Page 1

Operating instructions

Betriebsanleitung

Precision digital pressure gauge, model CPG1000

Präzisions-Digitalmanometer, Typ CPG1000

GB

D

Precision digital pressure gauge, model CPG1000

Page 2

GB

Operating instructions model CPG1000 Page 3 - 34

Betriebsanleitung Typ CPG1000 Seite 35 - 66

D

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2

WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 3

Contents

Contents

1. General information 4

2. Safety 6

2.1 Intended use 6

2.2 Personnel qualication 7

2.3 Additional safety instructions for instruments per ATEX 7

2.4 Special hazards 9

2.5 Labelling/safety marks 11

3. Specications 12

4. Design and function 17

4.1 Description 17

4.2 Scope of delivery 17

4.3 Front foil of the CPG1000 18

4.4 Integrated data logger 18

4.5 External voltage supply 18

4.5.1 Battery replacement 19

4.5.2 Battery life time 19

4.6 RS-232 Interface 19

4.7 Connections 19

5. Transport, packaging and storage 20

6. Commissioning, operation 21

6.1 Normal operation 21

6.2 Setup and conguration 21

6.3 Supervisor mode (Control mode) 26

7. Maintenance and cleaning and servicing 27

8. Faults 28

9. Dismounting, return and disposal 29

10. Accessories 30

Appendix 1: EC Declaration of conformity for CPG1000 31

Appendix 2: EC-type examination certicate for CPG1000 32

GB

Declarations of conformity can be found online at www.wika.com.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 3

Page 4

1. General information

1. General information

■

GB

The precision digital pressure gauge model CPG1000 described in the operating

instructions has been manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer’s liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 10.01

- Application consultant: Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-217

E-Mail: testequip@wika.de

4 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 5

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

DANGER!

...identies hazards caused by electric power. Should the safety instructions not be observed, there is a risk of serious or fatal injury.

GB

WARNING!

... indicates a potentially dangerous situation in the hazardous area that

can result in serious injury or death, if not avoided.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 5

Page 6

2. Safety

2. Safety

WARNING!

GB

2.1 Intended use

The CPG1000 precision digital pressure gauge can be used as a calibration instrument

and also for any application which requires high-accuracy pressure measurement.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

Before installation, commissioning and operation, ensure that the appropriate CPG1000 precision digital pressure gauge has been selected in terms

of measuring range, design and specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

Further important safety instructions can be found in the individual

chapters of these operating instructions.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications

requires the instrument to be taken out of service immediately and inspected by an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

6 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 7

2. Safety

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Additional safety instructions for instruments per ATEX

WARNING!

Non-observance of these instructions and their contents may result in the

loss of explosion protection.

GB

The CPG1000 is a precision digital pressure gauge. The sensor may be

bottom or back mounted. The case is about 10 cm in diameter and it may

be used as a hand-held gauge or it may be xed in place.

■

Battery operation:

Use AA alkaline batteries only! Only replace the batteries outside the

hazardous area!

■

Measuring instruments with an external power supply unit are not

approved for hazardous areas.

■

Operation of the serial interface in the hazardous area is prohibited.

■

Temperature range: -10 ... +55 °C

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 7

Page 8

2. Safety

Further hazardous area safety instructions:

Observe the operating information and the relevant country-specic regulations concerning use in hazardous areas (e.g. EN 60079-14).

GB

The precision digital pressure gauge is not intended for use with ammable

substances. It is only suitable for installation in locations which provide

sucient protection against the intrusion of solid foreign objects or water

which could impair the safety.

The instructions in these operating instructions must be followed strictly in

order to guarantee safe operation.

Information/Approval for hazardous locations

WARNING!

■

Hazardous areas

An hazardous area, as used in this manual, refers to an area made

hazardous by the potential presence of ammable or explosive vapours.

These areas are also referred to as hazardous locations, see NFPA 70

Article 500.

® LR110460, Class I, Division 2, Group A, B, C, D

II 3G Ex nA IIB T6

KEMA 09ATEX0096 X

T

= -10 ... +55 °C

a

WARNING!

Only precision digital gauges powered by alkaline batteries are approved

for use in hazardous rooms. Precision digital pressure gauges with an

external voltage supply are not approved for use in hazardous areas.

The replacement of any components impairs their suitability for use in

hazardous areas.

8 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 9

2. Safety

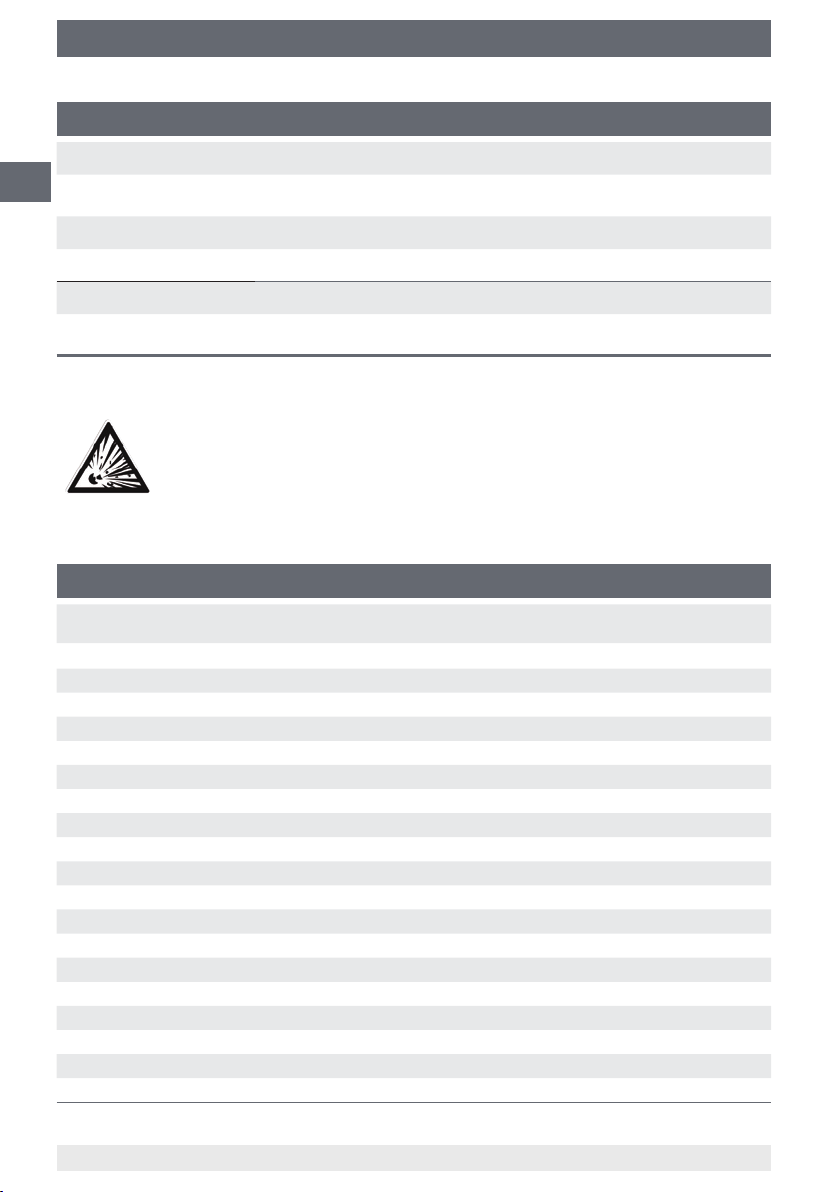

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination certicate and the relevant country-specic regulations for installation and use

in hazardous areas (e.g. IEC 60079-14, NEC, CEC). Non-observance can

result in serious injury and/or damage to equipment.

For additional important safety instructions for instruments with ATEX

approval see chapter 2.3 "Additional safety instructions for instruments per

ATEX".

WARNING!

■

Only connect or disconnect the CPG1000 once the system has been

depressurised!

■

Observe the working conditions in accordance with chapter 3 "Specications".

■

Always operate the pressure indicator within its overpressure limits.

■

For hazardous media such as oxygen, acetylene, ammable or toxic

gases or liquids, and refrigeration plants, compressors, etc., in addition

to all standard regulations, the appropriate existing codes or regulations

must also be followed.

■

If it is obvious that safe operation of the instrument is no longer possible, the instrument must be put out of operation and marked in order to

secure it against inadvertent use.

■

The circuitry for connection to other devices should be designed with

particular care. Under certain circumstances internal junctions in external devices (e.g. GND junctions with screen) could lead to impermissible voltage potentials that could impair the function of the device itself or

a device connected to it, or even destroy them.

■

The measurement signal of the reference (or test sample) can be inuenced by massive electromagnetic irradiation and/or the indication of

the signal could be completely absent.

■

If the CPG1000 is used in applications with oil as a pressure medium,

make sure it will not be used with ammable material or gases directly

afterwards since it can lead to dangerous explosions and danger to

personnel and machinery.

■

Residual media in the dismounted instrument can result in a risk to

persons, the environment and the equipment. Take sucient precautionary measures.

GB

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 9

Page 10

2. Safety

DANGER!

Danger of death caused by electric current

Operation using a defective power supply unit (e.g. short circuit from the

GB

Special conditions for safe use

mains voltage to the output voltage) can result in life-threatening voltages

at the instrument!

WARNING!

If the CPG1000 has been exposed to overload or sudden physical shock

(e.g. being dropped) it should be checked for signs of damage that may

cause concerns about safety. If there is any doubt, return the unit to WIKA

for evaluation. For information on returning the instrument see chapter

9.2 "Return".

The CPG1000 is not intended for use with ammable substances and must

be used only in locations which provide sucient protection against the

intrusion of solid foreign objects or water which could impair the safety.

CAUTION!

To avoid possible damage to the calibration reference or to equipment

under test:

■

If the message "OL" is displayed, the measuring range has been

exceeded and the pressure source must be removed immediately from

the CPG1000 in order to prevent damage to the internal sensor.

■

The maximum permitted torque of the thread is 13.5 Nm = 10 ftlbs. This

permitted torque must NEVER be exceeded.

■

When screwing the NPT thread of the CPG1000 to an adapter or

a process connection, it is necessary to use an additional sealing

compound, e.g. Teon tape between the threads.

■

The sealing has to be made with Teon tape directly via the NPT thread

and not via the manifold at the CPG1000.

10 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 11

2. Safety

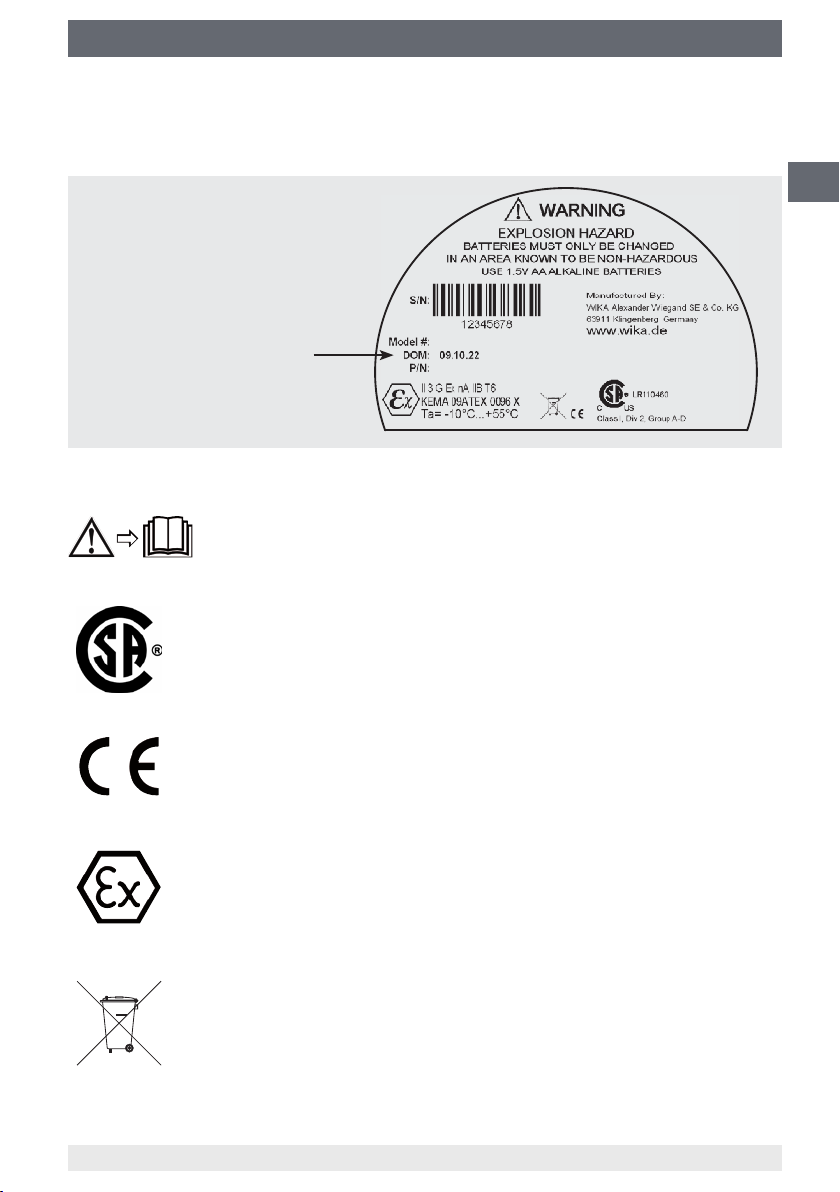

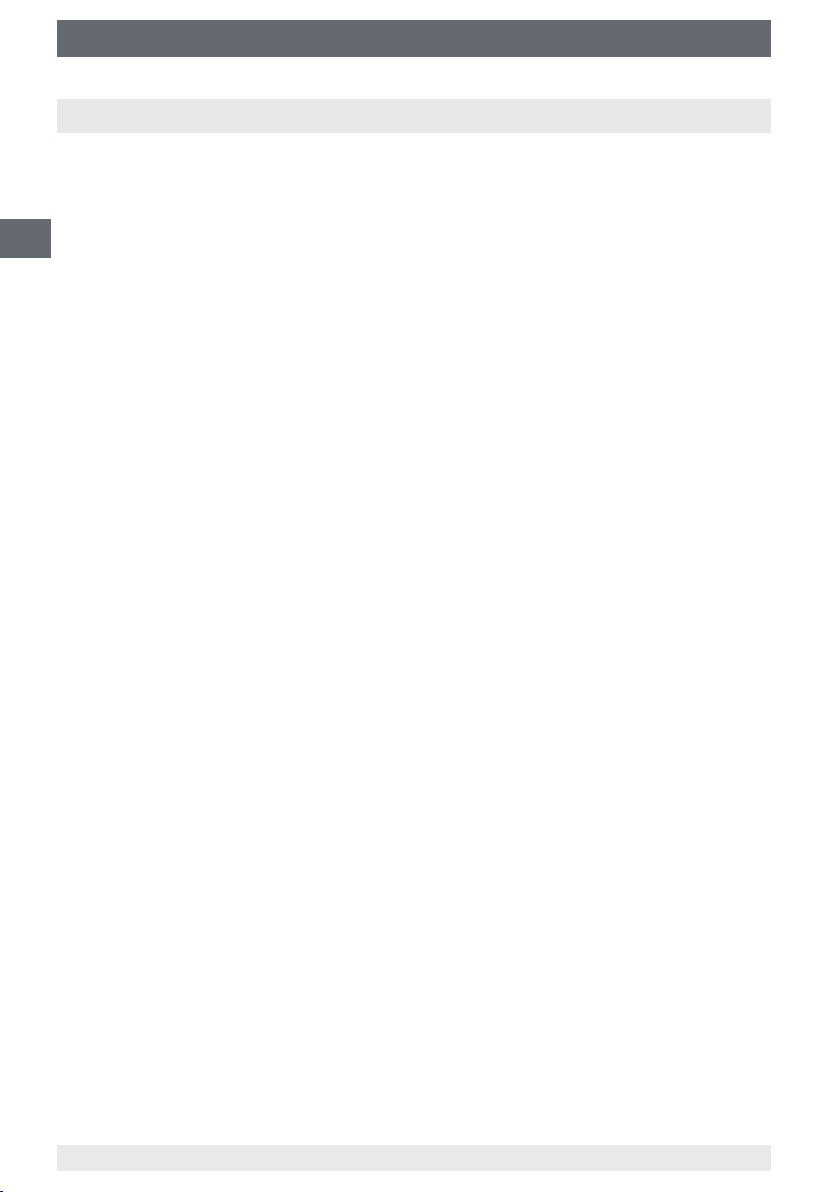

2.5 Labelling/Safety marks

Product label

Date of manufacture

Year/Month/Day

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

GB

CSA, Canadian Standard Association

The instrument was inspected and certied by CSA International.

Instruments bearing this mark comply with the applicable Canadian standards on safety (including explosion protection)

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the requirements of the European directive 94/9/EC (ATEX) on explosion protection.

This marking on the instruments indicates that they must not be disposed

of in domestic waste. The disposal is carried out by return to the manufacturer or by the corresponding municipal authorities (see directive 2002/96/

EC).

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 11

®

Page 12

3. Specications

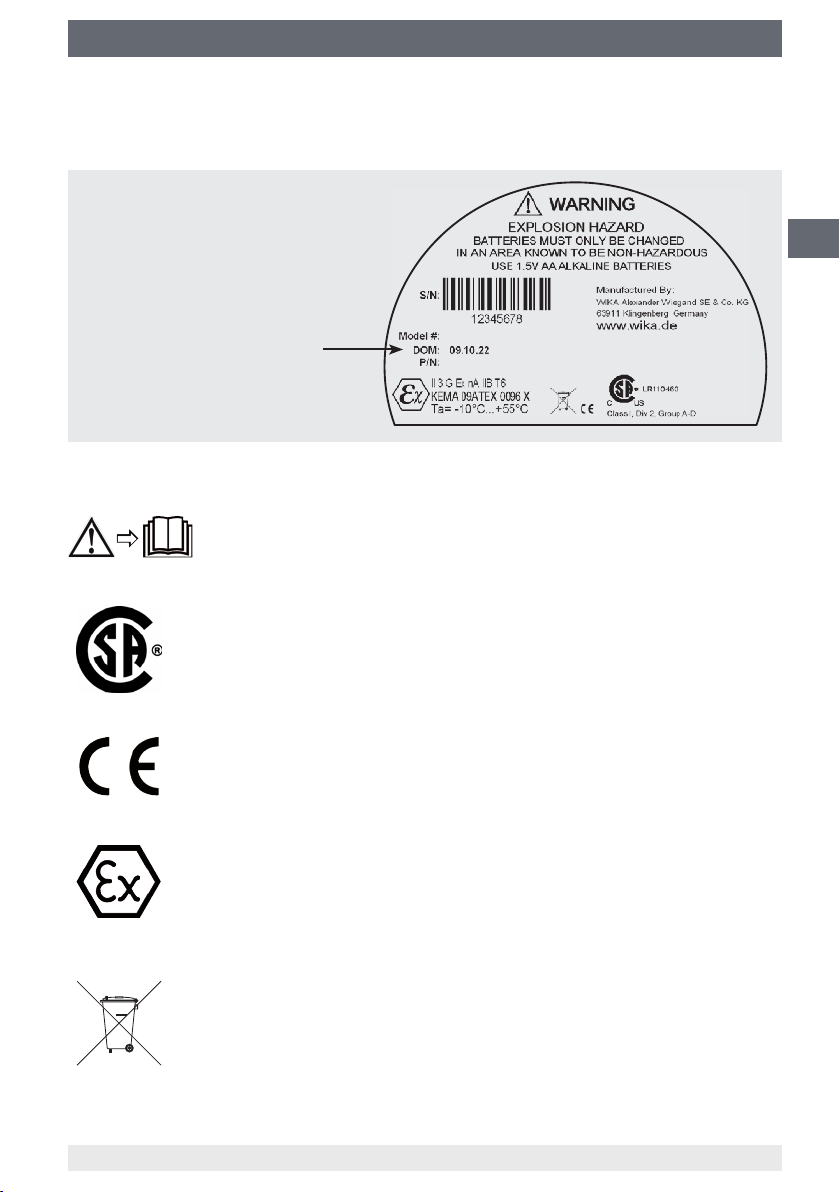

3. Specications

Sensor technology

GB

Measuring range mbar 0 … 70

Overpressure limit mbar 200

Burst pressure mbar 350

Resolution mbar 0.001

Measuring range bar 0 … 1 0 ... 2 -1 ... +1

Overpressure limit bar 4 4 4 4 14

Burst pressure bar 6 6 6 6 70

Resolution bar 0.0001

Measuring range bar 0 ... 20 0 ... 35 0 ... 70 0 ... 140 0 ... 200 0 ... 350 0 ... 700

Overpressure limit bar 42 70 140 210 420 700 1,100

Burst pressure bar 140 140 700 700 700 700 1,100

Resolution bar 0.001 0.01

Measuring range bar abs. 0 ... 1 0 ... 2 0 ... 7 0 ... 20

Overpressure limit bar abs. 4 4 14 42

Burst pressure bar abs. 35 35 70 140

Resolution bar abs. 0.0001 0.001

Accuracy 0.05 % FS

Compensated temperature

range

Temperature coecients 0.005 % of the span/°C outside of 0 ... 50 °C

Type of pressure relative pressure, absolute pressure (up to 20 bar abs) and vacuum measuring

Pressure connection ¼ NPT male (incl. ¼ NPT female to G ½ male adapter)

Pressure medium all liquids and gases compatible with 316 stainless steel

1) Only use the measuring ranges marked in this way with clean non-corrosive gases.

2) For measuring instruments with a maximum measuring range of up to 2 bar, operation in the vacuum measuring range is limited

to -350 mbar. (Measuring ranges -1 ... +1 bar and -1 ... +2 bar are excluded.) Measuring ranges ≥ 7 bar can be loaded with a full

vacuum.

3) Adapter not included in delivery for North America.

(0.1 % FS for measuring ranges 0 ... 70 mbar, -1 ... +1 bar and -1 ... +2 bar)

(0.25 % FS for vacuum measuring ranges with instruments from 7 bar to a max.

2)

35 bar)

0 ... 50 °C

ranges

1)

1)

-1 ... +2 1)0 ... 7

3)

1)

12 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 13

3. Specications

Base instrument

Indicator

Display 5 1/2 digit display, character size 16.53 mm (0.65")

Pressure units psi, bar, mbar, Kg/cm², inH

Functions

Measuring rate 0.5/sec. to 10/sec. selectable

Memory MIN/MAX, integrated data logger

Data logger

Material

Wetted parts stainless steel 316

Case stainless steel

Voltage supply

Power supply 3 x 1.5 V AA alkaline batteries

Battery life approx. 1,500 h without backlighting

Battery status indication Icon in display for low battery level

Permissible ambient conditions

Operating temperature -10 ... +55 °C

Medium temperature

Storage temperature -20 ... +70

Relative humidity < 95 % r.H. (non-condensing)

Communication

Interface USB, RS-232

Case

Dimensions 111 x 127 x 38 mm

Ingress protection IP 65

Weight approx. 455 g

4)

20 segment bargraph, 0 ... 100 %

O (4 °C, 20 °C or 60 °F), ft H2O (4 °C, 20 °C or

60 °F), cmH

mmHg, TORR, mSW, ft SW, user-dened unit

Cyclic logger: automatic recording of up to 8,500 values;

Cycle time: selectable from 1 ... 3,600 sec. in the following steps

1 sec., 2 sec., 5 sec., 10 sec., 30 sec., 1 min, 2 min, 5 min, 10 min, 30 min and

1 h

approx. 2,000 h at lower measuring rate

-10 ... +55 °C (lower temperature limit above the freezing point of the medium)

O (4 °C and 20 °C), mH2O (4 °C and 20 °C), kPa, MPa, inHg,

2

2

GB

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 13

Page 14

3. Specications

Approvals and certicates

CE conformity

GB

EMC directive 2004/108/EC, EN 61326-1 emission (group 1, class B) and interference

ATEX directive II 3G Ex nA IIB T6

CSA directive Class I, division 2, groups A, B, C, D

Certicate

Calibration 3.1 calibration certicate per DIN EN 10204

For further specications see WIKA data sheet CT10.01 and the order documentation.

For further important safety instructions for the operation in hazardous

areas see chapter 2.3 "Additional safety instructions for instruments per

ATEX".

Available measuring ranges and resolutions

Measuring ranges and factors part 1

Measuring range

in bar

Unit Conversion factor

psi 1 1.0000 15.000 30.000 100.00 300.00 500.00

bar 0.06894757 0.0689 1.0342 2.0684 6.8948 20.684 34.474

mbar 68.94757 68.948 1,034.2 2,068.4 6,894.8 20,684 34,474

kPa 6.894757 6.8948 103.42 206.84 689.48 2,068.4 3,447.4

MPa 0.00689476 0.0069 0.1034 0.2068 0.6895 2.0684 3.4474

kg/cm² 0.07030697 0.0703 1.0546 2.1092 7.0307 21.092 35.153

mmHg (0 °C) 51.71507 51.715 775.73 1,551.5 5,171.5 15,515 25,858

inHg (0 °C) 2.03603 2.0360 30.540 61.081 203.60 610.81 1,018.0

O (4 °C) 70.3089 70.309 1,054.6 2,109.3 7,030.9 21,093 35,154

cmH

2

O (20 °C) 70.4336 70.434 1,056.5 2,113.0 7,043.4 21,130 35,217

cmH

2

O (4 °C) 703.089 703.09 10,546 21,093 70,309 --

mmH

2

mmH2O (20 °C) 704.336 704.34 10,565 21,130 70,434 -mH2O (4 °C) 0.703089 0.7031 10.546 21.093 70.309 210.93 351.54

O (20 °C) 0.704336 0.7043 10.565 21.130 70.434 211.30 352.17

mH

2

O (4 °C) 27.68067 27.681 415.21 830.42 2,768.1 8,304.2 13,840

inH

2

O (20 °C) 27.72977 27.730 415.95 831.89 2,773.0 8,318.9 13,865

inH

2

O (60 °F) 27.70759 27.708 415.61 831.23 2,770.8 8,312.3 13,854

inH

2

O (4 °C) 2.306726 2.3067 34.601 69.202 230.67 692.02 1,153.4

ftH

2

immunity (Appendix A)

option: DKD/DAkkS calibration certicate

0 ... 0.07 0 ... 1

-1 ... +1

0 ... 2

-1 ... +2

0 ... 7 0 ... 20 0 ... 35

1)

1)

1)

--

1)

--

14 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 15

3. Specications

Measuring ranges and factors part 1

Measuring range

in bar

Unit Conversion factor

ftH

O (20 °C) 2.310814 3.3108 34.662 69.324 231.08 693.24 1,155.4

2

O (60 °F) 2.308966 2.3090 34.634 69.269 230.90 692.69 1,154.5

ftH

2

ft sea water 2.24719101 2.2472 33.708 67.416 224.72 674.16 1,123.6

m sea water 0.68494382 0.6849 10.274 20.548 68.494 205.48 342.47

Torr 51.71507 51.715 775.73 1,551.5 5,171.5 15,515 25,858

Measuring ranges and factors part 2

Measuring range in bar 0 ... 70 0 ... 140 0 ... 200 0 ... 350 0 ... 700

Unit Conversion factor

psi 1 1,000.0 2,000.0 3,000.0 5,000.0 10,000

bar 0.06894757 68.948 137.90 206.84 344.74 689.48

mbar 68.94757 68,948 -kPa 6.894757 6,894.8 13,790 20,684 34,474 68,948

MPa 0.00689476 6.8948 13.790 20.684 34.474 68.948

kg/cm² 0.07030697 70.307 140.61 210.92 351.53 703.07

mmHg (0 °C) 51.71507 51,715 -inHg (0 °C) 2.03603 2,036.0 4,072.1 6,108.1 10,180 20,360

O (4 °C) 70.3089 70,309 --

cmH

2

cmH2O (20 °C) 70.4336 70,434 -mmH2O (4 °C) 703.089 -mmH2O (20 °C) 704.336 -mH2O (4 °C) 0.703089 703.09 1,406.2 2,109.3 3,515.4 7,030.9

O (20 °C) 0.704336 704.34 1,408.7 2,113.0 3,521.7 7,043.4

mH

2

O (4 °C) 27.68067 27,681 55,361 83,042 --

inH

2

inH2O (20 °C) 27.72977 27,730 55,460 83,189 -inH2O (60 °F) 27.70759 27,708 55,415 83,123 -ftH2O (4 °C) 2.306726 2,306.7 4,613.5 6,920.2 11,534 23,067

O (20 °C) 2.310814 2,310.8 4,621.6 6,932.4 11,554 23,108

ftH

2

O (60 °F) 2.308966 2,309.0 4,617.9 6,926.9 11,545 23,090

ftH

2

ft sea water 2.24719101 2,247.2 4,494.4 6,741.6 11,236 22,472

m sea water 0.68494382 684.94 1,369.9 2,054.8 3,424.7 6,849.4

Torr 51.71507 51,715 --

1) Due to the limited screen resolution, no values are displayed here. The resolution is limited to 100,000 digits.

0 ... 0.07 0 ... 1

-1 ... +1

1)

1)

--

--

0 ... 2

-1 ... +2

1)

1)

1)

1)

1)

1)

1)

0 ... 7 0 ... 20 0 ... 35

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

1)

1)

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

GB

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 15

Page 16

3. Specications

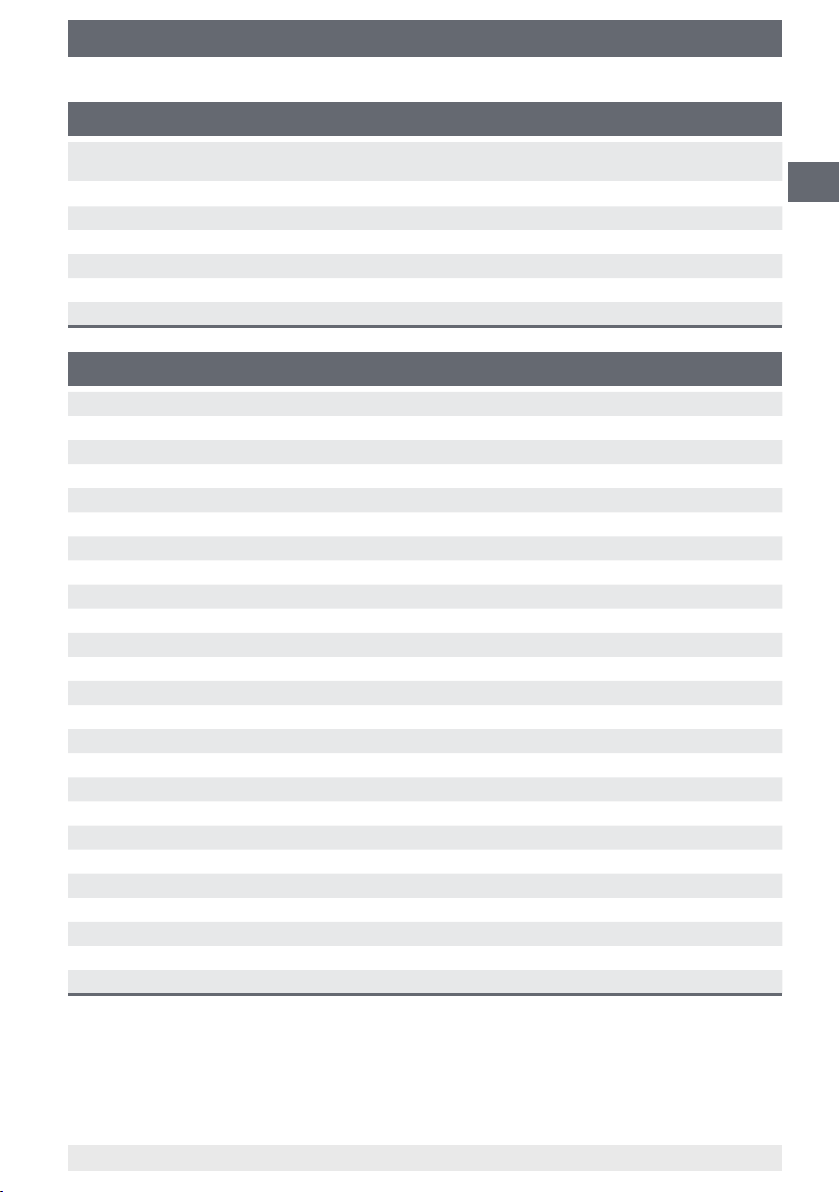

Dimensions in mm

Front view Side view

GB

Bottom view

16 WIKA operating instructions model CPG1000

Adapter included

11568047.02 08/2012 GB/D

Page 17

4. Design and function

4. Design and function

4.1 Description

The CPG1000 combines the high accuracy of the digital electronics with the convenience

and easy handling of an analogue test gauge. Accurate to ±0.05 % FS the CPG1000 can

be used as a calibration reference or in any application requiring high accuracy pressure

measurement.

Many user-congurable functions have been implemented in the CPG1000, for example

sampling rate, tare, damping, automatic disconnection and Min-Max measurement. Once

the digital pressure gauge is congured, the settings can be locked and password protected to prevent unauthorised changes to the conguration.

4.2 Scope of delivery

■

Precision digital pressure gauge model CPG1000

■

Operating instructions

■

3.1 calibration certicate per DIN EN 10204

■

3 x 1.5 V AA alkaline batteries

■

Adapter 1/4 NPT female to G 1/2 male

■

Protective rubber cap for case

1) Not included in delivery for North America.

1)

GB

Cross-check scope of delivery with delivery note.

The alkaline batteries are installed ex works, except in the variant with optional DC 24 V

voltage supply. In this case the alkaline batteries are not included in the scope of delivery.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 17

Page 18

4. Design and function

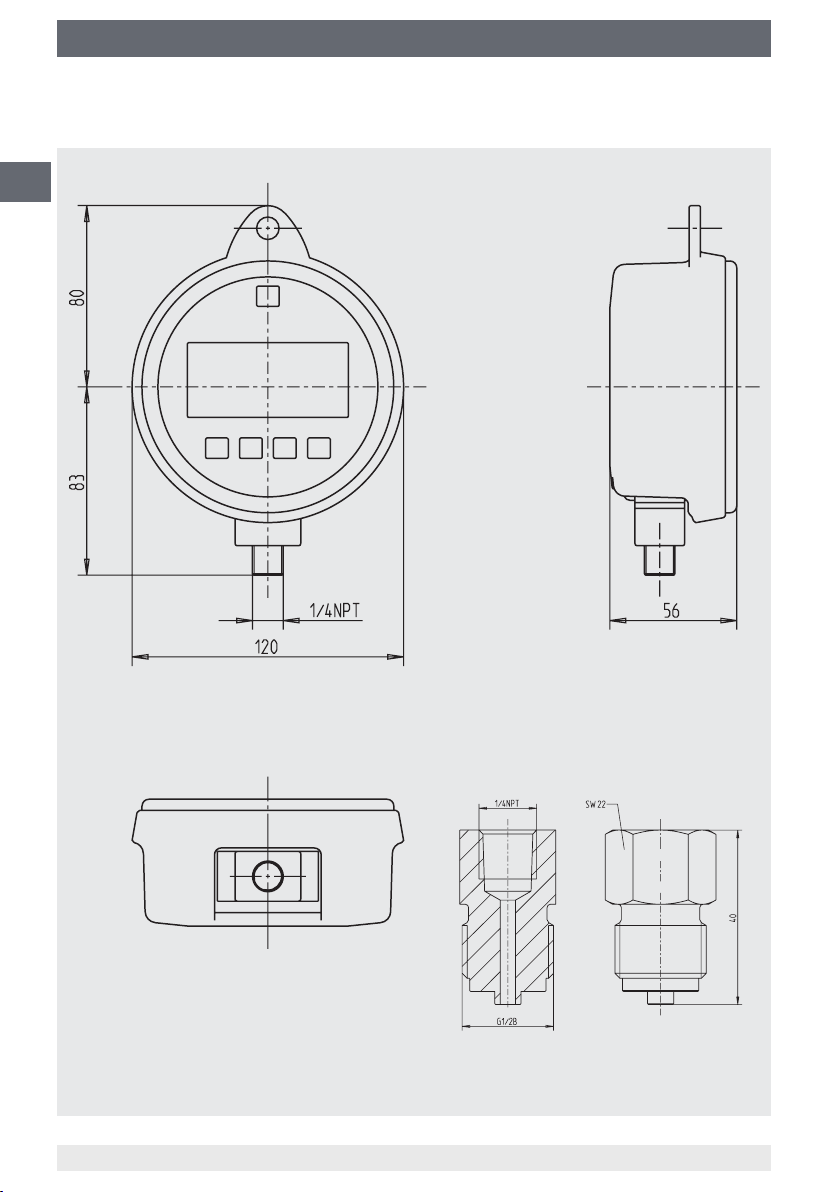

4.3 Front foil of the CPG1000 precision digital pressure gauge

1) Pressure display

1

GB

8

7

6

5

4.4 Integrated data logger

From the rmware Version 3.00 onwards, the CPG1000 has an integrated data logger. This

data logger can be activated and operated using the CPGLog software. For this, see the

CPGLog operating instructions.

2) Currently-set unit

3) Bargraph indicates the current pressure

graphically

4) Selecting a conguration option

2

3

4

Turning the backlighting on and o

5) Display of the MIN/MAX values, scrolls the

menu display backwards

6) Zero point adjustment carried out by

pressing, scrolls the menu display forward

7) Open the conguration menu

8) Switches the precision digital pressure

gauge on and o

4.5 External voltage supply

The standard version is supplied with three AA alkaline batteries. In the optional DC 24V

powered version with an external voltage supply, the alkaline batteries are not installed.

Connect the DC 24 V voltage supply to the terminals at the rear of the measuring instrument. Ensure the polarity is correct. Do not insert any batteries if an external power supply

is being used.

WARNING!

Prior to connecting the mains adapter to the mains power supply make

sure that the operating voltage specied on the mains adapter matches the

mains voltage.

Measuring instruments with an external power supply unit are supplied

without batteries inserted. For operation with an external voltage source,

batteries MUST NOT be inserted. Measuring instruments with an external

power supply unit are not approved for the hazardous areas.

18 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 19

4. Design and function

4.5.1 Battery replacement

WARNING!

Do not change the alkaline batteries in hazardous area!

Rotate the faceplate of the CPG1000 to the left by approx. 90° and remove it. After that the

front panel of the pressure gauge can be removed and the battery compartment is accessible. Insert the three AA-sized alkaline batteries in correct polarity.

WARNING!

Always use AA alkaline batteries and observe the correct polarity. During

enclosure assembly ensure that the front is aligned properly.

4.5.2 Battery life time

The battery life time is 1,500 hours (62 days) for continuous operation (without background

illumination). In the lower left corner of the display there is a symbol for the battery capacity.

This symbol appears if the battery voltage is too low. For instructions on batteries refer to

chapter 3 "Specications".

GB

4.6 RS-232 interface

The CPG1000 has as standard an RS-232 interface. Only the interface converter oered

by WIKA may be used. The serial data transmission can be used for conguration, calibration and transmission of the instrument’s measured values.

WARNING!

The RS-232 interface must not be used in hazardous areas.

4.7 Connections

The CPG1000 uses a ¼ NPT male thread connection for its process connection. An

adapter on G ½ male thread is included in the scope of delivery. Dierent adapters may

be necessary for connection to the pressure reference standard. When screwing the NPT

thread of the CPG1000 to an adapter or a process connection, it is necessary to use an

additional sealing compound, e.g. Teon tape between the threads. The hose, lines and

ttings etc. must always be approved, as a minimum, for the working pressure which corresponds to the pressure of the instrument. In addition, there must be no leaks during the

calibration process. If necessary, seal using Teon tape.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 19

Page 20

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

GB

Check the precision digital pressure gauge for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +70 °C

■

Humidity: 0 ... 90 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the CPG1000 in its original packaging in a location that fulls the conditions listed

above. If the original packaging is not available, pack and store the instrument as described

below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to

health, e.g. caustic, toxic, carcinogenic, radioactive, etc.

20 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 21

6. Commissioning, operation

6. Commissioning, operation

Only connect to test- and calibration installations in the depressurised

condition (atmospheric).

Push the power button briey to turn the instrument on. Push the button again to turn it o.

After switching on the rmware version is indicated on the display for approx. 1 second.

6.1 Normal operation

Turning on and o the background illumination: Press the Enter key.

Zeroing the display: Press and hold the ZERO key.

For absolute pressure gauge after pressing the ZERO key, the barometric reference value has to be entered. Use keys ▲ and ▼ to set the value.

Conrm with ENTER.

As the calibration was realised with this value, it is recommended not to

change the reference value set ex-works.

MAX/MIN: The CPG1000 stores the minimum and maximum pressure in the memory. If

the MAX/MIN key is pressed once, the maximum pressure from the memory is displayed.

If the MAX/MIN key is pressed again, the minimum pressure from the memory is displayed.

After 2 seconds the instrument returns to normal operation. To delete the memory registers

holding the values for MAX/MIN, hold the MAX/MIN key pressed for at least 2 seconds until

the “CLr” message is displayed. The bargraph on the lower edge of the display indicates

the present pressure proportional to the entire measuring range.

If a TARA value has been programmed for the CPG1000, the displayed pressure does not

correspond to the actual pressure applied.

GB

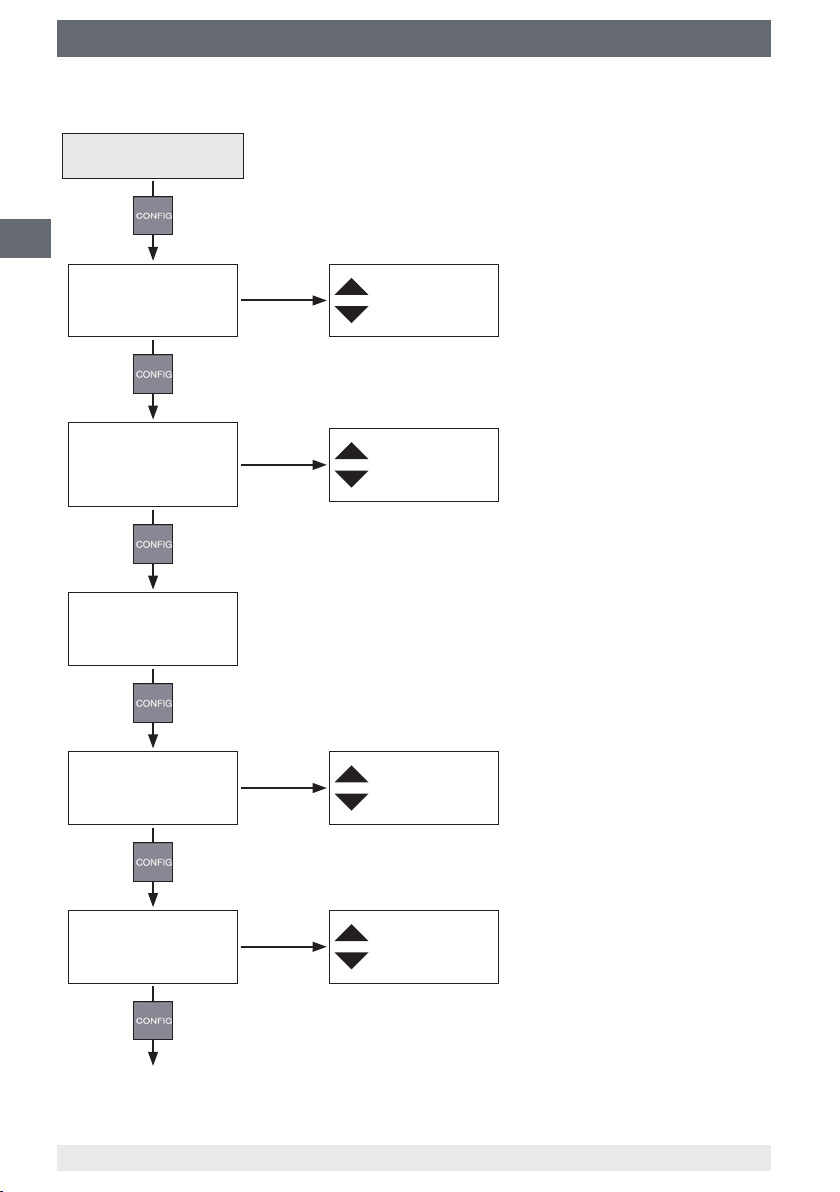

6.2 Setup and conguration

Press the CONFIG key to access the functions of the instrument which are adjustable by

the user. Every time the CONFIG key is pressed, the display switches to the next function.

As soon as a function is congured, press the Enter key to close the Conguration menu,

or the CONFIG key to continue conguration.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 21

Page 22

6. Commissioning, operation

Menu navigation

GB

Operating mode

Unit selection

UNITS SET

Automatic

disconnection

SET AUTO-

Battery status

OFF

BAR

PSI

MPA ...

OFF

1 ... 30 Min

Temperature display

Damping

SET DAMP

next page

°C

°F

ON

OFF

22 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 23

6. Commissioning, operation

Sampling rate

SET RATE

Tare function

SET TARE

Function locking

LOCK

FUnC

Operating mode

0,5/SEC

1/SEC

3/SEC

10/SEC

Values are

dependent on

the selected

unit

Password

request:

enter 101

Zero point adjustment

(ZERO button)

lock/unlock

GB

The password 101 is factory

set and cannot be changed.

UnLOC

LOC

Unit selection

lock/unlock

Automatic

disconnection

lock/unlock

next page

11568047.02 08/2012 GB/D

UnLOC

LOC

UnLOC

LOC

WIKA operating instructions model CPG1000 23

Page 24

6. Commissioning, operation

GB

Damping

lock/unlock

Sampling rate

lock/unlock

Tare function

lock/unlock

User-dened unit

(enter scaling)

SET FACTR

UnLOC

LOC

UnLOC

LOC

UnLOC

LOC

Setting see

chapter 6.3

Operating mode

24 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 25

6. Commissioning, operation

Pressure units

The instrument is factory congured to display "PSI". Using the ▲ and ▼ keys (ZERO

and MAX/MIN) you can scroll up and down through the 18 engineering units dened as a

standard, and through the user-dened units or scale. Once the required measuring unit

is displayed, press the Enter key or the CONFIG key. The pressure will then be displayed

in the selected engineering units. A list of available engineering units is given in chapter

3 "Specications", of this manual. Details on the conguration of user-dened measuring

units is given in chapter 6.3 "Supervisor mode".

Automatic Power-o

The function for automatic shut-down can be set in intervals of 1 minute, from 1 to

30 minutes, or it can be turned o (continuous operation). The measuring instrument is

delivered with an automatic power-o after 30 minutes. Dene the required interval using

the ▲ and ▼ keys. The OFF setting is at the very start of the options before setting for

1 minute.

Displaying battery voltage

The current battery voltage, and the remaining useful life of the battery, are displayed in the

form of a progress bar display.

Indication of the current temperature

The measuring instrument is temperature compensated. This option displays the temperature measured by the internal sensor. The display value can be switched from degrees

Fahrenheit to degrees Celsius.

GB

Setting damping

Using the ▲ and ▼ keys you can turn this option on and o. With damping enabled, the

measured values from pulsating pressure sources are smoothed.

Conguring the sampling rate

The sampling rate denes the frequency with which the pressure is measured and the

indication is refreshed. The options are 0.5, 1, 3 and 10 measurements per second. The

shortest response time is 10 measurements per second.

TARE (setting Tare)

Using this option you can set the constant oset value which will be subtracted from the

measured pressure. If, for example, TARE is set to 30 bar and the measured pressure is

37 bar, the measured value displayed will be 7 bar. A pressure of 27 bar would then be

displayed as -3 bar. The TARE value is set manually using the ▲ and ▼ keys, it depends on

the engineering units and the resolution selected for the indication. The TARE value can be

set to the maximum scale range. The progress bar indication always indicates the actual

pressure in relation to the entire measuring range, irrespective of the Tare setting. This is

performed for safety reasons so that when "0" is displayed, it can still be shown that there

is a corresponding pressure at the pressure gauge.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 25

Page 26

6. Commissioning, operation

Function lock

Access to adjustable parameters can be partially deactivated, once they are set, to prevent

unauthorised changes to the conguration. This is accomplished through a passwordprotected “supervisor mode”. Press the Enter key to access the Supervisor Mode or the

GB

CONFIG key to return to normal operation.

6.3 Supervisor mode (Control mode)

As soon as the "FUnC LOCK" message is displayed, press the Enter key. The 0PWRD

message appears on the display. The password for the Supervisor Mode is 101. It is

entered using the ▲ and ▼ keys. If a key is held pressed, the display scrolls more quickly

and the settings can be entered faster. The password is factory set and cannot be changed.

1. The CPG1000 is factory set in such a way that access to all settings is enabled and all

settings can be changed.

2. In the Supervisor Mode, any parameter can be locked or unlocked using the ▲ and ▼

keys. Parameters that should not be freely accessible are locked using the LOG option

and unlocked using the UnLOC option.

3. The functions that can be locked or unlocked are:

■

Zero function (enable/disable)

■

Set pressure units (enable/disable)

■

Setting of the automatic power o (enable/disable)

■

Damping settings (enable/disable)

■

Setting of the sampling rate (enable/disable)

■

Tare setting (enable/disable)

■

User-dened engineering units (set scale factor)

4. Using the CONFIG key search for the options mentioned above and lock and unlock

functions using the ▲ and ▼ keys. To scroll through the parameters press the CONFIG

key, and press the Enter key to save the settings and switch the CPG1000 back to

normal operation. If a function is locked, it can neither be accessed nor can you change

the current status. To modify a locked function, enter the Supervisor Mode and unlock

the function. Once it has been modied, if necessary, enter the Supervisor Mode to lock

it again.

5. Setting of a user-dened unit or scale: The last menu option in the Supervisor Mode is

SET FACTOR. Using this option you can dene a multiplier between 0.001 and 100 for

a user-dened unit. The dened factor is multiplied by the psi measured. The result is

displayed. Example: 40 psi corresponds to 1,000 g of a product in a tank. The weight

of the product should appear on the display, a pressure gauge for 100 psi is used. If 25

is dened as the multiplier, the pressure of 40 psi corresponds to the value 1.000 (40 x

25). "CUST" is displayed on the instrument as the engineering unit.

26 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 27

7. Maintenance, cleaning and servicing

7. Maintenance, cleaning and servicing

7.1 Maintenance

This CPG1000 precision digital pressure gauge is maintenance-free.

Repairs must only be carried out by the manufacturer.

This does not apply to the alkaline battery replacement.

7.2 Cleaning

CAUTION!

■

Before cleaning, correctly disconnect the CPG1000 from the pressure

supply, switch it o and disconnect it from the mains.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Residual media in the dismounted instrument can result in a risk to

persons, the environment and equipment. Take sucient precautionary

measures.

For information on returning the instrument see chapter 9.2 "Return".

GB

7.3 Recalibration

DKD certicate - Certicates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with time

intervals of approx. 12 months. Every factory recalibration includes, additionally, an extensive free-of-charge check of all system parameters with respect to their compliance with

the specication. The basic settings will be corrected if necessary.

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 27

Page 28

8. Faults

8. Faults

Indication Causes Measures

GB

OL

-OL

No display or undenable characters, the instrument

does not respond

to key press

CAUTION!

If faults cannot be eliminated by means of the measures listed above, the

CPG1000 must be shut down immediately, and it must be ensured that

pressure and/or signal are no longer present, and it must be prevented

from being inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

9.2 "Return".

Battery is low, functioning is only

guaranteed for a short period of

time

Reading is signicantly above or

below the measuring range

Battery is dead. Insert new alkaline batteries

Operation of mains adapter: false

voltage/polarity

System fault Turn o the CPG1000, wait for

CPG1000 is defective Send in for repair

Insert new alkaline batteries

Test: if pressure is within the

approved measuring range of the

sensor?

Check/replace mains adapter

a short period of time, switch on

again

28 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 29

9. Dismounting, return and disposal

9. Dismounting, return and disposal

WARNING!

Residual media on the dismounted precision digital pressure gauge can

result in a risk to persons, the environment and equipment. Take sucient

precautionary measures.

9.1 Dismounting

Only disconnect the test and calibration installations once the system has been depressurised!

9.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

GB

Information on returns can be found under the heading "Service" on our

local website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible way and in accordance with the country-specic waste disposal regulations.

This marking on the instruments indicates that they must not be disposed

of in domestic waste. The disposal is carried out by return to the manufacturer or by the corresponding municipal authorities (see EU directive

2002/96/EC).

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 29

Page 30

10. Accessories

10. Accessories

Connection adapters

■

GB

Various pressure adapters

Pressure generation

■

Pneumatic test pumps

■

Hydraulic test pumps

Test cases

■

Various calibration cases incl. pressure generation

Software

■

CPGLog data-logger evaluation software

■

USB interface cable

■

RS-232 interface cable

■

USB serial adapter

Installation

■

Mounting ange (only with back mount process connection)

Miscellaneous

■

DKD/DAkkS certied accuracy

■

Connection for external voltage supply via DC 24 V

■

Back mount process connection

30 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 31

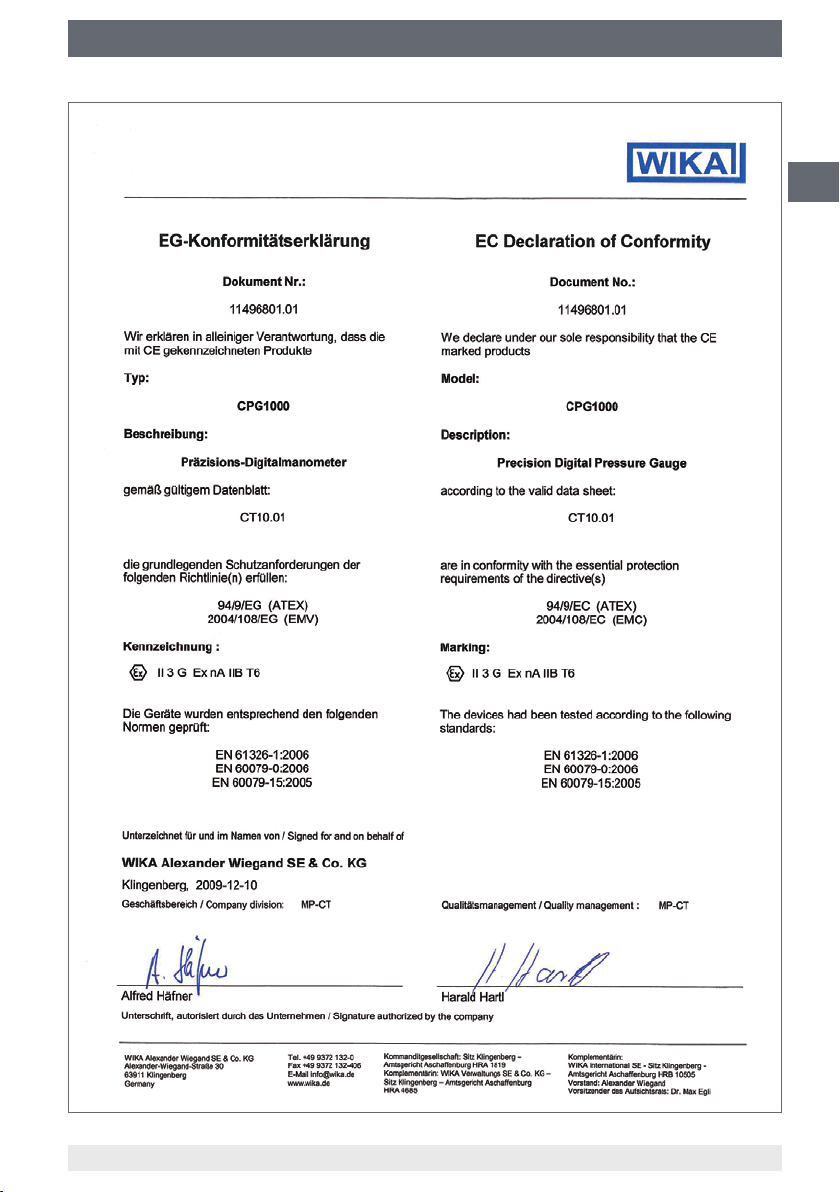

Appendix 1: EC Declaration of Conformity for model CPG1000

GB

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 31

Page 32

Appendix 2: EC-type examination certicate for model CPG1000

GB

32 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 33

Appendix 2: EC-type examination certicate for model CPG1000

GB

11568047.02 08/2012 GB/D

WIKA operating instructions model CPG1000 33

Page 34

GB

34 WIKA operating instructions model CPG1000

11568047.02 08/2012 GB/D

Page 35

Inhalt

Inhalt

1. Allgemeines 36

2. Sicherheit 38

2.1 Bestimmungsgemäße Verwendung 38

2.2 Personalqualikation 39

2.3 Zusätzliche Sicherheitshinweise für Gerät nach ATEX 39

2.4 Besondere Gefahren 41

2.5 Beschilderung / Sicherheitskennzeichnungen 43

3. Technische Daten 44

4 Aufbau und Funktion 49

4.1 Beschreibung 49

4.2 Lieferumfang 49

4.3 Frontfolie des CPG1000 50

4.4 Integrierter Datenlogger 50

4.5 Stromversorgung 50

4.5.1 Batteriewechsel 51

4.5.2 Batterielebensdauer 51

4.6 RS-232-Schnittstelle 51

4.7 Anschlüsse 51

5. Transport, Verpackung und Lagerung 52

6. Inbetriebnahme, Betrieb 53

6.1 Normalbetrieb 53

6.2 Setup und Konguration 53

6.3 Supervisormodus (Überwachungsmodus) 58

7. Wartung, Reinigung und Service (Rekalibrierung) 59

8. Störungen 60

9. Demontage, Rücksendung und Entsorgung 61

10. Zubehör 62

Anlage 1: EG-Konformitätserklärung für CPG1000 63

Anlage 2: EG-Baumusterprüfbescheinigung für CPG1000 64

D

Konformitätserklärungen nden Sie online unter www.wika.de.

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 35

Page 36

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Präzisions-Digitalmanometer Typ CPG1000

wird nach dem aktuellen Stand der Technik gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: CT 10.01

- Anwendungsberater: Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-217

E-Mail: testequip@wika.de

WIKA Betriebsanleitung Typ CPG100036

11568047.02 08/2012 GB/D

Page 37

1. Allgemeines

Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen

kann, wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

GEFAHR!

... kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

D

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen führen

kann, wenn sie nicht gemieden wird.

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 37

Page 38

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

CPG1000 hinsichtlich Messbereich, Ausführung und spezischen Messbe-

D

2.1 Bestimmungsgemäße Verwendung

Dieses Präzisions-Digitalmanometer CPG1000 kann als Kalibriergerät sowie für jede

Anwendung, bei der eine hochgenaue Druckmessung erforderlich ist, verwendet werden.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

dingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen

Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statischer Elektrizität und extremen Temperaturen schützen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und Buchsen vor

Verschmutzung schützen.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

WIKA Betriebsanleitung Typ CPG100038

11568047.02 08/2012 GB/D

Page 39

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Messund Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Zusätzliche Sicherheitshinweise für Geräte nach ATEX

D

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust des

Explosionsschutzes führen.

Das CPG1000 ist ein Präzisions-Digitalmanometer. Der Sensor wird unten

oder rückseitig montiert. Das Gehäuse hat eine Durchmesser von etwa

10 cm und kann als Hand-Held Manometer verwendet oder fest montiert

werden.

■

Batteriebetrieb:

Nur AA-Alkalibatterien verwendet! Den Batterietausch nur außerhalb

des explosionsgefährdeten Bereiches durchführen!

■

Messgeräte mit externem Netzteil sind nicht für explosionsgefährdete

Bereiche zugelassen.

■

Der Betrieb der seriellen Schnittstelle ist im Ex-Bereich nicht zulässig.

■

Temperaturbereich: -10 ... +55 °C

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 39

Page 40

2. Sicherheit

Zusätzliche Ex-Sicherheitshinweise:

Die Betriebshinweise sowie die jeweiligen Landesvorschriftenbezüglich

Ex-Einsatz (z. B. EN 60079-14) beachten.

Das Präzisions-Digitalmanometer ist nicht für den Einsatz mit brennbaren

D

Information/Zulassung für explosionsgefährdete Räume

Stoen bestimmt und ist nur für die Installation an Standorten geeignet, die

ausreichend gegen Eindringen von festen Fremdkörpern oder Wasser, die

die Sicherheit beeinträchtigen, geschützt sind.

Die Anweisungen in dieser Betriebsanleitung sind genau zu befolgen, um

einen sicheren Betrieb zu gewährleisten.

WARNUNG!

■

Explosionsgefährdete Bereiche

Explosionsgefährdete Bereiche, wie in diesem Handbuch erwähnt,

bezeichnen einen Bereich, der durch das mögliche Vorhandensein von

entzündlichen oder explosiven Dämpfen explosionsgefährdet ist. Diese

Bereiche werden auch als explosionsgefährdete Räume bezeichnet,

siehe NFPA 70 Artikel 500.

® LR110460, Klasse I, Division 2, Gruppen A, B, C, D

II 3G Ex nA IIB T6

KEMA 09ATEX0096 X

T

= -10 ... +55 °C

a

WARNUNG!

Nur alkalibatteriebetriebene Präzisions-Digitalmanometer sind für den

Einsatz in explosionsgefährdeten Räumen zugelassen. Präzisions-Digitalmanometer mit externer Spannungsversorgung sind nicht für den Einsatz

in explosionsgefährdeten Räumen zugelassen.

Der Austausch von Bauteilen beeinträchtigt die Tauglichkeit für explosionsgefährdete Räume.

WIKA Betriebsanleitung Typ CPG100040

11568047.02 08/2012 GB/D

Page 41

2. Sicherheit

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die

jeweiligen landesspezischen Vorschriften zur Installation und Einsatz in

explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC) einhalten. Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit ATEX-Zulassung siehe

Kapitel 2.3 „Zusätzliche Sicherheitshinweise für Geräte nach ATEX“.

WARNUNG!

■

Das CPG1000 nur in drucklosem Zustand montieren bzw. demontieren.

■

Betriebsparameter gemäß Kapitel 3 „Technische Daten“ beachten.

■

Druckmessgerät immer innerhalb der Überlast-Druckgrenze betreiben.

■

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc.

müssen über die gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

■

Wenn anzunehmen ist, dass das Präzisions-Digitalmanometer nicht

mehr gefahrlos betrieben werden kann, so ist es außer Betrieb zu

setzen und vor einer Wiederinbetriebnahme durch Kennzeichnung zu

sichern.

■

Die Beschaltung beim Anschluss an andere Geräte besonders sorgfältig konzipieren. Unter Umständen können interne Verbindungen in

Fremdgeräten (z. B. Verbindung GND mit Erde) zu nicht erlaubten

Spannungspotentialen führen, die das Präzisions-Digitalmanometer

selbst oder ein angeschlossenes Gerät in seiner Funktion beeinträchtigen oder sogar zerstören können.

■

Das Messsignal der Referenz (bzw. des Prüings) kann durch massive

elektromagnetische Einstrahlung beeinusst werden bzw. die Anzeige

des Signals ganz ausbleiben.

■

Wird das CPG1000 bei Applikationen mit Druckmedium Öl verwendet,

so ist ein anschließender Einsatz bei Brennstoen oder Gasen auszuschließen, da dies zu gefährlichen Explosionen und Gefahr für Mensch

und Maschine führen kann.

■

Messstoreste an ausgebauten Druckmessgeräten können zur Gefährdung von Personen, Umwelt und Einrichtung führen. Ausreichende

Vorsichtsmaßnahmen ergreifen.

D

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 41

Page 42

2. Sicherheit

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche

Spannungen auftreten!

D

Spezielle Bedingungen für eine sichere Verwendung

WARNUNG!

Wurde das CPG1000 Überlast oder einem plötzlichen Schlag (z. B. Herunterfallen) ausgesetzt, muss es auf sicherheitsbedenkliche Schäden

überprüft werden. In Zweifelsfällen das Präzisions-Digitalmanometer an

WIKA zur Bewertung zurücksenden. Hinweise zur Rücksendung des

CPG1000 siehe Kapitel 9.2 „Rücksendung“.

Das CPG1000 ist nicht für den Betrieb mit entzündlichen Stoen gedacht

und darf nur an Orten eingesetzt werden, die entsprechenden Schutz

gegen das Eindringen von Fremdkörpern oder Wasser bieten, wodurch die

Sicherheit beeinträchtigt werden könnte.

VORSICHT!

Um eine mögliche Schädigung des CPG1000 oder der Testeinrichtung zu

vermeiden:

■

Wenn die Meldung „OL“ angezeigt wird, ist der Messbereich überschritten und die Druckquelle muss sofort vom CPG1000 entfernt werden um

einen Schaden am internen Sensor zu vermeiden.

■

Das maximal zulässige Drehmoment des Gewindes beträgt 13,5 Nm =

10 ftlbs. Dieses zulässige Drehmoment darf NIE überschritten werden.

■

Beim Anschrauben des NPT-Gewindes des CPG1000 an einen Adapter

oder einen Druckanschluss ist zusätzlich die Verwendung eines Dichtmittels notwendig, z. B. Teonband zwischen den Gewinden.

■

Die Abdichtung muss direkt über das NPT-Gewinde mit Teonband

erfolgen und nicht über die Gewindehalterung am CPG1000.

WIKA Betriebsanleitung Typ CPG100042

11568047.02 08/2012 GB/D

Page 43

2. Sicherheit

2.5 Beschilderung/Sicherheitskennzeichnungen

Typenschild

Herstellerdatum

Jahr/Monat/Tag

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

D

CSA, Canadian Standard Association

Das Gerät wurde durch CSA International geprüft und zertiziert.

Geräte mit dieser Kennzeichnung stimmen überein mit den anwendbaren

kanadischen Normen zur Sicherheit (einschließlich Explosionsschutz).

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = EX)

Geräte mit dieser Kennzeichnung stimmen überein mit den Anforderungen

der europäischen Richtlinie 94/9/EG (ATEX) zum Explosionsschutz.

Bei Geräten mit dieser Kennzeichnung wird darauf hingewiesen, dass

diese nicht in den Hausmüll entsorgt werden dürfen. Die Entsorgung erfolgt

durch Rücknahme bzw. durch entsprechende kommunale Stellen (siehe

EU-Richtlinie 2002/96/EC).

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 43

®

Page 44

3. Technische Daten

3. Technische Daten

Sensorik

Messbereich mbar 0 … 70

Überlast-Druckgrenze mbar 200

D

Berstdruck mbar 350

Auösung mbar 0,001

Messbereich bar 0 … 1 0 ... 2 -1 ... +1

Überlast-Druckgrenze bar 4 4 4 4 14

Berstdruck bar 6 6 6 6 70

Auösung bar 0,0001

Messbereich bar 0 ... 20 0 ... 35 0 ... 70 0 ... 140 0 ... 200 0 ... 350 0 ... 700

Überlast-Druckgrenze bar 42 70 140 210 420 700 1.100

Berstdruck bar 140 140 700 700 700 700 1.100

Auösung bar 0,001 0,01

Messbereich bar abs. 0 ... 1 0 ... 2 0 ... 7 0 ... 20

Überlast-Druckgrenze bar abs. 4 4 14 42

Berstdruck bar abs. 35 35 70 140

Auösung bar abs. 0,0001 0,001

Genauigkeit 0,05 % FS

Kompensierter Temperaturbereich

Temperaturkoezienten 0,005 % der Spanne/°C außerhalb von 0 ... 50 °C

Druckart Relativdruck, Absolutdruck (bis 20 bar abs) und Vakuummessbereiche

Druckanschluss ¼ NPT außen (inkl. Adapter ¼ NPT innen auf G ½ außen)

Druckmedium alle Flüssigkeiten und Gase die mit CrNi-Stahl 316 kompatibel sind

1) Die so markierten Messbereiche ausschließlich mit sauberen nicht korrosiven Gasen verwenden.

2) Bei Messgeräten mit einem max. Messbereich von bis zu 2 bar ist der Betrieb im Vakuummessbereich auf -350 mbar begrenzt.

(Ausgenommen sind die Messbereiche -1 ... +1 bar und -1 ... +2 bar.) Die Messbereiche ≥ 7 bar können mit vollem Vakuum beaufschlagt werden.

3) Adapter nicht im Lieferumfang für Nordamerika.

(0,1 % FS für Messbereiche 0 ... 70 mbar, -1 ... +1 bar und -1 ... +2 bar)

(0,25 % FS für Vakuummessbereiche bei Geräten ab 7 bar bis max. 35 bar)

0 ... 50 °C

1)

1)

-1 ... +2 1)0 ... 7

3)

2)

1)

WIKA Betriebsanleitung Typ CPG100044

11568047.02 08/2012 GB/D

Page 45

3. Technische Daten

Grundgerät

Anzeige

Display 5 1/2-stellige Anzeige, Ziernhöhe 16,53 mm (0,65")

Druckeinheiten psi, bar, mbar, Kg/cm², inH

Funktionen

Messrate 0,5/sek. bis 10/sek. auswählbar

Speicher MIN/MAX, integrierter Datenlogger

Datenlogger

Werksto

Messstoberührte Teile CrNi-Stahl 316

Gehäuse CrNi-Stahl

Spannungsversorgung

Hilfsenergie 3 x 1,5 V AA-Alkalibatterien

Batterielebensdauer ca. 1.500 Std. ohne Hintergrundbeleuchtung

Batteriestandsanzeige Symbolanzeige im Display bei niedrigem Batteriestand

Zulässige Umgebungsbedingungen

Betriebstemperatur -10 ... +55 °C

Messstotemperatur -10 ... +55 °C (untere Temperaturgrenze über Gefrierpunkt des Mediums)

Lagertemperatur -20 ... +70

Relative Luftfeuchte < 95 % r. F. (nicht betauend)

Kommunikation

Schnittstelle USB, RS-232

Gehäuse

Abmessungen 111 x 127 x 38 mm

Schutzart IP 65

Gewicht ca. 455 g

4)

20 Segment-Bargraph, 0 ... 100 %

O (4 °C, 20 °C oder 60 °F), ft H2O (4 °C, 20 °C

oder 60 °F), cmH

mmHg, TORR, mSW, ft SW, benutzerdenierte Einheit

Zyklischer Logger: automatische Aufzeichnung von bis zu 8.500 Werten;

Zykluszeit: wählbar von 1 ... 3.600 sek. in folgenden Schritten

1 sek., 2 sek., 5 sek., 10 sek., 30 sek., 1 min, 2 min, 5 min, 10 min, 30 min und

1 Std.

ca. 2.000 Std. bei geringer Messrate

2

2

O (4 °C und 20 °C), mH2O (4 °C und 20 °C), kPa, MPa, inHg,

D

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 45

Page 46

3. Technische Daten

Zulassungen und Zertikate

CE-Konformität

EMV-Richtlinie

ATEX-Richtlinie II 3G Ex nA IIB T6

D

CSA-Richtlinie Klasse I, Division 2, Gruppe A, B, C, D

Zertikat

Kalibrierung Kalibrierzertikat 3.1 nach DIN EN 10204

Weitere technische Daten siehe WIKA-Datenblatt CT 10.01 und Bestellunterlagen.

Weitere wichtige Sicherheitshinweise für den Betrieb in explosionsgefährdeten Bereichen siehe Kapitel 2.3 „Zusätzliche Sicherheitshinweise für

Geräte nach ATEX“.

Verfügbare Messbereiche und Auösungen

Messbereiche und Faktoren, Teil 1

Messbereich in bar 0 ... 0,07 0 ... 1

Einheit Umrechnungsfaktor

psi 1 1,0000 15,000 30,000 100,00 300,00 500,00

bar 0,06894757 0,0689 1,0342 2,0684 6,8948 20,684 34,474

mbar 68,94757 68,948 1.034,2 2.068,4 6.894,8 20.684 34.474

kPa 6,894757 6,8948 103,42 206,84 689,48 2.068,4 3.447,4

MPa 0,00689476 0,0069 0,1034 0,2068 0,6895 2,0684 3,4474

kg/cm² 0,07030697 0,0703 1,0546 2,1092 7,0307 21,092 35,153

mmHg (0 °C) 51,71507 51,715 775,73 1.551,5 5.171,5 15.515 25.858

inHg (0 °C) 2,03603 2,0360 30,540 61,081 203,60 610,81 1.018,0

O (4 °C) 70,3089 70,309 1.054,6 2.109,3 7.030,9 21.093 35.154

cmH

2

O (20 °C) 70,4336 70,434 1.056,5 2.113,0 7.043,4 21.130 35.217

cmH

2

O (4 °C) 703,089 703,09 10.546 21.093 70.309 --

mmH

2

mmH2O (20 °C) 704,336 704,34 10.565 21.130 70.434 -mH2O (4 °C) 0,703089 0,7031 10,546 21,093 70,309 210,93 351,54

O (20 °C) 0,704336 0,7043 10,565 21,130 70,434 211,30 352,17

mH

2

O (4 °C) 27,68067 27,681 415,21 830,42 2.768,1 8.304,2 13.840

inH

2

O (20 °C) 27,72977 27,730 415,95 831,89 2.773,0 8.318,9 13.865

inH

2

O (60 °F) 27,70759 27,708 415,61 831,23 2.770,8 8.312,3 13.854

inH

2

O (4 °C) 2,306726 2,3067 34,601 69,202 230,67 692,02 1.153,4

ftH

2

2004/108/EG, EN 61326-1 Emission (Gruppe 1, Klasse B) und Störfestigkeit

(Anhang A)

Option: DKD/DAkkS-Kalibrierzertikat

-1 ... +1

0 ... 2

-1 ... +2

0 ... 7 0 ... 20 0 ... 35

1)

1)

1)

--

1)

--

WIKA Betriebsanleitung Typ CPG100046

11568047.02 08/2012 GB/D

Page 47

3. Technische Daten

Messbereiche und Faktoren, Teil 1

Messbereich in bar 0 ... 0,07 0 ... 1

-1 ... +1

Einheit Umrechnungsfaktor

ftH

O (20 °C) 2,310814 3,3108 34,662 69,324 231,08 693,24 1.155,4

2

O (60 °F) 2,308966 2,3090 34,634 69,269 230,90 692,69 1.154,5

ftH

2

ft sea water 2,24719101 2,2472 33,708 67,416 224,72 674,16 1.123,6

m sea water 0,68494382 0,6849 10,274 20,548 68,494 205,48 342,47

Torr 51,71507 51,715 775,73 1.551,5 5.171,5 15.515 25.858

Messbereiche und Faktoren, Teil 2

Messbereich in bar 0 ... 70 0 ... 140 0 ... 200 0 ... 350 0 ... 700

Einheit Umrechnungsfaktor

psi 1 1.000,0 2.000,0 3.000,0 5.000,0 10.000

bar 0,06894757 68,948 137,90 206,84 344,74 689,48

mbar 68,94757 68.948 -kPa 6,894757 6.894,8 13.790 20.684 34.474 68.948

MPa 0,00689476 6,8948 13,790 20,684 34,474 68,948

kg/cm² 0,07030697 70,307 140,61 210,92 351,53 703,07

mmHg (0 °C) 51,71507 51.715 -inHg (0 °C) 2,03603 2.036,0 4.072,1 6.108,1 10.180 20.360

cmH

O (4 °C) 70,3089 70.309 --

2

cmH2O (20 °C) 70,4336 70.434 -mmH2O (4 °C) 703,089 -mmH2O (20 °C) 704,336 -mH2O (4 °C) 0,703089 703,09 1.406,2 2.109,3 3.515,4 7.030,9

mH

O (20 °C) 0,704336 704,34 1.408,7 2.113,0 3.521,7 7.043,4

2

inH

O (4 °C) 27,68067 27.681 55.361 83.042 --

2

inH2O (20 °C) 27,72977 27.730 55.460 83.189 -inH2O (60 °F) 27,70759 27.708 55.415 83.123 -ftH2O (4 °C) 2,306726 2.306,7 4.613,5 6.920,2 11.534 23.067

ftH

O (20 °C) 2,310814 2.310,8 4.621,6 6.932,4 11.554 23.108

2

ftH

O (60 °F) 2,308966 2.309,0 4.617,9 6.926,9 11.545 23.090

2

ft sea water 2,24719101 2.247,2 4.494,4 6.741,6 11.236 22.472

m sea water 0,68494382 684,94 1.369,9 2.054,8 3.424,7 6.849,4

Torr 51,71507 51.715 --

1) Wegen der begrenzten Displayauösung können hier keine Werte angezeigt werden. Die Auösung ist auf 100.000 Digits

begrenzt.

1)

1)

--

--

0 ... 2

-1 ... +2

1)

1)

1)

1)

1)

1)

1)

0 ... 7 0 ... 20 0 ... 35

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

1)

1)

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

1)

--

D

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 47

Page 48

3. Technische Daten

Abmessungen in mm

Frontansicht Seitenansicht

D

Ansicht von unten

mitgelieferter Adapter

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG100048

Page 49

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Beschreibung

Das CPG1000 vereint die hohe Genauigkeit der Digitaltechnik mit dem Komfort und der

einfachen Handhabung eines analogen Prüfmanometers. Mit einer Genauigkeit von

±0,05 % FS kann das CPG1000 als Kalibriergerät verwendet werden sowie für jede

Anwendung, bei der eine hochgenaue Druckmessung erforderlich ist.

Viele benutzerdenierbare Funktionen wurden in das CPG1000 integriert (z. B. Abtastrate, Tara, Dämpfung, automatische Abschaltung und Min-Max-Messung). Sobald das

Präzisions-Digitalmanometer konguriert ist, können die Einstellungen mit einem Passwort

gesichert werden, um unbefugte Veränderungen der Konguration zu verhindern.

4.2 Lieferumfang

■

Präzisions-Digitalmanometer Typ CPG1000

■

Betriebsanleitung

■

Kalibrierzertikat 3.1 nach DIN EN 10204

■

3 x 1,5 V AA-Alkalibatterien

■

Adapter 1/4 NPT innen auf G 1/2 außen

■

Gummischutzkappe für Gehäuse

1)

D

1) Nicht im Lieferumfang für Nordamerika

Lieferumfang mit dem Lieferschein abgleichen.

Die Alkalibatterien sind bereits ab Werk eingesetzt, sofern es sich nicht um die Version

mit einer optionalen Spannungsversorgung von DC 24 V handelt. In diesem Fall sind die

Alkalibatterien nicht Teil des Lieferumfangs.

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 49

Page 50

4. Aufbau und Funktion

4.3 Frontfolie des CPG1000

1) Druckanzeige

1

8

D

7

6

5

4.4 Integrierter Datenlogger

Ab Firmware-Version 3.00 verfügt das CPG1000 über einen integrierten Datenlogger.

Dieser Datenlogger kann mit der Software CPGLog aktiviert und bedient werden. Hierzu

die separate CPGLog Betriebsanleitung beachten.

2) Aktuell eingestellte Einheit

3) Bargraph zeigt den aktuellen Druck grasch

an

4) Auswahl einer Kongurationsoption

2

3

4

Hintergrundbeleuchtung ein- und ausschalten

5) Anzeige des MIN-/MAX-Wertes, Rückwärtsblättern in der Menüanzeige

6) Durch Drücken Nullpunktabgleich durchführen, Vorwärtsblättern in der Menüanzeige

7) Kongurationsmenü önen

8) Präzisions-Digitalmanometer ein- und

ausschalten

4.5 Externe Spannungsversorgung

Die Standardversion wird mit drei AA-Alkalibatterien geliefert. Bei der optional erhältlichen

Version mit einer externen Spannungsversorgung mit DC 24 V sind die Alkalibatterien nicht

installiert. Die DC 24 V Spannungsversorgung mit den Anschlussklemmen an der Rückseite des Messgeräts verbinden. Auf korrekte Polarität achten. Keine Batterien einsetzen,

wenn eine externe Hilfsenergie verwendet wird.

WARNUNG!

Vor dem Verbinden des Netzgerätes mit dem Spannungsversorgungsnetz

ist sicherzustellen, dass die am Netzgerät angegebene Betriebsspannung

mit der Netzspannung übereinstimmt.

Präzisions-Digitalmanometer mit externem Netzteil werden ohne eingelegte Batterien geliefert. Bei Betrieb mit einer externen Spannungsquelle

dürfen KEINE Batterien eingesetzt werden. Messgeräte mit externem

Netzteil sind nicht für explosionsgefährdete Bereiche zugelassen.

WIKA Betriebsanleitung Typ CPG100050

11568047.02 08/2012 GB/D

Page 51

4. Aufbau und Funktion

4.5.1 Batteriewechsel

WARNUNG!

Die Alkalibatterien nicht im explosionsgefährdeten Bereich wechseln!

Die Blende des CPG1000 ca. 90° nach links drehen und abnehmen. Daraufhin kann die

Frontplatte des Präzisions-Digitalmanometer abgenommen werden und das Batteriefach

ist zugänglich. Drei Alkalibatterien der Größe AA mit korrekter Polarität einsetzen.

WARNUNG!

Ausschließlich AA-Alkalibatterien verwenden und auf korrekte Polarität

achten. Beim Zusammenbau des Gehäuses sicherstellen, dass die Vorderseite richtig ausgerichtet ist.

4.5.2 Batterielebensdauer

Die Batterielebensdauer beträgt 1.500 Stunden (62 Tage) bei Dauerbetrieb (ohne Hintergrundbeleuchtung). In der unteren linken Ecke der Anzeige bendet sich ein Symbol für

die Batteriekapazität. Dieses Symbol erscheint, wenn die Batteriespannung zu niedrig ist.

Hinweise zur Batterie siehe Kapitel 3 „Technische Daten“.

4.6 RS-232-Schnittstelle

Das CPG1000 besitzt standardmäßig eine Schnittstelle RS-232. Als Schnittstellenwandler

darf nur der von WIKA hierfür angebotene eingesetzt werden. Die serielle Datenübertragung kann zur Konguration, Kalibrierung und zur Übertragung von Messwerten des

Messgeräts verwendet werden.

WARNUNG!

Die RS-232-Schnittstelle darf nicht in explosionsgefährdeten Bereichen

betrieben werden.

D

4.7 Anschlüsse

Das CPG1000 benutzt einen Außengewindeanschluss ¼ NPT als Druckeingang.

Standardmäßig ist ein Adapter auf Außengewinde G ½ im Lieferumfang. Zum Anschluss

an das Druckvergleichsnormal können verschiedene Adapter erforderlich sein. Beim

Anschrauben des NPT-Gewindes des CPG1000 an einen Adapter oder einen Druckanschluss ist zusätzlich die Verwendung eines Dichtmittels notwendig, z. B. Teonband

zwischen den Gewinden. Der Schlauch, die Leitungen und Verschraubungen usw. müssen

immer mindestens für den Arbeitsdruck zugelassen sein, der dem Druck des Geräts

entspricht. Außerdem darf bei Durchführung der Kalibrierung keine Leckstelle vorhanden

sein, gegebenenfalls mit Teonband abdichten.

11568047.02 08/2012 GB/D

WIKA Betriebsanleitung Typ CPG1000 51

Page 52

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Das Präzisions-Digitalmanometer auf eventuell vorhandene Transportschäden untersuchen. Oensichtliche Schäden unverzüglich mitteilen.

D

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -20 ... +70 °C

■

Feuchtigkeit: 0 ... 90 % relative Feuchte (keine Betauung)

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

Das CPG1000 in der Originalverpackung an einem Ort lagern, der die oben gelisteten

Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät wie

folgt verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden

Messstoreste entfernen. Dies ist besonders wichtig, wenn der Messsto

gesundheitsgefährdend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

WIKA Betriebsanleitung Typ CPG100052

11568047.02 08/2012 GB/D

Page 53

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

Prüf- und Kalibrieraufbauten nur im drucklosen Zustand (Atmosphäre)

aufbauen.

Die Einschalttaste kurz drücken, um das Präzisions-Digitalmanometer zu aktivieren. Die

Taste erneut drücken, um es auszuschalten.

Nach dem Einschalten wird für ca. 1 Sekunde im Display die Version der Firmware

angezeigt.

6.1 Normalbetrieb

Hintergrundbeleuchtung ein- und ausschalten: Die Eingabetaste drücken.

Zurückstellung der Anzeige auf 0: Die ZERO-Taste drücken.