Page 1

Operating Instructions

Betriebsanleitung

Mode d'emploi

Manual de Instrucciones

Portable low-pressure controller, model CPC2000

Portabler Niederdruckcontroller, Typ CPC2000

Contrôleur basse pression portable, type CPC2000

Controlador portátil de bajas presiones, modelo CPC2000

GB

D

F

E

Portable low-pressure controller model CPC2000

Page 2

Operating instructions model CPC2000 Page 3 - 34

GB

Betriebsanleitung Typ CPC2000 Seite 35 - 66

D

Mode d'emploi type CPC2000 Page 67 - 98

F

Manual de instrucciones modelo CPC2000 Página 99 - 130

E

© 2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

2.1 Intended use 6

2.2 Personnel qualication 6

2.3 Special hazards 7

2.4 Labelling/Safety marks 8

3. Specications 9

4. Design and function 12

4.1 Short description 12

4.2 Scope of delivery 12

4.3 Electrical connections on the rear 12

4.4 Voltage supply 13

4.5 Front display of the CPC2000 13

4.6 Pressure connections 15

4.7 Overpressure protection 15

5. Transport, packaging and storage 16

6. Commissioning, operation 17

6.1 Operating mode 'Control' (CTRL) 17

6.2 Operating mode 'Measure' (MEAS) 18

6.3 Operating mode 'AUTO' 20

6.4 Leakage (LEAK) 22

6.5 SETUP settings (SETUP) 23

7. Interface 25

7.1 USB interface 25

7.2 RS-232 Interface 25

7.3 Interface conguration 25

7.4 Commands for serial interface 26

7.5 Driver 28

8. Maintenance, cleaning and service (recalibration) 29

9. Faults 30

10. Dismounting, return and disposal 30

11. Accessories 32

Appendix 1: EC Declaration of Conformity for model CPC2000 33

GB

Declarations of conformity can be found online at www.wika.com.

11155094.02 07/2012 GB/D/F/E

3WIKA operating instructions, model CPC2000

Page 4

1. General information

1. General information

■

The low-pressure controller described in the operating instructions has been designed

GB

and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer’s liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 27.51

- Application consultant:

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-mail: testequip@wika.com

4 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 5

1. General information / 2. Safety

Explanation of symbols

DANGER!

... indicates a directly dangerous situation resulting in serious injury or

death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

GB

DANGER!

...identies hazards caused by electric power. Should the safety instructions not be observed, there is a risk of serious or fatal injury.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate portable low-pressure controller has been selected in terms of measuring range, design and specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

Further important safety instructions can be found in the individual

chapters of these operating instructions.

11155094.02 07/2012 GB/D/F/E

5WIKA operating instructions, model CPC2000

Page 6

2. Safety

2.1 Intended use

The model CPC2000 low-pressure controller is used for testing and calibrating pressure

sensors.

GB

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to

equipment.

■

The activities described in these operating instructions may only

be carried out by skilled personnel who have the qualications

described below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

6 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 7

2. Safety

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Special hazards

WARNING!

Protection from electrostatic discharge (ESD) required.

The proper use of grounded work surfaces and personal wrist straps is

required when working with exposed circuitry (printed circuit boards),

in order to prevent static discharge from damaging sensitive electronic

components.

To ensure safe working on the instrument, the operating company must

ensure

■

that suitable rst-aid equipment is available and aid is provided

whenever required.

■

that the operating personnel are regularly instructed in all topics

regarding work safety, rst aid and environmental protection and

knows the operating instructions and, in particular, the safety instructions contained therein.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

Operation using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) can result in life-threatening voltages at the instrument!

GB

WARNING!

Residual media on the dismounted low-pressure controller can result

in a risk to persons, the environment and the equipment. Take sucient

precautionary measures.

Do not use this instrument in safety or Emergency Stop devices. Incorrect use of the instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature and under high pressure or vacuum may be present at the instrument.

P

max

11155094.02 07/2012 GB/D/F/E

= 1 bar atmospheric pressure

7WIKA operating instructions, model CPC2000

Page 8

2. Safety

2.4 Labelling/Safety marks

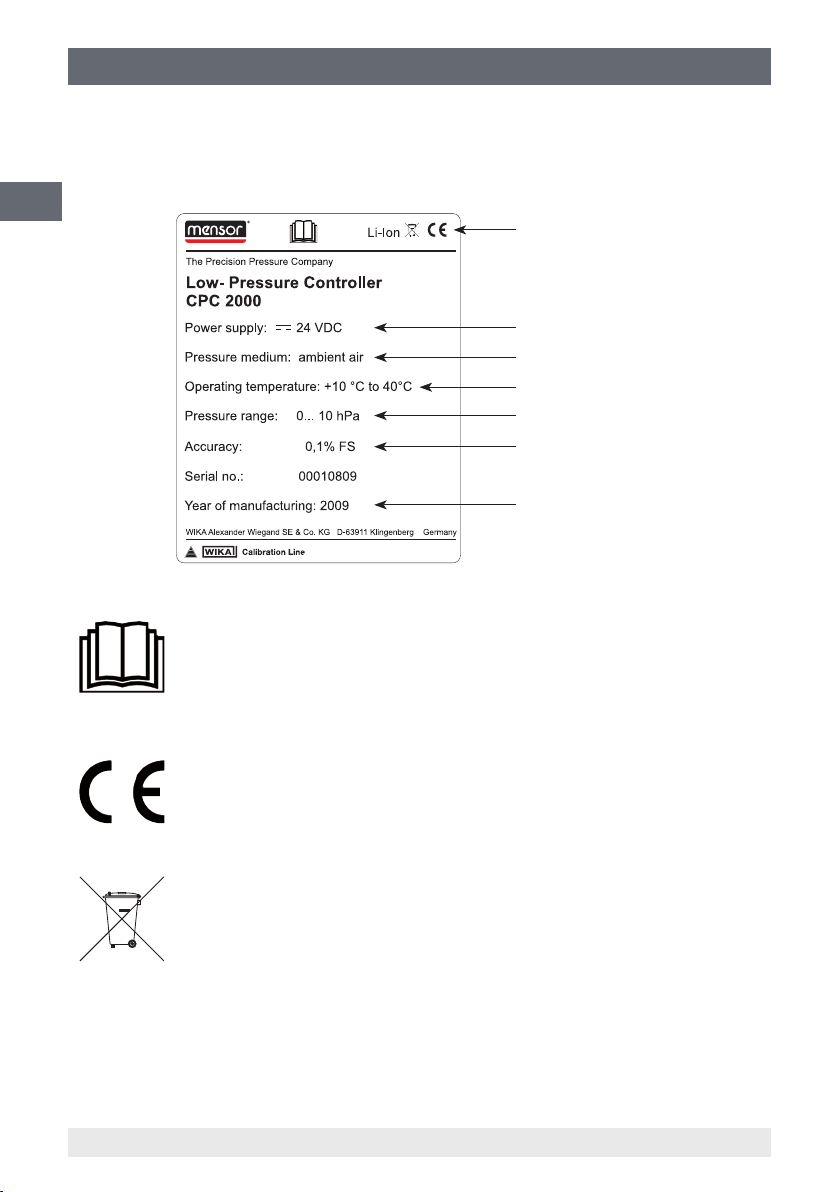

2.4.1 Product label

GB

2.4.2 Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

For an explanation of symbols,

see below

Power supply

Pressure medium

Operating temperature

Pressure range

Accuracy

Year of manufacture

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

This marking on the instruments indicates that they must not be disposed

of in domestic waste. The disposal is carried out by return to the manufacturer or by the corresponding municipal authorities (see directive 2002/96/

EC).

8 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 9

3. Specications

3. Specications

Reference pressure sensors

Pressure range mbar 1 10 50 100 500 1,000

Accuracy % FS 0.3 0.1 0.1 0.1 0.1 0.1

Type of pressure Positive or negative gauge pressure or dierential pressure

Pressure units Pa, kPa, hPa, bar, mbar, psi, inH

O, inHg, mmHg, Torr

2

Base instrument

Instrument

Instrument version desktop instrument with carry handle

Dimensions 102.6 x 257 x 271 mm without carry handle

Weight 4.6 kg

Ingress protection IP 20

Pressure generation internal, electric pump

Display

Screen backlit, multiline graphic display

Resolution 5 (4 digits for 50/500 mbar measuring range)

Keyboard Membrane keypad

Menu language German, English, Spanish and French

Connections

Pressure connections 6.6 x 11 (hose diameter, D = 6 mm)

Wetted parts Ni, Al, CuBe, PU

Voltage supply

Power supply DC 24 V, 1 A

Power consumption 24 VA

Battery type Li-Ion

Battery life approx. 8 h

Permissible ambient conditions

Media Ambient air

Operating temperature 10 ... 40 °C

Storage temperature -10 ... +70 °C

Relative humidity 30 ... 80 % r. h. (non-condensing)

GB

11155094.02 07/2012 GB/D/F/E

9WIKA operating instructions, model CPC2000

Page 10

3. Specications

Base instrument

Control parameter

GB

Control steps 0 ... 50 % individually adjustable or 100 %

Control rate approx. 5 s (dependent upon test volume)

Communication

Interface RS-232 and USB

Response time 1 value/s

Zero point adjustment automatic (at denable time intervals)

manual (ZERO button)

Approvals and certicates

CE conformity

EMC directive 2004/108/EC, EN 61000-6-3, emissions for residential, commer-

Certicate

Calibration

1) Calibration in a horizontal position.

1)

cial and light-industrial environments and EN 61000-6-2, interference immunity for industrial environments

incl. 3.1 calibration certicate per EN 10204

For further specications see WIKA data sheet CT 27.51 and the order documentation.

10 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 11

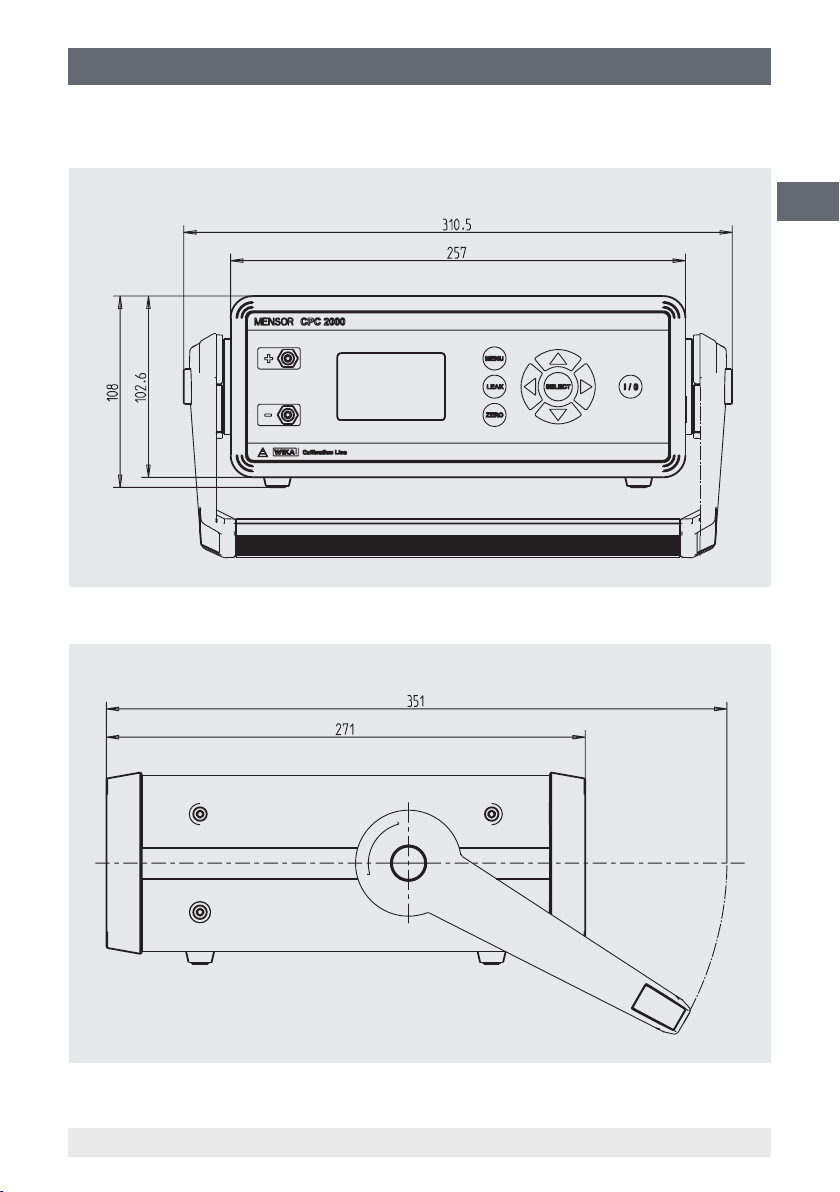

3. Specications

Dimensions in mm

Front view

Side view

GB

11155094.02 07/2012 GB/D/F/E

11WIKA operating instructions, model CPC2000

Page 12

4. Design and function

4. Design and function

4.1 Short description

GB

The microprocessor controlled CPC2000 low-pressure controller is used for the

■

simple generation of positive and negative reference pressures.

■

pressure measurement of positive and negative pressures.

■

dierential pressure measurement.

■

identication of leaks in test samples.

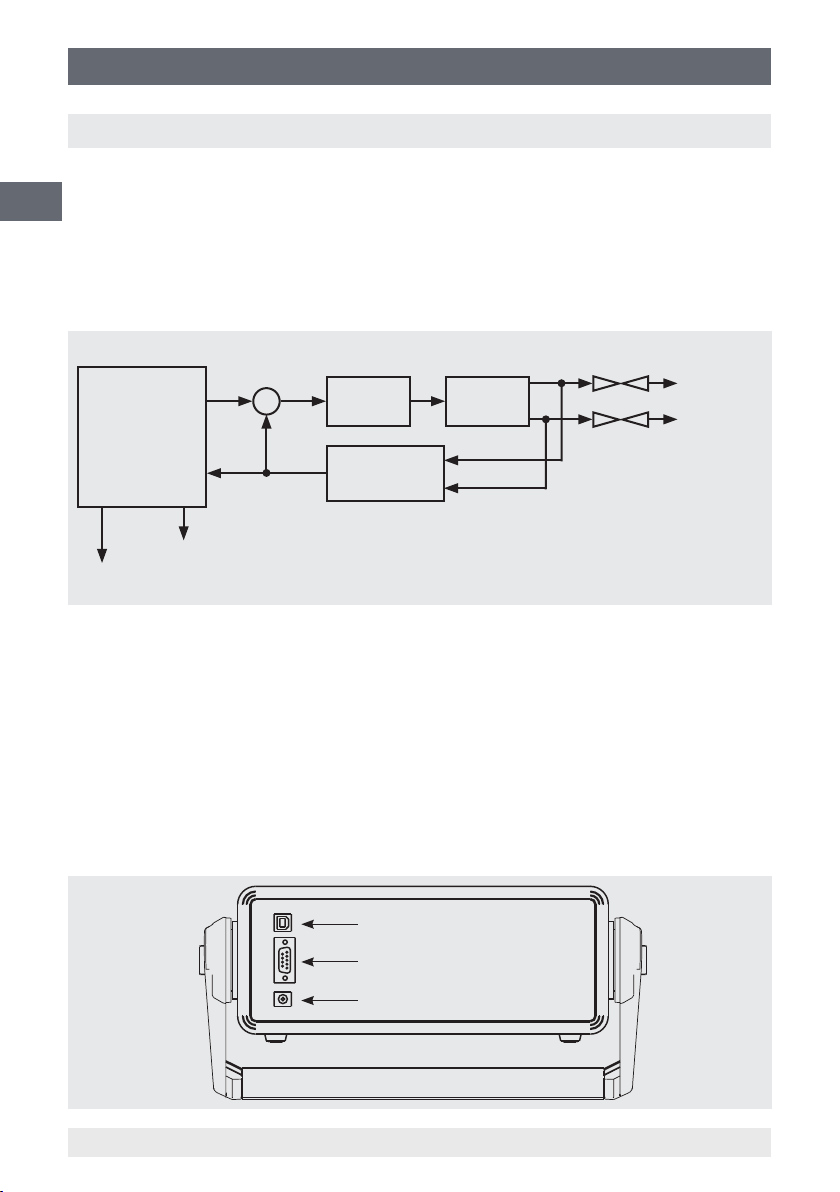

Microprocessor

Actual pressure

value

Pressure value

RS-232 PC interface

Display

USB interface

Set-actual value

comparison

Controller

Measuring

pressure

Pump

-

+

Valves

4.2 Scope of delivery

■

Model CPC2000 portable low-pressure controller

■

Power supply unit

■

Operating instructions

■

3.1 calibration certicate per DIN EN 10204 (optional DKD/DAkkS certicate)

Cross-check scope of delivery with delivery note.

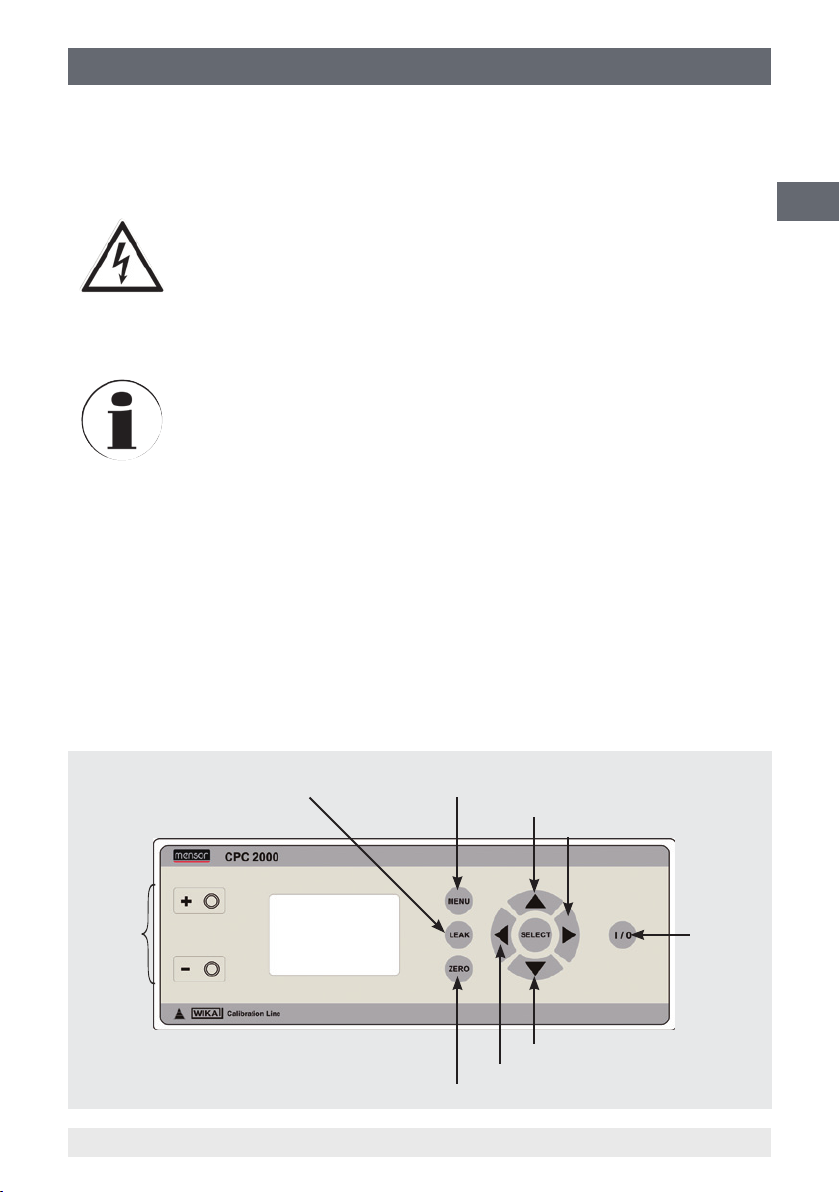

4.3 Electrical connections on the rear

USB Interface

neg. pressure

pos. pressure

RS-232 Interface

Connection for power supply unit

12 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 13

4. Design and function

4.4 Voltage supply

The low-pressure controller is factory set for connection to a voltage supply of DC 24 V.

The power supply connector is located on the rear panel.

DANGER!

Electric shock hazard! Before removing the fuse, the power supply must

be removed from the plug.

Operation using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) can result in life-threatening voltages at the instrument!

Only the original power supply unit included in initial delivery (Mascot

model 9926) should be used.

1. Design the wiring particularly carefully when connecting to other devices. Under

certain circumstances, internal connections in third-party devices (e.g. GND connected to the ground) can lead to impermissible voltages that could compromise or even

destroy the function of the device itself or a device connected to it.

2. The mains plug must always be plugged in to a mains socket and be accessible, so

that one can always remove it from the mains socket without diculty.

GB

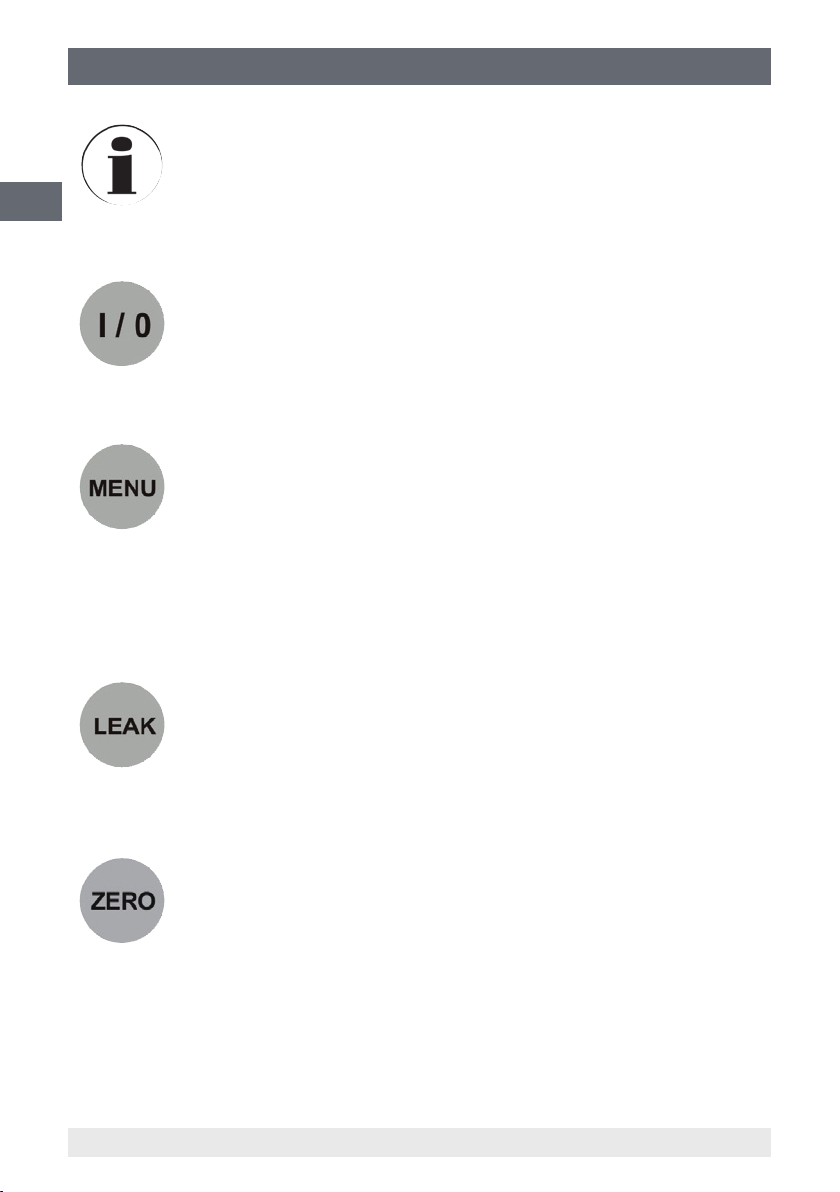

4.5 Front display of the CPC2000

In control mode: Starts the leak measurement, otherwise without function

Pressure

connections

11155094.02 07/2012 GB/D/F/E

During the control process → Vent

otherwise, selects SETUP

Increase set point by x %

Increase set point to 100 %

ON/OFF

button

decrease set point by x %

Set set point to 0 %

Zero point adjustment

13WIKA operating instructions, model CPC2000

Page 14

4. Design and function

The front screen of the display, behind the membrane, is made from

glass. If there is any possibility of the window breaking during operation

(including damage to the front membrane), all personnel in the vicinity of

GB

4.5.1 On/O button

4.5.2 Menu button

The SETUP menu items are made up of six submenu items. For a detailed description of

these items, see chapter 6.5 „SETUP settings (SETUP)“.

the instrument must wear eye protection before and during its use.

Button to turn the instrument on and o.

With this button the SETUP menu can be accessed, and there the

settings for each operating mode can be made. When the CTRL mode

is used, you will nd that the device is left in VENT mode on leaving the

SETUP menu.

4.5.3 LEAK button

With the LEAK button, a device connected to the controller can be

tested for leaks. (This feature is only available in CONTROL mode.)

4.5.4 ZERO button

Button for manually correcting the zero point of the integrated sensor.

External inuences such as temperature, pressure, mounting position or

surroundings, can alter the zero point of the instrument, i.e. the display

when the pressure ports are open. During zero adjustment, the device

automatically detects these changes and corrects them in the current

pressure display. The zero point adjustment requires a change of the

internal valves, which is not possible without loss of pressure.

(If this should interfere with the application, the automatic zero point

adjustment can be switched o.)

14 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 15

4. Design and function

4.6 Pressure connections

■

Dierential pressure instruments are connected to the j and the i connections of the

instrument.

■

Relative pressure instruments are connected to the j connection (i connection is

open to atmosphere).

■

Instruments for negative gauge pressure are connected to the i connection

j

(

connection is open to atmosphere).

Only connect test and calibration installations once the system has been

depressurised!

Never perform functional tests with compressed or medical air. This can

damage instruments with low pressure ranges.

The connection to the low-pressure controller is made via a 6.6 x 11 mm pressure connection.

The hose diameter should be 6 mm.

4.7 Overpressure protection

The maximum permissible pressure must not be exceeded:

Pressure range Oberload

GB

1 mbar 5 times overload

10 mbar 5 times overload

50 mbar 5 times overload

100 mbar 5 times overload

500 mbar 2 times overload

1,000 mbar 2 times overload

11155094.02 07/2012 GB/D/F/E

15WIKA operating instructions, model CPC2000

Page 16

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

GB

Check low-pressure controller for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -10 ... +70 °C

■

Humidity: 30 ... 80 % r. h. (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the low-pressure controller in its original packaging in a location that fulls the

conditions listed above. If the original packaging is not available, pack and store the

instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

4. Do not storage the instrument with the pressure connections closed! Barometric

pressure changes can damage instruments with low pressure ranges.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to

health, e.g. caustic, toxic, carcinogenic, radioactive, etc..

16 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 17

6. Commissioning, operation

6. Commissioning, operation

Never perform functional tests with compressed or medical air. This can

damage instruments with low pressure ranges.

Protect the instrument from sunlight, as this can lead to measuring

errors.

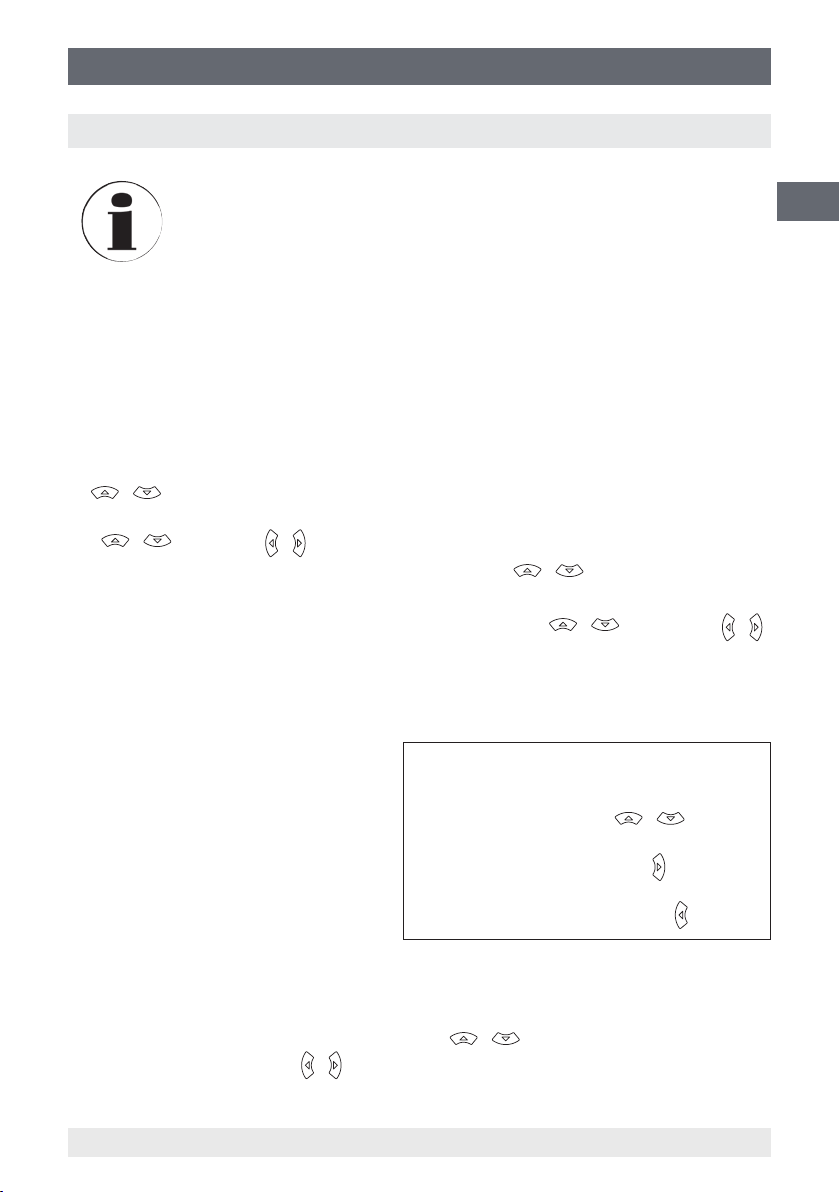

6.1 Operating mode 'Control' (CTRL)

The CTRL mode is used for the calibration of pressure sensors and other pressure

instruments. In CTRL mode, the pump is active and regulates according to the desired

pressure. The internal sensor provides the current value on the display.

Setting

■

Press the MENU button. Conrm the menu point MODE with SELECT and press the

/ button until CTRL appears. Conrm with SELECT.

■

In the submenu RANGE the upper limits of the pressure range are dened

(

/ button and / buttons) and conrmed with SELECT

■

In the submenu UNIT the pressure units are dened ( / buttons) and conrmed

with SELECT .

■

In the submenu STEP the step sequence in % is dened ( / buttons and /

buttons), conrmed with SELECT.

■

With the MENU button, you can exit the submenu

GB

Operation

The instrument will revert to VENT mode

on exiting the menus, meaning the

Change set point by x %

sensor of the calibrator will be vented. In

the top centre of the display, the set point

Pressure change in % via

of the pressure range will be displayed.

In the bottom centre of the display, the

Change pressure to 100 % via

percentage value can be read. On exiting

the menus, this value will be 0 %. With

Change pressure back to 0 % via

the SELECT button, one can switch

between the set pressure value and the

percentage value.

■

The percentage value can be altered with the / buttons (in the dened step

sizes) and altered with the

11155094.02 07/2012 GB/D/F/E

/

buttons.

/ buttons

button

button

17WIKA operating instructions, model CPC2000

Page 18

6. Commissioning, operation

■

The set pressure demand can only be changed with the / buttons. With the

buttons, you can jump to the location of the set pressure setting.

/

GB

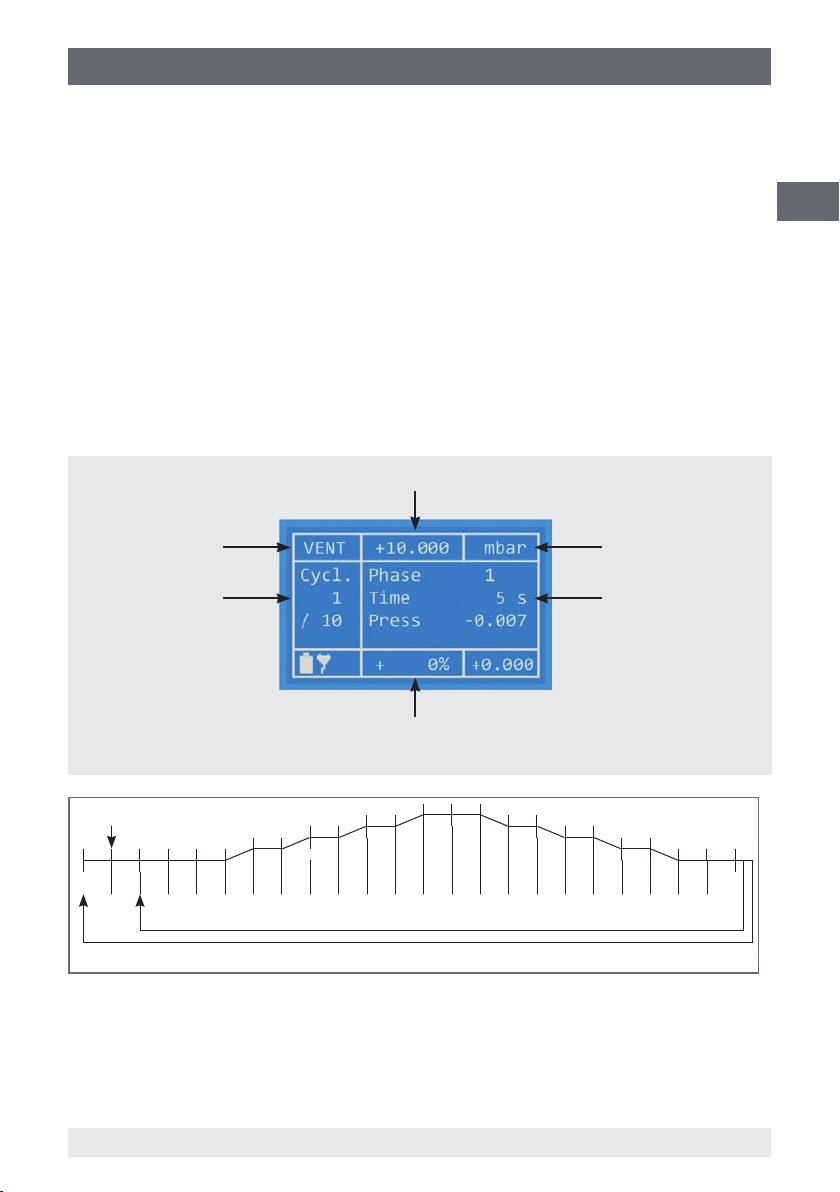

As soon as the controller display indicates a stable value, the data can be recorded:

Full scale value

Operating mode

Battery status

Set point in % of the full scale value

Pressure unit

Measured value

In CTRL mode it is possible to adjust the zero point of the controller manually and to

check the connected instrument for leaks.

■

Manual zero point adjustment: Conrm using the ZERO button and the reference

measuring cell of the instrument will be adjusted.

■

Leak test: By pressing the LEAK button, the control process will be deactivated and

the system closed. It can be controlled via the display if the value is stable. By pressing

the LEAK button again, the mode will be stopped and the unit placed back in Control

mode.

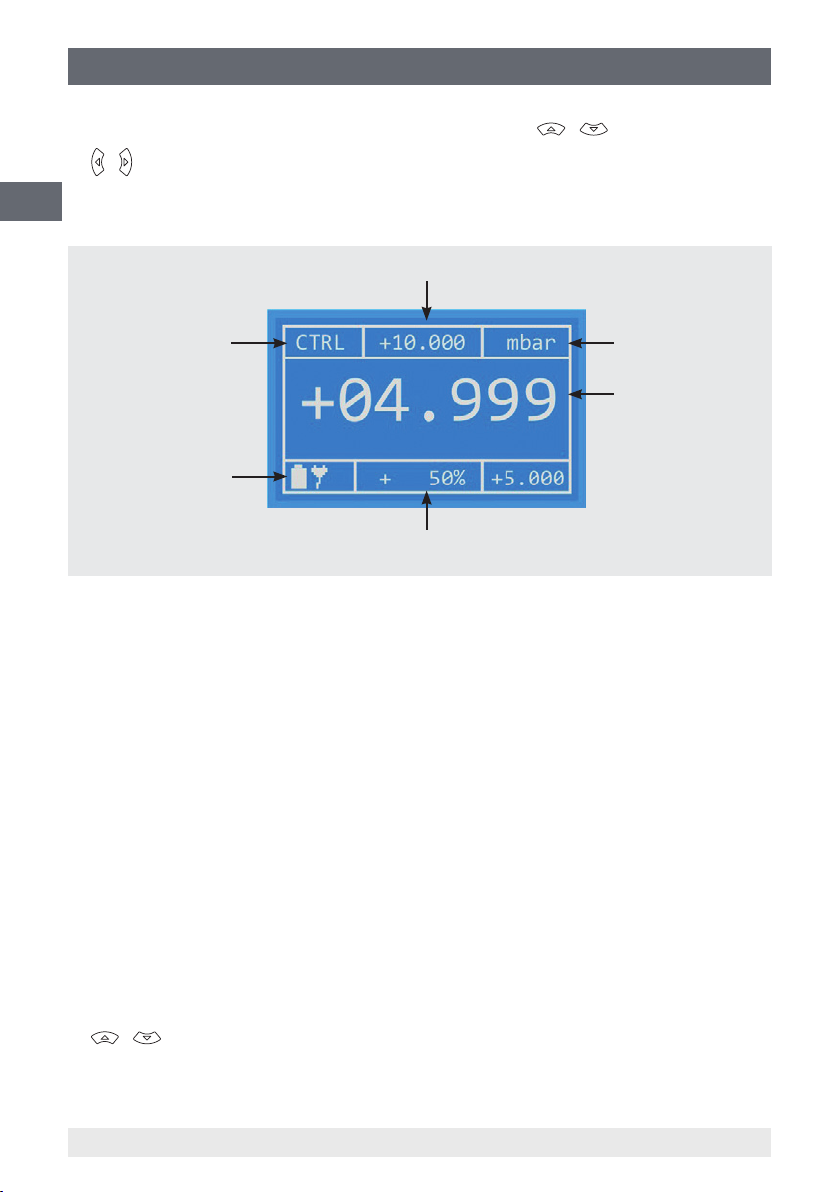

6.2 Operating mode 'Measure' (MEAS)

The Measure mode is used to measure a dierential or gauge pressure. The pump is not

active in this operating mode. The pressure is measured directly from the internal reference sensor.

Setting

■

Press the MENU button. Conrm the menu point MODE with SELECT and press the

/ button until MEAS appears. Conrm with SELECT.

■

For the MEAS mode, the submenu points RANGE and STEPS are not relevant.

18 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 19

6. Commissioning, operation

■

In the menu, go to the UNIT item with the / button, select the pressure unit and

conrm with SELECT.

■

Press the MENU button in order to exit the menu.

■

SETTINGS submenu:

■

Go to the SETTINGS menu item with the / button, conrm with SELECT.

■

In the submenu, go to the zero point adjustment item and conrm with SELECT.

■

Under the point, AUTO-ZERO, the automatic zero point adjustment for the MEAS

mode can be activated or deactivated.

Operation

On leaving the menu, the zero point of the internal sensor is adjusted, dependent upon

the setting. The instrument then begins to measure the subsequent pressures.

Full scale value

GB

Operating mode

Battery status

Set point in % of the full scale value

Pressure unit

Measured value

Using the ZERO button in MEAS mode, the instrument‘s zero point can be compensated

at any time.

CAUTION!

If the connected pressure should exceed the permissible highest loading

(125 %), the internal sensor will be closed o using a magnetic valve.

The display will then show ERROR. Using the SELECT button, the

instrument can be closed o and opened up freely.

11155094.02 07/2012 GB/D/F/E

19WIKA operating instructions, model CPC2000

Page 20

6. Commissioning, operation

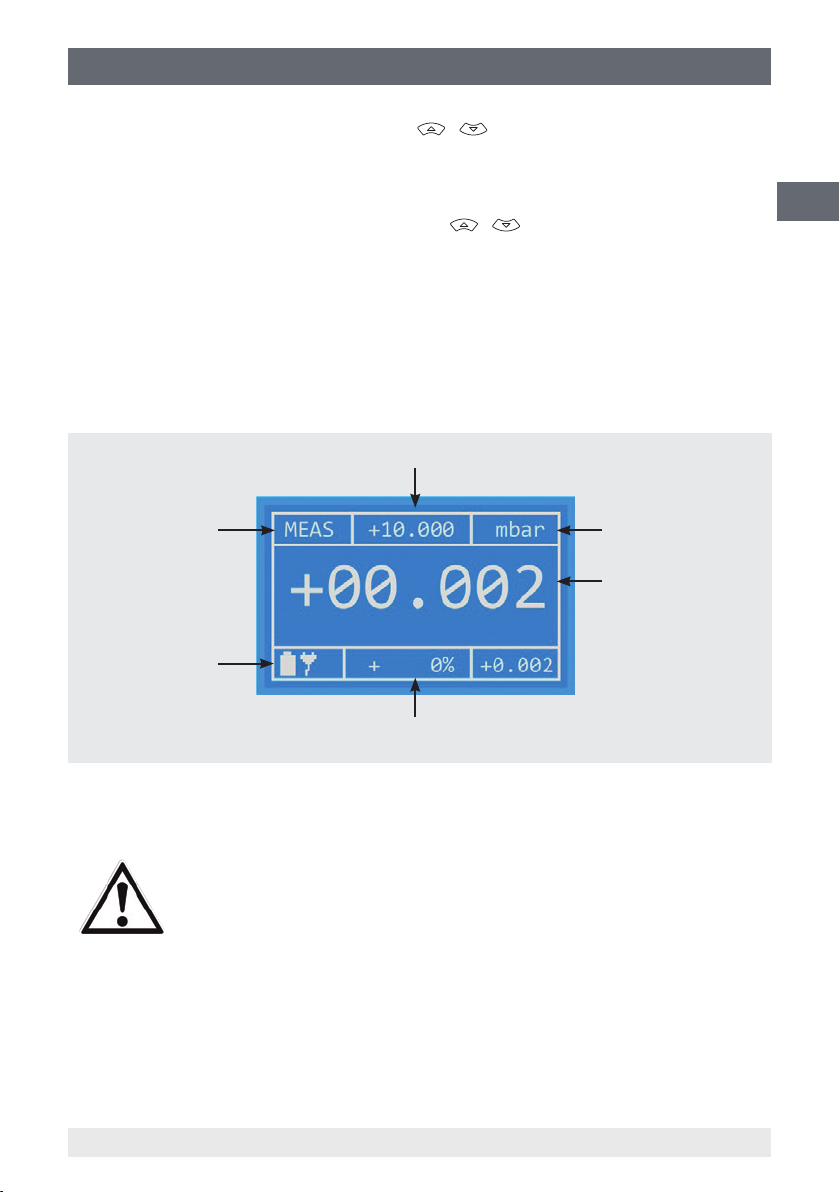

6.3 Operating mode 'AUTO'

In

AUTO

mode, a pressure prole can be stored. This is especially useful when multiple

pressure sensors or pressure switches are to be calibrated with the same values. The

mode also enables a dened prole to be traversed several times in succession.

GB

Setting

■

Press the MENU button. Conrm the menu item MODE with the SELECT button and

press the

■

For the AUTO mode, the submenu points RANGE, UNIT and STEPS are not relevant.

■

Go to the SETTINGS menu item with the / buttons and conrm with the

SELECT button. The submenu item zero point adjustment is not relevant.

■

In the submenu, go to the AUTO mode item with the UP/DOWN buttons and conrm

with SELECT.

■

RANGE: Pressure range that will be covered

■

UNIT: Pressure unit

■

STEPS

pressure. These increments are calculated by the controller itself.

/ button until AUTO appears. Conrm with SELECT.

: The number of steps which will be taken to increase and decrease the

In the submenu point, CONFIGURATION 1, further settings can be dened for the

AUTO

mode.

20 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 21

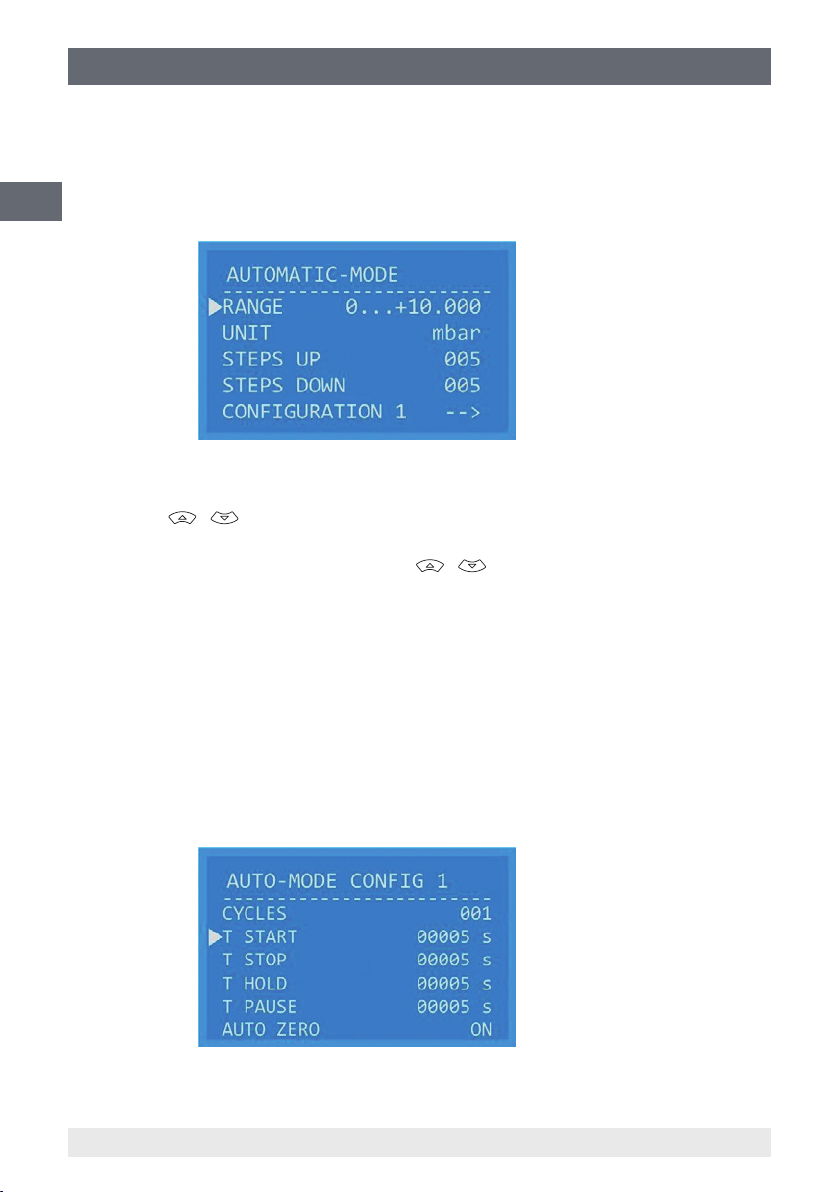

6. Commissioning, operation

Setting

■

CYCLES: Here the number of cycles to be carried out in AUTO mode will be set.

■

T START: Delay time to vent the sensor

■

T STOP: Delay time before reaching the maximum dened pressure

■

T HOLD: Hold time until a new pressure value is reached

■

T PAUSE: Delay time between two cycles

■

AUTO ZERO: Automatic zero point adjustment at the completion of each cycle

To exit the submenu, press the MENU button.

Operation

On leaving the menu, the calibrator will revert to 'Standby status'. All information about the

AUTO mode will be shown on the display.

Set pressure

GB

Operating mode

First of ten cycles Phase 1: It has been

percentage display of the current set

pressure

Start

1 2 4 5 7 9 10 9 10 9 10 9 10 13 15 16 15 16 15 16 15 16 18

Next cycle

End of cycle

Pressure unit

vented (Pressure = 0)

The gure shows the ow chart for the AUTO mode. Based on the table, one will know

which cycles are being carried out and the meaning of each.

11155094.02 07/2012 GB/D/F/E

21WIKA operating instructions, model CPC2000

Page 22

6. Commissioning, operation

Phase Description

1 Wait for the Start command with SELECT

2 Delay time can be dened in the Conguration

GB

4 Duration of the system zero point adjustment

7 Hold time at the zero point

9 Time to control up to the next step

10 Hold time

13 Delay time at the maximum set pressure

15 Time to control up to the next step

16 Delay time at the zero point

18 The delay times can be dened in the conguration.

Between phases 10 and 16, the calibrator data can be evaluated and recorded if a stable

value is displayed. The AUTO mode can be exited by pressing the MENU button. VENT

will be shown In the top left of the display.

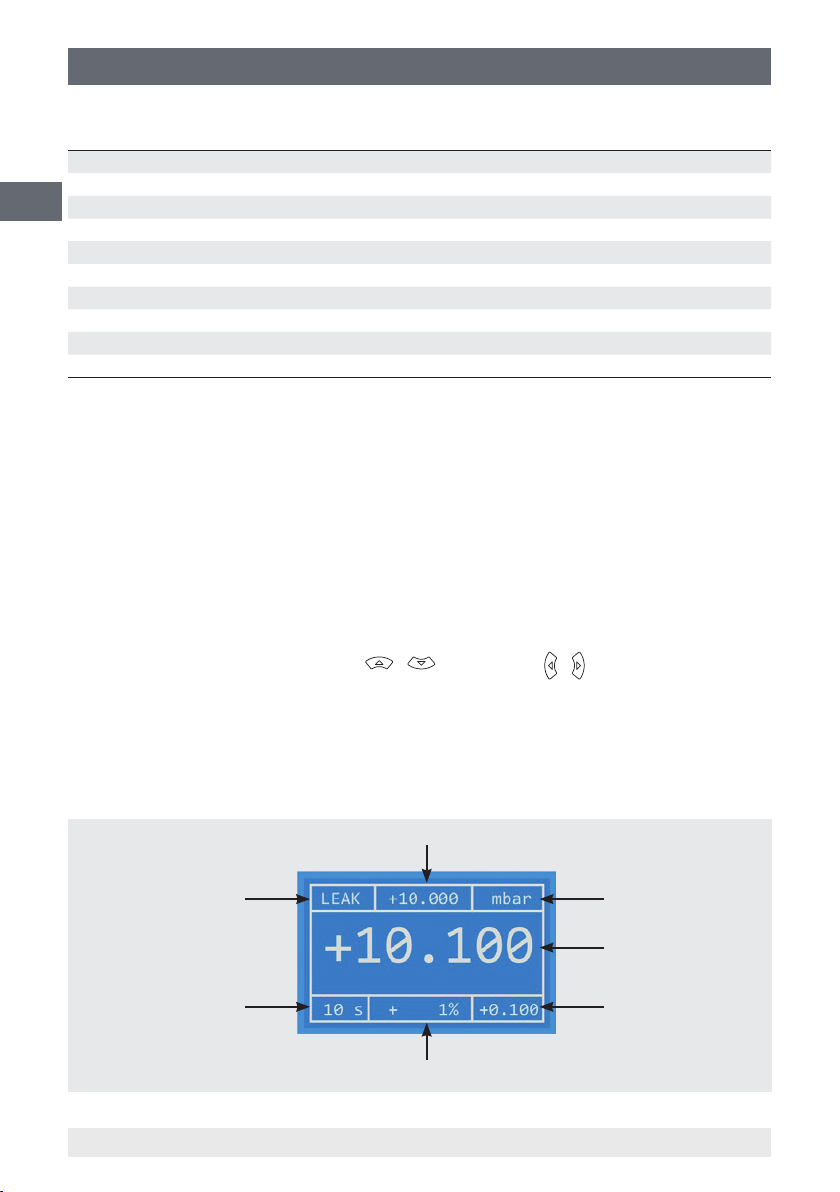

6.4 Leakage (LEAK)

In CTRL mode, the connected test item can be checked for leakage via LEAK button.

Setting

In order to be able to check a test item for leakage, the instrument must rst be placed in

CTRL mode.

■

Set the desired pressure using the / button or the / button (0 %/100 %)

buttons.

■

As soon as the pressure is reached and the value is stable, press the LEAK button.

The internal pump will be switched o and the applied pressure will be held.

Operation

Set pressure demand

Operating mode

Elapsed time

since start of the

Leak function

Percentage deviation from the set value

Pressure unit

Measured value

Actual deviation from

the set value

22 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 23

6. Commissioning, operation

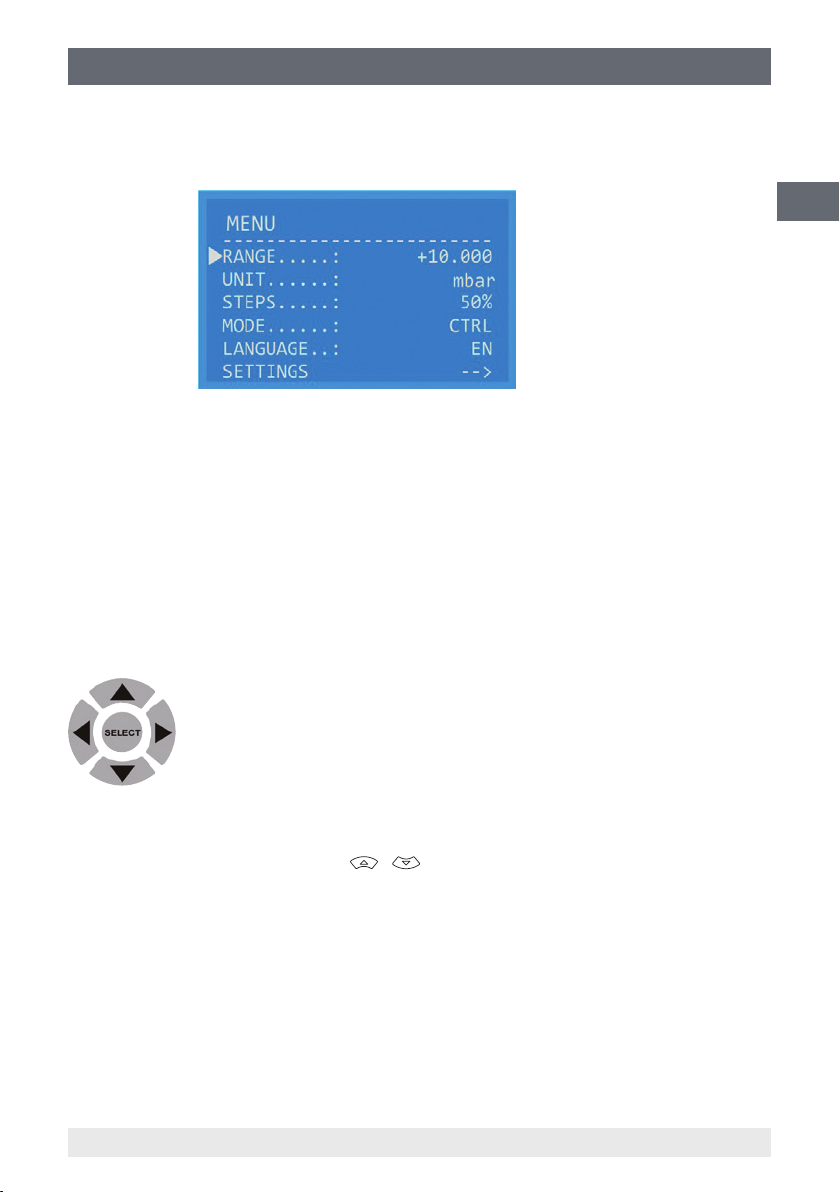

6.5 SETUP settings (SETUP)

The SETUP menu items are made up of six submenus.

■

RANGE: Setting of the pressure range (max. 100 % of the measuring span)

■

UNIT: Selection of the pressure unit (Pa, kPa, hPa, bar, mbar, psi, inH2O, inHg, mmHg,

Torr)

■

STEPS: Setting of the step size in x %. Settable in the range 1 ... 50 %

■

MODE: Selection of the operating mode

■

Control (CTRL): Regulates to the given set point

■

Measure (MEAS): Measurement of dierential and relative pressure

■

Automatic (AUTO): Carries out a stored test routine

■

LANGUAGE: Selection of the displayed language

■

SETTINGS: Here additional instrument settings can be made

GB

Navigation within the menu:

SELECT: Acts to conrm the relevant setting

Left/Right arrow: Setting of the active decimal point

Up/Down arrow: Change between the dierent submenu points.

6.5.1 The menu points

With the MENU button and with the

/ button, press the up and down until one is

at the required menu point. With the SELECT button, one reaches the desired submenu.

The following items are available in the submenu:

6.5.1.1 Range

Under the RANGE menu point the controller‘s nal control value can be changed for the

control.

11155094.02 07/2012 GB/D/F/E

23WIKA operating instructions, model CPC2000

Page 24

6. Commissioning, operation

6.5.1.2 Unit

Here the unit, in which the low-pressure controller will display the measured value on the

screen, can be selected. Dependent upon the measuring range of the instrument, various

units are not available since they could not be displayed.

GB

6.5.1.3 Steps

Here the step size for the STEP function, in x % of the set range, can be changed. Possible settings are from 1 … 50 %.

6.5.1.4 Mode

Here the operating mode of the controller can be set. The following modes can be

selected:

■

Measure (MEAS): The controller measures the pressure in the set pressure unit

■

Control (CTRL): A set point is automatically regulated.

■

Automatic (AUTO): A stored test routine will be carried out.

6.5.1.5 Language

Here the language in which the menu will be displayed can be set. There is the possibility

to choose between German, English, Spanish and French.

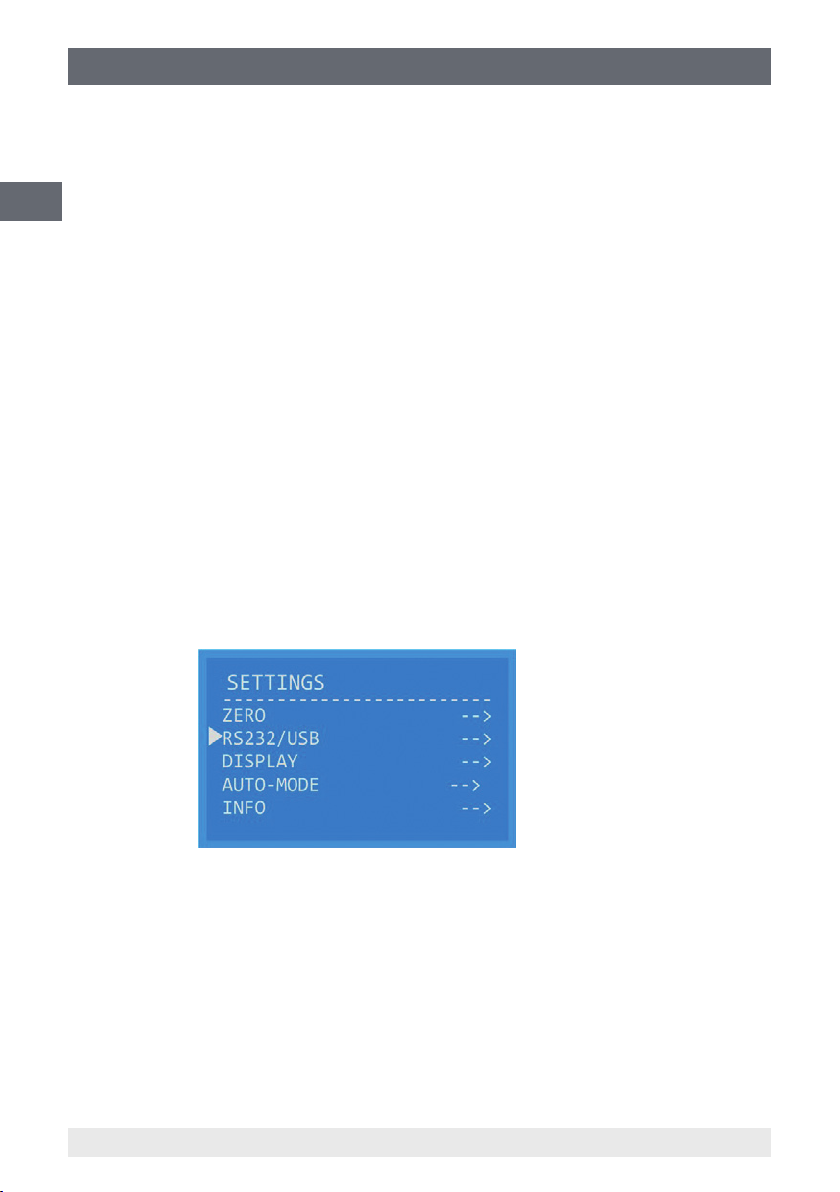

6.5.1.6 Settings

■

ZERO: Switching on and o of the automatic zero point adjustment following exit from

the menu. It is even possible to set at what intervals the instrument will automatically

perform a zero point adjustment.

■

RS232/USB: Selection of the appropriate serial interface

■

DISPLAY: Brightness setting

■

AUTO-MODE: Setting of the pressure range, the pressure unit and number of steps

the pressure range will be divided up into. The STEPS UP/STEPS DOWN can be

assigned dierent values.

■

INFO: Basic information on the instrument

24 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 25

7. Interface

7. Interface

Information on the Firmware release and issue number of the Operating Instructions

Manual Firmware

2.1.0 1.32

There is a possibility to control and monitor the controller via a PC over a serial interface

(USB or RS-232). In control, measure and automatic modes a cyclic output of the current

instrument status can be switched on and o. The output interval is 1 second.

7.1 USB interface

The PC provides a virtual COM port over the USB interface. The control of the instrument

is therefore no dierent from the control via the RS-232.

7.2 RS-232 Interface

To connect, the RxD, TxD and GND lines are required. The connection is made with an

in-line serial cable (1:1, male/female).

GB

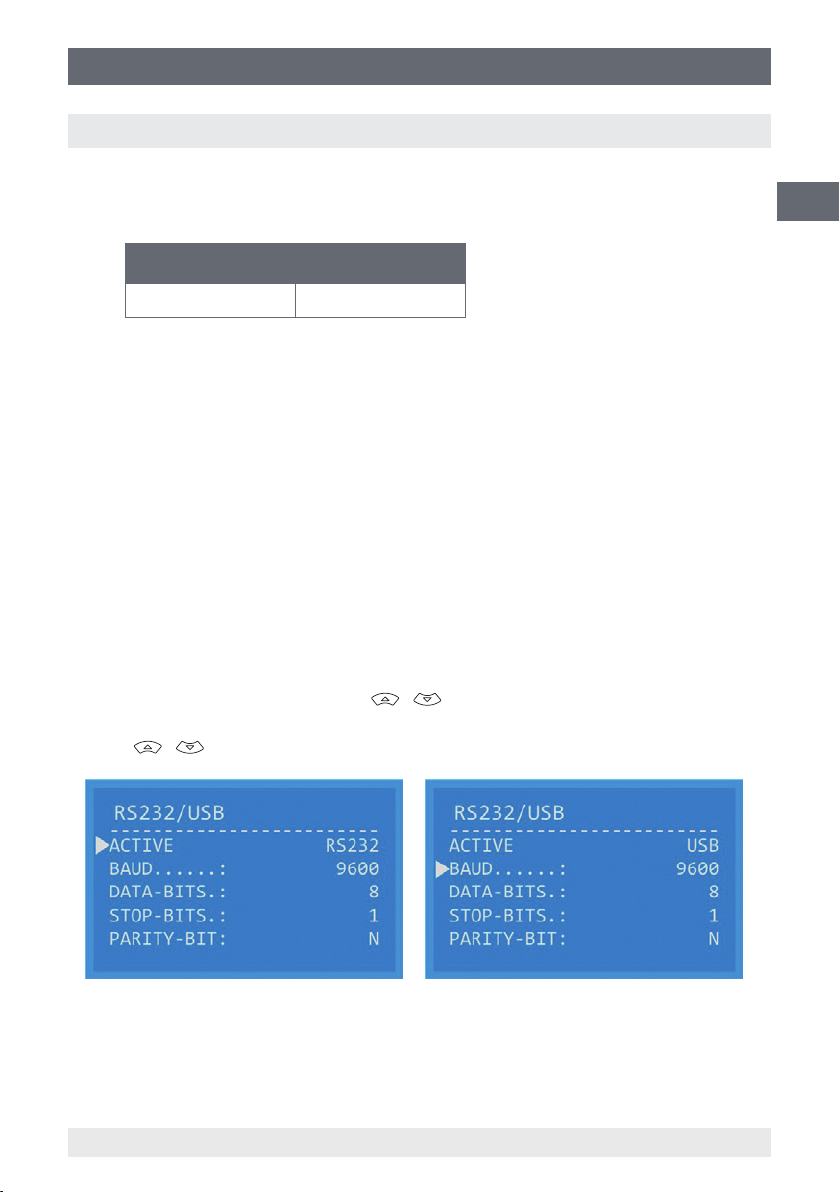

7.3 Interface conguration

Press the MENU button and press the

item appears and conrm with SELECT. In the submenu, go to the item RS-232/USB

with the

■

ACTIVE: Selection of whether a serial interface will be used and which serial interface

(USB, RS-232)

■

BAUD: Selection of the baud rate (1200, 2400, 4800, 9600, 14400, 19200, 28800,

38400, 56000, 57600)

11155094.02 07/2012 GB/D/F/E

/ button and conrm with SELECT. The following settings can be made:

/ button until the SETTINGS submenu

25WIKA operating instructions, model CPC2000

Page 26

7. Interface

■

DATA-BITS: Dened value (8)

■

STOP-BITS: Dened value (1)

■

PARITY-BITS: Dened value (N)

GB

7.4 Commands for serial interface

All interface commands are preceded by a colon and completed with the carriage return

(CR). Command and parameters must be separated by a space. By adding a question

mark to the appropriate action the parameter can be read rather than changed. Received

commands are acknowledged with SELECT, null or false commands with ERROR.

Command Answer function

Auto mode

:saaz <0 | 1> Auto zero before each cycle (phase 4)

:acy <1 ... 100> Cycles to be carried out

:asd <1 ... 100> Steps Down

:asu <1 ... 100> Steps Up

:ate <0 ... 10000> Delay time at the end point (phase 13)

:ath <1 ... 10000> Hold time (phase 10 and 16)

:atp <1 ... 10000> Pause time (phase 18)

:atr <1 ... 10000> Tolerance band

:ats <1 ... 10000> Start delay (phase 2)

0 --> o

1 --> on

1 ... 100 --> number of cycles

1 ... 100 --> number of steps to reach the end point

1 ... 100 --> number of steps to reach the end point

1 ... 10000 --> time in seconds

1 ... 10000 --> time in seconds

1 ... 10000 --> time in seconds

1 ... 10000 --> tolerance in 0.01 % FS (full scale) of the instrument

measuring range. Once the instrument has been controlled within

this tolerance band for 1 second, the hold time expires.

1 ... 10000 --> time in seconds

Interface output

:o <0 | 1> Output status information over interface

0 --> o

1 --> on

26 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 27

7. Interface

Command Answer function

Control mode

:pa <-110 ... 110> Increase the set pressure demand by x percent

:pd Decrease set pressure demand by currently-set step size in %

:pr <-1100 ... 11000> Adjust the current working and measuring ranges

:ps <-10 ... 110> Percentage set pressure demand -10 ... +110 --> set pressure

:pu Increase set pressure demand by currently-set step size in %

:saz<0 | 1> Set auto zero (in measuring and control modes)

:sbr<0 ... 1> Set baud rate RS-232

:sbu<0 ... 1> Set baud rate USB

:sci<n | u | r> Select active interface

sdb <0 ... 100> Display brightness

:spu <0 ... 9> Pressure unit

:ssl <d | e> System language

11155094.02 07/2012 GB/D/F/E

-110 ... +110 --> change in set pressure demand in %

(Step DOWN).

-1,100 ... +11,000 --> new measuring range in 0.01 % FS

demand in %

(Step UP).

0 --> o

1 --> on

0 --> 1200

1 --> 2400

2 --> 4800

3 --> 9600

4 --> 14400

0 --> 1200

1 --> 2400

2 --> 4800

3 --> 9600

4 --> 14400

Set communication interface

n --> Interface o

u --> USB active

r --> RS-232 active

0 ... 100 --> brightness in %

0 --> Pa

1 --> hPa

2 --> ka

3 --> mbar

4 --> bar

5 --> Torr

d = German

e = English

5 --> 19200

6 --> 28800

7 --> 38400

8 --> 56000

9 --> 57600

5 --> 19200

6 --> 28800

7 --> 38400

8 --> 56000

9 --> 57600

6 --> mmHg

7 --> inHg

8 --> psi

9 --> mmH

10 --> inH

O

2

O

2

GB

27WIKA operating instructions, model CPC2000

Page 28

7. Interface

Command Answer function

Menu settings

GB

:smm <a | c | m > Dene the operating modes of the instrument

:ssw <1 ... 100>

:swm <a | c | m | z l v | s> Dene the operating modes of the instrument

:szc <0,1> Zeroing before entry into control mode

:szi <1 ... 60> Zeroing interval

a --> start automatic mode

c --> start control mode

m --> start measure mode

Step size

1 ... 100 --> step size from operating the up and down buttons in %

a --> start automatic mode

c --> start control mode

m --> start measure mode

(only available in CONTROL and MEASURE modes)

z --> ZERO

(only available in CONTROL mode)

l --> LEAK test

l --> back to CTRL mode (like LEAK button)

v --> VENT (vent the entire system)

(only available in AUTOMATIC mode)

0 --> o

1 --> on

1 ... 60 --> time in minutes

7.5 Driver

The current USB interface driver is "Future Technology Devices International Limited"

(FTDI) provided for download on its website for all major operating systems (Windows,

Linux, Mac OS).

■

Homepage: http://www.ftdichip.com

■

Download: http://www.ftdichip.com/Drivers/VCP.htm (FTDI Homepage --> Drivers -->

VCPDrivers)

■

Installation instructions for the various operating systems:

http://www.ftdichip.com/Documents/InstallGuides.htm (FTDI Homepage -->

Documents --> Installation Guides)

28 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 29

8. Maintenance, cleaning and service (recalibration)

8. Maintenance, cleaning and service (recalibration)

8.1 Maintenance

This low-pressure controller is maintenance-free.

Repairs must only be carried out by the manufacturer.

The safety of the operator may be endangered by the low-pressure controller if, for

example:

■

there is visible damage to the instrument.

■

the instrument is not working as specied.

■

the instrument has been stored under unsuitable conditions for an extended period of

time.

If there is any doubt, please return the low-pressure controller to the manufacturer for

repair or maintenance.

8.2 Cleaning

CAUTION!

■

Before cleaning, correctly disconnect the low-pressure controller from

the pressure supply, switch it o and disconnect it from the mains.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to

protect persons and the environment from exposure to residual media.

■

Residual media on the dismounted low-pressure controller can result

in a risk to persons, the environment and equipment. Take sucient

precautionary measures.

GB

For information on returning the instrument see chapter 10.2 “Return”.

8.3 Recalibration

DKD/DAkkS certicate - Certicates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. Every factory recalibration includes, additionally, an

extensive free-of-charge check of all system parameters with respect to their compliance

with the specication. The basic settings will be corrected if necessary.

11155094.02 07/2012 GB/D/F/E

29WIKA operating instructions, model CPC2000

Page 30

9. Faults / 10. Dismounting, return and disposal

9. Faults

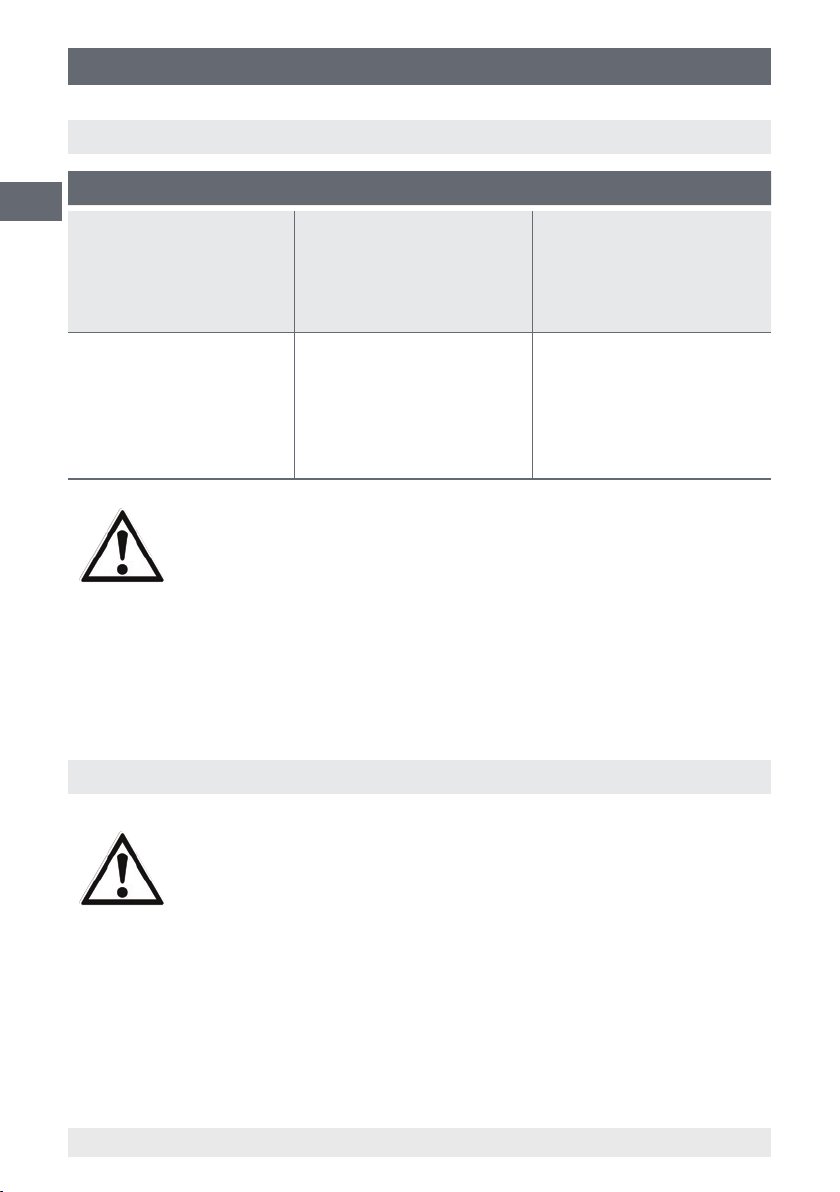

Faults Causes Measures

GB

Instrument is not working,

the display is dark.

No voltage supply

■

Check whether the plug is

correctly in the socket

■

Battery is empty and must

rst be recharged

Set pressure has not

been reached, the pump

is running continuously

CAUTION!

If faults cannot be eliminated by means of the measures listed above, the

low-pressure controller must be shut down immediately, and it must be

ensured that pressure and/or signal are no longer present, and it must be

prevented from being inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

10.2 “Return”.

System is not fully sealed;

to large hose diameter or

hose length

10. Dismounting, return and disposal

WARNING!

Residual media on the dismounted low-pressure controller can result in a

risk to persons, the environment and equipment. Take sucient precautionary measures.

■

Slide hose on correctly;

eliminate any leaks

■

Hose diameter max. 6 mm

(see chapter 3 "Specications“)

10.1 Dismounting

Only disconnect test and calibration installations once the system has been depressurised!

When disassembling the instrument the following must be followed:

1. Ensure that there is no positive or negative gauge pressure in the instrument and that

all parts of the instrument are at room temperature.

2. Switch the instrument o using the ON/OFF switch

30 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 31

10. Dismounting, return and disposal

3. First pull the power supply unit from the mains socket and then from the power supply

socket on the instrument.

4. Loosen the pressure connections

5. Do not close the pressure inputs!

6. Make sure there is no media left in the instrument.

10.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances (acids, bases, solutions etc.).

When returning the instrument, use the original packaging or a suitable transport

package.

To avoid damage:

1. Do not return the instrument with the pressure connections closed! Barometric

pressure changes can damage instruments with low pressure ranges.

2. Wrap the instrument in an antistatic plastic lm.

3. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

4. If possible, place a bag, containing a desiccant, inside the packaging.

5. Label the shipment as transport of a highly sensitive measuring instrument.

GB

Information on returns can be found under the heading “Service” on our

local website.

10.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

11155094.02 07/2012 GB/D/F/E

31WIKA operating instructions, model CPC2000

Page 32

10. Dismounting, return and disposal / 11. Accessories

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities (see EU

GB

directive 2002/96/EC).

11. Accessories

Interface cable

■

RS-232 interface cable

■

USB interface cable

Voltage supply

■

Power supply unit

Certicates

■

3.1 calibration certicate per DIN EN 10204

■

DKD/DAkkS certied accuracy

Miscellaneous

■

Robust transport case

■

Pneumatic hose

32 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 33

Appendix 1: EC Declaration of Conformity for model CPC2000

GB

11155094.02 07/2012 GB/D/F/E

33WIKA operating instructions, model CPC2000

Page 34

GB

34 WIKA operating instructions, model CPC2000

11155094.02 07/2012 GB/D/F/E

Page 35

Inhalt

Inhalt

1. Allgemeines 36

2. Sicherheit 37

2.1 Bestimmungsgemäße Verwendung 38

2.2 Personalqualikation 38

2.3 Besondere Gefahren 39

2.4 Beschilderung/Sicherheitskennzeichnungen 40

3. Technische Daten 41

4. Aufbau und Funktion 44

4.1 Kurzbeschreibung 44

4.2 Lieferumfang 44

4.3 Elektrische Anschlüsse auf der Rückseite 44

4.4 Spannungsversorgung 45

4.5 Frontfolie des CPC2000 45

4.6 Druckanschlüsse 47

4.7 Überdrucksicherung 47

5. Transport, Verpackung und Lagerung 48

6. Inbetriebnahme, Betrieb 49

6.1 Betriebsart 'Control' (CTRL) 49

6.2 Betriebsart 'Messen' (MEAS) 50

6.3 Betriebsart 'AUTO' 52

6.4 Leckage (LEAK) 54

6.5 SETUP-Einstellungen (SETUP) 55

7. Schnittstelle 57

7.1 USB-Schnittstelle 57

7.2 RS-232 Schnittstelle 57

7.3 Schnittstellenkonguration 57

7.4 Befehle für Serielle Schnittstelle 58

7.5 Treiber 60

8. Wartung, Reinigung und Rekalibrierung 61

9. Störungen 62

10. Demontage, Rücksendung und Entsorgung 62

11. Zubehör 64

Anlage: EG-Konformitätserklärung für Typ CPC2000 65

D

Konformitätserklärungen nden Sie online unter www.wika.de.

11155094.02 07/2012 GB/D/F/E

35WIKA Betriebsanleitung, Typ CPC2000

Page 36

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Niederdruckcontroller wird nach dem

aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschrif-

ten und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: CT 27.51

- Anwendungsberater:

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

36 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 37

1. Allgemeines / 2. Sicherheit

Symbolerklärung

GEFAHR!

… weist auf eine unmittelbar gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führt, wenn sie nicht gemieden wird.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden

führen kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

D

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder

tödlicher Verletzungen.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der

richtige Niederdruckcontroller hinsichtlich Messbereich, Ausführung und

spezischen Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

11155094.02 07/2012 GB/D/F/E

37WIKA Betriebsanleitung, Typ CPC2000

Page 38

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Der Niederdruckcontroller Typ CPC2000 dient zur Prüfung und Kalibrierung von Drucksensoren.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet

D

werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen

Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statische Elektrizität und extremen Temperaturen schützen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und Buchsen

vor Verschmutzung schützen.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezi-

38 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 39

2. Sicherheit

schen Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen

Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Besondere Gefahren

WARNUNG!

Schutz vor elektrostatischer Entladung (ESD) erforderlich!

Die ordnungsgemäße Verwendung geerdeter Arbeitsächen und

persönlicher Armbänder ist bei Arbeiten mit oenen Schaltkreisen

(Leiterplatten) erforderlich, um die Beschädigung empndlicher elektronischer Bauteile durch elektrostatische Entladung zu vermeiden.

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und

bei Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen

von Arbeitssicherheit, Erste-Hilfe und Umweltschutz unterwiesen

wird, sowie die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

D

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare

Lebensgefahr.

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von

Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche Spannungen auftreten!

WARNUNG!

Messstoreste am ausgebauten Niederdruckcontroller können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen. Fehlerhafte Anwendungen des Gerätes können zu Verletzungen

führen.

11155094.02 07/2012 GB/D/F/E

39WIKA Betriebsanleitung, Typ CPC2000

Page 40

2. Sicherheit

WARNUNG!

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur und unter hohem Druck oder Vakuum anliegen.

P

= 1 bar Umgebungsluft

max

D

2.4 Beschilderung/Sicherheitskennzeichnungen

2.4.1 Typenschild

Symbolerklärung siehe unten

Hilfsenergie

Druckmedium

Arbeitstemperatur

Druckbereich

Genauigkeit

Herstellungsjahr

2.4.2 Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

Bei Geräten mit dieser Kennzeichnung wird darauf hingewiesen, dass

diese nicht in den Hausmüll entsorgt werden dürfen. Die Entsorgung

erfolgt durch Rücknahme bzw. durch entsprechende kommunale Stellen

(siehe EU-Richtlinie 2002/96/EC).

40 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 41

3. Technische Daten

3. Technische Daten

Referenzdrucksensorik

Druckbereich mbar 1 10 50 100 500 1.000

% FS

Genauigkeit

Druckart Positiver oder negativer Überdruck bzw. Dierenzdruck

Druckeinheiten Pa, kPa, hPa, bar, mbar, psi, inH

Grundgerät

Gerät

Geräteausführung Tischgerät mit Tragegri

Abmessungen 102,6 x 257 x 271 mm ohne Tragegri

Gewicht 4,6 kg

Schutzart IP 20

Druckerzeugung interne, elektrische Pumpe

Anzeige

Bildschirm beleuchtetes, mehrzeiliges Graphikdisplay

Auösung 5 (4 digits für 50/500 mbar Messbereich)

Tastatur Folientastatur

Menüsprachen deutsch, englisch, spanisch und französisch

Anschlüsse

Druckanschlüsse 6,6 x 11 mm (Schlauchdurchmesser D = 6 mm)

Messstoberührte Teile Ni, Al, CuBe, PU

Spannungsversorgung

Hilfsenergie DC 24 V, 1 A

Energieverbrauch 24 VA

Akkutyp Li-Ionen

Akkulaufzeit ca. 8 h

Zulässige Umgebungsbedingungen

Medium Umgebungsluft

Betriebstemperatur 10 ... 40 °C

Lagertemperatur -10 ... +70 °C

Relative Luftfeuchte 30 ... 80 % r. F. (ohne Betauung)

0,3 0,1 0,1 0,1 0,1 0,1

O, inHg, mmHg, Torr

2

D

11155094.02 07/2012 GB/D/F/E

41WIKA Betriebsanleitung, Typ CPC2000

Page 42

3. Technische Daten

Grundgerät

Regelparameter

Regelstufen 0 ... 50 % individuell einstellbar oder 100 %

Regelgeschwindigkeit ca. 5 s (abhängig von Testvolumen)

D

Kommunikation

Schnittstelle RS-232 und USB

Antwortzeit 1 Wert/s

Nullpunktabgleich automatisch (in einstellbaren Zeitabständen)

manuell (ZERO-Taste)

Zulassungen und Zertikate

CE-Konformität

EMV-Richtlinie 2004/108/EG, EN 61000-6-3 Störaussendung für Wohnbereich,

Geschäfts- und Gewerbebereiche und EN 61000-6-2 Störfestigkeit für Industriebereiche

Zertikat

Kalibrierung

1) Bei waagerechter Aufstellung kalibriert.

1)

inkl. Kalibrierzertikat 3.1 nach EN 10204

Weitere technische Daten siehe WIKA Datenblatt CT 27.51 und Bestellunterlagen.

42 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 43

3. Technische Daten

Abmessungen in mm

Frontansicht

D

Seitenansicht

11155094.02 07/2012 GB/D/F/E

43WIKA Betriebsanleitung, Typ CPC2000

Page 44

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Kurzbeschreibung

Der mikroprozessorgesteuerte Niederdruckcontroller CPC2000 dient zur

■

einfachen Bereitstellung von positiven und negativen Referenzdrücken.

■

Druckmessung von positivem und negativem Druck.

D

■

Dierenzdruckmessung.

■

Feststellung von Undichtigkeiten eines Prüings.

Mikroprozessor

Druck-Istwert

Druckwert

Anzeige

PC-Schnittstelle RS-232

USB-Schnittstelle

Soll-Istwert

Vergleich

Regler

Druckmessung

Pumpe

-

+

Ventile

4.2 Lieferumfang

■

Portabler Niederdruckcontroller Typ CPC2000

■

Netzteil

■

Betriebsanleitung

■

Kalibrierzertikat 3.1 nach DIN EN 10204 (optional DKD/DAkkS-Zertikat)

Lieferumfang mit dem Lieferschein abgleichen.

4.3 Elektrische Anschlüsse auf der Rückseite

USB-Schnittstelle

neg. Druck

pos. Druck

RS-232 Schnittstelle

Anschluss für Netzteil

44 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 45

4. Aufbau und Funktion

4.4 Spannungsversorgung

Der Niederdruckcontroller ist werkseitig für den Anschluss an eine Spannungsversorgung

von DC 24 V ausgelegt. Der Anschluss für das Netzteil bendet sich auf der Geräterückseite.

GEFAHR!

Stromschlaggefahr! Unbedingt vor dem Ausstauchen der Sicherung den

Netzstecker aus der Steckdose ziehen!

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von

Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche Spannungen auftreten!

Es ist nur das im Lieferumfang enthaltene Original-Netzteil (Mascot

Typ 9926) zu verwenden.

1. Die Beschaltung beim Anschluss an andere Geräte besonders sorgfältig konzipieren.

Unter Umständen können interne Verbindungen in Fremdgeräten (z. B. Verbindung

GND mit Erde) zu nicht erlaubten Spannungspotentialen führen, die das Gerät selbst

oder ein angeschlossenes Gerät in seiner Funktion beeinträchtigen oder sogar zerstören können.

2. Der Netzstecker muss immer zugänglich in einer Netzsteckdose stecken, das heißt,

man muss ihn jederzeit ohne Schwierigkeiten aus der Netzsteckdose ziehen können.

4.5 Frontfolie des CPC2000

Im Regelmodus: Starten der Leckagemessung, ansonsten ohne Funktion

Während des Regelvorganges → Vent,

ansonsten SETUP aufrufen

Sollwert um x % erhöhen

Sollwert auf 100 % erhöhen

D

Druckanschlüsse

11155094.02 07/2012 GB/D/F/E

Ein-/AusTaste

Sollwert um x % verringern

Sollwert auf 0 % setzen

Nullpunktabgleich

45WIKA Betriebsanleitung, Typ CPC2000

Page 46

4. Aufbau und Funktion

Die Displayfrontscheibe hinter der Folie besteht aus Glas. Ist ein Zerbrechen der Scheibe inkl. Zerstörung der Frontfolie während der Benutzung

nicht vollständig auszuschließen, müssen alle Personen in der näheren

Umgebung des Gerätes, vor und während der Benutzung eine Schutzbrille tragen.

D

4.5.1 Taste Ein/Aus

Taste zum Ein- und Ausschalten des Gerätes.

4.5.2 Taste Menu

Über diese Taste gelangt man in das SETUP-Menü und kann dort die

Einstellungen für den jeweiligen Betriebsmodus vornehmen. Beim

Verwenden des CTRL-Modus bendet sich das Gerät nach Verlassen

des SETUP-Menüs im VENT-Modus.

Die SETUP-Menüpunkte setzen sich aus sechs Unterpunkten zusammen. Eine detaillierte Beschreibung der Punkte siehe Kapitel 6.5 „SETUP-Einstellungen (SETUP)“.

4.5.3 Taste LEAK

Mit der LEAK-Taste kann ein am Controller angeschlossenes Gerät

auf seine Dichtheit überprüft werden. (Diese Funktion ist jedoch nur im

CONTROL-Modus möglich.)

4.5.4 Taste ZERO

Taste zur manuellen Nullpunktkorrektur des integrierten Sensors.

Durch äußere Einüsse wie Temperatur, Lage oder Umgebungsdruck

kann sich der Nullpunkt des Geräts, d. h. die Anzeige bei oenen Druckeingängen, verändern. Während des Nullpunktabgleichs ermittelt das

Gerät automatisch diese Veränderungen und rechnet sie in die aktuelle

Druckanzeige ein. Der Nullpunktabgleich erfordert ein umschalten der

internen Ventile, welches nicht ohne Druckverlust möglich ist.

(Wenn dies im Einsatzfall stört kann der automatische Nullpunktabgleich

abgeschaltet werden.)

46 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 47

4. Aufbau und Funktion

4.6 Druckanschlüsse

■

Dierenzdruckgeräte werden an den j und an den i-Anschluss des Gerätes

angeschlossen.

■

Relativdruckgeräte werden an den j-Anschluss angeschlossen (i-Anschluss oen

zur Atmosphäre).

■

Geräte für negative Überdrücke werden an den i-Anschluss angeschlossen

j

(

-Anschluss oen zur Atmosphäre).

Prüf- und Kalibrieraufbauten nur im drucklosen Zustand montieren!

Keinen Funktionstest mit Druck- oder Atemluft durchführen. Geräte mit

niedrigen Messbereichen werden sonst beschädigt.

Der Anschluss an den Niederdruckcontroller erfolgt über einen Druckanschluss 6,6 x 11 mm.

Der Schlauchdurchmesser sollte 6 mm betragen.

4.7 Überdrucksicherung

Der zulässige maximale Druck darf nicht überschritten werden:

Druckbereich Überlast

D

1 mbar 5-fache Überlast

10 mbar 5-fache Überlast

50 mbar 5-fache Überlast

100 mbar 5-fache Überlast

500 mbar 2-fache Überlast

1.000 mbar 2-fache Überlast

11155094.02 07/2012 GB/D/F/E

47WIKA Betriebsanleitung, Typ CPC2000

Page 48

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Den Niederdruckcontroller auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

D

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -10 ... +70 °C

■

Feuchtigkeit: 30 ... 80 % r. F. (keine Betauung)

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Den Niederdruckcontroller in der Originalverpackung an einem Ort, der die oben gelisteten Bedingungen erfüllt, lagern. Wenn die Originalverpackung nicht vorhanden ist, dann

das Gerät wie folgt verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

4. Die Druckeingänge bei der Lagerung nicht verschließen! Barometrische Druckände-

rungen könnten Geräte mit niedrigen Messbereichen beschädigen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden

Messstoreste entfernen. Dies ist besonders wichtig, wenn der

Messsto gesundheitsgefährdend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw..

48 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 49

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

Keinen Funktionstest mit Druck- oder Atemluft durchführen. Geräte mit

niedrigen Messbereichen werden sonst beschädigt.

Das Gerät vor Sonneneinstrahlung schützen, da sonst Messfehler

entstehen.

6.1 Betriebsart 'Control' (CTRL)

Der CTRL-Modus wird für die Kalibrierung von Drucksensoren und -schaltern oder

anderen Druckgeräten verwendet. Im CTRL-Modus ist die Pumpe aktiv und regelt

entsprechend den Solldruck. Der interne Sensor liefert über die Anzeige den aktuellen

Ist-Wert.

Einstellung

■

Auf die Taste MENU drücken. Menüpunkt MODUS mit SELECT bestätigen und die

/ -Taste drücken bis CTRL erscheint. Mit SELECT bestätigen.

■

Im Untermenü BEREICH die obere Grenze des Druckbereichs festlegen

(

/ -Taste und / -Tasten) mit SELECT bestätigen

■

Im Untermenü EINHEIT die Druckeinheit festlegen ( / -Tasten) und mit

SELECT bestätigen.

■

Im Untermenü SCHRITTE wird die Schrittfolge in % festgelegt ( / -Tasten und

/ -Tasten), mit SELECT bestätigen.

■

Mit der Taste MENU das Untermenü verlassen

D

Nutzung

Das Gerät bendet sich bei Verlassen

Sollwert in x % ändern:

des Menüs im VENT-Modus, d. h. der

Sensor des Kalibrators ist entlüftet.

Druckänderung in % via

/ -Tasten

In der oberen Displaymitte wird der

Sollwert des Druckbereichs angezeigt.

Druckänderung auf 100 % via

In der unteren Displaymitte kann der

Prozentwert abgelesen werden. Bei

Druckänderung zurück auf 0 % via

verlassen des Menüs steht dieser Wert

auf 0 %. Mit der SELECT-Taste kann

zwischen der Solldruckvorgabe und dem

prozentualen Wert gewechselt werden.

■

Der prozentuale Wert kann mit den / -Tasten (in den festgelegten Schrittgrößen) und mit den

11155094.02 07/2012 GB/D/F/E

/ -Tasten geändert werden.

-Taste

-Taste

49WIKA Betriebsanleitung, Typ CPC2000

Page 50

6. Inbetriebnahme, Betrieb

■

Die Solldruckvorgabe kann nur mit den / -Tasten verändert werden. Mit den

/ -Tasten kann an die entsprechende Stelle der Solldruckvorgabe gesprungen

werden.

Sobald das Display des Controllers einen stabilen Wert anzeigt, können die Daten aufge-

D

zeichnet werden:

Endwert

Betriebsmodus

Batteriestatus

Sollwert in % des Endwertes

Druckeinheit

Messwert

Im CTRL-Modus besteht die Möglichkeit, den Nullpunkt des Controllers manuell

abzugleichen und das angeschlossene Gerät auf Dichtheit zu überprüfen.

■

Manueller Nullpunktabgleich: Die ZERO-Taste bestätigen und die Referenzmesszelle des Geräts wird abgeglichen.

■

Dichtheitstest: Durch Drücken der LEAK-Taste wird der Regelvorgang deaktiviert

und das System abgeschlossen. Über das Display kann kontrolliert werden ob der

Wert stabil ist. Durch erneutes drücken der LEAK-Taste wird der Modus wieder

beendet und das Gerät in den Control-Modus versetzt.

6.2 Betriebsart 'Messen' (MEAS)

Der Messmodus wird verwendet um einen Dierenz- oder Relativdruck zu messen. Die

Pumpe ist in diesem Betriebsmodus nicht aktiv. Der Druck wird direkt von dem internen

Referenzsensor erfasst.

Einstellung

■

Die Taste MENU drücken. Menüpunkt MODUS mit SELECT bestätigen und die

/ -Taste drücken bis MEAS erscheint. Mit SELECT bestätigen.

50 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 51

6. Inbetriebnahme, Betrieb

■

Für den MEAS-Modus sind die Untermenüpunkte BEREICH und SCHRITTE nicht von

Bedeutung.

■

Im Menü mit der / -Taste auf den Punkt EINHEIT gehen, die Druckeinheit

wählen und mit SELECT bestätigen.

■

Die MENU-Taste drücken um das Menü zu verlassen.

■

Untermenü EINSTELLUNGEN:

■

Mit den / -Tasten auf den Menüpunkt EINSTELLUNGEN gehen, bestätigen mit SELECT.

■

Im Untermenü auf den Punkt Nullpunktabgleich gehen und mit SELECT bestätigen.

■

Unter dem Punkt AUTO-NULL kann der automatischen Nullpunktabgleich für den

MEAS-Modus de- oder aktiviert werden.

Nutzung

Nach verlassen des Menüs wird der Nullpunkt des internen Sensors, je nach Einstellung,

abgeglichen. Danach beginnt das Gerät mit der Messung des anstehenden Drucks.

Endwert

D

Betriebsmodus

Batteriestatus

Sollwert in % des Endwertes

Druckeinheit

Messwert

Mit der ZERO-Taste kann der Nullpunkt des Geräts im MEAS-Modus jederzeit abgeglichen werden.

VORSICHT!

Überschreitet der angeschlossene Druck die zulässige Höchstlast

(125 %) wird der interne Sensor durch Magnetventile abgeriegelt. Im

Display erscheint ERROR. Mit der SELECT-Taste kann das Gerät wieder

entriegelt und freigegeben werden.

11155094.02 07/2012 GB/D/F/E

51WIKA Betriebsanleitung, Typ CPC2000

Page 52

6. Inbetriebnahme, Betrieb

6.3 Betriebsart 'AUTO'

Im AUTO-Modus kann ein Druckprol hinterlegt werden. Dies ist vor allem dann nützlich,

wenn mehrere Drucksensoren oder Druckschalter mit identischen Werten kalibriert

werden sollen. Der Modus ermöglicht es zusätzlich, ein festgelegtes Prol mehrfach

nacheinander abzufahren.

D

Einstellung

■

Auf die Taste MENU drücken. Menüpunkt MODUS mit SELECT bestätigen und die

/ -Tasten drücken bis AUTO erscheint. Mit SELECT bestätigen.

■

Für den AUTO-Modus sind die Untermenüpunkte BEREICH, EINHEIT und SCHRITTE

nicht von Bedeutung.

■

Mit den / -Tasten auf den Menüpunkt EINSTELLUNGEN gehen und mit der

Taste SELECT bestätigen. Der Unterpunkt Nullpunktabgleich ist nicht von Bedeutung.

■

Im Untermenü mit den UP/DOWN-Tasten auf den Punkt AUTO-MODUS gehen und mit

SELECT bestätigen.

■

BEREICH: Druckbereich der abgefahren wird

■

EINHEIT: Druckeinheit

■

STEPS: Anzahl der Schritte die beim aufbauen und abbauen des Drucks abgefahren werden. Dis Schrittweite wird vom Controller selbst errechnet.

Im Untermenüpunkt KONFIGURATION 1 können Sie weitere Einstellung für den AUTO-

Modus festlegen.

52 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 53

6. Inbetriebnahme, Betrieb

Einstellung

■

CYCLEN: Hier wird die Anzahl der Zyklen festgelegt, die im AUTO-Modus abgefahren

werden sollen.

■

T START: Wartezeit zum Entlüften des Sensors

■

T STOP: Wartezeit nach Erreichen des maximal festgelegten Drucks

■

T HALTEN: Haltezeit bis ein neuer Druckwert angefahren wird

■

T PAUSE: Wartezeit zwischen zwei Zyklen

■

AUTO ZERO: Automatischer Nullpunktabgleich nach Abfahren jedes Zyklus

Verlassen des Untermenü durch Drücken der Taste MENU.

Nutzung

Nach Verlassen des Menüs bendet sich der Kalibrator im Wartestatus. Im Display sind

alle Informationen über den AUTO-Modus dargestellt.

Solldruck

D

Betriebsmodus

Erster von zehn

Zyklen

prozentuale Anzeige des aktuellen

Solldrucks

Start

1 2 4 5 7 9 10 9 10 9 10 9 10 13 15 16 15 16 15 16 15 16 18

Nächster Zyklus

Zyklusende

Druckeinheit

Phase 1: es wird

entlüftet (Druck = 0)

Die Abbildung zeigt das Ablaufschema für den AUTO-Modus. Anhand der Tabelle erkennt

man, welche Zyklen durchlaufen werden und die jeweilige Bedeutung.

11155094.02 07/2012 GB/D/F/E

53WIKA Betriebsanleitung, Typ CPC2000

Page 54

6. Inbetriebnahme, Betrieb

Phase Bedeutung

1 Warten auf den Startbefehl mit SELECT

2 Wartezeit, die in der Konguration festgelegt werden kann

4 Dauer des Systems- Nullpunktabgleichs

7 Haltezeit am Nullpunkt

9 Zeit zum Einregeln bis zum nächsten Step

D

10 Haltezeit

13 Wartezeit am maximalen Solldruck

15 Zeit zum Einregeln bis zum nächsten Step

16 Wartezeit am Nullpunkt

18 Pausenzeit die in der Konguration festgelegt werden kann

Zwischen den Phasen 10 und 16 können die Daten des Kalibrators ausgewertet und

notiert werden, wenn ein stabiler Wert angezeigt wird. Den AUTO-Modus mit der Taste

MENU verlassen. Im Display wird oben links VENT angezeigt.

6.4 Leckage (LEAK)

Im CTRL-Modus können angeschlossene Prüinge über die LEAK-Taste auf ihre Dichtheit überprüft werden.

Einstellung

Um einen Prüing auf seine Dichtheit überprüfen zu können, muss sich das Gerät im

CTRL-Modus benden.

■

Den gewünschten Druck über die / -Taste oder die / -Taste (0 %/100 %)

eingeben.

■

Sobald der Druck erreicht und der Wert stabil ist, die LEAK-Taste drücken. Die interne

Pumpe wird abgeschaltet und der anliegende wird Druck gehalten.

Nutzung

Solldruckvorgabe

Betriebsmodus

Abgelaufene Zeit

seit Start der

Leak-Funktion

Prozentuale Abweichung vom Sollwert

Druckeinheit

Messwert

Tatsächliche Abweichung vom Sollwert

54 WIKA Betriebsanleitung, Typ CPC2000

11155094.02 07/2012 GB/D/F/E

Page 55

6. Inbetriebnahme, Betrieb

6.5 SETUP-Einstellungen (SETUP)

Die SETUP-Menüpunkte setzen sich aus sechs Unterpunkten zusammen.

■

BEREICH: Einstellung des Druckbereichs (max. 100 % der Messspanne)

■

EINHEIT: Auswahl der Druckeinheit (Pa, kPa, hPa, bar, mbar, psi, inH2O, inHg, mmHg,

Torr)

■

SCHRITTE: Einstellung der Schrittgröße in x %. Im Bereich von 1 ... 50 % einstellbar

■

MODUS: Auswahl des Betriebsmodus

■

Regeln (CTRL): Regelt den vorgegebenen Sollwert an

■

Messen (MEAS): Messung von Dierenz- und Relativdruck

■

Automatik (AUTO): Arbeitet eine hinterlegte Prüfroutine ab

■

SPRACHE: Auswahl der angezeigten Sprache

■

EINSTELLUNGEN: Hier können weitere Einstellungen für das Gerät vorgenommen

werden

D

Navigation im Menü:

SELECT: Dient zum Bestätigen der jeweiligen Einstellung

Pfeil Links/Rechts: Einstellung der aktiven Dezimalstellen

Pfeil Auf/Ab: Wechseln in die verschiedenen Untermenüpunkte.

6.5.1 Die Menüpunkte

Mit der Taste MENU und mit den

/ -Tasten so lange auf und ab drücken, bis man

auf dem gewünschten Menüpunkt ist. Mit der Taste SELECT gelangt man in das ausgewählte Untermenü. Folgende Punkte im Untermenü stehen zur Verfügung:

6.5.1.1 Bereich

Unter dem Menüpunkt BEREICH kann der Regelendwert des Controllers für die

Regelung verändert werden.

11155094.02 07/2012 GB/D/F/E

55WIKA Betriebsanleitung, Typ CPC2000

Page 56

6. Inbetriebnahme, Betrieb

6.5.1.2 Einheit

Hier kann die Einheit gewählt werden, in welcher der Niederdruckcontroller den Messwert

auf dem Display anzeigt. Abhängig vom Messbereich des Geräts sind verschiedene

Einheiten nicht verfügbar, da sie nicht mehr dargestellt werden können.

6.5.1.3 Schritte

D

Hier kann die Schrittweite der STEP-Funktion in x % des eingestellten Bereiches

geändert werden. Mögliche Einstellungen liegen zwischen: 1 … 50 %

6.5.1.4 Modus

Hier kann der Betriebsmodus des Controllers eingestellt werden. Folgende Modi stehen

zur Auswahl:

■

Messen (MEAS): Der Controller misst den Druck in der eingestellten Druckeinheit

■

Regeln (CTRL): Ein Sollwert wird automatisch angeregelt.

■

Automatik (AUTO): Ein hinterlegter Prüfablauf wird abgefahren.

6.5.1.5 Sprache