Page 1

Operating instructions

Betriebsanleitung

Digital pressure gauge mode l CPG500 GB

Digitalmanometer Typ CPG500 D

Digital pressure gauge model CPG500

Page 2

14034181.01 01/2013 GB/D

GB Operating instructions m ode l CP G 500 Page 1 -18

D Betriebsanleitung Typ CPG500 Seite 19 - 34

© 2011 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® i s a regis tered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2 WIKA Operating Instruction, Model CPG500

Page 3

Contents

14034181.01 01/2013 GB/D

GB

C

o

n

t

e

n

t

s

C

o

n

t

e

C

o

n

1 General Information ......................................................................................................... 4

2 Safety .............................................................................................................................. 6

2.1 Intended use .................................................................................................................... 6

2.2 Personnel qualification ..................................................................................................... 7

2.3 Special hazards ............................................................................................................... 7

3 Specifications .................................................................................................................. 8

4 Design and Function ........................................................................................................ 9

4.1 Short description / Description ......................................................................................... 9

4.2 Scope of delivery ............................................................................................................. 9

4.3 Functions and keys .......................................................................................................... 9

4.4 Menu functions .............................................................................................................. 10

4.5 Connection to the process ............................................................................................. 10

5 Transport, packaging and storage ................................................................................. 11

5.1 Transport ....................................................................................................................... 11

5.2 Packaging ...................................................................................................................... 11

5.3 Storage .......................................................................................................................... 11

6 Commissioning, operation ............................................................................................. 12

6.1 Commissioning .............................................................................................................. 12

6.1.1 Changing the batteries ................................................................................................... 12

6.2

Operating the CPG500 digital pressure gauge .............................................................. 13

6.2.1 Turning on (ON) ............................................................................................................. 13

6.2.2 Turn off (OFF) ............................................................................................................... 13

6.2.3 Turn on backlight ........................................................................................................... 13

6.2.4 MIN/MAX indication ....................................................................................................... 13

6.2.5 Full Scale (FS) indication ............................................................................................... 14

6.2.6 Erasing the MIN/MAX values ......................................................................................... 14

6.2.7 OFL Display ................................................................................................................... 14

6.2.8 Zero point correction (ZERO) ......................................................................................... 14

6.2.9 Resetting the zero point correction ................................................................................ 15

6.2.10 Automatic power off ....................................................................................................... 15

6.2.11 Changing the unit .......................................................................................................... 15

6.2.12 Filter settings ................................................................................................................. 16

6.2.13 Display serial number .................................................................................................... 16

7 Maintenance, cleaning and servicing ............................................................................. 17

7.1 Maintenance .................................................................................................................. 17

7.2 Cleaning ........................................................................................................................ 17

7.3 Recalibration ................................................................................................................. 17

8 Dismounting, return and disposal .................................................................................. 18

8.1 Dismounting .................................................................................................................. 18

8.2 Return ........................................................................................................................... 18

8.3 Disposal ........................................................................................................................ 18

n

t

e

n

t

s

t

s

WIKA Operating Instruction, Model CPG500 3

Page 4

1 General Information

14034181.01 01/2013 GB/D

GB

1 General Information

■ The CPG500 digital pressure gauge described in the operating instructions has been

manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during production. Our

management systems are certified to ISO 9001 and ISO 14001.

■ These operating instructions contain important information on handling the CPG500 digital

pressure gauge. Working safely requires that all safety instructions and work instructions are

observed.

■ Observe the relevant local accident prevention regulations and general safety regulations for the

range of use of t he CPG500 digit al pressure gauge.

■ The operating instructions are part of the instrument and must be kept in the immediate vicinity

of the CPG500 digital pressure gauge and readily accessible to skilled personnel at any time.

■ Skilled personnel must have carefully read and understood the operating instructions, prior to

beginning any work.

■ The manufacturer's liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instructions, assignment of

insufficiently qualified skilled personnel or unauthorised modifications to the CPG500 digital

pressure gauge.

■ The general terms and conditions, contained in the sales documentation, shall apply.

■ Subject to technical modifications.

■ Factory calibrations/DKD/DAkks calibrations are carried out in accordance with international

standards.

■ Further information:

- Internet address: www.wika.de / www.wika.c o m

- Relevant Data Sheet: CT 09.01

- Application consultant: Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

4 WIKA Operating Instruction, Model CPG500

Page 5

1 General Information

14034181.01 01/2013 GB/D

GB

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation, which can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can result in light

injuries or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

WIKA Operating Instruction, Model CPG500 5

Page 6

2 Safety

14034181.01 01/2013 GB/D

GB

2 Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

CPG500 digital pressure gauge has been selected in terms of measuring range,

design and specific measuring conditions. Serious injuries and/or damage can occur

should these not be observed.

Further important safety instructions can be found in the individual chapters of

these operating instructions.

2.1 Int ended use

The CPG500 digital pressure gauge can be used as a calibration instrument and also for any

application which requires accuracy pressure measurement.

The CPG500 digit al pressure gauge has been designed and built solely for the intended use

described here, and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the CPG500 digital pressure gauge outside of its technical

specifications requires the instrument to be shut down immediately and inspected by an authorised

WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from humidity,

impacts, strong magnetic fields, static electricity and extreme temperatures, do not insert any

objects into the instrument or its openings). Plugs and sockets must be protected from

contamination.

If the CPG500 digital pressure gauge is transported from a cold into a warm environment, the

formation of condensation may result in the instrument malfunctioning. Before putting it back into

operation, wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

6 WIKA Operating Instruction, Model CPG500

Page 7

2 Safety

14034181.01 01/2013 GB/D

GB

2.2 Personnel qualifi cati on WARNING!

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be

skilled personnel who have the qualifications described

below.

carried out by

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specific regulations, current standards and directives, are capable of carrying out the work

described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

2.3 Special hazards

WARNING!

■ Use the CPG500 digital pressure gauge only with safe gases and liquids per

directive 67/548/EEC.

■ If it is obvious that safe operation of the instrument is no longer possible, the

instrument must be put out of operation and marked in order to secure it against

inadvertent use.

■ The measurement signal of the reference (or test sample) can be influenced by

massive electromagnetic irradiation and/or the indication of the signal could be

completely absent.

■ If the digital pressure gauge CPG500 is used in applications with oil as a pressure

medium, make sure it will not be used with flammable material or gases directly

afterwards since it can lead to dangerous explosions and danger to personnel

and machinery.

■ Digital pressure gauges should only be fitted or remored when the system is free

from pressure.

■ Observe the working conditions in accordance with chapter “3. Specifications”.

■ Always operate the pressure indicator within its overload limits.

WIKA Operating Instruction, Model CPG500 7

Page 8

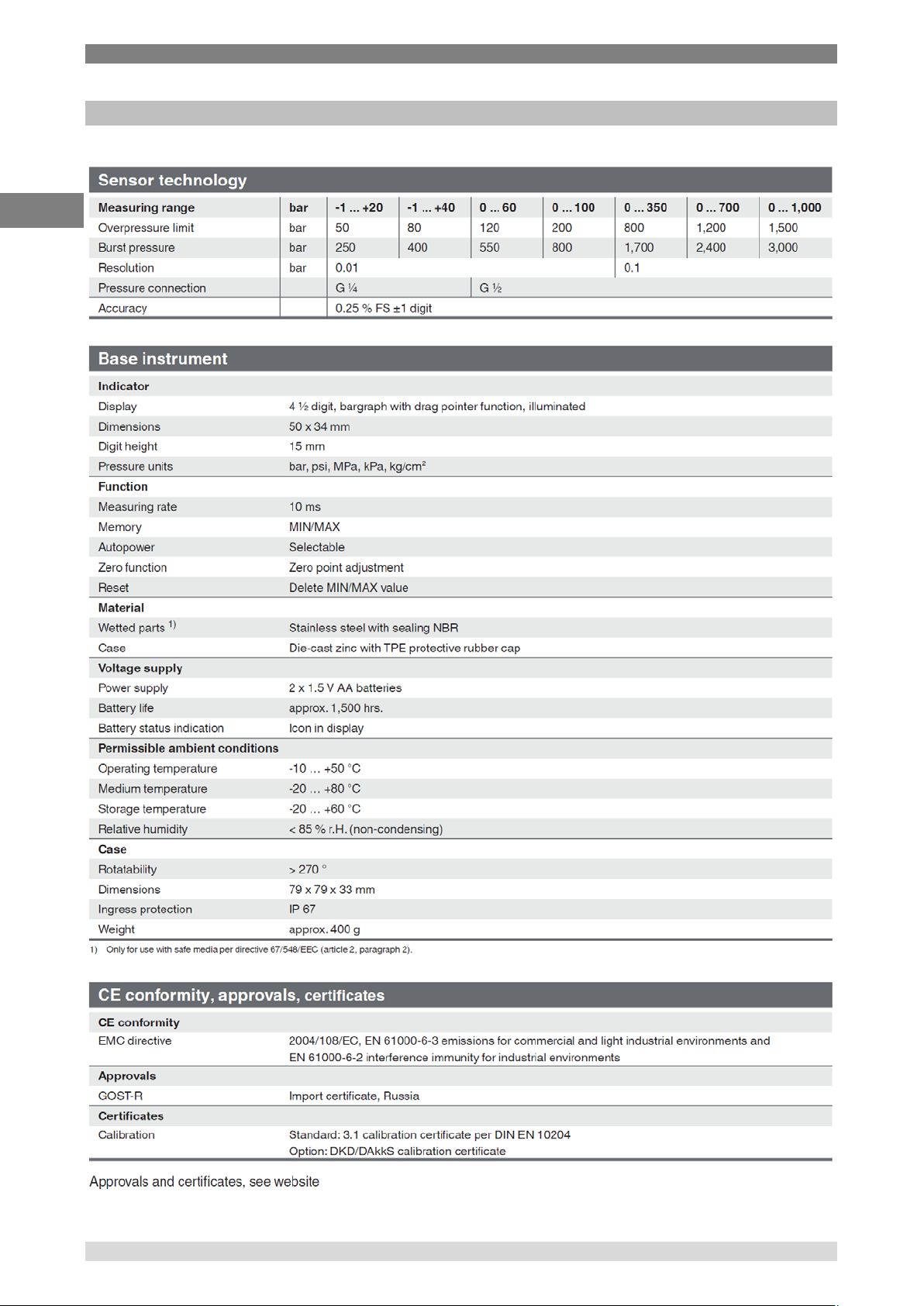

3 Specifications

14034181.01 01/2013 GB/D

GB

3 Specifications

8 WIKA Operating Instruction, Model CPG500

Page 9

4 Design and Function

14034181.01 01/2013 GB/D

GB

4 Design and Function

4.1 Short descripti on / Description

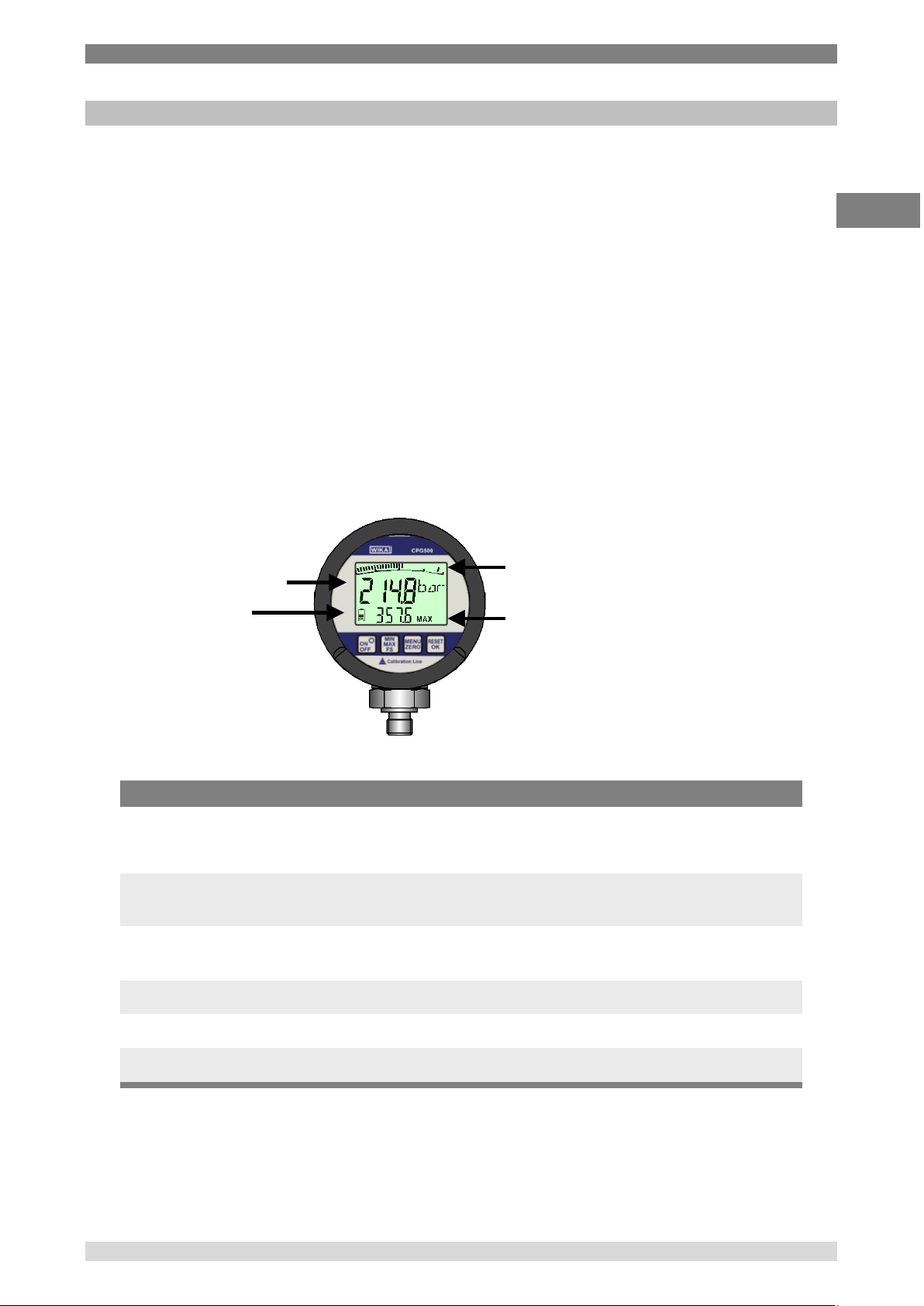

The CPG500 is a digital pressure gauge featuring a Min/Max display function. Full scale (FS)

accuracy is ± 0.25% based on the upper limit of the measurement range.

Dynamic pressure peaks are measured at a sampling rate of 10 ms (100 measurement

values/second). The MIN/Max memory is continuously updated and rewritten.

4.2 Scope of delivery

■ Cross-check scope of delivery with delivery note

■ Batteries are installed ex works

4.3 Functi ons and keys

■ 4½-digit LCD-Display with backlight

■ Displays measurement values and menu functions

Actual value display

Battery status

Display

Bar graph

ACT

MIN/MAX

Bargraph with Peak & Hold Funktion

MIN/MAX or FullScale (FS)

Description

Graphic indication of the actual pressure.

A pressure peak is indicated by means of a pixel (graduation mark).

The indicated value is refreshed at intervals of 50 ms (20 measurements/s).

Indicates the actual pressure.

The indicated value is refreshed at intervals of 300 ms (3 times/s).

Indicates the MIN, MAX or FS value according to setting.

The indicated value is refreshed at intervals of 300 ms (3 times/s).

FS Upper limit of the scale (e.g. 700 bar).

Units Indicates the chosen unit.

Battery Indicates the battery status (5 segments).

WIKA Operating Instruction, Model CPG500 9

Page 10

4 Design and Function

14034181.01 01/2013 GB/D

GB

Description

Pressure connection

Torque

G ¼

25 Nm

G ½

25 Nm

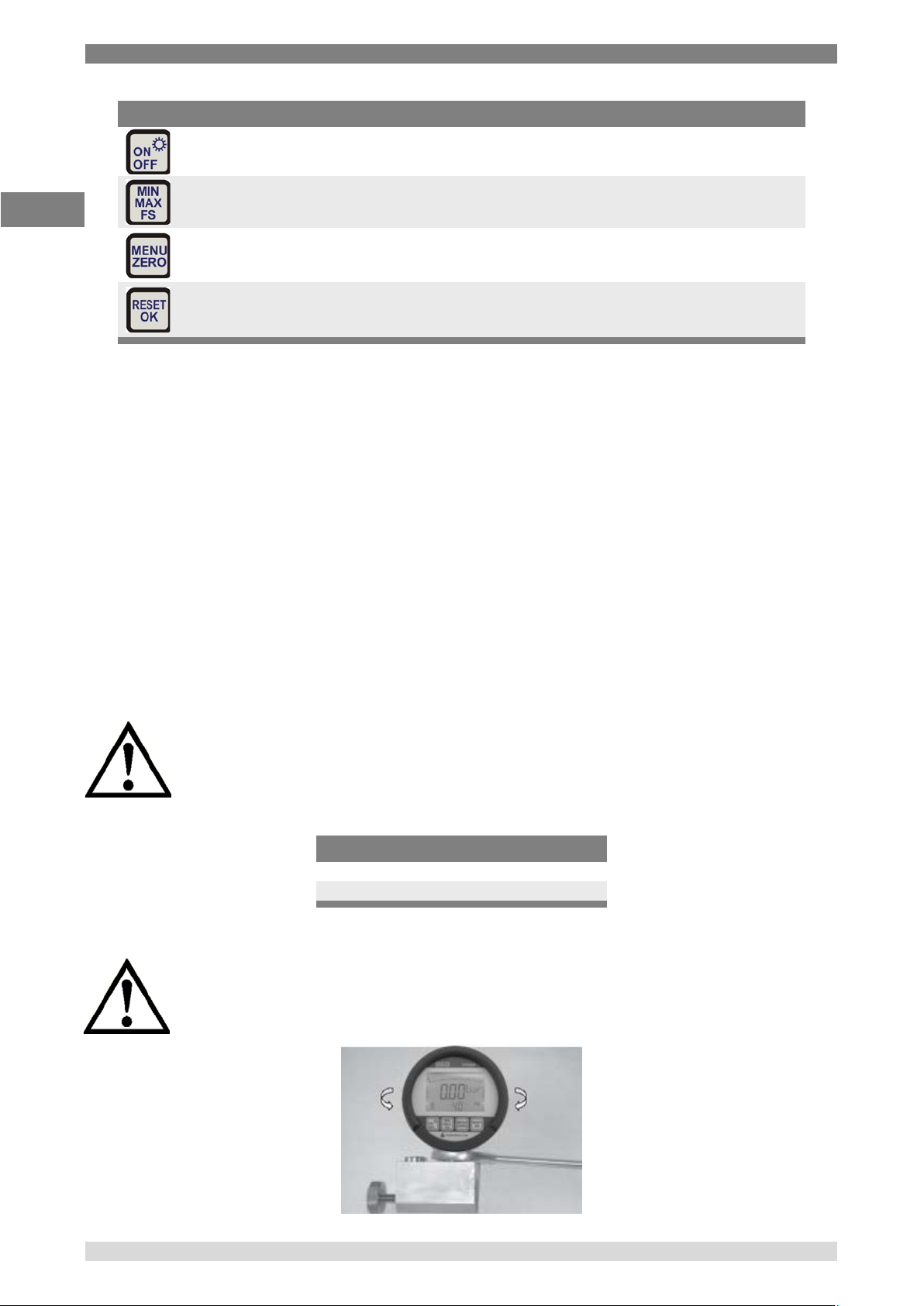

Key

Turns the device on / off.

Press for 2 seconds. Turns on the backlight (stays on for 20 seconds).

Selects display unit: MIN, MAX or FS Minimum value Pressure peak

Displays the upper limit of the scale (e.g. 700 bar)

Press for 2 seconds. Changes the unit.

Auto Power Off – on/off. Zero point calibration.

Erases MIN and MAX values from the memory.

Confirms the MENU functions.

4.4 Menu functions

The following settings can be made in the MENU function:

■ Auto Power Off – on or off

■ Unit selection (bar, PSI, kPa, MPa)

Press the MENU key for 2 seconds to activate the functions menu. Press the MENU key again to

select the next function.

Press the OK key to save the function setting.

The device then switches to the display mode.

4.5 Connection to the process

The CPG500 digital pressure gauge is available with male thread G1/4 or G1/2 for the

corresponding versions.

When fitting the CPG500 digital pressure gauge do not exceed the specified

torques.

When fittin g directly, ensure that the case of the CPG500 digital pressure gauge can

be rotated freely.

10 WIKA Operating Instruction, Model CPG500

Page 11

5 Transport, packaging and storage

14034181.01 01/2013 GB/D

GB

5 Transport, packaging and st orage

5.1 Transport

Check the CPG500 digital pressure gauge for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage Permissible conditions at the place of storage:

■ Storage temperature: -20…+60 °C

■ Humidity: <85 % relative humidity (non-condensing)

Avoid exposure to the following factors:

■ Direct sunlight or proximity to hot objects

■ Mechanical vibration, mechanical shock (putting it down hard)

■ Soot, vapour, dust and corrosive gases

■ Potentially explosive environments, flammable atmospheres

Store the CPG500 digital pressure gauge in its orig inal packaging in a location that fulfills the

conditions listed above. If the original packaging is not available, pack and store the CPG500

digital pressure gauge as described below:

1. Wrap the CPG500 digital pressure gauge in an antistatic plastic film.

2. Place the CPG500 digital pressure gauge, along with shock-absorbent material, in the

packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

WARNING!

Before storing the digital pressure gauge (following operation),

remove any residual media. This is of particular importance if the medium

is hazardous to health, e.g. caustic, toxic, carcinogenic, radioactive, etc.

WIKA Operating Instruction, Model CPG500 11

Page 12

6 Commissioning, operation

14034181.01 01/2013 GB/D

GB

6 Commissioning, operat ion

6.1 Commissioning

The CPG500 digital pressure gauge is supplied with batteries fitted. The device is operational as

soon as it is turned on.

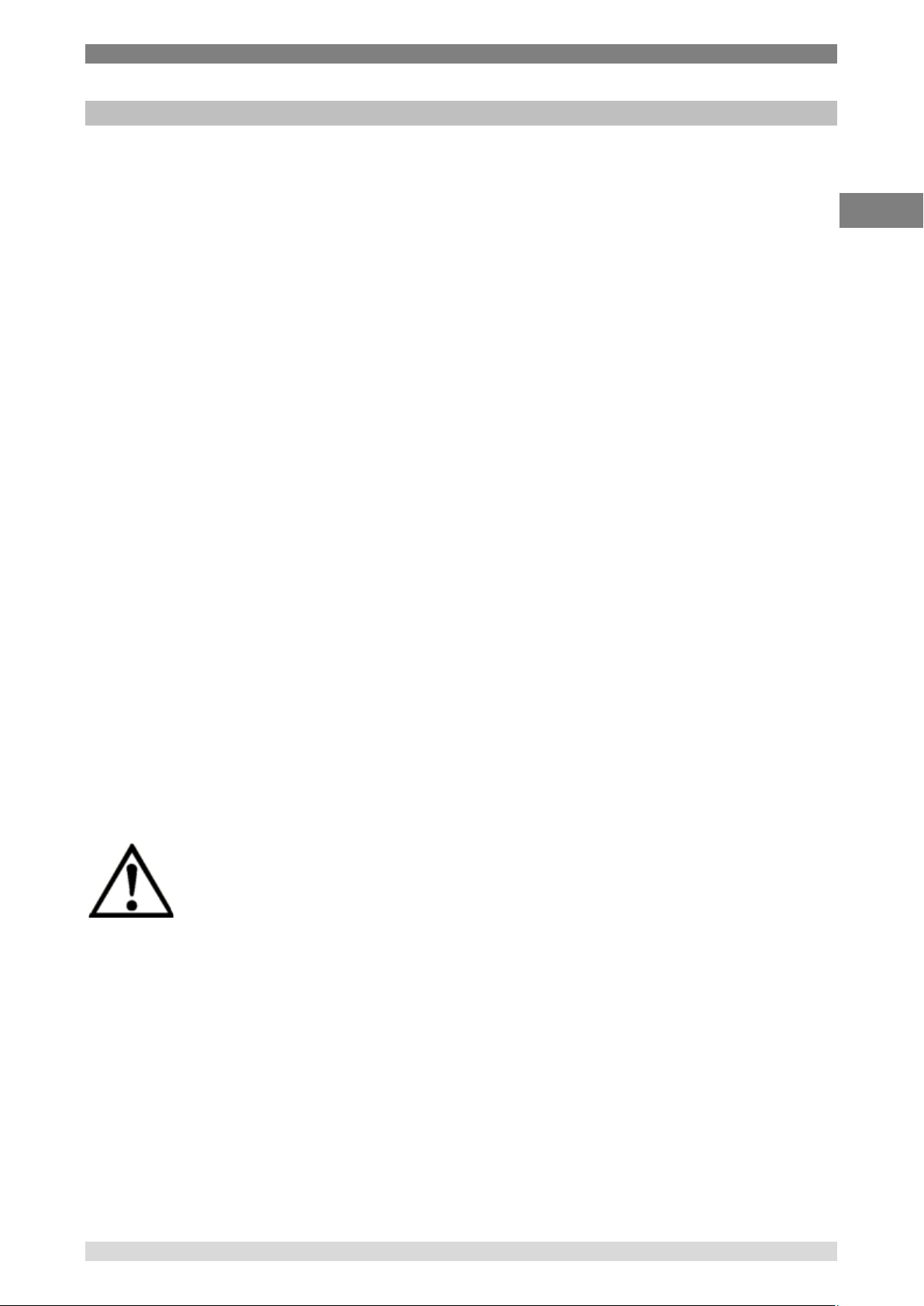

6.1.1 Changing the batteries

CAUTION!

Turn off the device before replacing the batteries.

Open the battery compartment. Insert the new batteries as

depicted.

Ensure correct polarity of the batteries. Batteries: 2 x 1.5 V

(LR6 - AA)

When in continuous operation (without light), the battery life is approx.

1,500 hours.

A battery symbol permanently displays the actual battery status

12 WIKA Operating Instruction, Model CPG500

Page 13

6 Commissioning, operation

14034181.01 01/2013 GB/D

GB

6.2 Oper ating the CPG500 digital pressure gauge

6.2.1 Turning on (ON)

6.2.2 Turn off (OFF)

Press once (briefly)

A self-test procedure is carried out

The measuring range is indicated (FS)

Auto Power Off function is active.

Power off activates automatically after

5 minutes. This function can be

altered in MENU.

Display mode:

ACT value displayed

6.2.3 Turn on backlight

Press for 2 seconds. The backlight is shut off automatically after 20 seconds.

6.2.4 MIN/MAX indication

Use this key to toggle the required value.

The key function is sequential; the values are indicated in the display in sequence.

The MIN/MAX function is used to measure pressure peaks. The respective lowest (MIN) and

highest (MAX) measured values are stored in the MIN/MAX memory. Values in the MIN/MAX

memory are erased when the device is turned off. If different pressure tests are to be carried out in

succession, the MIN/MAX memory must be erased after each measurement.

MIN/MAX-value is indicated in the display.

WIKA Operating Instruction, Model CPG500 13

Page 14

6 Commissioning, operation

14034181.01 01/2013 GB/D

GB

6.2.5 Full Scale (FS) indication

Displaying the upper limit of the scale (FS) is designed to increase readability of the bar graph

indication.

The upper limit of the measurement range is indicated numerically. FS is indicated in sequence

after MIN and MAX.

FS is displayed.

6.2.6 Erasing the MIN/MAX values

Erases MIN/MAX values.

6.2.7 OFL Display

This indicates that the applied pressure is outside of the full scale range.

If the message will remain displayed while the CPG500 is pressure less, please

contact WIKA.

6.2.8 Zero point correction (ZERO)

The zero point can be corrected manually if undesired deviations occur when no system pressure

is being applied (atmospheric pressure).

CAUTION!

The zero point correction sets the current ACT value to zero. In order to exclude faulty

measurements, ensure no system pressure is being applied when carrying out this

function.

This initiates the zero point correction. The ACT (actual) value is indicated in the display as 0.0 bar.

The correction remains active until the device is turned off.

OFL/ZEro is displayed for 3 seconds if the measured pressure (0 bar) is greater

than 5% of the measurement range.

Zero point correction cannot be carried out. Please ensure that no system

pressure is being applied.

14 WIKA Operating Instruction, Model CPG500

Page 15

6 Commissioning, operation

14034181.01 01/2013 GB/D

GB

Auto Power Off

Continuous operations

PO On

is activated after 5 minutes.

PO OFF

be turned off manually.

6.2.9 Resetting the zero point correction

Turn off the device. Zero point correction is no longer active when the device is turned off

and on again.

6.2.10 Automatic power off

Press for 2 seconds.

Depending on the device configuration, two different displays are possible:

Press Auto Power Off

The settings Auto Power Off or Continuous operations remain stored and are active

when the device is turned off and on again.

6.2.11 Changing the unit

Press for 2 seconds.

Press

Press The device must

Confirm unit selection.

WIKA Operating Instruction, Model CPG500 15

Press once (briefly)

The next unit is indicated

Page 16

6 Commissioning, operation

14034181.01 01/2013 GB/D

GB

6.2.12 Filter settings

Press for 2 seconds.

Press

Press

Press once (briefly)

Filter selection is indicated.

(Filter 0 no damping, Filter 3 max. damping)

Confirm filter configuration.

6.2.13 Display serial number

Press

Display of serial number (1. line).

Display of software version (2. line).

Press

16 WIKA Operating Instruction, Model CPG500

Page 17

7 Maintenance, cleaning and servicing

14034181.01 01/2013 GB/D

GB

7 Maintenance, cleaning and servicing

7.1 Maintenance

This CPG500 digital pressure gauge is maintenance-free.

Repairs must only be carried out by the manufacturer. Except for battery replacement.

7.2 Cleaning

CAUTION!

■ Before cleaning, correctly disconnect the CPG500 digital pressure gauge from

the pressure supply, and switch it off.

■ Clean the CPG500 digital pressure gauge with a moist cloth.

■ Wash or clean the dismounted CPG500 digital pressure gauge before returning it,

in order to protect staff and the environment from exposure to residual media.

■ Residual media in dismounted CPG500 digital pressure gauge can result in a risk

to persons, the environment and equipment. Take sufficient precautionary

measures.

For information on returning the CPG500 digital pressure gauge see chapter "8.2

Return".

7.3 Recalibration

DKD certificate - Certificates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with time

intervals of approx. 12 months. Every factory recalibration includes, additionally, an extensive freeof-charge check of all system parameters with respect to their compliance with the specification.

The basic settings will be corrected if necessary.

WIKA Operating Instruction, Model CPG500 17

Page 18

8 Dismounting, return and disposal

14034181.01 01/2013 GB/D

GB

8 Dismounting, return and dis pos al

WARNING!

Residual media in dismounted digital pressure gauge can result in a risk to persons,

the environment and equipment. Take sufficient precautionary measures.

8.1 Dismounting

Only disconnect test- and calibration installations once the system has been depressurised!

8.2 Return

WARNING!

Strictly observe when shipping the CPG500 digital pressure gauge:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.).

When returning the digital pressure gauge, use the original packaging or a suitable transport

package.

To avoid damage:

1. Wrap the CPG500 digital pressure gauge in an antista tic plastic film.

2. Place the CPG500 digital pressure gauge, along with the shock-absorbent material, in the

packaging. Place shock-absorbent material evenly on all sides of the shipping box.

3. If possible, place a bag, containing a desiccant, inside the packag ing.

4. Label the shipment as transport of a highly sensitive measuring instrument.

Enclose the completed return form with the CPG500 digital pressure gauge.

The return form is available on the internet:

www.wika.de / Service / Return

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible way

and in accordance with the country-specific waste disposal regulations.

18 WIKA Operating Instruction, Model CPG500

Page 19

Inhalt

14034181.01 01/2013 GB/D

D

I

n

h

a

l

t

I

n

h

I

n

h

1 Allgemeine Informationen .............................................................................................. 20

2 Sicherheit ...................................................................................................................... 22

2.1 Bestimmungsgemäße Verwendung ............................................................................... 22

2.2 Personalqualifikation ..................................................................................................... 23

2.3 Besondere Gefahren ..................................................................................................... 23

3 Technische Daten .......................................................................................................... 24

4 Aufbau und Funktion ..................................................................................................... 25

4.1 Kurzbeschreibung / Beschreibung ................................................................................. 25

4.2 Lieferumfang ................................................................................................................. 25

4.3 Funktionen und Tasten .................................................................................................. 25

4.4 Menü-Funktionen ........................................................................................................... 26

4.5 Anschluss an die Hydraulik ............................................................................................ 26

5 Transport, Verpackung und Lagerung ........................................................................... 27

5.1 Transport ....................................................................................................................... 27

5.2 Verpackung ................................................................................................................... 27

5.3 Lagerung ....................................................................................................................... 27

6 Inbetriebnahme, Betrieb ................................................................................................ 28

6.1 Inbetriebnahme.............................................................................................................. 28

6.1.1 Batteriewechsel ............................................................................................................. 28

6.2

6.2.1 Einschalten (ON) ........................................................................................................... 29

6.2.2 Ausschalten (OFF) ........................................................................................................ 29

6.2.3 Beleuchtung einschalten ................................................................................................ 29

6.2.4 MIN/MAX-Anzeige ......................................................................................................... 29

6.2.5 FS Full Scale Anzeige ................................................................................................... 30

6.2.6 Löschen der MIN/MAX Werte ........................................................................................ 30

6.2.7 OFL Display ................................................................................................................... 30

6.2.8 Nullpunktkorrektur (ZERO) ............................................................................................ 30

6.2.9 Zurücksetzen der Nullpunktkorrektur ............................................................................. 31

6.2.10 Automatische Abschaltung ............................................................................................ 31

6.2.11 Verändern der Einheiten ................................................................................................ 31

6.2.12 Verändern der Filtereinstellungen (Dämpfung) .............................................................. 32

6.2.13 Anzeige der Seriennummer ........................................................................................... 32

7 Wartung, Reinigung und Service ................................................................................... 33

7.1 Wartung ......................................................................................................................... 33

7.2 Reinigung ...................................................................................................................... 33

7.3 Rekalibrierung ............................................................................................................... 33

8 Demontage, Rücksendung und Entsorgung .................................................................. 34

8.1 Demontage .................................................................................................................... 34

8.2 Rücksendung ................................................................................................................ 34

8.3 Entsorgung .................................................................................................................... 34

a

l

t

a

l

t

Bedienung des CPG500 ................................................................................................ 29

WIKA Betriebsanleitung, Typ CPG500 19

Page 20

1 Allgemeine Informationen

14034181.01 01/2013 GB/D

D

1 Allgemeine Informationen

■ Das in der Betriebsanleitung beschriebene Digitalmanometer CPG500 wird nach

den neuesten Erkenntnissen gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien.

Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertifiziert.

■ Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Digitalmanometer

CPG500. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■ Die für den Einsatzbereich des Digitalmanometer CPG500 geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■ Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Digitalmanometer CPG500 für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■ Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen

und verstanden haben.

■ Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung,

Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualifizierten Fachpersonals sowie

eigenmächtiger Veränderung am Digitalmanometer CPG500.

■ Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■ Technische Änderungen vorbehalten.

■ Werkskalibrierungen/DKD/DAkkS-Kalibrierungen erfolgen nach internationalen Normen.

■ Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.c o m

- zugehöriges Datenblatt: CT 09.01

- Anwendungsberater : Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

20 WIKA Betriebsanleitung, Typ CPG500

Page 21

1 Allgemeine Informationen

14034181.01 01/2013 GB/D

D

Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder

leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen effizienten

und störungsfreien Betrieb hervor.

WIKA Betriebsanleitung, Typ CPG500 21

Page 22

2 Sicherheit

14034181.01 01/2013 GB/D

D

2 Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

Digitalmanometer CPG500 hinsichtlich Messbereich, Ausführung und spezifischen

Messbedingungen ausgewählt wurde. Bei Nichtbeachten können schwere

Körperverletzungen und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise befinden sich in den einzelnen Kapiteln dieser

Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Dieses Digitalma nome ter CPG500 kann als Kalibriergerät sowie für jede Anwendung, bei der eine

hochgenaue Druckmessung erforderlich ist, verwendet werden.

Das Digitalmanomete r CPG 500 ist ausschließlich für den hier beschriebenen

bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur

dementsprechend verwendet werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine unsachgemäße

Handhabung oder ein Betreiben des Digitalmanometer CPG500 außerhalb der technischen

Spezifikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten WIKAServicemitarbeiter erforderlich.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe, Stößen,

starken Magnetfeldern, statische Elektrizität und extremen Temperaturen schützen, keine

Gegenstände in das Gerät bzw. Öffnungen einführen). Stecker und Buchsen vor Verschmutzung

schützen.

Wird das Digitalmanometer CPG500 von einer kalten in eine warme Umgebung transportiert, so

kann durch Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

22 WIKA Betriebsanleitung, Typ CPG500

Page 23

2 Sicherheit

14034181.01 01/2013 GB/D

D

2.2 Personalqualifikation WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal

nachfolgend beschriebener Qualifikation durchführen lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess- und

Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landes-spezifischen Vorschriften,

geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen und

mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über aggressive

Medien.

2.3 Besondere Gefahren

WARNUNG!

■ Das Digitalmanometer CPG500 ausschließlich mit ungefährlichen Gasen und

Flüssigkeiten nach Richtlinie 67/548/EWG verwenden.

■ Wenn anzunehmen ist, dass das Digitalmanometer nicht mehr gefahrlos

betrieben werden kann, so ist es außer Betrieb zu setzen und vor einer

Wiederinbetriebnahme durch Kennzeichnung zu sichern.

■ Das Messsignal der Referenz (bzw. des Prüflings) kann durch massive

elektromagnetische Einstrahlung beeinflusst werden bzw. die Anzeige des

Signals ganz ausbleiben.

■ Wird das Digitalmanometer CPG500 bei Applikationen mit Druckmedium Öl

verwendet, so ist ein anschließender Einsatz bei Brennstoffen oder Gasen

auszuschließen, da dies zu gefährlichen Explosionen und Gefahr für Mensch und

Maschine führen kann.

■ Digitalmanometer nur in drucklosen Zustand montieren bzw. demontieren.

■ Betriebsparameter gemäß Kapitel „3. Technische Daten“ beachten.

■ Druckmessgerät immer innerhalb des Überlastgrenzbereiches betreiben

WIKA Betriebsanleitung, Typ CPG500 23

Page 24

3 Technische Daten

14034181.01 01/2013 GB/D

D

3 Technische Daten

24 WIKA Betriebsanleitung, Typ CPG500

Page 25

4 Aufbau und Funktion

14034181.01 01/2013 GB/D

D

4 Aufbau und Funktion

4.1 Kurzbeschreibung / Beschreibung

Das CPG500 ist ein digitales Manometer mit MIN/MAX-Anzeige. Die Genauigkeit ist ± 0,25%

bezogen auf den Messbereichsendwert (FS).

Mit einer Abtastrate von 10 ms (100 Messwerte/s) werden dynamische Druckspitzen gemessen.

Der MIN/MAX-Speicher wird permanent aktualisiert und überschrieben.

4.2 Lieferumfang

■ Lieferumfang mit dem Lieferschein abgleichen

■ Batterien sind bereits ab Werk eingesetzt

4.3 Funkti onen und Tasten

■ 4½-stelliges LCD-Disp lay m it Hintergrundbeleuchtung

■ Anzeige der Messwerte und Menüfunktionen

Anzeige

Bargraph

IST

MIN/MAX

Istwertanzeige

Batterie Status

Beschreibung

Zeigt den aktuellen Druck grafisch durch einen Bargraph an.

Eine Druckspitze wird in Form eines Pixel (Strich) angezeigt.

Diese Anzeige wird in einem Intervall von 50 ms aktualisiert (20 Messungen/s).

Zeigt den aktuellen Druck an.

Diese Anzeige wird in einem Intervall von 300 ms aktualisiert (3 Anzeigen/s).

Zeigt den MIN-, MAX- oder FS-Wert an, je nach Voreinstellung

Diese Anzeige wird in einem Intervall von 300 ms aktualisiert (3 Anzeigen/s).

Bargraph mit Peak & Hold Funktion

MIN/MAX oder FullScale (FS)

FS Skalenendwert (z.B. 700 bar).

Einheiten Zeigt die eingestellte Einheit an.

Batterie Zeigt den Batteriezustand an (5 Segmente).

WIKA Betriebsanleitung, Typ CPG500 25

Page 26

4 Aufbau und Funktion

14034181.01 01/2013 GB/D

D

Funktion

Druckanschluss

Drehmoment

G ¼

25 Nm

G ½

25 Nm

Taste

Gerät ein/-ausschalten.

2 s drücken. Hintergrundbeleuchtung ein (für 20 s eingeschaltet).

Auswahl Anzeigewert: MIN, MAX oder FS.

Minimalwert, Druckspitze, Anzeige des Skalenendwerts (z.B. 700 bar)

2 s drücken. Verändern der Einheiten.

Automatische Abschaltung ein oder aus. Nullpunktabgleich.

Löschen des MIN- und MAX-Messwertespeichers.

Bestätigen der MENU-Funktionen.

4.4 Menü-Funktionen

In der MENU-Funktion werden folgende Einstellungen vorgenommen:

■ Automatische Abschaltung ein oder aus

■ Einstellen der Messeinheit (bar, PSI, kPa, MPa)

Durch Drücken der Taste MENU (2 s) wird das Funktionsmenü aktiviert.

Durch erneutes Betätigen der Taste MENU wird die nächste Funktion gewählt.

Durch Betätigen der Taste OK wird die Funktion gespeichert. Danach schaltet das Gerät in den

Anzeigemodus.

4.5 Anschluss an den Prozess

Das Digitalmanometer CPG500 wird gemäß den verschiedenen Versionen mit G1/4 oder G1/2

Außengewinde ausgeliefert.

Bei Montage des Digitalmanometers CPG500 die angegebenen Drehmomente nicht

überschreiten.

Bei Direktmontage des Digitalmanometers CPG500 auf die Drehbarkeit des

Gehäuses achten.

26 WIKA Betriebsanleitung, Typ CPG500

Page 27

5 Transport, Verpackung und Lagerung

14034181.01 01/2013 GB/D

D

5 Transport, Verpack ung und Lagerung

5.1 Transport

Das Digitalmanometer CPG500 auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen Schutz

(z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■ Lagertemperatur: -20…+60 °C

■ Feuchtigkeit: <85 % relative Feuchte (keine Betauung)

Folgende Einflüsse vermeiden:

■ Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■ Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■ Ruß, Dampf, Staub und korrosive Gase

■ Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Digitalmanometer CPG500 in der Originalverpackung an einem Ort, der die oben gelisteten

Bedingungen erfüllt, lag ern. Wenn die Originalverpackung nicht vorhanden ist, dann das

Digitalmanometer CPG500 wie folgt verpacken und lagern:

1. Das Digitalmanometer CPG500 in eine antistatische Plastikfolie einhüllen.

2. Das Digitalmanometer CPG500 mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

WARNUNG!

Vor der Einlagerung des Digitalmanometer (nach Betrieb) alle anhaftenden

Messstoffreste entfernen. Dies ist besonders wichtig, wenn der Messstoff

gesundheitsgefährdend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

WIKA Betriebsanleitung, Typ CPG500 27

Page 28

6 Inbetriebnahme, Betrieb

14034181.01 01/2013 GB/D

D

6 Inbetriebnahme, Betrieb

6.1 Inbetriebnahme

Das Digitalmanometer CPG500 wird werkseitig mit eingebauten Batterien ausgeliefert. Nach dem

Einschalten ist das Gerät betriebsbereit.

6.1.1 Batteriewechsel

VORSICHT!

Zum Auswechseln der Batterien das Gerät ausschalten.

Öffnen Sie das Batteriefach. Setzen Sie die neuen Batterien

gemäß Abbildung ein. Achten Sie auf die Polarität der Batterie.

Batterie: 2 x 1,5 V (LR6 - AA)

Die Lebensdauer der Batterie beträgt ca. 1.500 Stunden bei kontinuierlichem Betrieb

(ohne Beleuchtung).

Die Batteriekapazität wird permanent mit dem Batteriesymbol dargestellt.

28 WIKA Betriebsanleitung, Typ CPG500

Page 29

6 Inbetriebnahme, Betrieb

14034181.01 01/2013 GB/D

D

6.2 Bedienung des Digitalmanometers CPG500

6.2.1 Einschalten (ON)

6.2.2 Ausschalten (OFF)

(kurz) drücken

Durchführen des Selbsttests

Anzeige des Messbereichs (FS)

Auto Power Off Funktion aktiv.

Automatische Abschaltung nach 5 min.

Diese Funktion kann im MENÜ geändert

werden.

Anzeigemodus: IST-Wert im Display

6.2.3 Beleuchtung einschalten

gedrückt halten (2 s). Die Beleuchtung wird nach 20 s automatisch ausgeschaltet

6.2.4 MIN/MAX-Anzeige

Das Darstellungsformat kann entsprechend mit dieser Taste umgeschaltet werden.

Die Tastenfunktion ist rollierend, die Werte erscheinen nacheinander in der Anzeige.

Um Druckspitzen zu messen wird die MIN/MAX-Funktion benutzt. Im MIN/MAX-Speicher stehen

die jeweils kleinsten (MIN), bzw. größten (MAX) Messwerte. Beim Ausschalten wird der MIN/MAXSpeicher gelöscht. Sollen nacheinander verschiedene Drucktests durchgeführt werden, muss der

MIN/MAX-Speicher nach jeder Messung gelöscht werden.

MIN/MAX-W ert ers c he in t im Dis p lay.

WIKA Betriebsanleitung, Typ CPG500 29

Page 30

6 Inbetriebnahme, Betrieb

14034181.01 01/2013 GB/D

D

6.2.5 Full Scale (FS) Anzeige

Die Anzeige des Skalenendwertes (FS) dient zur besseren Ablesbarkeit der Bargraphanzeige.

Nach der Anzeige von MIN und MAX erscheint FS.

Der Skalenendwert des Messbereichs wird numerisch dargestellt.

FS erscheint im Display.

6.2.6 Löschen der MIN/MAX Werte

MIN/MAX-Werte werden gelöscht.

6.2.7 OFL Display

Der gemessene Druck ist außerhalb des Messbereichs (Full Scale).

Erscheint diese Anzeige auch im drucklosen Zustand, nehmen Sie bitte Kontakt

mit WIKA auf.

6.2.8 Nullpunktkorrektur (ZERO)

Bei unerwünschten Abweichungen im drucklosen Zustand (Atmosphärendruck) kann der Nullpunkt

manuell korrigiert werden.

VORSICHT!

Die Nullpunktkorrektur setzt den aktuellen IST-Wert auf Null. Diese Funktion nur im

drucklosen Zustand ausführen, um Fehlmessungen auszuschließen.

Die Nullpunktkorrektur ist durchgeführt. Im Display erscheint 0.0 bar als IST-Wert. Der Abgleich

bleibt aktiviert, bis das Gerät ausgeschaltet wird.

Ist der gemessene Druck (0 bar) größer als 5% des Messbereichs, erscheint

OFL/ZEro (3 s).

Die Korrektur kann nicht durchgeführt werden. Bitte drucklosen Zustand

sicherstellen.

30 WIKA Betriebsanleitung, Typ CPG500

Page 31

6 Inbetriebnahme, Betrieb

14034181.01 01/2013 GB/D

D

Automatische Abschaltung

Dauerbetrieb

PO On

Abschaltung nach 5 min.

PO OFF

werden.

6.2.9 Zurücksetzen der Nullpunktkorrektur

Gerät ausschalten. Nach erneutem Einschalten ist die Nullpunktkorrektur nicht mehr aktiv.

6.2.10 Automatische Abschaltung

2 s drücken.

Je nach Konfiguration des Gerätes sind zwei verschiedene Anzeigen möglich:

Nach Betätigen von

erfolgt die automatische

Die Einstellungen Automatische Abschaltung oder Dauerbetrieb bleiben gespeichert

und sind beim Einschalten wieder aktiv.

6.2.11 Verändern der Einheiten

2 s drücken.

drücken

Nach Betätigen von muss

das Gerät manuell abgeschaltet

kurz drücken

Die nächste Einheit erscheint.

Bestätigen der Einheit.

WIKA Betriebsanleitung, Typ CPG500 31

Page 32

6 Inbetriebnahme, Betrieb

14034181.01 01/2013 GB/D

D

6.2.12 Verändern der Filtereinstellungen (Dämpfung)

2 s. drücken.

drücken

drücken

kurz drücken

Die Filterauswahl erscheint

(Filter 0 keine Dämpfung, Filter 3 hohe Dämpfung)

Bestätigen der Filtereinstellungen.

6.2.13 Anzeige der Seriennummer

drücken

Anzeige der Seriennummer (1. Zeile).

Anzeige der Software-Version (2. Zeile).

drücken

32 WIKA Betriebsanleitung, Typ CPG500

Page 33

7 Wartung Reinigung, und Service

14034181.01 01/2013 GB/D

D

7 Wartung, Reinigung und Service

7.1 Wartung

Das Digitalmanometer CPG500 ist wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen. Ausgenommen ist der Austausch

der Batterien.

7.2 Reinigung

VORSICHT!

■ Vor der Reinigung das Digitalmanometer CPG500 ordnungsgemäß von der

Druckversorgung trennen, und ausschalten.

■ Das Digitalmanometer CPG500 mit einem feuchten Tuch reinigen.

■ Das ausgebaute Digitalmanometer CPG500 vor der Rücksendung spülen bzw.

säubern, um Mitarbeiter und Umwelt vor Gefährdung durch anhaftende

Messstoffreste zu schützen.

■ Messstoffreste in dem ausgebauten Digitalmanometer CPG500 können zur

Gefährdung von Personen, Umwelt und Einrichtung führen. Ausreichende

Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Digitalmanometers CPG500 siehe Kapitel „8.2

Rücksendung“.

7.3 Rekalibrierung

DKD-Schein – amtliche Bescheinigungen:

Es wird empfohlen, das Digitalmanometer in regelmäßigen Zeitabständen von ca. 12 Monaten

durch den Hersteller rekalibrieren zu lassen. Jede werksseitige Rekalibrierung beinhaltet

außerdem eine umfangreiche und kostenfreie Überprüfung aller Systemparameter auf Einhaltung

der Spezifikationen. Die Grundeinstellungen werden wenn notwendig korrigiert.

WIKA Betriebsanleitung, Typ CPG500 33

Page 34

8 Demontage, Rücksendung und Entsorgung

14034181.01 01/2013 GB/D

D

8 Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoffreste in ausgebauten Digitalmanometern können zur Gefährdung von

Personen, Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen

ergreifen.

8.1 Demontage

Prüf-/und Kalibrieraufbauten nur im drucklosen Zustand demontieren!

8.2 Rücksendung

WARNUNG!

Beim Versand des Digitalmanometers CPG500 unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoffen (Säur en, Laugen,

Lösungen, etc.) sein.

Zur Rücksendung von Digitalmanometern die Originalverpackung oder eine geeignete

Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Digitalmanometer CPG500 in eine antistatische Plastikfolie einhüllen.

2. Das Digitalmanometer CPG500 mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

4. Sendung als Transport eines hochempfindlichen Messgerätes kennzeichnen.

Dem Digitalmanometer CPG500 das Rücksendeformular ausgefüllt beifügen.

Das Rücksendeformular steht im Internet zur Verfügung:

www.wika.de / Service / Rücksendung

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezifischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

34 WIKA Betriebsanleitung, Typ CPG500

Page 35

Notizen/Notes

14034181.01 01/2013 GB/D

D

Notizen/Notes

WIKA Betriebsanleitung, Typ CPG500 35

Page 36

WIKA Global

14034181.01 01/2013 GB/D

Europe

North America

Asia

Africa / Middle East

Austria

Romania

Canada

China

Egypt

WIKA Messgerätevertrieb

WIKA Instruments Romania

WIKA Instruments Ltd.

WIKA International Trading

WIKA Near East Ltd.

Ursula Wiegand

S.R.L.

Head Office

(Shanghai) Co., Ltd.

El-Serag City Towers

GmbH & Co. KG

Bucuresti, Sector 5

Edmonton, Alberta, T6N 1C8

A2615, NO.100, Zunyi Road

-Tower#2 - Office#67

1230 Vienna

Calea Rahovei Nr. 266-268

Tel. (+1) 780 46370-35

Changning District

Nasr City Cairo

Tel. (+43) 1 86916-31

Corp 61, Etaj 1

Fax: (+1) 780 46200-17

200051 Shanghai

Tel. (+20) 2 22733140

Fax: (+43) 1 86916-34

Tel. (+40) 21 4048327

E-Mail: info@wika.ca

Tel. (+86) 21 538525-72

Fax: (+20) 2 22703815

E-Mail: info@wika.at

Fax: (+40) 21 4563137

www.wika.ca

Fax: (+86) 21 538525-75

E-Mail: wika.repcairo@wika.de

www.wika.at

E-Mail: m.anghel@wika.ro

E-Mail: info@wika.cn

www.wika.com.eg

www.wika.ro

Mexico

www.wika.com.cn

Belarus

Instrumentos WIKA Mexico S.A.

Namibia

WIKA Belarus

Russia

de C.V.

WIKA Instrumentation

WIKA Instruments Namibia

Ul. Zaharova 50B

ZAO WIKA MERA

01210 Mexico D.F.

(Suzhou) Co., Ltd.

(Pty) Ltd.

Office 3H

127015 Moscow

Tel. (+52) 55 55466329

81, Ta Yuan Road

P.O. Box 31263

220088 Minsk

Tel. (+7) 495-648 01 80

Fax: (+52) 55 50205300

SND, Suzhou 215011

Pionierspark

Tel. (+375) 17-294 57 11

Fax: (+7) 495-648 01 81

E-Mail: ventas@wika.com

Tel. (+86) 512 6878 8000

Windhoek

Fax: (+375) 17-294 57 11

E-Mail: info@wika.ru

www.wika.com.mx

Fax: (+86) 512 6809 2321

Tel. (+26) 4 6123 8811

E-Mail: info@wika.by

www.wika.ru

E-Mail: info@wika.cn

Fax (+26) 4 6123 3403

www.wika.by

USA

www.wika.com.cn

E-Mail: info@wika.com.na

Serbia

WIKA Instrument Corporation

www.wika.com.na

Benelux

WIKA Merna Tehnika d.o.o.

Lawrenceville, GA 30043

India

WIKA Benelux

Sime Solaje 15

Tel. (+1) 770 5138200

WIKA Instruments India Pvt. Ltd.

South Africa

6101 WX Echt

11060 Belgrade

Fax: (+1) 770 3385118

Village Kesnand, Wagholi

WIKA Instruments (Pty.) Ltd

Tel. (+31) 475 535-500

Tel. (+381) 11 2763722

E-Mail: info@wika.com

Pune - 412 207

Gardenview,

Fax: (+31) 475 535-446

Fax: (+381) 11 753674

www.wika.com

Tel. (+91) 20 66293-200

Johannesburg 2047

E-Mail: info@wika.nl

E-Mail: info@wika.co.yu

Fax: (+91) 20 66293-325

Tel. (+27) 11 62100-00

www.wika.nl

www.wika.co.yu

WIKA Instrument Corporation

E-Mail: sales@wika.co.in

Fax: (+27) 11 62100-59

Houston Facility

www.wika.co.in

E-Mail: sales@wika.co.za

Bulgaria

Spain

950 Hall Court

www.wika.co.za

WIKA Bulgaria EOOD

Instrumentos WIKA, S.A.

Deer Park, TX 77536

Japan

Bul. „Al. Stamboliiski“ 205

C/Josep Carner, 11-17

Tel. (+1) 713-475 0022

WIKA Japan K. K.

United Arab Emirates

1309 Sofia

08205 Sabadell (Barcelona)

Fax (+1) 713-475 0011

Tokyo 105-0023

WIKA Middle East FZE

Tel. (+359) 2 82138-10

Tel. (+34) 933 938630

E-mail: info@wikahouston.com

Tel. (+81) 3 543966-73

Jebel Ali, Dubai

Fax: (+359) 2 82138-13

Fax: (+34) 933 938666

www.wika.com

Fax: (+81) 3 543966-74

Tel. (+971) 4 8839-090

E-Mail: t.antonov@wika.bg

E-Mail: info@wika.es

E-Mail: info@wika.co.jp

Fax: (+971) 4 8839-198

www.wika.es

Mensor Corporation

E-Mail:wikame@emirates.net.ae

Croatia

201 Barnes Drive

Kazakhstan

www.wika.ae

Switzerland

San Marcos, TX 78666

TOO WIKA Kazakhstan

.

WIKA Croatia d.o.o.

MANOMETER AG

Tel. (+1) 512 3964200-15

050050

.

Hrastovicka 19

6285 Hitzkirch

Fax (+1) 512 3961820

050050 Almaty, Kazakhstan

Australia

10250 Zagreb-Lucko

Tel. (+41) 41 91972-72

E-Mail: sales@mensor.com

Tel. (+7) 32 72330848

.

Tel. (+385) 1 6531034

Fax: (+41) 41 91972-73

www.mensor.com

Fax: (+7) 32 72789905

Australia

Fax: (+385) 1 6531357

E-Mail: info@manometer.ch

E-Mail: info@wika.kz

WIKA Australia Pty. Ltd.

E-Mail: info@wika.hr

www.manometer.ch

.

www.wika.kz

Rydalmere, NSW 2116

www.wika.hr

_

South America

Tel. (+61) 2 88455222

_

Turkey

Korea

Fax: (+61) 2 96844767

Finland

WIKA Instruments Istanbul

Argentina

WIKA Korea Ltd.

E-Mail: sales@wika.com.au

WIKA Finland Oy

Basinc ve Sicaklik Ölcme

WIKA Argentina S.A.

#569-21 Gasan-dong

www.wika.com.au

00210 Helsinki

Cihazlari

Buenos Aires

Seoul 153-771 Korea

Tel. (+358) 9-682 49 20

Ith. Ihr. ve Tic. Ltd. Sti.

Tel. (+54) 11 47301800

Tel. (+82) 2 869 05 05

New Zealand

Fax: (+358) 9-682 49 270

Bayraktar Bulvari No. 17

Fax: (+54) 11 47610050

Fax (+82) 2 869 05 25

WIKA Instruments Limited

E-Mail: info@wika.fi

34775 Yukari Dudullu - Istanbul

E-Mail: info@wika.com.ar

E-Mail: info@wika.co.kr

Unit 7 / 49 Sainsbury Road

www.wika.fi

Tel. (+90) 216 41590-66

www.wika.com.ar

www.wika.co.kr

St Lukes - Auckland 1025

.

Fax: (+90) 216 41590-97

Tel. (+64) 9 8479020

France

E-Mail: info@wika.com.tr

Brazil

Malaysia

Fax: (+64) 9 8465964

WIKA Instruments s.a.r.l.

www.wika.com.tr

WIKA do Brasil Ind. e Com. Ltda.

WIKA Instrumentation (M)

E-Mail: info@wika.co.nz

95610 Eragny-sur-Oise

.

CEP 18560-000 Iperó - SP

Sdn.Bhd

www.wika.co.nz

Tel. (+33) 1 343084-84

Ukraine

Tel. (+55) 15 34599700

47100 Puchong, Selangor

Fax: (+33) 1 343084-94

TOV WIKA Prylad

Fax: (+55) 15 32661650

Tel. (+60) 3 80 63 10 80

E-Mail: info@wika.fr

M. Raskovoy Str. 11, A

E-Mail: marketing@wika.com.br

Fax: (+60) 3 80 63 10 70

www.wika.fr

PO 200

www.wika.com.br

E-Mail: info@wika.com.my

.

.

02660 Kyiv

www.wika.com.my

.

Germany

Tel. (+38) 044 496-8380

Chile

.

WIKA Alexander Wiegand

Fax: (+38) 044 496-8380

WIKA Chile S.p.A.

Singapore

.

SE & Co. KG

E-Mail: info@wika.ua

Coronel Pereira 72

WIKA Instrumentation Pte. Ltd.

.

63911 Klingenberg

www.wika.ua

Oficina 101

569625 Singapore

.

Tel. (+49) 9372 132-0

.

Las Condes Santiago de Chile

Tel. (+65) 68 44 55 06

.

Fax: (+49) 9372 132-406

United Kingdom

Tel. (+56) 9 66084258

Fax: (+65) 68 44 55 07

.

E-Mail: info@wika.de

WIKA Instruments Ltd

www.wika.cl

E-Mail: info@wika.com.sg

.

www.wika.de

Merstham, Redhill RH13LG

www.wika.com.sg

.

.

Tel. (+44) 1737 644-008

. Italy

Fax: (+44) 1737 644-403

Taiwan

.

WIKA Italia Srl & C. Sas

E-Mail: info@wika.co.uk

WIKA Instrumentation Taiwan

.

20020 Arese (Milano)

www.wika.co.uk

Ltd. . Tel. (+39) 02 9386-11

Pinjen, Taoyuan

Fax: (+39) 02 9386-174

Tel. (+886) 3 420 6052

E-Mail: info@wika.it

Fax: (+886) 3 490 0080

www.wika.it

E-Mail: info@wika.com.tw

. www.wika.com.tw

Poland

WIKA Polska S.A.

Thailand

87-800 Wloclawek

WIKA Instrumentation Cor-

Tel. (+48) 542 3011-00

poration (Thailand) Co., Ltd

Fax: (+48) 542 3011-01

850/7 Ladkrabang Road,

E-Mail: info@wikapolska.pl

Ladkrabang

www.wikapolska.pl

Bangkok 10520

Tel. (+66) 2 326 6876-80

Fax: (+66) 2 326 6874

E-Mail: info@wika.co.th

www.wika.co.th

36 WIKA Betriebsanleitung, Typ CPG500

Loading...

Loading...