Page 1

Operating Instructions

Betriebsanleitung

Mode d’emploi

Manual de Instrucciones

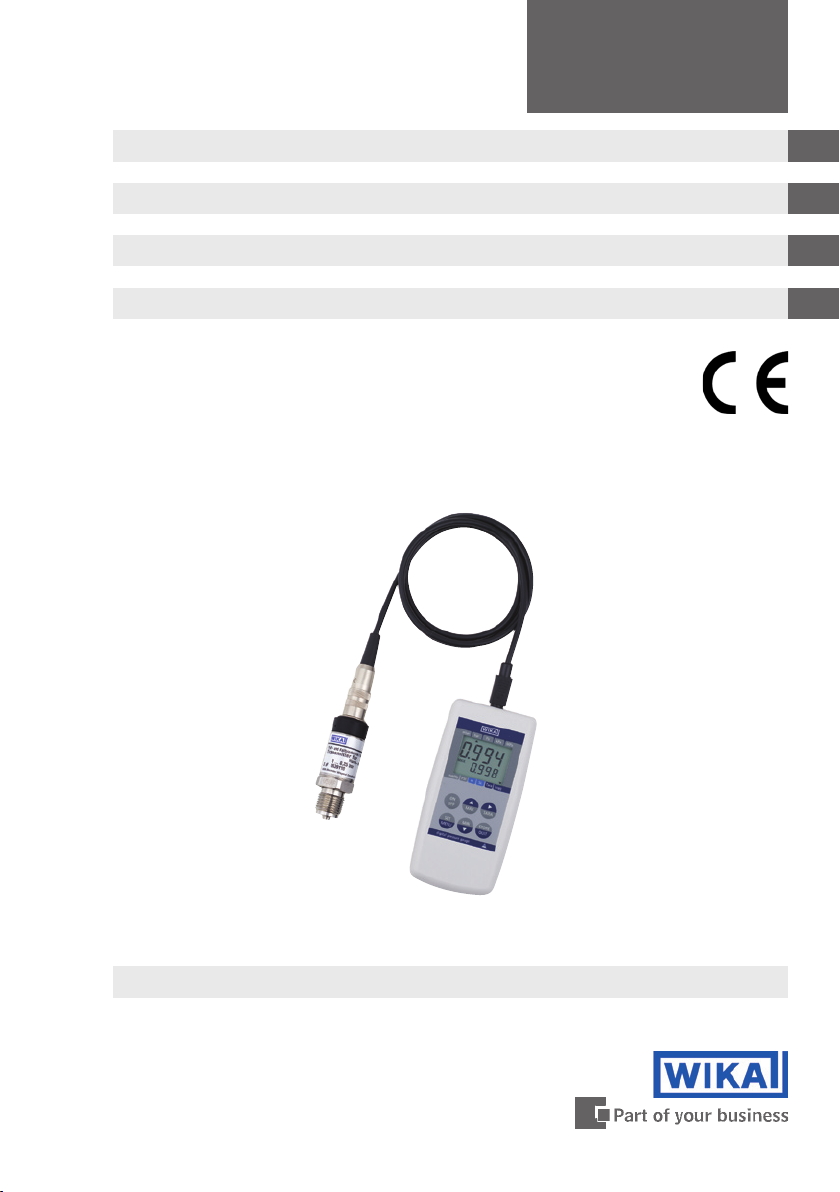

Hand-Held Pressure Indicator

Hand-Held Druckmessgerät

l'indicateur de pression portable

Manómetro portátil

CPH6200-S1

CPH6200-S2

GB

D

F

E

Model CPH6200-S1 / -S2

Page 2

Hand-Held Pressure Indicator Page 2 - 25

GB

D

Hand-Held Druckmessgerät Seite 26 - 49

F

l'indicateur de pression portable Page 50 - 73

E

Manómetro portátil Página 74 - 97

Information

This symbol provides you with information, notes and tips.

Warning!

This Symbol warns you against actions that can cause injury to

people or damage to the instrument.

11221780.1.3 01/2009 GB/D/F/E

2

Page 3

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

Contents

1. General 4

1.1 General safety instructions 5

1.2 Operation and maintenance advice 6

1.3 Electrical connections 7

1.4 Display 8

1.5 Basic operation 8

2. Configuration 12

2.1 (Unit) Choice of pressure units 13

2.2 (SL) Sea-level correction for absolute pressure sensors 13

2.3 (rAtE) Choice of measuring rates: „rAtE-Slo, -P.dEt, -FASt“ 13

2.3.1 rAtE-Slo: standard measuring 13

2.3.2 rAtE-P.dEt: peak detection 14

2.3.3 rAtE-FASt: fast filtered measuring 14

2.4 Averaging function 14

2.5 Zero correction sensor 1 (OFS.1) and sensor 2 (OFS.2) 15

2.6 Span correction sensor 1 (SCL.1) and sensor 2 (SCL.2) 15

2.7 (P.oFF) Power off function 15

2.8 (Out) Output 15

2.8.1 (Adr.) Serial communications address 15

2.8.2 (dAC.) Analogue output – scaling with dAC.0 and dAC.1 16

2.9 (AL.) Alarm 16

2.10 (CLOC) Real time clock 17

3. Operation of logger 17

3.1 “Func-Stor“: Storing discrete measurements 17

3.2 “Func-CYCL“: Automatic datalogging with adjustable cycletime

4. The serial interface 21

5. Available pressure sensors 21

6. Fault and system messages 22

7. Calibration services 23

8. Specifications 23

9. Accessories 25

19

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 3

Page 4

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator4

1. General

In the following chapters detailed information on the hand-held pressure

indicator CPH6200 and its proper use can be found.

Should you require further information, or should there be problems

which are not dealt within detail in the operating instructions, please

contact the address listed on the last page.

Factory calibration of the instrument is according to relevant international standards.

The warranty period for the CPH6200 hand-held pressure indicator is 24

months according to the general terms of supply of ZVEI.

The guarantee is void if the appliance is put to improper use or if the

operating instructions are not observed or if an attempt is made to open

the appliance.

We also point out that the content of these operating instructions

neither forms part of an earlier or existing agreement, assurance or

legal relationship nor is meant to change these. All obligations of WIKA

Alexander Wiegand GmbH & Co. KG result from the respective sales

contract and the general business terms of WIKA Alexander Wiegand

GmbH & Co. KG.

WIKA is a registered trade mark of WIKA Alexander Wiegand GmbH &

Co. KG. Names of companies or products mentioned in this handbook

are registered trade marks of the manufacturer.

We reserve the right to effect reasonable changes on the basis of technical improvements.

Any reproduction of this manual or parts thereof by any means is

prohibited.

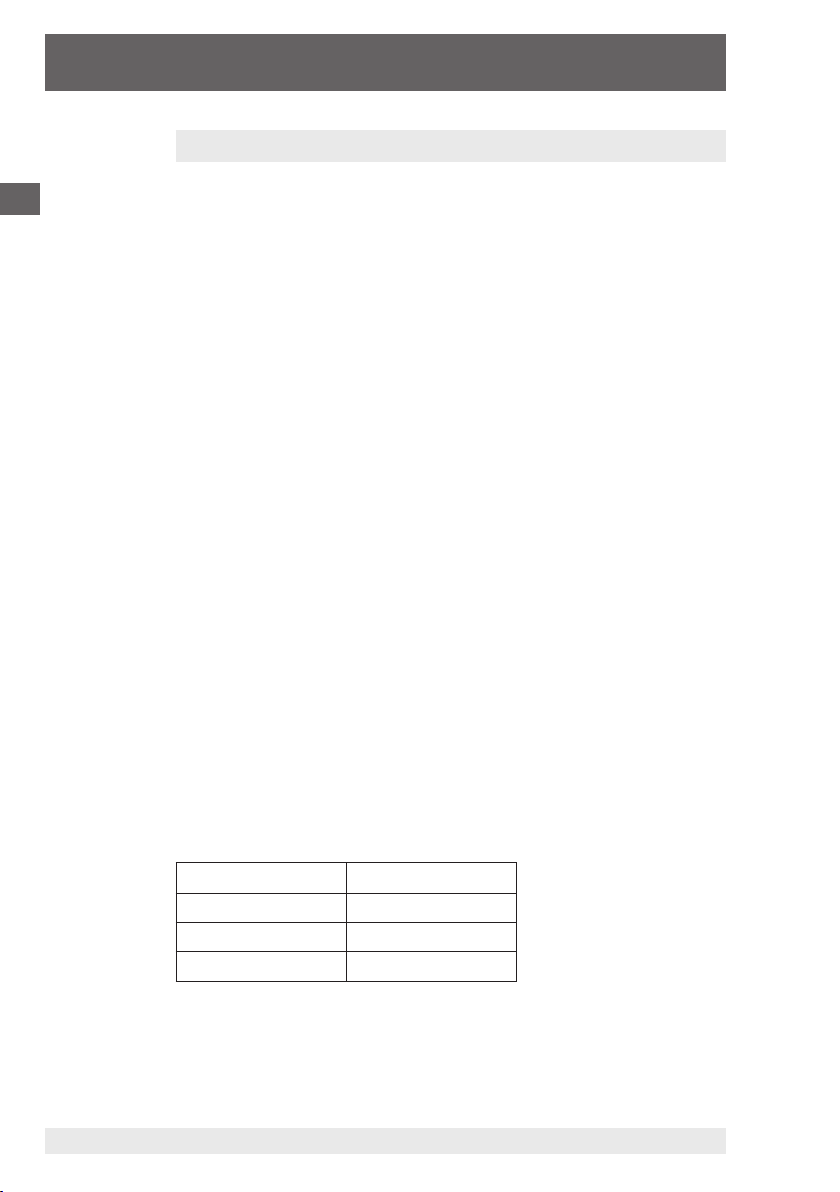

Version key regarding firmware and respective manual.

Manual Firmware

V 1.1 V 4.0 - V 4.9

V 1.2 V 5.0 - V 6.0

V 1.3 > V 6.0

© 2005 Copyright WIKA Alexander Wiegand GmbH & Co. KG

Page 5

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

1.1 General safety instructions

This device has been designed and tested in accordance with the

relevant safety regulations for electronic devices. However, its

trouble-free operation and reliability cannot be guaranteed unless

the standard safety measures and special safety advise given in this

manual is followed when using the device.

1. Trouble-free operation and reliability of the device can only be

guaranteed so long as the device is not subjected to any climatic

conditions other than those stated under “8. Specification“.

2. The device and sensors must be handled with care (don‘t throw, hit,

etc.). Protect plugs and sockets from contamination.

3. If the device is moved from a cold to a warm environment, condensa

tion may cause the equipment to fail. You should therefore ensure the

device temperature has adjusted to the ambient temperature before

trying to switch it on.

4. If the instrument is to be connected to other devices (e.g. via serial

interface) care must be taken when designing the equipment connections. It is possible that internal wiring within the external device (e.g.

connection of GND to Earth) may cause excessive voltages which

could harm or destroy the instrument or other connected devices.

If the device is operated with a faulty mains power supply (e.g.

short circuit from mains voltage to output voltage) this could result

in dangerous voltages at the device (e.g. at the sensor socket or

serial interface).

5. If there is any risk whatsoever involved in using it, the device must be

switched off immediately and marked accordingly to prevent re-use.

GB

-

Operator safety may be at risk if:

There is visible damage to the device

The device is not working as specified

The device has been stored under unsuitable conditions for an

extended period of time.

If there is any doubt, please return the device to the manufacturer for

repair or maintenance.

6. Customers must not attempt to alter or repair the device themselves.

Please return the device to the manufacturer for any repair or maintenance.

7. Any operation not included in the following instructions or outside the

specifications must not be attempted.

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 5

Page 6

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator

6

1.2 Operation and maintenance advice

Battery operation

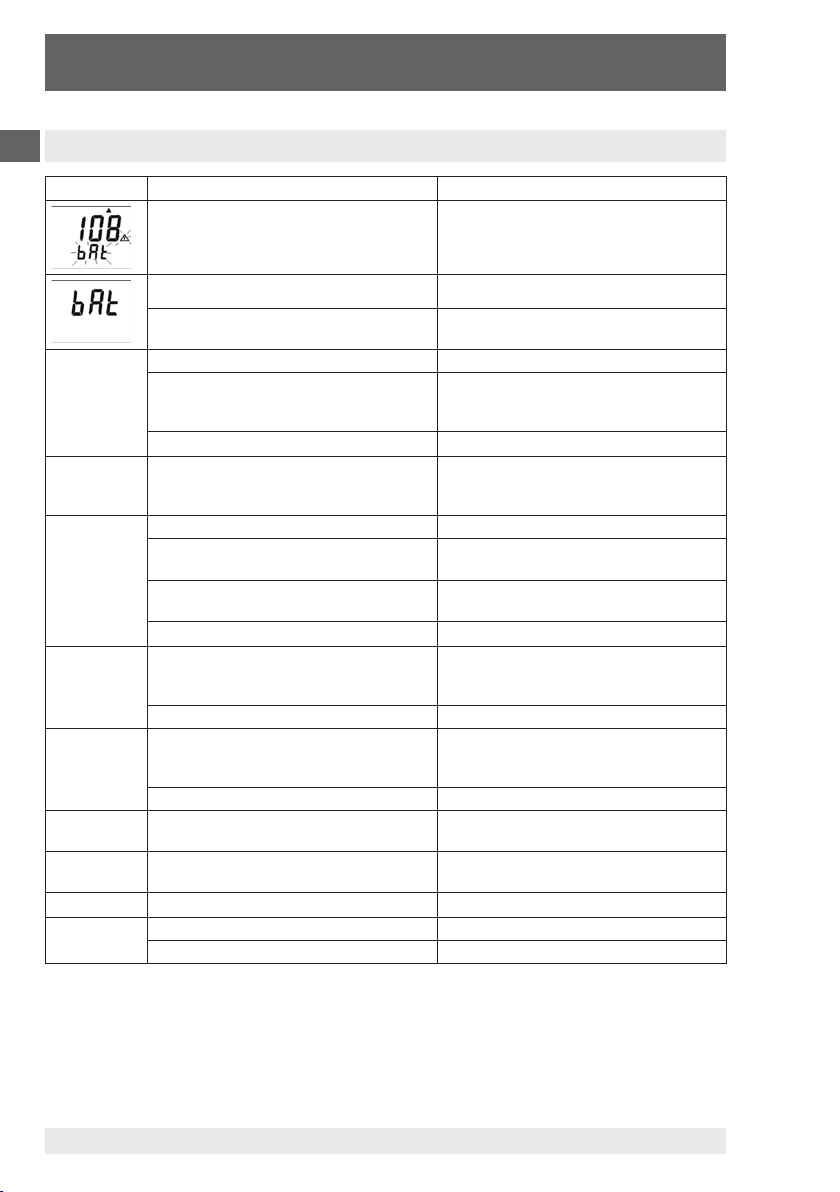

If ´bAt´ is shown in the lower display the battery is low and needs to

be replaced or recharged (using the appropriate battery charger as

shown in the current CPH6200 price list ).

The device will, however, work normally for a limited period. If ´bAt´

is shown in the upper display the voltage is too low to operate the

device; the battery will be completely flat.

A) If the device is not going to be used for some time, we advise that

the battery is removed.

B) The real time clock has to be set again after reconnect to the battery

Mains operation with power supply

When using a power supply please note that the operating voltage

must be 10.5 to 12 V DC. Do not use with higher voltages! Cheap

12 V-power supplies often have excessive no-load voltage, and

we therefore recommend using regulated-voltage power supplies.

Trouble-free operation can be ensured by using our own power

supply unit (see current CPH6200 price list). Before connecting the

power supply to the mains make sure that its operating voltage

matches the local mains voltage.

Connecting/Changing sensors

Only use sensors model CPT6200. Using other sensors can damage

the instrument! Switch off device before changing the sensor and

connect the sensor before turning the device back on, otherwise the

sensor may not be identified correctly.

The CPH6200 and the pressure transmitter are connected using a

discrete connecting cable. When changing the pressure transmitter,

always connect and disconnect at the transmitter end of the cable. To

connect the transmitter, rotate the plug till it locates in the guide slot,

allowing it to plug in. Then tighten the safety collar (by screwing it lightly

in a clockwise direction).

When connecting the cable to the CPH6200, the connector might not

locate properly in the socket. In this instance you should try holding the

plug by the cable strain relief, rather than by the connector housing. If

the plug is correctly located, it will slide in smoothly. To disconnect the

sensor hold it by the plug to release the connector lock. Do not pull the

cable to release it.

Page 7

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

For gauge sensors, the pressure compensation vent hole is found

at the top of the sensor housing. This vent (with integral membrane

seal) must be kept clear without fail.

Maintenance advice

Both the CPH6200 and sensors are manufactured using solidstate

technology, and contain no moving parts which could wear. If the

instrument housing has been opened, the warranty becomes invalid.

If cleaning is necessary, use a cloth wetted with mild detergent. Avoid

any solvents, caustic or abrasive substances.

As is normal for all measuring instruments, the accuracy of the device

should be tested at regular intervals (approx. once per year - see

Section 7).

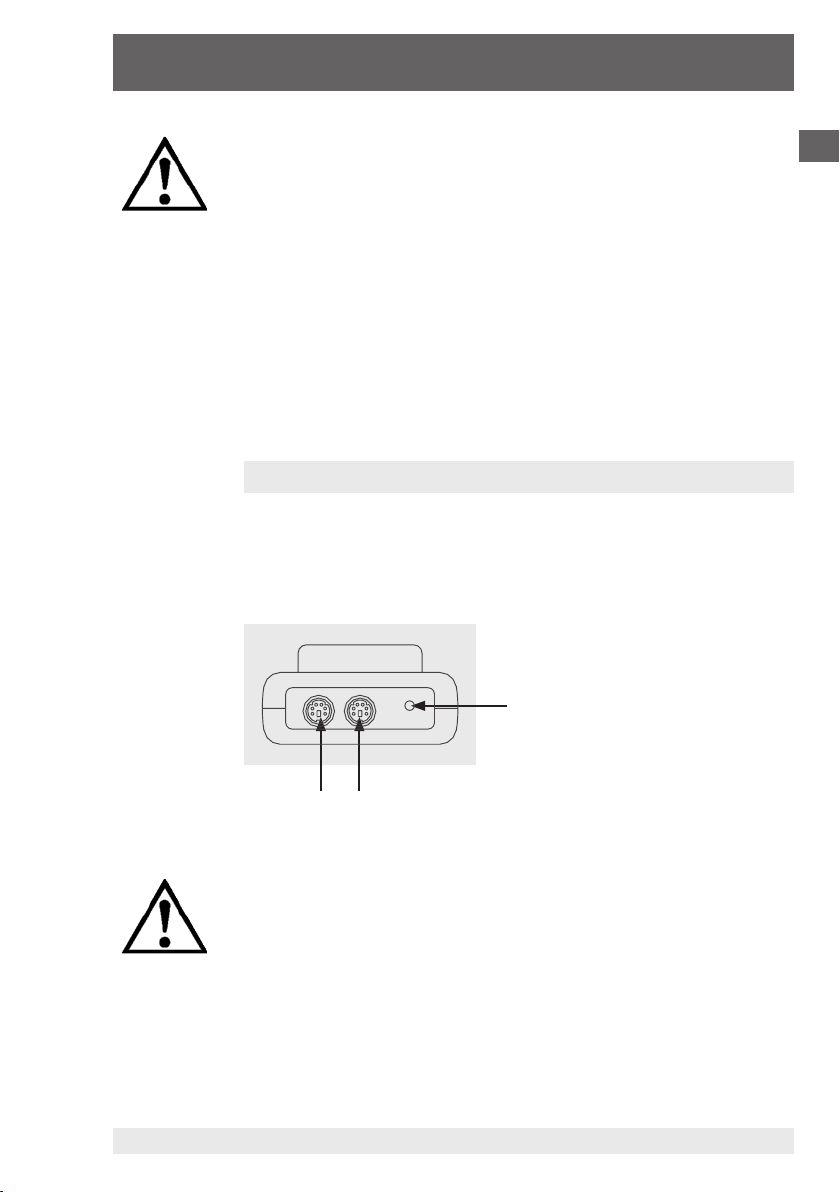

1.3 Electrical connections

On the upper edge of the device:

The connector sockets for attaching the CPH series pressure sensors,

CH1 and CH2 (CH2 only with the 2-channel version), are located on the

top edge of the CPH6200 (see Section 5), as is the socket for the WIKA

interface cable (see Section 4).

Connection for WIKA interface cable

or optional analogue output

GB

CH1 CH2 (only for 2-channel version: CPH6200-S2)

Operation as analogue output: connection via suitable cable.

The output mode has to be configured via menu and influences

battery life!

On the left side of the device:

The mains adapter socket for connecting the power supply unit (see

current CPH6200 price list) is located on the left side of the handheld

unit.

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 7

Page 8

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator

8

1.4 Display

1

2

6

3

4

5

1. Main display: shows the current measured value of CH1.

2. Lower display:

For 2-channel version shows the measured value

of CH2 or DIF (CH1-CH2). For 1 channel version it displays the min,

max or hold function values.

3. Logg:

shown if logger function is selected, flashes if cyclic logger is

running.

4. Tare:

5. SL:

6. Measuring unit:

indicates that tare function is activated.

indicates, that the sea level function is activated.

an arrow points to the chosen measuring unit.

1.5 Basic operation

On turning the device on; if the logger function is selected, the

integrated clock‘s time will be displayed briefly. If a zero point adjustment has been carried out, the display will indicate this by showing

"nuLL- Corr".

After changing the battery the menu for setting the clock is activated

automatically ('CLOC'). Check the clock and adjust if necessary (see

Section 2).

5

1

2

3

4

5

Page 9

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

1. On/Off key

2. Set/Menu: Enter Configuration Menu (press for 2 sec)

3. Tare: Activate tare function, zero point adjustment

4. Store/Quit: Activate hold function or logger function (see Section “3.

5. Min/Max: Display the respective min-/max-memory value in lower

Max-Function: Pressing ´Max´ shows the maximum measured value record-

Min-Function: Pressing ´Min´ shows the minimum measured value record-

Hold-Function:

Logger-Functions: Activated by the

Tare-Functions: By pressing ´Tare´, the display will be set to 0. All measure-

Operation of logger”.)

display

ed. Pressing it again hides it. To clear the max-memory press

the ´Max´ key for > 2 seconds.

ed. Pressing it again hides it. To clear the min-memory press

the ´Min´ key for > 2 seconds.

By pressing ´Store/Quit´ the instantaneous measured value

will be shown in the lower display. Pressing it again hides it.

(Only when the main menu item logger = ‘off‘ is selected).

been selected via the main menu (see Section “3. Operation

of logger”).

ments from then on will be displayed relative to the set tare

value. When the tare function is activated, the arrow ´Tare´

appears in the display. To deactivate the tare function press

´Tare´ for > 2 seconds.

´Store/Quit´

key, only if the logger has

Activating/deactivating tare clears the max- and min-memories.

Zero-Point Adjust: (for gauge pressure sensors only) If there is no pressure

applied to the pressure ports the device will display 0. If

there is a permanent offset (and the device is being used

under steady conditions), a permanent zero point adjustment can be carried out. To carry out the adjustment, press

´Tare´ for approx. 5 seconds. (Please note: A zeropoint

adjustment can only be made if the difference between the

display value and the factory calibration value is less than 2

%! E.g. for a measuring range of 0 ... 25 bar, => zeropoint

adjustment up to 0.5 bar possible). To revert to the factory

calibration, press ´Tare´ for approx. 15 seconds.

GB

A zero-point adjustment can only be carried out if the difference

between the value on display is less than 500 digits!

If a zero-point adjustment has been made, this will be signalled by the

message “nuLL-Corr“ being displayed briefly as the device is turned on.

Differential pressure: Pressing ´Set/Menu´ shows the difference between

the measured values of Channel 1 and Channel 2

(DIF=CH1-CH2) in the lower display. Pressing it again will

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 9

hide it (only with the 2-channel version and when 2 sensors

are connected).

Page 10

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator

10

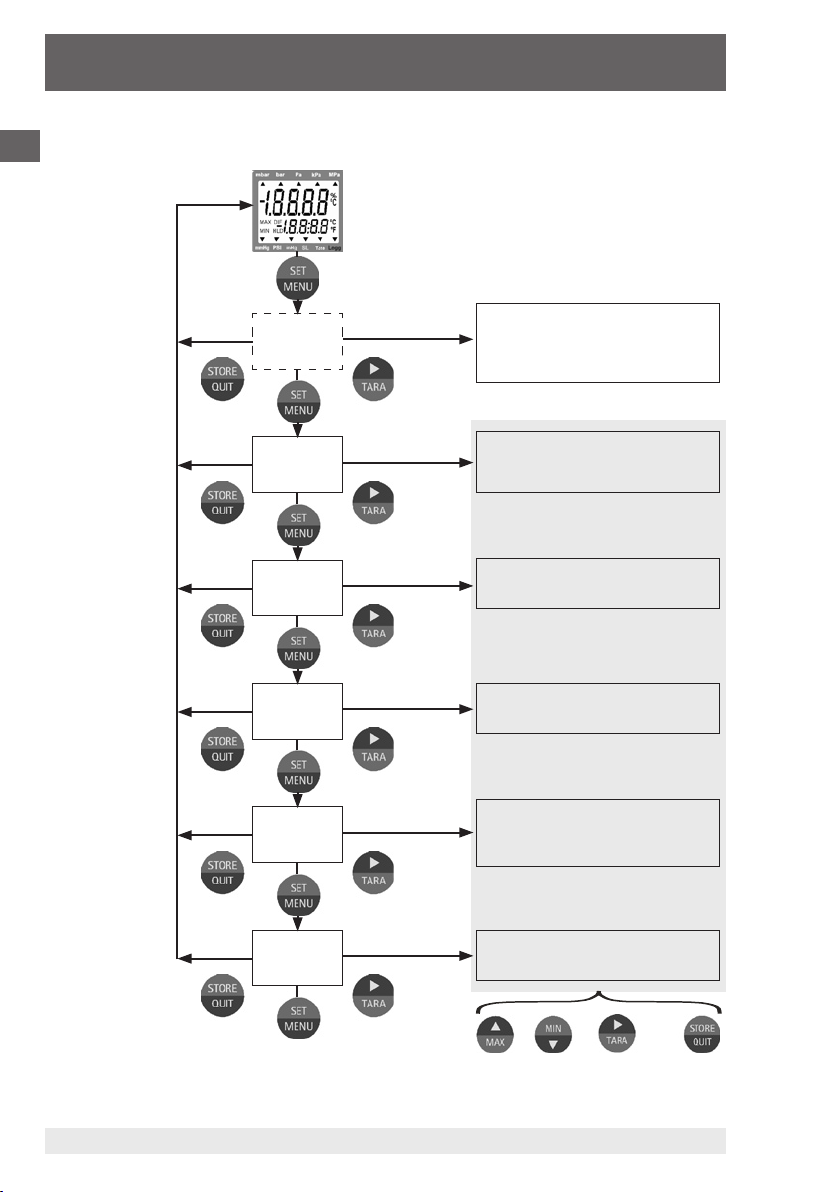

Main Menu

Read*

Logg

Set

Conf

Set

CAL

Set

AL

(2 sec)

Stored data*

Recall of individually logged data and

respective time stamp (Func-STOR

configuration (see Section “3. Operation

of logger”).

Configuration

Unit** / Sea-Level** / Measuring rate** /

Power-off / interface-address

Calibration

Adjustment of zero and span

Alarm

Min/Max alarm visual with/without sound

Set**

Logg

Set

Cloc

(ring - shift)

* appears only if data (Func-STOR) is in the logger memory.

** appears only if the logger memory is empty (see Section “3. Operation of logger”).

Logger**

Switch from simple ‘Hold’ to ‘Logger’

function: Single-point values (STOR) or

Cyclic (CYCL)

System-clock

time / day & month / year

set parameter next store

parameter & quit

Page 11

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

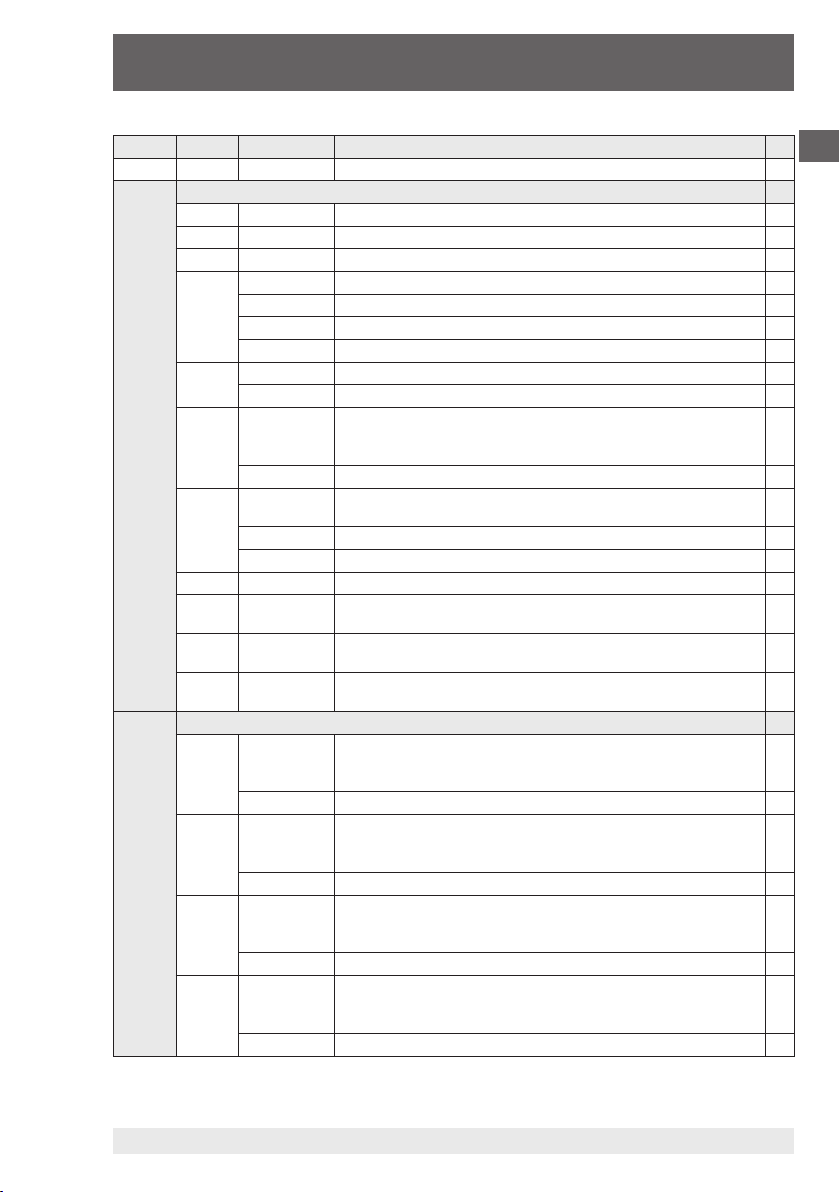

Menu Param. Setting Meaning

„Menu“

SEt

ConF

SEt

CAL

►

▲ or ▼

Set Configuration: Generic settings

Unit

SL

Alti

rAtE

t.AVG

P.oFF

Out

Adr.

dAC.

dAC.0

dAC.1

mbar, bar, ... Unit: Unit of display

oFF / on Sea-level correction: on or off

-200 ... +9999 Altitude: Input of altitude above sea-level [m] (only if on)

Rate: Measuring rate (see chapter 2.3)

Slo Slow: Measuring rate (4 Hz filtered, low power consumption)

FASt Fast: Measuring rate, filtered (> 100 Hz)

P.dEt Peak detection: fast measuring rate, unfildered (> 100 Hz)

1 ... 120 Averaging interval in seconds, used by the averaging function off

oFF Averaging function deactivated

1 ... 120 Auto Power-Off delay in minutes. Device will automatically switch

oFF Auto Power-Off function inactive (continuous operation)

oFF Function of the output: No output function, lowest power

SEr Output is serial interface

dAC Output is analogue output 0 ... 1 V

01, 11 ... 91 Communicationsaddress of interface

CH1, CH2 or

CH DIF

eg. -5.00 ...

+5.00 mbar

eg. -5.00 ...

+5.00 mbar

itself off if, during this interval, no key is pressed, or there is no

serial communication.

consumption

Choice of the input to be the source for the analogue output (if

Out = dAC)

Enter desired value at which the analogue output potential should

be 0 V (if Out = dAC)

Enter desired value at which the analogue output potential should

be 1 V (if Out = dAC)

Set Calibration: Adjustment of sensors

OFS.1

SCL.1

OFS.2

SCL.2

Sensordep.,

e.g. -5.00 ...

+5.00 mbar

OFF Zero displacement inactive (=0.0 °)

eg. -5.00 ...

+5.00 mbar

OFF Scale correction factor inactive (=0.000)

Sensordep.,

e.g. -5.00 ...

+5.00 mbar

OFF Zero dispacement inactive (=0.0°)

eg. -5.00 ...

+5.00 mbar

OFF Scale correction factor inactive (=0.000)

The offset of sensor 1 will be displaced by this value to compensate for deviations in the probe or in the measuring device.

The measuring scale of sensor 1 will be changed by this factor

[%] to compensate deviations of temperature probe or measuring

device.

The offset of sensor 2 will be displaced by this value to compensate for deviations in the probe or in the measuring device.

The measuring scale of sensor 2 will be changed by this factor

[%] to compensate deviations of temperature probe or measuring

device.

GB

*, **

*, **

*, **

*

*

*

*

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 11

Page 12

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator12

Menu Param. Setting Meaning

„Menu“

SEt

AL.

SEt

LoGG

SEt

CLOC

►

▲ or ▼

Set Alarm: Alarm function configuration

AL.

[1,2,DIF]

AL.Lo

[1,2,DIF]

AL.Hi

[1,2,DIF]

Set Logger: Logger function configuration

Func

CYCL

Lo.Po

Set Clock: Setting of real time clock

CLOC

dAtE

YEAr

on Alarm function on, with audio alarm

no. So Alarm function on without audio alarm

oFF No alarm function

Min-Range ...

... AL.Hi

AL.Lo ...

... Max-Range

CYCL Cyclic: logger function ‘cyclic logger’

Stor Store: logger function ‘discrete value logger’

oFF No logger function

1 ... 3600 Cycle time for cyclic logger [seconds]

on / oFF Low-power logger with very low power consumption (only if

HH:MM Clock: set time hours:minutes

TT.MM Date: set time day.month

YYYY Year: set time year

Min alarm limit

(not when AL.oFF, Min-Range is the lower display range of the

connected sensor)

Max alarm limit

(not when AL.oFF, Max-Range is the upper display range of the

connected sensor)

*

*

*

*

*

*

cyclic logger with slow measuring rate)

*

* If there is existing data in the logger memory, the menus/parameters

cannot be accessed! If these need to be adjusted, the logger memory

must first be cleared! (see Section “3. Operation of logger”.)

** This menu can oly be invoked if a refering sensor is connected to

connection 1. When using a second sensor at connection 2 then

changes are taken over.

2. Configuration

To change device settings, press the ´Set/Menu´ key for 2 seconds. This

will access the configuration menu (main display: “SEt“).

Pressing the ´Set/Menu´ key again scrolls down the menus, pressing

the ´Tare´ key scrolls across to the associated parameters, which can

then be selected with the ´Tare´ key.

The parameters can be altered using the ´Min´ or ´Max´ keys. Pressing

the ´Set/Menu´ key again saves the settings and returns you to the main

configuration menu.

The ´Store/Quit´ key exits the configuration and returns you to standard

measuring mode.

Page 13

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

2.1 (Unit) Choice of pressure units

Depending on the pressure range, the pressure value can be displayed

in any one of the following units: mbar, bar, Pa, kPa, MPa, mmHg, inHg

or psi.

2.2 (SL) Sea-level correction for absolute pressure sensors

If an absolute pressure sensor is connected to the instrument, then the

device displays the true absolute pressure measured by the sensor. This

does not necessarily equate to the values given by weather stations,

which give the pressure at sea-level. Usually the sensor is situated

above sea-level and therefore, if the value at sea-level (zero) is to be

measured, the pressure loss resulting from the elevation above sealevel must be considered! To correct the displayed value activate the

“Sea-Level-Function“ (SL). (Setting is only possible, if the abs. Pressure

sensor is connected to sensor socket 1.) Then enter the sensor‘s height

above sea-level in metres (Alti). When activated, the display shows the

SL-arrow and the device displays the absolute pressure value relative to

sea-level.

When two absolute pressure sensors are connected, the sea level

function for both is corresponding to the setting of sensor 1.

2.3 (rAtE) Choice of measuring rates: “rAtE-Slo, -P.dEt, -FASt“

GB

Three options of measuring rate are supported. Two of them work with

high measuring frequencies of over 1000 measurements per second.

Whichever one of them was selected during configuration (see above),

this will be displayed in the lower display: “P.dEt“ or “FASt“.

2.3.1 rAtE-Slo: standard measuring

Measuring rate 4 Hz, averaging and filter functions are active.

Application: Measurement of slowly changing or static pressures, e.g.

leak testing, atmospheric pressure...

Highest accuracy, high noise immunity (EMI and unstable measuring

signals), low power consumption.

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 13

Page 14

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator14

2.3.2 rAtE-P.dEt: peak detection

Measuring rate > 1000 Hz, the value is displayed unfiltered.

Application with logger function: Measuring of pressure spikes or fluctuating pressures with a resolution of < 1.5 ms. The cyclic logger function

records the arithmetic mean value, the highest and the lowest peak

during the chosen time interval.

Higher power consumption, measuring is sensitive to noise (EMI,..).

2.3.3 rAtE-FASt: fast filtered measuring

Measuring rate > 1000 Hz, but the value is filtered slightly (higher noise

immunity than P.dEt, small peaks will be filtered out), apart from that,

identical behaviour to P.dEt.

2.4 Averaging function

The averaging function acts on the displayed values (LCD and serial

interface). It is completely independent of the averaging within the

logger function, please don‘t mix them up!

The averaging integrates the measured values during a chosen time

interval and then calculates the average display value. It is independent

of the selected measuring rate (slow, fast, peak detect).

Until sufficient values to calculate an average value have been collected

(dependant on selected averaging time), the upper display shows “----“,

the lower display shows a ´countdown´.

During an active low-power-logging procedure the average is always

deactivated.

Operation of min/max-value memory in conjunction with the averaging

function:

If averaging is activated and 'slow' measuring rate is selected (rAtE-

Slo), the min-/max-memory value relates to the average display

value.

If averaging is activated and 'fast' measuring rate is selected (rAtE-

FASt or P.dEt), the min-/max-memory value relates to the internal

measured values (pressure spikes can be detected).

Page 15

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

2.5 Zero correction sensor 1 (OFS.1) and sensor 2 (OFS.2)

A zero displacement can be carried out for the measured value:

value displayed = value measured - offset

Standard setting: ‘off‘ = 0.0°, i.e. no zero displacement will be carried

out. Together with the scale correction (see below) this factor is mainly

used to compensate for sensor deviations. Input is in the display unit.

2.6 Span correction sensor 1 (SCL.1) and sensor 2 (SCL.2)

The scale of the measuring can be influenced by this setting (factor is in %):

displayed value = measured value * (1+Scal/100)

Standard setting: ‘off‘ =0.000, i.e. value is not corrected. Together with

the zero displacement (see above) this factor is mainly used to compensate for sensor deviations.

2.7 (P.oFF) Power off function

If no key is pressed, and no serial communication occurs during the

interval set in configuration (P.off), the device will automatically switch

itself off to save battery power.

If P.oFF = oFF then the automatic power off is deactivated.

GB

2.8 (Out) Output

The output can be used as interface (RS-232 or USB) or as analogue

output (0 ... 1 V).

2.8.1 (Adr.) Serial communications address

This parameter has been included in preparation for future operation

with multi-point monitoring systems.

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 15

Page 16

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator16

2.8.2 (dAC.) Analogue output – scaling with (dAC.0) and (dAC.1)

Analogue output can not be used during logger recordings

With the dAC.0 and dAC.1 values the output can be rapidly scaled to

your efforts.

Keep in mind not to connect low-resistive loads to the output, otherwise the output value will be wrong and battery life is decreased. Loads

above ca 10 kΩ are uncritical. If the display exceeds the value set by

dAC.1, then the device will apply 1 V to the output. If the display falls

below the value set by dAC.0, then the device will apply 0 V to the

output. In case of an error (Err.1, Err.2, no sensor, etc.) the device will

apply slightly above 1 V to the output.

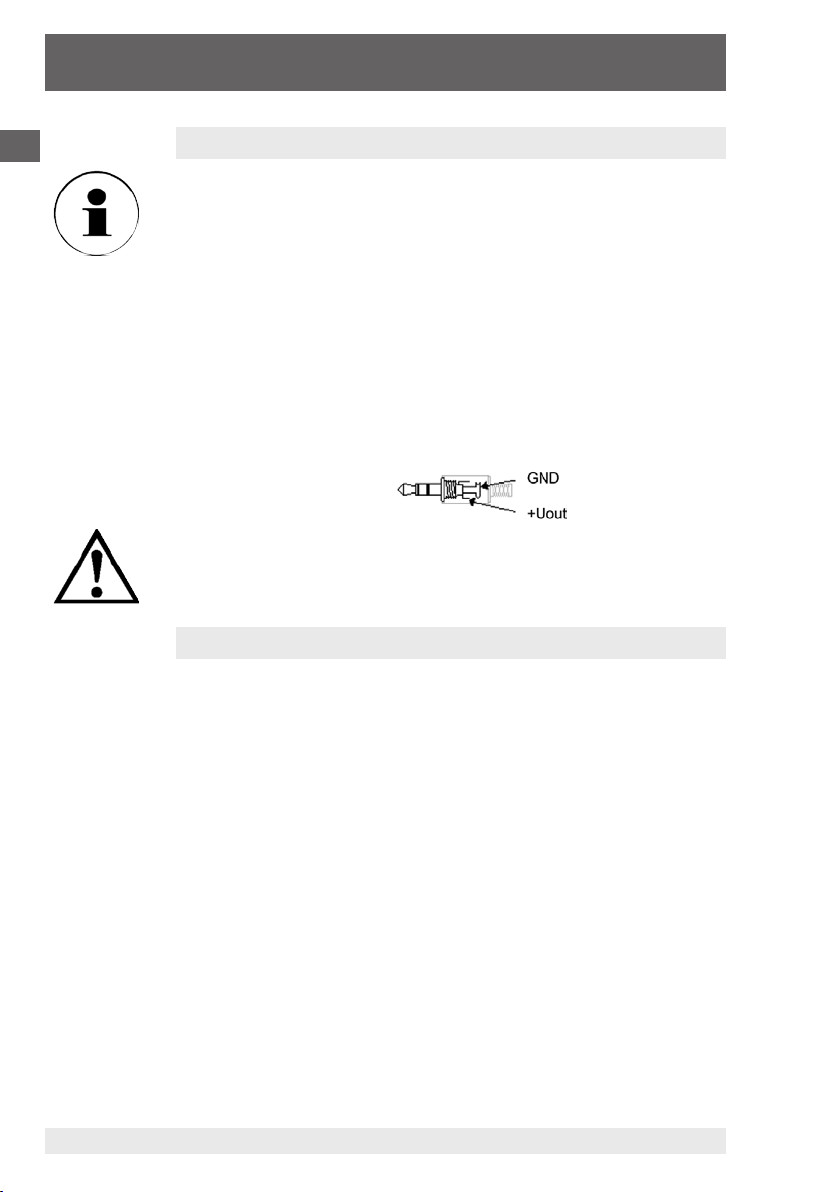

Plug wiring:

The 3rd contact has to be left floating! Only stereo plugs are

allowed!

2.9 (AL.) Alarm

There are three possible settings: Alarm off (AL.oFF), on with audio

alarm (AL.on), on without audio alarm (AL.no.So).

The following conditions will prompt an alarm to be displayed, if the

alarm function is activated (on or no.So):

Value is below lower alarm limit (AL.Lo) or above upper alarm limit

(AL.Hi).

Sensor error (Sens-Erro)

Low battery (bAt)

Fe 7: System error (always with sound)

When an alarm occurs, the alarm arrow flashes, and, during serial

communication, the 'PRIO'-flag is set within the transmitted message.

If the horn sound of one channel will be switched on/off (on or no.So),

then this horn sound setting will automatically be copied to the other

activated channels.

Page 17

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

2.10 (CLOC) Real time clock

The real time clock is needed for time-stamping each data point recorded within the logger function. As a result, the clock settings should be

checked regularly. If the battery has been replaced the appropriate

menu 'CLOC' will be accessed automatically.

3. Operation of logger

The device supports two different logger functions:

“Func-Stor“: each time the ´Store/Quit´ key is pressed a data point

will be recorded.

“Func-CYCL“: measurements will automatically be recorded at a

defined interval, set within the logger menu ‘CYCL‘ until

the logger is stopped or the logger memory becomes

full. Logging is started by pressing the ´Store/Quit´ key

for 2 seconds.

The logger records up to 3 measurement values for each interval:

Current or mean value (depending on logger setting, see below), Min-

Peak and Max-Peak. (Sensor 1, Sensor 2, difference)

To evaluate the data, WIKA's Data logger evaluation software GSOFT (V

2.3 or higher) must be used. The software also allows easy configuration

and operation of the logger.

GB

If the logger is selected (Func-STOR or Func-CYCL) the hold function is

deactivated; the ´Store/Quit´ key is then used solely for the operation of

the logger functions.

Min- and Max-Peak are, respectively, the minimum and the maximum

measured values during the last measurement interval. Therefore both

the instantaneous pressure values and the measured fluctuations can be

better analysed.

3.1 “Func-Stor“: Storing discrete measurements

In this mode, each time the ´Store/Quit´ key is pressed a measurement and its time stamp will be recorded. The data recorded can be

viewed either on the display (an additional menu item “REAd-LoGG“ is

displayed when scrolling through the Configuration menu) or through the

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 17

serial interface and a PC running the GSOFT-software.

Page 18

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator18

Max. number of measurements: 99

The data recorded includes the following values:

Sensor 1 instantaneous value at that data point

Sensor 1 Min-Peak, Max-Peak since last data point

Sensor 2* instantaneous value at that data point

Sensor 2* Min-Peak, Max-Peak since last data point

Instantaneous difference (Sensor 1 - Sensor 2)* at that data point

Min-Peak, Max-Peak of the difference (Sensor 1 - Sensor 2)*, Min-

Peak, Max-Peak since last data point

Time and date stamp of that data point

* Only for 2-channel version CPH6200-S2

After each recording “St. XX“ will be displayed for a short time. XX

represents the number of the data point.

If the logger memory already contains data:

When the ´Store/Quit´ key is pressed for 2 seconds, the option to clear

the logger memory will be displayed:

clear clear nothing

all data points (cancel menu)

clear the last

data point

Use the ´Min´ or the ´Max´ key to display the required option. The

´Store/Quit´ key selects that choice.

If the logger memory is full, the display will show:

Viewing Recorded Measurements

Within the “LoGG-Stor“ function the measurements can be viewed

directly on the instrument display as well as through a computer (“FuncCYCL“ only allows for the data to be viewed on computer). Press the

´Set/Menu´ key for 2 seconds: The first menu displayed is now “rEAdLoGG“ (read logger data). By then pressing the ´Tare´ key, the last

measurement recorded will be displayed; pressing the ´Tare´ key again

scrolls between the different values related to this data point.

Pressing the ´Min´ key or ´Max´ key selects different data points.

Page 19

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

3.2 Func-CYCL“: Automatic datalogging with adjustable

cycle-time

The Logger cycle-time is adjustable (see Configuration). For example,

setting “CYCL“ = 60: A measurement is made every 60 seconds.

When the slow measurement “rAtE-Slo“ is chosen, additionally a low

power function is available: “Lo.Po“.

If “Lo.Po“ is on, the device only will take a measurement at the point of

time of the recording. In between the recordings the measuring shut‘s

down. This decreases the power consumption enormously and therefore is recommended e.g. for long time recordings where no mains

adapter is available.

Max. number of measurements: CPH6200-S1: 10000

CPH6200-S2: 4000

(at max. 64 recording sequences)

Cycle-time: 1 ... 3600 seconds (=1 h), selectable

from the configuration menu

A measurement contains:

Slow measuring rate (rAtE-SLo):

- Sensor 1 current value at that data point

- Sensor 1 Min-Peak, Max-Peak since last data point

- Sensor 2* instantaneous value at that data point

- Sensor 2* Min-Peak, Max-Peak since last data point

- Instantaneous difference (Sensor 1 - Sensor 2)* at that data point

- Min-Peak, Max-Peak of difference (Sensor 1 - Sensor 2)*, MinPeak, Max-Peak since last data point

GB

Fast measuring rate (rAtE-FASt, -P.dEt):

- Sensor 1 average since last data point

- Sensor 1 Min-Peak, Max-Peak since last data point

- Sensor 2* average since last data point

- Sensor 2* Min-Peak, Max-Peak since last data point

- Average difference (Sensor 1 - Sensor 2)* since last data point

- Min-Peak, Max-Peak of difference (Sensor 1 - Sensor 2)*,

Min-Peak, Max-Peak since last data point

* Only for 2-channel version CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 19

Page 20

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator20

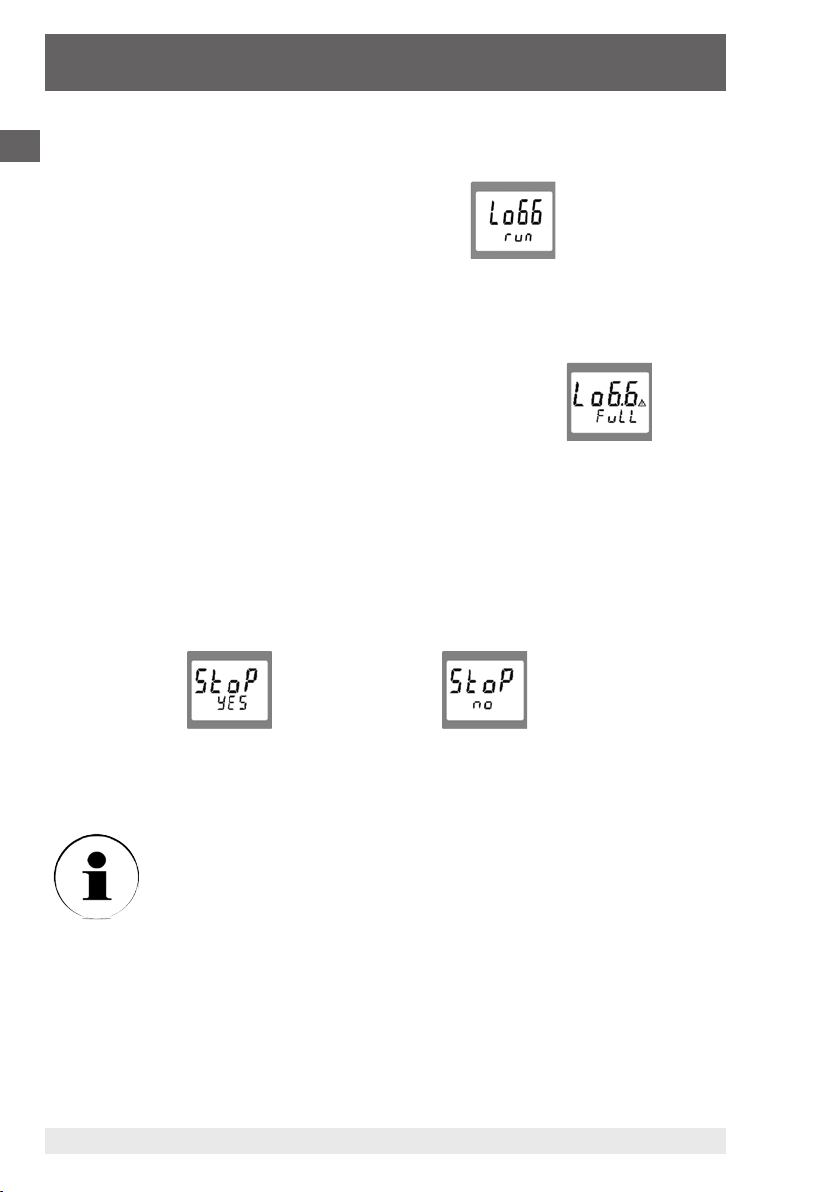

Starting logging:

By pressing ´Store/Quit´ for 2 seconds the logger operation will be

called. The display will show:

By pressing ´Store/Quit´ again the recording will be initiated.

After that the display shows ‘St.XXXX‘ for a short time whenever a

measuring is recorded. XXXX is the number of the measuring 1 ... 4000

or 10000.

If the logger memory is full, the display will show:

The recording automatically will be stopped.

If the Low-Power-Logger-function is selected („Lo.Po = on“) the device

switches itself off as soon as the memory becomes full.

Stopping the logging manually:

By pressing the ´Store/Quit´ key, recording can be manually interrupted.

The following choice then appears:

Stop Do not stop

recording recording

The selection can be made by key: ´Max´ and key: ´Min´.

Key ´Store/Quit´ enters the choice.

If you try to switch off the instrument during a logging cycle, you

will also be asked if you wish to stop recording. The device can only

be switched off after the recording has been stopped!

The Auto-Power-Off-function is deactivated during logging!

Page 21

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

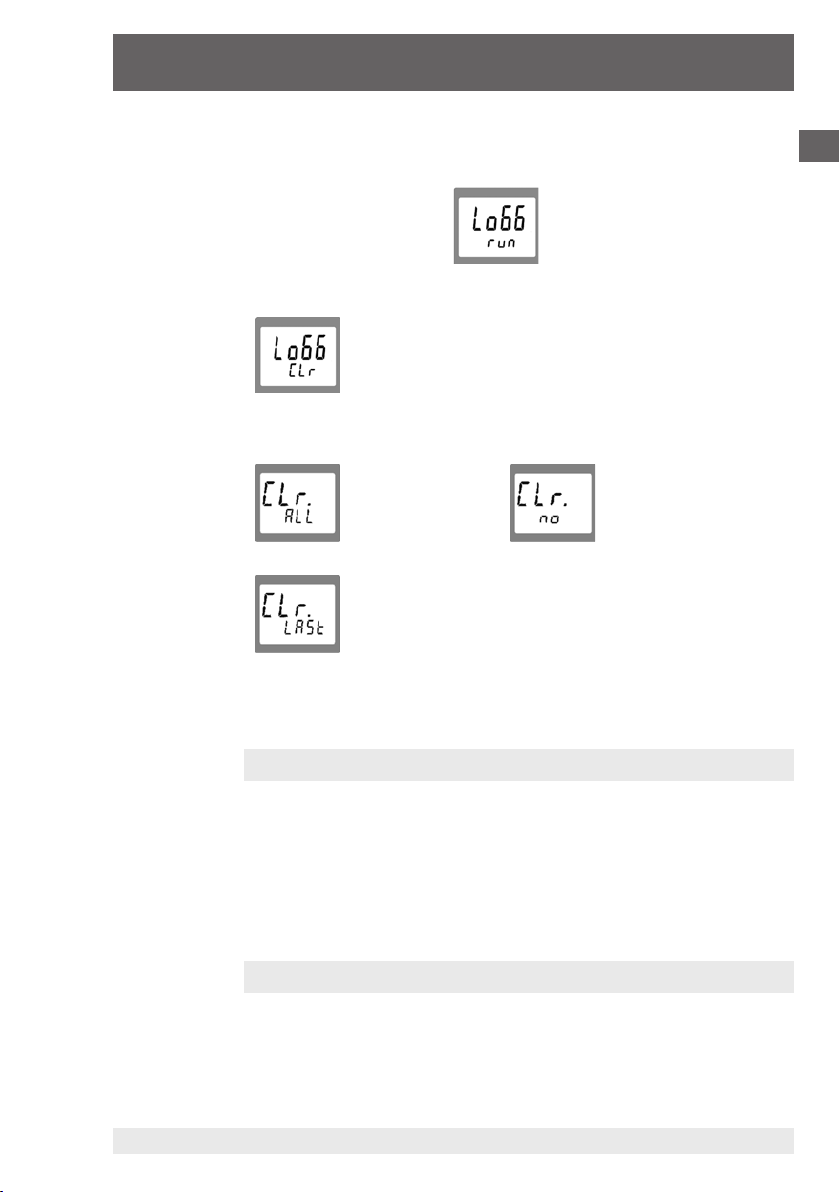

Clear data:

When the ´Store/Quit´ key is pressed for 2 seconds, the logger operation will be called.

The display will show:

By pressing the key ´Max´ or key ´Min´ the display will change to:

When ´Store/Quit´ is pressed, the choice for clearing the logger memory

will be displayed:

clear clear nothing

all recordings (cancel menu)

clear the last

recording sequence

The selection can be made by key ´Max´ or key ´Min´.

´Store/Quit´ enters the choice.

GB

4. The serial interface

For data transfer to a computer there are two electrically-isolated interface adapters available for the connection of the CPH6200 to a RS-232

or USB interface (USB-driver necessary).

WIKA‘s Data logger evaluation software GSOFT (see current CPH6200

price list) is used to display the data. To avoid transmission errors, there

are several security features implemented (e.g. CRC).

5. Available pressure sensors

The instrument has been designed so that all sensors model CPT6200

can be connected without the need for any configuration or recalibration. There is therefore a wide range of interchangeable sensors

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 21

available; with ranges of up to 1000 bar (see current price list for model

CPT6200 pressure transmitters).

Page 22

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator22

6. Fault and system messages

Display Meaning Remedy

Low battery power, device will only work

for a short while longer

Battery flat Replace battery

Replace battery

SEnS

Erro

or Err.9

- - - -

- - - -

No display

or strange

symbols,

device is not

responding to

input

Err.1

Err.2

Err.3

Err.4

Err.7

Err.11

Mains operation without battery: wrong

voltage

No sensor connected Switch off device and connect sensor

Connected sensor or device faulty If second sensor available, check if

Value extremely out of measuring range Check: pressure not within sensor range?

Logger data is being read by the serial

interface

Battery flat Replace battery

Mains operation without battery: wrong

voltage or polarity

System error Disconnect battery or power supply, wait

Instrument faulty Return to manufacturer for repair

Measured value above allowable range Check: Is the pressure outside the

Sensor faulty Return to manufacturer for repair

Measured value below allowable range Check: Is the pressure outside the

Sensor defective Return to manufacturer for repair

Display range overflow Check: value above 9999 -> to high to be

Display range underflow Check: value below ‚-2000‘ (Tare?) ->

System error Return to manufacturer for repair

Value coul not be calculated Choose different unit

Calculation overflow happened Choose different unit

Check power supply, change it if necessary

device is ok. Return defective device/

sensor to manufacturer for repair

When the data transfer is completed the

device will automatically return to normal

measuring display, no remedy necessary

Check power supply, change it if necessary

a while, re-connect

sensor‘s range? -> measured value to

high!

sensor‘s range? -> measured value to

low!

displayed!

to low!

Page 23

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

7. Calibration services

DKD-certificates - other certificates:

If the instrument requires calibration, we recommend returning it, along with its associated sensors, to the manufacturer. Only the manufacturer is able to verify the instrument‘s

basic settings and configuration, and if necessary correct them.

8. Specifications

Input 1: for CPH6200-S1; 2: for CPH6200-S2

Pressure range in bar 0.1 0.16 0.25 0.4 0.6 1.0 1.6 2.5 4.0 6.0

Overpressure safety in bar 1 1.5 2 2 4 5 10 10 17 35

Burst pressure in bar 2 2 2.4 2.4 4.8 6 12 12 20.5 42

Resolution in mbar 0.1 1

Pressure range in bar 10 16 25 40 60 100 160 250 400 600 1000

Overpressure safety in bar 35 80 50 80 120 200 320 500 800 1200 1500

Burst pressure in bar 42 96 250 400 550 800 1000 1200 1700 2400 3000

Resolution in bar 0.01 0.1 1

Type of pressure gauge {absolute 0.25 up to 16 bar & vacuum on request}

Accuracy of the measuring chain

Calibration* factory calibration certificate (optional: DKD calibration certificate)

Display large LCD display for display of 2 values and additional information

Range of display max. -19999 up to 99999, depending on sensors used

Units can be selected from the following: mbar, bar, Pa, kPa, MPa, mmHg, inHg, psi

CPH6200 Digital Instrument specific details:

Functions via key press Min-, Max-memory, Hold, Tare, Offset-correction, Logger (Start/Stop)

Functions via Menu Min-, Max-alarm (acoustic**/visual), Sea-level (barom. air pressure), Power-Off-

Data logger

Interface 1) (serial) RS-232 or USB interface via special interface cables

Power supply 9V-zinc-carbon battery, alternative**: 9V rechargeable battery or mains supply

Power consumption

Working temperature 0 ... 50 °C

Air humidity 0 ... 95 % relative humidity without moisture condensation

Storage temperature -20 ... +70 °C

Housing Impact-resistant ABS, membrane keyboard, transparent panels (CPH62I0 with

Weight Approx. 160 g

EMV- / CE-conformity The CPH6200 device corresponds to the essential protection requirements estab-

1) For the intrinsically safe version, the use of the interface is not permitted within an explosive atmosphere.

*) Calibrated in vertical mounting position with lower pressure connection.

**) Not available for the intrinsically safe version CPH62I0.

11221780.1.3 01/2009 GB/D/F/E

{} Items in curved brackets are optional extras at an additional price.

0.2 % FS +/- 1 digit at reference temperature of 20 °C (optional 0.1 %)

(dependent on range)

Function, measuring rate: 4/sec (“slow“); > 1000/sec (“fast“); > 1000/sec unfiltered (“peak-detect“) [via “peak-detect“ and min-/max-memory: pressure peaks

of 1.5 msec can be detected]

- discrete value-logger: up to 99 data points (incl. time-stamp) via key press

- cyclic-logger: automatic logging of up to 10000 values incl. time.

cycle-time: selectable between 1 ... 3600 seconds

Cycle-time slow: < 1.6 mA, fast: < 7.0 mA, Low-Power-Logger-Fct.: < 0.3 mA

cover)

lished in the regulations of the council for the approximation of legislation of the

member countries regarding electromagnetic compatibility (89/336/EWG).

GB

WIKA Operating Instructions Hand-Held Pressure Indicator 23

Page 24

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator24

CPT6200 Pressure Transmitter specific details:

Pressure connection G½ B; {flush diaphragm (G1 for 0.1 up to 1.6 bar) or various connection

Material wetted parts Wetted parts stainless steel, case stainless steel;

Internal transmission fluid Synthetic oil, (only for pressure ranges up to 16 bar or flush

One year stability 0.2 % of span at reference conditions

Permissible

- medium temperature

- ambient temperature 0 ... 50 °C

- storage temperature -40 ... +80 °C

Compensated range 0 ... 70 °C

Temperature coefficients

- mean TC of zero signal 0.2 %/10 K

- mean TC of span 0.2 %/10 K

Connection to CPH6200 via 1 m cable (plug and play); on request: up to 5 m

Weight approx. 220 g

2) O-ring made of Viton or EPDM for flush diaphragm with integrated cooling element.

3) The oxygen version must not be used with medium temperatures higher than 60 °C.

Cannot be manufactured for absolute pressure ranges < 1 bar abs.

{} Items in curved brackets are optional extras at an additional price.

adapters on request}

flush diaphragm version: stainless steel {Hastelloy C4};

O-Ring 2): NBR {FKM/FPM or EPDM}

diaphragm), {Halocarbon oil for oxygen applications}

{Listed by FDA for food industry}

3)

-25 ... +100 °C

3)

;

Page 25

Hand-Held Pressure Indicator

CPH6200-S1 / CPH6200-S2

9. Accessories

For accessories such as pressure pumps (pneumatic/hydraulic), flexible

pressure hose, pressure adapters, data logger-evaluation software Gsoft

or calibration software, power supply unit, battery charger, rechargeable

batteries, etc. see current “WIKA Testing and Calibration Technology

pricelist”.

GB

11221780.1.3 01/2009 GB/D/F/E

WIKA Operating Instructions Hand-Held Pressure Indicator 25

Page 26

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät26

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise oder Tipps.

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an Personen

oder am Gerät verursachen können.

Page 27

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

Inhalt

1. Allgemeines 28

1.1 Allgemeine Sicherheitshinweise 29

1.2 Betriebs- und Wartungshinweise 30

1.3 Anschlüsse 31

1.4 Anzeige 32

1.5 Bedienung 32

2. Konfiguration des Gerätes 36

2.1 (Unit) Verschiedene Druckeinheiten 37

2.2 (SL) Höhenkorrektur bei Absolutdruck-Sensoren 37

2.3 (rAtE) Verschiedene Messarten: „rAtE-Slo, -P.dEt, -FASt“ 37

2.3.1 rAtE-Slo: Standardmessung 37

2.3.2 rAtE-P.dEt: Peak detection = Spitzenwertdetektion 38

2.3.3 rAtE-FASt: Fast = Schnelle Messung 38

2.4 Mittelwertbildung 38

2.5 Nullpunktkorrektur Sensor 1 (OFS.1) bzw. Sensor 2 (OFS.2) 39

2.6 Steigungskorrektur Sensor 1 (SCL.1) bzw. Sensor 2 (SCL.2) 39

2.7 (P.oFF) Abschaltverzögerung 39

2.8 (Out) Geräteausgang 39

2.8.1 (Adr.) Schnittstellen-Adresse 39

2.8.2 (dAC.) Analogausgang-Skalierung mit dAC.0 und dAC.1 40

2.9 (AL.) Alarm 40

2.10 (CLOC) Echtzeituhr 41

3. Bedienung der Loggerfunktion 41

3.1 „Func-Stor“: Einzelwerte speichern 41

3.2 „Func-CYCL“: Autom. Aufzeichnung mit einstellbarer Zykluszeit

4. Die serielle Schnittstelle 45

5. Verfügbare Drucksensoren 45

6. Fehler- und Systemmeldungen 46

7. Hinweis zum Kalibrierservice 47

8. Technische Daten 47

9. Zubehör 49

D

43

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 27

Page 28

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät28

1. Allgemeines

In den folgenden Kapiteln erhalten Sie nähere Informationen zum

Hand-Held Messgerät CPH6200 und seinen ordnungsgemäßen Einsatz.

Sollten Sie weitere Informationen wünschen, oder treten besondere

Probleme auf, die in der Betriebsanleitung nicht ausführlich behandelt

werden, erhalten Sie Auskunft unter den auf der letzten Seite aufgelisteten Adressen.

Bei der Werkskalibrierung der Instrumente wurde sich an entsprechende

internationalen Normen orientiert.

Die Gewährleistungszeit für das Hand-Held Messgerät CPH6200

beträgt 24 Monate nach den Allgemeinen Lieferbedingungen des ZVEI.

Sämtliche Gewährleistungsansprüche verfallen, bei unsachgemäßer

Handhabung bzw. bei Nichtbeachtung der Betriebsleitungen oder bei

dem Versuch das Gerät zu öffnen.

Außerdem weisen wir darauf hin, dass der Inhalt dieser Betriebsanleitung nicht Teil einer früheren oder bestehenden Vereinbarung, Zusage

oder Rechtsverhältnisses ist oder diese abändern soll. Sämtliche

Verpflichtungen der WIKA Alexander Wiegand GmbH & Co. KG ergeben

sich aus dem jeweiligen Kaufvertrag und den Allgemeinen Geschäftsbedingungen der WIKA Alexander Wiegand GmbH & Co. KG.

WIKA ist ein eingetragenes Warenzeichen der WIKA Alexander Wiegand

GmbH & Co. KG.

Firmen- oder Produktnamen, die in diesem Handbuch erwähnt werden,

sind eingetragene Warenzeichen dieser Hersteller.

Zumutbare Änderungen aufgrund technischer Verbesserungen behalten

wir uns vor.

Eine Vervielfältigung dieses Handbuches oder Teilen davon ist untersagt.

Firmware - Betriebsanleitung-Versionsschlüssel

Manual Firmware

V 1.1 V 4.0 - V 4.9

V 1.2 V 5.0 - V 6.0

V 1.3 > V 6.0

© 2005 Copyright WIKA Alexander Wiegand GmbH & Co. KG

Page 29

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

1.1 Allgemeine Sicherheitshinweise

Dieses Gerät ist gemäß den Sicherheitsbestimmungen für elektronische Messgeräte gebaut und geprüft. Die Funktion und Betriebssicherheit des Gerätes kann nur dann gewährleistet werden, wenn

die nationalen Sicherheits- und Unfallverhütungsvorschriften sowie

die Sicherheitshinweise der Betriebsanleitung beachtet werden.

1. Die einwandfreie Funktion und Betriebssicherheit des Gerätes

kann nur unter den klimatischen Verhältnissen, die im Kapitel „8.

Technische Daten“ spezifiziert sind, eingehalten werden.

2. Gerät und Sensor müssen pfleglich behandelt werden (nicht werfen,

aufschlagen, etc.). Stecker und Buchsen sind vor Verschmutzung zu

schützen.

3. Wird das Gerät von einer kalten in eine warme Umgebung transpor

tiert, so kann durch Kondensatbildung eine Störung der Gerätefunktion eintreten. In diesem Fall muss die Angleichung der Gerätetemperatur an die Raumtemperatur vor einer erneuten Inbetriebnahme

abgewartet werden.

4. Konzipieren Sie die Beschaltung beim Anschluss an andere Geräte

besonders sorgfältig. Unter Umständen können interne Verbindungen in Fremdgeräten (z. B. Verbindung GND mit Erde) zu nicht

erlaubten Spannungspotentialen führen, die das Gerät selbst oder ein

angeschlossenes Gerät in seiner Funktion beeinträchtigen oder sogar

zerstören können.

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von

Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche Spannungen auftreten!

5. Wenn anzunehmen ist, dass das Gerät nicht mehr gefahrlos betrie

ben werden kann, so ist es außer Betrieb zu setzen und vor einer

Wiederinbetriebnahme durch Kennzeichnung zu sichern.

-

-

D

Die Sicherheit des Benutzers kann durch das Gerät beeinträchtigt sein,

wenn es zum Beispiel:

Sichtbare Schäden aufweist.

Nicht mehr wie vorgeschrieben arbeitet.

Längere Zeit unter ungeeigneten Bedingungen gelagert wurde.

In Zweifelsfällen das Gerät grundsätzlich an den Hersteller zur Reparatur

bzw. Wartung einschicken.

6. Es dürfen am Gerät keine Veränderungen oder Reparaturen vom

Kunden vorgenommen werden. Zur Wartung oder Reparatur muss

das Gerät zum Hersteller eingesandt werden.

7. Ein anderer Betrieb als der in der folgenden Anleitung beschriebene

oder außerhalb der Spezifikationen, ist bestimmungswidrig und muss

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 29

deshalb ausgeschlossen werden.

Page 30

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät30

1.2 Betriebs- und Wartungshinweise

Batteriebetrieb

Wird in der unteren Anzeige "bAt" angezeigt, so ist die Batterie

verbraucht und muss erneuert werden bzw. der Akku ist leer und

muss mit dem dafür vorgesehen Akkuladegerät (siehe aktuelle Preisliste CPH6200) geladen werden. Jedoch ist noch für eine gewisse Zeit

die Gerätefunktion gewährleistet. Wird in der oberen Anzeige "bAt"

angezeigt, so ist die Batterie ganz verbraucht. Batterie und Akku

sind nur sachgemäß zu benutzen und ordnungsgemäß den aktuellen,

nationalen Vorschriften zu entsorgen. Bei Lagerung des Gerätes über

50 °C muss die Batterie entnommen werden.

Wird das Gerät längere Zeit nicht benutzt, sollte die Batterie / der Akku

herausgenommen werden.

Die Uhrzeit muss nachher jedoch wieder neu eingestellt werden.

Netzgerätebetrieb

Beim Anschluss eines Netzgerätes muss dessen Spannung

zwischen 10,5 und 12 V DC liegen. Keine Überspannungen anlegen!

Einfache Netzgeräte können eine zu hohe Leerlaufspannung haben,

dies kann zu einer Fehlfunktion bzw. Zerstörung des Gerätes

führen! Wir empfehlen daher unser Netzgerät (siehe aktuelle Preisliste CPH6200) zu verwenden.

Vor dem Verbinden des Netzgerätes mit dem Stromversor-gungsnetz ist sicherzustellen, dass die am Netzgerät angegebene

Betriebsspannung mit der Netzspannung übereinstimmt.

Sensoren anstecken/wechseln

Nur Sensoren des Types CPT6200 verwenden! Mit anderen Sensoren

kann es zur Zerstörung des Messgerätes und des Sensors kommen.

Zum Sensorwechsel Gerät ausschalten. Sensor vor dem Einschalten

des Gerätes anstecken, sonst wird er vom Gerät evtl. nicht richtig

erkannt.

Digitalgerät und Sensor werden mittels eines separaten Verbindungskabels elektrisch miteinander verbunden. Für den Sensorwechsel sollte

bevorzugt der 7-polige Steckkontakt am Sensor benutzt werden.

Zum Anschluss eines Sensors stecken Sie die 7-polige Steckverbindung

am Sensor gemäß der Orientierungsführung zusammen und sichern Sie

diese durch die Überwurfhülse (Überwurfhülse ohne größeren Kraftaufwand in Uhrzeigersinn drehen).

Beim Anstecken des Kabels am Digitalgerät kann es vorkommen, dass

der Stecker nicht richtig in die Buchse einrastet. In diesem Fall den

Stecker beim Anstecken nicht an Steckerhülse sondern am Knickschutz

halten. Stecker nicht verkantet anstecken. Bei richtig angesetztem

Page 31

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

Stecker kann dieser ohne größeren Kraftaufwand eingesteckt werden.

Beim Abstecken des Sensors nicht am Kabel ziehen, sondern nur an der

Steckerhülse.

Im hinteren Teil des Sensorgehäuses befindet sich, bei Überdruckbzw. relativ Drucksensoren, das Loch für den Druckausgleich, diese

Öffnung (mit integrierter Membrane) muss unbedingt frei bleiben!

Wartung

Digitalgerät und Sensoren enthalten keinerlei Verschleißteile, so dass

das Öffnen der Geräte-Gehäuse nicht erforderlich ist und für die

Aufrechterhaltung der Gewährleistungsansprüche unbedingt unterbleiben sollte.

Für die Reinigung der Gehäuse-Oberflächen empfehlen wir ein weiches,

wenig fusselndes, in Seifenwasser angefeuchtetes Tuch.

Wie für Messmittel allgemein üblich, sollten sie in regelmäßigen Abständen (ca. 1 x jährlich) auf Einhaltung der Spezifikationen überprüft werden

(siehe Kapitel „7. Hinweis zum Kalibrierservice).

1.3 Anschlüsse

D

Am oberen Ende des Gerätes

befindet sich die Anschlussbuchse CH1 und CH2 (CH2 nur bei 2-Kanal

Ausführung) zum Anschluss der Drucksensoren der CPH-Serie (siehe

Kapitel 5) und die Buchse zum Anschluss des WIKA Schnittstellenkabels (siehe Kapitel 4).

Anschluss für WIKA Schnittstellenkabel (RS-232/USB) oder Optionaler

Analogausgang

CH1 CH2 (nur bei 2-Kanal-Ausführung: CPH6200-S2)

Betrieb als Analogausgang: Anschluss über entsprechendem

Analogkabel. Achtung: Die jeweilige Betriebsart muss konfiguriert

werden und beeinflußt die Batterielebensdauer!

An der linken Seite des Gerätes

befindet sich die Netzbuchse zum Anschluss des erhältlichen Netzge-

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 31

rätes (siehe aktuelle Preisliste CPH6200).

Page 32

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät32

1.4 Anzeige

1. Hauptanzeige: zeigt den aktuellen Messwert an.

2. Nebenanzeige:

bzw. DIF an und bei 1-Kanal Ausführung werden hier Min-, Max- oder

Holdwerte angezeigt.

3. Logg:

bei laufendem Logger

4. Tara:

erscheint bei aktivierter Höhenkorrektur (Sea-Level)

5. SL:

6. Einheiten:

1

2

6

3

4

5

zeigt bei 2-Kanal Ausführung den Messwert von CH2

erscheint, falls Loggerfunktion ausgewählt wurde und blinkt

signalisiert, ob Tara-Funktion aktiviert ist.

ein Pfeil zeigt auf die gewählte Messeinheit

1.5 Bedienung

Beim Einschalten wird, falls eine Loggerfunktion gewählt wurde, kurz

die Uhrzeit angezeigt. Falls ein Nullpunktabgleich durchgeführt worden

ist, wird dies mit der Anzeige „nuLL-Corr“ signalisiert.

Nach einem Batteriewechsel erscheint automatisch das UhrzeitEinstellungs-Menü (‚CLOC‘). Überprüfen und korrigieren Sie ggf. die

Uhrzeit (siehe Kapitel „2. Konfigurieren des Gerätes“).

5

1

2

3

4

5

Page 33

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

1. Ein-/Ausschalter

2. Set/Menu: Aufruf der Konfiguration

3. Tara: Aufruf der Tara-Funktion, Nullpunktabgleich

4. Store/Quit: Aufruf der Hold-Funktion bzw. der Loggerfunktionen

(Siehe Kapitel „3. Bedienung der Loggerfunktion“.)

5. min/max: Aufruf des Min- bzw. Max-Speichers

D

Max-Speicher: Die Taste ´Max´ zeigt den maximal gemessenen Wert.

Min-Speicher: Die Taste ´Min´ zeigt den minimal gemessenen Wert.

Hold-Funktion: Durch Drücken der Taste ´Store/Quit´ wird der letzte

Logger-Funktionen: Aktivierung über ´Store/Quit´-Taste, falls im Haupt-

Tara-Funktion: Durch Drücken der Taste ´Tara´ wird die Anzeige auf 0

Beim Aktivieren von Tara werden Max.- & Min.-Speicher gelöscht.

Nullpunktabgleich: (für Relativdruck-Sensoren) Wenn an den Druckstut-

Erneutes Drücken blendet ihn wieder aus. Zum Löschen

des Max-Wertes ´Max´ für > 2 sec. drücken.

Erneutes Drücken blendet ihn wieder aus. Zum Löschen

des Min-Wertes ´Min´ für > 2 sec. drücken.

Messwert in der unteren Anzeige gehalten. Erneutes

Drücken blendet den Wert wieder aus (nur falls Logger

deaktiviert).

menü von Hold auf eine Logger Funktion umgeschaltet

wurde (siehe Kapitel „3. Bedienung der Loggerfunktion“).

gesetzt. Alle Messungen werden von nun an relativ zu

dem gesetzten Tara-Wert angezeigt. Ist die Tara-Funktion

aktiviert, wird der Pfeil ´Tara´ angezeigt. Zum Deaktivieren

die Taste ´Tara´ für > 2 sec. gedrückt halten.

zen kein Druck angelegt wird zeigt das Gerät 0 an. Sollte

jedoch doch eine ständige Abweichung vorhanden sein

(bei Betrieb in störungsfreien Umgebungsbedingungen),

so besteht die Möglichkeit einen dauerhaften Nullpunktabgleich durchzuführen. Um einen Nullpunktabgleich

durchzuführen die Taste ´Tara´ für ca. 7 sec. lang drücken.

(Nur möglich, wenn Anzeigewert weniger als 2 % von

der Werkskalibrierung abweicht, z. B. 0 ... 25 bar ->

Nullpunktabgleich bis 0,5 bar möglich). Wiederherstellen

der Werkskalibrierung: ´Tara´-Taste für ca. 15 sec. lang

drücken.

Abgleich ist nur möglich, wenn Abweichung weniger als 500 Digits beträgt.

Wurde ein Nullpunktabgleich durchgeführt, wird dies beim Einschalten des

Gerätes mit der Meldung „nuLL-Corr“ signalisiert.

Differenzbildung: Durch Drücken der ´Set/Menu´-Taste wird in

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 33

der Nebenanzeige die Differenz von Kanal 1- Kanal 2

(DIF=CH1-CH2) angezeigt. Erneutes Drücken macht den

Vorgang wieder rückgängig. (nur bei 2 Kanal Ausführung

und 2 angeschlossenen Sensoren).

Page 34

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät34

Menüführung des Hauptmenüs

(2 sec)

Read*

Logg

Set

Conf

Set

CAL

Set

AL

Set**

Logg

Speicherdaten*

Aufruf der gespeicherten EinzelwertloggerDaten (Siehe Kapitel „3. Bedienung der

Loggerfunktion“)

Konfiguration

Einheit ** / Sea-Level** / Messrate** /

Power-off / Schnittstellen-Adresse

Justage

Von Nullpunkt und Spanne

Alarm

Min/Max Alarm visuell mit/ohne Hupe

Logger**

Umschalten von Hold auf Logger Fkt:

Einzelwert (STOR) bzw. zyklisch (CYCL)

Set

Cloc

(ring - shift)

* erscheint nur, wenn Daten im Einzelwert-Logger gespeichert sind

** erscheint nur, wenn keine Daten im Logger gespeichert sind (siehe „3. Bedienung der Loggerfunktion“).

System-Uhr

Uhrzeit / Tag & Monat / Jahr

Parameter Nächster Übernahme

einstellen Parameter & Abbruch

Page 35

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

Menu Param. Werte Bedeutung

„Menu“

SEt

ConF

SEt

CAL

►

▲ oder ▼

Set Configuration: Allgemeine Einstellungen

Unit

SL

Alti

rAtE

t.AVG

P.oFF

Out

Adr.

dAC.

dAC.0

dAC.1

mbar, bar, ... Unit: Anzeigeeinheit

oFF / on Sea-Level: Meereshöhen-Korrektur an/aus

-200 ... +9999

Slo

FASt Fast: schnelle Messung, gefiltert (> 100 Hz)

P.dEt Peak detection: schnelle Messung, ungefiltert (> 100 Hz)

1 ... 120 Zeit in Sekunden, über der die Mittelwertbildung errechnet wird

oFF Mittelwertbildung deaktiviert

1 ... 120 Auto Power-Off (Abschaltverzögerung) in Minuten. Wird keine

oFF Automatische Abschaltung deaktiviert (Dauerbetrieb)

oFF Keine Ausgabefunktion, niedrigster Stromverbrauch

SEr Geräteausgang ist serielle Schnittstelle

dAC Geräteausgang ist Analogausgang 0 ... 1 V

01, 11 ... 91 Basisadresse der Schnittstelle

CH1, CH2 or

CH DIF

eg. -5.00 ...

+5.00 mbar

eg. -5.00 ...

+5.00 mbar

Altitude: Meereshöhen-Korrektur in [m] (nur wenn SL an)

Rate: Messgeschwindigkeit (siehe Kapitel 2.3)

Slow: langsame Messung (4 Hz gefiltert, geringer Stromverbrauch)

Taste gedrückt und findet kein Datenverkehr über die Schnittstelle statt, so schaltet sich das Gerät nach Ablauf dieser Zeit

automatisch ab.

Messeingang, der für die Analogausgabe verwendet werden soll

(nur bei Out = dAC)

Nullpunkteinstellung bei Out = dAC: Eingabe des Messwertes bei

dem der Analogausgang 0 V ausgeben soll (nur bei Out = dAC)

Steigungseinstellung bei Out = dAC: Eingabe des Messwertes bei

dem der Analogausgang 1 V ausgeben soll (nur bei Out = dAC)

Set Calibration: Sensorabgleich

OFS.1

Sensordep.,

e.g. -5.00 ...

+5.00 mbar

Der Nullpunkt des Sensors 1 wird um diesen Wert

verschoben, damit können Fühler- und Messgeräte-Abweichungen ausgeglichen werden.

OFF Nullpuntverschiebung ist deaktiviert (= 0.0 °)

SCL.1

eg. -5.00 ...

+5.00 mbar

Die Mess-Steigung des Sensors 1 wird um diesen Faktor [%]

verändert, damit können Fühler- und Messgeräte-Abweichungen ausgeglichen werden.

OFF Faktor ist deaktiviert (= 0.000)

OFS.2

Sensordep.,

e.g. -5.00 ...

+5.00 mbar

Der Nullpunkt des Sensors 2 wird um diesen Wert

verschoben, damit können Fühler- und Messgeräte-Abweichungen ausgeglichen werden.

OFF Nullpunktverschiebung ist deaktiverit (= 0.0°)

SCL.2

eg. -5.00 ...

+5.00 mbar

Die Mess-Steigung des Sensors 2 wird um diesen Faktor [%]

verändert, damit können Fühler- und Messgeräte-Abweichungen ausgeglichen werden.

OFF Faktor ist deaktiviert (= 0.000)

*, **

*, **

*, **

*

*

*

*

D

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 35

Page 36

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät36

Menu Param. Werte Bedeutung

►

▲ oder ▼

Set Alarm: Einstellung der Alarmfunktion

AL.

[1,2,DIF]

AL.Lo

[1,2,DIF]

AL.Hi

[1,2,DIF]

Set Logger: Einstellung der Loggerfunktion

Func

CYCL

Lo.Po

Set Clock: Einstellung der Echtzeituhr

CLOC

dAtE

YEAr

on Alarm Sensor an, mit Hupe

no. So Alarm Sensor an, ohne Hupe

oFF Keine Alarmfunktion

Min-Range ...

... AL.Hi

AL.Lo ...

... Max-Range

CYCL Cyclic: Loggerfunktion zyklischer Logger

Stor Store: Loggerfunktion Einzelwertlogger

oFF Keine Loggerfunktion

1 ... 3600 Zykluszeit in [Sekunden] bei zyklischem Logger

on / oFF Low-Power-Logger mit geringer Stromaufnahme (nur bei

HH:MM Clock: Einstellen der Uhrzeit Stunden:Minuten

TT.MM Date: Einstellen des Datums Tag.Monat

YYYY Year: Einstellen der Jahreszahl

„Menu“

SEt

AL.

SEt

LoGG

SEt

CLOC

Min-Alarm-Grenze (nicht wenn AL.oFF, Sensor-Min ist die untere

Anzeigebereichs-Grenze des angesteckten Sensors)

Max-Alarm-Grenze (nicht wenn AL.oFF, Sensor-Max ist die obere

Anzeigebereichs-Grenze des angesteckten Sensors)

*

*

*

*

*

*

zyklischem Logger und langsamer Messung)

*

* Befinden sich Daten im Loggerspeicher, können diese Menüpunkte,

nicht aufgerufen werden. Sollen diese verändert werden, müssen

zunächst die Daten gelöscht werden (siehe Kapitel 3).

** Menü kann nur aufgerufen werden, wenn ein entsprechender Sensor

an Anschluss 1 angesteckt ist. Bei einem zweiten entsprechenden

Sensor an Anschluss 2 werden die Einstellungen übernommen.

2. Konfigurieren des Gerätes

Zum Ändern von Einstellungen 2 sec lang die Taste ´Set/Menu´

drücken, dadurch wird das Menü (Hauptanzeige „SEt“) aufgerufen.

Mit ´Set/Menu´ wählen Sie das Menü und mit ´Tara´ können Sie zu den

zugehörigen Parametern springen, den Sie dann verändern können.

Die Einstellung der Parameter erfolgt mit den Tasten ´Min´ oder ´Max´.

Erneutes Drücken von ´Set/Menu´ wechselt zurück zum Hauptmenü

und speichert die Einstellungen.

Mit ´Store/Quit´ wird die Konfiguration beendet.

Page 37

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

2.1 (Unit) Verschiedene Druckeinheiten

Abhängig vom Messbereich des aktuellen Drucksensors kann die

Einheit: mbar, bar, Pa, kPa, MPa, mmHg, inHg oder psi gewählt werden.

2.2 (SL) Höhenkorrektur bei Absolutdruck-Sensoren

Bei angeschlossenem Absolutdrucksensor misst das Gerät den

Absolutdruck. Dieser ist jedoch nicht mit dem von Wetterstationen

angegebenen „Luftdruck auf Meereshöhe“ zu verwechseln! Bei dieser

Druckangabe wird die höhenbedingte Luftdruckabnahme herausgerechnet. Das Gerät ist in der Lage, diese Luftdruck-Höhenkorrektur vorzunehmen. Aktivieren Sie hierzu die „Sea-Level-Funktion“ (SL).

(Einstellung ist nur möglich wenn ein Absolutdrucksensor an Sensorbuchse 1 angeschlossen ist.)

Bei aktivierter Sea-Level-Funktion wird unten in der Anzeige der Pfeil

für „SL“ angezeigt. Wurde die Höhe des Aufenthaltsortes über dem

Meeresspiegel eingegeben (Alti), zeigt das Gerät jetzt den Absolutdruck

auf Meereshöhe bezogen an.

Bei 2 angesteckten Absolutdrucksensoren wird die Sea-Level-Funktion

für beide Sensoren entsprechend den Einstellung von Sensor 1 durchgeführt

2.3 (RatE) Verschiedene Messarten: „rAtE-Slo, -P.dEt, -FASt“

Das Gerät unterstützt 3 verschiede Messarten für verschiedene Anwendungszwecke. Zwei davon arbeiten mit einer erhöhten Messfrequenz

von > 1000 Messungen/sek. Ist eine der beiden aktiv, wird in der unteren

Anzeige entsprechend P.dEt oder FASt angezeigt.

D

2.3.1 rAtE-Slo: Standardmessung

Messfrequenz 4 Hz, Mittelungsverfahren und Messfilter sind aktiv.

Anwendungsbereich: Messen von langsamen Druckänderungen

und statischen Drücken, z. B. Kalibrierungen, Dichtheitsprüfungen,

Luftdruckmessungen u.ä. höchste Messgenauigkeit, störungsunempfindlich, niedriger Stromverbrauch.

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 37

Page 38

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät38

2.3.2 rAtE-P.dEt: Peak detection = Spitzenwertdetektion

Messfrequenz > 1000 Hz, das Messsignal wird ungefiltert wiedergegeben. Anwendungsbereich in Verbindung mit Logger-Funktion: Messen

von Spitzendrücken und schnellen Druckschwankungen mit einer

Auflösung < 1,5 ms. Bei zyklischer Loggerfunktion werden jeweils der

arithmetische Mittelwert, der höchste und der niedrigste Druck des

Intervalls aufgezeichnet.

Erhöhter Stromverbrauch, Messung ist störungsempfindlich (auch

gegenüber elektromagnetischen Störungen).

2.3.3 rAtE-FASt: Fast = Schnelle Messung

Messfrequenz > 1000 Hz, aber das Messsignal wird gefiltert wiedergegeben (weniger störungsempfindlich, kurze Spitzen werden‚ herausgefiltert), ansonsten identisch zu „rAtE-P.dEt“.

2.4 Mittelwertbildung

Die Mittelwertbildung bezieht sich auf die Anzeigewerte (Display und

Schnittstelle). Sie ist komplett unabhängig von der Mittelwertbildung der

Loggerfunktion (bitte nicht verwechseln!).

Die Mittelwertbildung integriert über eine einstellbare Zeit sämtliche

Messwerte und errechnet dann den resultierenden gemittelten Anzeigewert. Die Funktion ist unabhängig von der Messart (schnelle/langsame

Messung).

Solange noch nicht eine ausreichend lange (eingestellte Zeit in Sekunden) gemessen wurde um den Mittelwert errechnen zu können, wird

in der Anzeige „----“ angezeigt, in der unteren Anzeige erscheint ein

‚Countdown‘.

Während des Low-Power-Loggerbetriebes ist die Mittelwertbildung

immer deaktiviert.

Funktion des Min/Max-Wertspeichers in Kombination mit der Mittelwertbildung:

Ist die Mittelwertbildung aktiviert, und die Messfunktion langsame

Messung (rAtE-Slo) gewählt, so bezieht sich der Min/Max-Wertspeicher auf die gemittelten Anzeigewerte.

Ist die Mittelwertbildung aktiviert, und eine schnelle Messfunktion

(rAtE-FASt oder -P.dEt) gewählt, so bezieht sich der Min/MaxWertspeicher auf die intern gemessenen Werte (> 1000 Hz Messfrequenz).

Page 39

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

2.5 Nullpunktkorrektur Sensor 1 (OFS.1) bzw. Sensor 2 (OFS.2)

Für die entsprechende Messung kann eine Nullpunktverschiebung

vorgenommen werden:

Angezeigter Wert = gemessener Wert – Offset

Standardeinstellung: ‚off‘ = 0.0, d.h. es wird keine Korrektur vorgenommen. Die Nullpunktkorrektur wird zusammen mit der Steigungskorrektur

(s.u.) vor allem zum Abgleich von Sensorabweichungen verwendet. Die

Eingabe erfolgt in der eingestellten Anzeigeeinheit.

2.6 Steigungskorrektur Sensor 1 (SCL.1) bzw. Sensor 2 (SCL.2)

Die Steigung der entsprechenden Messung kann mit diesem Faktor

beeinflusst werden (Faktor ist in %):

Angezeigter Wert = (gemessener Wert – Offset) * (1+Scal/100)

Standardeinstellung: ‚off‘ =0.000, d.h. es wird keine Korrektur vorgenommen. Die Steigungskorrektur wird zusammen mit der Nullpunktkorrektur (s.o.) vor allem zum Abgleich von Sensorabweichungen verwendet.

2.7 (P.oFF) Abschaltverzögerung

Wird für die Dauer der Abschaltverzögerung keine Taste gedrückt bzw.

keine Schnittstellenkommunikation vorgenommen, so schaltet sich das

Gerät automatisch ab.

Die Abschaltverzögerung ist zwischen 1 und 120 min wählbar.

Ist P.oFF = oFF, so ist die Abschaltverzögerung deaktiviert.

D

2.8 (Out) Geräteausgang

Der Ausgang kann entweder als Schnittstelle (RS-232 oder USB) oder

als Analogausgang (0 ... 1 V) verwendet werden.

2.8.1 (Adr.) Schnittstellen-Adresse

In Vorbereitung für Multiplexerbetrieb.

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 39

Page 40

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät40

2.8.2 (dAC.) Analogausgang-Skalierung mit dAC.0 und dAC.1

Der Analogausgang kann nicht bei einer Loggeraufzeichnung verwendet

werden.

Mit dAC.0 und dAC.1 kann der Analogausgang sehr einfach skaliert

werden.

Es ist darauf zu achten, dass der Analogausgang nicht zu stark belastet

wird, da sonst der Ausgangswert verfälscht werden kann und die Stromaufnahme des Gerätes entsprechend steigt. Belastungen bis ca. 10 kΩ

sind unbedenklich. Überschreitet die Anzeige den mit dAC.1 eingestellten Wert, so wird 1 V ausgegeben Unterschreitet die Anzeige den mit

dAC.0 eingestellten Wert, so wird 0 V ausgegeben. Im Fehlerfall (Err.1,

Err.2, ----, usw.) wird am Analogausgang eine Spannung leicht über 1 V

ausgegeben.

Klinkensteckerbelegung:

Der 3. Anschluß darf nicht benutzt werden! Nur Stereo-Klinkenstecker sind zulässig!

2.9 (AL.) Alarm

Es sind 3 Einstellungen möglich: aus (AL.oFF), an mit Hupe (AL.on), an

ohne Hupe (AL.no.So).

Bei folgenden Bedingungen wird bei aktiver Alarmfunktion (on oder

no.So) ein Alarm ausgegeben:

Untere (AL.Lo) bzw. obere Alarmgrenze (AL.Hi) unter- bzw. überschritten.

Sensorfehler (Sens-Erro)

Schwache Batterie (bAt)

Fe 7: Systemfehler (wird immer mit Hupe gemeldet)

Im Alarmfall blinkt die Anzeige, bei Schnittstellenzugriffen wird das

‚PRIO'-Flag gesetzt.

Wird von einem Alarmkanal die Hupe zu oder abgeschaltet (on oder

no.So), so wird diese Hupeneinstellung für die restlichen aktivierten

Kanäle automatisch übernommen.

Page 41

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

2.10 (CLOC) Echtzeituhr

Die Echtzeituhr wird für die zeitliche Zuordnung der Loggerdaten benötigt. Kontrollieren Sie deshalb bei Bedarf die Einstellungen. Nach einem

Batteriewechsel wird nach dem Einschalten des Gerätes automatisch

das Uhrzeit-Einstellungs-Menü gestartet.

3. Bedienung der Loggerfunktion

Grundsätzlich besitzt das Gerät zwei verschiedene Loggerfunktionen,

die man über das Hauptmenü aktiviert:

„Func-STOR“: Jeweils ein Messergebnis wird aufgezeichnet, wenn die

Taste ´Store/Quit´ gedrückt wird.

„Func-CYCL“: Messergebnisse werden automatisch im Abstand der

eingestellten Zykluszeit aufgezeichnet, die Aufzeichnung

wird mit 2 sek. lang ´Store/Quit´ drücken gestartet.

Der Logger zeichnet bis zu drei Messergebnisse auf:

Messwert oder Mittelwert (je nach gewählter Funktion), Min.-Wert

und Max Wert. (Sensor 1, Sensor 2, Differenz)

Zur Auswertung der "Func-CYCL"-Daten benötigen sie die Auswerte-Software GSOFT (V 2.3 oder höher), mit der auch der Logger sehr

einfach gestartet und eingestellt werden kann.

Bei aktivierter Loggerfunktion: "Func-STOR" oder "Func-CYCL" (siehe

Menüführung des Hauptmenüs) steht die Hold Funktion nicht zur Verfügung.

D

Min.- und Max.-Wert sind dabei die minimal bzw. maximal gemessenen

Druckwerte seit dem letzten Speichervorgang. Somit können sowohl

der aktuelle Druckwert als auch vorhandene Druckschwankungen sehr

genau analysiert werden.

3.1 „Func-Stor“: Einzelwerte speichern

Jeweils ein Messergebnis wird aufgezeichnet, wenn die Taste ´Store/

Quit´ gedrückt wird. Die gespeicherten Daten können in der Anzeige

selbst betrachtet werden (bei Aufrufen der Konfiguration erscheint ein

zusätzliches Menü: „REAd-LoGG“) oder mit Hilfe der Schnittstelle in

einen PC eingelesen werden.

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät 41

Page 42

D

Hand-Held Druckmessgerät

CPH6200-S1 / CPH6200-S2

11221780.1.3 01/2009 GB/D/F/E

WIKA Betriebsanleitung Hand-Held Druckmessgerät42

Speicherbare Datensätze: 99

Ein Datensatz besteht max. aus:

Sensor 1: Messwert zum Zeitpunkt des Speicherns

Sensor 1: Min.-Peak, Max-Peak seit dem letzten Speichern

Sensor 2*: Messwert zum Zeitpunkt des Speicherns

Sensor 2*: Min.-Peak, Max-Peak seit dem letzten Speichern

Differenz Sensor 1 - Sensor 2*: Messwert zum Zeitpunkt des Speicherns

Differenz Sensor 1 - Sensor 2*: Min.-Peak, Max-Peak seit dem

letzten Speichern

Uhrzeit und Datum zum Zeitpunkt des Speicherns

* Gilt nur für 2-Kanal-Version CPH6200-S2