Return to manufacturer for repair

Check: Is the pressure outside the

sensor‘s range? -> measured value

too high!

GB

Err.2

Err.3

Err.4

Err.7

Err.11

Measured value below allowable

range

Sensor defective Return to manufacturer for repair

Display range exceeded Check: value above 9999 -> too high

Display range underow Check: value below ‚-2000‘ (Tare?)

System error Return to manufacturer for repair

Value could not be calculated Choose dierent unit

Calculation range exceeded Choose dierent unit

Check: Is the pressure outside the

sensor‘s range? -> measured value

too low!

to be displayed!

-> too low!

WARNING!

If faults cannot be eliminated by means of the measures listed above,

the instrument must be shut down immediately, and it must be ensured

that pressure and/or signal are no longer present, and it must be

prevented from being inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter “9.2

Return”.

11221801.02 02/2011 GB/D/F/E

33WIKA operating instructions, model CPH62I0

Page 34

9. Dismounting, return and disposal

9. Dismounting, return and disposal

GB

9.1 Dismounting

Only disconnect test and calibration installations once the system has been depressurised!

9.2 Return

When returning the hand-held pressure indicators, use the original packaging or a

suitable transport package.

To avoid damage:

1. Wrap the hand-held pressure indicator in an antistatic plastic lm.

2. Place the hand-held pressure indicator, along with the shock-absorbent material, in

the packaging. Place shock-absorbent material evenly on all sides of the transport

packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

WARNING!

Residual media in dismounted hand-held pressure indicator can result

in a risk to persons, the environment and equipment. Take sucient

precautionary measures.

WARNING!

Strictly observe when shipping the hand-held pressure indicators:

All hand-held pressure indicators delivered to WIKA must be free from

any kind of hazardous substances (acids, bases, solutions, etc.).

Enclose the completed return form with the hand-held pressure indicator.

The return form is available on the internet:

www.wika.de / Service / Return

34 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 35

9. Dismounting, return and disposal / 10. Accessories

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities. See EU

Directive 2002/96/EC.

10. Accessories

You can nd accessories such as various pressure adapters, “Minimess” quick-connect

process connection system, pressure generation, reservoir and pressure hoses, service

cases, data logger evaluation software GSoft, light calibration software EasyCal for

CPH6200/CPH62I0, 9 V-battery, AC power supply unit/charger for Europe, Japan, UK or

USA, etc. in the current WIKA price list: Testing and calibration technology.

GB

11221801.02 02/2011 GB/D/F/E

35WIKA operating instructions, model CPH62I0

Page 36

Appendix 1: Declaration of Conformity for model CPH62I0

GB

36 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 37

Appendix 2: Declaration of Conformity for model CPT62I0

GB

11221801.02 02/2011 GB/D/F/E

37WIKA operating instructions, model CPH62I0

Page 38

Appendix 3: EC-type examination certicate for model CPH62I0

GB

38 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 39

Appendix 3: EC-type examination certicate for model CPH62I0

GB

11221801.02 02/2011 GB/D/F/E

39WIKA operating instructions, model CPH62I0

Page 40

Appendix 3: EC-type examination certicate for model CPH62I0

GB

40 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 41

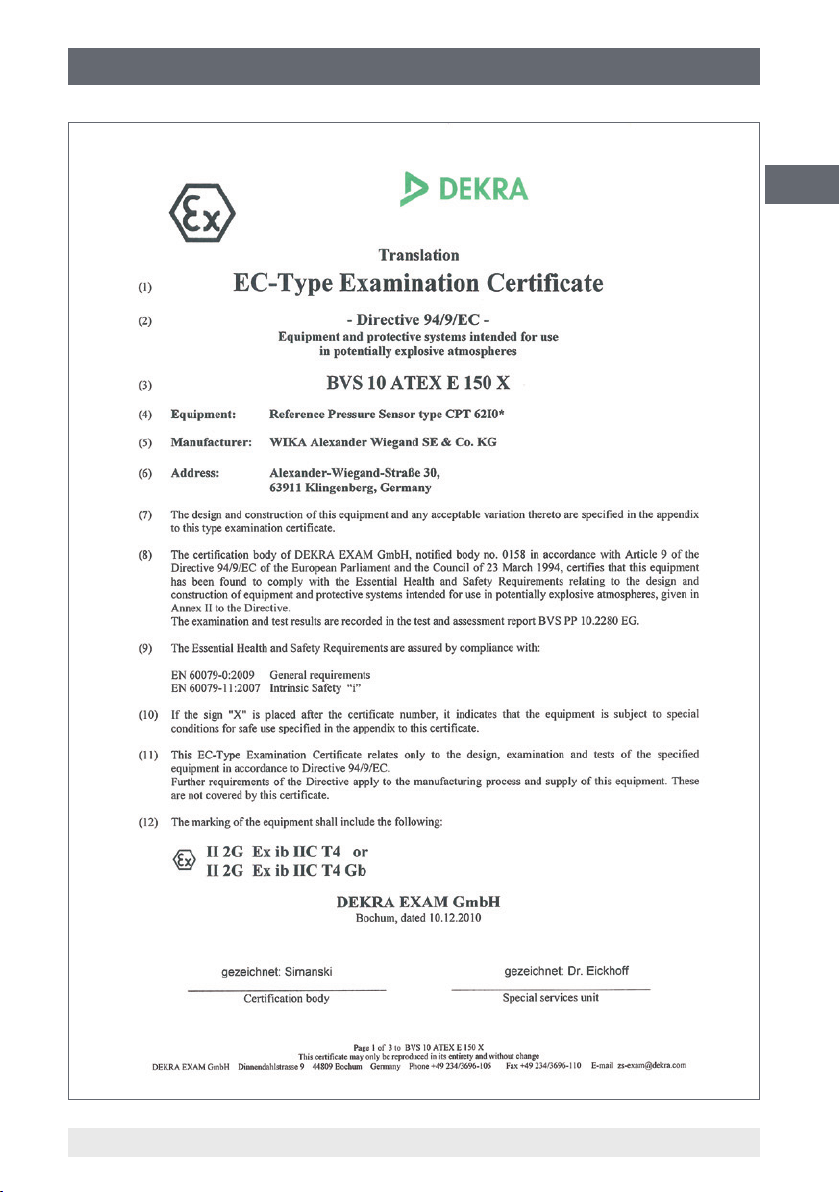

Appendix 4: EC-type cxamination certicate for model CPT62I0

GB

11221801.02 02/2011 GB/D/F/E

41WIKA operating instructions, model CPH62I0

Page 42

Appendix 4: EC-type cxamination certicate for model CPT62I0

GB

42 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 43

Appendix 4: EC-type cxamination certicate for model CPT62I0

GB

11221801.02 02/2011 GB/D/F/E

43WIKA operating instructions, model CPH62I0

Page 44

GB

44 WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 45

Inhalt

Inhalt

1. Allgemeines 46

2. Sicherheit 47

3. Technische Daten 53

4. Aufbau und Funktion 56

5. Transport, Verpackung und Lagerung 59

6. Inbetriebnahme, Betrieb 60

7. Wartung, Reinigung und Rekalibrierung 73

8. Störungen 74

9. Demontage, Rücksendung und Entsorgung 76

10. Zubehör 77

Anlage 1: EG-Konformitätserklärung für Typ CPH62I0 78

Anlage 2: EG-Konformitätserklärung für Typ CPT62I0 79

Anlage 3: EG-Baumusterprüfbescheinigung für CPH62I0 80

Anlage 4: EG-Baumusterprüfbescheinigung für CPT62I0 83

D

Konformitätserklärungen nden Sie online unter www.wika.de.

11221801.02 02/2011 GB/D/F/E

45WIKA Betriebsanleitung, Typ CPH62I0

Page 46

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Hand-Held Druckmessgerät wird nach

den neuesten Erkenntnissen konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

D

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Hand-Held

Druckmessgerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller

angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Hand-Held Druckmessgerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Hand-Held Druckmessgerätes für das Fachpersonal jederzeit zugänglich aufbewahrt

werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Hand-Held Druckmessgerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: CT 11.02

- Anwendungsberater:

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

46 WIKA Betriebsanleitung, Typ CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 47

1. Allgemeines

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu

geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für

einen ezienten und störungsfreien Betrieb hervor.

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder

tödlicher Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen

führen kann, wenn sie nicht gemieden wird.

D

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das

richtige Hand-Held Druckmessgerät und der richtige Drucksensor

hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

11221801.02 02/2011 GB/D/F/E

47WIKA Betriebsanleitung, Typ CPH62I0

Page 48

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Das Hand-Held Druckmessgerät CPH62I0 kann als Kalibriergerät sowie für jede

Anwendung, bei der eine genaue Druckmessung erforderlich ist, im explosionsgefährdeten Bereich verwendet werden.

Das Hand-Held Druckmessgerät ist ausschließlich für den hier beschriebenen bestim-

D

mungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Hand-Held Druckmessgerätes

außerhalb der technischen Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten WIKA-Servicemitarbeiter erforderlich.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statische Elektrizität und extremen Temperaturen schüt-

zen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und Buchsen

vor Verschmutzung schützen.

Wird das Hand-Held Druckmessgerät von einer kalten in eine warme Umgebung transportiert, so kann durch Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor

einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezi-

schen Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen

Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

48 WIKA Betriebsanleitung, Typ CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 49

2. Sicherheit

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Zusätzliche Sicherheitshinweise für Geräte mit ATEX-Zulassung

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust

des Explosionsschutzes führen.

Das Hand-Held Druckmessgerät CPH62I0 dient zur Messung von

Absolut- und/oder Relativdruck. Die 2-Kanal-Ausführung dient zusätzlich zur Messung von Dierenzdruck. Die Messung erfolgt mit zugehörigem externen Drucksensor.

■

Batteriebetrieb:

Es dürfen nur zulässige 9 V-Batterien verwendet werden!

Der Batterietausch nur außerhalb des explosionsgefährdeten Bereiches durchführen!

Zulässige Batterien sind:

Batterietyp Hersteller Batteriebezeichnung

6F22 GB GREENCELL, 9 V (1604G)

6LF22

oder

6LR61

GP SUPER Alkaline, 9 V (1604A)

Duracell DURACELL PLUS, Alkaline, 9 V

Varta powerone alkaline, 9 V (No. 4122)

Varta INDUSTRIAL, Alkaline, 9V (No. 4022)

D

11221801.02 02/2011 GB/D/F/E

■

Ex-Betrieb:

Im explosionsgefährdeten Bereich die zugehörige Ledertasche

verwenden!

■

Schnittstelle:

Der Betrieb der seriellen Schnittstelle ist im explosionsgefährdeten

Bereich nicht zulässig!

Der Anschluss und Betrieb ist nur außerhalb des explosionsgefährdeten Bereiches zulässig!

Nur die von WIKA bestimmten Schnittstellenkonverter verwenden!

■

Drucksensor:

Es dürfen nur Drucksensoren Typ CPT62I0 verwendet werden! Mit

anderen Drucksensoren kann es zur Zerstörung des Messgerätes

und des Drucksensors kommen.

49WIKA Betriebsanleitung, Typ CPH62I0

Page 50

2. Sicherheit

D

Bei Verwendung von zwei Drucksensoren Typ CPT62I0 darauf

achten, dass diese nicht auf Oberächen gelegt, bzw. eingeschraubt werden, die unterschiedliche Potentiale aufweisen!

Für die elektrische Verbindung zwischen Drucksensor CPT62I0 und

Hand-Held Druckmessgerät CPH62I0 ist nur das hierfür vorgesehene original WIKA Anschlusskabel zu verwenden. Dies gilt ebenfalls

für das Verlängerungskabel, womit die maximal zulässige Gesamtkabellänge von knapp 5 m erreicht wird.

■

Temperaturbereich:

Das Gerät darf unter -10 °C nicht betrieben werden. Zulässige

Umgebungstemperatur: -10 ... +50 °C.

■

Netzgerätebetrieb:

Nur von WIKA bestimmte Netzteile verwenden! Der Betrieb des

Gerätes mit externer Stromversorgung ist im explosionsgefährdeten

Bereich nicht zugelassen.

■

Analogausgang:

Der Betrieb des Analogausganges ist im explosionsgefährdeten

Bereich nicht zulässig!

Nur passive Spannungsmessgeräte am Analogausgang anschließen.

■

Potentialausgleich:

Die am Gerät angeschlossenen Komponenten (Drucksensor,

Netzteil, Schnittstelle) nicht auf unterschiedliche Potentiale legen

oder mittels Potentialausgleich verbinden.

Für den Ex-Betrieb nur Drucksensoren anschließen!

Bei zwei angeschlossenen Drucksensoren beachten, dass diese

an dem selben elektrischen Potential angeschlossen sind oder ein

Potentialausgleich besteht.

■

Umgebungsbedingungen:

Das Gerät keinen Umgebungen aussetzen, die das Eindringen von

Feuchtigkeit, Wasser, leitenden Flüssigkeiten oder Staub in das

Gerät ermöglichen.

■

Nicht-eigensicherer Einsatz:

Das Hand-Held Druckmessgerät ist auch als nicht-eigensicheres

Gerät zum Anschluss an nicht-eigensichere Geräte (z. B. Netzteil,

Schnittstellenkonverter) einsetzbar.

Auch in diesem Betriebszustand nur freigegeben Zubehörteile

verwenden!

Vor der Wiederbenutzung des Hand-Held Druckmessgerätes als

eigensicheres Gerät, ist vor dem Einschieben in die Ledertasche

eine allgemeine Prüfung auf äußere Schäden und Funktionalität

vorzunehmen!

50 WIKA Betriebsanleitung, Typ CPH62I0

11221801.02 02/2011 GB/D/F/E

Page 51

2. Sicherheit

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die

jeweiligen landesspezischen Vorschriften zur Installation und Einsatz

in explosionsgefährdeten Bereichen (z. B. VDE 0165, IEC 60079-14,

NEC, CEC) einhalten. Bei Nichtbeachten können schwere Körperver-

letzungen und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit ATEX-Zulassung

siehe Kapitel „2.3 Zusätzliche Sicherheitshinweise für Geräte mit

ATEX-Zulassung“.

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc.

müssen über die gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare

Lebensgefahr.

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von

Netzspannung zur Ausgangsspannung) können am Hand-Held Druckmessgerät lebensgefährliche Spannungen auftreten!

D

WARNUNG!

Messstoreste am ausgebauten Hand-Held Druckmessgerät oder

Drucksensor können zur Gefährdung von Personen, Umwelt und

Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Am Drucksensor können im Fehlerfall aggressive Medien mit extremer

Temperatur und unter hohem Druck oder Vakuum anliegen.

Wenn anzunehmen ist, dass das Gerät nicht mehr gefahrlos betrieben werden kann, so

ist es außer Betrieb zu setzen und vor einer Wiederinbetriebnahme durch Kennzeichnung zu sichern.

Die Sicherheit des Benutzers kann durch das Gerät beeinträchtigt sein, wenn es zum

Beispiel:

■

sichtbare Schäden aufweist.

■

nicht mehr wie vorgeschrieben arbeitet.

■

längere Zeit unter ungeeigneten Bedingungen gelagert wurde.

In Zweifelsfällen das Gerät grundsätzlich an den Hersteller zur Reparatur bzw. Wartung

einschicken.

11221801.02 02/2011 GB/D/F/E

51WIKA Betriebsanleitung, Typ CPH62I0

Page 52

2. Sicherheit

2.5 Beschilderung / Sicherheitskennzeichnungen

2.5.1 Typenschild für Hand-Held Druckmessgerät

Symbolerklärung siehe unten

D

2.5.2 Typenschild für Drucksensor

Symbolerklärung

Vor Montage und Inbetriebnahme des Hand-Held Druckmessgerätes

unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Hand-Held Druckmessgeräte mit dieser Kennzeichnung stimmen

überein mit den zutreenden europäischen Richtlinien.

Typ:

1-Kanal-Version: CPH62I0-S1

2-Kanal-Version: CPH62I0-S2

Zulassungsnummer

Herstellungsdatum (Jahr/Monat)

Kennnummer der benannten Stelle, die

das Qualitätssicherungssystem für die

Produktion überwacht

Symbolerklärung siehe unten

Typ

Zulassungsnummer

Herstellungsdatum (Jahr/Monat)

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = Ex)