Page 1

Operating instructions

Betriebsanleitung

Precision digital pressure gauge model CPG1500

Präzisions-Digitalmanometer Typ CPG1500

EN

DE

Precision digital pressure gauge with protective rubber cap, model CPG1500

Page 2

Operating instructions model CPG1500 Page 3 - 48

EN

Betriebsanleitung Typ CPG1500 Seite 49 - 95

DE

Further languages can be found at www.wika.com.

© 06/2016 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2

WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 3

Contents

Contents

1. General information 5

2. Short overview 6

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . 6

2.4 Product pass . . . . . . . . . . . . . . . . . . . . . . 7

3. Safety 9

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . 9

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . .10

3.4 Personnel qualification . . . . . . . . . . . . . . . . . . . 10

3.5 Labelling, safety marks . . . . . . . . . . . . . . . . . . .11

3.6 Ex marking . . . . . . . . . . . . . . . . . . . . . . . 12

3.6.1 Special conditions for use. . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.6.2 Permitted batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4. Design and function 14

4.1 Front foil . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Integrated data logger . . . . . . . . . . . . . . . . . . . 16

4.3 Voltage supply . . . . . . . . . . . . . . . . . . . . . .16

4.4 WIKA-Wireless. . . . . . . . . . . . . . . . . . . . . . 17

4.5 Connections . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Protective rubber cap for case . . . . . . . . . . . . . . . . 17

5. Transport, packaging and storage 18

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Packaging and storage . . . . . . . . . . . . . . . . . . .18

6. Commissioning, operation 19

6.1 Mechanical mounting . . . . . . . . . . . . . . . . . . . 19

6.2 Electrical mounting . . . . . . . . . . . . . . . . . . . .20

6.3 Normal operation . . . . . . . . . . . . . . . . . . . . .20

6.4 Menu functions. . . . . . . . . . . . . . . . . . . . . . 21

6.4.1 Pressure units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.4.2 Automatic power-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.4.3 Battery voltage display . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.4.4 Current temperature display . . . . . . . . . . . . . . . . . . . . . . . . .25

6.4.5 Setting the damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.4.6 Configuring the sampling rate. . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.7 TARE (setting tare). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.8 Function locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

14161966.04 06/2017 EN/DE

EN

3WIKA operating instructions, model CPG1500

Page 4

Contents

6.5 Communication with WIKA-Cal calibration software . . . . . . . . . 27

6.5.1 Activating WIKA-Wireless in CPG1500. . . . . . . . . . . . . . . . . . . .27

6.5.2 WIKA-Cal configuration (also possible with the demo version) . . . . . .27

EN

6.5.3 WIKA-Cal - Log-Template . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.5.4 App “myWIKA device” . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7. Faults 32

8. Maintenance, cleaning and recalibration 33

8.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . 33

8.2 Battery replacement . . . . . . . . . . . . . . . . . . . .34

8.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . .35

8.4 Recalibration . . . . . . . . . . . . . . . . . . . . . .35

9. Dismounting, return and disposal 36

9.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . 36

9.2 Return. . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . .37

10. Specifications 38

10.1 Sensor technology . . . . . . . . . . . . . . . . . . . .38

10.2 Basic instrument. . . . . . . . . . . . . . . . . . . . . 40

10.3 WIKA-Wireless . . . . . . . . . . . . . . . . . . . . . 41

10.4 Certificates . . . . . . . . . . . . . . . . . . . . . . 43

10.5 Dimensions in mm (in). . . . . . . . . . . . . . . . . . . 43

10.5.1 CPG1500 without protective rubber cap . . . . . . . . . . . . . . . . . . .43

10.5.2 CPG1500 with protective rubber cap. . . . . . . . . . . . . . . . . . . . .44

10.6 Threaded connections. . . . . . . . . . . . . . . . . . .44

11. Accessories 47

Appendix: EU declaration of conformity 48

Declarations of conformity can be found online at www.wika.com.

4 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 5

1. General information

1. General information

■

The model CPG1500 precision digital pressure gauge described in the operating

instructions has been manufactured using state-of-the-art technology. All components

are subject to stringent quality and environmental criteria during production. Our

management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions on to the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

EN

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 10.51

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Abbreviations, definitions

“XXX” Menu XXX will be selected

[XXX] Press XXX button

14161966.04 06/2017 EN/DE

5WIKA operating instructions, model CPG1500

Page 6

2. Short overview

2. Short overview

2.1 Overview

EN

1

Display

2

Process connection

2.2 Description

The model CPG1500 precision digital pressure gauge combines the high accuracy of

digital technology with the convenience and easy handling of an analogue master gauge.

Accurate to ±0.1 % FS, the CPG1500 can be used as a calibration instrument or in any

application requiring high-accuracy pressure measurement. Many user-configurable

functions have been implemented in the CPG1500 (e.g. logging, sampling rate, tare,

damping, automatic power-off and Min-Max measurement).

Once the precision digital pressure gauge is configured, the settings can be locked and

password-protected to prevent unauthorized changes to configuration. The password

protection is implemented via the WIKA-Cal calibration software.

2.3 Scope of delivery

■

Precision digital pressure gauge model CPG1500

■

Operating instructions

■

3.1 calibration certificate per DIN EN 10204

■

3 x 1.5 V AA alkaline batteries

Cross-check scope of delivery with delivery note.

Manufacturer-dependent colour shades of the metal case do not lead to any

quality impairment.

6 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 7

2. Short overview

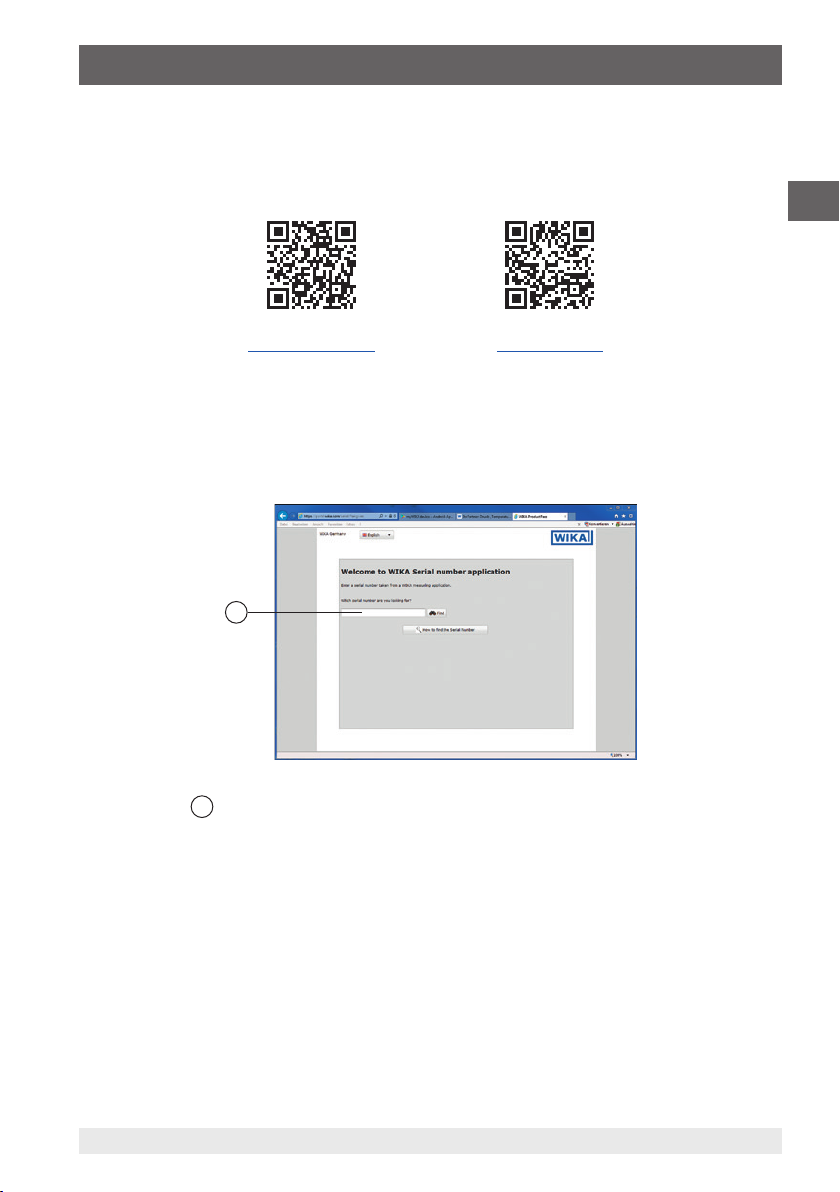

2.4 Product pass

The product pass can be retrieved from the product page or directly from the

corresponding web application .

Web application Product page

WIKA - Intelligent serial number

The WIKA intelligent serial number and the corresponding web application is the central

tool in which all the required information on the specific instrument can be found.

1

EN

1

After entering

specific details on the manufactured version are displayed.

14161966.04 06/2017 EN/DE

the intelligent serial number into the web application, all instrument-

7WIKA operating instructions, model CPG1500

Page 8

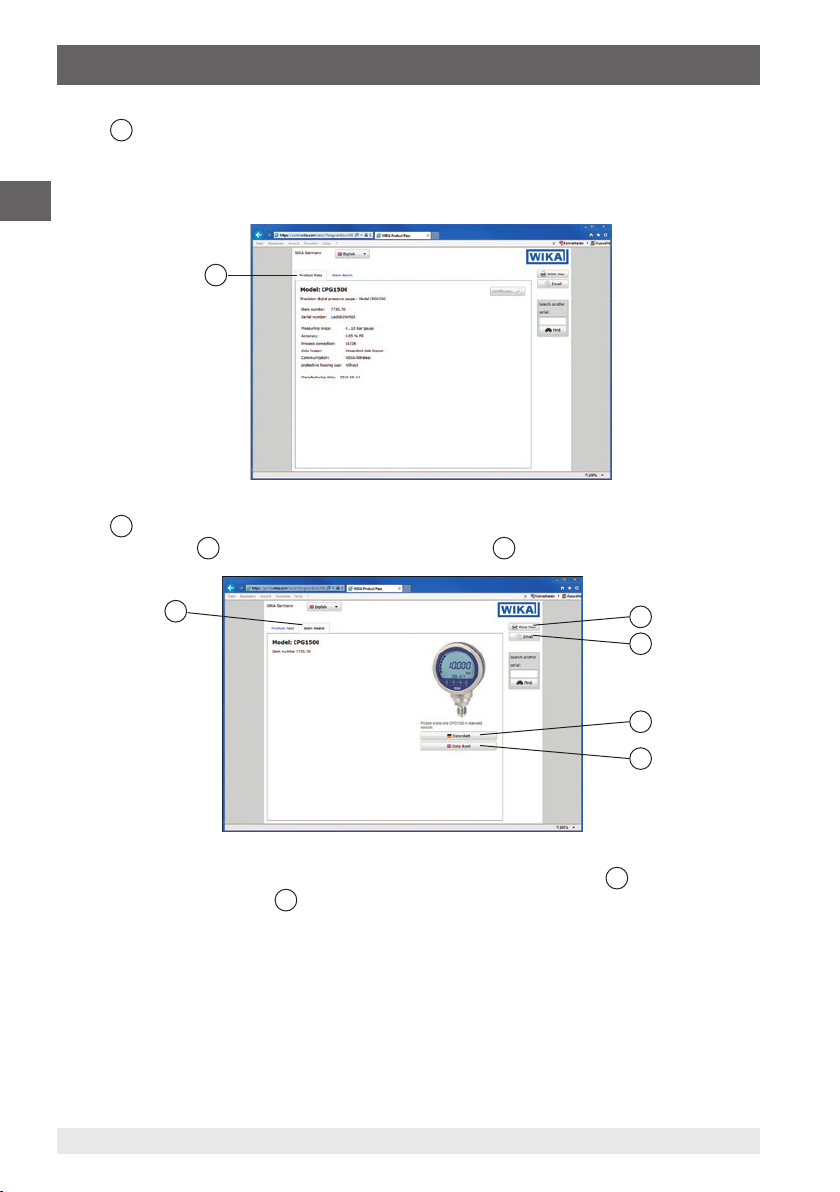

2. Short overview

Under 2 “Product passport”, all the most-important additional information on the

instrument, such as measuring range, accuracy, process connection, manufacturing date,

etc., can be retrieved. You can also download (calibration) certificates directly from this

location.

EN

2

3

Under

as the data sheet

“Article details”, further article details are listed, as well as documentation such

6

and current operating instructions 7.

3

4

5

6

7

From this view, the required information can be printed directly via the

Furthermore, by clicking on

5

[e-mail], an e-mail is opened which already contains the

4

[print view].

intelligent serial number of the currently retrieved instrument and this can be sent to any

recipient, but also, for example, to a corresponding WIKA contact, in order to re-order

exactly the same product, as an example.

8 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 9

3. Safety

3. Safety

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to equipment or the environment, if not avoided.

DANGER!

... indicates a potentially dangerous situation in the hazardous area that can

result in serious injury or death, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

3.2 Intended use

This CPG1500 precision digital pressure gauge can be used as a calibration instrument

and also for any application which requires high-accuracy pressure measurement.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

EN

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specifications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic fields, static electricity and extreme temperatures, do

not insert any objects into the instrument or its openings).

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

14161966.04 06/2017 EN/DE

9WIKA operating instructions, model CPG1500

Page 10

3. Safety

3.3 Improper use

WARNING!

Injuries through improper use

EN

Any use beyond or different to the intended use is considered as improper use.

3.4 Personnel qualification

Improper use of the instrument can lead to hazardous situations and injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument with abrasive or viscous media.

▶

If the CPG1500 is used in applications with oil as a pressure medium,

make sure it will not be used with combustibles or gases directly after that

because it can lead to dangerous explosions and danger to personnel and

machinery.

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to

equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who,

based on their technical training, knowledge of measurement and control technology and

on their experience and knowledge of country-specific regulations, current standards and

directives, are capable of carrying out the work described and independently recognising

potential hazards.

Special knowledge for working with instruments for hazardous areas:

The skilled personnel must have knowledge of ignition protection types, regulations and

provisions for equipment in hazardous areas.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

10 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 11

TYPES IN NON-HAZARDOUS AREA ONLY

3. Safety

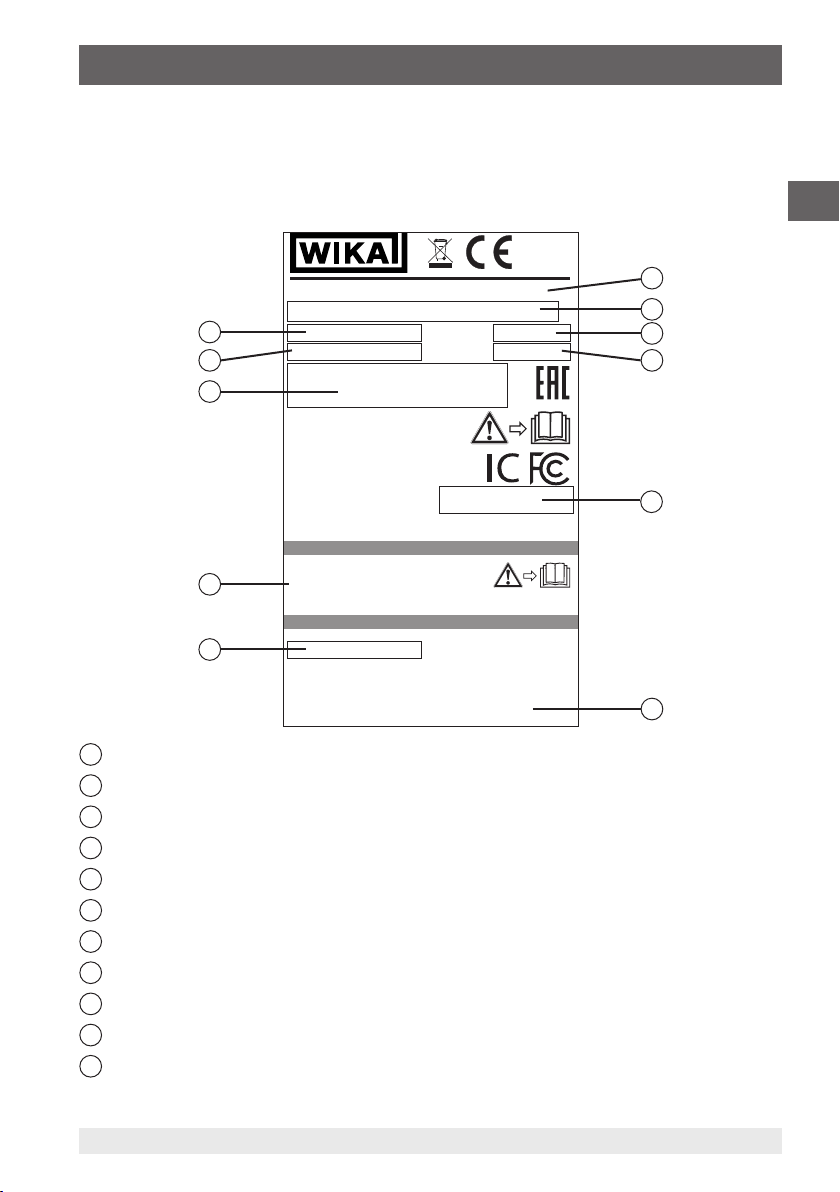

3.5 Labelling, safety marks

Product label

The product label is located on the rear of the CPG1500 on the cover of the battery

compartment.

0158

Precision digital pressure gauge

CPG1500-ST-A-S-BG440-GDSZ-53-W

11

10

9

0...40 bar

S# 12345678901

BVS 16 ATEX E043 X

II 1G Ex ia IIC T4 Ga

0,05 % FS

06/2016

IECEx BVS 16.0033X

1

2

3

4

EN

8

7

1

Product name

2

Order code

3

Accuracy

4

Date of manufacture

5

Radio approval

6

Safety instructions for voltage supply

7

Serial number

8

Information on the batteries

9

Approval-related data

10

Serial number

11

Pressure measuring range

14161966.04 06/2017 EN/DE

Contains IC: 216Q-PAN10

Contains FCC ID: T7VPAN10

WIKA Alexander Wiegand SE & Co. KG 63911 Klingenberg

USE 3 x 1.5V AA (LR6)

ALKALINE BATTERIES

Approved types: Refer to manual for CPG1500

S# 12345678901

RE-PLACE BATTERIES WITH APPROVED

5

6

11WIKA operating instructions, model CPG1500

Page 12

3. Safety

Symbols

EN

3.6 Ex marking

Before mounting and commissioning the instrument, ensure you read

the operating instructions!

This marking on the instruments indicates that they must not be disposed of

in domestic waste. The disposal is carried out by return to the manufacturer

or by the corresponding municipal authorities.

DANGER!

Danger to life due to loss of explosion protection

Non-observance of these instructions and their contents may result in the

loss of explosion protection.

▶

Observe the safety instructions in this chapter and further explosion

instructions in these operating instructions.

▶

Observe the information given in the applicable type examination

certificate and the relevant country-specific regulations for installation and

use in hazardous areas (e.g. IEC/EN 60079-14).

▶

The precision digital pressure gauge is not intended for use with

flammable substances. It is only suitable for installation in locations

providing adequate protection against intrusion of solid foreign objects or

water which can impair safety.

▶

Only use the listed batteries, see chapter 3.6.2 “Permitted batteries”!

▶

Only replace the batteries outside the hazardous area, see chapter

8.2 “Battery replacement”!

▶

Temperature range: -10 ... +50 °C

▶

Only use the protective rubber cap included in the delivery. Protective

rubber caps that are prohibited in hazardous areas must be marked with

“No Ex” on the rear.

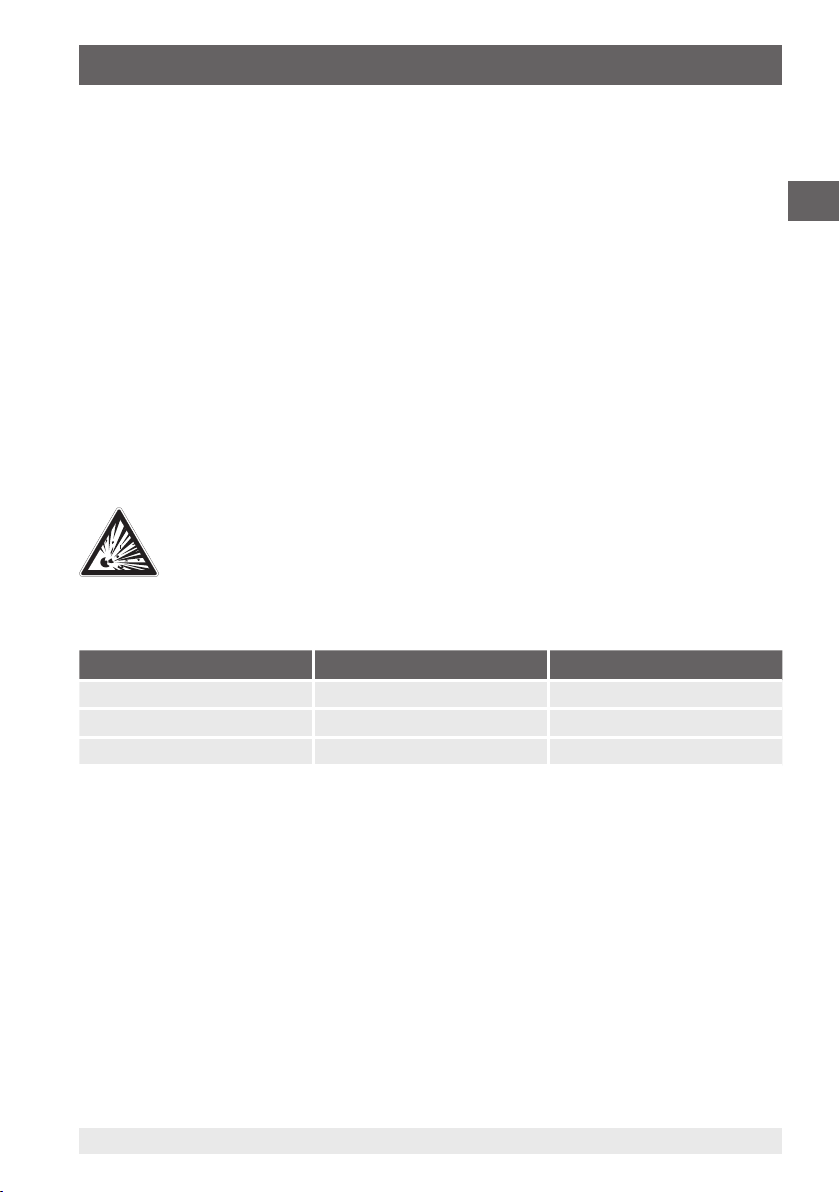

3.6.1 Special conditions for use

For the use in category 1G (EPL Ga):

■

The case is made of aluminium. The instrument is protected against mechanical

impacts in order to prevent stroke and friction sparks during installation.

■

The instrument must be installed in such a way that process-related electrostatic

charges (e.g. caused by flowing media) are prevented.

12 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 13

3. Safety

For the use in category 1/2G (EPL Ga/Gb):

The separation (membrane) from the wetted area (category 1) indicates a wall thickness

of less than 0.2 mm which is function-related. In operation, it must be ensured that any

impairment of the separation, e.g. by aggressive media or through mechanical damage, is

eliminated.

The thread of the process connection and the partition wall (membrane of the sensor)

built into a partition wall of the end use application separating an area requiring EPL Ga

from a less hazardous area are made of stainless steel.

The process connection is a gas-tight standardized thread connection with an IP67 rating

according to IEC/EN 60529 between area requiring EPL Ga and the less hazardous area.

The process connection thread shall be self-sealing or sealed by means of sealing

material in the thread or sealed by a gasket.

3.6.2 Permitted batteries

DANGER!

Danger to life due to loss of explosion protection

Non-observance of these instructions and their contents may result in the

loss of explosion protection.

▶

Only use the batteries listed below!

▶

Only replace the batteries outside the hazardous area!

EN

Battery type Manufacturer Battery name

4006 Rayovac Rayovac Maximum Plus

MN1500 Duracell Duracell Plus Power

MN1500 Duracell Duracell Simply

14161966.04 06/2017 EN/DE

13WIKA operating instructions, model CPG1500

Page 14

4. Design and function

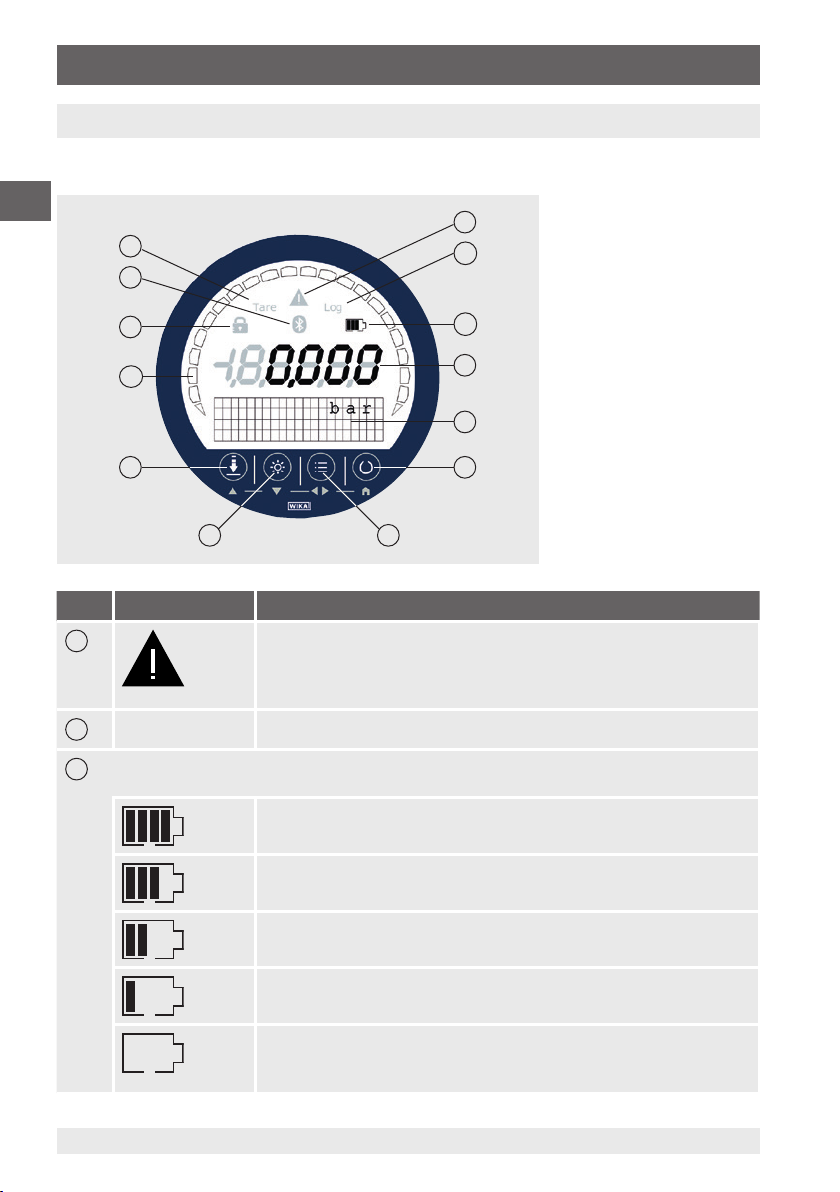

4. Design and function

4.1 Front foil

EN

13

12

11

10

9

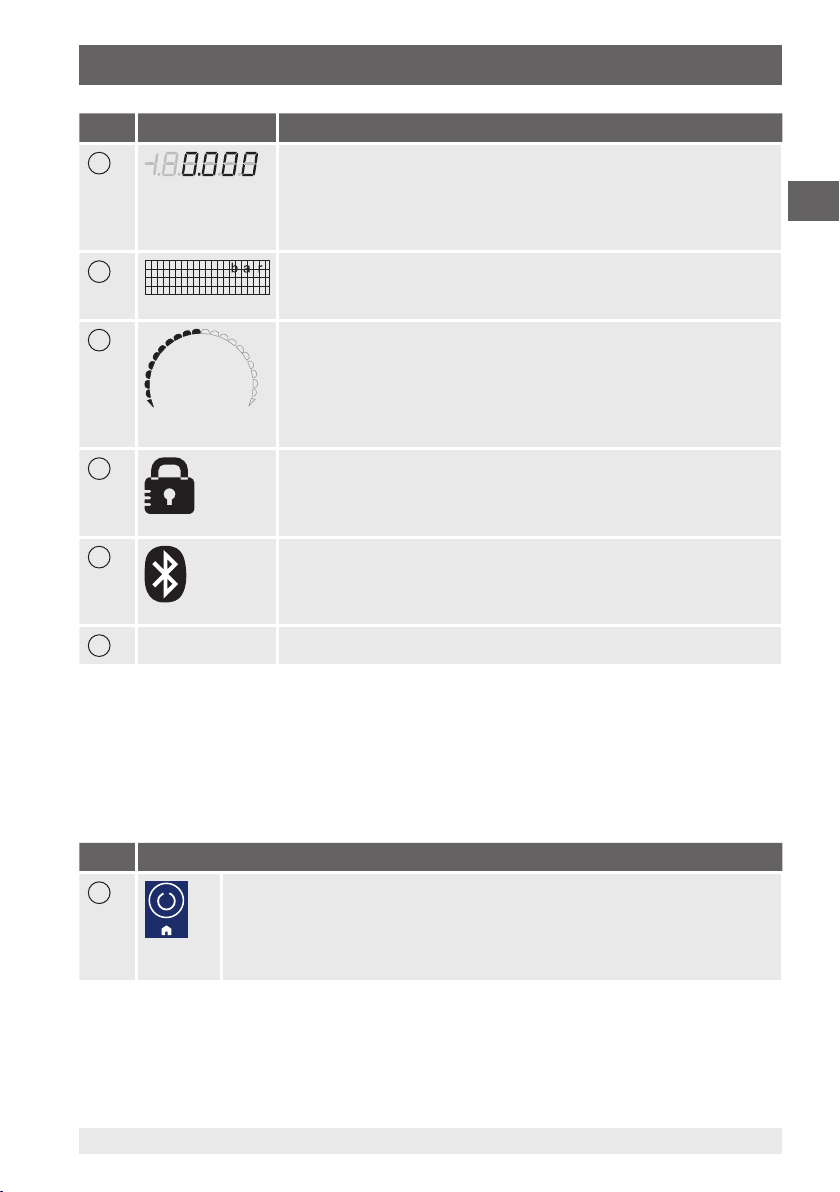

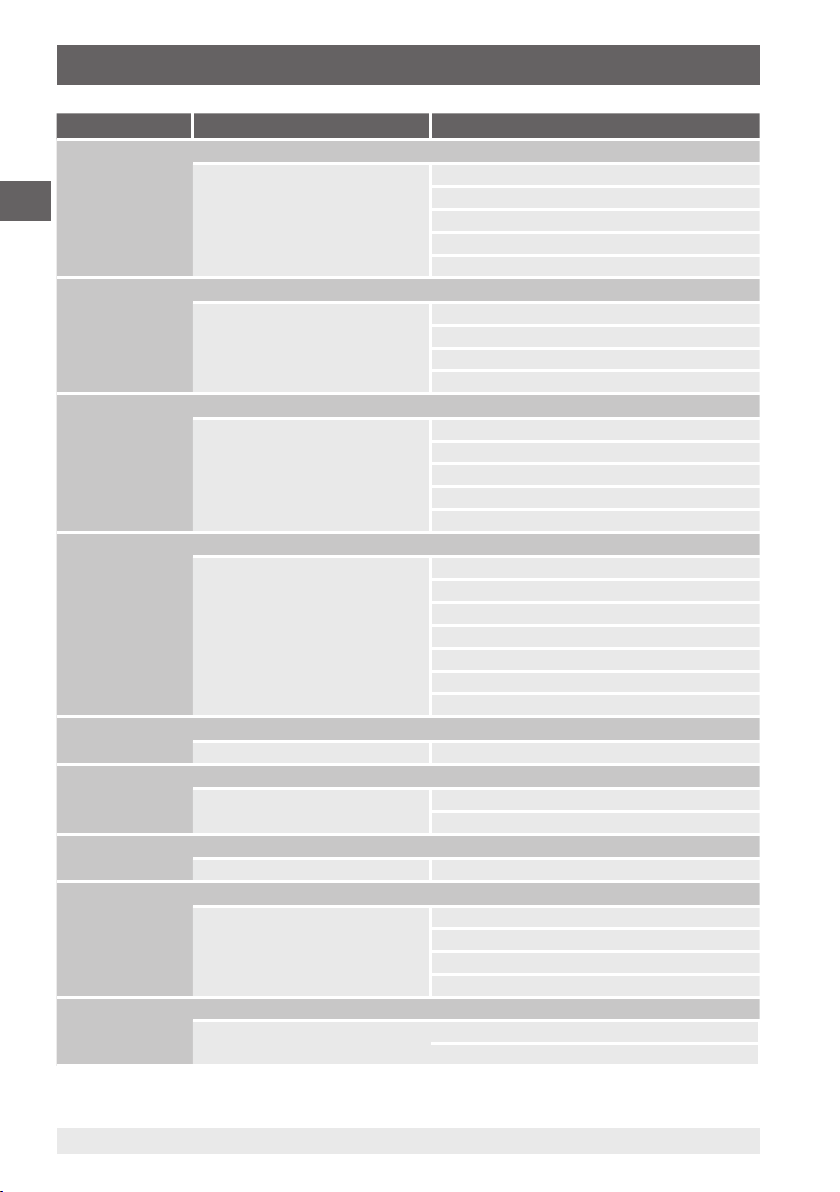

Pos. Symbol The symbol lights up on:

■

1

Log

2

The battery symbol is lit continuously and is dependent upon the current battery

3

status.

Exceeding or dropping below the pressure range

■

Exceeding or dropping below the temperature range

■

Logger memory is more than 90 % full

■

Instrument error or battery status < 10 %

Logger function active

Battery status 100 %

Outline and all segments are lit

1

2

3

4

5

6

78

Battery status 80 %

Outline and first three segments are lit

Battery status 60 %

Outline and first two segments are lit

Battery status 40 %

Outline and first segment are lit

Battery status 20 %

Outline is lit continuously

Insert new batteries (see chapter 8.2 “Battery replacement”).

⇒

14 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 15

4. Design and function

Pos. Symbol The symbol lights up on:

4

5

10

11

12

Tar e

13

Pressure indication

The 5 ½ digit 7-segment display always indicates the current pressure

value.

If the pressure value is no longer current, lines will be displayed (in

low-power mode over 10 s)

Matrix field serves as menu and secondary display

The matrix field consists of 4 x 21 cells (rows x columns) and serves

as a menu and secondary display.

Bar graph indicates the current pressure graphically

The bar graph consists of 20 segments and two end points at the

front and rear ends. The bar graph indicates the current pressure

proportionally to the measuring range. If the measuring range has

been underrun, the front point lights up; with an overrun, the rear point

lights up.

When the [ZERO] or [MENU] button has been locked via WIKA-Cal

and must be activated manually.

The password protection is implemented via the WIKA-Cal calibration

software.

WIKA-Wireless (only for instruments with option

WIKA-Wireless)

■

Symbol is blinking: WIKA-Wireless is active but not connected

■

Symbol is lit continuously: WIKA-Wireless is active and connected

TARE function active

EN

Function buttons

The CPG1500 is controlled via 4 function buttons, with each button having a main and

a secondary function. In general, the information printed on the buttons corresponds to

the main function: “ZERO”, “LIGHT”, “MENU”, “ON/OFF”. Once the [MENU] button is

active, the secondary function applies. These are, from left to right: Cursor up “UP / ▲”,

cursor down “DOWN / ▼”, left/right cursor “L / ◀” or “R / ▶” and “HOME”.

Pos. Button

6

14161966.04 06/2017 EN/DE

ON/OFF button

The main function is switching the CPG1500 on and off.

If the digital pressure gauge is already in menu mode, a short press on

the [On/Off] button brings up “HOME”. A long press (at least 3 seconds)

switches the CPG1500 off.

15WIKA operating instructions, model CPG1500

Page 16

4. Design and function

Pos. Button

7

EN

8

9

MENU button

Calling up the menu

By activating the [MENU] button, the menu mode is enabled. If the CPG1500

is already inside the menu mode, depending on the display, “ L” or “R” will be

done. If the button is pressed for longer, after 2 seconds the cursor switches

(right ◀ or ▶ left).

Inputs are confirmed with the [MENU] button.

LIGHT button

Turning the backlighting on and off

By activating the [LIGHT] button (short or long press) the light is switched on.

The duration of the light being on depends on “LIGHT-OFF” in “SETTINGS”.

■

1 x pressing the [LIGHT] button (Light = On)

■

2 x pressing the [LIGHT] button (Light = Off)

If the CPG1500 is in menu mode, with a short press on the [LIGHT] button,

the cursor can be moved downwards.

ZERO button

The current pressure value will be set to “0” (gauge) or reference pressure

(abs.).

By activating the [ZERO] button, the current pressure value is set to “0”. A

maximum of 5 % of the measuring span can be corrected.

If the CPG1500 is in menu mode, with a short press on the [ZERO] button, the

cursor can be moved upwards.

For gauge pressure measuring instruments, in the range of the zero point,

±5 % of the measured value will be set to “0”.

With absolute pressure sensors, on pressing the [ZERO] button, an input

window appears. Here, the current reference pressure must be entered.

The reference pressure must also be within ±5 % of the initial absolute

pressure of the instrument, then the measured value will be set to the

reference pressure entered.

4.2 Integrated data logger

The CPG1500 features an integrated data logger.

This data logger can be switched on and set via [MENU] / [Logger] (respectively).

4.3 Voltage supply

Three AA alkaline batteries are used as the voltage supply for the instrument. These are

included in delivery.

The battery life time is up to 2,000 hours for continuous operation (without backlighting

and with WIKA-Wireless deactivated).

In the upper right half of the display there is a symbol for the battery capacity. Instructions

on batteries (see chapter 8.2 “Battery replacement”).

16 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 17

4. Design and function

The battery indicator lights up

To avoid false readings, replace the batteries.

Instructions on batteries (see chapter 8.2 “Battery replacement”).

4.4 WIKA-Wireless

To start wireless data transmission, you must set it to “On” under “Menu / Basic

settings / Wireless”. Once this has been done, the wireless symbol blinks in the display.

As soon as the CPG1500 is connected to a computer via this wireless interface, the

symbol lights continuously.

Under “Menu / Basic settings / Wireless / Wireless”, a distinction can be made

between the communication type WIKA-Wireless Classic or WIKA-Wireless Classic with

WIKA-Wireless Low Energy (= LE).

WIKA-Wireless Low Energy (= LE) is required to communicate with an IOS-enabled

mobile phone via the myWIKA-device smartphone app.

It is recommended to select WIKA-Wireless Classic for a connection with PC and/or an

Android-enabled instrument.

The WIKA-Wireless USB stick is suitable for enabling smooth communication

with the computer. It is optionally available as an accessory.

EN

4.5 Connections

The CPG1500 is available with all standard industrial threaded connections, as standard

G ½ B is specified.

When screwing the NPT thread of the CPG1500 to an adapter or a pressure connection,

it is necessary to use additional sealing material between the threads, e.g. PTFE tape.

The hose, lines and fittings etc. must always be approved at least for the working pressure

which corresponds to the pressure of the instrument. In addition, there must be no leaks

during calibration process - if necessary, seal using PTFE tape.

4.6 Protective rubber cap for case

Optionally, the CPG1500 can be fitted with an impact-resistant protective rubber cap.

14161966.04 06/2017 EN/DE

17WIKA operating instructions, model CPG1500

Page 18

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the model CPG1500 precision digital pressure gauge for any damage that may

EN

have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal

transport, proceed carefully and observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter

5.2 “Packaging and storage”.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

5.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +70 °C (-4 ... +158 °F)

■

Humidity: 0 ... 90 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the instrument in its original packaging in a location that fulfils the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

1. Remove the batteries from the instrument and store them separately, see chapter

8.2 “Battery replacement”.

2. Wrap the instrument in an antistatic plastic film.

3. Place the instrument, along with the shock-absorbent material, in the packaging.

4. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

18 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 19

6. Commissioning, operation

6. Commissioning, operation

Personnel: Skilled personnel

Tools: Open-ended spanner SW 27 or torque spanner

Only use original parts (see chapter 11 “Accessories”).

DANGER!

Danger to life from explosion!

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only carry out set-up work in non-hazardous environments!

▶

Only connect test and calibration installations once the system has been

depressurised (atmospheric).

WARNING!

Physical injuries and damage to property and the environment caused

by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature

and under high pressure or vacuum may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate

existing codes or regulations must also be followed.

EN

6.1 Mechanical mounting

CAUTION!

Damage to the instrument

To avoid possible damage to CPG1500 or to test equipment, follow the steps

below:

▶

Make sure the threaded connections are clean and undamaged.

▶

When screwing the threads of the CPG1500 to an adapter or a pressure

connection, it is necessary to use additional sealing material between the

threads, e.g. PTFE tape.

▶

With an NPT connection, the sealing must be made directly on the thread

with PTFE tape and not via the threaded fitting at the CPG1500.

▶

The maximum permitted torque of the thread is 13.5 Nm = 10 ftlbs. This

permitted torque must NEVER be exceeded.

▶

The instrument should be installed in such a way that process-related

electrostatic charges (e.g. caused by flowing media) can be excluded.

▶

14161966.04 06/2017 EN/DE

The case is rotatable by 330°. When turning do not touch the display.

19WIKA operating instructions, model CPG1500

Page 20

6. Commissioning, operation

▶

If the message “OL” is displayed, the measuring range has been

exceeded and the pressure source must be removed immediately from the

CPG1500 to prevent damage to the internal sensor.

EN

1. Seal the sealing faces.

2. Screw the precision digital pressure gauge into the mounting point by hand.

▶

When screwing in, do not cross the threads.

3. Tighten with a torque spanner using the spanner flats.

▶

The maximum torque of the CPG1500 is 13.5 Nm = 10 ftlbs.

6.2 Electrical mounting

DANGER!

Danger to life from explosion!

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only carry out set-up work in non-hazardous environments!

▶

Only connect test and calibration installations once the system has been

depressurised (atmospheric).

▶

Do not use rechargeable batteries!

▶

Only use the listed batteries, see chapter 3.6.2 “Permitted batteries”!

▶

Only replace the batteries outside the hazardous area, see chapter

8.2 “Battery replacement”!

▶

Always replace all three batteries together!

6.3 Normal operation

Make a long press on the [On/Off] button, in order to activate the precision digital

pressure gauge. Push the button again to turn it off.

After switching on, the start-up screen with pressure range and firmware version is shown

on the display for approx. 3 seconds.

Zeroing the display: Press and hold the [ZERO] button.

The CPG1500 has to be set to 0 with the [ZERO] button before each use.

MAX/MIN: The CPG1500 stores the minimum and maximum pressure in the memory.

This value can be activated under “MENU / MEASURING MODE / PEAK VALUES” and

is displayed in the text field.

20 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 21

6. Commissioning, operation

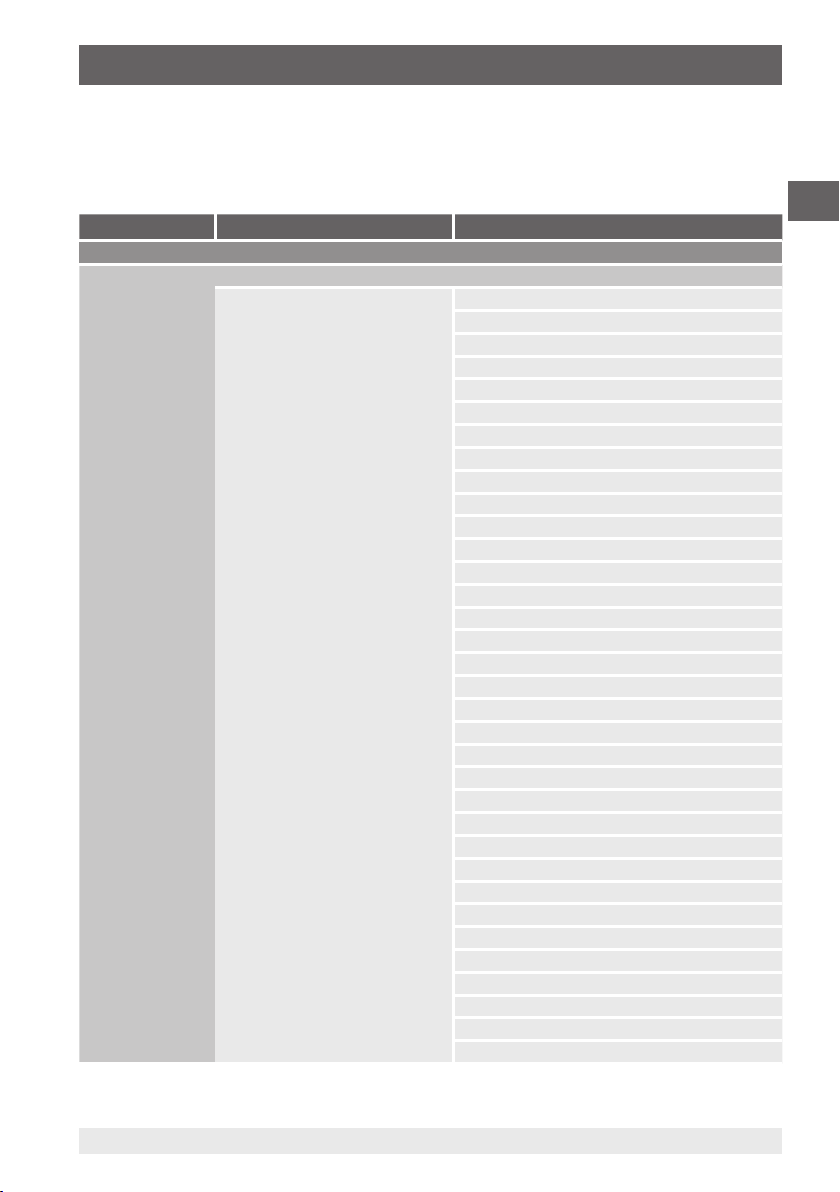

6.4 Menu functions

▶

Press [MENU] button to start

Press the buttons (▶) to enter the individual menu level.

Set the parameters or the menu level using the buttons (▼ or ▲).

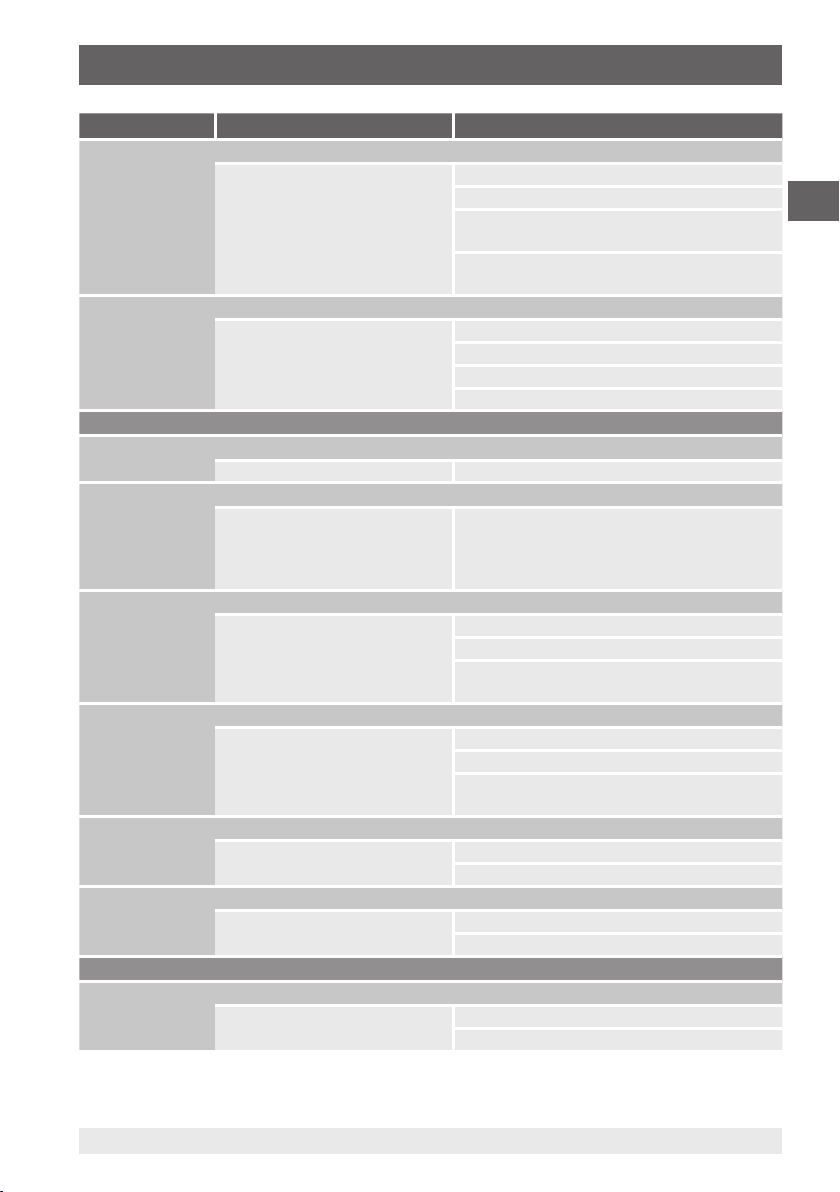

Menu level Menu level 2 Menu level 3

Measuring mode

Unit

bar (default)

mbar

psi

kg/cm²

Pa

kPa

hPa

MPa

mmH

O

2

mH

O

2

inH

O

2

inH

O (4 °C)

2

inH

O (60 °F)

2

inH

O (20 °C)

2

ftH

O

2

mmHg

cmHg

inHg

inHg (0 °C)

inHg (60 °F)

kp/cm²

lbf/ft²

kN/m²

atm

Torr

micron

m

cm

mm

feet

inch

UserUnit 1

UserUnit 2

UserUnit 3

EN

14161966.04 06/2017 EN/DE

21WIKA operating instructions, model CPG1500

Page 22

6. Commissioning, operation

Menu level Menu level 2 Menu level 3

Peak values

EN

Temperature

Tar e

Mean value

Rate

Resolution

Damping

Measuring rate

Off (default)

On

reset

Off (default)

°C

°F

K

Off (default)

On

Offset (0.0000)

[Limit: ±9.9999 {depending on resolution}]

Off (default)

On

Interval (10 s) [Limit: 300 s]

Off (default)

/s

/min

4

5 (default)

5-1/2

Off (default)

low

medium

high

1/s

3/s (default)

10/s

50/s [max. speed]

Logger interval

22 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 23

6. Commissioning, operation

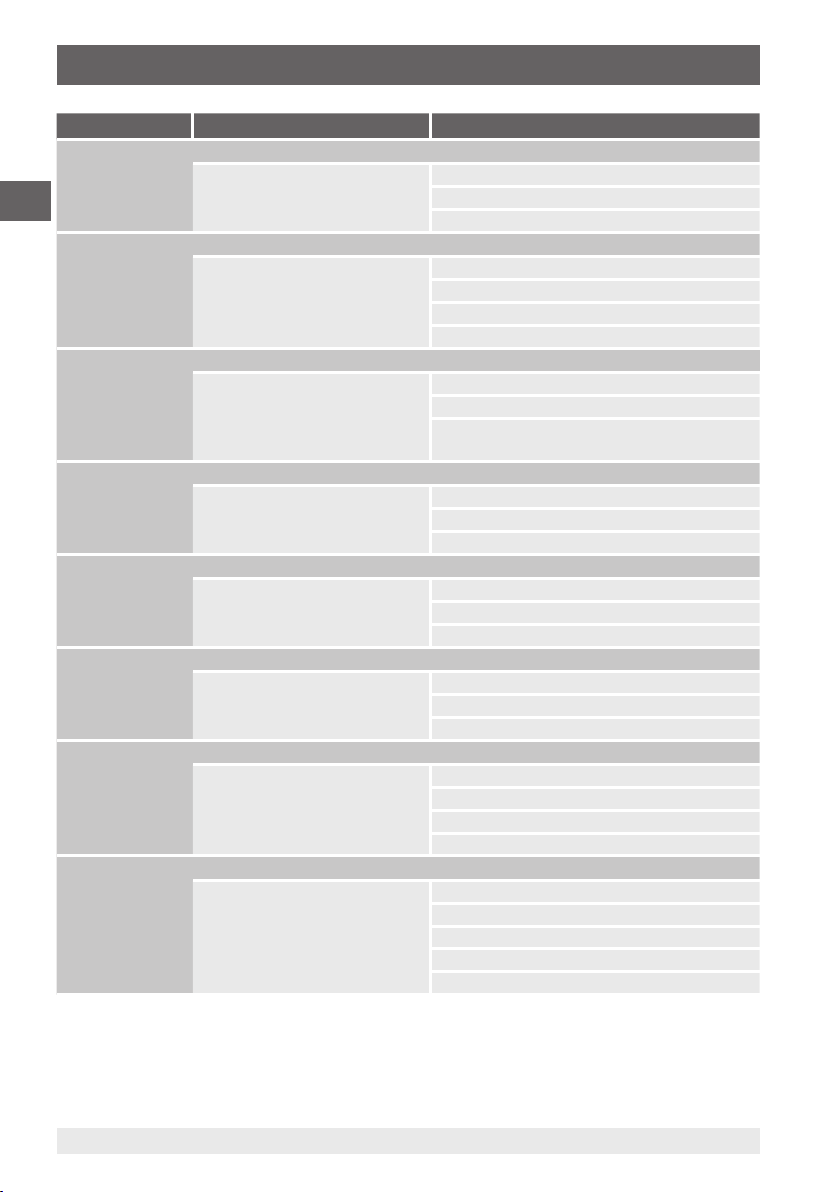

Menu level Menu level 2 Menu level 3

Alarm

Off (default)

On

lower (1.0000)

[Limit: ±measuring range limit – 10 %]

upper (10.000)

[Limit: ±measuring range limit + 10 %]

Level

Density 1.0 [kg/dm³]

kg/dm³ (default)

lb/ft³

kg/m³

Logger

Start / Stop

Start / Stop

Interval

10.0 s (default)

[Limit: 0 … 3,600 s]

0 corresponds to the logging with measuring

rate.

Duration

Off

On

Duration (0000 h 00 min 01 s)

[Limit: 9999 h 59 min 59 s]

Start time

Off

On

Start time (00 h 00 min)

[Limit: 23 h 59 min]

Clear last

No (default)

Yes

Clear all

No (default)

Yes

Default

Wireless

Off (default)

On

EN

14161966.04 06/2017 EN/DE

23WIKA operating instructions, model CPG1500

Page 24

6. Commissioning, operation

Menu level Menu level 2 Menu level 3

Language

EN

Switch-off time

Light off

Contrast

Time

Time format

Date

Date format

Factory reset

English (default)

German

Spanish

French

Italian

Off

5 min

15 min (default)

30 min

Off (=light is permanently on)

10 s (default)

30 s

60 s

120 s

20 %

30 %

40 %

50 % (default)

60 %

70 %

80 %

hh : mm : ss [AM / PM]

24 h (default)

12 h [AM / PM]

DD / MM /YYYY

dd.mm.yyyy (default)

dd/mm/yyyy

mm/dd/yyyy

yyyy-mm-dd

No (default)

Yes

24 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 25

6. Commissioning, operation

Menu level Menu level 2 Menu level 3

Info

S# (e.g.: 1A00023458) = serial number

T# (e.g.: ABCDEFG12345) = tag number

MR: (e.g.: 0…100 bar) = measuring range

ManufDat. (e.g.: 10/05/2016) = date of manufacture

CalibDat. (e.g.: 10/05/2016) = calibration date

Firmware

Memory status In %

Op hrs [d h]

O. pressure [bar]

O. temp [ °C]

6.4.1 Pressure units

The CPG1500 is factory preset to the pressure unit of “bar” or “psi”. Via the menu,

the instrument can be changed to 31 predefined pressure and level units, as well as 3

customer-specific units.

For a list of the available technical units of measure, see chapter 10 “Specifications”.

6.4.2 Automatic power-off

The time duration for automatic power-off can be selected from four predefined and

fixed steps. Thus it can be set to “5 min”, “15 min”, “30 min” or “Off”. With “Off”, the

instrument remains activated until it is switched off using the [ON/OFF] button or until the

batteries are empty.

If a time has been set, then the CPG runs from the last button press for this time and then

switches itself off automatically. Also, during a wireless transmission or through a log, the

time is stopped and restarted after completion of this.

EN

6.4.3 Battery voltage display

The current battery voltage as well as the remaining useful life of the battery are displayed

via the battery symbol.

6.4.4 Current temperature display

The CPG1500 is temperature-compensated. This option displays the temperature

measured by the internal sensor. The value indication can be switched from degrees of

Fahrenheit to degrees of Celsius.

6.4.5 Setting the damping

With the “Damping” setting, one can select between three different, fixed, preconfigured

filter settings. With “Off”, the filter is inactive and not in operation. Thus only the

display on the CPG1500 is damped. The pressure value that is read over the wireless

transmission or the value written to the logger will not be damped.

14161966.04 06/2017 EN/DE

25WIKA operating instructions, model CPG1500

Page 26

6. Commissioning, operation

6.4.6 Configuring the sampling rate

The sampling rate defines how frequently the pressure is measured. The options

available are 1, 3, 10 and 50 measurements per second or logger interval. The shortest

response time is 50 measurements per second.

EN

The display rate is set permanently at 3 x display refresh/s.

6.4.7 TARE (setting tare)

With this option, a constant offset value can be set. If, for example, TARE is set to 30 bar

and the measured pressure is 37 bar, the measured value will be displayed as 7 bar. A

pressure of 27 bar would then be displayed as -3 bar. The TARE value is set manually

using the ▲ and ▼ buttons and depends on the technical units of measure and the

resolution selected for the display. The TARE value can be set to the maximum scale

range.

The bar graph always indicates the actual pressure with respect to the entire measuring

range, irrespective of the tare setting. This is performed for safety reasons so that in case

of “0” indication it can still be displayed that the corresponding pressure is present at the

pressure gauge.

Contrary to the operating principle of the ZERO button, the offset value under tare does

not contribute to the shift of the characteristic curve. If you change the pressure unit, the

configured offset value will be automatically converted to match the new unit.

6.4.8 Function locking

Access to adjustable parameters can be selectively turned off, once set, to prevent

unauthorized changes to configuration.

Locking the Zero button

The operator can no longer make a “ZERO” using the keypad - it is still possible over the

wireless transmission.

Locking the Menu button

Access to the “Menu” is locked. If “ZERO” is not locked, this can still be executed. Over

the wireless transmission, all settings can still be read or written.

Instrument write protection

When this lock is set, via the menu on the local display menu as well as over the wireless

transmission, access to the settings is read-only - thus no alteration of the settings is

possible.

If the “ZERO” lock is not set, the “ZERO” function is still possible.

The individual locks can only be set via WIKA-Cal calibration software over the wireless

transmission. For this, the input of a 4-digit PIN is required. This is set to “0000” on supply

and can be changed.

26 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 27

6. Commissioning, operation

6.5 Communication with WIKA-Cal calibration software

As soon as a connection exists over WIKA-Wireless, it can communicate with the

WIKA-Cal calibration software. It can transmit and evaluate live measurements or also

measurements that have already been made, without difficulty.

6.5.1 Activating WIKA-Wireless in CPG1500

4. Press the Menu button.

5. Press and hold the ▶ or ◀ button until the “Wireless” default setting appears in the

matrix field.

6. Switch on wireless by pressing the ▼ or ▲ button.

7. Confirm the setting by pressing the Menu button.

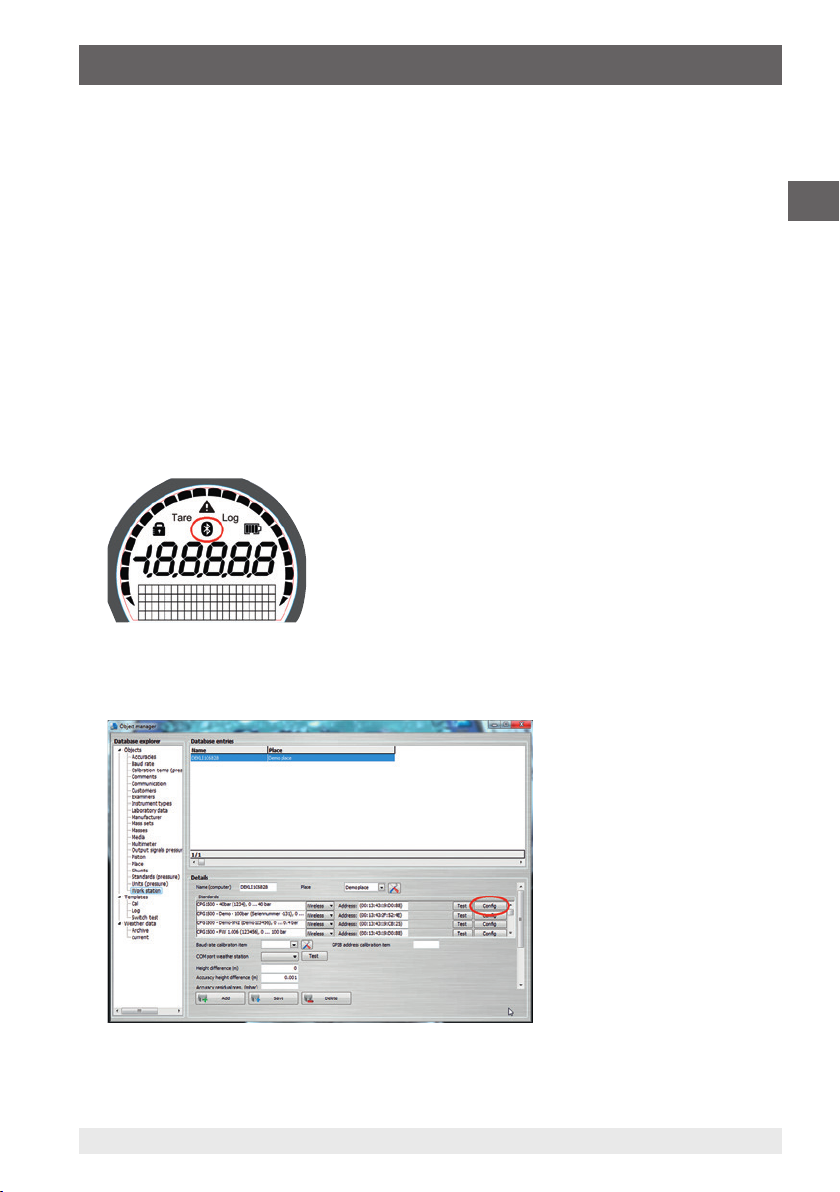

Once wireless has been switched on, the WIKA-Wireless symbol blinks in the

⇒

display

The WIKA-Wireless symbol is lit continuously when a connection has been

⇒

created.

EN

6.5.2 WIKA-Cal configuration (also possible with the demo version)

1. In the WIKA-Cal, define CPG1500 as standard in “Object manager / Standards

(pressure)” and assign it to the workplace.

14161966.04 06/2017 EN/DE

27WIKA operating instructions, model CPG1500

Page 28

6. Commissioning, operation

2. Open the menu item “Object manager / Workplace”.

3. Call the wireless function.

The wireless monitor opens.

⇒

4. Click in the address field.

EN

The address will be displayed automatically. If required, correct this.

⇒

The communication is working properly if the pressure value displayed on the

⇒

instrument is shown after pressing the [Test] button.

If the “WIKA-Wireless” function is not activated in CPG1500, an error message

⇒

shows up. Activate “WIKA-Wireless” in CPG1500, see chapter 6.5.1 “Activating

WIKA-Wireless in CPG1500”.

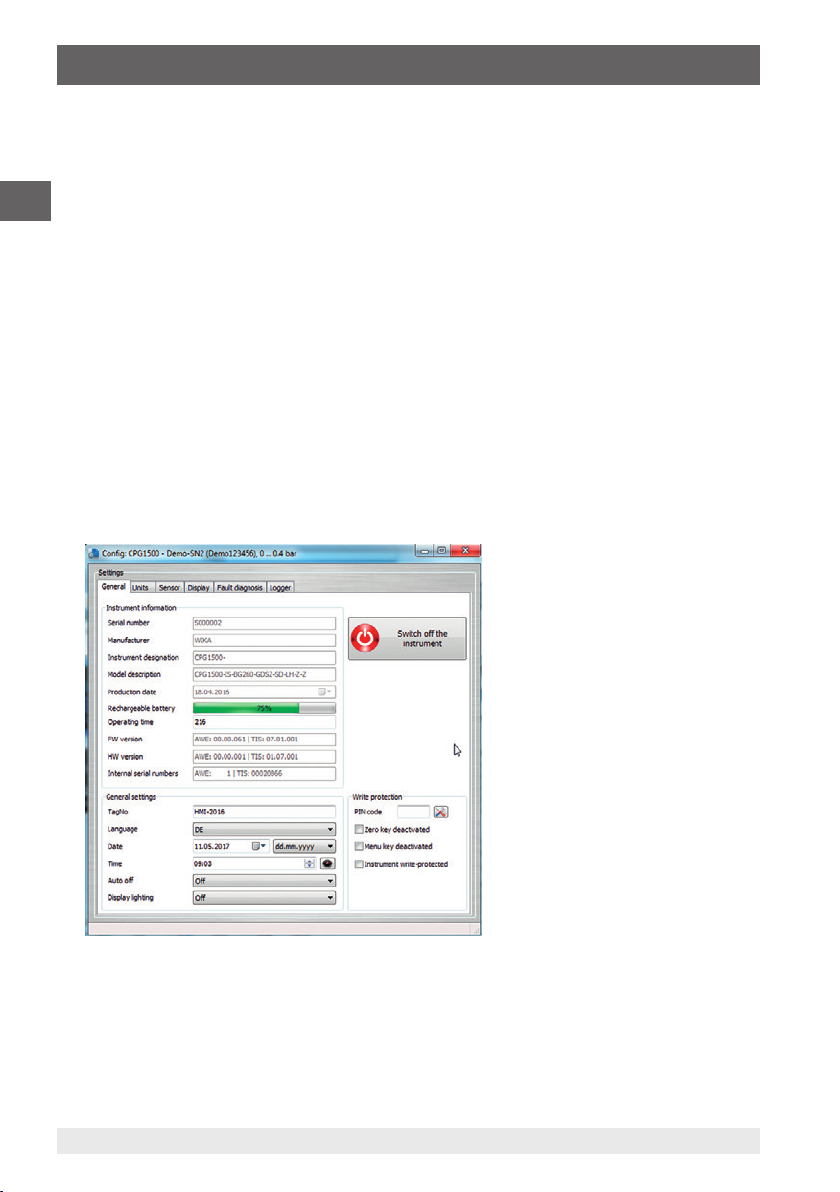

5. Access the configuration of the instrument via [Config] in the dialog window.

The “General”, “Units”, “Sensor”, “Display”, “Error diagnosis” and “Logger”

functions are available in the configuration window.

General information

Here are all the general parameters of the CPG1500 used.

It features the write protection via a PIN code. Therefore the setting is protected against

unauthorized access.

28 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 29

6. Commissioning, operation

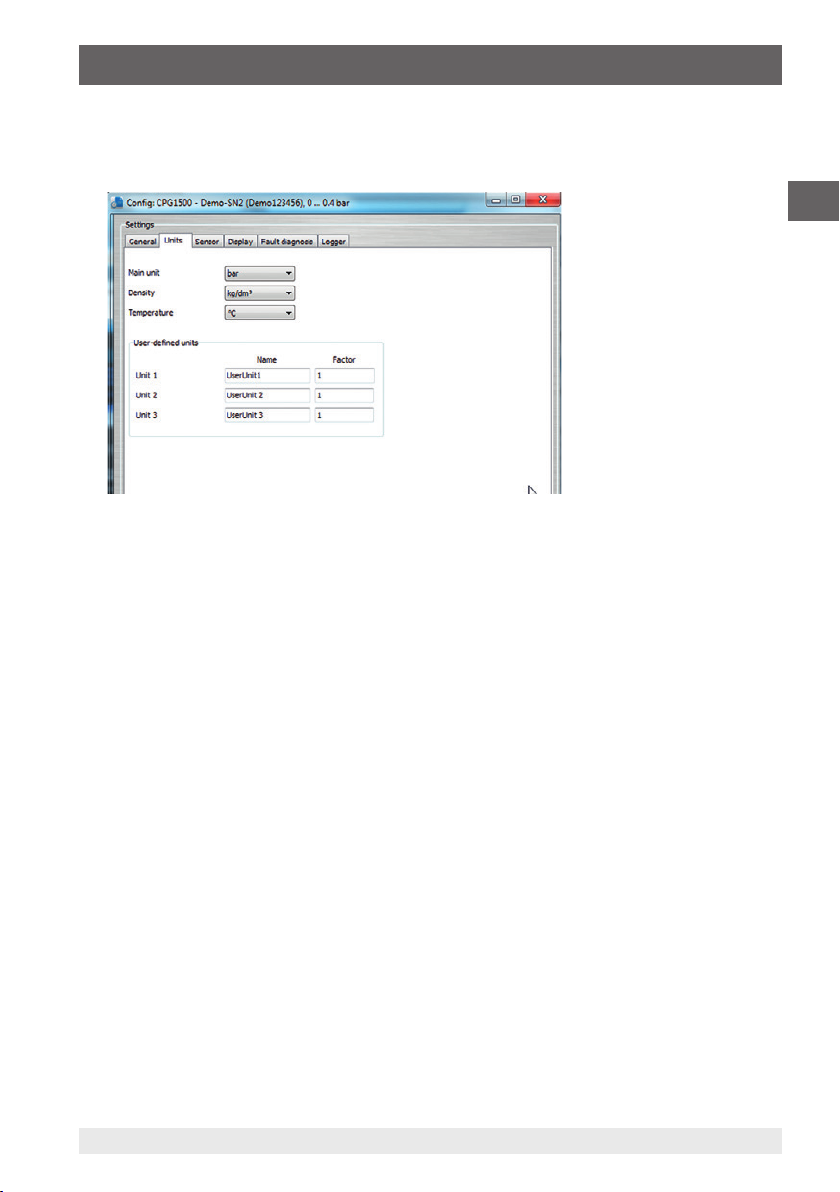

Units

You can set specific pressure units with associated factor or enter user-defined units.

Sensor

The sensor values can be displayed and be readout:

Display

Here you can set the display

EN

Fault diagnosis

An error description and error code are displayed.

14161966.04 06/2017 EN/DE

29WIKA operating instructions, model CPG1500

Page 30

6. Commissioning, operation

Logger

Here you can configure and start the logger.

The logger data are shown and can be downloaded as CSV file by a right click on the

mouse.

EN

6.5.3 WIKA-Cal - Log-Template

The following options are available with the “Log-Template”:

New log

The “New Log” function opens a new logger protocol.

Following the input of all parameters, the “Wireless address” line must be pressed in

the communication window. Select the CPG1500 used and confirm.

By pressing the [Measuring results] graphic, the logger process is started.

Repeat logging

Logger processes can be repeated

Download

The logger sequences stored on the CPG1500 can be downloaded and archived using

“Download”.

30 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 31

6. Commissioning, operation

6.5.4 App “myWIKA device”

Via the app “myWIKA device” and the WIKA-Wireless connection,

the CPG1500 can be configured for calibration and log routines in

a comfortable way through a mobile phone. During the pressure

measurement, the value is displayed in the required unit directly on

the phone.

Moreover, further parameters like temperature and pressure change

rate can be checked. It is also possible to retrieve more detailed

device information directly from the WIKA website. In addition, the

app allows configuration, control and saving of log procedures.

Logs that were saved on the mobile phone can be transferred

to a PC and be read by WIKA-Cal. With that they can be further

processed and the app fills the gap to provide a thorough solution of dealing with data on

the CPG1500.

EN

For iOS-based mobile phones, the app is

available in the Apple Store under below

link.

Download here Download here

14161966.04 06/2017 EN/DE

For mobile phones with an Android

operating system, the app is available in

the Play Store under below link.

31WIKA operating instructions, model CPG1500

Page 32

7. Faults

7. Faults

Personnel: Skilled personnel

Protective equipment: Protective gloves, safety goggles

EN

Tools: Open-ended spanner SW 27 or torque spanner

DANGER!

Danger to life from explosion

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only rectify faults in non-flammable atmospheres!

WARNING!

Physical injuries and damage to property and the environment caused

by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature

and under high pressure or vacuum may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate

existing codes or regulations must also be followed.

▶

Use the requisite protective equipment.

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the model

CPG1500 precision digital pressure gauge must be taken out of operation

immediately.

▶

Ensure that pressure or signal is no longer present and protect against

accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter

9.2 “Return”.

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

32 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 33

7. Faults / 8. Maintenance, cleaning and recalibration

Display Causes Measures

OL

-OL

No display or

instrument is not

responding to button

press

Low battery voltage, functioning is

only guaranteed for a short period

of time

Reading is significantly above or

below the measuring range = >

10 % FS

Battery is empty Insert new alkaline batteries,

Batteries inserted incorrectly Ensure the correct polarity

System error Switch off the CPG1500, wait for

Defect in the CPG1500 Send in for repair

Insert new alkaline batteries,

see chapter 8.2 “Battery

replacement”.

Check: Is the pressure within the

permissible measuring range of

the sensor?

see chapter 8.2 “Battery

replacement”.

see chapter 8.2 “Battery

replacement”.

a short period of time, switch on

again

EN

8. Maintenance, cleaning and recalibration

Personnel: Skilled personnel

Protective equipment: Protective gloves, safety goggles

Tools: Open-ended spanner SW 27 or torque spanner

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

8.1 Maintenance

The CPG1500 precision digital pressure gauge is maintenance-free.

Repairs must only be carried out by the manufacturer.

This does not apply to the replacement of alkaline batteries.

Only use original parts (see chapter 11 “Accessories”).

14161966.04 06/2017 EN/DE

33WIKA operating instructions, model CPG1500

Page 34

8. Maintenance, cleaning and recalibration

8.2 Battery replacement

DANGER!

Danger to life from explosion

EN

Procedure

1. Turn off the instrument and lay it face down.

2. Loosen the three screws of the battery compartment, see Fig. 1 “Position of the battery

compartment”.

3. Remove the battery cover.

4. Insert the three AA-sized batteries in correct polarity. Only use permitted batteries, see

chapter 3.6.2 “Permitted batteries”.

5. Put the battery cover on and screw it tight with the three screws.

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only use the listed batteries, see chapter 3.6.2 “Permitted batteries”!

▶

Do not use rechargeable batteries!

▶

The instruments must not be opened in hazardous areas!

▶

Only replace the batteries outside the hazardous area!

▶

Always replace all three batteries together!

▶

The battery cover must be closed and locked in place!

▶

Secure the battery cover with the three screws!

▶

Ensure the correct polarity.

Tighten the upper screw first.

⇒

Fig. 1 - Position of the battery compartment

If the instrument is not used for a long time, remove the batteries.

34 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 35

8. Maintenance, cleaning and recalibration

8.3 Cleaning

CAUTION!

Physical injuries and damage to property and the environment

Improper cleaning may lead to physical injuries and damage to property and

the environment. Residual media at the dismounted instrument can result in a

risk to persons, the environment and equipment.

▶

Use the requisite protective equipment.

▶

Carry out the cleaning process as described below.

1. Prior to cleaning, isolate the instrument properly from the pressure source and switch

it off.

2. Use the requisite protective equipment.

3. Clean the instrument with a moist cloth. Electrical connections must not come into

contact with moisture!

CAUTION!

Damage to property

Improper cleaning may lead to damage to the instrument!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any pointed and hard objects for cleaning.

▶

Do not use solvent or scouring agents for cleaning.

4. Wash or clean the dismounted instrument, in order to protect persons and the

environment from exposure to residual media.

EN

8.4 Recalibration

Traceable calibrations such as DKD/DAkkS certificate, NIST or comparable

certificates - official certificates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. The basic settings will be corrected if necessary.

The calibration label is attached at the side of CPG1500. For instruments with protective

rubber cap(s), the calibration label is located beneath the protection cap.

Fig. 2 - CPG1500 with protective

rubber cap

14161966.04 06/2017 EN/DE

Fig. 3 - CPG1500 without protective

rubber cap

35WIKA operating instructions, model CPG1500

Page 36

9. Dismounting, return and disposal

9. Dismounting, return and disposal

Personnel: Skilled personnel

Protective equipment: Protective gloves, safety goggles

EN

Tools: Open-ended spanner SW 27 or torque spanner

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media at the dismounted model CPG1500 precision digital pressure

gauge can result in a risk to personnel, the environment and equipment.

▶

Observe the information in the material safety data sheet for the

corresponding medium.

▶

Use the requisite protective equipment.

▶

Wash or clean the dismounted instrument, in order to protect persons and

the environment from exposure to residual media.

9.1 Dismounting

WARNING!

Physical injuries and damage to property and the environment

through residual media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

▶

Before storage of the dismounted instrument (following use) wash or

clean it, in order to protect persons and the environment from exposure to

residual media.

WARNING!

Physical injury

When dismounting, there is a danger from aggressive media and high

pressures.

▶

Disconnect test and calibration installations once the system has been

depressurised.

1. Switch of the CPG1500 precision digital pressure gauge

2. Unscrew the digital pressure gauge with a spanner or torque spanner till it is loose

using the spanner flats.

3. Screw out the digital pressure gauge by hand.

4. If required, clean the digital pressure gauge, see chapter 8.3 “Cleaning”.

36 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 37

9. Dismounting, return and disposal

9.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media at the dismounted instrument can result in a risk to persons,

the environment and equipment.

▶

With hazardous substances, attach the material safety data sheet for the

corresponding medium.

▶

Clean the instrument (see chapter 8.3 “Cleaning”).

When returning the instrument, use the original packaging or a suitable transport

packaging.

To avoid damage:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with the shock-absorbent material, in the packaging. Place

shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

EN

Information on returns can be found under the heading “Service” on our local

website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

This marking on the instruments indicates that they must not be disposed of

in domestic waste. The disposal is carried out by return to the manufacturer

or by the corresponding municipal authorities.

14161966.04 06/2017 EN/DE

37WIKA operating instructions, model CPG1500

Page 38

10. Specifications

10. Specifications

DANGER!

EN

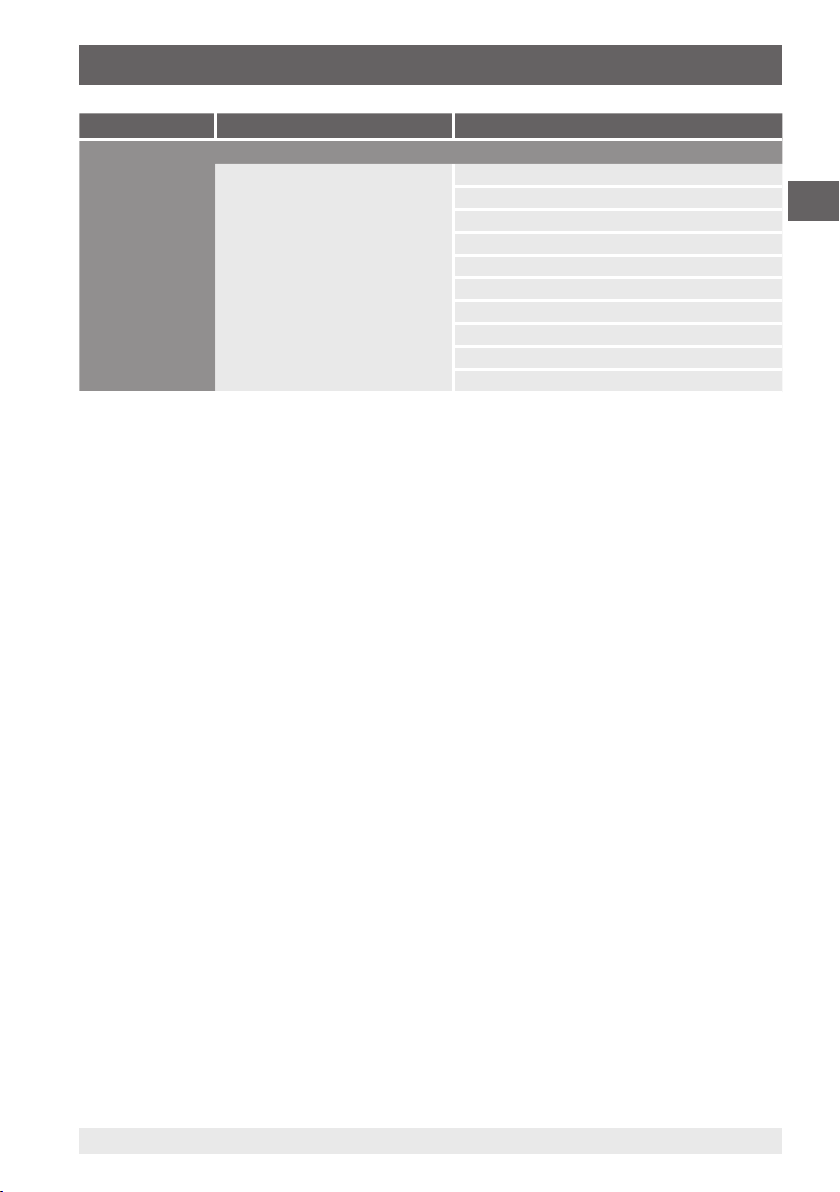

10.1 Sensor technology

Sensor technology

Measuring range

Gauge pressure bar 0 ... 0.1

Absolute pressure bar 0 ... 0.25

Danger to life due to loss of explosion protection

The non-observance of the instructions for use in hazardous areas can lead

to the loss of the explosion protection.

▶

Adhere to the following limit values and instructions.

▶

The radio regulations of the respective location must be observed.

1)

0 ... 0.25

2)

0 ... 0.4

2)

0 ... 0.6

0 ... 1 0 ... 1.6 0 ... 2.5 0 ... 4

0 ... 6 0 ... 10 0 ... 16 0 ... 25

0 ... 40 0 ... 60 0 ... 100 0 ... 160

0 ... 200 0 ... 250 0 ... 400 0 ... 600

0 ... 700

0 ... 4,000

0 ... 10,000

psi 0 ... 1.5

3)

1)

0 ... 1,000

4)

0 ... 6,000

4)

0 ... 5

3)

0 ... 1,600

4)

0 ... 7,000

2)

0 ... 10

4)

0 ... 2,500

4)

0 ... 8,000

2)

0 ... 15

0 ... 20 0 ... 30 0 ... 50 0 ... 60

0 ... 100 0 ... 150 0 ... 160 0 ... 200

0 ... 300 0 ... 500 0 ... 700 0 ... 1,000

0 ... 1,500 0 ... 2,000 0 ... 3,000 0 ... 5,000

3)

2)

0 ... 15,000

0 ... 1

0 ... 6,000 0 ... 8,000 0 ... 10,000

0 ... 20,000

0 ... 150,000

4)

0 ... 30,000 4)0 ... 50,000 4)0 ... 100,000

4)

2)

0 ... 0.4

2)

0 ... 0.6

0 ... 1.6 0 ... 2.5 0 ... 4 0 ... 6

0 ... 7 0 ... 10 0 ... 16 0 ... 20

0 ... 25 0 ... 40

psi 0 ... 3.5

2)

0 ... 5

2)

0 ... 10

2)

0 ... 15

0 ... 20 0 ... 30 0 ... 50 0 ... 60

0 ... 100 0 ... 150 0 ... 200 0 ... 300

0 ... 500

2)

4)

4)

3)

4)

14161966.04 06/2017 EN/DE

38 WIKA operating instructions, model CPG1500

Page 39

10. Specifications

Sensor technology

Vacuum and +/measuring ranges

Overpressure limit

Sensor 3 times; ≤ 25 bar (≤ 300 psi)

Display > 110 % FS or -10 % FS

Accuracy

5)

Compensated

temperature range

Type of pressure Gauge pressure, absolute pressure (up to 20 bar abs. (290 psi abs.)) and

Process connection

Standard

≤ 1,000 bar

(≤15,000 psi)

High-pressure

version

> 1,000 bar

(> 15,000 psi)

Pressure medium All liquids and gases which are compatible with 316 stainless steel

1) Expanded accuracy of 0.2 % FS

2) Expanded accuracy of 0.15 % FS

3) Not possible as flush version

4) Expanded accuracy of 0.5 % FS, at reference conditions 23 °C ±3 °C

4) It is defined by the total measurement uncertainty, which is expressed with the coverage factor (k = 2) and includes the following

factors: the intrinsic performance of the instrument, the measurement uncertainty of the reference instrument, long-term

stability, influence of ambient conditions, drift and temperature effects over the compensated range during a periodic zero point

adjustment.

5) At a measuring rate of ≤ 3 measured values per second

bar -0.25 ... +0.25 2)-0.4 ... +0.4 2)-0.6 ... +0.6 -1 ... 0

-1 ... +0.6 -1 ... +1.5 -1 ... 2.5 -1 ... 3

-1 ... 5 -1 ... 7 -1 ... 9 -1 ... 10

-1 ... 15 -1 ... 24 -1 ... 25 -1 ... 39

-1 ... 40

psi -14.5 ... 0 -14.5 ... +15 -14.5 ... 40 -14.5 ... 70

-5 ... 0

2)

2)

-14.5 ... 100 -14.5 ... 130 -14.5 ... 300 -3 ... +3

-5 ... +5

-8 ... 0

2)

2)

-8 ... +8 -3 ... 0

2)

2 times; > 25 ... ≤ 600 bar (> 300 ... ≤ 5,000 psi)

1.7 times; > 600 bar (> 5,000 psi)

0.1 % FS

0.05 % FS (optional)

6)

-10 … +50 °C (14 ... 122 °F)

vacuum measuring ranges

G ½ B, G ¼ B, ½ NPT, ¼ NPT, G 1 B flush, G ½ B flush

■

M16 x 1.5 female with sealing cone

■

M20 x 1.5 female with sealing cone

■

9/16 - 18 UNF female F 250-C

EN

14161966.04 06/2017 EN/DE

39WIKA operating instructions, model CPG1500

Page 40

10. Specifications

10.2 Basic instrument

Basic instrument

Display

EN

Display 5 ½ digit 7-segment display (including a large matrix area for auxiliary

Rotatable case The case is rotatable by 330°.

Resolution 4 ... 5 ½ digits; adjustable; depending on the selected pressure unit

Pressure units Standard: psi, bar

Functions

Measuring rate max. 50/s

Menu languages Standard: English

Memory Standard: Min./Max.

Menu functions Min./Max. alarm (visual), Power-off function, measuring rate, mean

Mean value interval 1 ... 300 seconds, adjustable

Data logger

Material

Wetted parts Stainless steel 316

Case Aluminium die-casting, nickel-plated

Voltage supply

Power supply 3 x 1.5 V AA alkaline batteries

Maximum voltage DC 4.95 V (spark ignition)

Battery life typical 2,000 ... 2,500 h (without backlighting and WIKA-Wireless not

Battery status display Symbol display, with 4 bars displaying the battery status in segments

information)

Bar graph, 0 ... 100 %

Selectable backlighting

Selectable to: mbar, kg/cm², Pa, hPa, kPa, Mpa, mmH

inH2O, inH2O (4 °C), inH2O (20 °C), inH2O (60 °F), ftH2O, mmHg,

cmHg, inHg, inHg (0 °C), inHg (60 °F), kp/cm2, lbf/ft2, kN/m2, atm,

Torr, micron as well as user-defined units

Selectable: German, Italian, French, Spanish, Russian and Polish

Optional: Integrated data logger

value filter, pressure rating, mean value (via adjustable interval), filling

level display, tare offset, indicator damping

8)

Cyclic logger: Automatic recording of up to 1,000,000 values;

Cycle time: selectable from 1 ... 3,600 s in steps of 1 second or by

measuring rate in the following steps: 1/s, 3/s, 10/s and

50/s

9)

active)

of 25 %

7)

O, mH2O,

2

40 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 41

10. Specifications

Basic instrument

Permissible ambient conditions

Operating temperature -10 ... +50 °C (14 ... 122 °F)

Medium temperature -10 ... +50 °C (14 ... 122 °F) (lower temperature limit above the freezing

point of the medium)

Storage temperature -20 ... +70 °C (-4 ... +158 °F)

Relative humidity < 95 % r. h. (non-condensing)

Communication (optional)

Interface WIKA-Wireless

Case

Dimensions approx. 100 x 150 x 59 mm (3.9 x 5.9 x 2.3 in)

Ingress protection IP65

Weight Standard: incl. batteries approx. 680 g (1.5 lbs)

with protective rubber cap: approx. 820 g (1.81 lbs)

7) The user-defined units can only be set via the WIKA-Cal software. The CPG1500 must feature WIKA-Wireless.

8) To use the logger function, WIKA-Cal software is needed.

The logger data can be downloaded as CSV file using the demo version of WIKA-Cal. You can use the live logger for an accurate

data analysis or a direct generation of certificates by means of the logger template of the WIKA-Cal.

9) Only the following models are allowed in Ex area:

■

Duracell, Simply by Duracell MN1500

■

Duracell, Duralock Plus Power MN1500

■

Varta, RAYOVAC Maximum Plus 4006

10) Requires a PC with Bluetooth® 2.1 interface

10)

EN

10.3 WIKA-Wireless

WIKA-Wireless

Frequency range 2,400 ... 2,500 MHz

HF output power max. 2 dBm (+ 2 dBi)

Number of channels

Classic 79

Low Energy 40

Channel spacing

Classic 1 MHz

Low Energy 2 MHz

Bandwidth 1 or 2 MHz

Output power 4 dBm / 10 mW

10) Requires a PC with Bluetooth® 2.1 interface

14161966.04 06/2017 EN/DE

10)

Maximum output power under fault conditions for Ex ia: 490 mW

41WIKA operating instructions, model CPG1500

Page 42

10. Specifications

The use of the radio module is subject to the provisions and regulations of

the respective country and the module may only be used in the countries for

which a country certification is available:

EN

Dieses Gerät erfüllt Teil 15 der FCC-Vorschriften.

Der Betrieb unterliegt den beiden folgenden Bedingungen:

1. Dieses Gerät darf keine schädlichen Störungen verursachen.

2. Dieses Gerät muss alle empfangenen Störungen annehmen, einschließlich Störungen, die zu unbeabsichtigtem Betrieb führen können.

FCC and IC Notice:

This instrument complies with part 15 of the FCC rules.

Operation is subject to the following two conditions:

1. This instrument may not cause harmful interference.

2. This instrument must accept any interference received, including interference that may

cause undesired operation.

Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden,

the Netherlands, the United Kingdom, Switzerland and Norway

Instruments with FCC / IC marking are also allowed in USA and Canada.

Check whether these approvals apply to your country. It is not permitted to

use WIKA-Wireless in countries without valid radio approval.

Cet instrument satisfait à la section 15 de la réglementation FCC.

L’exploitation est autorisée aux deux conditions suivantes :

1. l'appareil ne doit pas produire de brouillage, et

2. l‘utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d’en compromettre le fonctionnement.

This instrument has been tested and found to comply with the limits for a

class B digital instrument, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation.

42 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 43

10. Specifications

Ø 100,7 (3,96)

58,9 (2,32)

10.4 Certificates

Certificate

Calibration

Recommended

recalibration interval

1) Calibrated in vertical mounting position with process connection facing downwards

Approvals and certificates, see website

For further specifications see WIKA data sheet CT 10.51 and the order documentation.

10.5 Dimensions in mm (in)

10.5.1 CPG1500 without protective rubber cap

1)

Standard: 3.1 calibration certificate per EN 10204

Option: DKD/DAkkS calibration certificate

1 year (dependent on conditions of use)

EN

14161966.04 06/2017 EN/DE

G 1/2

Ø 36 (1,42)

Ø 44,4 (1,75)

114,9 (4,53)

110,1 (4,33)

36

20 (0,79)

32,5 (1,28

35,5 (1,40)

3 (0,12)

34,7 (1,37)

43WIKA operating instructions, model CPG1500

Page 44

Ø 108,4 (4,27)

66,4 (2,61)

10. Specifications

10.5.2 CPG1500 with protective rubber cap

EN

Ø 44,4 (1,75)

Ø 10 (0,39)

G 1/2

Ø 36 (1,42)

5 (0,20)

116 (4,57)

120,8 (4,75)

172,4 (6,79)

36

32,5 (1,28

20 (0,79)

35,5 (1,40)

3 (0,12)

36,8 (1,45)

10.6 Threaded connections

Threaded connection G ½

32,5 (1,28

20 (0,79)

35,5 (1,40)

3 (0,12)

G 1/2

Ø 36 (1,42)

Ø 44,4 (1,75)

44 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 45

10. Specifications

Threaded connection G ¼

32,5 (1,28

35,5 (1,40)

EN

G 1/4

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connection ½ NPT

1/2 NPT

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connection ¼ NPT

2 (0,08)

19 (0,75)

13 (0,51)

31,5 (1,24)

25,5 (1,00)

1/4 NPT

Ø 36 (1,42)

Ø 44,4 (1,75)

14161966.04 06/2017 EN/DE

13 (0,51)

45WIKA operating instructions, model CPG1500

Page 46

10. Specifications

Threaded connection M16

EN

M16

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connection M20

27,5 (1,08)

39,2 (1,55)

39,2 (1,55)

M20

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connection 9/16 - 18 UNF

39,2 (1,55)

9/16"

Ø 36 (1,42)

Ø 44,4 (1,75)

46 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 47

11. Accessories

11. Accessories

Connection adapters

■

Various process connection adapters

Pressure generation

■

Pneumatic test pumps

■

Hydraulic test pumps

Test case

■

Various calibration cases incl. pressure generation

Software

■

WIKA-Cal calibration software

Installation

■

Mounting flange

Other

■

DKD/DAkkS certified accuracy

■

Protective rubber cap for case

WIKA accessories can be found online at www.wika.com.

EN

14161966.04 06/2017 EN/DE

47WIKA operating instructions, model CPG1500

Page 48

Appendix: EU declaration of conformity

EN

48 WIKA operating instructions, model CPG1500

14161966.04 06/2017 EN/DE

Page 49

Inhalt

Inhalt

1. Allgemeines 51

2. Kurzübersicht 52

2.1 Überblick. . . . . . . . . . . . . . . . . . . . . . . . 52

2.2 Beschreibung . . . . . . . . . . . . . . . . . . . . . .52

2.3 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . 52

2.4 Produktpass . . . . . . . . . . . . . . . . . . . . . . 53

3. Sicherheit 55

3.1 Symbolerklärung . . . . . . . . . . . . . . . . . . . . . 55

3.2 Bestimmungsgemäße Verwendung. . . . . . . . . . . . . . . 55

3.3 Fehlgebrauch . . . . . . . . . . . . . . . . . . . . . .56

3.4 Personalqualifikation. . . . . . . . . . . . . . . . . . . . 56

3.5 Beschilderung, Sicherheitskennzeichnungen . . . . . . . . . . . 57

3.6 Ex-Kennzeichnung . . . . . . . . . . . . . . . . . . . .58

3.6.1 Besondere Bedingungen für die Verwendung . . . . . . . . . .58

3.6.2 Zugelassene Batterien . . . . . . . . . . . . . . . . .59

4. Aufbau und Funktion 60

4.1 Frontfolie. . . . . . . . . . . . . . . . . . . . . . . . 60

4.2 Integrierter Datenlogger. . . . . . . . . . . . . . . . . . . 62

4.3 Spannungsversorgung . . . . . . . . . . . . . . . . . . . 62

4.4 WIKA-Wireless. . . . . . . . . . . . . . . . . . . . . . 63

4.5 Anschlüsse . . . . . . . . . . . . . . . . . . . . . . .63

4.6 Gummischutzkappe für Gehäuse . . . . . . . . . . . . . . . 63

5. Transport, Verpackung und Lagerung 64

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . 64

5.2 Verpackung und Lagerung. . . . . . . . . . . . . . . . . . 64

6. Inbetriebnahme, Betrieb 65

6.1 Mechanische Montage . . . . . . . . . . . . . . . . . . .65

6.2 Elektrische Montage . . . . . . . . . . . . . . . . . . . .66

6.3 Normalbetrieb . . . . . . . . . . . . . . . . . . . . . .66

6.4 Menüfunktionen . . . . . . . . . . . . . . . . . . . . .67

6.4.1 Druckeinheiten . . . . . . . . . . . . . . . . . . . . 71

6.4.2 Automatische Abschaltung . . . . . . . . . . . . . . . . 71

6.4.3 Batteriespannung anzeigen . . . . . . . . . . . . . . . .71

6.4.4 Anzeige der aktuellen Temperatur . . . . . . . . . . . . . . 71

6.4.5 Dämpfung einstellen . . . . . . . . . . . . . . . . . . 71

6.4.6 Abtastrate konfigurieren . . . . . . . . . . . . . . . . . 72

6.4.7 TARE (Tara einstellen). . . . . . . . . . . . . . . . . . 72

6.4.8 Funktionssperre . . . . . . . . . . . . . . . . . . . .72

14161966.04 06/2017 EN/DE

DE

49WIKA Betriebsanleitung, Typ CPG1500

Page 50

Inhalt

6.5 Kommunikation mit der Kalibriersoftware WIKA-Cal . . . . . . . . . 73

6.5.1 WIKA-Wireless im CPG1500 aktivieren . . . . . . . . . . . .73

6.5.2 WIKA-Cal-Konfiguration (auch mit der Demoversion möglich) . . . . 73

6.5.3 WIKA-Cal - Log-Template. . . . . . . . . . . . . . . . . 76

6.5.4 App „myWIKA device”. . . . . . . . . . . . . . . . . . 77

7. Störungen 78

DE

8. Wartung, Reinigung und Rekalibrierung 79

8.1 Wartung . . . . . . . . . . . . . . . . . . . . . . . . 79

8.2 Batteriewechsel . . . . . . . . . . . . . . . . . . . . . 80

8.3 Reinigung . . . . . . . . . . . . . . . . . . . . . . . 81

8.4 Rekalibrierung . . . . . . . . . . . . . . . . . . . . . .81

9. Demontage, Rücksendung und Entsorgung 82

9.1 Demontage . . . . . . . . . . . . . . . . . . . . . . .82

9.2 Rücksendung . . . . . . . . . . . . . . . . . . . . . . 83

9.3 Entsorgung . . . . . . . . . . . . . . . . . . . . . . .83

10. Technische Daten 84

10.1 Sensorik . . . . . . . . . . . . . . . . . . . . . . . 84

10.2 Grundgerät . . . . . . . . . . . . . . . . . . . . . . 86

10.3 WIKA-Wireless . . . . . . . . . . . . . . . . . . . . . 87

10.4 Zertifikate/Zeugnisse . . . . . . . . . . . . . . . . . . . 89

10.5 Abmessungen in mm (in). . . . . . . . . . . . . . . . . . 89

10.5.1 CPG1500 ohne Gummischutzkappe . . . . . . . . . . . . .89

10.5.2 CPG1500 mit Gummischutzkappe . . . . . . . . . . . . . 90

10.6 Gewindeanschlüsse . . . . . . . . . . . . . . . . . . .90

11. Zubehör 93

Anlage: EU-Konformitätserklärung 94

Konformitätserklärungen finden Sie online unter www.wika.de.

50 WIKA Betriebsanleitung, Typ CPG1500

14161966.04 06/2017 EN/DE

Page 51

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Präzisions-Digitalmanometer Typ

CPG1500 wird nach dem aktuellen Stand der Technik gefertigt. Alle Komponenten

unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere

Managementsysteme sind nach ISO 9001 und ISO 14001 zertifiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

DE

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Zugehöriges Datenblatt: CT 10.51

- Anwendungsberater: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Abkürzungen, Definitionen

„XXX“ Menü XXX wird aufgerufen

[XXX] Taste XXX drücken

14161966.04 06/2017 EN/DE

51WIKA Betriebsanleitung, Typ CPG1500

Page 52

2. Kurzübersicht

2. Kurzübersicht

2.1 Überblick

DE

1

Anzeige

2

Prozessanschluss

2.2 Beschreibung