Page 1

Precision digital pressure gauge

Model CPG1500

Applications

■

Oil and gas industry

■

Maintenance and service facilities

■

Calibration service companies and service industry

■

Simple calibrations directly on site

■

Pressure test

Special features

Calibration technology

WIKA data sheet CT 10.51

for further approvals

see page 4 - 5

■

Measuring ranges up to 0 ... 10,000 bar (0 ... 150,000 psi),

vacuum and absolute pressure ranges also available

■

Accuracy: up to 0.05 % (incl. calibration certicate)

■

Intrinsically safe version

■

Logger function with up to 50 measured values per

second

■

Communication with WIKA-Cal software over

WIKA-Wireless

Description

General information

The model CPG1500 precision digital pressure gauge takes

the concept of an analogue gauge, and raises it to a level

only matched by digital calibrators. The accuracy of digital

measurement technology and the simplicity of an analogue

gauge are combined together to create the CPG1500,

which in terms of performance, ease-of-use, and instrument

features, is unmatched in the pressure measurement market.

Accuracy

The CPG1500 oers an accuracy of 0.1 % of span (optional

0.05 % of span) and is temperature-compensated in the

range of -10 … +50 °C (14 ... 122 °F). Readings can be

displayed in one of 26 pressure and 5 level units or also in

customer-specic units, so that intricate conversions are

avoided.

Precision digital pressure gauge, model CPG1500

Sampling rate

The measuring rate can be user-dened to match the type

of measurement required. Standard applications usually use

three measured values per second. If required, this rate can

also be set to 50 measured values per second.

Via an energy-saving function, the CPG1500 switches

automatically into “sleep” mode, in this mode the battery life

can be increased up to 2,500 hours.

Features

Through the new and innovative menu navigation, simple

operation is ensured. The clear display, with integral bar

graph display and large text area, assists with the eective

analysis of the widest variety of measuring points.

With the MIN/MAX function, the highest and lowest pressures

can be accessed immediately and saved automatically.

∙ 05/2017

Data sheets showing similar products:

Digital pressure gauge; model CPG500; see data sheet CT 09.01

Test pumps, hydraulic; CPP series; see data sheet CT 91.05

Test pumps, pneumatic; model CPP30; see data sheet CT 91.06

Calibration software WIKA-Cal; see data sheet CT 95.10

Page 1 of 11WIKA data sheet CT 10.51

Page 2

Software

WIKA-Cal calibration software is available for the CPG1500.

WIKA-Cal also oers, over and above PC-supported

calibration, the management of the calibration and instrument

data in an SQL database. WIKA-Wireless is available for the

Certied accuracy

For each digital pressure gauge, the accuracy is certied

by a factory calibration certicate which accompanies the

instrument. On request, we can provide a DKD/DAkkS

calibration certicate for this instrument.

data transfer.

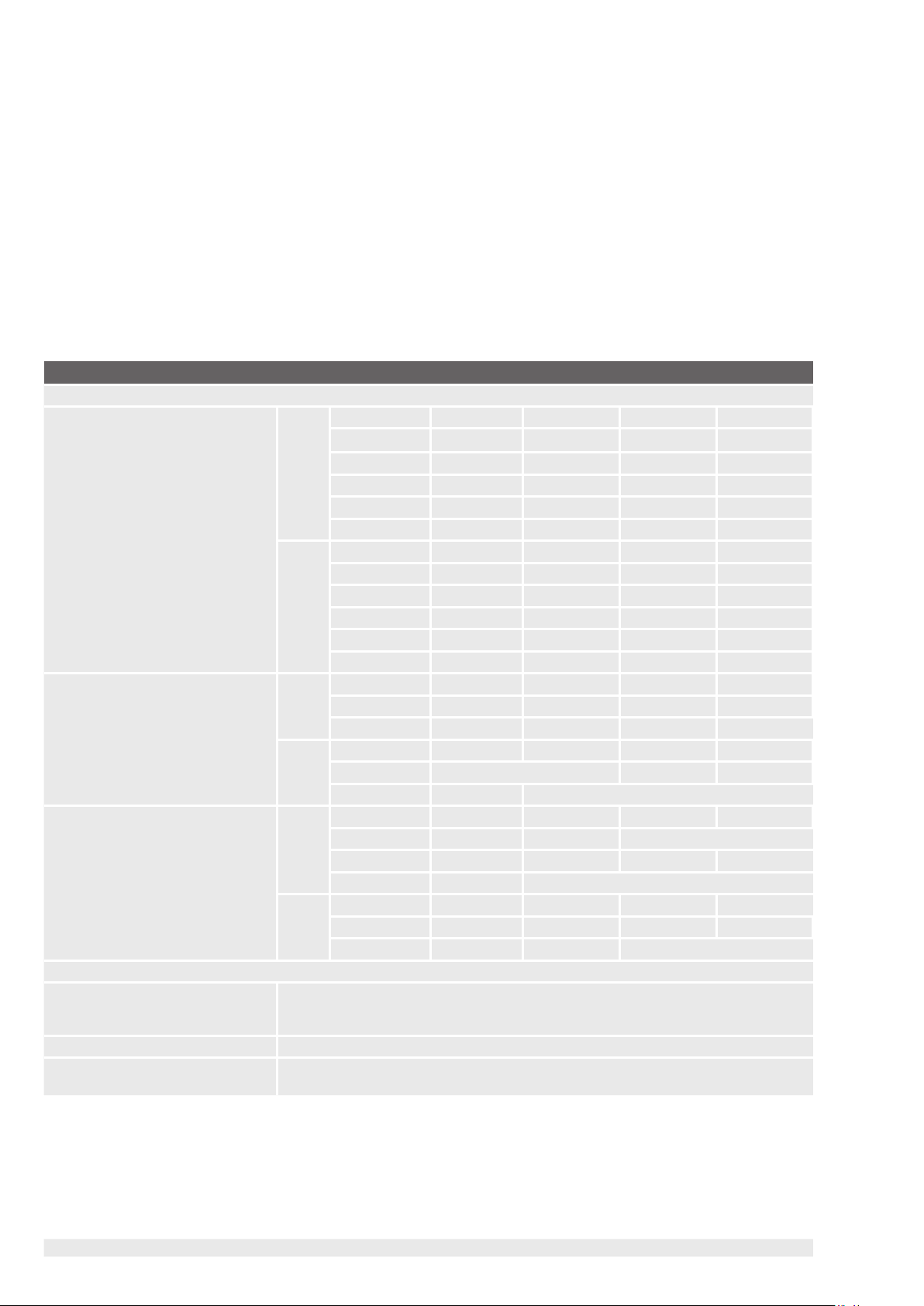

Specications

Model CPG1500

Sensor technology

Measuring range

Gauge pressure bar 0 ... 0.1

1)

0 ... 0.25

0 ... 1.6 0 ... 2.5 0 ... 4 0 ... 6 0 ... 10

0 ... 16 0 ... 25 0 ... 40 0 ... 60 0 ... 100

0 ... 160 0 ... 200 0 ... 250 0 ... 400 0 ... 600

0 ... 700

0 ... 6,000

psi 0 ... 1.5

3)

1)

0 ... 1,000

4)

0 ... 7,000

0 ... 5

0 ... 30 0 ... 50 0 ... 60 0 ... 100 0 ... 150

0 ... 160 0 ... 200 0 ... 300 0 ... 500 0 ... 700

0 ... 1,000 0 ... 1,500 0 ... 2,000 0 ... 3,000 0 ... 5,000

0 ... 6,000 0 ... 8,000 0 ... 10,000

0 ... 30,000

Absolute pressure bar 0 ... 0.25

4)

0 ... 50,000 4)0 ... 100,000 4)0 ... 150,000

2)

0 ... 0.4

0 ... 2.5 0 ... 4 0 ... 6 0 ... 7 0 ... 10

0 ... 16 0 ... 20 0 ... 25 0 ... 40

psi 0 ... 3.5

2)

0 ... 5

0 ... 30 0 ... 50 0 ... 60 0 ... 100 0 ... 150

0 ... 200 0 ... 300 0 ... 500

2)

Vacuum and +/- measuring ranges bar -0.25 ... +0.25

-0.4 ... +0.4 2)-0.6 ... +0.6 -1 ... 0 -1 ... +0.6

-1 ... 1.5 -1 ... 2.5 -1 ... 3 -1 ... 5 -1 ... 7

-1 ... 9 -1 ... 10 -1 ... 15 -1 ... 24 -1 ... 25

-1 ... 39 -1 ... 40

psi -14.5 ... 0 -14.5 ... +15 -14.5 ... 40 -14.5 ... 70 -14.5 ... 100

-14.5 ... 130 -14.5 ... 300 -3 ... +3

-3 ... 0

2)

-5 ... 0

Overpressure limit

Sensor 3 times; ≤ 25 bar (≤ 300 psi)

2 times; > 25 ... ≤ 600 bar (> 300 ... ≤ 5,000 psi)

1.7 times; > 600 bar (> 5,000 psi)

Display > 110 % FS or -10 % FS

Accuracy

1) Expanded accuracy of 0.2 % FS

2) Expanded accuracy of 0.15 % FS

3) Not possible as ush version

4) Expanded accuracy of 0.5 % FS, at reference conditions 23 °C ±3 °C

4) It is dened by the total measurement uncertainty, which is expressed with the coverage factor (k = 2) and includes the following factors: the intrinsic performance of the instrument, the

measurement uncertainty of the reference instrument, long-term stability, inuence of ambient conditions, drift and temperature eects over the compensated range during a periodic

zero point adjustment.

5) At a measuring rate of ≤ 3 measured values per second

5)

0.1 % FS

0.05 % FS (optional)

6)

2)

3)

4)

2)

2)

2)

2)

2)

0 ... 0.4

0 ... 1,600

0 ... 8,000

2)

0 ... 10

2)

0 ... 0.6

2)

0 ... 10

2)

2)

-8 ... 0

2)

0 ... 0.6

4)

0 ... 2,500

4)

0 ... 10,000

0 ... 15 0 ... 20

3)

0 ... 15,000

0 ... 1 0 ... 1.6

0 ... 15 0 ... 20

2)

-5 ... +5

4)

4)

3)

4)

0 ... 1

0 ... 4,000

0 ... 20,000

-8 ... +8

4)

4)

Page 2 of 11 WIKA data sheet CT 10.51 ∙ 05/2017

Page 3

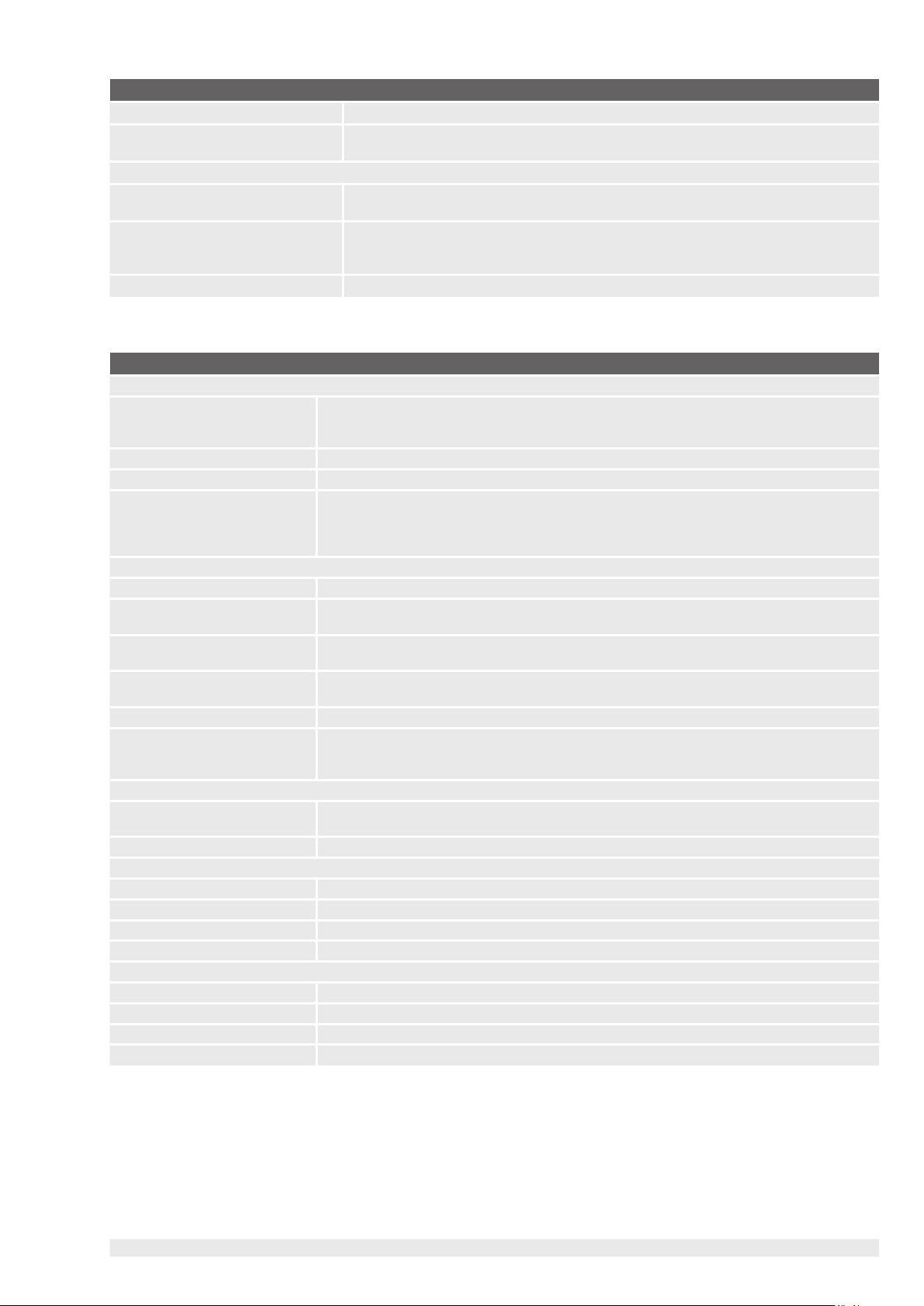

Sensor technology

Compensated temperature range -10 … +50 °C (14 ... 122 °F)

Type of pressure Gauge pressure, absolute pressure (up to 20 bar abs. (290 psi abs.)) and vacuum measuring

ranges

Process connection

Standard

G ½ B, G ¼ B, ½ NPT, ¼ NPT, G 1 B ush, G ½ B ush

≤ 1,000 bar (≤ 15,000 psi)

■

High-pressure version

> 1,000 bar (> 15,000 psi)

M16 x 1.5 female with sealing cone

■

M20 x 1.5 female with sealing cone

■

9/16 - 18 UNF female F 250-C

Pressure medium All liquids and gases which are compatible with 316 stainless steel

Base instrument

Display

Display 5 ½ digit 7-segment display including a large matrix area for auxiliary information

Bar graph, 0 ... 100 %

Selectable backlighting

Rotatable case The case is rotatable by 330°.

Resolution 4 ... 5 ½ digit; adjustable; dependent on the selected pressure unit

Pressure units Standard: psi, bar

Selectable to: mbar, kg/cm², Pa, hPa, kPa, Mpa, mmH

inH2O (60 °F), ftH2O, mmHg, cmHg, inHg, inHg (0 °C), inHg (60 °F), kp/cm2, lbf/ft2, kN/m2, atm, Torr,

micron as well as user-dened units

7)

Functions

Measuring rate max. 50/s

Menu languages Standard: English

Selectable: German, Italian, French, Spanish, Russian and Polish

Memory Standard: Min./Max.

Optional: integrated data logger

Menu functions Min./Max. alarm (visual), power-o function, measuring rate, mean value lter, pressure rate, mean

value (via adjustable interval), level indicator, Tare oset, display damping

Mean value interval 1 ... 300 seconds, adjustable

Data logger

8)

Cyclic logger: Automatic recording of up to 1,000,000 values;

Cycle time: selectable from 1 ... 3,600 s. in steps of 1 second or by measuring rate in the following

steps: 1/s, 3/s, 10/s and 50/s

Material

Wetted parts ≤ 1.000 bar: Stainless steel 316

> 1.000 bar: Stainless steel 1.4534

Case Aluminium die-casting, nickel-plated

Voltage supply

Power supply 3 x 1.5 V AA alkaline batteries

9)

Maximum voltage DC 4.95 V (spark ignition)

Battery life typical 2,000 ... 2,500 h (without backlighting and WIKA-Wireless not active)

Battery status indication Symbol display, with 4 bars displaying the battery status in segments of 25 %

Permissible ambient conditions

Operating temperature -10 ... +50 °C (14 ... 122 °F)

Medium temperature -10 ... +50 °C (14 ... 122 °F) (lower temperature limit above the freezing point of the medium)

Storage temperature -20 ... +70 °C (-4 ... +158 °F)

Relative humidity < 95 % r. h. (non-condensing)

7) The user-dened units can only be set via the WIKA-Cal software. The CPG1500 must feature WIKA-Wireless.

8) To use the logger function, WIKA-Cal software is needed.

The logger data can be downloaded with the WIKA-Cal demo version as a CSV le. The live logger, an accurate data analysis or a direct certicate creation can be used with the logger

template WIKA-Cal.

9) For hazardous areas, only the following types are allowed:

■

Duracell, Simply by Duracell MN1500

■

Duracell, Duralock Plus Power MN1500

■

Varta, RAYOVAC Maximum Plus 4006

O, mH2O, inH2O, inH2O (4 °C), inH2O (20 °C),

2

WIKA data sheet CT 10.51 ∙ 05/2017 Page 3 of 11

Page 4

Base instrument

Communication (optional)

Interface WIKA-Wireless

Case

Dimensions approx. 100 x 150 x 59 mm (3.9 x 5.9 x 2.3 in)

Ingress protection IP65

Weight Standard: incl. batteries approx. 680 g ( 1.5 lbs)

with protective rubber cap: approx. 820 g (1.81 lbs)

10)

WIKA-Wireless

10)

Frequency range 2,400 ... 2,500 MHz

HF output power max. 2 dBm (+ 2 dBi)

Number of channels 40

Channel spacing 1 or 2 MHz

Bandwidth 1 or 2 MHz

Output power 4 dBm / 10 mW

Maximum output power under fault conditions for Ex ia: 490 mW

10) Requires a PC with Bluetooth® 2.1 interface

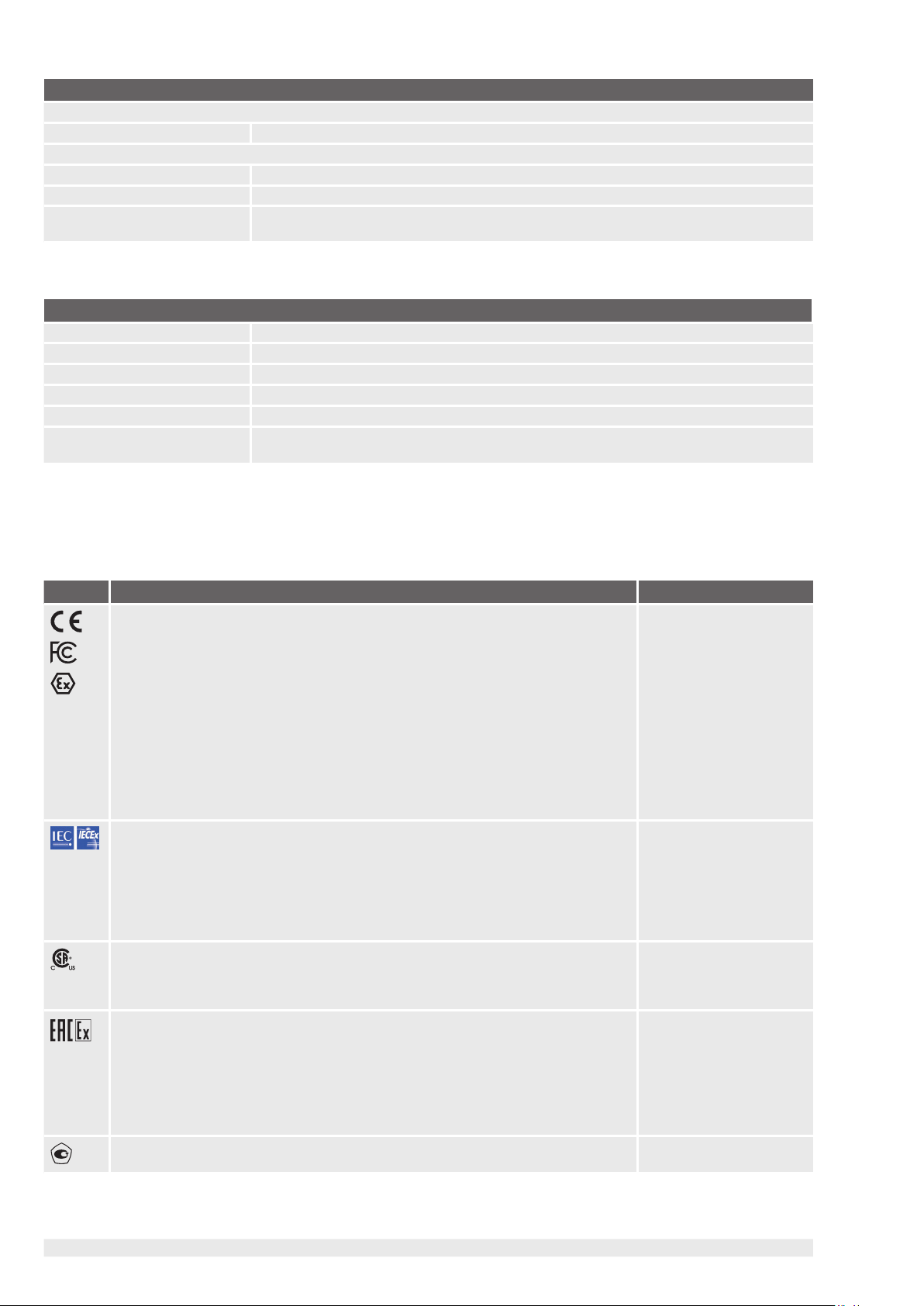

Approvals

Logo Description Country

EU declaration of conformity

■

EMC directive

■

Pressure equipment directive

■

R&TTE directive

EN 300 328 harmonised frequency range 2,400 … 2,500 MHz is used; Bluetooth® Classic,

max. transmission power 10 mW. The instrument may be used without limitations in the EU

and also CH, NO and LI.

■

RoHS directive

■

ATEX directive

Ex i Zone 0 gas II 1G Ex ia IIC T4 Ga

Zone 1 connection to zone 0 gas II 1/2G Ex ia IIC T4 Ga/Gb

Zone 1 gas II 2G Ex ia IIC T4 Gb

T4 at -10 … +50 °C

IECEx

Hazardous areas

Ex i Zone 0 gas Ex ia IIC T4 Ga

Zone 1 connection to zone 0 gas Ex ia IIC T4 Ga/Gb

Zone 1 gas Ex ia IIC T4 Gb

Zone 2 gas Ex ia IIC T4 Gc

T4 at -10 … +50 °C

CSA

Safety (e.g. electr. safety, overpressure, ...)

■

Class - 3631 06 - Electrical measurement and test equipment

■

Class - 3631 86 - Electrical equipment for measurement use - Certied to US Standards

EAC

■

EMC directive

■

Hazardous areas

Ex i Zone 0 gas Ex ia IIC T4 Ga

Zone 1 connection to zone 0 gas Ex ia IIC T4 Ga/Gb

Zone 1 gas Ex ia IIC T4 Gb

T4 at -10 … +50 °C

European Union

International

USA and Canada

Eurasian Economic

Community

GOST

Russia

Metrology, measurement technology

Page 4 of 11 WIKA data sheet CT 10.51 ∙ 05/2017

Page 5

Ø 100,7 (3,96)

58,9 (2,32)

Logo Description Country

DNOP (MakNII)

■

Mining

■

Hazardous areas

KazInMetr

Metrology, measurement technology

- PESO

Hazardous areas

Ex i Zone 1 connection to zone 0 gas Ex ia IIC T4 Ga/Gb

Ukraine

Kazakhstan

India

Certicates

Certicate

Calibration

Recommended recalibration interval 1 year (dependent on conditions of use)

1) Calibrated in vertical mounting position with process connection facing downwards

Approvals and certicates, see website

1)

Standard: 3.1 calibration certicate per EN 10204

Option: DKD/DAkkS calibration certicate

Dimensions in mm (in)

CPG1500 without protective rubber cap

36

3 (0,12)

20 (0,79)

114,9 (4,53)

110,1 (4,33)

32,5 (1,28

35,5 (1,40)

G 1/2

Ø 36 (1,42)

Ø 44,4 (1,75)

34,7 (1,37)

WIKA data sheet CT 10.51 ∙ 05/2017 Page 5 of 11

Page 6

Ø 108,4 (4,27)

66,4 (2,61)

CPG1500 with protective rubber cap

Ø 10 (0,39)

5 (0,20)

116 (4,57)

120,8 (4,75)

172,4 (6,79)

36

32,5 (1,28

20 (0,79)

35,5 (1,40)

3 (0,12)

G 1/2

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connections G ½ and G ¼

G 1/2

Ø 36 (1,42)

Ø 44,4 (1,75)

3 (0,12)

20 (0,79)

32,5 (1,28

35,5 (1,40)

36,8 (1,45)

32,5 (1,28

35,5 (1,40)

G 1/4

2 (0,08)

13 (0,51)

Ø 36 (1,42)

Ø 44,4 (1,75)

Page 6 of 11 WIKA data sheet CT 10.51 ∙ 05/2017

Page 7

Threaded connections ½ NPT and ¼ NPT

1/2 NPT

Ø 36 (1,42)

Ø 44,4 (1,75)

31,5 (1,24)

19 (0,75)

25,5 (1,00)

1/4 NPT

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connections M16 and M20

M20

Ø 36 (1,42)

Ø 44,4 (1,75)

Threaded connection 9/16 - 18 UNF

39,2 (1,55)

13 (0,51)

27,5 (1,08)

39,2 (1,55)

M16

Ø 36 (1,42)

Ø 44,4 (1,75)

39,2 (1,55)

9/16"

Ø 36 (1,42)

Ø 44,4 (1,75)

WIKA data sheet CT 10.51 ∙ 05/2017 Page 7 of 11

Page 8

Front foil

13

12

11

10

9

78

Warning notice when:

1

■

Exceeding or dropping below the pressure range

■

Exceeding or dropping below the temperature range

■

Logger memory is more than 90 % full

■

Instrument error or battery status < 10 %

Log: Logger function active/inactive

1

2

3

4

2

Battery status

3

Pressure indication

4

Matrix eld serves as menu and secondary display

5

On/O button

6

MENU button

7

Access the menu

LIGHT button

5

6

8

Turning the backlighting on and o

ZERO button

9

The current pressure value will be set to "0" (rel.) or

reference pressure (abs.)

10

Bar graph indicates the current pressure graphically

11

Lock symbol: Menu button or ZERO button locked/

unlocked

12

WIKA-Wireless: WIKA-Wireless active/inactive

13

Tara: TARE active/inactive

App “myWIKA device”

Via the app “myWIKA device” and

the WIKA-Wireless connection,

the CPG1500 can be congured

for calibration and log routines

in a comfortable way through a

mobile phone. During the pressure

measurement, the value is displayed in

the required unit directly on the phone.

Moreover, further parameters like

temperature and pressure change rate

can be checked. It is also possible

to retrieve more detailed device

information directly from the WIKA website. In addition,

the app allows conguration, control and saving of log

procedures.

Logs that were saved on the mobile phone can be transferred

to a PC and be read by WIKA-Cal.

With that they can be further processed and the app lls the

gap to provide a thorough solution of dealing with data on the

CPG1500.

For iOS-based mobile

phones, the app is

available in the Apple Store

under below link.

For mobile phones with an

Android operating system,

the app is available in the

Play Store under below link.

Download here Download here

Page 8 of 11 WIKA data sheet CT 10.51 ∙ 05/2017

Page 9

WIKA-Cal calibration software

Easy and fast creation of a high-quality calibration certicate

The WIKA-Cal calibration software is used for generating

calibration certicates or logger protocols for pressure

measuring instruments and is available as a demo version for

a cost-free download.

A template helps the user and guides him through the

creation process of a document.

In order to switch from the demo version to a full version of

the respective template, a USB stick with the template has to

be purchased.

The pre-installed demo version automatically changes to

the selected full version when the USB stick is inserted and

is available as long as the USB stick is connected to the

computer.

■

Creation of calibration certicates for mechanical and

electronic pressure measuring instruments

■

A calibration assistant guides you through the calibration

■

Automatic generation of the calibration steps

■

Generation of 3.1 certicates per DIN EN 10204

■

Creation of logger protocols

■

User-friendly interface

■

Languages: German, English, Italian and more due with

software updates

For further information see data sheet CT 95.10

Calibration certicates can be created with the Cal-Template and logger protocols can be created with the Log-Template.

Cal Demo

Generation of calibration certicates limited to 2 measuring points, with

automatic initiation of pressures via a pressure controller.

Cal Light

Generation of calibration certicates with no limitations on measuring

points, without automatic initiation of pressures via a pressure

controller.

Calibration certificate

Kalibrierzeugnis

General

Allgemein

Calibration certificate

Kalibrierschein

Customer Demo customer

Kunde

Demo street

DE-12345 Demo city

Customer order No.

Kundenbestellnummer

Order date

Bestelldatum

Date of calibration 01/02/2017

Datum der Kalibrierung

Operator Demo User

Bearbeiter

Environmental conditions

Umgebungsbedingungen

Temperature (20,0 ± 0,1) °C

Temperatur

Atmospheric pressure (1013,0 ± 0,1) hPa

Atmosphärischer Luftdruck

Rel. humidity (40 ± 1) %

Rel. Luftfeuchte

Measurement conditions

Messbedingungen

Working standard (WS) Pressure controller

Gebrauchsnormal (GN) Druckcontroller

Model Demo CPC

Typ

Calibration mark Demo 12345

Kalibrierzeichen

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.02 % FS

Genauigkeit

Demo laboratory

Tel.: 01234/56789

Demo street 123

Fax: 01234/56789

12345 Demo city

E-Mail: demo@demo.com

Demo country

www.demo.com

Certificate No. 00000122

Zeugnis-Nr.

Device under test (DUT)

Kalibriergegenstand (KG)

Electrical gauge

Elektrisches Druckmessgerät

Model D-10

Typ

Serial number demo1234

Seriennummer

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.05 % FS

Genauigkeit

Resolution (scale division) 0.0001 bar

Auflösung (Skalenwert)

Measuring point No. demo tag

Messstellen-Nr

Place of calibration

Ort der Kalibrierung

g = (9.80946 ± 0.01) m/s²

Demo place

Musterort

Calibration certificate

Kalibrierzeugnis

Measurement results

Messergebnisse

Reference value WS Reading DUT

Statement of compliance

Konformitätsaussage

Object keeps the specifications!

Der Kalibriergegenstand hält die Herstellerspezifikationen ein!

Demo laboratory

Page 1 / 2

Demo street 123

Seite

12345 Demo city

Demo country

Referenzwert GN Ablesung KG

bar bar

↑ ↓

0.00000 0.0000 0.0010

10.00000 10.0010 10.0020

Tel.: 01234/56789

Fax: 01234/56789

E-Mail: demo@demo.com

www.demo.com

Certificate No. 00000122

Zeugnis-Nr.

Log Demo

Creation of data logger test reports, limited to 5 measured values.

Log

Creation of data logger test reports without limiting the measured

values.

Page 2 / 2

Seite

WIKA data sheet CT 10.51 ∙ 05/2017 Page 9 of 11

Page 10

Complete test and service cases

Calibration case with model CPG1500 precision digital

pressure gauge and model CPP30 hand test pump,

for pressures -0.95 ... +35 bar (-28 inHg ... +500 psi),

consisting of:

■

Plastic service case with foam insert

■

Precision digital pressure gauge model CPG1500

■

Pneumatic hand test pump model CPP30; -0.95 ... +35 bar

(-28 inHg ... +500 psi)

Available measuring ranges see specications

Basic version incl. pneumatic pressure generation

Basic version incl. hydraulic pressure generation

Recommended pressure generation

For further specications see data sheet CT 91.06

Calibration case with model CPG1500 precision digital

pressure gauge and model CPP700-H hand test pump,

for pressures 0 ... 700 bar (0 ... 10.000 psi), consisting

of:

■

Plastic service case with foam insert

■

Precision digital pressure gauge model CPG1500

■

Model CPP700-H hydraulic hand test pump; 0 … 700 bar

(0 ... 10.000 psi)

Available measuring ranges see specications

Further specications see data sheet CT 91.07

Model CPP30 pneumatic hand test pump

Pressure range: -0.95 ... +35 bar (-28 inHg ... +500 psi)

Further specications see data sheet CT 91.06

Hydraulic hand test pump model CPP700-H

Pressure range:

0 ... 700 bar (0 ... 10.000 psi)

Further specications see data sheet CT 91.07

Page 10 of 11 WIKA data sheet CT 10.51 ∙ 05/2017

Page 11

Scope of delivery

■

Precision digital pressure gauge model CPG1500

■

Operating instructions

■

3.1 calibration certicate per DIN EN 10204

■

3 x 1.5 V AA alkaline batteries

Options

■

DKD/DAkkS calibration certicate

■

Protective rubber cap for case

Accessories

Connection adapters

■

Various process connection adapters

Pressure generation

■

Pneumatic test pumps

■

Hydraulic test pumps

Test case

■

Various calibration cases incl. pressure generation

Precision digital pressure gauge with protective

rubber cap, model CPG1500

Software

■

WIKA-Cal calibration software

Installation

■

Mounting ange

Ordering information

Model / Version / Explosion protection / Instrument variant / Unit / Type of pressure / Measuring range / Process connection /

Wetted parts / Specialities due to medium / Accuracy / Type of certicate / Communication / Data logger / Case protection

cover / Carrying case / Certicates / Additional ordering information

05/2017 EN

© 04/2016 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

WIKA data sheet CT 10.51 ∙ 05/2017 Page 11 of 11

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Loading...

Loading...