Page 1

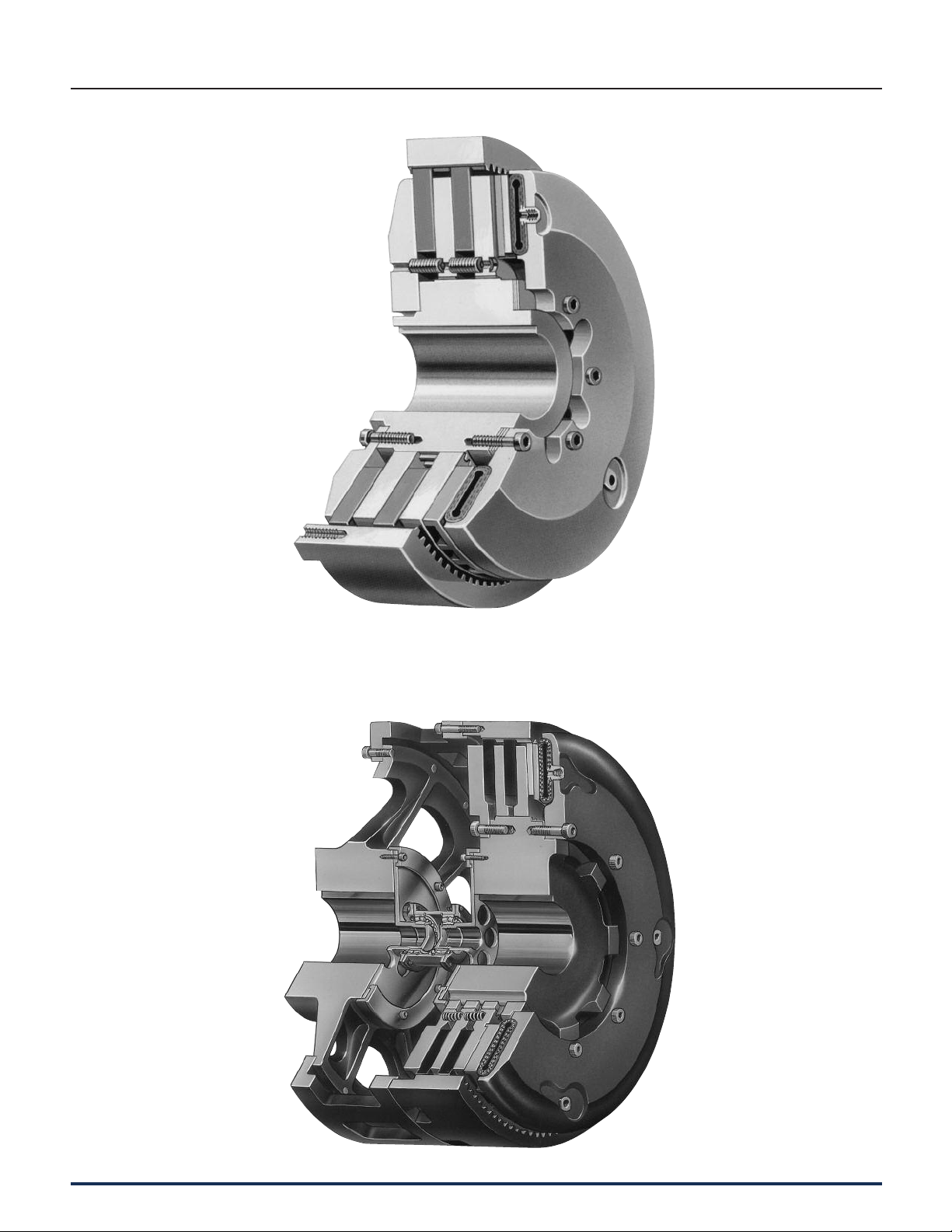

Standard Vent Clutches

Coupling Clutches

The Wichita Standard Vent Com bi na tion

Clutch-Coupling is designed for reliable

in-line power transmission. The simple

air-tube design, with small air vol ume,

speeds en gage ment and dis en gage ment.

It is un af fect ed by centrifugal force and has

no self-energization like drum clutch

de signs. Ideally suited for large inertia loads

where smooth controlled starts are needed.

See pages 131 thru 135.

Grinding Mill Clutches

Wichita Grinding Mill Clutches are

spe cial ly designed to provide

quick, smooth starts with limited

current surge for heavy duty

grinding mills. The clutch

is adapt able to remote control

allowing centralized op er a tion

through simple air or electric

circuits.

See pages 136 thru 143.

122 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 2

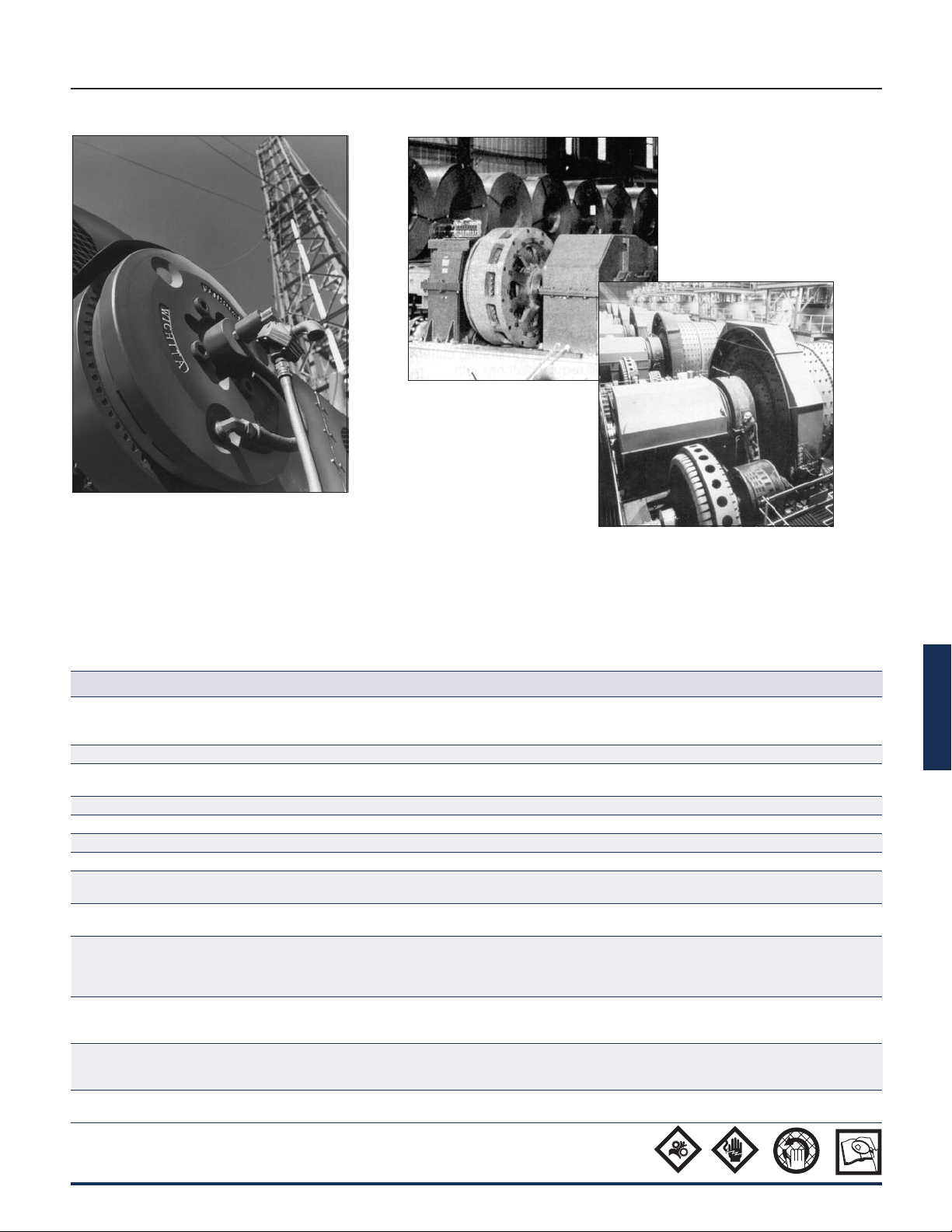

Application Guidelines

Reliable, trouble-free

Wichita Standard Vent

Clutches handle

maximum loads on

drilling rigs.

Standard Vent Clutches

Typical Applications

Wichita ATD-342 Clutches allow

smooth acceleration of coil

transporter.

Wichita Grinding Mill

Clutches provide shock-free

start-up of large inertia

loads.

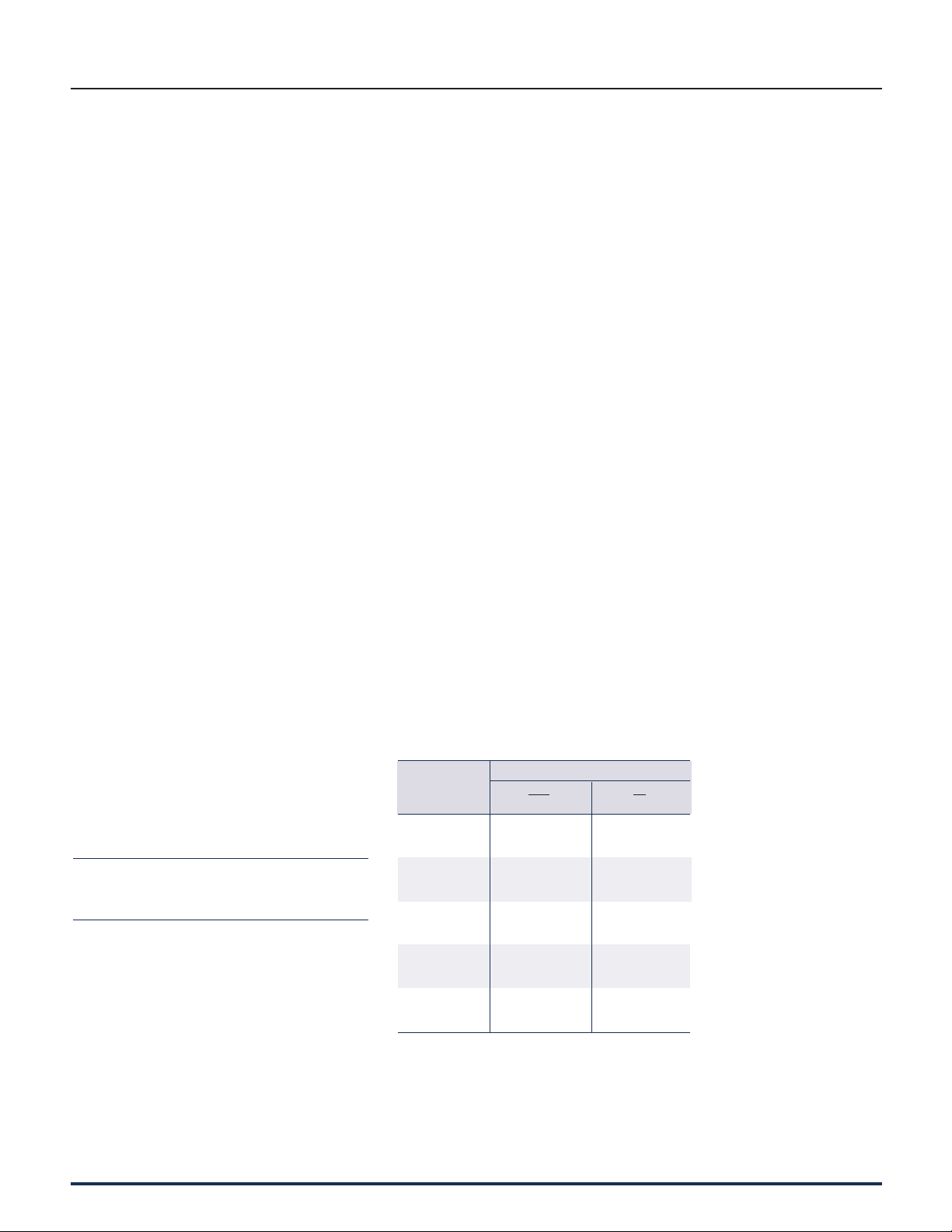

Clutch selection is made by knowing the

application horse pow er/100 RPM, the

available air pressure, required torque and

the clutch heat horse pow er. The Re quire ments

Table (Chart A) gives application factors

ranging from light duty (the A group) to extra

heavy duty (the D group).

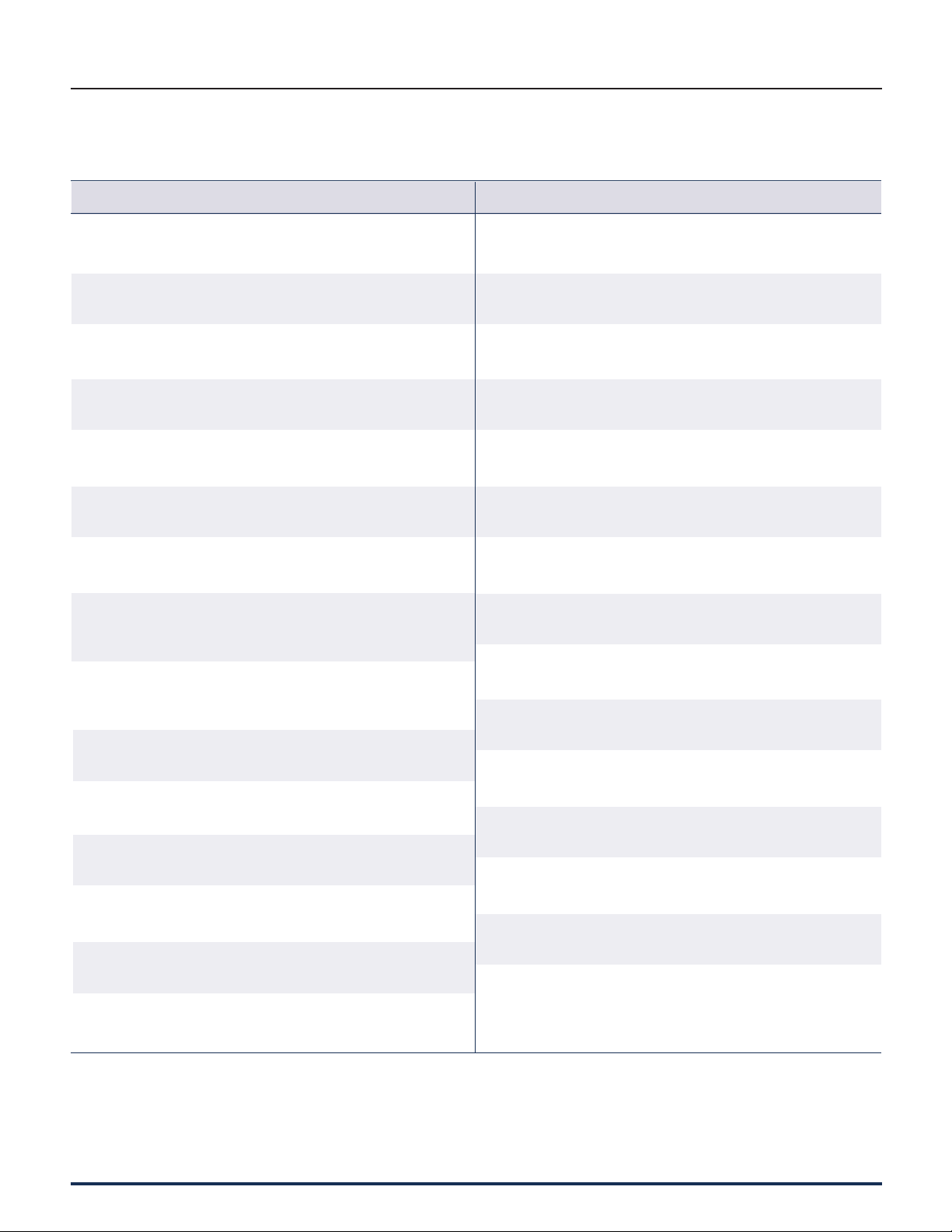

Chart A

Field of Application Group A Group B Group C Group D

Pumps Centrifugal Reciprocating compressors Reciprocating compressors

compressors over 2 cylinders, one or two cylinders

centrifugal fans & blowers

Agitators Liquid Semi-solid Solids

Brick Brick press, extruder, pug mill

manufacturing

Can & bottling machine Bottle-can feeders, filling, mixers

Engine driven equipment Crane, hoist, engine Crowd

Grinding mills Ball-rod-sag-pebble Crushers, shakers

Lumber processing Yarder Carriages, conveyers Chipper, logger

Marine Propulsion clutch CP wheel Shaft brakes, propulsion

reversing type, anchor winch

Bulk material Conveyors evenly loaded, Feeders Elevators

handling line shaft evenly loaded

Metal production & Coilers, slitters, press brake, Draw bench, rolling mill, Hammer mill, forming

metalforming non-geared press, geared press shear, back geared press, press, forging press,

deep draw press, transfer header press, knuckle press

press, toggle press

Paper industry dryer Fourdrinier to 500 FPM, Fourdrinier to 1800 RPM

sections & calenders paper mill plane & press selections, calenders

consult factory smoothing press & dryers

Petroleum Drilling & service rig master Mud pumps,

production clutches, compound clutches, PTO clutches

rotary, drum

Rubber Transfer machines Banberry mixer, drum mixer, Centrifuge

manufacturing evenly loaded extruder, calender

E

P-1100-WC 1/12

Wichita Clutch 800-964-3262 123

Page 3

Standard Vent Clutches

Coupling and Grinding Mill Clutches

Selection

Clutch sizes are affected by the following

variables:

1. Machines that operate under smooth loads

require smaller clutches. These machines

are driven by either multi-cylinder high

speed engines or electric motors with

reduced starting current.

2. Drives that require high starting current

motors will require clutches with sufficient

torque to prevent excessive slipping while

starting.

3. Starting torque may be high, which

re quires fast clutch response time to

transmit the required torque or extended

clutch slip time to protect the prime mover.

4. Starting torques may be very low

com pared to the normal torque, which

may result in the clutch not being fully

pres sur ized prior to the time of torque

re quire ment. This will cause the clutch

to over-heat from slippage. Clutch inflation

time in this instance is very important.

5. Clutches on most machines are designed

to slip prior to damage from shockloads.

As a result, the clutch may require periodic

maintenance; therefore the clutch should

be located, for easy access, in the power

train. Clutches should also be located for

maximum cooling air. In instances where

this is not possible, forced air cooling may

be nec es sary for extended clutch life.

6. Safe operating speeds for clutches should

be maintained in design. The following

material specifications are rec om mend ed

for safe operation. The max i mum speeds

shown are safe op er at ing speeds based

upon years of Wichita experience.

Maximum Clutch

Contact Velocity FPM Material

6,000 (Recommended upper limit for slip) cast iron

9,000 ductile iron

12,000 steel

These velocities are measured at the nominal

outside diameter of the clutch plates.

Selection Example

To properly select a clutch for your ap pli ca tion,

the following information is re quired:

1. Application horsepower

2. Re quired air pressure

3. Required torque

4. Clutch heat horsepower

5. Shaft diameter

Chart A (page 123) gives application re quire ments ranging from light duty (the A group) to

extra heavy duty (the D group). This chart will

give the initial se lec tion which is then compared

with the selection made using the Clutch Heat

Horsepower Chart B and the Clutch area (see

“lining area” column) in the Spec i fi ca tion Table

(Chart C, page 125-126).

Machine required:

Rock crusher (Grinding mill)

(Group D duty requirement)

PSI

2

HP

2

in.

WR2................................1,000 lb.ft.

RPM ..................................1,800

Clutch Slip Time ................6 sec.

HP......................................325 (diesel 8

............................................ cylinder)

Available air pressure ...

.....120

Clutch must slip while bringing equipment

up to speed.

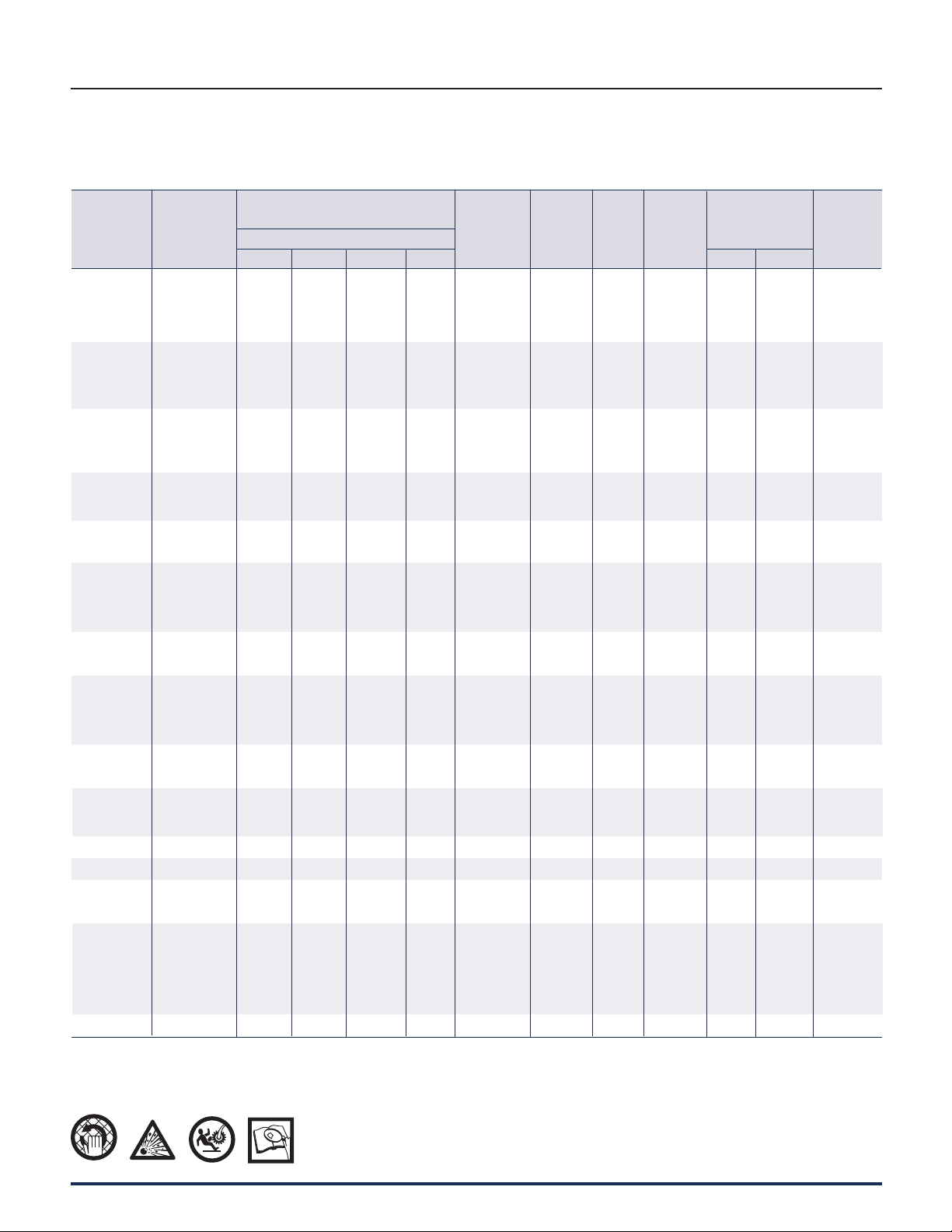

Chart B

Clutch heat horsepower absorption rate*

ft.lb.

in.

Heat Input

2

Slip

Time

Seconds

0 to 1 380 .7

2 617 .56

3 820 .5

4 1,000 .45

5 1,175 .43

6 1,330 .4

7 1,485 .38

8 1,630 .37

9 1,770 .36

10 1,900 .34

* This chart is for use when clutch is at ambient temperature of 120°

F max.

124 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 4

Standard Vent Clutches

Coupling and Grinding Mill Clutches

Calculations

Engine torque =

RPM 1800

Engine torque = 11,375 lb.in.

Clutch torque required while slipping:

Clutch torque =

(g) (t

W = Weight to be accelerated lb.

R = Radius of gyration ft.

g = Acceleration of gravity ft./sec.

ts= Time of slip, in seconds

T

= Clutch torque = 11,707 lb.in.

c

Clutch heat HP is 1/2 of the total

area in the diagram.

Clutch heat HP =

63,000

Clutch heat HP =

63,000

From Clutch Heat Horsepower (Chart B)

for a 6 second start:

2

HP / in.

Area required =

.4

= .4

To properly select a clutch for this rock

crusher application, the following

information is required:

1. Application horsepower

2. Re quired air pressure

3. Required torque

4. Clutch heat horsepower

5. Shaft diameter

The Specification Table on pages 126-127 gives

ap pli ca tion factors ranging from light duty (the A

group) to extra heavy duty (the D group). This

chart will give the initial se lec tion which is then

compared with the selection made using the

Clutch Heat Horsepower Chart and the Clutch

Area Chart.

(HP) (63,000) =(325) (63,000)

2

(WR

) (RPM) (π) lb.in.

) (2.5)

s

2

2

(T

c) (input RPM)

(11,375) (1,800)

(1/2)

(1/2)

= 162.5 HP

162.5

= 406 in.

2

How to select

Clutch torque

energy

rotating

mass

Torque

clutch

heat horsepower

RPM

1. The area required is 406 inches. Consult the

column head “Lining Area” in Spec i fi ca tion

Table (pages 126-127). Applicable clutch es

chosen are:

ATD-218, 528 in.

ATD-314H, 504 in.

2

; ATD-124H, 574 in.2;

2

2. Determine the application

horsepower necessary:

HP/100 RPM =

1,800

325

(100) HP

HP/100 = 18 HP/100 RPM

Clutches selected with this application

horsepower are as follows:

ATD-214H 18 HP/100 RPM, ATD-314H

27 HP/100 RPM, ATD-118 21 HP/100 RPM.

The ATD-314 is selected as having both

sufficient area and torque with min i mum

diameter.

Contact velocity =

12

(clutch size) (π) (1,800)

= 6,597 ft./min.

Ductile material required.

Note: This application example is for

pre lim i nary sizing only. Contact a Wichita Sales

Engineer or the factory for final selection.

Use engine torque for calculations.

When selecting the proper clutch, heat must

be considered. When a clutch is slipped under

load, heat is gen er at ed within the clutch. This

heat as shown to the left is equal to the energy

of the mass that was ac cel er at ed to speed by

the clutch.

Input RPM

E

P-1100-WC 1/12

In applications where thermal re quire ments are

of concern, consult factory for special

ventilated and super ventilated clutch options.

Wichita Clutch 800-964-3262 125

Page 5

Standard Vent Clutches

Coupling and Grinding Mill Clutch Selection

Specifications

Chart C

Recom- Hi-Spd.

Slip Torque mended Airtube

Model lb.in. Clear- Max. Total Total Lining

Size at 100 PSI ances Speed Wt. WR2 Area

ATD– .3 CF A B C D Inches RPM lb. lb. ft.2 Wt. WR

108 STVC 7,000 11.1 8 4 2 1/16-1/8 3,000 36 3 8 1.2 56

208 STVC 14,000 22.2 16 8 4 3/32-5/32 3,000 58 38 18 1.8 112

308 STVC 21,000 33.3 24 12 6 3/32-5/32 3,000 80 5.1 28 2.4 168

111 STVC 15,900 25 18 9 5 1/16-1/8 2,800 65 11 20 5 114

211 STVC 31,800 50 37 18 10 3/32-5/32 2,800 106 18 37 10 228

311 STVC 47,700 75 55 27 15 3/32-5/32 2,800 147 25 54 15 342

114H STVC 35,800 56 40 20 9 1/16-1/8 2,200 165 55 38 14 168

214H STVC 71,600 113 80 40 18 3/32-5/32 2,200 220 75 58 24 336

314H STVC 107,400 170 120 60 27 3/32-5/32 2,200 275 85 78 34 504

116 STVC 40,400 64 45 22 11 1/16-1/8 2,200 189 62 41 23 228

216 STVC 80,800 134 90 44 22 3/32-5/32 2,200 272 87 90 47 456

118 STVC 64,500 102 75 35 21 1/16-1/8 2,000 266 95 47 33 264

218 STVC 129,000 204 150 70 42 3/32-5/32 2,000 390 150 65 63 528

118H STVC 75,000 119 85 40 21 1/16-1/8 1,650 290 103 47 33 264

218H STVC 150,000 238 175 80 42 3/32-5/32 1,650 415 160 65 63 528

318H STVC 225,000 357 260 120 63 1/8-3/16 1,650 540 215 83 153 792

221STVC 175,300 278 195 97 49 3/32-5/32 1,650 500 256 127 114 724

321 STVC 263,000 417 300 150 84 1/8-3/16 1,650 735 360 210 185 1,086

124H STVC 153,700 243 180 90 40 3/32-5/32 1,400 580 390 90 100 574

224H STVC 307,400 487 360 180 80 1/8-3/16 1,400 790 535 180 200 1,148

324H STVC 461,100 731 540 270 120 5/32-7/32 1,400 1000 680 270 300 1,722

227 STVC 345,000 548 383 192 96 1/8-3/16 1,400 890 700 200 275 1,460

327 STVC 517,500 821 600 300 165 5/32-7/32 1,400 1,200 945 265 350 2,190

230H STVC 654,000 1,038 760 380 200 1/8-3/16 1,100 1,375 1,350 265 460 1,664

330H STVC 981,000 1,557 1,150 570 300 3/16-1/4 1,100 2,500 2,325 380 570 2,496

336 STVC 1,524,000 2,418 1,800 885 495 3/16-1/4 900 2,700 3,770 540 1,260 3,450

342 STVC 2,179,000 3,458 2,550 1,275 705 3/16-1/4 800 3,600 7,700 1,100 3,375 4,212

248 STVC 2,805,000 4,452 3,200 1,600 915 1/8-3/16 700 4,500 11,200 785 3,130 4,020

348 STVC 4,207,500 6,678 4,800 2,400 1,370 3/16-1/4 700 5,590 13,850 1,140 4,360 6,030

260 STVC 5,950,000 9,440 6,950 3,470 1,940 3/16-5/16 550 7,525 24,700 1,665 9,400 7,240

360 STVC 8,925,000 14,160 10,400 5,200 2,900 1/4-3/8 550 9,350 32,250 2,500 14,020 10,850

460 STVC 11,900,000 18,880 13,900 6,940 3,880 5/16-7/16 550 12,000 41,000 2,900 16,615 14,480

560 STVC 14,875,000 23,611 16,528 8,264 4,132 1/2-9/16 550 11,750 — — — 18,100

372 STVC 13,965,000 22,167 15,517 7,758 3,879 5/16-7/16 400 — — — — 14,460

Note: Maximum air pressure – 100 PSI

Max. Horsepower

Per 100 RPM

Duty

Driving Ring

& Friction

Disc

2

2

in.

126 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 6

Standard Vent Clutches

Coupling and Grinding Mill Clutch Selection

Specifications

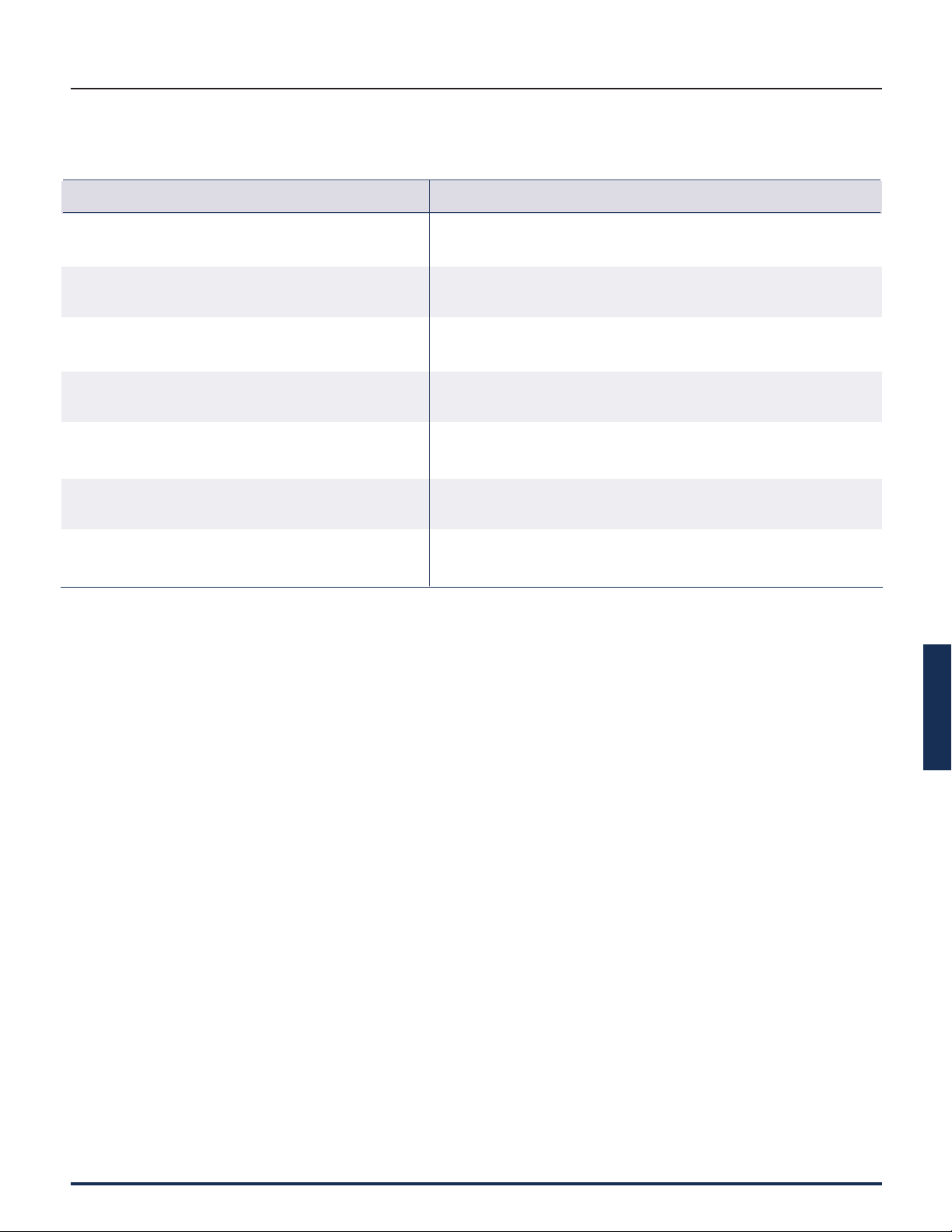

Inflation Coefficient

Operating Air Pressure

50 PSI

K U K U K U R E V R E V R E V

15,800 2.2 7,100 2 265 1.2 60 .016 1 525 .02 1.6 240 .02 1.4

890 1.7 880 1.6 5,100 2.2 1,000 .032 2 8,200 .04 2.8 4,930 .048 2.8

456 2 825 2.2 300 1.75 3,180 .068 3 8,270 .076 3.5 8,000 .088 3.7

456 2 825 2.2 300 1.75 3,180 .068 3 8,270 .076 3.5 8,000 .088 3.7

9,600 3.1 1,560 2.4 9,600 3.8 44 .068 1.4 40 .072 1.4 34 .08 1.4

1,350 2.5 1,350 2.5 1,350 2.5 113 .052 1.6 36 .064 1.3 630 .076 2.5

75 PSI 100 PSI

50 PSI

Exhaust Coefficient

Operating Air Pressure

75 PSI 100 PSI

1,350 2.5 1,350 2.5 1,350 2.5 71 .07 1.6 26 .077 1.3 490 .084 2.5

145 1.8 90 1.6 87 1.6 360 .096 2.5 240 .112 2.5 270 .136 2.8

145 1.8 90 1.6 87 1.6 360 .096 2.5 240 .112 2.5 270 .136 2.8

185 2 150 2 93 1.8 120 .104 2.1 140 .128 2.4 146 .158 2.7

170 2 250 2.2 160 2 124 .112 2.2 92 .128 2.2 76 .152 2.3

115 2 125 2 111 2 132 .12 2.3 89 .144 2.3 6.1 .168 2.3

25 1.6 22 1.6 26 1.8 20 .224 2 20 .256 2.2 19 .308 2.5

28 1.8 22 1.8 20 1.8 24 264 2.4 10 .304 2.3 9.9 .352 2.2

E

P-1100-WC 1/12

Wichita Clutch 800-964-3262 127

Page 7

Standard Vent Clutches

Coupling and Grinding Mill Clutch Selection

Specifications

Model Clutch Mounting Assembly Drawing

Size ATD- Options Number Number

STV 108

STV 208

STV 308

STV 111 Clutch w/ QCDA 6-211-100-303-0 -904-9

STV 211 Clutch w/ QCDA 6-111-200-311-0 -912-9

STV 311 Clutch w/ QCDA 6-111-300-303-0 -903-9

STV 114H Clutch w/ QCDA 6-115-100-300-0 -903-9

STV 214H Clutch w/ QCDA 6-115-200-300-0 -907-9

STV 314H Clutch w/ QCDA 6-115-304-300-0 -900-9

STV 116 Clutch w/ QCDA —

STV 216 Clutch w/ QCDA —

STV 316 Clutch w/ QCDA —

STV 118 Clutch w/ QCDA —

STV 218 Clutch w/ QCDA —

STV 318 Clutch w/ QCDA —

Note: QCDA - Quick Change Driving Adapter. A favorite of OEMs for the extra clearance gap between the clutch and Quick Change Driving Adapter, making the clutch

maintenance less time consuming. SDA - Standard Driving Adapter. A close couple design where clutch maintenance is not of prime importance.

Clutch only 6-208-100-110-0 -900-9

Clutch w/ SDA 6-208-100-302-0 -901-9

Clutch only 6-208-200-103-0 -900-9

Clutch w/ SDA 6-208-200-309-0 -901-9

Clutch only 6-208-300-101-0 -900-9

Clutch w/ SDA 6-208-300-304-0 -901-9

Clutch only 6-211-100-101-0 -900-9

Clutch w/ SDA 6-211-100-304-0 -905-9

Clutch only 6-111-200-101-0 -902-9

Clutch w/ SDA 6-111-200-312-0 -913-9

Clutch only 6-111-300-103-0 -901-9

Clutch w/ SDA 6-111-300-304-0 -904-9

Clutch only 6-115-180-102-0 -902-9

Clutch w/ SDA 6-115-100-301-0 -904-9

Clutch only 6-115-280-104-0 -903-9

Clutch w/ SDA 6-115-200-301-0 -908-9

Clutch w/ DIC Flange Ring 6-115-204-301-0 -900-9

Clutch only 6-115-380-100-0 -901-9

Clutch w/ SDA 6-115-300-100-0 -100-9

Clutch w/ DIC Flange Ring 6-115-300-104-0 -904-9

Clutch only 6-116-100-112-0 -900-9

Clutch w/ SDA —

Clutch only 6-116-200-121-0 -900-9

Clutch w/ SDA —

Clutch only 6-116-300-118-0 -901-9

Clutch w/ SDA —

Clutch only 6-118-100-120-0 -904-9

Clutch w/ DIC Flange Ring 6-118-100-304-0 D-3545

Clutch only 6-118-200-143-0 -909-9

Clutch w/ DIC Flange Ring 6-118-204-300-0 -901-9

Clutch only 6-118-300-309-0 -908-9

Clutch w/ DIC Flange Ring 6-118-300-311-0 -909-9

Model Clutch Mounting Assembly Drawing

Size ATD- Options Number Number

Clutch only 6-119-100-100-0 -900-9

STV 118H Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-119-200-100-0 D-3709

STV 218H Clutch w/ QCDA 6-119-200-106-0 -106-9

Clutch w/ SDA —

Clutch only 6-119-300-100-0

STV 318H Clutch w/ QCDA —

Clutch w/ SDA 6-119-304-305-0 -908-9

Clutch only 6-121-100-106-0 D-2769

STV 121 Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-121-200-143-0 -903-9

STV 221 Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-121-300-120-0 -904-9

STV 321 Clutch w/ QCDA —

Clutch w/ DIC Flange Ring 6-121-300-312-0 -912-9

Clutch only 6-125-100-110-0 -900-9

STV 124H Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-125-200-129-0 -915-9

STV 224H Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-125-300-113-0 -912-9

STV 324H Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-127-100-112-0 -901-9

STV 127 Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-127-200-130-0 -905-9

STV 227 Clutch w/ QCDA 6-127-200-127-0 -905-9

Clutch w/ SDA —

Clutch only 6-127-300-112-0 -903-9

STV 327 Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-131-100-101-0 D-4008

STV 130H Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-131-200-307-0 -903-9

STV 230H Clutch w/ QCDA —

Clutch w/ SDA —

Clutch only 6-131-300-303-0 -904-9

STV 330H Clutch w/ QCDA —

Clutch w/ SDA —

128 Wichita Clutch 800-964-3262

P-1100-WC • 1/11

Page 8

Standard Vent Clutches

Coupling and Grinding Mill Clutch Selection

Specifications

Model Clutch Mounting Assembly Model Clutch Mounting Assembly

Size ATD- Options Number Size ATD- Options Number

Clutch only —

STV 430H Clutch w/ QCDA — STV 248

Clutch w/ SDA —

STV 236 Clutch only 6-136-200-107-0

Clutch w/ QCDA —

Clutch w/ SDA —

STV 336 Clutch only 6-136-300-109-0

Clutch w/ QCDA —

Clutch w/ SDA —

STV 336H Clutch only 6-137-300-300-0

Clutch w/ QCDA 6-137-300-301-0 STV 260

Clutch w/ SDA —

Clutch only 6-142-200-301-0

STV 242 — STV 360

Clutch w/ SDA —

Clutch only 6-142-300-300-0

STV 342 Clutch w/ QCDA — STV 460

Clutch w/ SDA —

Clutch only —

STV 442 Clutch w/ QCDA — STV 560

Clutch w/ SDA —

Note: QCDA - Quick Change Driving Adapter. A favorite of OEMs for the extra clearance gap between the clutch and Quick Change Driving Adapter, making the clutch maintenance less time consuming.

SDA - Standard Driving Adapter. A close couple design where ease of clutch maintenance is not of prime importance.

STV 348

STV 448

Clutch only 6-148-200-100-0

Clutch w/ QCDA

Clutch only 6-148-300-100-0

Clutch w/ QCDA —

Clutch only —

Clutch w/ QCDA —

Clutch only 6-160-200-307-0

Clutch w/ QCDA —

Clutch only 6-160-300-304-0

Clutch w/ QCDA —

Clutch only —

Clutch w/ QCDA 6-160-430-301-0

Clutch only —

Clutch w/ QCDA 6-160-582-300-0

—

E

P-1100-WC • 1/11

Wichita Clutch 800-964-3262 129

Page 9

Standard Vent Clutches

Coupling and Grinding Mill Clutch Selection

Component Parts

1. Hub

2. Hex Head Bolt

3. Backplate

4. Shim

5. Driving Ring

6. Friction Disc

7. Release Spring

8. Center Plate

130 Wichita Clutch 800-964-3262

9. Pressure Plate

10. Hose Assembly

11. Air Tube

12. Air Tube Holding Plate

14. Socket Head Capscrew

16. Elbow

17. Bolt (Furnished by cus tom er)

P-1100-WC 1/12

Page 10

• In-line power applications

• Smooth, controlled acceleration

• Unaffected by centrifugal force

Releasing springs insure

complete disengagement.

Air passages through

clutch greatly assist in

keeping clutch cool.

Standard Vent Clutches

Coupling Clutches

Optional high speed air tube

reinforced to withstand speeds

even greater than permissible

with cast iron.

All air connections on

outside for easy access.

Demountable back

plate for accessibility.

(Optional)

Friction discs available in

halves easily replaceable

without dismounting.

Full width molded composition

teeth on friction disc minimize

wear on driving ring.

The Wichita Standard Vent Combination

Clutch-Coupling is designed for reliable

in-line power transmission. The simple

air-tube design, with small air volume,

speeds en gage ment and dis en gage ment.

It is un af fect ed by centrifugal force and has

no self-energization like drum clutch designs.

Ideally suited for large inertia loads where

smooth controlled starts are needed.

The Wichita air-tube disc design combines all

the best features of a disc type clutch with all

the advantages of direct air en gage ment. It is

E

Air-tube easily

replaceable without

dismounting by simply

removing these

capscrews.

the simplest and most trouble-free method of

applying air pres sure yet designed.

Problems of speed, smoothness, en gage ment

or disengagement with all types of

loads…problems of compactness …prob lems

of simplifying main te nance and many other

prob lems in a wide range of ap pli ca tions are

quickly solved with Wichita clutches or

brakes.

P-1100-WC 1/12

Wichita Clutch 800-964-3262 131

Page 11

Standard Vent Clutches

Coupling Clutches

Notes:

1. Air Hose Kits, page 141.

2. Quick Release Valves, page 144.

3. Roto-couplings, page 144.

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

132 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 12

Standard Vent Clutches

Coupling Clutches

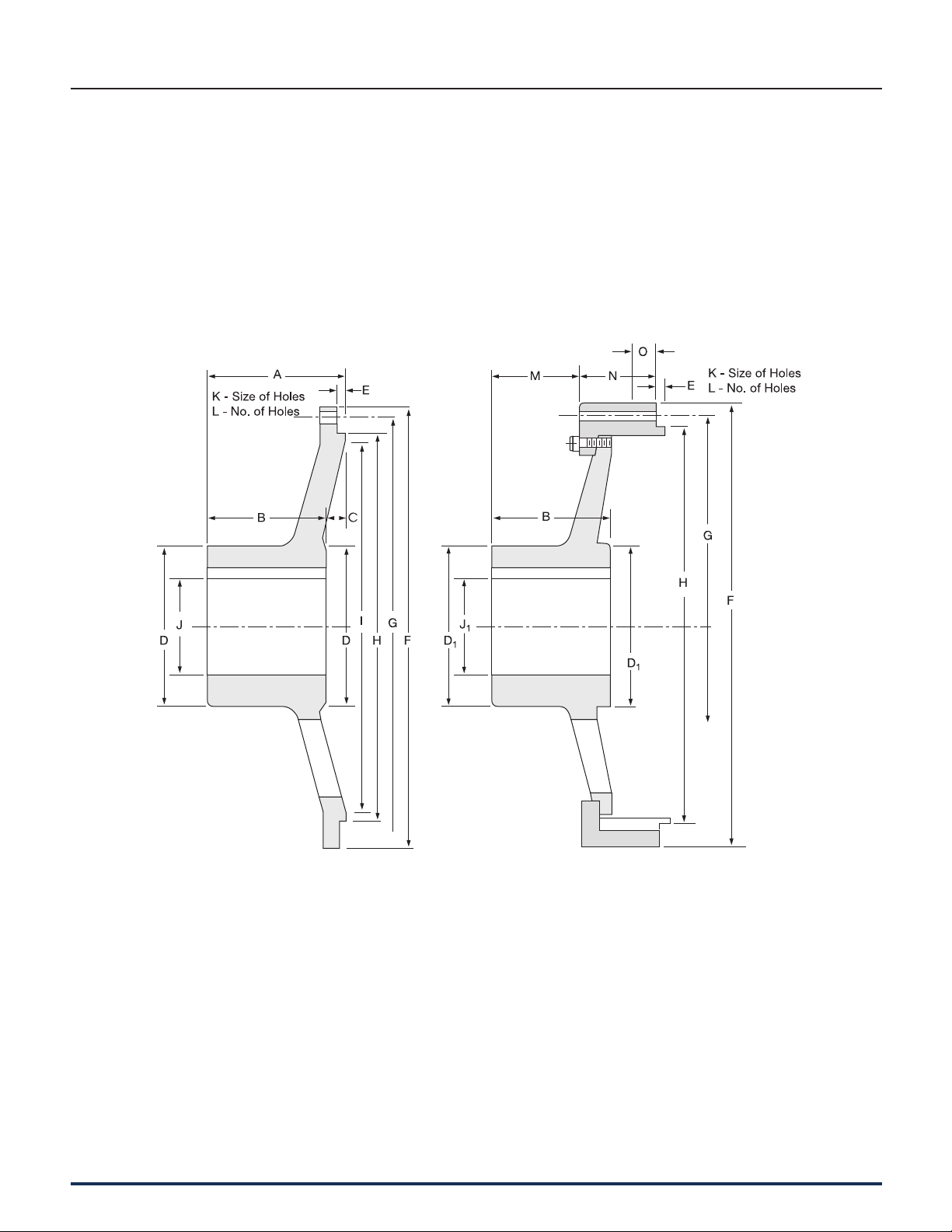

Dimensions: inches (Consult factory for drawing before final layout.)

Model +.003" Max Bore

Size -.000" Rect. Key

ATD– A B C D E F G H I J

108 STVC 9.625 8.873 8.50 8 8 1.93 2.75 1.938 6.625 9.625

208 STVC 9.625 8.873 8.50 8 8 1.93 4.125 1.938 6.625 9.625

308 STVC 9.625 8.873 8.50 8 8 1.93 5.50 1.938 6.625 9.625

111 STVC 13.375 12.375 12 11 11 3.00 3 3 8.50 11.938

211 STVC 13.375 12.375 12 11 11 3.00 4.25 3 8.50 11.938

311 STVC 13.375 12.375 12 11 11 3.00 5.563 3 8.50 11.938

114H STVC 16.25 15.125 14.67 14 9.375 3.38 4.313 4.50 12.50 16.313

214H STVC 16.25 15.125 14.67 14 9.375 3.38 5.75 4.50 12.50 16.313

314H STVC 16.25 15.125 14.67 14 9.375 3.38 7.188 4.50 12.50 16.313

118 STVC 20.75 19.500 18.75 18 11.50 4.00 4.75 5.25 14 19.375

218 STVC 20.75 19.500 18.75 18 11.50 4.00 6.25 5.25 14 19.375

118H STVC 20.75 19.500 18.75 18 11.50 4.00 4.75 5.25 16 21.625

218H STVC 20.75 19.500 18.75 18 11.50 4.00 6.25 5.25 16 21.625

318H STVC 20.75 19.500 18.75 18 11.50 4.00 7.75 5.25 16 21.625

321 STVC 23.75 22.500 21.75 21 14 5.38 9.125 7 16 21.625

124H STVC 26.75 25.500 24.75 24 16 5.38 5.875 7 21 27

224H STVC 26.75 25.500 24.75 24 16 5.38 7.25 7 21 27

324H STVC 26.75 25.500 24.75 24 16 5.38 9.375 7 21 27

327 STVC 29.75 28.500 27.75 27 19.50 7.00 9.75 9 21 27

230H STVC 32.75 31.500 30.75 30 22.50 7.00 8.50 9 24.75 32.375

330H STVC 32.75 31.500 30.75 30 22.50 7.00 11.50 9 24.75 32.375

336H STVC 39.75 38.500 37.50 36 28 8.00 12.625 13.50 30.50 38.25

342 STVC 47.25 45.000 44 42 42 10.00 11.875 21 35 44.125

248 STVC 54 52.000 51 48 35 12.00 10.875 21 40 52.375

348 STVC 54 52.000 51 48 35 12.00 13.625 21 40 52.375

260 STVC 64.75 62.750 62 60 36.125 14.00 16.25 22.625 46.50 61.50

360 STVC 64.75 62.750 62 60 36.125 14.00 20 22.625 46.50 61.50

460 STVC 64.75 62.750 62 60 36.125 14.00 23.50 22.625 46.50 61.50

Model

Size

ATD– K L M N P R S T U V W X Y Z

108 STVC 8.247 4 .75 — .438 10.375 1.375 .50 1/2 NC 6 2.25 .50 1/2 2

208 STVC 8.247 5.313 .75 1.75 .438 10.375 2.625 .50 1/2 NC 6 2.25 .50 1/2 2

308 STVC 8.247 6.625 .75 3.063 .438 10.375 3.875 .50 1/2 NC 6 2.25 .50 1/2 2

111 STVC 11.763 4.125 .875 — .50 14.375 1.50 .50 5/8 NC 8 2.50 .438 1/2 2

211 STVC 11.763 5.25 .875 1.75 .50 14.375 2.875 .50 5/8 NC 8 2.50 .438 1/2 2

311 STVC 11.763 6.75 .875 3 .50 14.375 4.25 .50 5/8 NC 8 2.50 .438 1/2 2

114H STVC 14.451 5.125 1.125 — .625 17.50 1.875 .625 5/8 NC 6 2.25 .75 1/2 2

214H STVC 14.451 6.50 1.125 2 .625 17.50 3.25 .75 5/8 NC 6 2.25 .75 1/2 2

314H STVC 14.451 8 1.125 3.375 .625 17.50 4.75 .75 5/8 NC 6 2.25 .75 1/2 2

118 STVC 18.375 5.625 1.313 — .625 22 1.938 .75 5/8 NC 6 2.438 1 1/2 3

218 STVC 18.375 7.125 1.313 2.125 .625 22 3.50 .75 5/8 NC 6 2.438 1 1/2 3

118H STVC 18.375 5.625 1.313 — .625 22 1.938 .75 5/8 NC 6 2.438 1 1/2 3

218H STVC 18.375 7.25 1.313 2.125 .625 22 3.50 .75 5/8 NC 6 2.438 1 1/2 3

318H STVC 18.375 8.688 1.313 3.75 .625 22 5.125 .75 5/8 NC 6 2.438 1 1/2 3

321 STVC 21.350 10.125 1.625 4.25 .75 25 6.125 1 5/8 NC 6 2.375 1 1/2 3

124H STVC 24.312 6.563 1.625 — .875 28 2.813 .75 5/8 NC 6 2.75 1 1/2 3

224H STVC 24.312 8.625 1.625 2.75 .875 28 4.50 .75 5/8 NC 6 2.75 1 1/2 3

324H STVC 24.312 10.563 1.625 4.625 .875 28 6.25 .75 5/8 NC 6 2.75 1 1/2 3

327 STVC 27.361 10.75 1.625 4.625 .875 31 6.50 1.375 5/8 NC 12 2.375 1 1/2 3

230H STVC 30.361 10.125 1.625 3.75 1.25 34 5.625 1.125 5/8 NC 12 2.875 1 1/2 4

330H STVC 30.361 12.75 1.625 6.25 1.25 34 8.125 1.125 5/8 NC 12 2.875 1 1/2 4

336H STVC 37.159 14.375 1.938 7.125 1.375 41 9 1.50 5/8 NC 16 2.875 1 1/2 4

342 STVC 43.627 14 2 7.375 1.375 49.25 9.625 1.75 1" NC 12 3.50 1.25 1/2 4

248 STVC 50.815 13.75 2.625 4.125 1.375 56 7.125 2 1" NC 12 3.50 1.25 1/2 4

348 STVC 50.815 15.75 2.625 6.875 1.375 56 9.875 2 1" NC 12 3.50 1.25 1/2 4

260 STVC 61.700 16.25 3 5.50 3 66.75 9 2.50 1" NC 24 2 2 1/2 6

360 STVC 61.700 20 3 9 3 66.75 13 2.50 1" NC 24 2 2 1/2 6

460 STVC 61.700 23.375 3 12.50 3 66.75 16.50 2.50 1" NC 24 2 2 1/2 6

E

P-1100-WC 1/12

Wichita Clutch 800-964-3262 133

Page 13

Standard Vent Clutches

Coupling Clutches

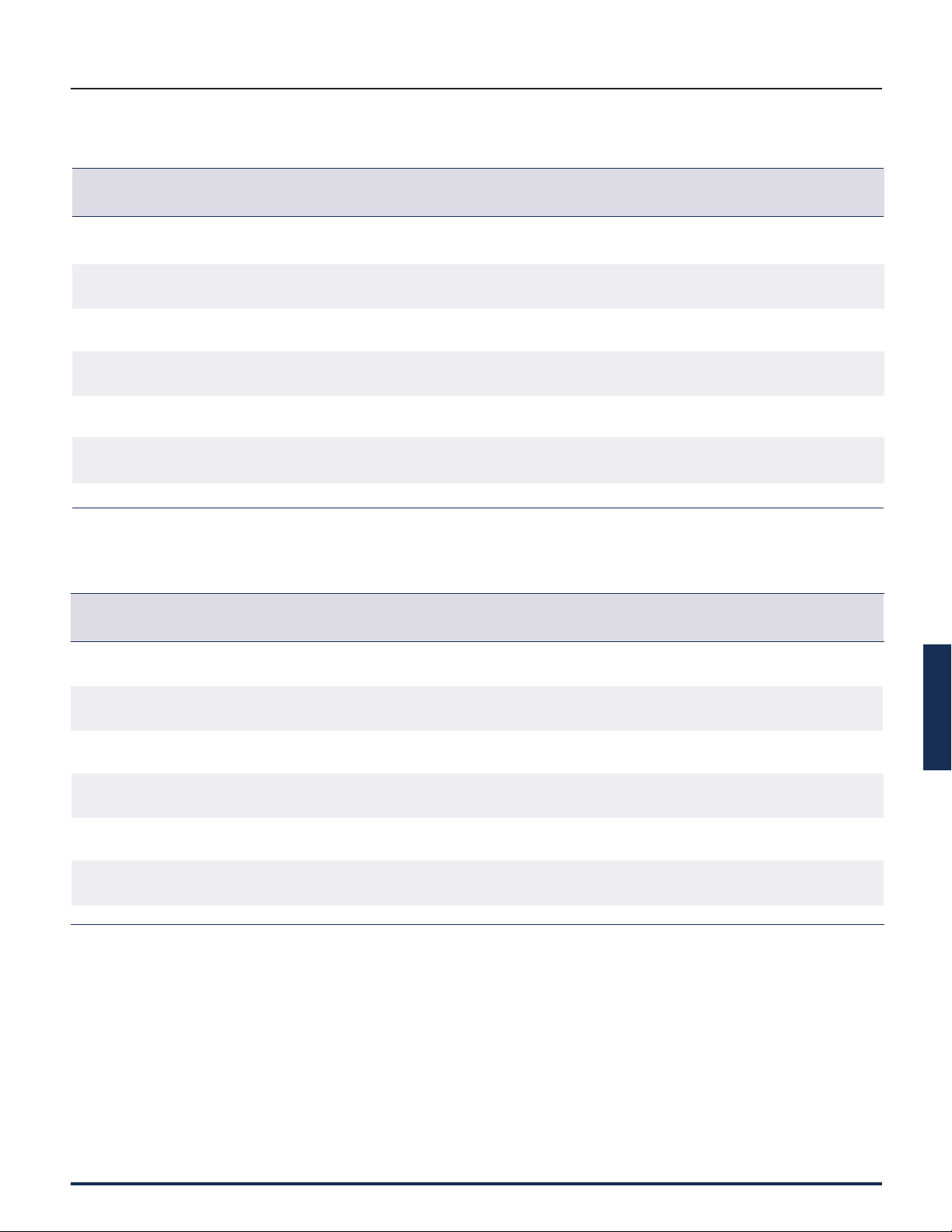

Standard Driving Adapters

The driving adapter is designed to allow the

clutch to be used in a shaft-to-shaft or

through-shaft coupling arrangement.

Quick Change Adapters

The quick change feature, using a driving

elbow piece between the driving adapter and

the clutch driving ring, enables replacement of

any wearing clutch part without disturbing

either shaft.

Standard Adapter (Standard Gap)

134 Wichita Clutch 800-964-3262

Quick Change Adapter (Access Gap)

P-1100-WC 1/12

Page 14

Standard Vent Clutches

Coupling Clutches

Dimensions: inches

+.003"

-.000"

Size A B C D D1 E F G H

8 3.125 3 .125 3.75 — .125 10.375 9.625 8.869

11 3.625 3.25 .375 6.25 5 .125 14.375 13.375 12.371

14H 5.375 4.75 .625 7 6.25 .25 17.50 16.25 15.121

18 6.875 5.75 1.125 8 8 .375 22 20.75 19.496

18H 6.875 5.75 1.125 8 8 .375 22 20.75 19.496

21 6.75 6 .75 9.50 9 .25 25 23.75 22.496

24H 8.375 7.313 1.063 10 12 .25 28 26.75 25.495

27 8.75 7.75 1 11 11.50 .25 31 29.75 28.495

30H 9.25 8.75 .50 14 14 .25 34 32.75 31.495

36 10.50 10 .50 15 14 .25 41 39.75 38.495

42 11 10 1 15 15 .25 49.25 47.25 44.995

48 — 13.625 — — 20 .50 56 54 52.000

60 — 16.25 — 24 — .375 66.75 64.75 62.750

Max. Bore

Rect. Key

Size I J J

8 8.375 2.50 — .531 6 1.875 * —

11 11.75 4.13 3.375 .656 8 2 2.50 —

14H 14.50 4.75 4.125 .656 6 2.125 3.125 —

18 18.50 5.25 5.25 .688 6 4.375 3.50 —

18H 18.50 5.25 5.25 .688 6 4.375 3.50 —

21 21.75 6.25 6 .688 6 4 6.25 —

24H 24.50 6.63 6.625 .688 6 5.188 5.50 —

27 27.75 7.25 7.625 .688 12 5.563 4.625 —

30H 30.50 9.25 9.25 .688 12 6.50 5.75 —

36 37.50 10.00 9.25 .688 16 7.875 4.125 —

42 44 10.00 10 1.031 12 7.438 5.688 —

48 — — 15 1.031 12 10.125 6.125 —

60 — 18.00 — 1.031 24 12.25 11.50 2.50

* Consult Factory

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

1

K L M N O

E

P-1100-WC 1/12

Wichita Clutch 800-964-3262 135

Loading...

Loading...