Page 1

Operating Instructions

Pneumatic High-Speed Pressure Controller

CPC3000

Pneumatic High-Speed Pressure Controller Model CPC3000 Version 1.1

Page 2

Pneumatic High-Speed Pressure Controller CPC3000

Warning

Caution

Notice

This Warning symbol indicates that danger of injury for persons and the

environment and/or considerable material damage (mortal danger, danger

of injury) will occur if the respective safety precautions are not taken.

This Caution symbol indicates danger for the system and material if the

respective safety precautions are not taken.

This Notice symbol does not indicate safety notices but information for a

better understanding of the facts.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.12

Page 3

Pneumatic High-Speed Pressure Controller CPC3000

Contents

1. General notices 5

1.1 FCC Radio frequency emission notice

1.2 Software license agreement

1.3 Accreditations

1.4 Packaging for Shipment

2. Safety notices 7

2.1 User Responsibilities

2.2 General safety notices

2.3 Safety notices regarding operation

3. Product description 10

3.1 Proper use

3.2 Features

3.3 Turning on the CPC3000

3.4 Front panel

3.5 Main menu

3.5.1 Keys, Tabs, Check Boxes, Labels/Graphics

3.6 Front Panel Variations and Navigation

3.6.1 Operating modes

3.7 Main menu setpoint entry options

4. Specifications 17

5. Installation 18

5.1 Introduction

5.2 Unpacking of the system

5.3 Dimensions of the available version in mm

5.4 Installation of the system

5.5 Rear panel

5.6 Pressure connections

5.7 Function of pressure connections

5.8 Electrical connections

5.8.1 Connecting the power supply and turning on the instrument

5.8.2 Connecting the Communications interfaces

6. Starting operation 23

7. Operation via Touch-screen 24

7.1 Setting the operating language

7.2 Display configuration

7.3 Setpoint Entry

7.4 Operating modes

7.5 Data Entry

7.6 Pressure unit, Pressure mode and Emulation mode

7.7 Bar Chart

11498171.01 08/2009 GB

6

6

6

7

7

7

8

10

11

12

12

13

13

14

14

16

18

18

18

19

20

20

21

22

22

22

24

24

26

27

30

30

31

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 3

Page 4

Pneumatic High-Speed Pressure Controller CPC3000

7.8 SETUP Menus

7.8.1 SETUP Display

7.8.2 SETUP Control

7.8.3 SETUP Remote

7.8.4 SETUP Info

7.8.5 SETUP Service

8. Remote Operation 40

8.1 Remote SETUP

8.2 Remote SETUP - Ethernet

8.3 Remote SETUP - USB

8.4 Remote SETUP - IEEE-488

8.5 Remote Command Set

8.5.1 Mensor Command Set

8.5.2 PCS 400 Commands Emulated

8.5.3 PCS 200 Commands Emulated

8.5.4 DPI 510 Commands Emulated

8.5.5 IEEE 488.2 Commands

8.5.6 SCPI Commands

9. Trouble-shooting measures 56

9.1 Table: Fault description and measures

10. Re-calibrating and servicing 58

11. Removal of the system 59

12. Transport of the system 60

13. Storage of the system 61

14. Placing out of service 62

15. Appendix 63

1. Table - Measurement Units

2. Table - Conversion factors, Pascal

31

32

33

34

35

36

40

41

41

42

42

43

48

50

52

52

53

56

64

65

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.14

Page 5

Pneumatic High-Speed Pressure Controller CPC3000

1. General notices

In the following chapters detailed information on the pneumatic high-speed pressure control-

ler model CPC3000 and its proper use can be found.

Should you require further information, or should there be problems which are not dealt with

in detail in the manual, please contact the following address:

WIKA Alexander Wiegand SE & Co. KG

Alexander Wiegand Strasse

D-63911 Klingenberg

Tel. +49 - (0) 93 72 / 132-9986

Fax +49 - (0) 93 72 / 132-217

E-mail: testequip@wika.de

All integrated pressure sensors are calibrated.

The warranty period for the pneumatic high-speed pressure controller model CPC3000 is 24

months according to the general terms of supply of ZVEI.

All guarantee claims lapse if the system is put to improper use or if the operating instructions

are not observed or if an attempt is made to open the system.

We also point out that the contents of these operating instructions does not form part of an

earlier or existing agreement, assurance or legal relationship or is meant to change these. All

obligations of WIKA Alexander Wiegand SE & Co. KG result from the respective sales contract

and the general business terms of WIKA Alexander Wiegand SE & Co. KG.

WIKA is a registered trade mark of WIKA Alexander Wiegand SE & Co. KG. All other brand

and product names are trademarks or registered trademarks of their respective companies.

We reserve the right to effect reasonable changes on the basis of technical improvements.

Any reproduction of this manual or parts thereof by any means is prohibited.

Version key regarding firmware and respective manual

Manual Firmware

V1.1 V 1.0

© 2009 Copyright WIKA Alexander Wiegand SE & Co. KG.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 5

Page 6

Pneumatic High-Speed Pressure Controller CPC3000

1.1 FCC Radio frequency emission notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interfer-

ence to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference

at his or her own expense.

Use shielded cables to connect external devices to this instrument to minimize

rf radiation.

Notice

1.2 Software license agreement

This product contains intellectual property, i.e., software programs, that are licensed for use

by the end user/customer (hereinafter “end user”).

This is not a sale of such intellectual property.

The end user shall not copy, disassemble or reverse compile the software program.

The software programs are provided to the end user “as is” without warranty of

any kind, either express or implied, including, but not limited to, warranties of

merchantability and fitness for a particular purpose. The entire risk of the quality

Notice

and performance of the software program is with the end user.

WIKA, Mensor and its suppliers shall not be held to any liability for any damages

suffered or incurred by the end user (including, but not limited to, general,

special, consequential or incidental damages including damages for loss of

business profits, business interruption, loss of business information and the

like), arising from or in connection with the delivery, use or performance of the

software program.

1.3 Accreditations

WIKA is registered to ISO 9001:2000. The calibration program at WIKA is accredited by DKD,

as complying with both the ISO/IEC 17025:2005 standards. All Mensor primary standards are

traceable to PTB.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.16

Page 7

Pneumatic High-Speed Pressure Controller CPC3000

1.4 Packaging for Shipment

If the product must be shipped to a different location or returned to WIKA for any reason

through a common carrier it must be packaged properly to minimize the risk of damage.

The recommended method of packing is to place the instrument in a container, surrounded on

all sides with at least 10 cm of shock attenuation material such as styrofoam peanuts.

2. Safety notices

2.1 User Responsibilities

To ensure safety, the user must make sure that:

The system is used properly (refer to 3.1 "Proper use" in the chapter 3. "Product descrip-

tion"), no dangerous media are used and that all technical specifications are observed.

Safety mechanisms exist, which exclude any danger to persons or machinery through

improper pressurisation.

The system is only operated in perfect operative condition.

This operation manual is legible and accessible to the user at the system's location.

The system is operated, serviced and repaired only by staff which is authorised and quali-

fied to do so.

The operator receives instruction on industrial safety and environmental protection, and is

knowledgeable of the operating instructions and the safety notices contained therein.

2.2 General safety notices

The system should only be operated by trained personnel who are familiar

with this manual and the operation of the instrument.

Caution

A condition for trouble-free and safe operation of this system is proper

transport, proper storage, installation, assembly and proper use as well as

careful operation and maintenance.

Warning

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 7

Any operation not described in the following instructions should be prohibited.The system must be handled with the care required for an electronic

precision instrument (protect from humidity, impacts, strong magnetic

fields, static electricity and extreme temperatures). Do not insert any

objects into the instrument.

The system is powered via the power cable with a voltage that can cause

physical injury. Even after disconnecting the system from the power

supply, dangerous voltages can temporarily occur due to capacitance.

Page 8

Pneumatic High-Speed Pressure Controller CPC3000

Extreme care must be taken with pressure connections when using

hazardous or toxic media.

Warning

Repairs must only be performed by authorized service personnel.

Additional safety notices are found throughout this manual.

2.3 Safety notices regarding operation

HIGH PRESSURE! High pressure gases are potentially hazardous. Energy

stored in these gases can be released suddenly and with extreme force.

High pressure systems should be assembled and operated only by person-

Warning

nel who have been trained in proper safety practices.

POSSIBLE INJURY! The tubing, valves and other apparatus attached to

the controller must be adequate for the maximum pressure which will be

applied, otherwise physical injury to the operator or bystander is possible.

Caution: use the proper pressure medium. Use only clean, dry non-corrosive gases. This instrument is not designed for oxygen use.

Caution

The user must use caution when controlling from a very high pressure

down to a very low pressure when a vacuum pump is connected to the

Vacuum/Exhaust port. Large volumes of gas may be present in the device

Warning

under test and will exhaust through the Vacuum/Exhaust port in excess

of the capacity of the internal relief valve, possibly causing damage to the

vacuum pump.

Caution

Warning

HIGH SOUND LEVELS! Pressures from 40 bar and up can generate sound

levels above 100 db for brief periods when they are exhausted directly to

atmosphere. If no muffling devices are attached to the VACUUM/EXHASUT

or VENT port, then ear protection is advised for personnel in the vicinity of

the instruments that will be operated under such conditions.

NOT EXPLOSION PROOF! Installation of this instrument in an area requiring devices rated as intrinsically safe is not recommended.

Caution: ESD protection required.

The proper use of grounded work surfaces and personal wrist straps are

required when coming into contact with exposed circuits (printed circuit

boards) to prevent static discharge damage to sensitive electronic components.

Before the system is switched on, the user must verify that the system was

installed correctly and that all connections meet current regulations.

The user must ensure that all specifications such as supply voltage,

operating temperature, humidity, sensor-specific pressure media and

pressure ranges are observed.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.18

11498171.01 08/2009 GB

Page 9

Pneumatic High-Speed Pressure Controller CPC3000

Before pressurizing, the user must ensure through appropriate protective

measures that the system or the device will not be overpressurized. When

working with or on an instrument, safety glasses should be worn.

Warning

In areas where the system is operated there must be sufficient air ventilation due to inert gases that will escape during use.

High pressure can accelerate parts in a manner that could be hazardous

and cause physical injury.

Additional warning and caution notes are included throughout this manual.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 9

Page 10

Pneumatic High-Speed Pressure Controller CPC3000

3. Product description

3.1 Proper use

The Pneumatic High-Speed Controller model CPC3000 is a bench top or rack mounted Digital

Pressure Calibrator/Controller used for test and calibration of mechanical pressure gauges,

pressure switches, sensors, transducers, transmitters and any pressure related devices where

time to set point is the most critical requirement.

Only dry clean air or nitrogen should be used as the pressure medium.

Shop air should be avoided and corrosive, oxidizing, condensing, explosive

gasses should be strictly avoided.

Warning

The maximum permissible supply pressure at the SUPPLY port should be

10 % over full scale value of the sensor installed.

Very fast pressure changes can damage the sensor, due to mechanical

stress on the sensor; especially if the fast pressure change leads to an

internal pressure which is higher then the full scale of the internal sensor

(even if it is only for a fraction of a second). In some cases, the internal

relief valves cannot react quickly enough to protect the sensor.

Notice

Warning

The Internal pressure sensors have a calibration certificate (see enclosure:

calibration certificate) for the entire measuring chain.

The system is not suitable for use in areas with an explosion hazard.

If the CPC3000 is not used according to this manual, safe operation of the

system is not guaranteed.

The user of the system and not the manufacturer is responsible for all

personal and material damage resulting from improper use!

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.110

Page 11

Pneumatic High-Speed Pressure Controller CPC3000

3.2 Features

1. The CPC3000 will control (up scale or down

scale) into a 150 ml volume, to within

0.025 % of the set point, in 3 seconds or

less.

2. Accuracy of 0.025 % FS, one year calibra

-

tion interval.

3. Lightweight compact case with bezel and

handle or 19" rack mount kit.

4. Manual operation via the color touch screen

and easy access to auxiliary screens allow

quick changes to the set point using the

"STEP" and "JOG" screens.

5. Remote operation over IEEE-488, USB 2.0,

or Ethernet.

6. Emulation of other conventional controllers.

7. An optional internal high accuracy baromet

-

ric reference sensor for emulation of gauge

pressure and absolute pressure.

8. A large color SVGA LCD display with a

touch screen for intuitive operator interface.

9. Multiple languages.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 11

Page 12

Pneumatic High-Speed Pressure Controller CPC3000

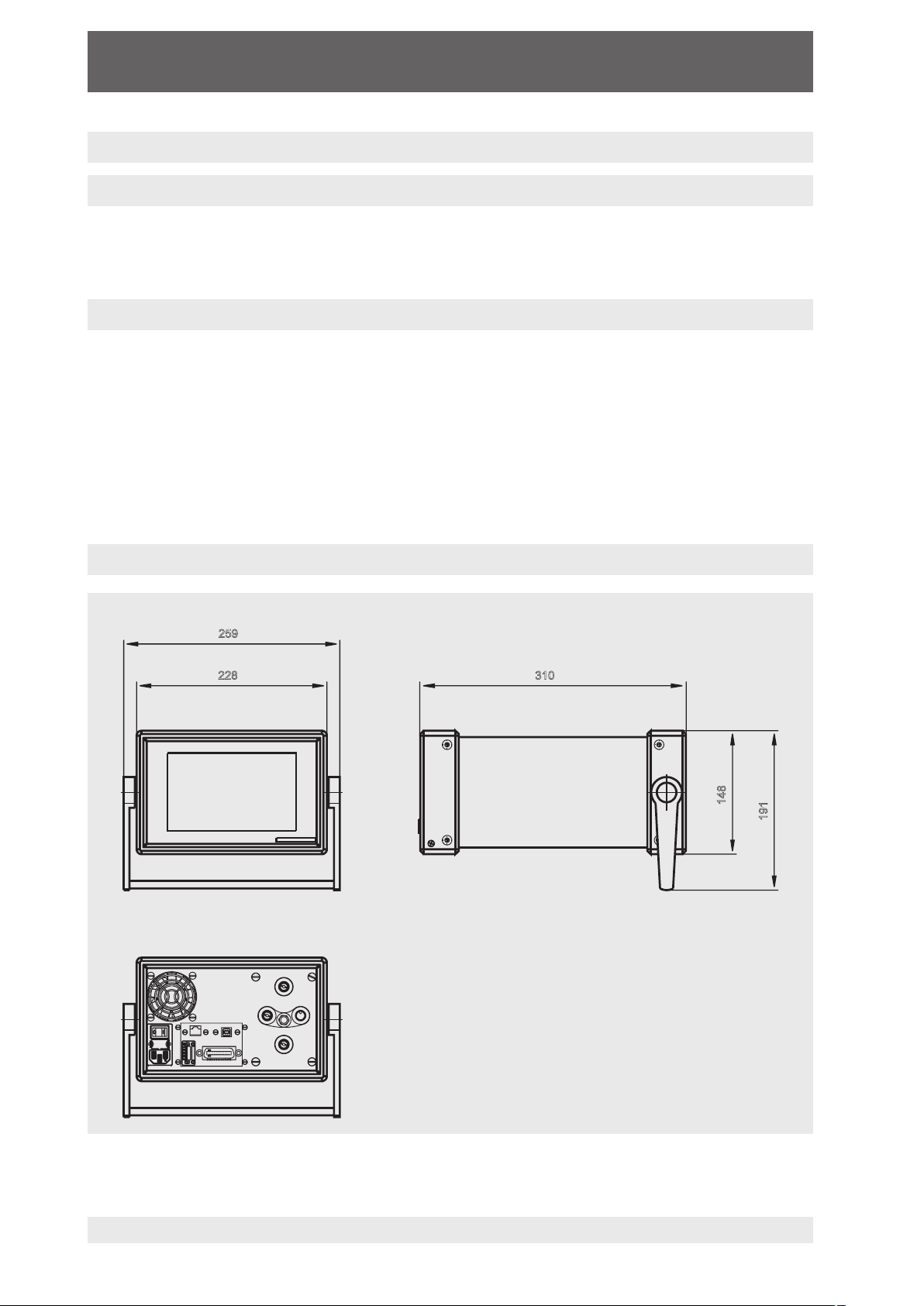

310

228

259

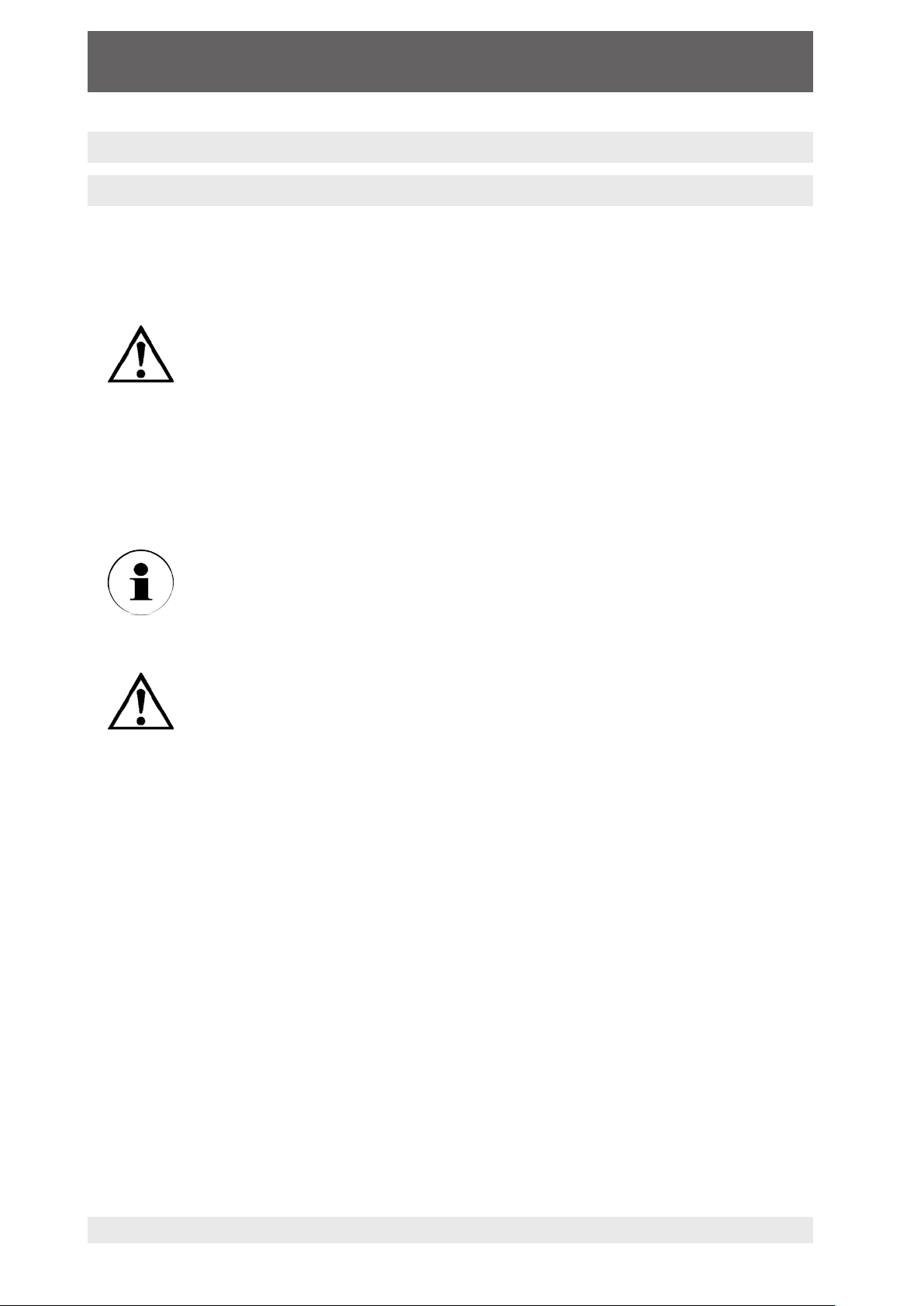

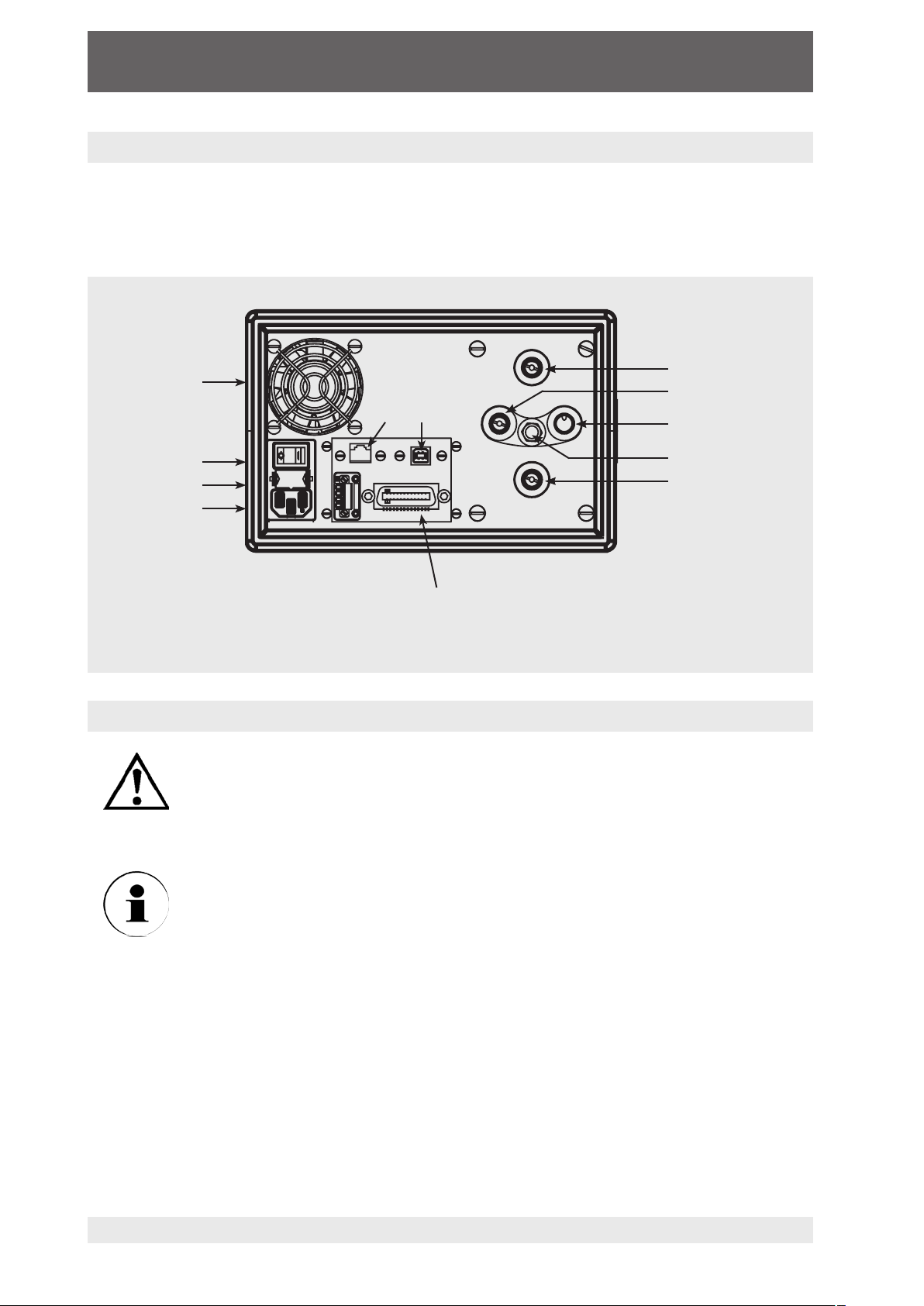

3.3 Turning on the CPC3000

The power switch is located on the rear of the instrument as shown in "Figure - Rear Panel".

Power Switch

Figure - Rear Panel

3.4 Front panel

The CPC3000 front panel (see above: "Figure - Front panel") includes a 7 inch colour SVGA

display featuring touch screen technology. Operator input is accomplished by pressing the

number, words or symbols presented on the display. There are no mechanical keypads or

switches on the front panel.

Figure - Front Panel

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.112

Page 13

Pneumatic High-Speed Pressure Controller CPC3000

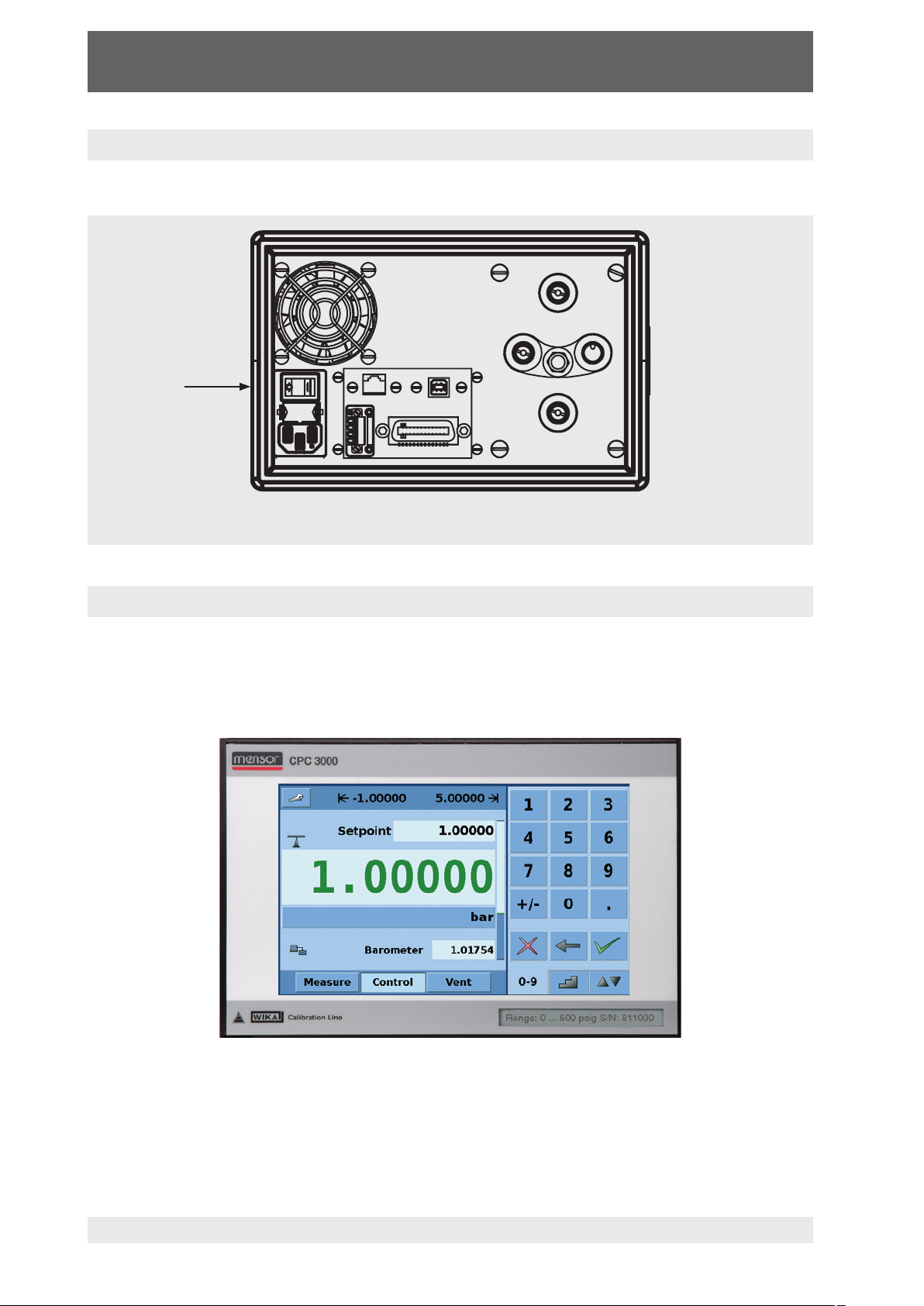

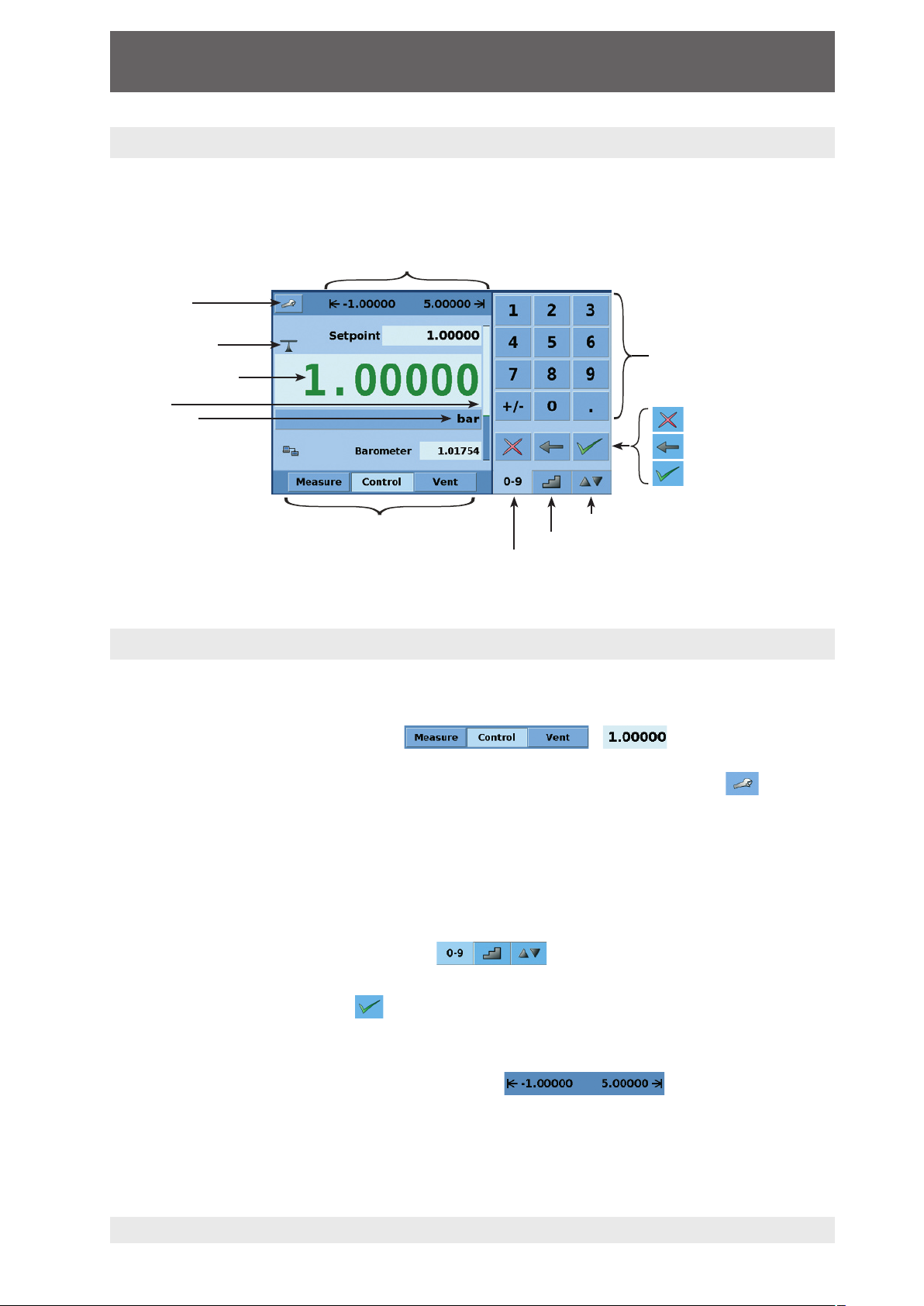

3.5 Main menu

When the CPC3000 is powered up it takes about one minute for initialization, then displays a

screen similar to the "Figure - Initial Screen" below.

User defined control range limits

(configurable via SETUP-CONTROL)

SETUP menu

Stability indication

Current pressure value

Bar graph

Pressure Units

Operating mode

JOG key pad selection tab

STEP key pad selection tab

Numeric key pad selection tab

Numeric keypad

Delete selected set point

Delete last entered digit

Accept selected set point

Figure - Initial Screen

3.5.1 Keys, Tabs, Check Boxes, Labels/Graphics

Keys: There are two types of keys: those that act as a switch to change a condition and

those that open a data entry screen when pressed. Keys have borders with a three dimensional, shadowed effect (examples: , ). Throughout this

manual keys are represented with the displayed characters enclosed in brackets (Example

[MEASURE] ) or a description and the actual graphic icon (Example [SETUP] ). Pressing a key will have one of the following results: 1) instant, single step response, 2) continuously repeating steps while the key is held down, 3) the key will change colors indicating

that the associated function is active or 4) a data entry dialog box will open. Operators will

quickly become accustomed to the particular characteristics of the frequently used keys.

Tabs: Tabs are analogous to tabs in a notebook that allow switching quickly between relat-

ed screens. Tabs are keys that allow the operator to switch between a group of screens that

have a similar purpose, for example the tabs allow the operator to quickly

switch between three screens used to enter the setpoint.

Check Boxes: Check Boxes allow for the inclusion or exclusion of specific elements or

conditions.

Labels and Graphics: Labels and Graphics are text, or graphic that display information,

but do not respond to being touched (examples: ). They indicate

choices that have been made in the SETUP menus or indicate existing conditions as

pressure is controlled or measured.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 13

Page 14

Pneumatic High-Speed Pressure Controller CPC3000

3.6 Front panel variations and navigation

Bar Graph: The bar graph shows the relative indication of the range of the internal sensor, the

user defined limits on the internal sensor, the unused portion of the internal pressure sensor

range, the setpoint and the magnitude of the actual controlled pressure. The user defined

control limits can be selected in the MAIN -> [SETUP] -> CONTROL SCREEN and can be

set to correspond to the range of the device under test. It is important to note that when

the STEP key pad is active in percent mode each step is a percent of the user defined

limit not the full scale of the internal sensor. This is useful when calibrating or testing

various range devices. "Figure - Bar Graph" shows the bar graph when the CPC3000 is in

control mode controlling a pressure at the setpoint.

Bar graph shows relative indication of:

Range of the Internal sensor

User defined limits

Unused portion of the internal sensor range

Setpoint

Current pressure reading

Figure - Bar Graph

3.6.1 Operating modes

Press to select mode:

MEASURE

In MEASURE mode, the instrument measures the pressure connected to the MEASURE

port (on changing from CONTROL mode: the last controlled pressure will be held/sealed in

the connected test assembly).

CONTROL

In CONTROL mode the instrument provides a very precise pressure at the MEASURE port.

VENT

VENT opens MEASURE port to atmospheric pressure.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.114

Page 15

Pneumatic High-Speed Pressure Controller CPC3000

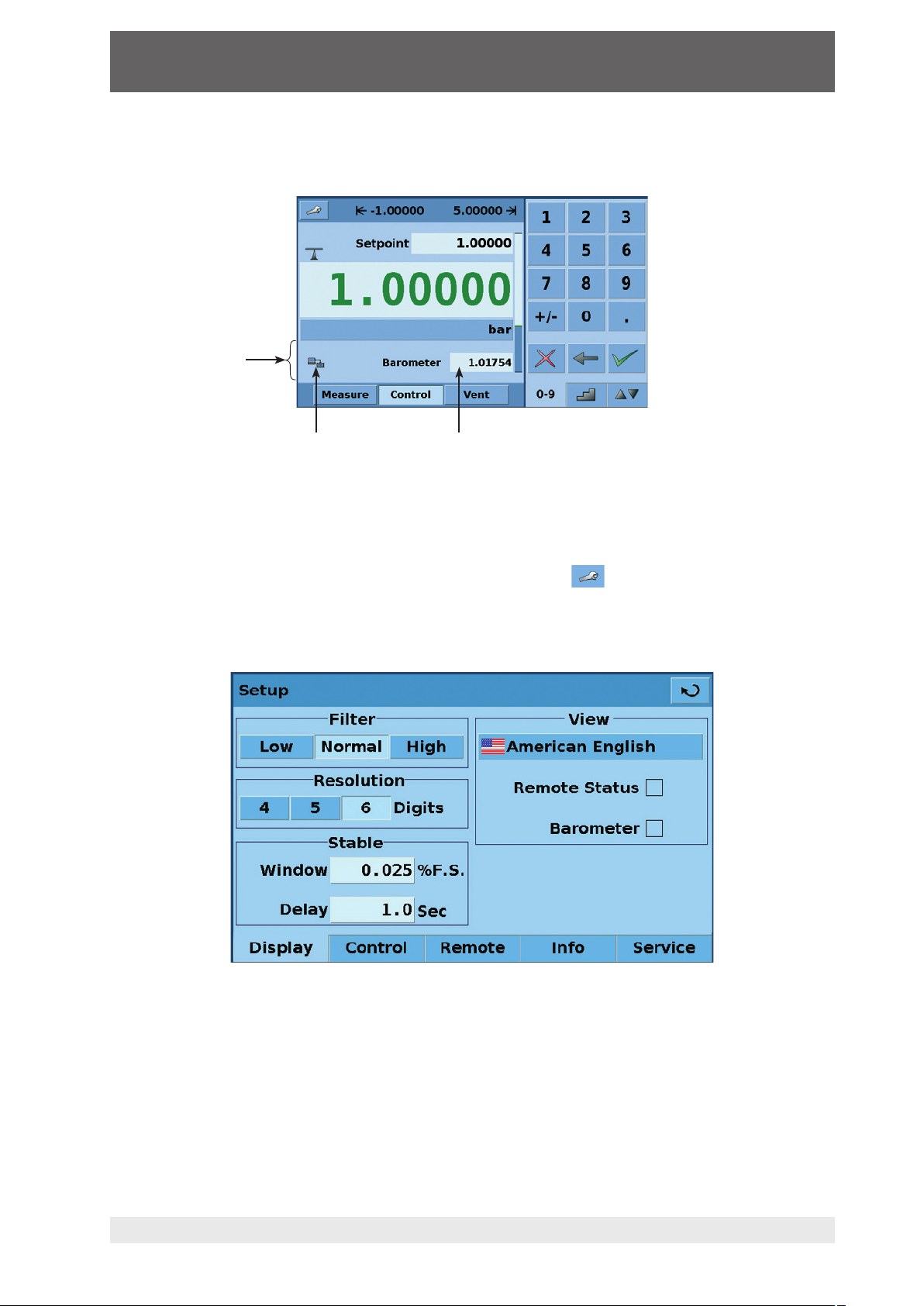

Optional elements can be chosen in the [SETUP-DISPLAY] screen explained in chapter 7.8.1

of this manual. Each optional element is displayed in the area below the pressure units.

Area for optional

elements

Communication status

Optional barometric reference display

Figure - Optional Display elements

Navigation to the SETUP screens is achieved pressing the Icon. SETUP "Figure -

SETUP Display Screen" shows the SETUP screen with the display table activated. Other

tabs at the bottom are used to navigate to additional SETUP screens. SETUP screens will be

discussed in detail in chapter 7.8 of this manual.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 15

Figure - SETUP Display Screen

Page 16

Pneumatic High-Speed Pressure Controller CPC3000

3.7 Main menu setpoint entry options

Pressure setpoint entry options are chosen using the tab keys .

"Figure - Numeric Keypad" shows the main menu with the numeric keypad selected.

Figure - Numeric Keypad

"Figure - STEP Keypad" shows the main menu with the STEP keypad selected.

Figure - STEP Keypad

"Figure - JOG Keypad" shows the main menu with the JOG keypad selected.

Figure - JOG Keypad

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.116

11498171.01 08/2009 GB

Page 17

Pneumatic High-Speed Pressure Controller CPC3000

4. Specifications

Specifications CPC3000

Pressure ranges bar -1 ... +70 (depending on sensor)

Pressure types Absolute, gauge or bi-directional ranges

Precision % FS < 0.015

Accuracy % FS < 0.025

Pressure units 33 selectable and 2 freely definable

Control stability % FS < 0.004

Slew rate sec.

Control range % FS 0 up to 100

Test volume ccm 50 ... 1,000 (without throttle)

Pressure ports mm 4 ports with 7/16"- 20 F SAE. incl. 6 mm tube fitting adaptors

Filter elements 40 micron filter element included in each pressure port

Permissible pressure media clean dry non-corrosive gases

Wetted parts aluminium, brass, 316 and 316L stainless steel, Buna N, FPM/FKM,

Overpressure protection safety relief valve

Instrument version desk top/optional: incl. rack mounting kit

Screen 7.0" colour LCD with touch-screen

Resolution digits 4 ... 6

Internal measuring rate 1/sec 25

Display update 1/sec 4

Warm-up time min approx. 15

Digital Interface Ethernet, IEEE-488, USB

Command sentences Mensor, SCPI, others optional

Power Supply V AC 100 … 240, 50-60 Hz

Energy Consumption VA maximum 90

Permissible pressure

Supply port % FS ~ 110

Measure/Control port % FS max. 105

Permissible

Operating temperature °C 10 … 50

Storage temperature °C 0 ... 70

Air humidity % 0 … 95 (relative humidity without moisture condensation)

Operating position Horizontal or slightly tilted

Compensated temperature

range

Weight kg approx. 9.1

Dimensions mm see technical drawings

CE-mark Conformity certificate

Calibration* Incl. factory calibration certificate 3.1 per DIN EN 10 204

°C 15 …. 45

< 3 (with a sudden pressure increase of 10 % FS in a 150 ml test volume)

glass filled epoxy, RTV, Nylon, Ceramic

* Calibration in a horizontal position.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 17

Page 18

Pneumatic High-Speed Pressure Controller CPC3000

310

148

191

228

259

5. Installation

5.1 Introduction

The initial installation of the CPC3000 includes the following steps: Unpack the system, place

it in a suitable workspace, connect it, switch it on and configure.

5.2 Unpacking the system

Unpack all components of the CPC3000 carefully and check the parts for damage. Report

any damage immediately to the forwarding agent.

Apart from any additional components ordered, a shipment consists of:

CPC3000 controller

¼" and 6 mm tube fitting adapters

Main cable

Manual with calibration certificates in the enclosure

Optional: recommend Interface cable or any other accessories ordered

5.3 Dimensions of the available version in mm

Front view Side view

Rear view

The instrument can be set up on a table top or it can be rack-mounted. Rack mount adapters

are optional on the CPC3000 and require an adapter panel.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.118

11498171.01 08/2009 GB

Page 19

Pneumatic High-Speed Pressure Controller CPC3000

5.4 Installation of the system

The installation site must meet the following conditions:

Operating Temperature: 10 to 50 °C

Humidity: 0 to 95 % relative humidity non-condensation

Flat, horizontal location; secure fixed working surface (desk top model) or installation in a

19" rack mount.

At the back of the instrument sufficient air circulation must be provided for to avoid an

accumulation of the heat conducted to the outside via the fan.

During operation, pressure escapes through the VENT port in the back of the instrument.

Personnel should not have access to the rear VENT and EXHAUST port during operation.

Avoid the following influences:

Direct sunlight or proximity to hot objects

Unstable installation position

Mechanical vibration

Proximity to sources of strong electromagnetic fields, such as high tension appliances,

mobile telephones or mains

Soot, steam, dust and corrosive gases

Environment with explosion hazard, inflammable atmospheres

Pressure supply requirements:

Stable supply pressure 10 % higher than the full scale of the internal transducer

Permissible media: dry, clean air or nitrogen

Vacuum: min. 50 litres/min (if required)

An angle of inclination of the system of more than 3 degrees can cause a deviation in the measured pressure and should be avoided. Zeroing the unit at the

angle of inclination will nullify this deviation.

Notice

Applying supply pressure higher than the recommended pressure can

cause permanent damage to the control channel!

Warning

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 19

Page 20

Pneumatic High-Speed Pressure Controller CPC3000

310

228

259

5.5 Rear panel

Four pneumatic pressure ports are located on the rear panel (see below: "Figure - Rear

panel"). Positioned on the left are the ethernet and RS-232 and GPIB connector, the off/on

switch, the line fuses, and a protective grill covering the ventilating fan.

Fan

Mains input socket

Micro fuse

Power supply

5.6 Pressure connections

The pressure connections must be installed according to the following

instructions, observing the relevant regulations. The installation should be

performed by persons familiar with, and who can work according to, the

Warning

safety regulations for working on pneumatic/hydraulic systems.

Ethernet USB

IEEE-488.2

Figure - Rear panel

Supply Port

Measure/Control Port

Reference Port

Vent

Exhaust/Vacuum Port

When making up a connection to an o-ring adapter port use a back-up wrench

to prevent over-stressing the threads in the manifold block.

Notice

All of the pressure ports on the rear are female 7/16 - 20 SAE/MS straight threads per

MS16142 and SAE J514 table 14.

They require a tube fitting boss seal with an o-ring per MS33656.

WIKA provides female 1/4 inch and 6 mm tube fittings with the instrument.

The pressure connections can be made to these adapters with the proper mating hardware.

Do not use sealant on fittings sealed with an o-ring.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.120

11498171.01 08/2009 GB

Page 21

Pneumatic High-Speed Pressure Controller CPC3000

5.7 Function of pressure connections

MEASURE/CONTROL port

Below the label "MEASURE/CONTROL" is a pressure connection. In MEASURE mode

this connection connects the pressure applied to the internal sensor where the pressure

is measured (within the range of the internal sensor). In CONTROL mode this connection

supplies an output pressure controlled by the internal regulator at the commanded setpoint.

SUPPLY port

Below the label "SUPPLY" is a pressure connection. This connection should be supplied

with a pressure that is approximately equal to 110 % of the full scale pressure of the internal sensor. In other words, 10 % above the full scale pressure of the internal sensor

“SUPPLY Pressure” in the specifications chapter for supply pressure and pressure media

requirements.)

EXHAUST/VACUUM port

Below the label "EXHAUST/VACUUM" is a pressure connection.

If a sub-atmospheric control pressure is required a vacuum pump must be connected to

this port. Otherwise, this port may be left open to atmosphere.

(see

The user must use caution when controlling from a very high pressure

down to a very low pressure when a vacuum pump is connected to the

exhaust port. Large volumes of gas may be present in the device under

Warning

test and will exhaust through the EXHAUST/VACUUM port in excess of

the capacity of the internal relief valve, possibly causing damage to the

vacuum pump.

VENT outlet

Below the label "VENT" is the pressure outlet. In VENT mode the pressure within the system

is released through this outlet.

HIGH SOUND LEVELS! Pressures from 40 bar and up can generate sound

levels above 100 db for brief periods when they are exhausted directly to

atmosphere. If no muffling devices are attached to the EXHAUST/VACUUM

Warning

and VENT port, then ear protection is advised for personnel in the vicinity

of the instruments that will be operated under such conditions.

REFERENCE port

On gauge units this port is connected to the reference side of the transducer, and on

absolute units it is internally capped. This port is normally left open to atmosphere.

The controller must be protected from over pressure.

Warning

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 21

Pipes, couplings and other components used for connecting the supply

exhaust and the MEASURE/CONTROL port must be suitable for the application and rated for the applied pressures.

The user must ensure that the pressure media are clean and dry. If necessary, the internal sensors and mechanisms must be protected by using a

liquid trap or coalescing filter.

Page 22

Pneumatic High-Speed Pressure Controller CPC3000

5.8 Electrical connections

The electrical installation has to be carried out according to the following

instructions while observing the relevant regulations. It is to be carried out

by a qualified electrician.

Warning

5.8.1 Connecting the power supply and turning on the instrument

Before connecting the power supply, make sure that the mains voltage

agrees with the specification of the power unit. Switch off the system before

connecting the mains via the main switch at the rear of the instrument.

Warning

Only the mains cable supplied should be used.

The 3-pole mains cable supplied is fitted with an earth lead. You should

therefore operate the system only from a three-pin socket and always make

sure that the earth lead is properly connected.

The mains input socket is to be connected according to the regulations with the countryspecific connection cable supplied to a power supply that lies within the required specifica-

tion. To power-on the instrument switch the power switch ON (located on the rear of the

instrument; also see chapter "6. Starting operation").

5.8.2 Connecting the Communications interfaces

USB 2.0 FS Interface

The USB 2.0 FS connection on the rear panel of the CPC3000 is a USB-B Type connector.

The manufacturer of the USB interface board provides the drivers and product information on

a CD that is included with the CPC3000.

IEEE-488 Interface (GPIB)

The connection of the IEEE-488 interface is designed as a 24 pole IEEE-488-socket.

The manufacturer of the host IEEE-488 interface board provides software to allow communication between the board and various programming languages.

An interactive program for debugging is usually provided as well. Refer to the board manufacturer’s documentation for more information.

ETHERNET Interface

The ethernet communication port allows the CPC3000 to communicate with computers using

10/100 Based-T specifications.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.122

Page 23

Pneumatic High-Speed Pressure Controller CPC3000

Please consult your Computer Resources Department prior to connecting

this instrument to your network to verify there are no conflicts with existing

IP addresses.

Warning

Ethernet communications are transmitted over a standard RJ-45 cable.

Prior to first time use of ethernet communication, the four parameters "IP", "Netmask",

"Gateway" and "Port" must be SETUP. These are configured in the communications SETUP

screen.

6. Starting operation

Before the system is switched on, verify that the system was installed

according to the instructions of the previous chapter and that all connections installed are fitted according to the current regulations.

Warning

Operators must ensure that all specifications that apply to supply voltage,

operating temperature, humidity, pressure media and pressure ranges are

observed.

Condensation can occur inside the system when the temperature changes

abruptly. Give the system sufficient time for acclimatisation in such cases.

Before pressurizing, the operator must ensure that the system and the

device under test will not be over pressurized. When working with or on

the instrument, safety glasses have to be worn.

In the rooms in which the CPC3000 is operated sufficient air ventilation has

to be ensured.

When the above points have been met you can switch on the system, (the switch is located

on the rear of the instrument) and configure it as required after you have familiarised yourself

with the operation (see chapter: "7. Operation via Touch-screen").

After turning the power switch to ON, the instrument will go through a brief initialization

process and system check, which will take about 40 seconds.

As soon as the system check is completed the system will default to an operating screen

similar to "Figure - Initial screen" in chapter 3.6.

Allow at least 15 minutes of warm up time to achieve thermal equilibrium between the controller and its environment before performing critical pressure measurements.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 23

Page 24

Pneumatic High-Speed Pressure Controller CPC3000

7. Operation via Touch-screen

This chapter describes the procedures for operating the CPC3000 from the front panel.

Tabs, Keys, Value Entry and Check Boxes:

Local operation is accomplished by observing the data presented in the display menus,

then pressing the on-screen tab, key, value entry or check box for the desired sub-menu,

function or selection. Tabs are used to access the subset of a menu, keys open new menus,

make selections or change a parameter, value entry opens a keypad to enter a value, and

check boxes allow choice of associated display option.

Screen hierarchy:

Navigation within the CPC3000 is similar to a computer file system or a web page. Keys or

tabs activate sub-menus. Within the sub-menus there may be related sub-menus or selections. To return back through the hierarchy of screens the [BACK] key is provided.

Throughout this manual screen hierarchy will be designated using the following conven-

tion: "MAIN -> SUB-MENU -> SELECTION" or "MAIN -> SUB-MENU -> TAB -> SELECTION". The hierarchical menu structure is very intuitive and will become more obvious after

reviewing following examples.

7.1 Setting the operating language

In the upper left corner of the main display is the [SETUP] key . To change the language

select the SETUP key and select the [DISPLAY] tab if not already active. In the box labelled

"VIEW" on the upper right side of the resulting "MAIN -> SETUP -> DISPLAY" screen there is

a [FLAG] key. Press the [FLAG] key and a selection of language keys will appear. Select

the desired language. Then press the [BACK] key to return to the main menu which will now

display in the selected language. Using our convention, selecting English would be described

by the following: "MAIN -> SETUP -> DISPLAY -> FLAG -> ENGLISH".

7.2 Display configuration

The CPC3000 main menu "Figure - Main Menu" shows the main screen that appears when

the unit is turned on. A point by point description of each element is shown in this figure. The

[SETUP] key opens the SETUP menu where changes can be made and information

viewed. Each sub-menu in the SETUP menu can be activated by pressing the [DISPLAY],

[CONTROL], [REMOTE], [INFO] or [SERVICE] tab. Each of these SETUP sub-menus will be

discussed in detail in chapter 7.8.

The points on the main menu that are independent of the SETUP menus are the setpoint indication, the actual pressure reading, the units of measure and the control modes (MEASURE,

CONTROL and VENT), plus the three tab menus used for selecting a setpoint.

The [PRESSURE UNIT] key indicates the currently chosen pressure unit and can be pressed to

open a menu that allows selection of English, metric, or user defined pressure units.

The CPC3000 main menu shown in "Figure - Optional Elements" shows elements that can

be displayed on the main menu and describes the three choices available for setpoint entry

(Numeric keypad, STEP and JOG). Optional elements include the Communication status icon

which indicates a connection or disconnection from a remote computer, and the barometric

reference indication showing the value of the atmospheric pressure measured by the optional

internal barometric reference sensor.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.124

11498171.01 08/2009 GB

Page 25

Pneumatic High-Speed Pressure Controller CPC3000

User defined DUT / control range

limits (configurable via SETUP)

SETUP menu

Setpoint

Stable indication

Current pressure value

Pressure mode indication

Pressure unit key

Bar graph

Numeric keypad

- Delete selected set point

- Delete last entered digit

-

Accept selected set point

MEASURE

Measure mode pneumatically connects the pressure sensor directly

to the device under test. In measure mode pressure regulation is

inactive.

SETUP menu

Pressure emulation

mode key

Communication

status*

CONTROL

In the control mode, the device

regulates the pressure output

according to the set point value,

providing a precise pressure at the

test or measure port.

Figure - Main Menu

VENT

Vents the system and the device

under test to atmospheric pres-

sure.

SETUP menu

The SETUP menu allows

access to the following tabs.

Display

Control

Remote

Info

Service

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 25

Optional barometric

reference display*

JOG key pad selection tab

STEP key pad selection tab

Numeric key pad selection tab

Note: See the following page for detailed information on

each set point entry screen.

Figure - Optional Elements

Page 26

Pneumatic High-Speed Pressure Controller CPC3000

7.3 Setpoint Entry

The control setpoint can be entered using the default numeric keypad or the alternate STEP

or JOG keypads that appear on the right side of the main menu when selected using the

[SETPOINT ENTRY SIDE-MENU] tabs on the lower right hand side of the

main menu. These alternative methods of entering the setpoint have advantages in different

situations and have been designed to increase ease of use and productivity.

The numeric keypad shown in "Figure - Numeric Keypad" to the left,

is the default keypad that appears every time the unit is turned on or

can be activated using the [0-9] tab. A setpoint value can be entered

directly using this keypad. As the value of the setpoint is entered the

setpoint field will turn blue and the entered value will appear in the field.

The Setpoint value can be deleted completely using the [DELETE]

key, the last digit of the entered setpoint can be deleted using

the [CLEAR ENTRY] key or the setpoint value can be accepted

using the [ACCEPT ENTRY] key. When the [ACCEPT ENTRY] key

is pressed the setpoint field will turn white and the new setpoint will

become active. In control mode, the controller output will ramp to the

entered setpoint. Caution: If the [ACCEPT ENTRY] key is not pressed

Figure - Numeric Keypad

the previously entered setpoint will remain active.

Figure - STEP Keypads

Figure - JOG Keypad

The STEP keypads shown in "Figure - STEP

Keypads", provide a way to increment the

setpoint by defined steps. Steps are a percent of

the user defined limits set in the MAIN -> SETUP

-> CONTROL or actual pressure values that are

displayed in the pressure units selected in the

main menu. A total of 12 steps are provided.

When a step is pressed the related setpoint is

immediately entered as the active setpoint. In

control mode, the controller output will ramp to

this setpoint. The STEP Keypad can be modified

in the MAIN -> SETUP -> DISPLAY menu

discussed in chapter 7.8.1.

The JOG Keypad shown in "Figure - JOG Keypad", provides a way to

jog the setpoint up or down by small increments. The increments are

determined by the resolution, the maximum control limit and/or the

units of measure. For example, if the resolution is set to display four

decimals then the small triangle pointing up will change the setpoint by

+0.0001 and the small triangle pointing down will change the setpoint

by -0.0001. In the same way, the medium triangles will change the

setpoint by ±0.0010 and the large triangles will change the setpoint by

±0.0100 as shown in the figure. When the Resolution, the maximum

control limit or the units of measure are changed so that three decimals

are displayed, then the JOG functions will change to ±0.001, ±0.010

and ±0.100 respectively. This is useful when adjusting the pointer of a

manometer congruent to the skale.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.126

Page 27

Pneumatic High-Speed Pressure Controller CPC3000

7.4 Operating modes

The selection keys for the operating modes MEASURE, CONTROL and VENT are located at

the bottom of the main menu.

[MEASURE]:

In MEASURE mode, the instrument measures the pressure connected to the MEASURE/

CONTROL port. "Figure - MEASURE Mode" shows the state of the isolation valves in

MEASURE mode.

When the CPC3000 is turned off all the valves close and could trap pressurized gas within the pneumatics. It is safe practice to vent after use and

before connecting any devices to the MEASURE/CONTROL port.

Warning

MEASURE Mode

SUPPLY VENT Optional barometric

reference

Optiona

Regulator

is inactive

barometric

sensor

Pressure

transducer

Valve is open Valve is closed

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 27

REFERENCEMEASURE / CONTROLEXHAUST / VACUUM

Figure - MEASURE Mode

Page 28

Pneumatic High-Speed Pressure Controller CPC3000

[CONTROL]:

In CONTROL mode the instrument provides a precise pressure output (equal to the setpoint

+/- the stability specification) at the MEASURE/CONTROL port. The indication of the

current pressure value will turn green when the setpoint has been reached and the stable

window settings have been satisfied. "Figure - CONTROL Mode" shows the state of the

isolation valves in measure mode. Notice that the regulator is active in the CONTROL

mode.

CONTROL Mode

SUPPLY VENT Optional barometric

reference

Regulator

is active

Valve is open Valve is closed

Figure - CONTROL Mode

Optiona

barometric

sensor

Pressure

transducer

REFERENCEMEASURE / CONTROLEXHAUST / VACUUM

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.128

Page 29

Pneumatic High-Speed Pressure Controller CPC3000

[VENT]:

VENT mode vents the pneumatic system and shuts off the supply. "Figure - VENT mode"

shows the state of the isolation valves in VENT mode.

VENT Mode

SUPPLY VENT Optional barometric

reference

Regulator

is inactive

Valve is open Valve is closed

Figure - VENT Mode

Optional

barometric

sensor

Pressure

transducer

REFERENCEMEASURE / CONTROLEXHAUST / VACUUM

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 29

Page 30

Pneumatic High-Speed Pressure Controller CPC3000

7.5 Data Entry

When there is a requirement to enter specific numeric or alpha values into the system, the

method of entry is consistent for all instances. When a [VALUE ENTRY] key is pressed a

dialog box will appear similar to "Figure - Value Entry". This Value Entry dialog box will have

a numeric or alpha keypad, when appropriate minimum and maximum value limits, current

value and a window that shows the new value entered. The value can be deleted completely

using the [DELETE] key, the last digit of the entered setpoint can be deleted using the

[CLEAR ENTRY] key or the setpoint value can be accepted using the [ACCEPT ENTRY]

key.

Figure - Value Entry

7.6 Pressure unit, Pressure mode and Emulation mode

The Pressure [UNIT] key is shown on the main screen below the current pressure value and

displays the most recently chosen pressure units and the mode (absolute or gauge). If the

optional barometric reference is installed a [MODE] key replaces the mode indication to the

right of the units key. This [MODE] key indicates absolute or gauge mode. When the key is

pressed it will switch between the "native mode" of the internal sensor to the emulation mode.

The "native mode" is the mode of the sensor that is installed and is either absolute or gauge.

Emulation mode uses the value of the barometric reference to emulate the mode that is alternate to the native mode. The CPC3000 can emulate gauge from a native absolute sensor or

absolute from a native gauge sensor. The [MODE] key indicates the native mode with a blue

key background and emulation mode with a light blue key background. The units and mode

chosen remain the same when the CPC3000 is turned off then back on.

Native sensor is gauge, no barometric reference installed.

Native sensor is gauge, barometric reference installed.

Native sensor is gauge, barometric reference installed

and absolute emulation active.

Pressing the [UNITS] Key will open a dialog box that shows the available pressure units with

a tabs for [ENGLISH], [METRIC] and [USER UNITS] units. Pressing a tab will open a menu

with the related set of units available. The [USER UNITS] tab menu includes [USER 1] and

[USER 2] keys and allows the user to enter customized pressure units. Press the [MULTIPLIER VALUE

] key to enter a multiplier that defines the user unit as the multiplier times one psi

or one Pascal, whichever is currently pressed.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.130

11498171.01 08/2009 GB

Page 31

Pneumatic High-Speed Pressure Controller CPC3000

A gray background on a [PRESSURE UNITS] key indicates that it is the current selection.

Touch any other [PRESSURE UNITS] key, and press [BACK] key to enable change and

return to previous operation screen. All of the displayed pressure values will have changed to

correspond to the newly selected units.

7.7 Bar Chart

The Bar chart shows the relative indication of the current pressure value with

respect to the full scale value of the

portion of the internal sensor range

outside of the user defined limits

internal sensor and the user defined

minimum and maximum limits (see

chapter "7.8.7 for SETUP of user

defined limits"). The full height of the

bar graph is proportional to the internal

Setpoint (green line)

sensor range. The green line indicates

the magnitude of the setpoint. The blue

column indicates the magnitude of the

current pressure. The cross hatched

section indicates the portion of the

internal sensor range

internal sensor above or below the user

defined limits that is not being used.

User defined limits

Current pressure

7.8 SETUP Menus

The SETUP menus are opened by pressing the [SETUP] key. This opens the menu

shown in "Figure - SETUP". The SETUP menu has five tabs: [DISPLAY], [CONTROL],

[REMOTE]

, [INFO] and [SERVICE]. Each tab is described in detail in the following chapters.

The screen below has the [DISPLAY] tab active.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 31

Figure - SETUP

Page 32

Pneumatic High-Speed Pressure Controller CPC3000

7.8.1 SETUP Display

The MAIN -> SETUP -> DISPLAY menu contains elements that change the appearance

and function of components displayed on the main menu. Following is a description of the

elements of this menu.

Filter: The filter selection keys [LOW], [NORMAL], and [HIGH] dampen the pressure

display to reduce the affect of pneumatic noise associated with the device under test or the

test environment.

Resolution: The resolution section of the SETUP Display menus allows the user to change

the resolution of the current pressure reading to be [4], [5] or [6] digits.

Stable Window and Delay: The stable window is the percentage of the full scale value

of the internal sensor that the current pressure can deviate (+/-) from the setpoint and still

display a stable indication. The stable delay is the number of seconds that the instrument

must remain within the stable window before the stable indication is displayed.

Language: The "VIEW" section of the SETUP display menu shows a flag, a country and a

language on a key. This is the current language. Press this key to access a menu containing

other languages that are available. "Figure - Languages" below shows the language selection screen.

Figure - Languages

Remote Status Checkbox: The Remote status check box enables or disables the remote

status icon on the main menu. This icon will show a broken wire when there is no connection to a remote computer or a connected wire if the computer is connected.

Barometer (optional): The Barometer check box enables or disables the indication of the

barometric pressure on the main menu.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.132

11498171.01 08/2009 GB

Page 33

Pneumatic High-Speed Pressure Controller CPC3000

7.8.2 SETUP Control

Configuration of parameters associated with setting limits and adjusting parameters used

to control pressure are configured in the MAIN -> [SETUP] -> [CONTROL] menu shown in

"Figure - SETUP Control".

Figure - SETUP Control

Maximum and Minimum Control Limits: The [DATA ENTRY] keys next to the [MINIMUM]

and [MAXIMUM] labels in "Figure - SETUP Control" allow the operator to select any

range within the full scale range of the internal sensor. This is the "user defined range". For

example: if the CPC3000 has a 0-5 bar internal sensor, the user can define a range of 0-4

bar. When the user defined range is changed, a corresponding change occurs in the STEP

menu so that the percent STEP will equal the corresponding value within the user defined

range. For example: the 80 % value of a 0-4 bar user defined range will be 3.2 bar but for a

user defined range of 0-2 the 80 % value equals 1.6 bar. The user defined range can be

set to the same range as the pressure device being tested. This useful when there is

a test that requires calibration at intervals equal to a percentage of the range. Each

individual step can also be changed by pressing the [STEP] key and entering a

new value.

Bar or %FS: The [SELECTED UNITS] and [%FS] keys switch the

STEP keypad display in the main menu and on the SETUP screen from the user selected

units to percent of the full scale of the user defined range. The values when shown in the

[SELECTED UNITS] mode correspond to the values in the [%FS] mode. For example, in

"Figure - PSI Mode", the [PSI] key is pressed

and the value shown in the 100 % step is

4.0000 corresponding to the maximum limit

chosen in this same screen.

Individual steps in %FS or selected units

mode can be included or excluded from the

step menu by changing the [Check Box]

next to the STEP.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 33

Figure - "PSI Mode"

Page 34

Pneumatic High-Speed Pressure Controller CPC3000

[Preset Points] allows the operator to select the number of points that appear as steps.

For example: in "Figure - preset points" [5] is entered as the preset points value, this

automatically configures 5 points from 0 to 100 % of user defined range. It automatically

calculates the steps that populate the STEP keypad in the main menu.

Figure - Preset Points

7.8.3 SETUP Remote

Configuration of parameters associated with remote communication are set up in the

MAIN -> [SETUP] -> [REMOTE] screen. Detailed information on SETUP of Ethernet USB and

IEEE-488 are given in chapter 8. "Remote Operation".

Figure - SETUP Remote

The ethernet SETUP key opens a dialog box where host name, IP, netmask, gateway,

port, and client IP can be entered. There is also a check box that will activate (checked) or

deactivate (unchecked) Dynamic Host Configuration Protocol (DHCP). DHCP is a protocol

used by networked devices (clients) to obtain the parameters necessary for operation in an

Internet Protocol network. This protocol reduces system administration workload, allowing

devices to be added to the network with little or no manual configuration.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.134

11498171.01 08/2009 GB

Page 35

Pneumatic High-Speed Pressure Controller CPC3000

The USB SETUP key opens a dialog box where baud rate (9600, 19200, 38400, 57600, or

115200), data bit (7 or 6), stop bit (1 or 2), parity (none, odd or even) can be chosen. There

is also a check box that turns echo on (checked) or off (unchecked).

The IEEE address data entry button when pressed will open a data entry dialog box where

the IEEE address can be entered.

In the Communication section there are three remote command set emulation settings. The

[MENSOR] key enables the standard mensor command set, the [SCPI WIKA] key enables

the WIKA SCPI (Standard Commands for Programmable Instrumentation) command set

structure, and the [DPI510] key enables the command set that will communicate with the

Druck DPI 500 series of controllers. In this section there is also a [REMOTE MONITOR]

key that will open a screen that shows the most recent commands and responses sent and

received plus any errors. Details of each command set are given in chapter 8.5.

7.8.4 SETUP Info

The MAIN -> [SETUP] -> [INFO] screen, "Figure - SETUP info", provides MENSOR contact

information plus the Model number, serial number, min and max range and the native pressure

units of the internal sensor, date of calibration and the software version installed. This is an

information screen only and does not contain any interactive keys.

Figure - SETUP Info

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 35

Page 36

Pneumatic High-Speed Pressure Controller CPC3000

7.8.5 SETUP Service

The SETUP service screen is a password protected area where calibration of the sensor and

SETUP of the regulator is acomplished.

Figure - SETUP Service

The SETUP service screen allows zero adjustment without entering the password. A zero

adjustment screen, "Figure - Zero", opens when the [ZERO] button is pressed. A new zero

value can be entered in this screen.

Figure - Zero

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.136

Page 37

Pneumatic High-Speed Pressure Controller CPC3000

To access the password protected portion of the SETUP service screen press the key.

This opens a password entry screen, "Figure - Password", where the password can be

entered. Entering the password will open the SETUP service screen, "Figure - SETUP Service

Unlocked", and allow access to all the SETUP options.

Figure - Password

Figure - SETUP Service Unlocked

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 37

Page 38

Pneumatic High-Speed Pressure Controller CPC3000

After the password has been entered the SETUP Service screen allows access to the

Calibrate, Seal Point, Linerize, and Adaptation screens.

Consult factory before changing any Seal Point, Linerization or Adaptation

parameters.

Warning

Press the [CALIBRATE] key to access the calibrate screen, "Figure - Calibrate Data".

Figure - Calibrate Data

The Calibrate screen contains three tabs: DATA, EDIT AND CALIBRATE. When entering the

calibrate screen the first time the Data Screen is the default. The Data screen allows changes

to be made to the Zero, Span, Date of calibration and displays the sensor reading.

The screen accessed by pressing the [EDIT] Tab, "Figure - Calibration Edit", allows calibra-

tion using data available from a previous calibration. An example of this is when an As-Found

calibration is performed and the applied and measured pressures from the calibration are

available. The low true pressure should be less than 20 %FS and the high true pressure

should be greater than 80 %FS for best results. To edit the calibration from known data, enter

the applied pressures in the Desired column and the measured pressures in the Actual column

by pressing the number to be adjusted. When the values are changed, a new key “APPLY” will

appear on the screen. Press the Apply key to save the calibration data.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.138

Page 39

Pneumatic High-Speed Pressure Controller CPC3000

Figure - Calibrate Edit

The Screen accessed by pressing the [CALIBRATE] tab, "Figure - Calibrate Calibrate", allows

the operator to perform a live calibration while connected directly to a primary standard. In

this mode, the CPC3000 will display the currently measured pressure in the Actual column

when the measured pressure is within a few percent of the value in the Desired column. The

Desired column allows the actual pressures applied to the CPC3000 to be entered. Press the

Apply key to save changes. For best results, the two points should be as near the endpoints

of the sensor’s calibration as possible. When calibrating an absolute transducer, set the low

calibration point at or above a pressure of 0.4 mbar. At or above that pressure the system

will have a viscous flow so that the entire system should have the same pressures after a few

minutes.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 39

Figure - Calibrate Calibrate

Page 40

Pneumatic High-Speed Pressure Controller CPC3000

8. Remote Operation

When the instrument is turned on, BIOS routines test the system CPU board. These tests may

take up to 60 seconds. After the BIOS tests, LINUX is loaded. LINUX will then call the executable file. The executable file will go through a series of software and hardware initialization.

The following hardware/software is initialised:

8.1 Remote SETUP

To SETUP any of the remote communication protocols start in the SETUP remote screen,

"Figure - Remote SETUP".

Figure - Remote SETUP

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.140

Page 41

Pneumatic High-Speed Pressure Controller CPC3000

8.2 Remote SETUP – Ethernet

The Ethernet communication port allows the CPC3000 to communicate with computers using

10/100 Bases-T specification. Ethernet communications are transmitted over a standard

RJ-45 cable. Connecting directly to a PC requires a crossover Ethernet cable. Hub or router

connections require a straight Ethernet cable.

Before using Ethernet communication, four parameters must be set up: IP, Netmask, Gateway

and Port. In "Figure - Ethernet SETUP" the Ethernet SETUP screen is shown. Each value entry

key opens an alpha or numeric data entry screen to change values of the Ethernet parameters.

Figure - Ethernet SETUP

8.3 Remote SETUP – USB

The USB communication port allows the CPC3000 to communicate with computers using a

USB cable. The connection on the back panel of the CPC3000 is a Type B receptical.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 41

Figure - USB SETUP

Page 42

Pneumatic High-Speed Pressure Controller CPC3000

8.4 Remote SETUP – IEEE-488

The IEEE-488 communication port allows the CPC3000 to communicate with computers

using an IEEE-488 cable. This screen, "Figure - IEEE-488 Address", is accessed by pressing the IEEE-488 numeric value box in the SETUP Remote screen. After pressing the numeric

value box a number entry keypad will appear for entering the new IEEE-488 address. The

manufacturer of the host IEEE-488 interface board provides software to allow communication

between the board and various programming languages. An interactive program for debugging is usually provided as well. Refer to the board manufacturer’s documentation for more

information.

Figure - IEEE-488 Address

8.5 Remote Command Set

This remote command set is the default set available on the CPC3000. All CPC3000 remote

operation commands are included in the lists below. All commands must be terminated with a

<CR> or a <LF>.

For a query command (ends with a ?), the data column represents the response of the

CPC3000. All response strings begin with a space character or an “E” representing that there

is an error in the CPC3000 error queue. All response strings are terminated with a <CR> and a

<LF>. The error queue holds the last 10 errors identified by the CPC3000.

For all commands without a question mark (?), the data column represents the required

parameters to be sent to the CPC3000 following the string in the command column. For any

command that requires multiple parameters to be sent to the CPC3000, the parameters must

be separated by commas.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.142

Page 43

Pneumatic High-Speed Pressure Controller CPC3000

8.5.1 Mensor Command Set

Command Data Response/Function

? See Table Below Returns data per the current output

Acquire? 15 char string.

Address 0-31 Sets the GPIB Address.

Address? <sp> xx <cr><lf> Returns the GPIB Address.

A? <sp>n.nnnnne+nn<cr><lf> Returns the A channel pressure

AR? <sp>n.nnnnne+nn<cr><lf> Returns the A channel rate.

ARS? <sp>(Yes or No)<cr><lf> Returns the A channel rate stable flag.

AS? <sp>(Yes or No)<cr><lf> Returns the A channel stable flag.

Autorange On or Off Sets whether the auto range function is

Autorange? <sp>(on or off)<cr><lf> Returns whether the autorange

Baro? <sp>n.nnnnne+nn<cr><lf> Returns reading from barometric

Caldisable Yes,no Sets whether or not calibration of the

Caldisable? <sp>(Yes or No)<cr><lf> Returns whether or not calibration of

Cerr None Clears the error queue.

CID? Returns the ID string of the regulator

Cmdset Mensor, DPI510, DPR60c, SCPI Activates remote command set for

Cmdset? <sp>X<cr><lf> Returns active command set identifier.

Control Instrument placed in Control Mode.

Control? <sp>(yes or no)<cr><lf> Returns Yes if instrument is in control,

Crate Slow, Medium, Fast Sets the control rate.

Crate? <sp>CCCC<cr><lf> Returns the control rate – CCCC is

Ctype? <sp>HPSVR<cr><lf> Returns the type of regulator for the

11498171.01 08/2009 GB

Ex:

Acquire? Test_stand_1

Returns:

<sp>(Yes or No), CCC…

CCC<cr><lf>

format.

This command is used when multiple

computers would like to control the

instrument.

Yes if acquisition is successful, No if

instrument is being controlled with

another

computer.

CCC… = name of controlling computer

See: Release? and Unlock

reading.

enabled or disabled.

function is enabled or disabled.

sensor.

active sensor is disabled.

the active sensor is disabled.

for the active channel.

instrument emulation modes.

No if otherwise.

variable in length and corresponds

to the parameters for the CRATE

command.

active channel.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 43

Page 44

Pneumatic High-Speed Pressure Controller CPC3000

Command Data Response/Function

Decpt? <sp>n<cr><lf> Returns the number of decimal points

for the active channel. (see Resolution)

Default None Sets the default values.

DHCP Reserved for DHCP SETUP

DHCP? Reserved for DHCP SETUP

DIO Integer 2 turns on digital output, 0 turns it off.

DIO? Bit0 = input, bit1 = output

DOC mm/dd/yyyy Sets the date of cal for the active

sensor and turndown.

DOC? <sp>mmddyy<cr><lf> Returns the date of cal for the active

sensor and turndown.

DOM? <sp> mm/dd/yyyy<cr><lf> Returns the date of manufacture.

DUTLABEL Reserved for DUT option

DUTLABEL? Reserved for DUT option

DUTTYPE Reserved for DUT option

DUTTYPE? Reserved for DUT option

DUTAMIN Reserved for DUT option

DUTAMIN? Reserved for DUT option

DUTAMAX Reserved for DUT option

DUTAMAX? Reserved for DUT option

DUTLOOP Reserved for DUT option

Error? <sp> text message <cr><lf> Returns the next error in the error

queue.

Errorno? <sp>Enn-text<cr><lf> Returns pcs400 error code and text.

Filter Off, Low, Normal, High Sets the reading filter 0, 80 %, 92 %,

95 %.

Filter? <sp> (filter)<cr><lf> Returns the reading filter.

Gasdensity Value in lb/cuft Sets the head pressure gas density in

lb/cuft.

Gasdensity? <sp>n.nnnnne+nn<cr><lf> Returns the head pressure gas density.

Gastemp Value in degrees F

Gastemp? <sp>n.nnnnne+nn<cr><lf> Returns the head pressure gas temper-

Gateway nnn.nnn.nnn.nnn Sets the Ethernet gateway address.

Gateway? <sp>nnn.nnn.nnn.nnn<cr><lf> Returns the Ethernet gateway address.

Height Value in inches Sets the head pressure height in

Height? <sp>n.nnnnne+nn<cr><lf> Returns the head pressure height.

Id? <sp> MENSOR, CPC3000,

ssssss,v.v.vv

Install Start software installer.

IP nnn.nnn.nnn.nnn Sets the IP address of the instrument.

Sets the head pressure gas temperature

in degrees F.

ature.

inches.

Ssssss is the serial number, v.vv is the

CPC3000 software version.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.144

Page 45

Pneumatic High-Speed Pressure Controller CPC3000

Command Data Response/Function

IP? <sp>nnn.nnn.nnn.nnn<cr><lf> Returns the IP address of the instru-

Keylock Yes or No Locks or unlocks keyboard.

Keylock? <sp>(Yes or No)<cr><lf> Returns Yes or No.

List? <sp>Pri,X,X;Sec,X,X;Bar,1<cr><lf> Returns list of available turn-downs on

Listrange? PRI,1, min,max,2, min, max;SEC,1,

Localgravity Value in ft/s² Sets the local gravity in feet/sec².

Localgravity? <sp>n.nnnnne+nn<cr><lf> Returns the local gravity in feet/sec².

LowerLimit Value inside primary xducer Range

LowerLimit? <sp>xxxxxxx<cr><lf> Returns the lower control limit for the

Measure None Instrument placed in Measure Mode.

Measure? <sp>(Yes or No)<cr><lf> Returns YES if instrument is in

Netmask nnn.nnn.nnn.nnn Sets the Ethernet network mask.

Netmask? <sp>nnn.nnn.nnn.nnn<cr><lf> Returns the Ethernet network mask.

Outform 1 to 8 – see table below Sets the output format.

Outform? <sp>X<cr><lf> Returns the output format – see table

Peakmax? <sp>n.nnnnne+nn<cr><lf> Returns the maximum pressure since

Peakmin? <sp>n.nnnnne+nn<cr><lf> Returns the minimum pressure since

Peakreset None Resets the peak values.

Port nnnnnn Sets the Ethernet port of the instru-

Port? <sp>nnnnn<cr><lf> Returns the Ethernet port of the instru-

Ptype Absolute or Gauge Sets the instrument pressure type

Ptype? <sp>CCCCC<cr><lf> Returns “Absolute” or “Gauge” for the

RangeMax? <sp>XXXXXXX<cr><lf> Returns the maximum range of the

RangeMin? <sp>XXXXXXX<cr><lf> Returns the minimum range of the

Rate? <sp>XXXXXXX<cr><lf> Returns the rate reading of the instru-

11498171.01 08/2009 GB

min,max,2, min,max,Bar,min,max

on turndown #1 in current units.

ment.

installed sensors in the active channel.

X will be non-existent if the turndown

isn’t available.

Returns the ranges of the installed

sensors for the active channel.

Sets the lower control limit for the

instrument.

instrument in current units.

measure, No if otherwise.

below

peakreset was sent.

peakreset was sent.

ment

ment

– gauge only works if the optional

barometric sensor is installed

pressure type

active transducer and turndown in the

current units.

active transducer and turndown in the

current units.

ment in current units/second.

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.1 45

Page 46

Pneumatic High-Speed Pressure Controller CPC3000

Command Data Response/Function

Rdecpt? <sp>n<cr><lf> Returns the number of rate decimal

points for the active channel. (see

Resolution)

Release? 15 char string.

Ex:

Release? Test_stand_1

Returns:

<sp>(Yes or No), CCC…

CCCcr><lf>

Resolution n Sets the number of significant digits.

Resolution? <sp>n<cr><lf> Returns the number of significant

Rfilter Value in % Sets the % of the rate filter

Rfilter? <sp>n.nnnnne+nn<cr><lf> Returns the rate filter.

Rsetpt Value in current units Sets the rate setpoint

Rsetpt? <sp>n.nnnnne+nn<cr><lf> Returns the rate setpoint

Rfreq Value in frequency Sets rate Butterworth corner frequency.

Rfreq? <sp>n.nnnnne+nn<cr><lf> Returns rate Butterworth corner

Rwindow Value in current units Sets rate exponential filter window.

Rwindow? <sp>n.nnnnne+nn<cr><lf> Returns rate exponential filter window.

Sbaud 9600, 19200, 38400, 57600 Sets the serial baud rate.

Sbaud? <sp>XXXX<cr><lf> Returns the serial baud data.

Sdata 7 or 8 Sets the serial data bits.

Sdata? <sp>X<cr><lf> Returns the serial data bits number.

Sensor C, X Sets the active sensor where C =

Sensor? <sp>C,X<cr><lf> Returns active sensor as above.

Sensorid? <sp>Mensor QRS,SN XXXXXX,VER

V.VV

Setpt value inside upper and lower limits

and inside the range of the active

sensor and turndown.

Setpt? <sp>XXXXXXX<cr><lf> Returns the control setpoint in current

Setpt% Value in % of current range Sets the control setpoint in % of

Setptpct Value in % of current range Sets the control setpoint in % of

Setptpct? <sp>n.nnnnne+nn<cr><lf> Returns the current setpoint in % of

This command is used to release

control of the instrument in a multiple

computer environment.

Yes if release is successful.

No if instrument is being controlled

with another computer.

CCC… = name of controlling computer

or AVAILABLE

See: Acquire? and Unlock

See decpt.

digits. See decpt.

frequency.

Primary or Secondary and X is the

turndown.

Returns the active sensor’s serial

number and firmware version.

Sets the control setpoint for the instru-

ment.

units.

current range.

current range.

current range.

11498171.01 08/2009 GB

WIKA Operating Instruction Pneumatic High-Speed Pressure Controller ∙ Version 1.146

Page 47

Pneumatic High-Speed Pressure Controller CPC3000

Command Data Response/Function

Span desired pressure or ? Sets span on active transducer or for

Span? <sp>XXXXXXX<cr><lf> Returns span scale factor for active

Sparity Even, Odd, None Sets the serial parity.

Sparity? <sp>CCCC<cr><lf> Returns the serial parity.

Sstop 1 or 2 Sets the serial stop bits.

Sstop? <sp>X<cr><lf> Returns the serial stop bits.

Stable? <sp>(Yes or No)<cr><lf> Returns YES if instrument is stable, or

Stabledelay 0 to 65535 Sets the stable time to the number of

Stabledelay? <sp>XXXXXXX<cr><lf> Returns the stable time.

stabletime 0 to 65535 Sets the stable time to the number of

Stabletime? <sp>XXXXXXX<cr><lf> Returns the stable time.

StableWin %fs value Sets the stable window as a %FS for

StableWin? <sp>XX<cr><lf> Returns the stable window.