Page 1

Operating instructions

Pneumatic High Pressure Controller, Model CPC7000

EN

Pneumatic High Pressure Controller, Model CPC7000

Page 2

EN

Operating instructions model CPC7000 Page 3 - 89

Further languages can be found at www.wika.com

© 08/2017, Mensor, LP. All rights reserved.

Mensor is a registered trademark of Mensor, LP.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Prior to starting any work, read the operating instructions!

Keep for later use!

2

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2017 EN

Page 3

Contents

Contents

1. General Information 7

1.1 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2 Radio Frequency Emission Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 FCC Emission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 CE Emission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.3 Software License Agreement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Mensor Service Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 After the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.2 Calibration Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.3 Certifications and Accreditations . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. Short Overview 9

2.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Turning On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Safety 13

3.1 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Improper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Responsibility of the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Personnel Qualification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 Personal Protective Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7 Labelling, Safety Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7.1 Product Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7.2 Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.8 Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4. Transport, Packaging and Storage 18

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Packaging and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Installation 19

5.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 Supply Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.3 VENT PROP Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.4 VENT NO Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.5 Measure / Control Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.6 Vent Ref Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.7 Barometric Reference Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.8 Optional: Barometric Sensor Port . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.9 Remote Communication Connections. . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.10 Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6. Operation 21

6.1 General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

0019104001D 10/2018 EN

6.1.1 Setup Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

3

Page 4

EN

Contents

6.1.2 Display Screen Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Initial Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.1 Contact and Version Information Application . . . . . . . . . . . . . . . . . . . . . 22

6.2.2 Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Application Selection and Parameter Inputs. . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1 Home Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1.1 Range Hold/ Autorange . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.1.2 Control Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.1.3 Units and Pressure Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.1.4 Bar Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.1.5 Auxiliary Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.1.6 Zero Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.1.7 Tare Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.1.8 Operating Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.2 Settings Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.2.1 Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.2.2 Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.2.3 Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.2.4 User Base Units/ Base Units Multiplier . . . . . . . . . . . . . . . . . . . . . . 33

6.4.2.5 Barometer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.2.6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.3 Control Settings Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.3.1 Control Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.3.2 Stability Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.3.3 Rate Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.3.4 Rate Stability Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.3.5 Vent Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.3.6 Vent Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.3.7 Control Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.4 Display Settings Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.4.1 Reading Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.4.2 Reading Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.4.3 Bar Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.4.4 Cal Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.5 Remote Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.5.1 Remote Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.5.2 Remote Communication Settings. . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.6 Step Settings Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.6.1 Preset Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.4.7 Programs Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.7.1 Edit Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.8 Favorites Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.4.9 Information Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.4.10 Troubleshooting Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.4.11 Digital I/O Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.4.12 Leak Test Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.4.13 Switch Test Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4.14 Burst Test Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.4.15 Service Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

0019104001D 10/2018EN

4

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Page 5

6.4.16 Unlocked Service Application . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7. Remote Operation 55

7.1 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1.1 Digital I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Remote Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3 Command Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4 IEEE-488 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4.1 IEEE-488.2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.5 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.6 Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.6.1 Serial Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.7 Mensor Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.8 Command and Query Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.9 Command Set Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.10 Output Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.11 CPC7000 Commands and Queries . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.11.1 Units Command Syntax for Measurement Units . . . . . . . . . . . . . . . . . . . . 66

7.11.2 CPC7000 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.11.3 SCPI Commands and Queries . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.11.4 SCPI Commands Error Messages and Error Codes . . . . . . . . . . . . . . . . . . . 70

8. Faults 71

9. Maintenance and Recalibration 72

9.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.1 Beyond the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.2 Transducer Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.3 Barometric Sensor (optional) Removal . . . . . . . . . . . . . . . . . . . . . . . 74

9.1.4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.2 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.2.1 Calibration Services by Mensor or WIKA worldwide . . . . . . . . . . . . . . . . . . . 75

9.2.2 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.2.3 Pressure Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.2.4 Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.2.5 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.2.6 Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.2.7 One Point Cal Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.2.8 Two Point Cal Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

9.2.9 Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.2.10 Head Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10. Dismounting, Return and Disposal 82

10.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11. Specifications 84

11.1 Measure Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.2 Base Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.3 Approvals and Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.4 Dimensions in mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.4.1 Desktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

0019104001D 10/2018 EN

11.4.2 19” Rackmount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

5

Page 6

12. Accessories 87

12.1 Barometric Reference Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.1.1 Gauge Pressure Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.1.2 Absolute Pressure Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . 87

EN

12.1.3 Emulation Mode Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.1.4 Barometric Reference Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.2 Additional Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.3 19” Rackmount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.4 Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.5 Pressure Booster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13. Appendix 89

13.1 Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.2 Conversion Factors, PSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

13.3 Conversion Factors, Millitorr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.4 Conversion Factors, Pascal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Declarations of conformity can be found online at www.wika.com.

6

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 7

1. General information

1. General Information

■

The CPC7000 pneumatic high pressure controller described in the operating instructions has been designed and manufactured

using state-of-the-art technology. All components are subject to stringent quality and environmental criteria during production.

Our management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's operating range.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity of the instrument and readily

accessible to skilled personnel at any time. Pass the operating instructions onto the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with international standards.

EN

■

Further information:

Mensor Corporation

- Internet address: www.mensor.com

- Relevant data sheet: CT 27.63

- Application consultant: Tel.: (+1) 512-396-4200

(+1) 800-984-4200 (USA only)

Fax: (+1) 512-396-1820

E-Mail: sales@mensor.com

tech.support@mensor.com

WIKA Alexander Wiengand SE & Co. KG

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 27.63

- Application consultant: Tel.: (+49) 9372/132-5015

E-Mail: CTsales@wika.com

1.1 Warranty

All products manufactured by Mensor are warranted to be free of defects in workmanship and materials for a period of two year

from the date of shipment. No other express warranty is given, and no affirmation of Seller, by words or actions, shall constitute

a warranty. SELLER DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSES WHATSOEVER. If any defect in workmanship or material should develop under conditions of normal use and service

within the warranty period, repairs will be made at no charge to the original purchaser, upon delivery of the product(s) to the

factory, shipping charges prepaid. If inspection by Mensor or its authorized representative reveals that the product was damaged

by accident, alteration, misuse, abuse, faulty installation or other causes beyond the control of Mensor, this warranty does not

apply. The judgment of Mensor will be final as to all matters concerning condition of the product, the cause and nature of a defect,

and the necessity or manner of repair. Service, repairs or disassembly of the product in any manner, performed without specific

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

7

Page 8

1. General Information

factory permission, voids this warranty.

MENSOR MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Mensor shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this

material.

EN

1.2 Radio Frequency Emission Notices

USE SHIELDED CABLES TO CONNECT EXTERNAL DEVICES TO THIS INSTRUMENT TO

MINIMIZE RF RADIATION

1.2.1 FCC Emission Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his

or her own expense.

1.2.2 CE Emission Notice

This equipment is of the emission class A, intended for operation in industrials environments. It can cause interference under

certain circumstances if operated in other environments, i.e. residential or commercial areas. In this case, the user may be asked to

take appropriate measures to correct it.

1.3 Software License Agreement

This product contains intellectual property, i.e. software programs, that are licensed for use by the end user/customer (hereinafter

“end user”).

This is not a sale of such intellectual property.

The end user shall not copy, disassemble or reverse compile the software program.

The software programs are provided to the end user “as is” without warranty of any kind, either express

or implied, including, but not limited to, warranties of merchantability and fitness for a particular purpose.

The entire risk of the quality and performance of the software program is with the end user.

Mensor and its suppliers shall not be held to any liability for any damages suffered or incurred by the end user (including, but

not limited to, general, special, consequential or incidental damages including damages for loss of business profits, business

interruption, loss of business information and the like), arising from or in connection with the delivery, use or performance of the

software program.

1.4 Mensor Service Plus

1.4.1 After the Warranty

Mensor’s concern with the performance of this instrument is not limited to the warranty period. We provide complete repair,

calibration and certification services after the warranty for a nominal fee.

1.4.2 Calibration Services

In addition to servicing our own products Mensor can perform a complete pressure calibration service, up to 20,000 psi, for all of

your pressure instruments. This service includes an accredited calibration.

1.4.3 Certifications and Accreditations

Mensor is registered to ISO 9001:2008. The calibration program at Mensor is accredited by A2LA, as complying with both the ISO/

IEC 17025:2005 and the ANSI/NCSL Z540-1-1994 standards.

8

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 9

2. Short Overview

2. Short Overview

The CPC7000 pneumatic high pressure controller is a multi-range automatic pressure controller designed to test and calibrate a

variety of pressure devices such as pressure gauges, pressure switches, sensors, transducers and transmitters in either absolute

or gauge pressure modes. The CPC7000 can have up to three internal pressure reference transducers and an optional barometric

reference for gauge or absolute emulation. The CPC7000 is available as a desktop or a rack mountable instrument.

EN

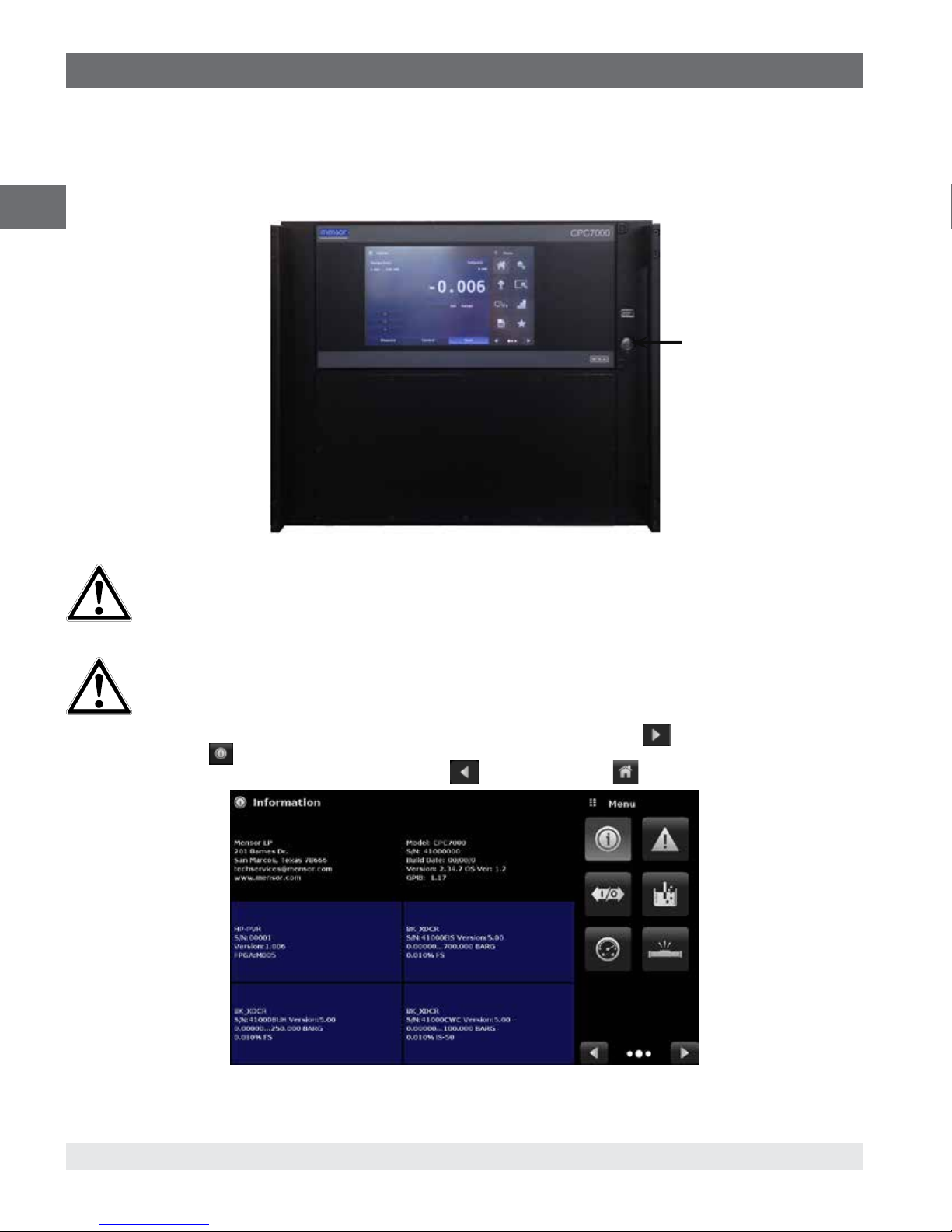

Figure 2.1 Desktop version

2.1 Features

Here is a short list of significant features designed into the CPC7000:

■

Up to three removable / interchangeable, highly stable, temperature compensated, internal pressure transducers

■

Operating pressure range from 0… 700 bar (0 … 10,000 psi)

■

0.01% Intelliscale-50 accuracy

■

Easily removable transducers from the front of the CPC7000 This facilitates “out of instrument” recalibration of individual

transducers using the optional calibration sled

■

An optional removable / interchangeable internal high accuracy barometric reference transducer providing gauge pressure

emulation for absolute ranges and absolute pressure emulation for gauge ranges

■

8.9” color LCD display with touch screen

■

Multiple languages; change the language for on-screen text and number/date formats by simply touching one of the “national

flag” icons available in the setup screen.

■

Desk top or rack mount

■

Local operation, or command and read remotely

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

9

Page 10

2. Short overview

2.2 Turning On

You can confirm that your CPC7000 is operational right now. Apply power to the power connector on the rear of the instrument

with the included power cord, remove any plastic plugs from the rear panel pressure ports, and press the power switch to ON. The

system will go through an initialization process, which takes about 30 seconds, and then a display will appear similar to the screen

shown below

EN

Power Switch ON/

OFF

Earth Ground! Any power adaptors or surge protection devices that negate the protective earth ground

should not be used. The power cord must be accessible and contain a protective earth ground. Do not

position the equipment so that it is difficult to remove the power cord.

Ventilation! Do not block airflow to ventilating fans located on rear of instrument.

To see information about the configuration of your new CPC7000, touch the Next Page Button [

Application (App) icon [

transducers that are installed. Press the Previous Page Button [

] on the menu and a window will appear listing the Mensor contact information, model number and the

] then the Home App [ ] to return to the main screen.

] then the Information

10

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Figure 2.2 Information application

0019104001D 10/2018EN

Page 11

2. Short overview

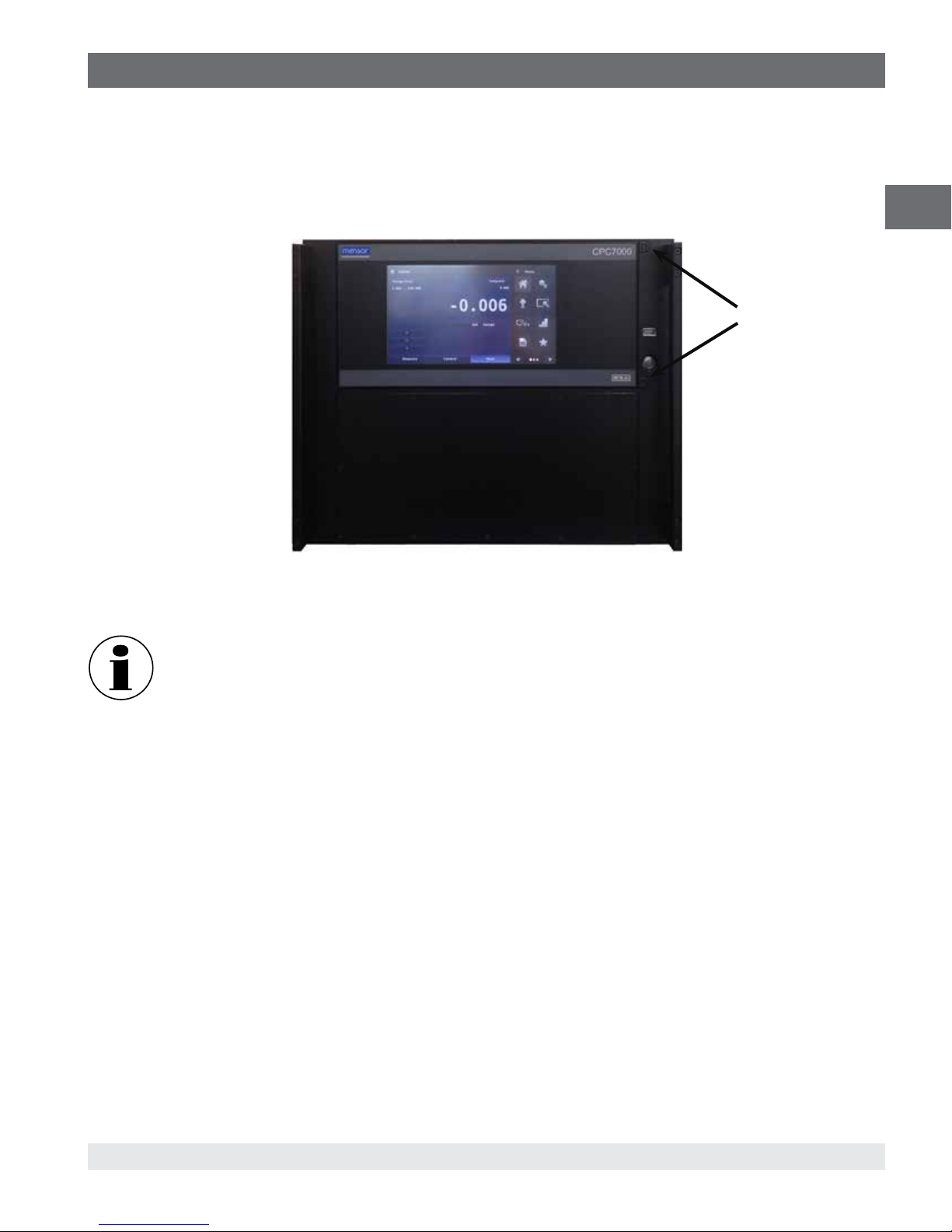

2.3 Front Panel

The CPC7000 front panel includes an 8.9” color LCD display with touch screen. Operator input is accomplished by pressing the

words or symbols and the App icons presented on the display. There is a single discrete on/off button and a USB on the right hand

side. The front panel is hinged for easy access to remove or replace the transducers inside. The instructions for accessing the

transducers are provided in Section 9.4 Transducer removale. The front panel also shows the model number designation and brand

logos

Screws to open

front panel

EN

2.3.1 Power Switch

The power switch is a two-state device with an action similar to that of a ball point pen. Push the button with enough force to latch it

in to turn the unit ON. Push it again to release it to turn the system OFF.

If power to the instrument is interrupted while ON it will shut down until the power is restored, then

immediately resume operation

2.3.2 USB Port

The front panel USB port is the Host USB and is intended for future expansion or software upgrades.

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

11

Page 12

2. Short overview

2.4 Display

The display is made up of two sections. In the main screen (“Home Application”), the left three fourths shows the operating screen

displaying the active pressure reading, units, mode (absolute or gauge), active range of the internal transducer, pressure control

setpoint, a bar graph (if enabled), an auto zero or tare button (if enabled) and any auxiliary displays that have been chosen. The

right one fourth of the screen has Application Icons (“Apps”) for setting general instrument settings, control settings, display

EN

settings, program settings, favorites plus a “Next Page” button [

for remote communication, troubleshooting, switch test, leak test, digital I/O and service applications.

Active transducer range

Optional Zero or Tare

Current Value

Units and Mode

Auxiliary Displays

] that, when pressed, shows a second and third page of icons

{

Operating Modes

Operating Screen Settings Apps

Buttons, Labels and Windows: The CPC7000 touch screen has many buttons with relevant graphic icons or text which, when

touched, will open a related window where changes can be made or information viewed. Some of these buttons will toggle from

one state to another, others present choices or display a numerical data entry screen. Text or icons that are displayed, but do not

respond to being touched, are called labels or windows. Operators will quickly become accustomed to the particular characteristics

of the frequently used buttons.

Main Screen: The main screen or “Home Application”, appears after power-up. This screen contains the operating screen and

Settings application screen. It will remain as configured after a power cycle.

Operating screen: The operating screen (left 3/4 of the main screen) contains information relevant

to the measurement. Up to three auxiliary displays can be shown simultaneously along with the current pressure value

2.5 Scope of Delivery

■

Pneumatic high pressure controller model CPC7000

■

Power cord with 1.5 m (5 ft) length

■

Operating instruction

■

Factory calibration certificate

Cross-check scope of delivery with delivery note.

12

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 13

3. Safety

3. Safety

3.1 Explanation of Symbols

DANGER!

... indicates a directly dangerous situation resulting in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage to property or the environment,

if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety instructions not be observed, there is a risk of

serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused by hot surfaces or liquids, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and trouble-free operation.

EN

3.2 Intended Use

The CPC7000 pneumatic high pressure controller is designed to automate the testing and calibration of pressure devices and

instruments for pressures up to 10,000 psi. Up to three removable / interchangeable pressure transducers are available in full

scale (FS) ranges from 1500 to 10,000 psi (100 to 700 bar) gauge or absolute. Each transducer module is configured with its own

calibration parameters on board and have 0.01% FS or optional 0.01% IS-50 uncertainty.

The three transducers, in combination with the special control valve regulator, provide a dynamic output. The operator can choose

to control pressure either using a single, selected transducer or auto-range control across all three transducers. The three ranges

can be chosen to optimize uncertainty levels across the full pressure span of the instrument.

In addition to the capacity for three active ranges, a fourth, barometric transducer is available as an option. With this option installed

a CPC7000, with absolute or gauge pressure transducers, can emulate pressure of the opposite type.

The operational safety on the instrument is achieved with relief valves and blow out disks to ensure overpressure protection along

with automatic venting of unused transducers.

CAUTION!

Instrument is intended to be used with pressure media Nitrogen (Class 2.8 or better) only.

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

13

Page 14

3. Safety

CAUTION!

Instrument is intended to be used up to a maximum altitude of 2,000 meters

EN

CAUTION!

Instrument is intended to be used just indoors and in a dry environment

WARNING!

The pressurized volume of the device under test including any tubing and manifold should not exceed 100 cc.

This instrument is not permitted to be used in hazardous areas!

The instrument has been designed and built solely for the intended use described here, and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed. Improper handling or operation of the

instrument outside of its technical specifications requires the instrument to be taken out of service immediately and inspected by

an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from humidity, impacts, strong magnetic fields,

static electricity and extreme temperatures, do not insert any objects into the instrument or its openings). Plugs and sockets must

be protected from contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended use.

3.3 Improper Use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

▶

Do not use the instrument with abrasive or viscous media.

Any use beyond or different to the intended use is considered as improper use. Do not use this instrument in safety or emergency

stop devices.

3.4 Responsibility of the Operator

The instrument is used in the industrial sector. The operator is therefore responsible for legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident prevention and environmental protection

regulations for the application area must be maintained.

The operator is obliged to maintain the product label in a legible condition.

To ensure safe working on the instrument, the operating company must ensure

■

that the operating personnel are regularly instructed in all topics regarding work safety, first aid and environmental protection

and know the operating instructions and in particular, the safety instructions contained therein.

■

that the instrument is suitable for the particular application in accordance with its intended use.

■

that personal protective equipment is available.

14

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 15

3. Safety

3.5 Personnel Qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be carried out by skilled personnel who have the

qualifications described below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who, based on their technical training, knowledge

of measurement and control technology and on their experience and knowledge of country-specific regulations, current standards

and directives, are capable of carrying out the work described and independently recognising potential hazards.

Operating personnel

The personnel trained by the operator are understood to be personnel who, based on their education, knowledge and experience,

are capable of carrying out the work described and independently recognising potential hazards.

Special knowledge for working with instruments for hazardous areas:

The skilled (electrical) personnel must have knowledge of ignition protection types, regulations and provisions for equipment in

hazardous areas.

EN

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

15

Page 16

3. Safety

3.6 Personal Protective Equipment

The personal protective equipment is designed to protect the skilled personnel from hazards that could impair their safety or health

during work. When carrying out the various tasks on and with the instrument, the skilled personnel must wear personal protective

equipment.

EN

Wear safety goggles!

Protect eyes from flying particles and liquid splashes.

Wear safety shoes!

Protect feet from falling objects or objects lying around, as well as against toxic or hazardous liquids and aggressive

media.

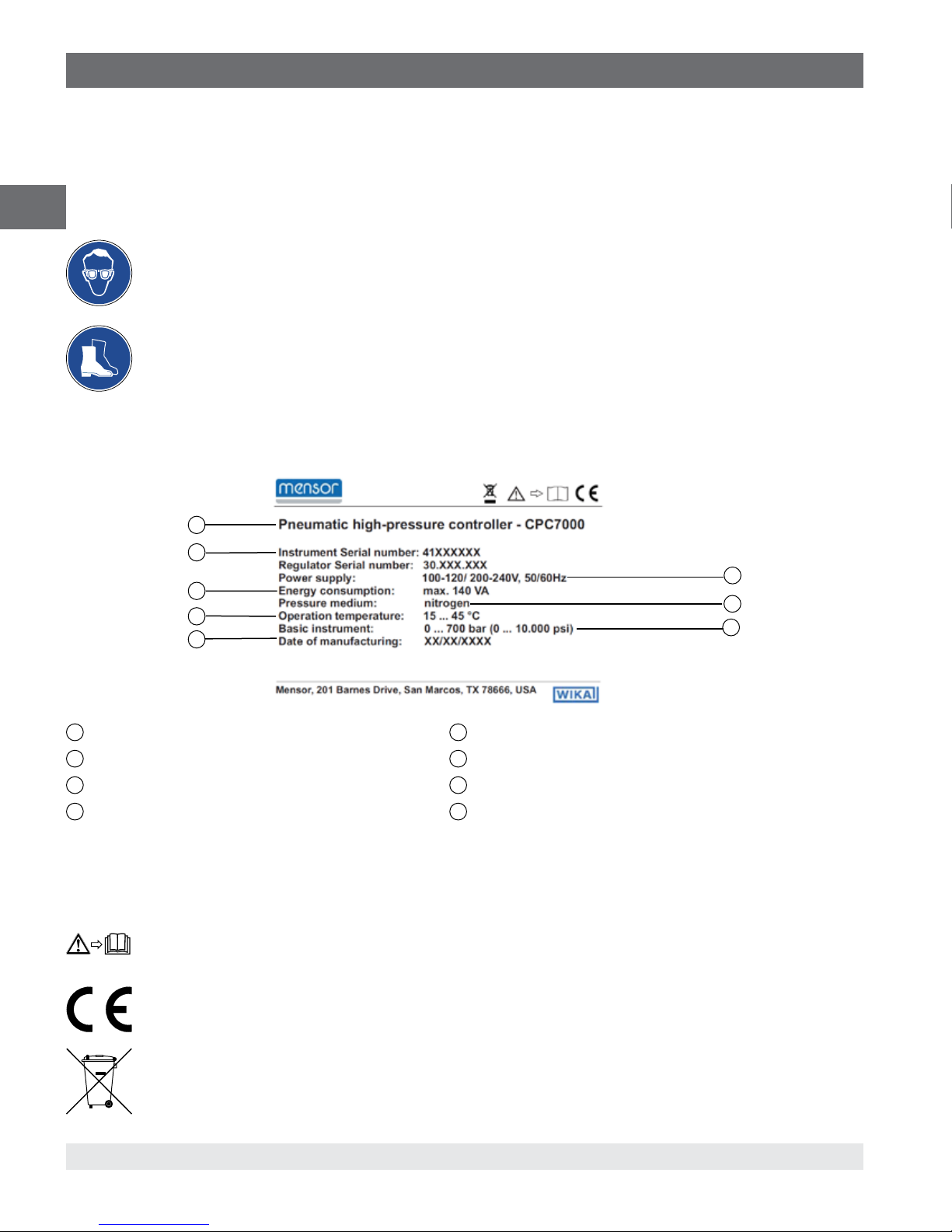

3.7 Labelling, Safety Marks

3.7.1 Product Label

1

2

4

6

8

1

Model

2

Serial number (Instrument and Regulator)

3

Power supply

4

Energy consumption

3.7.2 Symbols

Before mounting and commissioning the instrument, ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

5

Pressure medium

6

Operating temperature

7

Pressure rating

8

Date of manufacturing

3

5

7

This marking on the instruments indicates that they must not be disposed of in domestic waste. The disposal is

carried out by return to the manufacturer or by the corresponding municipal authorities (see EU directive 2012/19/

16

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 17

4. Transport, Packaging and Storage

EU).

3.8 Warnings and Cautions

WARNING!

HIGH PRESSURE! High pressure gases are potentially hazardous. Energy stored in these gases and liquids can

be released suddenly and with extreme force. High pressure systems should be assembled and operated only by

personnel who have been trained in proper safety practices.

WARNING!

NOT EXPLOSION PROOF! Installation of this instrument in an area requiring devices rated as intrinsically safe is not

recommended.

WARNING!

POSSIBLE INJURY! The tubing, valves, and other apparatus attached to the gauge must be adequate for the

maximum pressure which will be applied, otherwise physical injury to the operator or bystanders is possible.

CAUTION

USE THE PROPER PRESSURE MEDIUM! Use only clean, dry, nitrogren of class 2.8 or better unless otherwise

specified by Mensor. This instrument is not designed for air use.

CAUTION

As with most sensitive electronic equipment, switch the power switch off before connecting or disconnecting to a

power source to prevent data loss. Do not position the equipment so that it is difficult to disconnect the AC power

cord.

EN

WARNING!

Detachable main power supply cord delivered with inadequate ratings should not be used, it is recommended to use

the power cord delivered with the instrument. See Section 11 Specifications for power ratings.

Additional Warning and Caution notices are found throughout this manual.

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

17

Page 18

4. Transport, Packaging and Storage

4.1 Transport

Check the pneumatic high pressure controller model CPC7000 for any damage that may have been caused by transport.

EN

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal transport, proceed carefully and observe

the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter 5.2 “Packaging and storage”.

If the instrument is transported from a cold into a warm environment, the formation of condensation may result in instrument

malfunction. Before putting it back into operation, wait for the instrument temperature and the room temperature to equalise.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for repair).

Permissible conditions at the place of storage:

■

Storage temperature: 0 ... 70 °C

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the instrument in its original packaging in a location that fulfils the conditions listed above. If the original packaging is not

available, pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument along with shock-absorbent material in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a desiccant inside the packaging.

0019104001D 10/2018EN

18

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Page 19

5. Installation

5. Installation

Personnel: Skilled electrical personnel

WARNING!

READ THSE INSTRUCTIONS BEFORE INSTALLATION!

Only use original parts (see chapter 11 “Accessories”).

CAUTION

Damage to the instrument

When working on open electrical circuits (printed circuit boards) there is a risk of damaging sensitive electronic

components through electrostatic discharge.

▶

The correct use of grounded working surfaces and personal armbands is required.

5.1 Mounting

The instrument can be set up on a desk top or it can be rack-mounted. Rack mount hardware is optional on the CPC7000 (see

Section Specifications11 and Section 12 Options and Accessories).

The special transducers used in the CPC7000 are relatively insensitive to tilt and vibration. However to further assure stability and

accuracy, avoid mounting the instrument on surfaces subject to excessive motor or machinery vibration

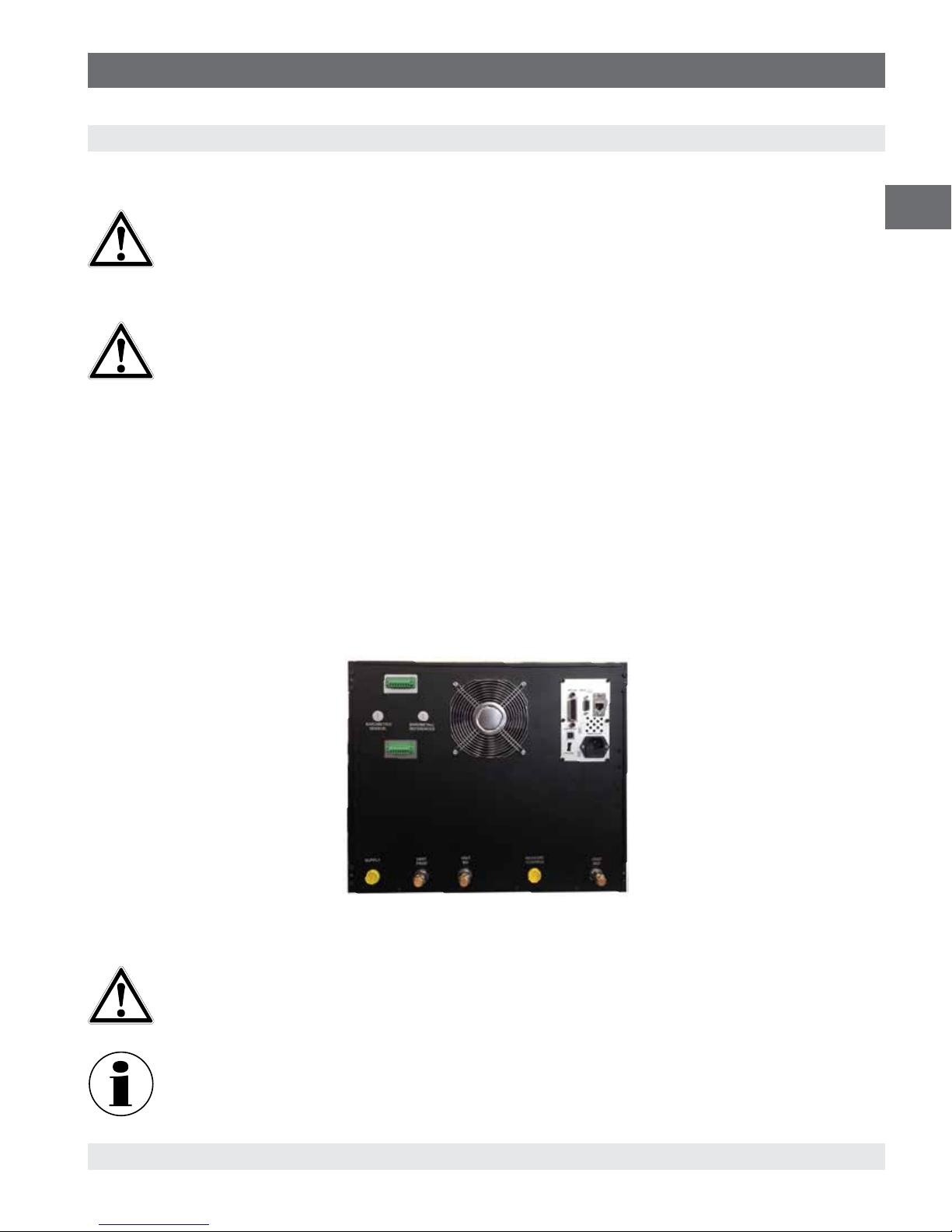

5.2 Rear Panel

Up to five pneumatic pressure ports are located across the bottom of the rear panel. The instrument with gauge transducers will

have a reference and a pressure port. The instrument with absolute transducers will use the pressure port. In the upper left corner

under the digital I/O connector is a M12 fitting , which is connected to the barometric reference sensor if installed. The connections

for digital I/O - 1 & 2 are located on the top on left side of the ventilation fan. Positioned on the right side is the RS-232, Ethernet,

IEEE- 488, USB device connections for communication, as well as a USB host connection and the 12 VDC power input.

EN

5.2.1 Rear Panel

WARNING!

The pressure connections must be installed according to the following instructions, observing the relevant

regulations. The installation is to be performed by trained, authorized personnel, knowledgeable in the safety

regulations for working on pneumatic/hydraulic systems

Up to 7 pressure connections are on the rear panel. Pressure connections that are not assigned are plugged.

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Figure 5.2 Rear Panel

19

Page 20

5. Installation

5.2.2 Supply Port

The pressure supplied to the pressure connection labeled “Supply” should be approximately the greater of 30 ... 50 bar (435 ... 725

EN

psi) or 7-10% higher than the full scale of the highest pressure transducer installed in the controller.

5.2.3 VENT PROP Port

The pressure connection labeled “VENT PROP” is the port where the system pressure is vented to the atmosphere under certain

conditions. Leave this port as is.

5.2.4 VENT NO Port

The pressure connection labeled “Vent NO” is the port where the system pressure is vented to the atmosphere under emergent

conditions. Leave this port as is.

5.2.5 Measure / Control Port

The Measure / Control port (when in the Control mode) supplies pressure that is precisely controlled by the controller. In the

Measure mode, a pressure applied to the Measure / Control port is measured by the internal transducers.

5.2.6 Vent Ref Port

The pressure connection labeled “Vent Ref” is the port where the not in use reference transducer pressure is vented to the

atmosphere under certain conditions. Leave this port as is.

5.2.7 Barometric Reference Port

The barometric references port is available on gauge units that have transducers that are not sealed gauge units. For these units

this port is available to connect to the reference side of the transducer. This port is normally left open to atmosphere but may be

connected to a stable reference pressure. In an absolute pressure transducer this port is not used

5.2.8 Optional: Barometric Sensor Port

The Barometric Sensor port is connected to the optional internal barometer and should be left open to atmospheric pressure.

5.2.9 Remote Communication Connections

See Section 8, Remote Operation for connections and commands for operation over IEEE-488, Ethernet, USB or RS-232 ports.

5.2.10 Power Up

Apply power to the power connector on the rear of the instrument using the power adaptor included, and switch the power switch

on the front of the unit ON. The instrument will go through an initialization process and system check. As soon as the system check

is completed the system will default to a screen similar to the one shown in Section 6.1.2, Display Screen Features. The main

measurement screen may be configured in many different ways but initially it will be in a default configuration. Subsequently, the

unit will power up in the configuration that it was in when last powered off. Allow at least 15 minutes of warm up before performing

critical pressure measurements.

Do not position the equipment so that it is difficult to remove the power cord. The instrument is not intended for

connection of long-distance lines, i.e. lines within a building that are longer than 30 m, or that leave the building

(including lines of outdoor installations).

20

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 21

6. Operation

6. Operation

6.1 General Operation

This section describes the procedures for operating the CPC7000 from the front panel. Instructions for operating the device

remotely from an external computer are covered in Section 8, Remote Operation. By following the procedures provided in these

two sections and Section 9.2, Recalibration, you can expect your CPC7000 to deliver maximum accuracy and dependability for

many years of useful service.

6.1.1 Setup Applications

Configuration of the CPC7000 is achieved by changing settings accessed through the Application (“App”) buttons. Local operation

is accomplished by observing the data presented in the display. The appearance and functionality of the display can be changed

by pressing the App button for the related function. After an app has been chosen, a set of related parameters will appear on the

left. After choosing one of these parameters, a set of selections related to that parameter will appear on the right or a data entry

keypad. The desired selection or data can be entered here.

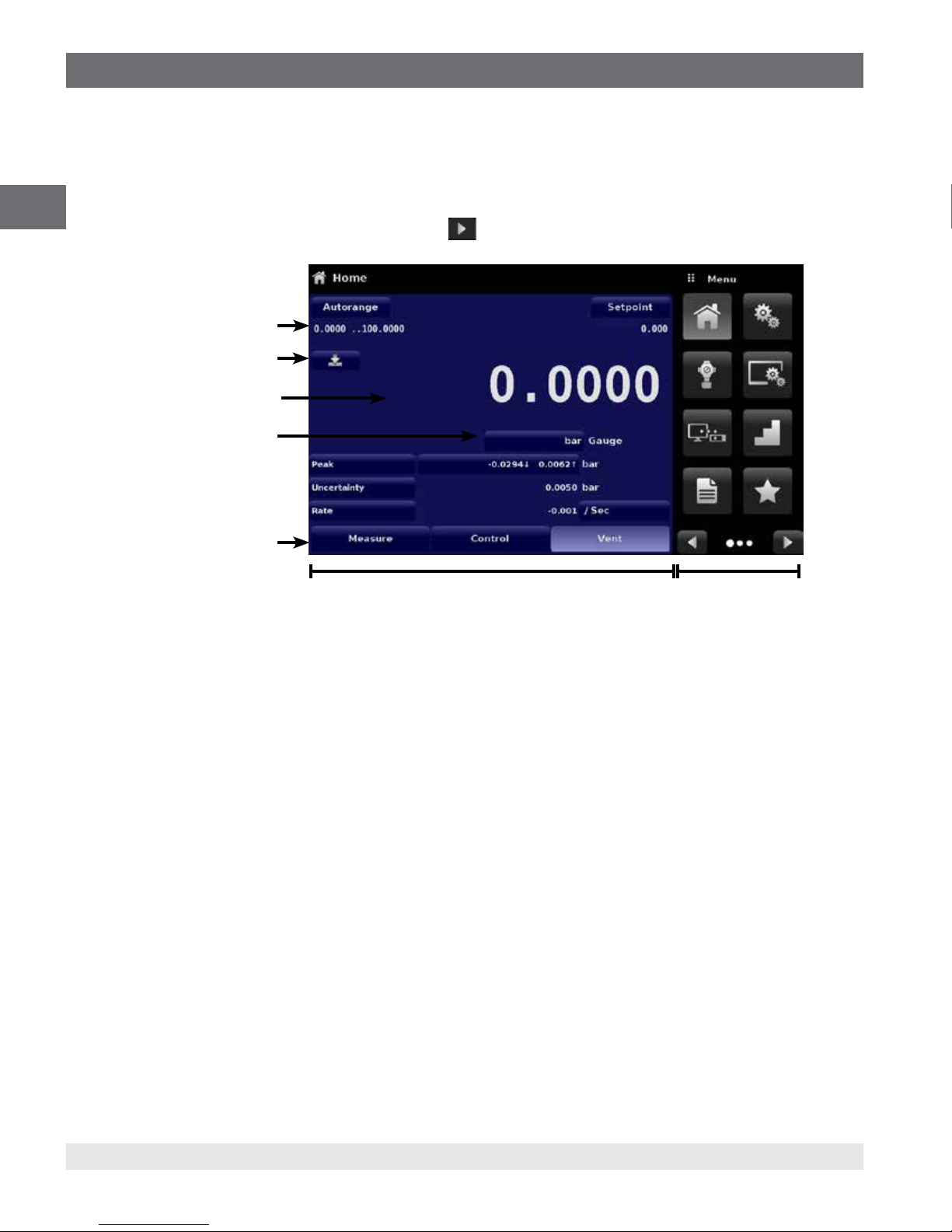

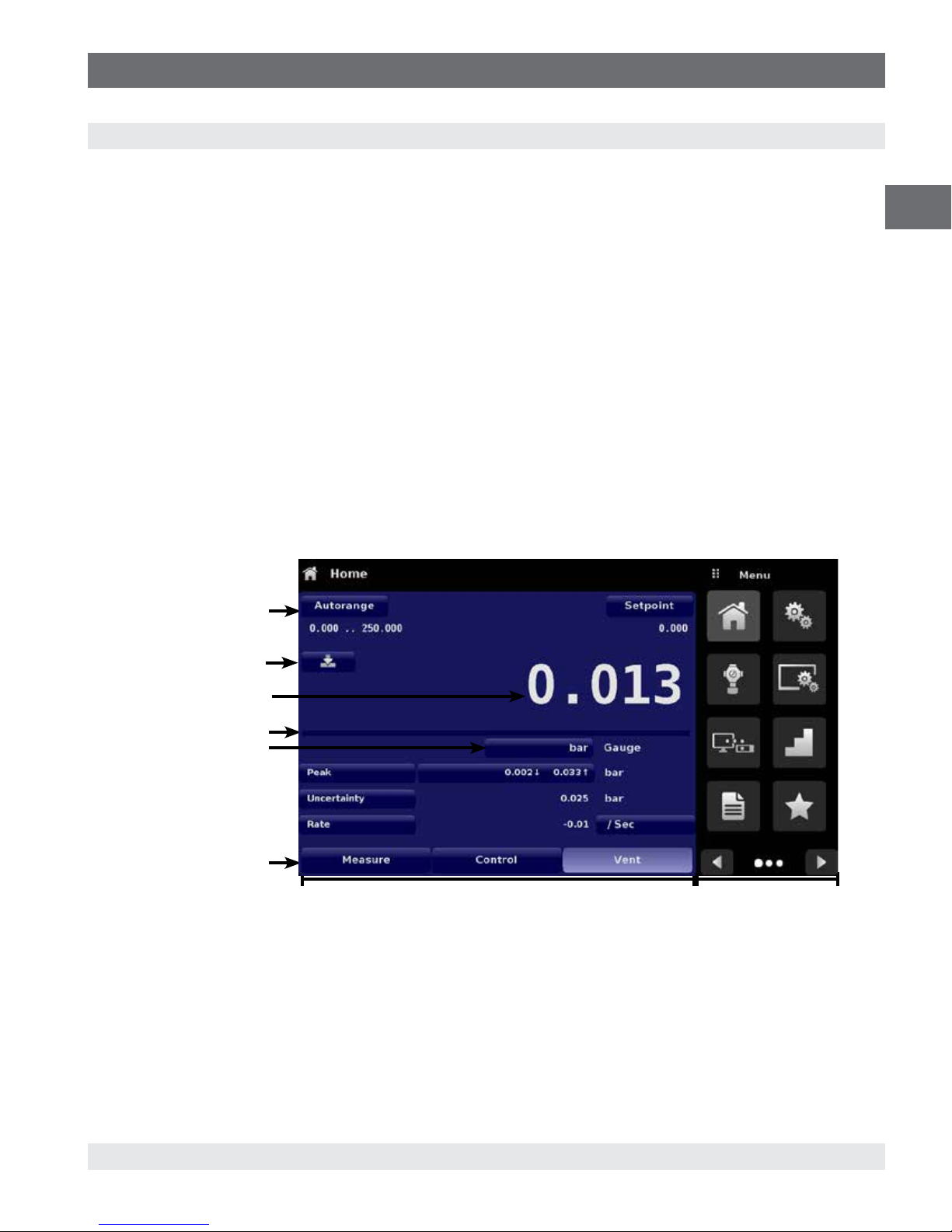

6.1.2 Display Screen Features

The screen shown below provides an overview of the features that may appear on the display after initialization. The left three

fourths of the display contains the area where information is displayed (in this case the Home Application) and the right one fourth

contains the selection icons for each application. A zero or tare button, bar graph and none or 3 of the 7 available auxiliary displays

(Peak, Rate, Rate Setpoint,Uncertainty, Units, Digital I/O and Source Pressure) will appear in the Home App if activated. All of the

CPC7000 screen features are described in more detail throughout this manual. The active App is represented with a light gray

background color compared to the other Apps.

EN

Active transducer

range

Optional Zero or Tare

Current Value

Optional Bar graph

Units / Pressure Type

Auxiliary Displays

Operating Modes

{

Operating Screen

Figure 6.1.2 Display Screen Features

Settings Apps

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

21

Page 22

6. Operation

6.2 Initial Setup

Section 6.2.1 and 6.2.2 are provided first so that the operator can initially check the information screen to verify the installed

components and to change the language if needed.

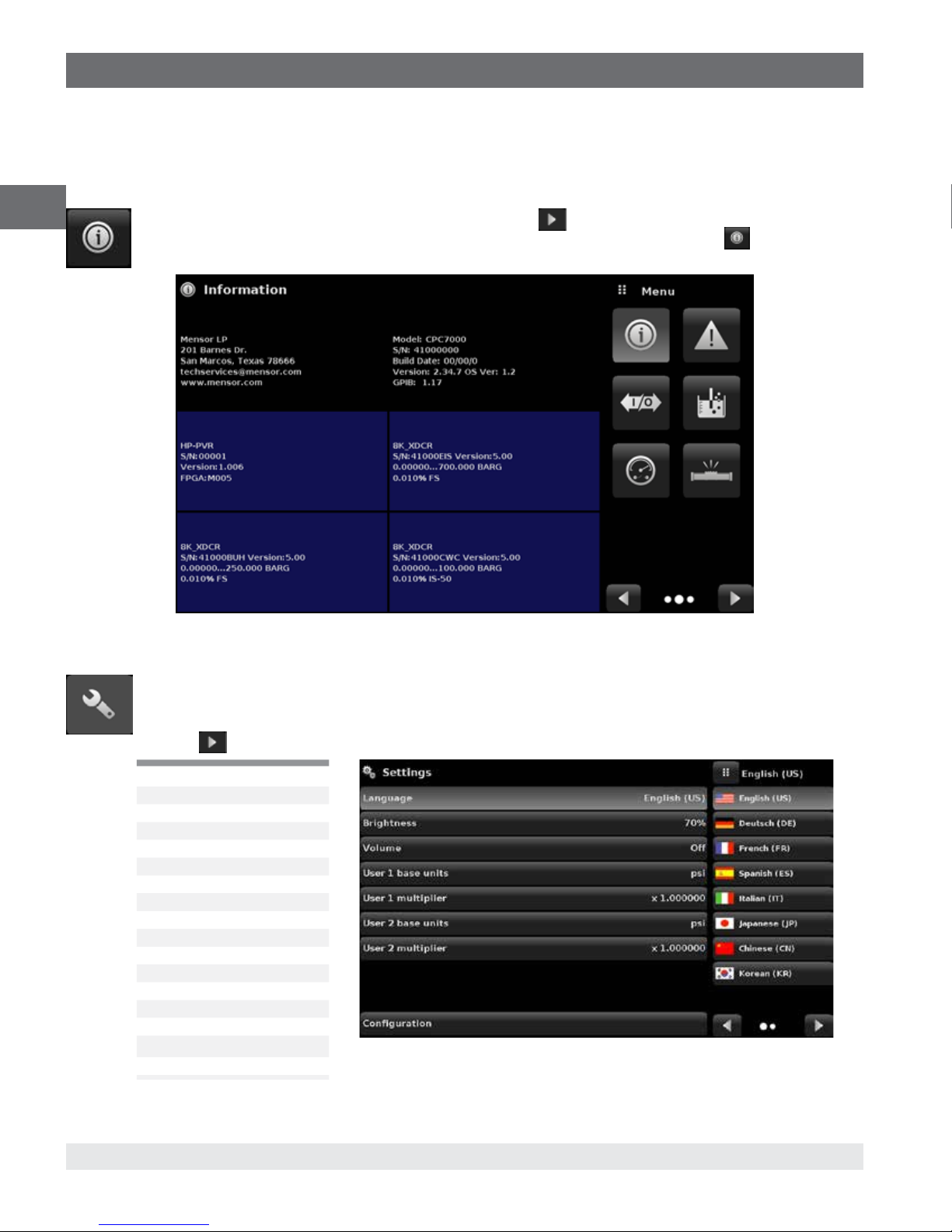

6.2.1 Contact and Version Information Application

EN

Navigate to additional Apps by pressing the Next Page button [ ] at the right bottom of the App buttons. This

gives access to the second page of the App selection area. Press the Information App button [

Mensor contact, installed transducers, installed regulator along with instrument and software version information

] to display

6.2.2 Language Selection

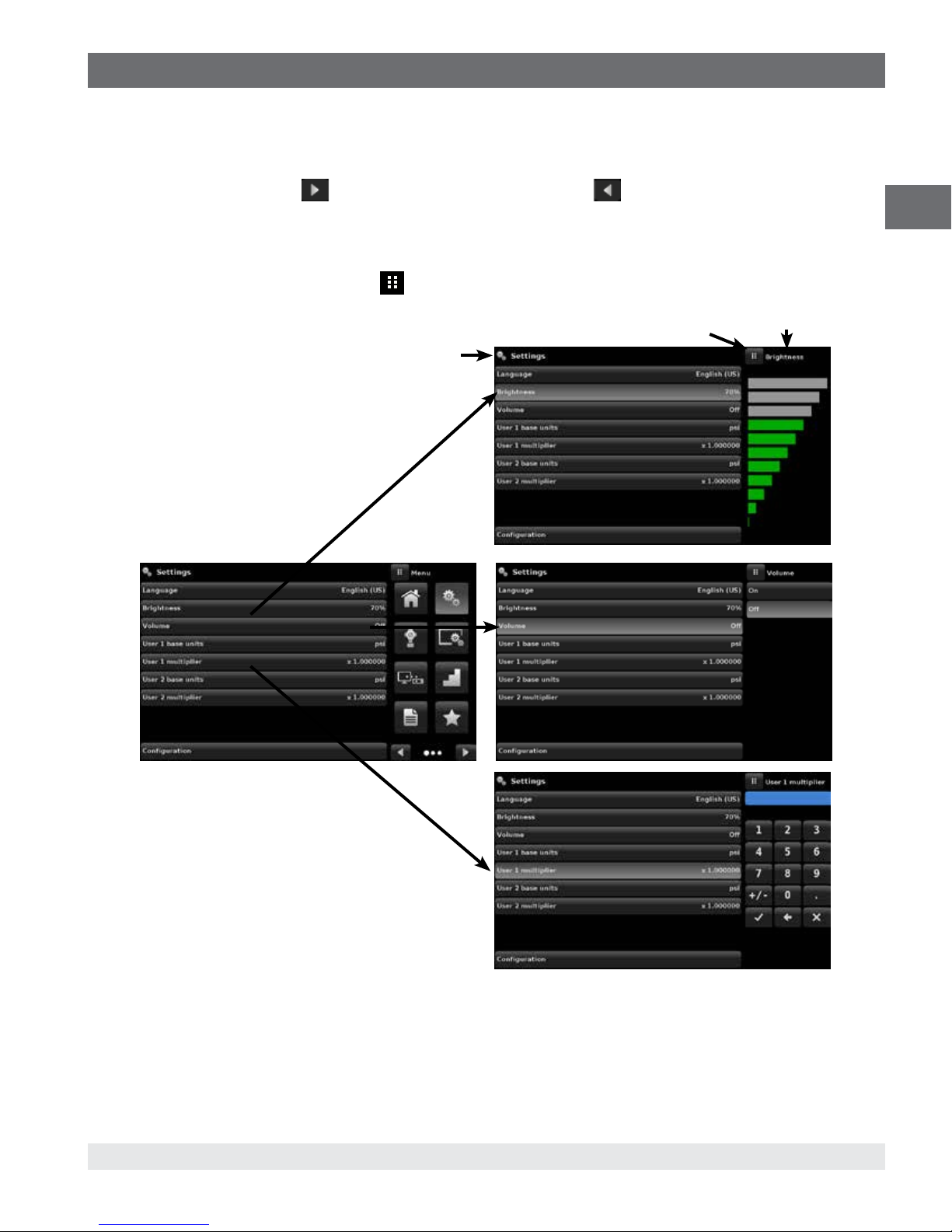

Pressing the settings application button will open a screen where the language, display brightness, volume, user

base units/multiplier and configuration loading/saving, can be changed. The current language selections available

are shown in the table below. Additional language choices will appear on the screen after pushing the Next Page

button [

Language Country

English USA

German Germany

French France

Spanish Spain

Italian Italy

Japanese Japan

Chinese China

Korean Korea

English Great Britain

English Canada

French Canada

Spanish Latin America

Polish Poland

Portuguese Portugal

Portuguese Brasil

Russian Russia

]:

Figure 6.2.1 Information

22

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 23

6. Operation

6.3 Application Selection and Parameter Inputs

The application selection area on the right one fourth of the screen (see Figure 6.1 Display Screen Features) is the area where

setup, information, calibration, service and other Apps can be chosen. Multiple pages of application selections can be accessed

by pressing the Next Page button [

on the bottom right indicate the active page by a larger circle. As each App is chosen, related application parameters will appear

on the left three fourth of the screen along with the name of the application, and a reduced size icon in the top title section. When

a parameter is chosen, related selections, sliding scales or a data entry key pad will appear in the input area on the right where

the application selection buttons were previously displayed. An example of each type of input is shown below. To return to the App

selection menu, simply press the Menu button [

intuitively apparent and will become second nature with minimal exposure to the menu structure.

] or by pressing the Previous Page button [ ] A series of horizontally placed circles

] above the input area. The purpose and use of each selection and menu is

Menu Button

Input Title

App Title

EN

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

23

Page 24

6. Operation

6.4 Applications

6.4.1 Home Applications

The Home App is the normal operation screen. This application is different from the others in that it is not used to

EN

The screen in Figure 6.4.1-A shows the basic Home App in an instrument. The user can change the display to show multiple

auxiliary displays by pressing the auxiliary button on the left corner of the screen (Figure 6.4.1-B Home App With Auxilliary). The

Units button is always displayed. When the Units button is pressed a selection of imperial and metric units will be displayed on the

right (Figure 6.4.1-C Pressure Units); notice that the Units button has a lighter background when the selection menu is active. If a

barometric reference is installed, the Mode button, described below, will toggle from Gauge to Absolute mode when pressed.

setup the configuration but is used to monitor the pressure applied to the installed transducers

Figure 6.4.1-A Basic Home App

Figure 6.4.1-B Home App with Auxiliary Display Figure 6.4.1-C Pressure Units

24

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 25

6. Operation

6.4.1.1 Range Hold/ Autorange

The Range Hold / Autorange button allows the user to select the active range of the transducers. By clicking the Range Hold

button, the user can select the active transducer from the primary, secondary and tertiary transducers or utilize the “Autorange”

feature to let the instrument automatically select the active range based on the current pressure value.

Range Hold button

Figure 6.4.1.1 Range Hold Button

6.4.1.2 Control Setpoint

The Setpoint button allows the user to enter the desired pressure value to be controlled by the instrument. There are multiple ways

of entering the control setpoint: numeric keypad, step increments, percentage entry, digital step or a program data entry. These

methods can be accessed by the user by pressing the “Setpoint” button and the various setpoint entry methods can be navigated

with the Next Page [

] and Previous Page [ ] buttons.

EN

Figure 6.4.1.2 Setpoint Button

Setpoint button

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

25

Page 26

6. Operation

6.4.1.2.1 Numeric Keypad

The first entry method provides 10 digits for numeric entry, plus the decimal point and a sign key (Figure 6.4.1.2.1 Numeric Keypad

Setpoint Entry). The sign key [+/-] will toggle between positive and negative values. Each stroke on the key pad will echo in the

blue input value window above the pad. A change between plus and minus values [+/-] can be entered at any time during the string

entry. Pressing the Enter [

EN

value when the Enter button is pressed the system will respond with an error tone and the entry will turn red. When that happens

determine the cause of rejection, delete the entry using the Delete [

can only be entered within the minimum and maximum control range set in the Control Settings App (6.4.3 Control Settings

Application). These limits are shown above the numeric entry keypad.

] button will accept the value and it will become the setpoint. If the input window holds an illegal

] button and then enter a valid number. The setpoint

Min & Max

setpoint values

Figure 6.4.1.2.1 Numeric Keypad Setpoint Entry

6.4.1.2.2 Step Increments

The second entry method allows the user to enter the setpoint in the same way as the Numeric Keypad by keying in the value and

then pressing Enter [

Step Down [

setpoint value. Subsequent touches of the Step Up or Step Down button will continue to increase or decrease the setpoint by the

step value. If the Enter [

rather than a step value.

] button, without pressing the Enter button. This number will then be used to decrease or increase the existing

] button. The user can then enter the desired value of step increment and press Step Up [ ] or

] button is pressed the newly entered value will register as a new setpoint value on the Home Screen

Figure 6.4.1.2.2 Numeric Keypad with Step Increments

26

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 27

6. Operation

6.4.1.2.3 Percentage Entry

The third entry method is the Percentage Entry method (Figure 6.4.1.2.3-A Percentage Entry) which allows the user to select

a setpoint value as a percentage of the pressure range of device under test (DUT). The user can choose between various

percentage values by clicking on the desired button. The setpoint will instantly change to the selected percentage value of the DUT.

The user can also configure the minimum and maximum pressure values of the DUT by clicking the button displaying pressure

range. This would take the user to the Step Settings App (Figure 6.4.1.2.3-B Step Settings App) which is explained in Section 6.4.6

Step Settings Application.

Figure 6.4.1.2.3-A Percentage Entry Figure 6.4.1.2.3-B Step Percentage

EN

6.4.1.2.4 Digital Step Entry

The fourth entry method is the Digital Step data entry method. This method allows the user to increase or decrease the setpoint

value by one digit at a time. The digit to be changed can be selected from a string of five zeroes (0) and one blue numeral one (1)

by sliding a finger across the zeroes and converting the desired digit to a blue 1. The right most digit in the Digital Step corresponds

to the lease significant digit of the setpoint. Each digit of the setpoint can then be increased or decreased by pressing the

Up [

] or Down [ ] button.

Figure 6.4.1.2.4 Digital Step Entry

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

27

Page 28

6. Operation

6.4.1.2.5 Program Data Entry

The fifth entry method is through the automated Programs stored in the CPC7000 memory. The Program Player allows the user to

select one of the stored Programs and use it for setpoint entry. A Program can be chosen by using the Up [

buttons. After selecting the desired program, press the Play [

Player and how to create/ edit programs is available in Section 6.4.7, Programs Application.

EN

Figure 6.4.1.2.5 Program Data Entry

6.4.1.3 Units and Pressure Type

The Units button is always displayed. When the units button is pressed a selection of imperial and metric units will be displayed

on the right (Figure 6.4.1.3-A).The Pressure Type button is only active if there is an optional Barometer installed. Otherwise, the

Pressure Type button becomes a label (Figure 6.4.1.3-B) indicating the native mode of the instrument (absolute or gauge). When

an optional barometer is installed, a native gauge transducer can emulate absolute pressure using the barometric reference.

Alternatively, a native absolute transducer can emulate gauge pressure. Emulation can be activated simply by pressing the

Pressure Type button

Pressure Units button

] button to start the program. More information on the Program

Pressure Type button

] or Down [ ]

Figure 6.4.1.3-A Pressure units Figure 6.4.1.3-B Pressure type

6.4.1.4 Bar Graph

An optional bar graph can be displayed below the current pressure value. The bar graph indicates the relative position of the

current value within the maximum range of the primary transducer. This bar graph will appear in the Home App when selected from

the Display Settings App (Section 6.4.4).

28

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 29

6. Operation

6.4.1.5 Auxiliary Displays

The screen in Figure 6.4.1.5-A shows all of the possible auxiliary display items that can be included in the Home App. The

instrument can have up to three auxiliary displays which can be chosen by clicking on each button and then selecting the display

item from the menu on the right side of the screen (Figure 6.4.1.5-B)

Figure 6.4.1.5-A Home App with Auxiliary Displays Figure 6.4.1.5-B Auxiliary Display Selection

Some of the auxiliary display can be modified by pressing the displayed button. Others simply display auxiliary information.

■

Peak: Pressing the Peak button will reset the upper and lower peak value to the current reading, subsequent negative or

positive divergence from that reading will be recorded in the button.

■

Rate: Pressing the Rate button will display a choice of time rate units for the rate denominator.

■

Rate Setpoint: Pressing the Rate Setpoint button will let the user enter the new Rate Setpoint via the numeric Keypad

(“Variable”) or select “Slow” (.1% of the span of the primary transducer), Medium (1% of the span of the primary transducer), or

“Fast” (10% of the span of the primary transducer).

■

Uncertainty: Displays the accuracy at the pressure being displayed.

■

Units: Pressing the Auxiliary Units button will display the same set of units available for the primary units. Pressing any of these

units will change the auxiliary units to that chosen unit.

■

Digital I/O: Displays the current state of digital inputs and outputs as “1” for high and “0” for low.

■

Source Pressure: Displays the current source pressure at the supply port.

EN

6.4.1.6 Zero Button

If the Zero Calibration function has been chosen in the Display Settings App (Section 6.4.4), then the Zero Cal Button [ ]

will appear in the Home App. If the instrument is measuring absolute pressure, and the Zero Cal Button is pressed, a keyboard will

appear to allow a single point calibration. If the instrument is measuring gauge pressure, pressing the button will set the current

reading to zero. If the instrument is in emulation mode (absolute or gauge) then the value will not be saved to the transducer but

only as a temporary adjustment while in emulation mode. After exiting the emulation mode or after a power cycle, the temporary

adjustment will be cleared. The zero adjustment for an instrument not in emulation mode will be saved to the transducer as if single

point calibration had been performed.

Figure 6.4.1.6 shows the zero cal function been enabled for instrument. The background color of the zero button will momentarily

change to a lighter color as the zero calibration is performed then will revert back to a darker color when complete. The screen on

the right shows this.

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

29

Page 30

6. Operation

EN

Figure 6.4.1.6 Zero Button

6.4.1.7 Tare Button

If the Tare calibration function has been chosen in the Display Settings App (Section 6.4.4), then the Tare

Button [

in yellow when active. The Tare button and the Zero Button cannot appear on the screen at the same

time. When the Tare button is pressed, the instrument will subtract the current pressure reading (the tare

pressure) so that the indicator will display zero. Subsequent deviations in pressure will be relative to the

tare pressure.

] will appear in the Home screen. For safety reasons, the tare button will be highlighted

Tare button

Figure 6.4.1.7 Tare Button

Pressing the tare button again will deactivate the tare and change the pressure indication back to the reading corresponding to the

calibrated output of the transducer. An active tare will revert to a deactivated state after a power cycle.

30

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 31

6. Operation

6.4.1.8 Operating Mode Selection

The operating modes are permanently displayed on bottom of the Home App. The CPC7000 has three operating modes: Measure,

Control and Vent. After the system has switched on, the instrument will automatically be placed in Vent mode. The user can switch

from one mode to the other by using the mode selection keys.

When switching from Control mode to Measure mode, the system will not be vented and the last applied pressure

will be locked in the system by means of a solenoid valve

■

Measure Mode: In Measure mode the CPC7000 acts like a precision pressure measuring instrument and measures the

pressure applied at the Measure/Control port. If the Control mode was the last used mode before switching into Measure mode,

the last controlled pressure is held in the test assembly.

■

Control Mode: In Control mode the CPC7000 provides a controlled pressure at the Measure/Control port equal to the setpoint

value. It is activated by pressing the Control button. In order to ensure smooth operation in the control mode, following measures

must be taken and respective parameters must be set.

The control stability and the control rate can be set in the Control Settings App [

Control limits can be set in the Control Settings App [

■

Vent Mode: The Vent function will vent the system to the atmosphere, including the test assembly connected to the Measure/

Control port. The Vent mode can be activated from the Measure or Control mode by pressing the Vent button. The rate at which

the pressure is released in vent mode is set in the Control Settings App [

WARNING!

Venting will cause a loss of pressure at the vent rate in the system and the plumbing connected to the Measure/

Control port. Care must be taken that the device under test is not damaged during venting.

]

]

]

EN

6.4.2 Settings Application

The Settings App is used to set up general settings for the display. Settings parameters include Language,

Brightness, Volume, User 1 base units, User 1 multiplier, User 2 base units, User 2 multiplier, Barometer units, and

Configuration. Figure 6.4.2 Settings application shows these parameters as indicated when the Settings App has

been chosen. As each parameter is pressed, an input screen will appear on the right where selections can be made.

The Settings App provides a place to change the language, display brightness, volume, user units, and barometer units.

Configuration settings of the unit can also be saved within this application plus the default configuration can be activated.

Figure 6.4.2 Settings App

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

31

Page 32

6. Operation

6.4.2.1 Languages

The Language parameter provides a selection of different languages. Once a language is chosen all words within all menus will

appear in the chosen language and the radix character (decimal mark) will change from a dot (.) to a comma (,) depending on the

language chosen. More languages can be accessed by navigating to the next page of the language selection menu on the right

side of the screen.

EN

Figure 6.4.2.1 Languages

6.4.2.2 Brightness

The Brightness setting provides a sliding scale to increment the screen brightness in all screens. Sliding your finger along the bar

graph or touching anywhere in the bar graph will change the brightness of the screen. After the setting is made and your finger is

removed from the screen the menu will show the brightness percent selected and revert back to the main settings menu.

Figure 6.4.2.2 Brightness

32

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 33

6. Operation

6.4.2.3 Volume

The Volume setting provides a way to turn on or off the touch screen audio feedback.

Figure 6.4.2.3 Volume

EN

6.4.2.4 User Base Units/ Base Units Multiplier

When choosing a unit of measure from the Home Application (main screen), standard units can be chosen in addition to two user

defined units. User units 1 and 2 are defined in the Settings App using “User 1 base units”, “User 1 multiplier” and / or “User 2 base

units”, “User 2 multiplier”. If the display of a special unit is needed, then a base unit should be chosen (psi, bar or Pascal) as the

“User base unit” and the “User multiplier” can be entered to derive the special unit using the formula: Special unit = Base Unit x

Unit multiplier. When set this way, and the user unit has been chosen from the main screen, then the user unit will now display the

Special unit as derived.

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Figure 6.4.2.4 User base units/ Base units multiplier

33

Page 34

6. Operation

6.4.2.5 Barometer Units

When the Barometer Units button has been chosen, a list of Imperial or Metric units is presented on the

right side of the screen. Any of these units can be chosen from this list for the barometric readout. The

barometric pressure readout can be seen on the bottom right of the Home App.

EN

Figure 6.4.2.5 Barometer units

6.4.2.6 Configuration

Configuration is the last parameter in the Settings App. It allows the operator to save instrument settings and load them as a

group, as needed, in the future. Configuration variables that are currently set in all Apps can be saved using the Configuration

“Save” button and recalled using the Configuration “Load” button. Simply set all desired variables in each app, then go to

Settings-Configuration, press one of the numbered Configuration buttons then press the “Save” button. This will save the current

configuration in that button. To reload a saved configuration at a later time, go to Settings-Configuration and press the numbered

configuration button corresponding to the saved configuration and then press the “Load” button.

The instrument default conguration can be activated simply by pressing the “Default” Button.

34

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Figure 6.4.2.6 Configuration

0019104001D 10/2018EN

Page 35

6. Operation

6.4.3 Control Settings Application

The Control Settings App allows the user to select and configure the control parameters for the instruments pressure

regulating module (PVR module). Figure 6.4.3 shows the Control Settings Application screen.

Figure 6.4.3 Control Settings App

EN

6.4.3.1 Control Limits

The Maximum and Minimum Limit buttons in the Control Settings App provide a place to limit the set point value that can be

chosen in the Home App. These limits can only be set within the range of the active transducer. When the instrument is in

Autorange the limits can only be set within the range of the primary transducer which, by convention, will have the widest range.

The minimum limit must be lower than the maximum limit. The user cannot enter set points and thereby not control to pressures

outside of these limits. Figure 6.4.3.1 shows the data entry keyboard to enter the limits. Note that the keyboard displays the

maximum value that can be entered.

Figure 6.4.3.1Control limit setting

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

35

Page 36

6. Operation

6.4.3.2 Stability Parameters

Stability parameters for the controlled pressure can be configured using the Stable Window and Stable Delay buttons. When the

controller enters a stable condition the pressure indication color on the Home App will change from white to green. The Stable

Window button allows the user to enter a value as a percentage of the highest range transducer. This value represents the

pressure window within which any setpoint value would be considered stable by the user. The Stable Delay button lets the user

EN

add a desired delay until the pressure value is considered stable while being in the stable window.

Stability

Parameters

Figure 6.4.3.2 Stability Parameters

6.4.3.3 Rate Setpoint

The Rate Setpoint button allows the user to set the rate of pressure change when the CPC7000 is controlling up or down to a

setpoint (Figure 6.4.3.3). The rate is limited from 1 bar/second to 10% of span of active range of the transducer / second upto a

maximum of 10 bar/second.

Figure 6.4.3.3 Rate Setpoint

36

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 37

6. Operation

6.4.3.4 Rate Stability Parameters

Rate parameters for the control rate can be found in the Control Settings App and can be configured using the Rate Stable Window

and Rate Stable Delay buttons. The Rate Stable Window button allows the user to enter a value as a percentage of the active

range of transducer. This value represents the pressure window within which the control rate value would be considered stable by

the user. The Rate Stable Delay button lets the user add a desired delay until the control rate is considered stable while being in

the rate stable window.

Rate Stability

Parameters

EN

Figure 6.4.3.4 Rate Stability Parameters

6.4.3.5 Vent Rate

The Vent Rate button in the Control Settings App lets the user to determine the rate at which pressure will vent in vent mode. By

default the rate of the vent is set similar to the control rate. Figure 6.4.3.5 displays the vent rate setting. The maximum allowable

rate of vent is 60 bar/second and the minimum vent rate is limited to 1 bar/second.

Figure 6.4.3.5 Vent Rate

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

37

Page 38

6. Operation

6.4.3.6 Vent Limit

This is the pressure at which controlled vent stops and the vent solenoid is opened causing the pressure to vent through the vent

NO port uncontrolled. The vent limit can be set within the values of the primary transducer.

EN

Figure 6.4.3.6 Vent Limit

6.4.3.7 Control Volume

The Control Volume button in the Control Settings App allows the user to set the control pressure volume in cubic centimeters (cc)

between 0 ... 50 cc. By default this is set to 25 cc. Figure 6.4.3.7 displays the control volume setting for the instrument.

Figure 6.4.3.7 Control Volume

38

WIKA operating instructions pneumatic high pressure controller, model CPC7000

0019104001D 10/2018EN

Page 39

6. Operation

6.4.4 Display Settings Application

The Display Settings Application allows the user to configure display properties like the filter for the reading to

reduce fluctuations due to electrical noise, and to set the resolution of the reading. In addition, the bar graph display

and calibration function can be specified here.

EN

Figure 6.4.4 Display Settings App

6.4.4.1 Reading Filter

The Filter is an electronic filter to smooth out the pressure readings. Because of differences in resolution, greater filtering may

display a more stable reading for some pressure units. Turn off the Filter by selecting “Off”, select varying degrees of filtering for the

current units by selecting “Low”, “Normal” or “High”.

Figure 6.4.4.1 Reading Filter

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

39

Page 40

6. Operation

6.4.4.2 Reading Resolution

The Resolution of the displayed pressure value can be set in the Display Settings Application using the resolution Parameter. The

resolution can be set to 4, 5 or 6 digits.

EN

Figure 6.4.4.2 Reading Resolution

6.4.4.3 Bar Graph

The Bar Graph visible on under the displayed pressure value can be turned on/off in the Display Settings Applicaiton. The bar

graph indicates the relative position of the current value with the maximum range of the primary transducer.

6.4.4.4 Cal Function

The Cal Function presents a choice of None, Tare or Zero. Choosing Zero will enable the Zero Cal Button [

App. Choosing Tare will enable the Tare Button [

on the screen at the same time. See Section 6.4.1.6 and 7.4.1.7 for operation of the Zero and Tare buttons in the Home App (main

screen).

] in the Home App. The Tare button and the Zero Button cannot appear

] in the Home

40

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Figure 6.4.4 Cal Function

0019104001D 10/2018EN

Page 41

6. Operation

6.4.5 Remote Application

With the Remote Settings application users can select the remote command set for all interfaces. The GPIB address,

Ethernet network parameters and Serial parameters can also be set here.

Details about the Remote Operation (command sets, cable requirements, etc.) can be found in Section 8, Remote

Operation.

Figure 6.4.5 Remote App

6.4.5.1 Remote Command Set

The remote command set parameter provides a choice of the Mensor command set or the WIKA SCPI command set (Figure

6.4.5.1-A). All sets of commands are listed in Section 8, Remote Operation. The termination character sets the output termination

character for all remote communication command sets (Figure 6.4.5.1-B).

EN

0019104001D 10/2018 EN

WIKA operating instructions pneumatic high pressure controller, model CPC7000

Figure 6.4.5.1-A Remote Command Set

Figure 6.4.5.1-B Termination Character

41

Page 42

6. Operation

6.4.5.2 Remote Communication Settings