Page 1

Industrial Clutch Products

MODEL HBA

Air or Hydraulically Actuated Brakes

MODEL HBS

Spring-Set Air or Hydraulically Released Brakes

I N D U S T R I A L C L U T C H P R O D U C T S 74

Page 2

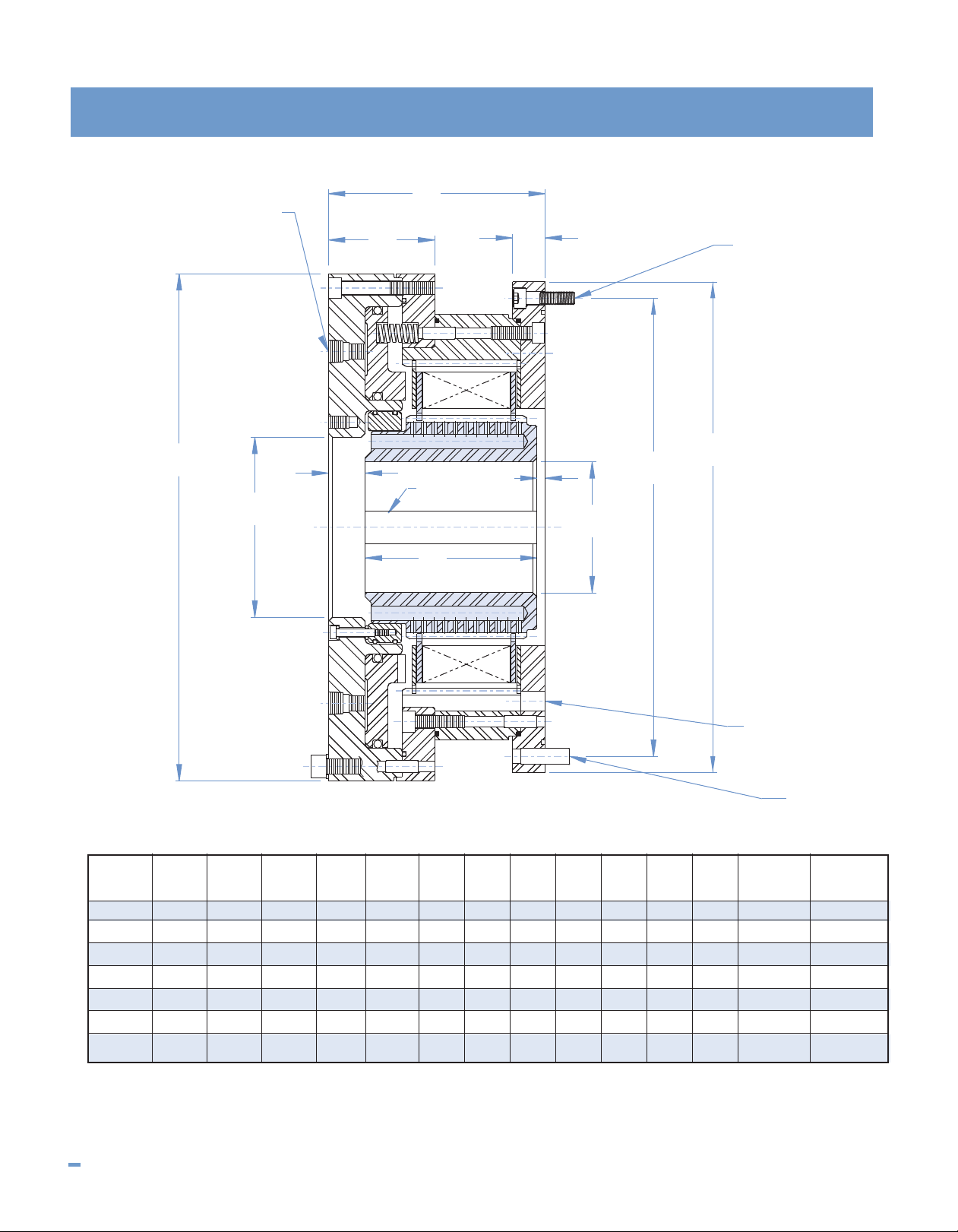

Model HBA

I

A

C

H

J

F

G

K

E

D

B

L

M

N

MAX.

K'W'Y.

OIL DRAINBACK HOLES

THRU TO SUMP

MAX.

+.002"

-.000"

+.000"

-.002"

(2) NPT ACTUATION PORTS

AT 180° ON VERT. CTR. LINE

DIMENSIONAL DATA All dimensions in inches

Brake

Model ABCDEFGHIJKL M N

HBA-8 13.25 12.875 12.000 3.000 4.000 2.63 0.84 5.88 0.75 0.19 4.94 0.75 (8) - M8 (4) - .375

HBA-10 15.50 15.000 14.000 4.000 5.500 3.25 1.00 6.63 1.13 0.25 5.25 1.00 (8) - M10 (4) - .500

HBA-13 21.25 19.750 18.750 6.000 8.750 3.50 1.13 7.31 1.19 0.13 6.00 1.50 (8) - M12 (4) - .500

HBA-15 24.50 23.500 22.000 6.500 8.750 4.13 1.38 9.31 1.25 0.25 7.81 1.50 (8) - M16 (4) - .625

HBA-16 27.50 25.500 24.000 7.500 10.000 4.25 1.38 9.44 1.38 0.25 7.81 1.50 (8) - M16 (4) - .750

HBA-18 30.25 28.750 27.000 8.000 11.000 4.69 1.75 11.84 1.56 0.50 9.78 1.50 (8) - M20 (4) - 1.00

HBA-20 32.25 31.000 29.250 9.000 12.000 5.06 1.88 12.28 1.63 0.63 10.03 1.50 (8) - M20 (4) - 1.00

NOTES: 1.) Use certified drawing dimensions only for final layouts.

2.) DXF and IGES files available upon request.

75 I N D U S T R I A L C L U T C H P R O D U C T S

3.) Dimensions subject to change without notice.

4.) All threaded fasteners are metric.

Page 3

OPERATIONAL DATA

Model HBA/HBS

rake Static Dynamic Act. Vol. Weight Weight WR

B

odel Torque (lb.-in.) Torque (lb.-in.) (in.

M

BA-8 63,000 45,000 10.6 148.6 29.5 1.43 4,000

H

HBA-10 105,000 75,000 19.2 227.7 48.2 3.48 3,400

HBA-13 280,000 200,000 37.7 411.0 106.0 15.75 2,400

HBA-15 420,000 300,000 50.0 719.0 152.0 28.68 2,150

HBA-16 595,000 425,000 66.0 900.0 197.0 45.30 1,900

HBA-18 770,000 550,000 97.0 1,385.0 308.0 84.80 1,750

BA-20 1,035,000 740,000 135.0 1,655.0 356.0 119.40 1,600

H

OTES: 1.) Operating pressure: 100 PSIG Hydraulic actuation available

N

.) Torque capacities can be modified. Consult engineering.

2

3.) Consult factory for service factors required per application.

MODEL HBA BRAKE DESCRIPTION

The Model HBA brake is an oil immersed, air or hydraulically

set brake designed to be mounted on a drive train shaft

extension. In the majority of installations, the Model HBA

brake utilizes the system’s lubricating oil for cooling.

Cooling oil is fed into the brake at the cylinder end of the unit

where it is directed into the oil distribution holes incorporated

3

)

Outer (lbs.) Inner (lbs.) (lb-ft.

.) Consult factory for oil flow requirements per application and

4

haft oil hole diameters.

s

MODEL HBS BRAKE DESCRIPTION

The Model HBS brake is identical to the Model HBA brake

except the unit is designed to be spring-set and hydraulically

or pneumatically released. This spring-set actuation feature

makes it suitable for those applications requiring the

presence of full braking torque in the event of loss of

actuation pressure or machine power.

2

nner Maximum

I

2

)

within the rotating hub for dispersal through-out the disc pack.

Unique friction plate grooving patterns, as well as the forced

oil cooling feature, allow the Model HBA brake to dissipate

the heat generated by stopping the high energy loads

common to today’s heavy duty industrial equipment.

All torque transmitting members are designed to withstand

the rigors of the loads imposed. The unit incorporates high

quality, time proven materials selected to provide strength,

durability, and reliable performance.

The Model HBA housing contains the stationary plates of the

disc pack. This housing is bolted to the stationary machine

member and provides the grounding path for stopping the

rotating components of the drive train when the disc pack is

engaged. The housing also serves as a containment for the

cooling oil and provides a path for the oil to return to the

machine reservoir.

USAGES

Any type of industrial equipment that requires braking of

high speed-high energy loads with maximum reliability

and longevity.

Those applications that must operate in adverse

environments due to the Model HBA and HBS brake’s

totally enclosed features.

Tensioning control systems.

Propeller shaft brakes, winch holding brakes, mining safety

brakes (Model HBS), conveyors, lumber and paper making

equipment are some examples of where these brakes can

be applied. They are particularly suited to mounting directly

to gear cases. This allows sharing of the lubrication and

cooling system as well as provides system compactness

and a professional design appearance.

RPM

I N D U S T R I A L C L U T C H P R O D U C T S 76

Page 4

Model HBS

+

.002"

-.000"

+.000"

-.002"

M

AX.

K'W'Y'.

M

L

D

C

B

G

J

I

K

E

A

H

F

N

OIL DRAINBACK

HOLES THRU

TO SUMP

(2) NPT

RELEASE PORTS

DIMENSIONAL DATA All dimensions in inches

Brake

Model ABCDEFGHIJKL M N

HBS-8 11.25 12.875 12.000 3.000 4.000 2.75 0.84 7.25 0.75 0.19 4.94 0.75 (8) - M8 (4) - .375

HBS-10 14.25 15.000 14.000 4.000 5.500 3.38 1.00 8.13 1.13 0.25 5.25 1.00 (8) - M10 (4) - .500

HBS-13 17.50 19.750 18.750 6.000 8.750 3.69 1.13 9.00 1.19 0.13 6.00 1.50 (8) - M12 (4) - .500

HBS-15 20.50 23.500 22.000 6.500 8.750 4.31 1.38 11.31 1.25 0.25 7.81 1.50 (8) - M16 (4) - .625

HBS-16 22.50 25.500 24.000 7.500 10.000 4.44 1.38 11.44 1.38 0.25 7.81 1.50 (8) - M16 (4) - .750

HBS-18 25.50 28.750 27.000 8.000 11.000 4.88 1.75 14.38 1.56 0.50 9.78 1.50 (8) - M20 (4) - 1.00

HBS-20 27.50 31.000 29.250 9.000 12.000 5.31 1.88 14.88 1.63 0.63 10.03 1.50 (8) - M20 (4) - 1.00

NOTES: 1.) Use certified drawing dimensions only for final layouts.

2.) DXF and IGES files available upon request.

OPERATIONAL DATA

Brake Static Dynamic Act. Vol. Weight Weight WR2Inner Maximum

Model Torque (lb.-in.) Torque (lb.-in.) (in.3) Outer (lbs.) Inner (lbs.) (lb-ft.2) RPM

HBS-8 37,000 26,500 6.8 135 29.5 1.43 4,000

HBS-10 63,000 45,000 12.3 205 48.2 3.48 3,400

HBS-13 168,000 120,000 24.1 370 106.0 15.75 2,400

HBS-15 245,000 175,000 32.0 650 152.0 28.68 2,150

HBS-16 350,000 250,000 42.2 815 197.0 45.30 1,900

HBS-18 455,000 325,000 62.0 1250 308.0 84.80 1,750

HBS-20 605,000 435,000 86.0 1495 356.0 119.40 1,600

NOTES: 1.) Release pressure: 400 PSIG

2.) Torque capacities can be modified. Consult engineering.

3.) Consult factory for service factors required per application.

3.) Dimensions subject to change without notice.

4.) All threaded fasteners are metric.

4.) Consult factory for oil flow requirements per application and shaft oil hole

diameters.

77 I N D U S T R I A L C L U T C H P R O D U C T S

Loading...

Loading...