Page 1

Air Tube Disc Clutches and Brakes

Typical Applications

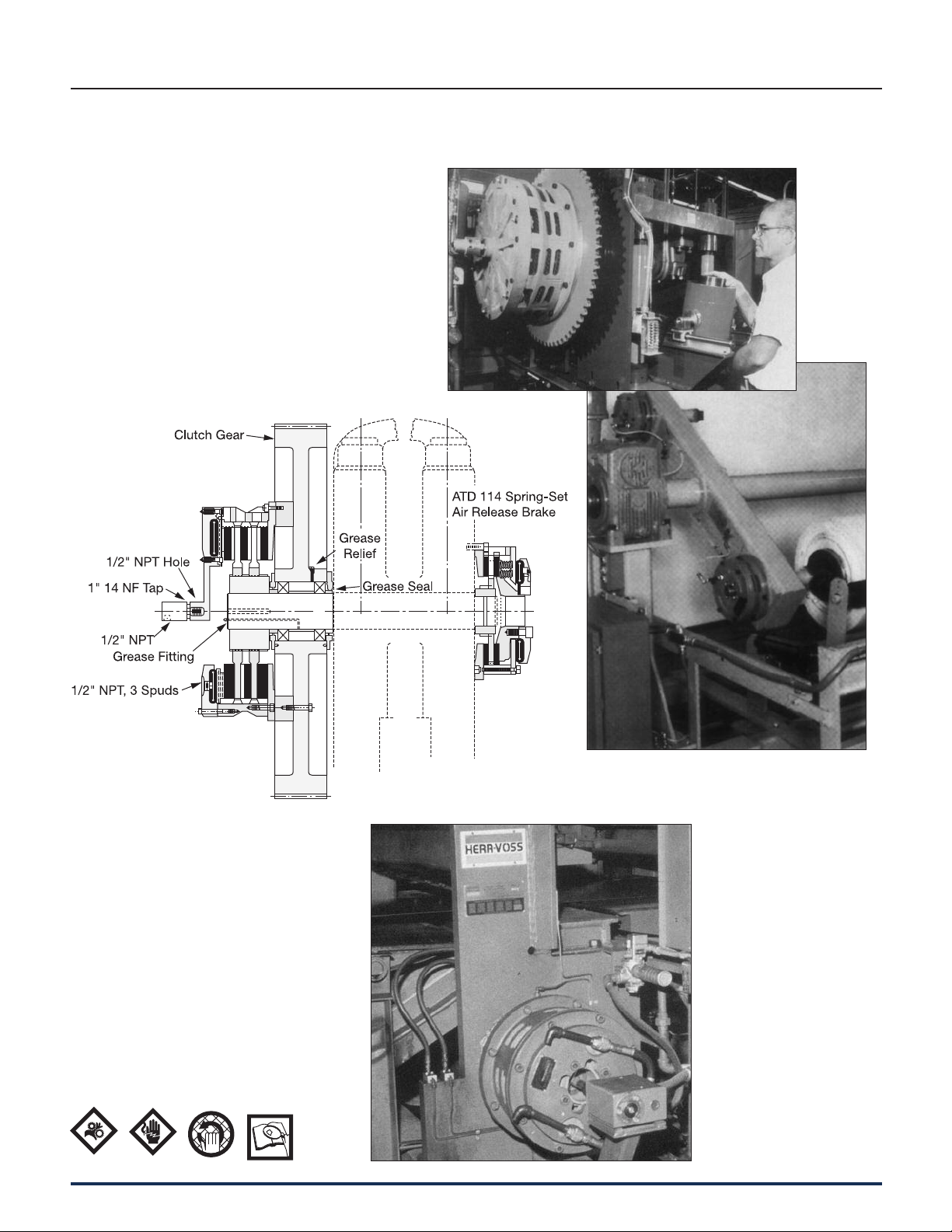

Wichita High Torque Clutch

provides fast acceleration and

long life on metalforming

punch presses.

Typical Wichita clutch

and brake mounting

on a press

22 Wichita Clutch 800-964-3262

Wichita Low Inertia Brakes increase tension control for

paper unwind stands.

Wichita Spring-Set

Air Release Brakes

insure accuracy and

high performance for

a metal shear.

P-1100-WC 1/12

Page 2

Clutch sizes are affected by the

following variables:

Air Tube Disc Clutches and Brakes

Application Factors

1. Machines that operate under smooth

loads require smaller clutches. These

machines are driven by either

multi-cylinder high speed engines or

electric motors with reduced starting

current.

2. Drives that require high starting

current motors will require clutches

with sufficient torque to prevent

excessive slipping while starting.

3. Starting torque may be high, which

requires a fast clutch response time

to transmit the required torque; or,

extended clutch slip time is required

to protect the prime mover.

This chart gives application factors

ranging from light duty (the A group) to

extra heavy duty (the D group).

After initial usage is determined, see

4. Starting torques may be very low

compared to the normal torque,

which may result in the clutch not

being fully pressurized prior to the

time of full torque requirement. This

will cause the clutch to overheat from

slippage. Clutch inflation time in this

instance is very important.

5. Clutches on most machines are

designed to slip prior to damage

from shockloads. As a result, the

clutch may require periodic

main te nance; therefore, the clutch

should be located for easy access in

the power train.

Clutch es should also be located for

max i mum cooling air. In instances

“Selection Requirements” to com plete

the selection process. The in fla tion and

exhaust time should also be checked to

insure proper response.

where this is not pos si ble, forced air

cooling may be nec es sary for

extended clutch life.

6. Safe clutch operating speeds should

be maintained in product design.

Maximum Clutch Contact Velocity

FPM Material

(Recommended

6,000

9,000

upper limit for slip)

ductile iron

cast iron

12,000 steel

Dynamic balancing recommended when

peripheral speeds exceed 3500 FPM.

The maximum speeds shown are safe

op er at ing speeds based on years of

Wichita testing. Please do not exceed

these limits.

Application Guidelines

B

Field of Application Group A Group B Group C Group D

Pumps Centrifugal Reciprocating compressors Reciprocating compressors

compressors over 2 cylinders, one or two cylinders

centrifugal fans & blowers

Agitators Liquid Semi-solid Solids

Brick Brick press, extruder, pug mill

manufacturing

Canning & bottling machine Bottle-can feeders, filling, mixers

Engine driven equipment Crane, hoist, engine Crowd

Grinding mills Ball-rod-sag-pebble Crushers, shakers

Lumber processing Yarder Carriages, conveyers Chipper, logger

Marine Propulsion clutch CP wheel Shaft brakes, propulsion

reversing type, anchor winch

Bulk material Conveyors evenly loaded, Feeders Elevators

handling line shaft evenly loaded

Metal production & Coilers, slitters, press brake, Draw bench, rolling mill, Hammer mill, forming

metalforming non-geared press, geared press shear, back geared press, press, forging press,

deep draw press, transfer header press, knuckle press

press, toggle press

Paper industry dryer Fourdrinier to 500 FPM, Fourdrinier to 1800 RPM

sections & calenders paper mill plane & press selections, calenders

Consult factory smoothing press & dryers

Petroleum Drilling & service rig master Mud pumps,

production clutches, compound clutches, PTO clutches

rotary, drum

Rubber Transfer machines Banberry mixer, drum mixer, Centrifuge

manufacturing evenly loaded extruder, calender

P-1100-WC 1/12

Wichita Clutch 800-964-3262 23

Page 3

Air Tube Disc Clutches and Brakes

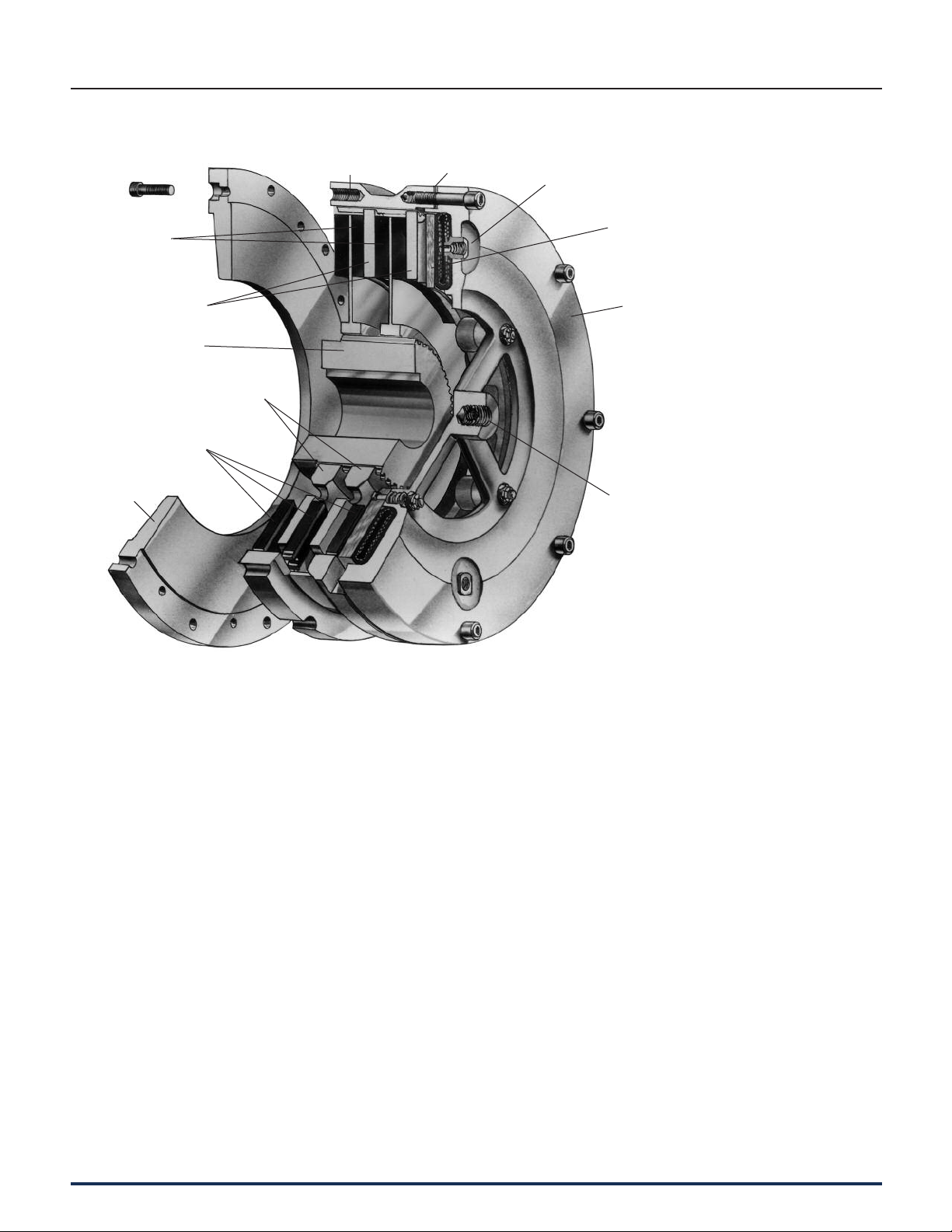

Low Inertia and Very Low Inertia Clutches and Brakes

Very Low Inertia

Drive Plate Assembly

with Bonded or

Riveted Pads

Floating Plate

Grooved

Friction Disc

Demountable

Backplate

(Optional)

Hub

Ductile

Center Plate

Ring Shims

Multiple Spud

Airtube

Pressure

Plate

Airtube

Holding

Plate

Roto-Coupling

Spider

Operating Features

The Wichita Air-Tube Disc Clutch com bines

all the best features of the disc type clutch with

all the advantages of direct air engagement.

The simplest and most trouble-free method of

applying air pressure is through direct axial

pressure ap pli ca tion by com pressed air in a

special com po si tion full-circle tube.

Wichita Clutches engage smoothly without

noise, shock or impact and release com plete ly

in a fraction of a second. Extremely fast action

is possible because of the small volume of air

re quired.

Clutches may be slipped moderately to control

the acceleration rate.

When large inertia loads are powered from

electric motors, smooth, controlled slip starts

by Wichita Clutches can keep power demands

below the allowed max i mum.

Heat generated by controlled slipping or

high cycle rate operation is dissipated by

the cen trif u gal blower design of these units.

Wichita Low Inertia and Very Low Inertia

Clutches and Brakes are de signed to be

com plete ly free from effects of cen trif u gal

force and self energization.

Torque developed is in direct proportion to air

pressure ap plied.

These clutches and brakes interface well with

automated controls through simple air and/or

electric circuits.

Water cooled, copper disc clutches are

available for use when power trans mis sion

needs require excessive or con stant slipping

which demands higher heat

dis si pa tion.

Wichita Clutches operate perfectly when

teamed with Wichita Brakes in pro duc tion

situations requiring tension control, cyclic

duty, or positioning.

Wichita Brakes have the same outstanding

performance characteristics as Wichita

Clutch es.

24 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 4

Air Tube Disc Clutches and Brakes

Low Inertia and Very Low Inertia Clutches and Brakes

Selection Requirements

The selection of a Low Inertia Brake is

based on:

1. Torque required to stop a load.

2. Friction area necessary to absorb

rotational energy.

3. Contact velocity of rotating discs.

4. Maximum bore capacity of unit.

Selection example

To properly select a Low Inertia Brake for

a controlled deceleration application, the

following information is needed:

Speed . . . . . . . . . . . . . . . . . . 750 RPM

Shaft Dia.. . . . . . . . . . . . . . . . 5 in.

Inertia to Stop . . . . . . . . . . . . 2,473 lb.ft.

Stop Time . . . . . . . . . . . . . . . 5 sec.

Air Pressure Available . . . . . . 80 PSI

Calculations

Avg. HP =

3.2 x 106x Stop Time

WR

2

X (RPM)

= 2,473 X (750)

3.2 x 106x 5 sec.

Swept Avg. HP

Friction =

HP ab sorp tion rate for 5 seconds

Area (see page 174)

=87 HP

= 202 in.

0.43

2

2

= 87 HP

2

Summary

As calculated, the torque required to stop the

load in 5 seconds is 14,547 lb.in. Wichita Low

Inertia Brakes are rated at 100 PSI.

This application has only 80 PSI available.

To determine the torque rating of a Low Inertia

brake at 80 PSI apply the following formula:

Application: Torque for a Low Inertia Brake

= Torque X Catalog Rated Pressure

Available Air Pressure

= 14,547 X = 18,183 lb.in.

100

80

Consult pages 26 and 36 for clutch and brake

spec i fi ca tions. A Low Inertia model 114 Brake

2

pro duc es 27,625 lb.in. torque at 100 PSI.

However, the bore capacity is 4.125 inches.

This application requires a 5 inch bore.

There fore, a Low Inertia 118 is to be

in ves ti gat ed.

Catalog Torque Rating = 64,500 lb.in.

@ 100 PSI

Maximum Bore Capacity = 5.25 in.

Catalog Swept Friction Area = 264 in.

2

Calculations show this application needs at

least 202 in.

2

to absorb the heat.

All of these ratings are acceptable for the given

application data.

Next, check contact velocity of rotating discs.

= Diameter of centerplate X RPM

3.82

B

P-1100-WC 1/12

Torque

25.5 x Stop Time

25.5 x 5

WR2x RPM

=

=

2.473 x 750

= 14,547 lb.in.

Using the above calculations, consult the

Low Inertia Specifications Chart on

pages 26 and 27.

=18" X 750

3.82

= 3,534 FPM

Standard material is sufficient up to 6,000 FPM

(see page 23). Balancing is recommended

above 3,500 FPM.

Therefore, a Low Inertia ATD-118 brake is

the optimum choice for this application.

A Spring-Set Air Release Brake is also

available (see page 58).

Note:

This application example is for pre lim i nary

sizing only. Contact a Wichita Sales Engineer

or the factory for final selection.

Wichita Clutch 800-964-3262 25

Page 5

Air Tube Disc Clutches and Brakes

Low Inertia Clutches

Specifications

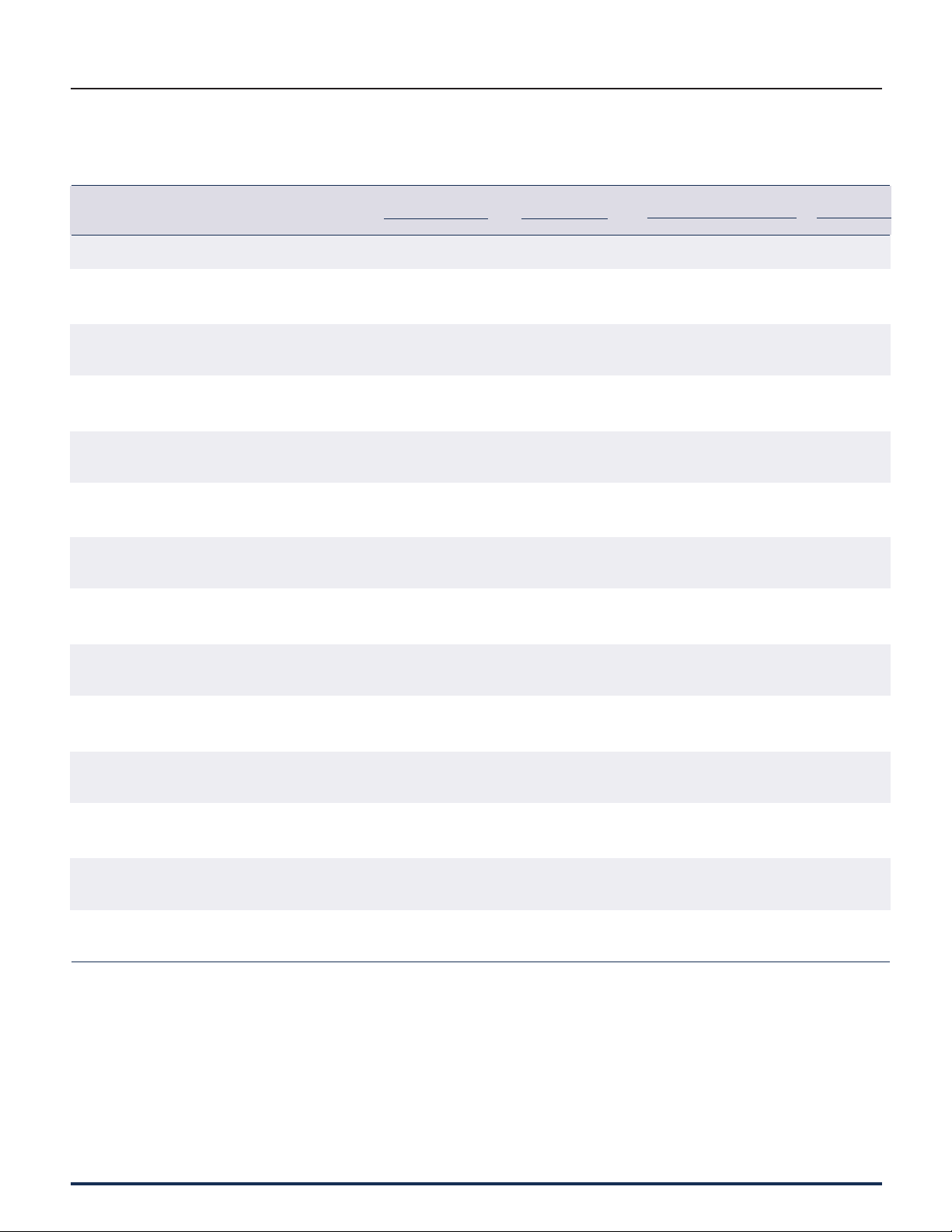

Model Slip Torque Capacity Duty Factors Max. Bore

Size Assembly Drawing lb.in. Nm HP/100 RPM Rect. Key

ATD- Number Number 80 PSI 100 PSI 5.5 BAR 7 BAR ABCDin. (mm)

LIC 106 6-006-100-211-0 -100-900-9 3,160 3,950 340 435 6.2 4.4 2.2 1.1

LIC 206 6-006-200-200-0 -200-900-9 6,320 7,900 680 870 12.5 8.8 4.4 2.2

LIC 108 6-008-100-103-0 D-1718 5,600 7,000 620 790 11.1 842

LIC 208 6-008-200-101-0 -200-900-9 11,200 14,000 1,240 1,580 22.2 16 842.25 (57)

LIC 308 6-008-300-103-0 D-2843 16,800 21,000 1,865 2,375 33.3 24 12 6

LIC 111 6-011-100-102-0 -100-900-9 12,720 15,900 1,400 1,785 25 18 95

LIC 211 6-011-200-102-0 -200-900-9 25,440 31,800 2,800 3,570 50 36 18 10 2.50 (64)

LIC 311 6-011-300-100-0 B-322 38,160 47,700 4,235 5,390 75 54 27 15

LIC 114 6-014-100-102-0 -100-900-9 22,100 27,625 2,435 3,100 44 31 16 8

LIC 214 6-014-200-104-0 -200-900-9 44,200 55,250 4,870 6,200 88 62 32 16 3.50 (89)

LIC 314 6-014-300-100-0 B-329 66,300 82,875 7,355 9,365 132 93 48 24

LIC 116 6-016-100-100-0 D-327 30,270 37,838 3,360 4,275 60 46 24 12

LIC 216 6-016-200-100-0 -200-900-9 60,541 75,676 6,720 8,550 120 92 48 24 4.00 (102)

LIC 316 6-016-300-100-0 D-1205 90,811 113,514 10,080 12,825 180 139 72 36

LIC 118 6-018-100-100-0 -100-100-0 51,600 64,500 5,705 7,260 102 75 35 21

LIC 218 6-018-200-100-0 -200-900-9 103,200 129,000 11,410 14,520 204 150 70 42 4.75 (121)

LIC 318 6-018-300-101-0 D-680 154,840 193,550 17,115 21,780 306 225 105 63

LIC 121 6-021-100-100-0 D-127 69,887 87,359 7,755 9,870 139 107 55 28

LIC 221 6-021-200-100-0 -200-900-9 139,775 174,719 15,510 19,740 277 213 111 55 6.00 (152)

LIC 321 6-021-300-100-0 D-783 209,662 262,078 23,265 29,610 416 320 166 83

LIC 124H 6-025-100-100-0 D-347 122,960 153,700 13,575 17,275 243 180 90 40

LIC 224H 6-025-200-100-0 -200-900-9 245,920 307,400 27,150 34,550 487 360 180 80 6.00 (152)

LIC 324H 6-025-300-201-0 -300-900-9 368,880 461,100 40,725 51,825 729 540 270 120

LIC 127 6-027-100-100-0 -100-900-9 137,509 171,886 15,260 19,420 273 210 109 55

LIC 227 6-027-200-100-0 -200-900-9 275,018 343,773 30,520 38,840 546 420 218 109 6.50 (165)

LIC 327 6-027-300-100-0 D-689 412,527 515,659 45,780 58,260 819 630 327 164

LIC 130H 6-031-100-100-0 B-195 261,600 327,000 29,630 37,710 519 380 190 100

LIC 230H 6-031-200-349-0 -200-900-9 523,200 654,000 59,260 75,420 1,038 760 380 200 7.25 (184)

LIC 330H 6-031-300-104-0 -300-902-9 784,800 981,000 88,890 113,130 1,557 1,140 570 300

LIC 136 6-036-100-100-0 -100-900-9 406,400 508,000 44,920 57,175 805 600 295 165

LIC 236 6-036-200-100-0 D-570 812,800 1,016,000 89,840 114,350 1,610 1,200 590 330 9.00 (229)

LIC 336 6-036-300-100-0 -300-900-9 1,219,200 1,524,000 134,760 171,525 2,415 1,800 885 495

LIC 142 6-042-100-303-0 -100-900-9 580,800 726,000 69,160 81,660 1,150 850 425 235

LIC 242 6-042-200-309-0 -200-900-9 1,162,240 1,452,800 128,320 163,320 2,300 1,700 850 470 14.00 (355)

LIC 342 6-042-300-302-0 -300-303-9 1,742,400 2,178,000 192,480 244,980 3,450 2,550 1,275 705

LIC 148 6-048-100-300-0 -100-901-9 1,122,000 1,402,500 118,800 151,200 2,225 1,600 800 455

LIC 248 6-048-200-300-0 -200-906-9 2,244,000 2,805,000 237,600 302,400 4,450 3,200 1,600 915 18.00 (455)

LIC 348 6-048-300-110-0 -300-900-9 3,366,000 4,207,500 356,400 453,600 6,675 4,800 2,400 1,365

LIC 260 6-060-200-302-0 -200-907-9 4,760,000 5,950,000 473,000 602,000 9,440 5,950 3,470 1,940

LIC 360 6-060-300-201-0 -300-901-9 7,140,000 8,925,000 709,000 902,300 14,160 8,925 5,205 2,910 19.00 (480)

LIC 460 6-060-400-300-0 E-236 14,280,000 17,850,000 946,000 1,204,000 18,880 11,900 6,940 3,880

Maximum Air Pressure is 130 PSI / 9 BAR.

2.00 (50)

26 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 6

Air Tube Disc Clutches and Brakes

Low Inertia Clutches

Specifications

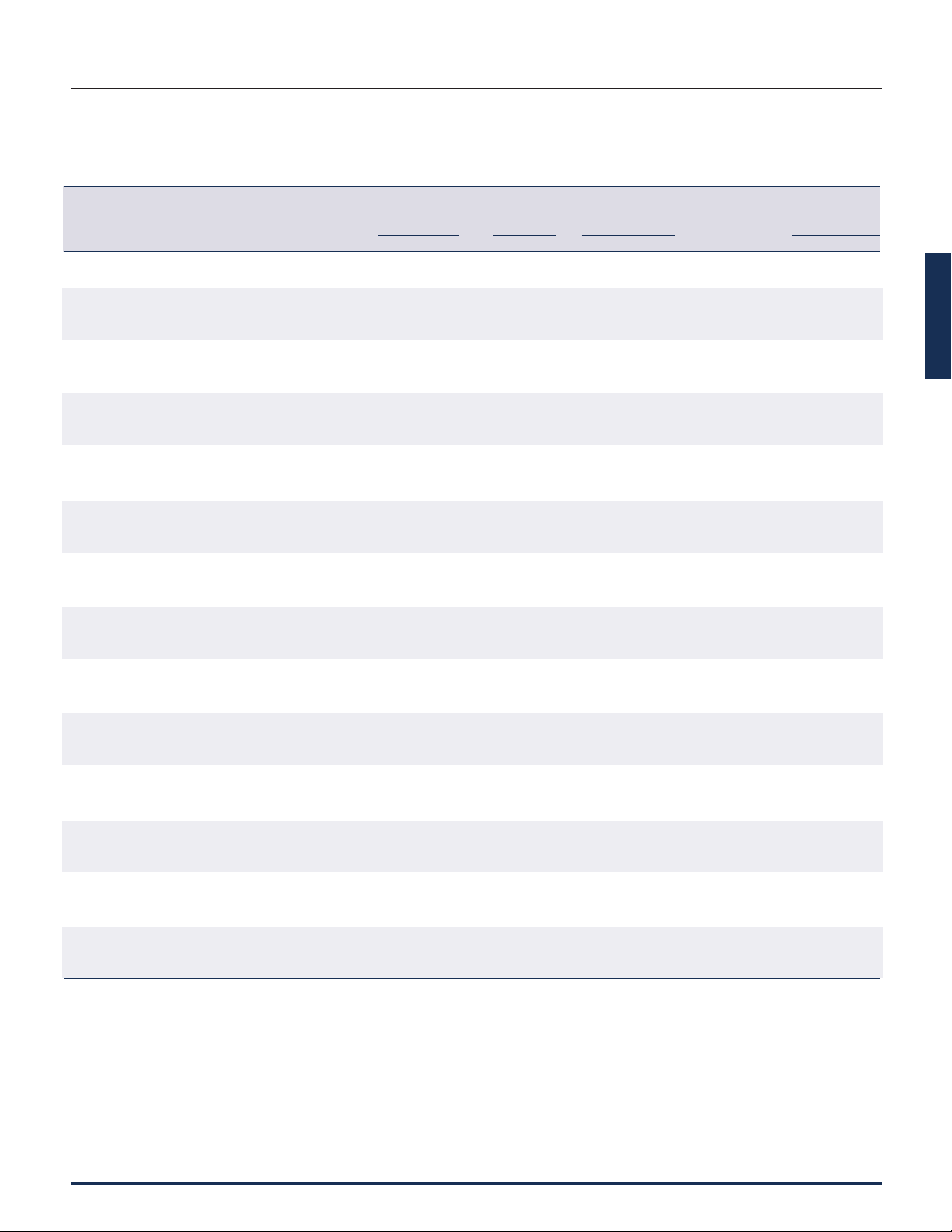

Recom- Airtube Type Airtube

Model mended Balance Reg- High Swept Volume Total Clutch Hub & Center Plate

Size Clearance Speed Speed Speed Area in.3/(cm3) Wt. WR2/ J=mr

ATD- in. RPM RPM RPM* in.2New Worn lb. (kg) lb.ft.

LIC 106 1/16-3/32

LIC 206 3/32-5/32 78

LIC 108 1/16-1/8 56

LIC 208 3/32-5/32 1,675 1,750 3,000* 112 70 (32) 8.5 (0.357) 19 (8.6) 1.00 (0.042)

LIC 308 1/8-3/16 168

LIC 111 1/16-1/8 114

LIC 211 3/32-5/32 1,200 1,400 2,800* 228 170 (77) 34 (1.43) 45 (20.4) 4.50 (0.190)

LIC 311 1/8-3/16 342

LIC 114 1/16-1/8 158

LIC 214 3/32-5/32 950 1,200 2,200* 316 233 (106) 70 (2.95) 77 (34.9) 11.0 (0.464)

LIC 314 1/8-3/16 474

LIC 116 1/16-1/8 228

LIC 216 3/32-5/32 835 1,200 2,000* 455 326 (148) 125 (5.27) 106 (48.1) 19.6 (0.826)

LIC 316 1/8-3/16 683

LIC 118 1/16-1/8 264

LIC 218 3/32-5/32 750 1,000 2,000* 528 377 (171) 183 (7.72) 120 (54.4) 28.8 (1.214)

LIC 318 1/8-3/16 792

LIC 121 3/32-5/32 362

LIC 221 1/8-3/16 650 900 1,650* 724 582 (264) 356 (15.01) 198 (89.8) 61 (2.57)

LIC 321 5/32-7/32 1,086

LIC 124H 3/32-5/32 574

LIC 224H 1/8-3/16 550 700 1,400* 1,148 830 (376) 618 (26.05) 260 (117.9) 109 (4.6)

LIC 324H 5/32-7/32 1,722

LIC 127 3/32-5/32 730

LIC 227 1/8-3/16 500 700 1,400* 1,460 950 (431) 862 (36.3) 322 (146.1) 193 (8.1)

LIC 327 5/32-7/32 2,190

LIC 130H 3/32-5/32 827

LIC 230H 1/8-3/16 450 600 1,100* 1,654 1,411 (640) 1,552 (65.4) 546 (247.7) 370 (15.6)

LIC 330H 5/32-7/32 2,481

LIC 136 3/32-5/32 1,150

LIC 236 1/8 -3/16 375 600 900* 2,300 1,992 (904) 3,247 (136.9) 708 (321.1) 725 (30.6)

LIC 336 5/32-7/32 3,450

LIC 142 5/32-7/32 1,400

LIC 242 3/16-1/4 325 500 800* 2,800 2,732 (1,239) 5,750 (242) 1,197 (543) 1,385 (58)

LIC 342 7/32-9/32 4,200

LIC 148 1/8-1/4 2,010

LIC 248 5/32-7/32 275 400 700* 4,020 4,700 (2,132) 13,775 (581) 1,942 (881) 3,335 (141)

LIC 348 3/16-5/16 6,030

LIC 260 3/16-5/16 7,230

LIC 360 1/4-3/8 225 320 550* 10,845 11643 (5,281) 57,286 (2,415) 3,870 (1,755) 10,615 (448)

LIC 460 5/16-7/16 14,460

* Consult Factory for Special Assembly Number.

2,225 1,800 2,600*

39

1.8 11.9

(30) (195)

3.4 18.3

(56) (300)

5.5 30.5

(90) (500)

7.6 42.7

(125) (700)

9.8 56.1

(161) (919)

15.3 85.4

(251) (1,400)

18.3 97.6

(300) (1,599)

29.9 159

(490) (2,606)

29.9 159

(490) (2,606)

58.6 311

(960) (5,096)

110 415

(1,803) (6,801)

128 488

(2,098) (7,997)

217 824

(3,550) (13,500)

513 1,788

(8,407) (29,300)

27.5 (12) 2.5 (0.105) 6.40 (2.9) 0.24 (0.010)

40.5 (18) 3.3 (0.139) 12.17 (5.5) 0.46 (0.019)

62 (28) 7.5 (0.315) 11 (5.0) 0.54 (0.023)

92 (42) 99 (4.174) 28 (12.7) 2.00 (0.084)

133 (60) 27 (1.14) 23 (10.4) 2.30 (0.097)

208 (94) 52 (2.19) 121 (54.9) 7.00 (0.295)

184 (83) 56 (2.36) 46 (20.9) 5.7 (0.240)

292 (132) 80 (3.37) 121 (54.9) 16.7 (0.704)

257 (117) 103 (4.34) 59 (26.8) 10.2 (0.430)

358 (162) 125 (5.27) 151 (68.5) 29.6 (1.248)

311 (141) 158 (6.66) 73 (33.1) 15.0 (0.632)

472 (214) 219 (9.23) 180 (81.6) 43.2 (1.821)

467 (212) 303 (12.77) 116 (52.6) 32 (1.35)

730 (331) 450 (18.97) 272 (123.4) 92 (3.88)

637 (289) 468 (19.73) 132 (60.0) 56 (2.4)

1,025 (465) 735 (31.00) 379 (172.0) 160 (6.8)

770 (349) 706 (29.8) 187 (84.8) 98 (4.1)

1,112 (504) 969 (40.9) 555 (251.7) 285 (12.0)

1,035 (469) 1,170 (49.3) 298 (135.2) 189 (8.0)

1,751 (794) 1,788 (75.4) 810 (367.4) 477 (20.1)

1,455 (660) 2,368 (99.8) 461 (209.1) 372 (15.7)

2,610 (1,184) 4,057 (171.0) 1,134 (514.4) 1,091 (46.0)

1,967 (892) 4,721 (199) 680 (308) 705 (30)

3,704 (1,680) 9,191 (387) 1,324 (601) 1,809 (76)

3,158 (1,432) 9,325 (393) 1,101 (499) 1,785 (75)

6,540 (2,966) 18,000 (759) 2,950 (1,338) 4,925 (208)

9,453 (4,288) 48,733 (2,055) 2,567 (1,164) 7,077 (298)

14500 (6,577) 68,980 (2,908) 5,700 (2,585) 15,070 (635)

2

2

Wt. WR2/ J=mr

(kgm2) lb. (kg) lb.ft.2(kgm2)

2

B

P-1100-WC 1/12

Wichita Clutch 800-964-3262 27

Page 7

Air Tube Disc Clutches and Brakes

Air System Data

PSI pressure

Inflation

Exhaust

Overlap

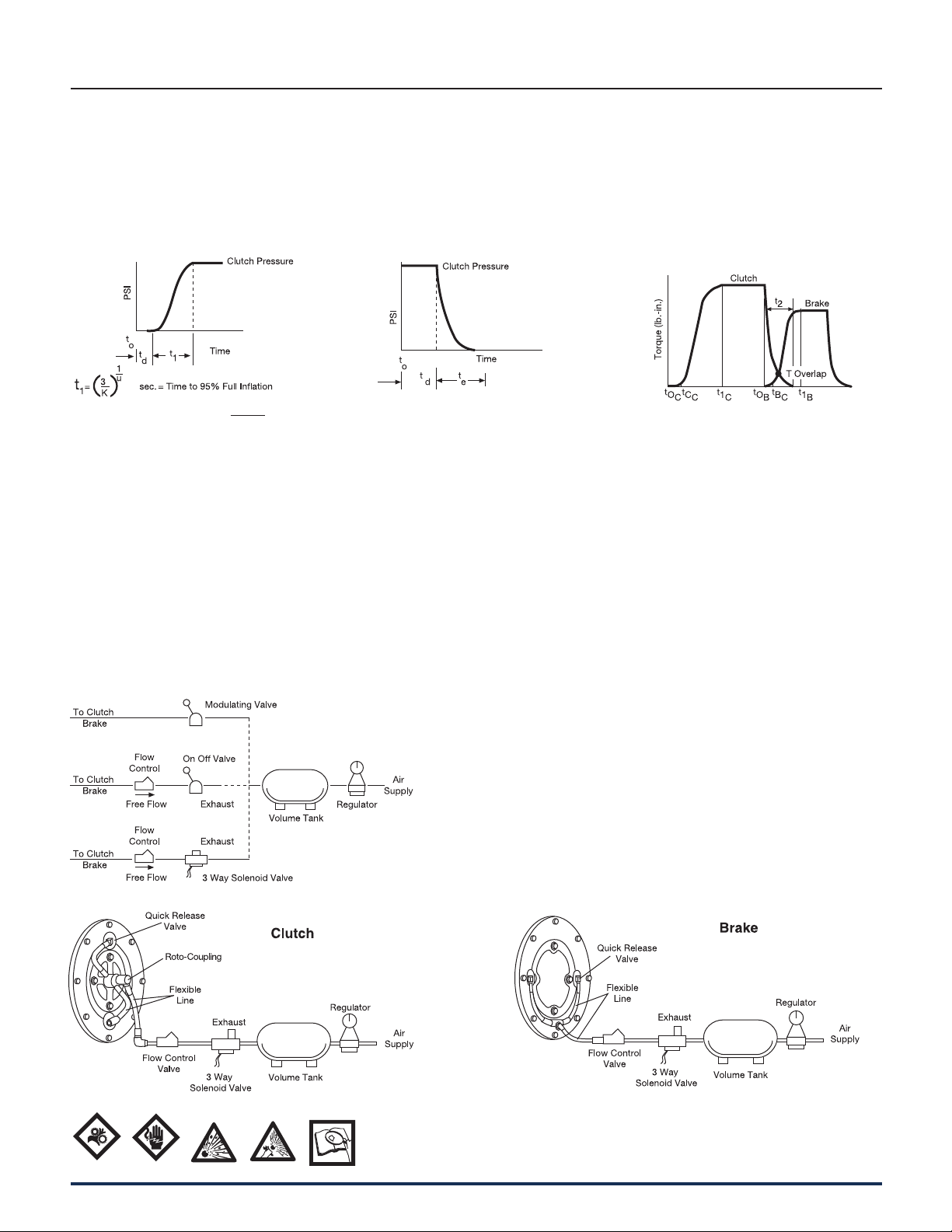

Clutch air pressure during inflation can

be closely estimated by the following:

Clutch pressure = P

(inflation)

1

1 – )PSI

1

u

Kt

(

e

This equation is accurate from 5% up

to 95% P

= Line pressure to clutch PSI

P

1

.

1

K and U = coefficients for specific

clutch and air pressure from

Spec i fi ca tion Table

e = Naperian base log

t

= Time at initiation of signal for

o

inflation sec.

t

= Time delay of air system – sec.

d

Clutch air pressure during exhaust

can be closely estimated by the

fol low ing:

Clutch pressure = (P

) (R) (E-t)vPSI

1

(exhaust)

R, E and V = coefficients for specific clutch

and air pressurefrom Spec i fi ca tion

Table

t

= Time to exhaust = E from

e

Spec i fi ca tion Table

t = Time variable – seconds. In the ex -

haust equa tion “t” cannot exceed

the value of “E” sec.

Shown are some of the air systems used

on Wichita clutches. These systems are

ac cept able for remote op er a tion where

clutch reaction time is not important.

Faster clutch re ac tion time is ac com

plished as in di cat ed in the

di a gram by lo cat ing the flow

control valve, if re quired,

and the so le noid valve as

close as possible to the

roto-cou pling. Where

clutches are located on long shafts, the

use of quick release valves on the clutch

will fa cil i tate faster clutch response.

A typical clutch-brake torque curve for

a single backshaft press (cyclic ap pli ca tion) would appear as shown below.

Time (sec.)

t

= time at which disengaged clutch

O

c

receives signal

t

= time of clutch en gage ment

C

c

= time of clutch full inflation

t

1

c

= time at which disengaged brake

t

O

B

receives signal

t

= time of brake engagement

B

c

= time of brake full exhaust

t

1

B

t2 = overlap time at which clutch and

brake are both engaged

28 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 8

Air Tube Disc Clutches and Brakes

Low Inertia and Very Low Inertia Clutches and Brakes

Inflation Coefficients

Model Inflation Coefficients Operating Air Pressure

Size 50 PSI 75 PSI 100 PSI

ATD- K U K U K U

108 15,800 2.2 7,100 2 265 1.2

208 15,800 2.2 7,100 2 265 1.2

111 890 1.7 880 1.6 5,100 2.2

211 890 1.7 880 1.6 5,100 2.2

114 980 2.3 980 2.3 980 2.3

214 980 2.3 980 2.3 980 2.3

118 9,600 3.1 1,560 2.4 9,600 3.1

218 9,600 3.1 1,560 2.4 9,600 3.1

124H 145 1.8 90 1.6 87 1.6

224H 145 1.8 90 1.6 87 1.6

130H 185 2 150 2 93 1.8

230H 185 2 150 2 93 1.8

136 170 2 250 2.2 160 2

236 170 2 250 2.2 160 2

142 115 2 125 2 111 2

242 115 2 125 2 111 2

148 25 1.6 22 1.6 26 1.8

248 25 1.6 22 1.6 26 1.8

260 28 1.8 22 1.8 20 1.8

360 28 1.8 22 1.8 20 1.8

B

Exhaust Coefficients

Model Exhaust Coefficients Operating Air Pressure

Size 50 PSI 75 PSI 100 PSI

ATD- R E V R E V R E V

108 60 .016 1.0 525 .02 1.6 240 .02 1.4

208 60 .016 1.0 525 .02 1.6 240 .02 1.4

111 1,000 .032 2 8,200 .04 2.8 4,930 .048 2.8

211 1,000 .032 2 8,200 .04 2.8 4,930 .048 2.8

114 720 .072 2.5 800 .069 2.5 1,840 .082 3

214 720 .072 2.5 800 .069 2.5 1,840 .082 3

118 44 .068 1.4 40 .072 1.4 34 .08 1.4

218 44 .068 1.4 40 .072 1.4 34 .08 1.4

124H 360 .096 2.5 240 .112 2.5 270 .136 2.8

224H 360 .096 2.5 240 .112 2.5 270 .136 2.8

130H 120 .104 2.1 140 .128 2.4 146 .158 2.7

230H 120 .104 2.1 140 .128 2.4 146 .158 2.7

136 124 .112 2.2 92 .128 2.2 76 .152 2.3

236 124 .112 2.2 92 .128 2.2 76 .152 2.3

142 132 .12 2.3 89 .144 2.3 61 .168 2.3

242 132 .12 2.3 89 .144 2.3 61 .168 2.3

148 20 .224 2 20 .256 2.2 19 .308 2.5

248 20 .224 2 20 .256 2.2 19 .308 2.5

260 24 .264 2.4 10 .367 2.3 9.9 .352 2.2

360 24 .264 2.4 10 .367 2.3 9.9 .352 2.2

P-1100-WC 1/12

Wichita Clutch 800-964-3262 29

Page 9

Air Tube Disc Clutches and Brakes

Low Inertia Clutches

Sizes 8-36

30 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 10

Air Tube Disc Clutches and Brakes

Low Inertia Clutches

Sizes 8-36

Dimensions: inches (mm)

Model AB C DE FGH

Size ATD- Hole Circle Pilot

LIC 108 12.13 11.125 8.375 / 8.378 11.13 6.31 (160.3) 2.00 (50.8) .25 (6.4) 4.56 (115.8)

LIC 208 (308.1) (282.58) (212.73 / 212.80) (282.7) 7.69 (195.3) 3.25 (82.6) .31 (7.9) 5.94 (150.9)

LIC 111 16.00 14.750 11.375 / 11.378 14.75 7.25 (184.2) 2.75 (69.9) .13 (3.3) 5.50 (139.7)

LIC 211 (406.4) (374.65) (288.93 / 289.00) (374.7) 9.00 (228.6) 4.38 (111.3) .25 (6.4) 7.25 (184.2)

LIC 114 18.75 17.500 14.375 / 14.378 17.50 7.56 (192.0) 3.75 (95.3) .13 (3.3) 6.06 (153.9)

LIC 214 (476.3) (444.50) (365.13 / 365.20) (444.5) 9.38 (238.3) 4.50 (114.3) .38 (9.7) 7.88 (200.2)

LIC 116

LIC 216 9.75 (247.7) 4.75 (120.7) .38 (9.7) 8.25 (209.6)

LIC 316

LIC 118

LIC 218 10.13 (257.3) 4.75 (120.7) .44 (11.2) 8.63 (219.2)

LIC 318

LIC 121

LIC 221 10.94 (277.9) 5.13 (130.3) .63 (16.0) 9.44 (239.8)

LIC 321

LIC 124H

LIC 224H 11.38 (289.1) 5.13 (130.3) .75 (19.1) 9.88 (251.0)

LIC 324H

LIC 127

LIC 227 11.88 (301.8) 6.88 (174.8) 10.38 (263.7)

LIC 327

LIC 130H

LIC 230H 15.94 7.13 (181.1) 1.88 (47.8) 11.69 (296.9)

LIC 330H

LIC 136

LIC 236 16.63 (422.4) 9.00 (228.6) .63 (16.0) 12.75 (323.9)

LIC 336

21.25 20.000 16.250 / 16.253 20.00

(539.8) (508.00) (412.75 / 412.83) (508.0)

23.25 22.000 18.250 / 18.253 22.00

(590.6) (558.80) (463.55 / 463.63) (558.8)

27.00 25.500 21.375 / 21.378 24.88

(685.8) (647.70) (542.93 / 543.00) (632.0)

30.00 28.750 24.375 / 24.378 29.00

(762) (730.25) (619.13 / 619.20) (736.6)

32.75 31.500 27.375 / 27.378 31.00

(831.9) (800.10) (695.33 / 695.40) (787.4)

37.00 35.500 30.375 / 30.3783 34.75

(939.8) (901.70) (771.53 / 771.60) (882.7)

43.50 42.000 36.375 / 36.378 41.00

(1,104.9) (1,066.80) (923.93 / 924.00) (1,041.4)

7.81 (198.4) 4.00 (101.6) 6.31 (160.3)

11.69 (296.9) 6.63 (168.4) 10.19 (258.8)

8.19 (208.0) 4.00 (101.6) 6.69 (169.9)

12.13 (308.1) 6.50 (165.1) 10.63 (270.0)

8.88 (225.6) 4.00 (101.6) .75 (19.1) 7.38 (187.5)

13.25 (336.6) 7.13 (181.1) .75 (19.1) 11.75 (298.5)

9.13 (231.9) 4.00 (101.6) .69 (17.5) 7.63 (193.8)

13.75 (349.3) 7.50 (190.5) .75 (19.1) 12.25 (311.2)

9.38 (238.3) 4.50 (114.3)

————

12.5 5.00 (127.0) .63 (16.0) 8.25 (209.6)

————

12.94 (328.7) 5.63 (143.0) 9.44 (239.8)

19.88 (505.0) 12.38 (314.5) 16.38 (416.1)

.75 (19.1)

7.88 (200.2)

B

Dimensions: inches (mm)

Model IJ L M NQR S U

Size ATD- No. - Size No. - Size Min. Max.

LIC 108 1.78 (45.2) .25

LIC 208 1.88 (47.8) (6.4) (136.7) (88.9) (12.7) (25) (50.8)

LIC 111

LIC 211 (9.7) 21/32 (16.7) (177.8) (101.6) (16.0) (25) (63.5)

LIC 114 1.44 (36.6) .38

LIC 214 2.13 (54.1) (9.7) (239.8) (139.7) (16.0) (35.1) (88.9)

LIC 116 1.13 (28.7)

LIC 216 2.31 (58.7) 12 - 21/32 (16.7) 2 - 1/2 NPT 1"-14NF

LIC 316 2.31 (58.7)

LIC 118 1.25 (31.8)

LIC 218 2.50 (63.5) 12 - 21/32 (16.7) 3 - 1/2 NPT 1"-14NF

LIC 318 2.75 (69.9)

LIC 121 1.63 (41.4)

LIC 221 2.68 (68.1) 12 - 21/32 (16.7) 3 - 1/2 NPT 1"-14NF

LIC 321 2.75 (69.9)

LIC 124H 1.75 (44.5)

LIC 224H 2.94 (74.7) 12 - 21/32 (16.7) 3 - 1/2 NPT 1"-14NF

LIC 324H 2.88 (73.2)

LIC 127 1.38 (35.1) .25

LIC 227 1.50 (38.1) (6.4) 16 - 21/32 (16.7) 3 - 1/2 NPT 1"-14NF

LIC 327 ——

LIC 130H 1.81 (46.0)

LIC 230H 1.88 (47.8) 18 - 25/32 (19.8) 4 - 1/2 NPT 1" NPT

LIC 330H —

LIC 136 1.38 (35.1)

LIC 236 1.63 (41.4) 18 - 25/32 (19.8) 4 - 1/2 NPT 1" NPT

LIC 336 1.75 (44.5)

2.00 (50.8)

.38

.38 10.50 6.00 .63 1.38 4.00

(9.7) (266.7) (152.4) (16.0) (35.1) (101.6)

.38 12.50 7.00 .63 2.00 4.75

(9.7) (317.5) (177.8) (16.0) (50.8) (120.7)

.31 14.50 9.00 .75 2.00 6.00

(7.9) (368.3) (228.6) (19.1) (50.8) (152.4)

.25 14.50 9.00 .75 2.00 6.00

(6.4) (368.3) (228.6) (19.1) (50.8) (152.4)

.25 19.25 10.00 .75 2.50 7.25

(6.4) (489) (254) (19.1) (63.5) (184.2)

.25 23.63 12.00 .88 6.00 9.00

(6.4) (600.2) (304.8) (22.4) (152.4) (228.6)

6 - 17/32 (13.5)

11/16 (17.5) 7.00 4.00 .63

6 -

8 - 21/32 (16.7)

5.38 3.50 .50

9.44 5.50 .63

16.25 9.00 .75 2.50 6.50

(412.8) (228.6) (19.1) (63.5) (165.1)

2 - 1/2 NPT 1"-14NF

2 - 1/2 NPT 1"-14NF

2 - 1/2 NPT 1"-14NF

1.00 2.00

1.00 2.50

1.38 3.50

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a. (Consult factory for drawing before final layout.)

P-1100-WC 1/12

Wichita Clutch 800-964-3262 31

Page 11

Air Tube Disc Clutches and Brakes

Low Inertia Clutches

Sizes 6, 42-60

Size 6

32 Wichita Clutch 800-964-3262

Size 42-60

P-1100-WC 1/12

Page 12

Air Tube Disc Clutches and Brakes

Low Inertia Clutches

Sizes 6, 42-60

Dimensions: inches (mm)

Model AB C DE FGH

Size ATD- Hole Circle Pilot

LIC 106 8.75 8.000 7.377 / 7.379 8.81 5.19 (131.8) 2.00 (50.8) 0.00 (0.0) 3.75 (95.3)

LIC 206 (222.3) (203.20) (187.38 / 187.43) (223.8) 6.43 (163.3) 3.25 (82.6) 0.06 (1.5) 5.00 (127.0)

LIC 142 52.00 49.250 44.625 / 44.628 49.00 10.81 (274.6) 5.63 (143.0)

LIC 242 (1,320.8) (1,250.95) (1,133.48 / 1,133.55) (1,244.6) 14.56 (369.8) 7.50 (190.5) 13.5 (342.9)

LIC 148 61.00 58.000 52.000 / 52.005 56.75 14.69 (373.1) 6.00 (152.4) 0.00 (0.0) 10.69 (271.5)

LIC 248 (1,549.4) (1,473.20) (1,320.80 / 1,320.93) (1,441.5) 19.07 (484.4) 8.75 (222.3) 1.00 (25.4) 15.07 (382.8)

1

LIC 260

LIC 360

LIC 460

70.50 66.500 62.750 / 62.760 70.50

1

(1,790.7) (1,689.10) (1,593.85 / 1,594.10) (1,790.7)

1

20.30 (515.6) 9.38 (238.3) 0.25 (6.4) 17.99 (456.9)

22.00 (558.8) 12.25 (311.2) 0.00 (0.0) 19.63 (498.6)

28.25 (717.6) 18.63 (473.2) 0.25 (6.4) 27.13 (689.1)

1.00 (25.40)

Dimensions: inches (mm)

Model IJL M NQR S U

Size ATD- No.- Size No. - Size Min. Max.

LIC 106 1.56 (39.6) 0.06

LIC 206 1.50 (38.1) (1.5) (106.4) (68.3) (14.2) (15.2) (50.8)

LIC 142 1.75 (44.5) 0.25

LIC 242 3.63 (92.2) (6.4) (749.3) (457.2) (38.1) (203.2) (355.6)

LIC 148 3.69 (93.7) 0.25

LIC 248 4.32 (109.7) (6.4) (812.8) (654.1) (38.1 (254.0) (457.2)

1

LIC 260

LIC 360

LIC 460

6.17 (156.7)

1

5.19 (131.8) 24 - 4.5"NC — 6 - 1/2 NPT 2"-12NF

1

6.38 (162.1)

0.25 36.00 27.00 11.00 19.00

(6.4) (914.4) (685.8) (279.4) (482.6)

4 - 0.34 (8.6)

24 - 1.06 (26.9)

24 - 1.06 (26.9)

4.19 2.69 0.56

29.50 18.00 1.50

32.00 25.75 1.50)

— 5/8"-11NF

4 - 1/2 NPT 1.5"-12NF

4 - 1/2 NPT 1" NPT

9.75 (247.7)

0.60 2.00

8.00 14.00

10.00 18.00

B

1

Less backplate.

NOTE: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

(Consult factory for drawing before final layout.)

P-1100-WC 1/12

Wichita Clutch 800-964-3262 33

Page 13

Air Tube Disc Clutches and Brakes

Low Inertia Clutch Air Hose Kits

Size Part Number

8" 8-908-812-200-5

8-908-821-201-5 QRV

11" 8-911-812-201-5

8-911-821-201-5 QRV

14" 8-914-812-200-5

8-914-821-200-5 QRV

Size Part Number

18" 8-918-812-301-5

8-918-821-300-5 QRV

24"H 8-924-812-300-5

8-924-821-301-5 QRV

Air hose kits contain all nec es sary parts

(fittings, hoses and extensions) to

com plete ly plumb the clutch air system.

Optional Quick Release Valves

can replace elbows on most

units (see page 35).

Roto-couplings (see page 35).

Size Part Number

30" 8-930-812-400-5

8-930-821-400-5 QRV

36" 8-936-821-400-5 QRV

42" 8-942-821-400-5 QRV

48" 8-948-821-400-5 QRV

Size Part Number

60" 8-960-800-500-7 QRV

34 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 14

Air Tube Disc Clutches and Brakes

1/2" NPT (for Optional Mufer 4-263-605-002-0)

Quick Release Valve

8-263-610-011-1 7/8" – 14 Thread

8-263-610-021-1 1/2" NPT

4-263-605-002-0 Optional Muffler

The Wichita Springless Quick Release Valve

discharges twice as fast as any other valve

tested in our laboratory and is four to five times

faster than some common makes of valves.

This valve will close and seal with less than 20

lbs. pressure. Most others require 25 to 30 lbs. to

definitely seal. In actual tests, the Wichita Valve

made many hundreds of thousands of

engagements and dis en gage ments before the

slightest leak occurred, or any parts needed re place ment. Other valves which were tested

required major re place ment in fewer than 20,000

cycles.

Quality Material

Body and Cap: High strength aluminum alloy

Stem: Molded nylon

Check Valve: Nylon ball

"O" Ring: Neoprene

B

Standard thread arrangement of 1/2" size.

1/2" pipe thread on the tube connection and

choice of 1/2" pipe thread, or stan dard

7/8-14NF thread for flared fitting thread on

inlet connection. (Fits standard No. 10 highpressure hose fitting.)

Roto-couplings

• Long life, no maintenance.

• Felt seal eliminates bearing con tam i na tion.

• Fast, easy installation.

The Wichita Roto-coupling is a device to

connect, or couple, a non-rotating air, gas,

or fluid line to a rotating shaft.

Dimensions: inches

Wichita Part No. AA B C D E F G H Max. RPM

8-240-701-003-1 5/8-18NF 1/4" NPT .40 1.046 2.250 1.500 2.13 3.297 3500

8-240-705-001-1 1"-14 NF 1/2" NPT .75 1.250 3.188 2.500 3.00 4.438 3500

8-240-708-001-1 1"-14 NF 3/4" NPT .75 1.313 4.688 2.875 3.69 5.440 3500

8-240-710-002-1 1-1/2"-12 NF 1" NPT 1.13 1.937 4.875 3.250 3.44 6.812 2500

8-240-712-001-1 2"-12 NF 1-1/2" NPT 1.13 2.813 5.250 4.250 5.38 8.062 2500

8-240-714-001-3 2" NPT 2" NPT 1.50 3.000 7.062 4.625 7.00 10.062 1000

8-240-716-000-3 2-1/2" NPT 2-1/2" NPT 1.88 3.250 9.375 7.000 7.75 12.625 750

P-1100-WC 1/12

Wichita Clutch 800-964-3262 35

Page 15

Air Tube Disc Clutches and Brakes

Low Inertia Brakes

Specifications

Model Slip Torque Capacity Duty Factors Max. Bore

Size Assembly Drawing lb.in. Nm HP/100 RPM Rect. Key

ATD- Number Number 80 PSI 100 PSI 5.5 BAR 7 BAR ABCDin. (mm)

LIB 104 7-004-100-803-0 -100-901-9 800 1,000 90 113 1.6 1.2 0.6 0.3

LIB 204 7-004-200-801-0 B-518 1,600 2,000 90 225 3.2 2.4 1.2 0.6

LIB 106 7-006-100-203-0 -100-901-9 3,160 3,950 340 435 6.2 4.4 2.2 1.1

LIB 206 7-006-200-200-0 D-465 6,320 7,900 680 870 12.5 8.8 4.4 2.2

LIB 108 7-008-100-108-0 -100-900-9 5,600 7,000 620 790 11.1 842

LIB 208 7-008-200-105-0 -200-900-9 11,200 14,000 1,240 1,580 22.2 16 84 2.25 (57)

LIB 308 7-008-300-100-0 D-164 16,800 21,000 1,865 2,375 33.3 24 12 6

LIB 111 7-011-100-107-0 B-105 12,720 15,900 1,400 1,785 25 18 95

LIB 211 7-011-200-102-0 -200-902-9 25,440 31,800 2,800 3,570 50 36 18 10 2.50 (64)

LIB 311 7-011-300-100-0 B-408 38,160 47,700 4,235 5,390 75 54 27 15

LIB 114 7-014-100-102-0 -100-900-9 22,100 27,625 2,435 3,100 44 31 16 8

LIB 214 7-014-200-101-0 -200-902-9 44,200 55,250 4,870 6,200 88 62 32 16 3.50 (89)

LIB 314 7-014-300-102-0 B-288 66,300 82,875 7,355 9,365 132 93 48 24

LIB 116 7-016-100-100-0 D-461 30,270 37,838 3,360 4,275 60 46 24 12

LIB 216 7-016-200-100-0 -200-904-9 60,541 75,676 6,720 8,550 120 92 48 24 4.00 (102)

LIB 316 7-016-300-100-0 -300-900-9 90,811 113,514 10,080 12,825 180 139 72 36

LIB 118 7-018-100-100-0 -100-901-9 51,600 64,500 5,705 7,260 102 75 35 21

LIB 218 7-018-200-100-0 -200-900-9 103,200 129,000 11,410 14,520 204 150 70 42 4.75 (121)

LIB 318 7-018-300-103-0 D-1218 154,840 193,550 17,115 21,780 306 225 105 63

LIB 121 7-021-100-100-0 D-373 69,887 87,359 7,755 9,870 139 107 55 28

LIB 221 7-021-200-100-0 D-267 139,775 174,719 15,510 19,740 277 213 111 55 6.00 (152)

LIB 321 7-021-300-100-0 D-740 209,662 262,078 23,265 29,610 416 320 166 83

LIB 124H 7-025-100-101-0 D-779 122,960 153,700 13,575 17,275 243 180 90 40

LIB 224H 7-025-200-101-0 D-371 245,920 307,400 27,150 34,550 487 360 180 80 6.00 (152)

LIB 324H 7-025-300-201-0 -300-900-9 368,880 461,100 40,725 51,825 729 540 270 120

LIB 127 7-027-100-100-0 D-151 137,509 171,886 15,260 19,420 273 210 109 55

LIB 227 7-027-200-100-0 D-428 275,018 343,773 30,520 38,840 546 420 218 109 6.50 (165)

LIB 327 6-027-300-100-0 D-689 412,527 515,659 45,780 58,260 819 630 327 164

LIB 130H 7-031-100-100-0 B-312 261,600 327,000 29,630 37,710 519 380 190 100

LIB 230H 7-031-200-316-0 B-296 523,200 654,000 59,260 75,420 1,038 760 380 200 7.25 (184)

LIB 330H 7-031-300-304-0 -300-904-9 784,800 981,000 88,890 113,130 1,557 1,140 570 300

LIB 136 7-036-100-100-0 -100-901-9 406,400 508,000 44,920 57,175 805 600 295 165

LIB 236 7-036-200-100-0 D-722 812,800 1,016,000 89,840 114,350 1,610 1,200 590 330 9.00 (229)

LIB 336 6-036-300-100-0 -300-900-9 1,219,200 1,524,000 134,760 171,525 2,415 1,800 885 495

LIB 142 7-042-100-303-0 -100-900-9 580,800 726,000 69,160 81,660 1,150 850 425 235

LIB 242 7-042-200-311-0 -200-901-9 1,162,240 1,452,800 128,320 163,320 2,300 1,700 850 470 14.00 (355)

LIB 342 6-042-300-302-0 -300-303-9 1,742,400 2,178,000 192,480 244,980 3,450 2,550 1,275 705

LIB 148 7-048-100-300-0 -100-900-9 1,122,000 1,402,500 118,800 151,200 2,225 1,600 800 455

LIB 248 7-048-200-300-0 -200-901-9 2,244,000 2,805,000 237,600 302,400 4,450 3,200 1,600 915 18.00 (455)

LIB 348 7-048-300-301-0 -300-900-9 3,366,000 4,207,500 356,400 453,600 6,675 4,800 2,400 1,365

LIB 260 7-060-200-302-0 -200-901-9 4,760,000 5,950,000 473,000 602,000 9,440 5,950 3,470 1,940

LIB 360 7-060-300-301-0 -300-901-9 7,140,000 8,925,000 709,000 902,300 14,160 8,925 5,205 2,910 19.00 (480)

LIB 460 6-060-400-300-0 E-236 14,280,000 17,850,000 946,000 1,204,000 18,880 11,900 6,940 3,880

Maximum Air Pressure is 130 PSI / 9 BAR.

1.00 (25)

2.00 (50)

36 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 16

Air Tube Disc Clutches and Brakes

Low Inertia Brakes

Specifications

Recom- Hub & C.P. Airtube

Model mended Balance Reg- High Swept Volume Total Brake Hub & Center Plate

Size Clearance Speed Speed Speed Area in.3(cm3) Wt. Wt. WR2/ J=mr

ATD- in. RPM RPM RPM* in.

LIB 104 1/32

LIB 204 1/16 34 (14.8) (56) 14.0 (6) 3.88 (1.8) 0.04 (0.002)

LIB 106 1/16-3/32

LIB 206 3/32-5/32 78 (30) (195) 40.5 (18) 12.17 (5.5) 0.46 (0.019)

LIB 108 1/16-1/8 56

LIB 208 3/32-5/32 1,675 2,870 4,300* 112 70 (32) 19 (8.6) 1.00 (0.042)

LIB 308 1/8-3/16 168

LIB 111 1/16-1/8 114

LIB 211 3/32-5/32 1,200 2,090 3,125* 228 166 (75) 45 (20.4) 4.50 (0.190)

LIB 311 1/8-3/16 342

LIB 114 1/16-1/8 158

LIB 214 3/32-5/32 950 1,640 2,450* 316 233 (106) 77 (34.9) 11.0 (0.464)

LIB 314 1/8-3/16 474

LIB 116 1/16-1/8 228

LIB 216 3/32-5/32 835 1,430 2,150* 455 326 (148) 106 (48.1) 19.6 (0.826)

LIB 316 1/8-3/16 683

LIB 118 1/16-1/8 264

LIB 218 3/32-5/32 750 1,270 1,910* 528 377 (171) 120 (54.4) 28.8 (1.214)

LIB 318 1/8-3/16 792

LIB 121 3/32-5/32 362

LIB 221 1/8-3/16 650 1,090 1,650* 724 575 (261) 198 (89.8) 61 (2.57)

LIB 321 5/32-7/32 1,086

LIB 124H 3/32-5/32 574

LIB 224H 1/8-3/16 550 950 1,410* 1,148 840 (381) 260 (117.9) 110 (4.6)

LIB 324H 5/32-7/32 1,722

LIB 127 3/32-5/32 730

LIB 227 1/8-3/16 500 850 1,250* 1,460 924 (419) 329 (149.2) 191 (8.1)

LIB 327 5/32-7/32 2,190

LIB 130H 3/32-5/32 827

LIB 230H 1/8-3/16 450 765 1130* 1,654 1,350 (612) 546 (247.7) 370 (15.6)

LIB 330H 5/32-7/32 2,481

LIB 136 3/32-5/32 1,150

LIB 236 1/8 -3/16 375 640 950* 2,300 1,993 (904) 708 (321.1) 725 (30.6)

LIB 336 5/32-7/32 3,450

LIB 142 5/32-7/32 1,400

LIB 242 3/16-1/4 325 545 805* 2,800 2,732 (1,239) 1,197 (543) 1,385 (58)

LIB 342 7/32-9/32 4,200

LIB 148 1/8-1/4 2,010

LIB 248 5/32-7/32 275 475 705* 4,020 4,700 (2,132) 1,942 (881) 3,335 (141)

LIB 348 3/16-5/16 6,030

LIB 260 3/16-5/16 7,230

LIB 360 1/4-3/8 225 380 575* 10,845 11,643 (5,281) 3,870 (1,755) 10,615 (448)

LIB 460 5/16-7/16 14,460

* Consult Factory for Special Assembly Number.

3,325 5,250 5,250*

2,225 3,800 5,700*

2

17 0.9 3.4 11.0 (7) 1.54 (0.7) 0.021 (0.001)

39 1.8 11.9 27.5 (12) 6.40 (2.9) 0.24 (0.010)

New Worn lb. (kg) lb. (kg) lb.ft.2(kgm2)

3.4 18.3

(56) (300)

5.5 30.5

(90) (500)

7.6 42.7

(125) (700)

9.8 56.1

(161) (919)

15.3 85.4

(251) (1,400)

18.3 97.6

(300) (1,599)

29.9 159

(490) (2,606)

29.9 159

(490) (2,606)

58.6 311

(960) (5,096)

110 415

(1,803) (6,801)

128 488

(2,098) (7,997)

217 824

(3,550) (13,500)

513 1,788

(8,407) (29,300)

62 (28) 11 (5.0) 0.54 (0.023)

87 (39) 28 (12.7) 2.00 (0.084)

130 (59) 23 (10.4) 2.30 (0.097)

208 (94) 121 (54.9) 7.00 (0.295)

184 (83) 46 (20.9) 5.7 (0.240)

290 (132) 121 (54.9) 16.7 (0.704)

254 (115) 59 (26.8) 10.2 (0.430)

358 (162) 151 (68.5) 29.6 (1.248)

311 (141) 73 (33.1) 15.0 (0.632)

461 (209) 180 (81.6) 43.2 (1.821)

460 (209) 116 (52.6) 32 (1.35)

723 (328) 312 (141.5) 122 (5.14)

618 (280) 132 (60.0) 56 (2.4)

1,025 (465) 379 (172.0) 160 (6.8)

760 (345) 187 (84.8) 98 (4.1)

1,112 (504) 555 (251.7) 285 (12.0)

972 (441) 298 (135.2) 189 (8.0)

1,751 (794) 810 (367.4) 477 (20.1)

1,388 (630) 461 (209.1) 372 (15.7)

2,610 (1,184) 1,134 (514.4) 1,091 (46.0)

1,967 (892) 680 (308) 705 (30)

3,704 (1,680) 1,324 (601) 1,809 (76)

3,158 (1,432) 1,101 (499) 1,785 (75)

6,540 (2,966) 2,950 (1,338) 4,925 (208)

9,453 (4,288) 2,567 (1,164) 7,077 (298)

14,500 (6,577) 5,700 (2,585) 15,070 (635)

2

B

P-1100-WC 1/12

Wichita Clutch 800-964-3262 37

Page 17

Air Tube Disc Clutches and Brakes

Low Inertia Brakes

Sizes 8-36

38 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 18

Air Tube Disc Clutches and Brakes

Low Inertia Brakes

Dimensions: inches (mm)

Sizes 8-36

Model BC

Size ATD- A Hole Circle Pilot DF GH

LIB 108 12.13 11.125 8.375 / 8.378 11.13 2.00 (50.8) .25 4.56 (115.8)

LIB 208 (308.1) (282.58) (212.73 / 212.80) (282.7) 3.25 (82.6) (6.4) 5.94 (150.9)

LIB 111 16.00 14.750 11.375 / 11.378 14.75 2.75 (69.9) .13 (3.3) 5.44 (138.2)

LIB 211 (406.4) (374.65) (288.93 / 289.00) (374.7) 4.38 (111.3) .25 (6.4) 7.19 (182.6)

LIB 114 18.75 17.500 14.375 / 14.378 17.50 3.75 (95.3) .13 (3.3) 6.06 (153.9)

LIB 214 (476.3) (444.50) (365.13 / 365.20) (444.5) 4.50 (114.3) .38 (9.7) 8.00 (203.2)

LIB 116

LIB 216 4.75 (120.7) 8.25 (209.6)

LIB 316

LIB 118

LIB 218 4.75 (120.7) 8.63 (219.2)

LIB 318

LIB 121

LIB 221 5.13 (130.3) 9.31 (236.5)

LIB 321

LIB 124H

LIB 224H 5.13 (130.3) .75 (19.1) 9.94 (252.5)

LIB 324H

LIB 127

LIB 227 6.88 (174.8) 10.38 (263.7)

LIB 327

LIB 130H

LIB 230H 7.13 (181.1) 1.88 (47.8) 11.81 (300.0)

LIB 330H

LIB 136 43.50 42.000 36.375 / 36.378 41.00 5.63 (143.0) 0.63 9.50 (241.3)

LIB 236 (1,104.9) (1,066.80) (923.93 / 924.00) (1,041.4) 9.00 (228.6) (16.0) 12.88 (327.2)

21.25 20.000 16.250 / 16.253 20.00

(539.8) (508.00) (412.75 / 412.83) (508.0)

23.25 22.000 18.250 / 18.253 22.00

(590.6) (558.80) (463.55 / 463.63) (558.8)

27.00 25.500 21.375 / 21.378 24.88

(685.8) (647.70) (542.93 / 543.00) (632.0)

30.00 28.750 24.375 / 24.378 29.00

(762) (730.25) (619.13 / 619.20) (736.6)

32.75 31.500 27.375 / 27.378 31.00

(831.9) (800.10) (695.33 / 695.40) (787.4)

37.00 35.500 30.375 / 30.378 34.75

(939.8) (901.70) (771.53 / 771.60) (882.7)

4.00 (101.6)

6.63 (168.4)

4.00 (101.6)

6.50 (165.1)

4.00 (101.6)

7.13 (181.1)

4.00 (101.6) .69 (17.5) 7.63 (193.8)

7.50 (190.5) .75 (19.1) 12.25 (311.2)

4.50 (114.3)

———

5.00 (127.0) .63 (16.0) 8.38 (212.9)

11.88 (301.8) .63 (16.0) 15.31 (388.9)

0.38

(9.7)

0.44

(11.2)

.75

(19.1)

0.75 (19.1)

6.31 (160.3)

10.19 (258.8)

6.69 (169.9)

10.63 (270.0)

7.38 (187.5)

11.75 (298.5)

7.88 (200.2)

B

Dimensions: inches (mm)

Model LRU

Size ATD- J No. - Size MNQNo. - Size T Min. Max.

LIB 108 0.25

LIB 208 (6.4) (136.7) (88.9) (12.7) (25) (50.8)

LIB 111 0.38

LIB 211 (9.7) 11/16 (17.5) (177.8) (101.6) (16.0) (25) (63.5)

LIB 114 0.38

LIB 214 (9.7) (239.8) (139.7) (16.0) (35.1) (88.9)

LIB 116

LIB 216 12 - 21/32 (16.7) 2 - 1/2 NPT 6.13

LIB 316

LIB 118

LIB 218 12 - 21/32 (16.7) 3 - 1/2 NPT 7.75

LIB 318

LIB 121

LIB 221 12 - 21/32 (16.7) 3 - 1/2 NPT 9.25

LIB 321

LIB 124H

LIB 224H 12 - 21/32 (16.7) 3 - 1/2 NPT 13.25

LIB 324H

LIB 127 0.25

LIB 227 (6.4) 16 - 21/32 (16.7) 3 - 1/2 NPT 13.25

LIB 327 —

LIB 130H

LIB 230H 18 - 25/32 (19.8) 4 - 1/2 NPT 15.00

LIB 330H

LIB 136 0.25

LIB 236 (6.4) 25/32 (19.8) (600.2) (304.8) (22.4) (152.4) (228.6)

0.38 10.50 6.00 0.63 1.38 4.00

(9.7) (266.7) (152.4) (16.0) (35.1) (101.6)

0.38 12.50 7.00 0.63 2.00 4.75

(9.7) (317.5) (177.8) (16.0) (50.8) (120.7)

0.31 14.50 9.00 .75 2.00 6.00

(7.9) (368.3) (228.6) (19.1) (50.8) (152.4)

0.25 14.50 9.00 .75 2.00 6.00

(6.4) (368.3) (228.6) (19.1) (50.8) (152.4)

0.25 19.25 10.00 .75 2.50 7.25

(6.4) (489) (254) (19.1) (63.5) (184.2)

6 - 17/32 (13.5)

21/32 (16.7) 7.00 4.00 0.63

6 -

8 - 21/32 (16.7)

13/16 (20.6) 23.63 12.00 .88

18 -

5.38 3.50 0.50

9.44 5.50 0.63

16.25 9.00 .75 2.50 6.50

(412.8) (228.6) (19.1) (63.5) (165.1)

2 - 1/2 NPT 2.25

2 - 1/2 NPT 3.25

2 - 1/2 NPT 5.06

4 - 1/2 NPT 22.75

1.00 2.00

1.00 2.50

1.38 3.50

6.00 9.00

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

(Consult factory for drawing before final layout.)

P-1100-WC 1/12

Wichita Clutch 800-964-3262 39

Page 19

Air Tube Disc Clutches and Brakes

Low Inertia Brakes

Sizes 6, 42-60

Size 6

40 Wichita Clutch 800-964-3262

Sizes 42-60

P-1100-WC 1/12

Page 20

Air Tube Disc Clutches and Brakes

Low Inertia Brakes

Sizes 6, 42-60

Dimensions: inches (mm)

Model BC

Size ATD- A Hole Circle Pilot DFGH

LIB 106 8.75 8.000 7.377 / 7.379 8.81 2.00 (50.8) 0.00 (0.0) 3.75 (95.3)

LIB 206 (222.3) (203.20) (187.38 / 187.43) (223.8) 3.25 (82.6) 0.06 (1.5) 5.00 (127.0)

LIB 142 52.00 49.250 44.625 / 44.628 49.00 5.63 (143.0)

LIB 242 (1,320.8) (1,250.95) (1,133.48 / 1,133.55) (1,244.6) 7.50 (190.5) 13.5 (342.9)

LIB 148 61.00 58.000 52.000 / 52.005 56.75 6.00 (152.4) 0.00 (0.0) 10.69 (271.5)

LIB 248 (1,549.4) (1,473.20) (1,320.80 / 1,320.93) (1,441.5) 8.75 (222.3) 1.00 (25.4) 15.06 (382.5)

LIB 260 70.50 74.500 60.000 / 59.990 70.50 9.38 (238.3)

LIB 360 (1,790.7) (1,892.30) (1,524.0 / 1,523.7) (1,790.7) 12.25 (311.2) 22.88 (581.2)

1.00 (25.40)

3.50 (88.9)

Dimensions: inches (mm)

Model LRU

Size ATD- J No.- Size MNQNo. - Size T Min. Max.

LIB 106 0.06

LIB 206 (1.5) (106.4) (14.2) (50.8) (15.2) (50.8)

LIB 142 0.25

LIB 242 (6.4) (749.3) (38.1) (606.6) (203.2) (355.6)

LIB 148 0.25

LIB 248 (6.4) (812.8) (38.1) (641.4) (254.0) (457.2)

LIB 260 0.38

LIB 360 (9.5) (901.7) 28.15 (715.0) (797.6) (723.9) (279.4) (482.6)

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

(Consult factory for drawing before final layout.)

4 - 0.34 (8.6)

24 - 1.06 (26.9)

24 - 1.06 (26.9)

24 - 2.06 (52.3)

4.19

29.50

32.00

35.50 27.00 (685.8) 3.25

2.69 (68.3)

18.00 (457.2)

25.75 (654.1)

0.56

1.50

1.50

2 - 1/4 NPT

4 - 1/2 NPT

4 - 1/2 NPT

6 - 1/2 NPT

23.88 8.00 14.00

25.25 10.00 18.00

9.75 (247.7)

B

21.25 (539.8)

2.00 0.60 2.00

28.5 11.00 19.00

P-1100-WC 1/12

Wichita Clutch 800-964-3262 41

Page 21

Air Tube Disc Clutches and Brakes

Brake Air Hose Kits

Model Part Number

8" 8-908-912-100-5

8-908-924-100-5 QRV

Model Part Number

6" 8-906-912-200-4

8-906-931-201-5 QRV

8" 8-908-913-200-5

8-908-931-200-5 QRV

11" 8-911-913-200-5

8-911-931-200-5 QRV

14" 8-914-913-200-5

8-914-921-200-5 QRV

16" 8-916-913-200-5

8-916-921-200-5 QRV

Model Part Number

18" 8-918-912-200-5

8-918-931-200-5 QRV

21" 8-921-913-200-5

8-921-931-200-5 QRV

24" 8-924-913-200-5

8-924-931-200-5 QRV

27" 8-927-913-200-5

8-927-921-200-5 QRV

Air hose kits contain all

nec es sary parts (fittings, hoses

and extensions) to com plete ly

plumb the brake air system.

Optional Quick Release Valves

can replace elbows on most

units (see page 35).

Roto-couplings

(see page 35).

Model Part Number

30" 8-930-913-400-5

8-930-931-400-5 QRV

36" 8-936-913-400-6

8-936-931-400-6 QRV

42" 8-942-913-400-6

8-924-931-400-6 QRV

48" 8-948-912-400-6

8-948-923-400-6 QRV

42 Wichita Clutch 800-964-3262

Model Part Number

60" 8-960-912-500-5

8-960-923-400-6 QRV

P-1100-WC 1/12

Page 22

Air Tube Disc Clutches and Brakes

Low Inertia Clutches and Brakes

Component Parts

3

2

4

1

6

B

7

8

7

6

20

19

10

11

1. Hub

2. Demountable Back Plate

3. Socket Head Capscrews

4. Ring

6. Grooved Friction Disc

(grooved on one side)

7. Center Plate

8. Grooved Friction Disc

(grooved on both sides)

12

13

14

10. Pressure Plate

11. Airtube

12. Shims

13. Airtube Holding Plate

14. Socket Head Capscrews

19. Pressure Plate Lugs

20. Hex Head Capscrews

24

21

22

21. Release Springs

22. Flexloc Nuts

23. Roto-coupling

24. “O” Ring

25. Snap Ring

23

25

P-1100-WC 1/12

Wichita Clutch 800-964-3262 43

Loading...

Loading...