Page 1

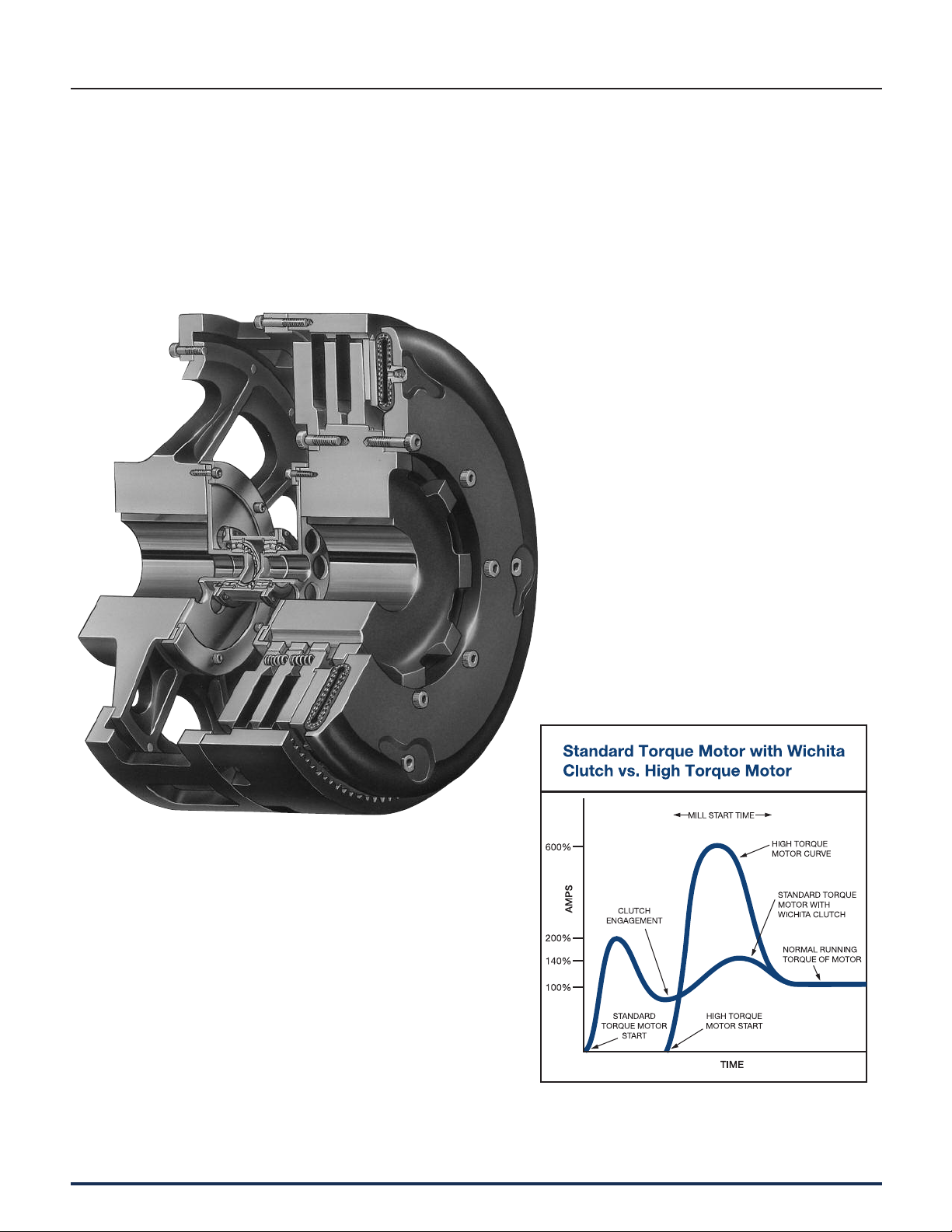

Standard Vent Clutches

Grinding Mill Clutches

• Designed for heavy duty applications

• Quick, smooth starting

• High heat dissipation for jogging and inching

Wichita Grinding Mill Clutches are specially

designed to provide quick, smooth starts with

limited current surge for heavy duty grinding

mills. The clutch is adaptable to remote

control allowing centralized op er a tion through

simple air or electric circuits.

• No adjustment or lubrictation

• Eliminates need for special high torque

motors

• Torque capacity not affected by

centrifugal force

• High heat dis si pa tion for jogging

and inching

• New high coefficient, high energy

absorbing friction material standard for

grinding mill applications

136 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 2

Standard Vent Clutches

Grinding Mill Clutches

Specifications

Technical

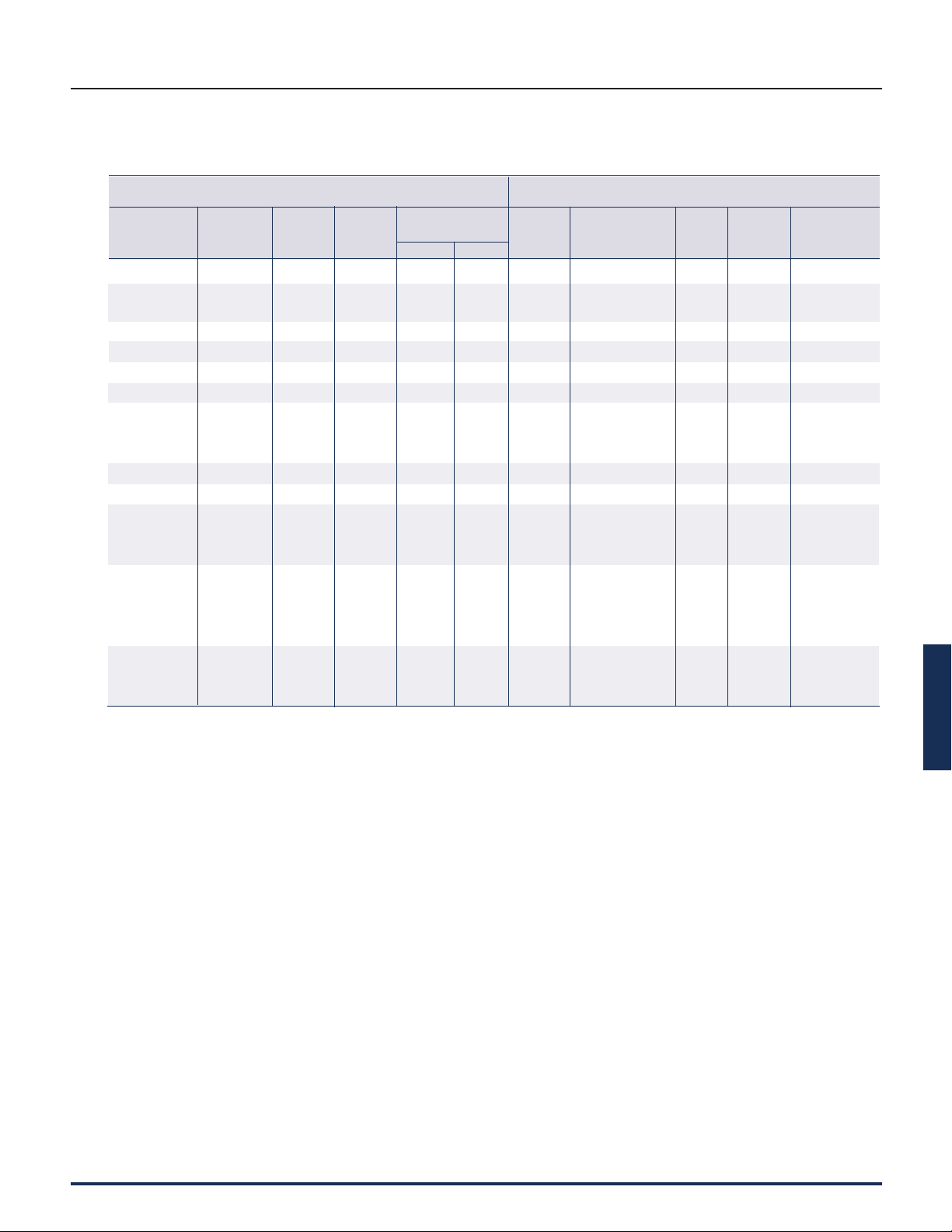

Model Total Total Driving Adapter Diameter Max. Speed (RPM) HP Lining Rated Torq.

Size Air Weight WR2 Ring & Disc Friction For 6000 FPM @ per 100 Area in.lbs.

ATD– Supply lb. lb.ft.2 Wt. WR2 Disc-in. Fric Disc O.D. RPM in.

211-X GMC 5/8"-18 130 24 57 16 11 2,100 18 228 42,294

214H-X GMC 5/8"-18 333 111 152 58 14 1,640 40 336 95,228

314H-X GMC 5/8"-18 385 132 190 75 14 1,640 60 504 142,842

318H-X GMC 1"-14 727 333 356 220 18 1,275 120 792 299,250

321-X GMC 1"-14 980 663 500 280 21 1,100 150 1,086 349,790

324H-X GMC 1"-14 1,350 970 590 600 24 950 270 1,722 613,130

327-X GMC 1"-14 1,580 1,130 675 540 27 850 300 2,190 688,275

230H-X GMC 1"-14 2,126 2,046 1,036 1,150 30 760 380 1,664 869,820

330H-X GMC 1"-14 2,600 2,100 1,125 1,250 30 760 570 2,496 1,304,730

430H-X GMC 1"-14 3,578 2,980 1,497 1,148 30 760 760 3,328 1,739,640

336H-X GMC 1"-14 3,550 4,650 1,510 2,215 36 640 885 3,450 2,134,650

342-X GMC 1-1/2"-12 4,815 10,505 2,315 6,130 42 540 1,275 4,212 2,898,070

248-X GMC 1-1/2"-12 6,580 16,275 2,825 9,523 48 475 1,600 4,020 3,730,650

348-X GMC 1-1/2"-12 7,540 18,470 3,274 9,700 48 475 2,400 6,030 5,595,975

448-X GMC 1-1/2"-12 48 475 3,200 8,040 7,461,300

260-X GMC 1-1/2"-12 10,600 37,300 5,750 23,600 60 380 3,470 7,240 7,913,500

360-X GMC 1-1/2"-12 13,390 47,850 5,900 27,550 60 380 5,200 10,850 11,870,250

460-X GMC 1-1/2"-12 16,860 57,705 7,500 33,238 60 380 6,940 14,480 15,827,000

560-X GMC 1-1/2"-12 20,050 78,642 8,300 28,512 60 380 8,675 18,100 19,783,750

372-X GMC 1-1/2"-12 72 300 7,758 14,460 18,573,450

472-X GMC 1-1/2"-12 72 300 10,344 19,280 24,764,600

572-X GMC 1-1/2"-12 72 300 12,930 24,100 30,955,750

Capacity

2

100 PSI

E

P-1100-WC • 1/11

Wichita Clutch 800-964-3262 137

Page 3

Standard Vent Clutches

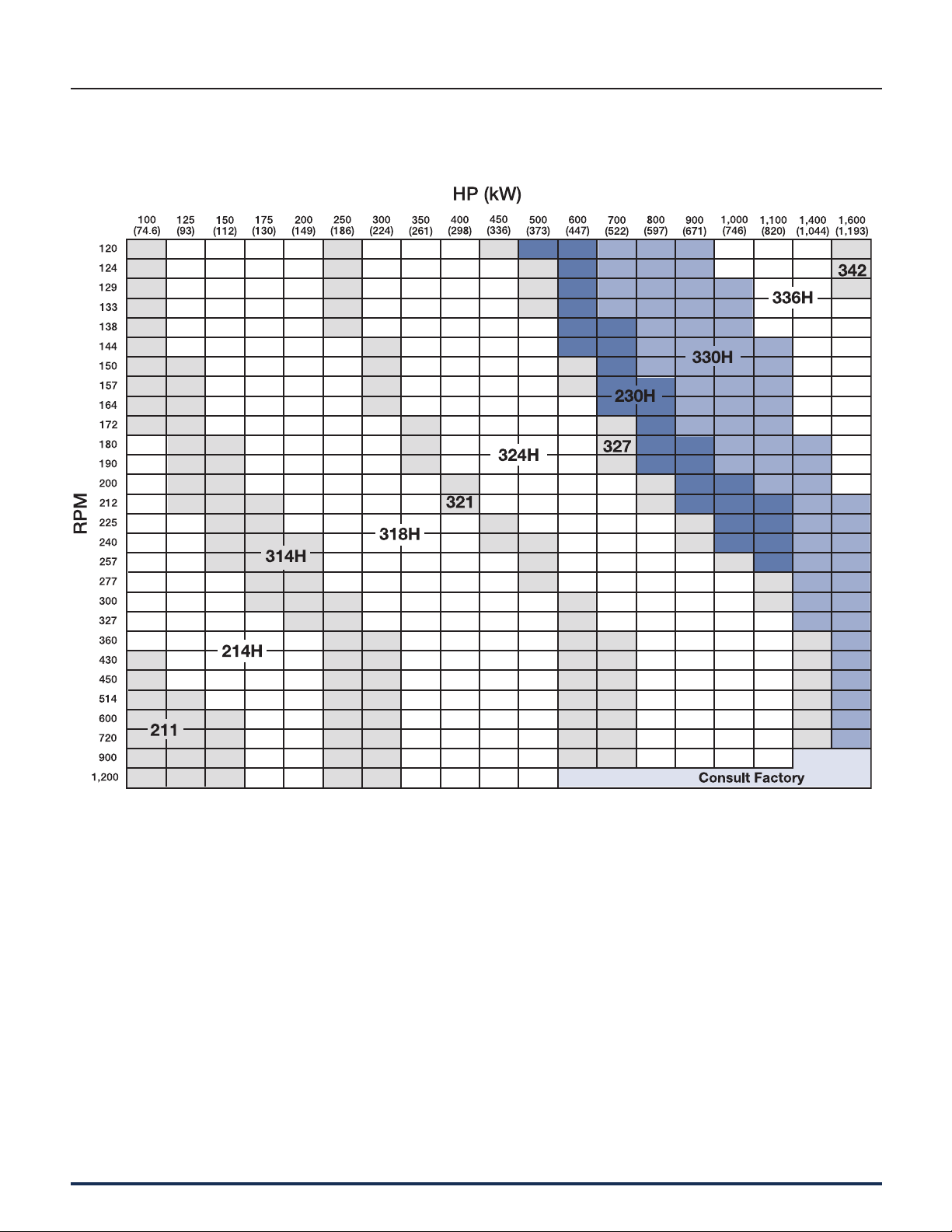

Grinding Mill Quick Selection Chart

138 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 4

Standard Vent Clutches

Grinding Mill Quick Selection Chart

E

P-1100-WC 1/12

Wichita Clutch 800-964-3262 139

Page 5

Standard Vent Clutches

Grinding Mill Quick Selection Chart

140 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 6

Standard Vent Clutches

Air Hose Kits

Model Part Number

8" 8-908-812-200-3

8-908-821-200-4 QRV

8-911-813-200-3 HS

11" 8-911-812-200-4

8-911-821-200-5 QRV

8-911-813-200-3 HS

14" 8-914-812-201-5

8-914-821-202-5 QRV

8-914-813-204-3 HS

Model Part Number

30"H 8-931-821-400-5 QRV

Model Part Number

18" 8-918-812-301-5

8-918-821-300-5 QRV

8-918-815-301-3 HS

21"/18H 8-921-812-301-5

8-921-821-302-5 QRV

8-921-812-300-5 HS

24" 8-924-812-300-5

8-924-821-302-5 QRV

27"/24H 8-927-812-300-5

8-927-821-301-5 QRV

8-927-812-302-5 HS

Model Part Number

60" 8-960-812-300-5

8-960-834-300-5 QRV

Model Part Number

30" 8-930-815-201-5

30"H 8-931-821-200-5 QRV

8-931-812-200-5 HS

36" 8-936-815-200-5

8-936-821-200-5 QRV

8-936-815-201-5 HS

42" 8-942-815-200-5

8-942-821-200-5 QRV

48" 8-948-815-200-5

8-948-821-200-5 QRV

Air hose kits contain all

nec es sary parts (fittings, hoses

and extensions) to com plete ly

plumb the clutch.

Optional Quick Release Valves

can replace elbows on most

units (see page 144).

Roto-couplings

(see page 144).

E

P-1100-WC 1/12

1 Spud Hose Kits

Model Part Number

18" 8-918-815-101-3 HS

21" 8-921-815-101-3 HS

Wichita Clutch 800-964-3262 141

Page 7

Standard Vent Clutches

Grinding Mill Clutches

Driving Adapters

The driving adapter is

de signed to allow the clutch

to be used in a shaft-toshaft or through-shaft

coupling ar range ment. The

quick-change feature, using

a driving elbow piece be tween the driving adapter

and the clutch driving ring,

enables replacement of any

wearing clutch part without

dis turb ing either shaft.

(See Notes 1 & 2)

Without axial

locking device

Dimensions: inches (Consult factory for drawing before final layout.)

Model C* C1* F*

Size

ATD– B

211 GMC 3.00 3.00 — 5.00 2.00 3.00 4.25 11.94 10.00 —

214H GMC 3.25 4.13 — 6.25 2.13 3.38 5.75 16.31 11.88 —

314H GMC 3.25 4.13 — 6.25 2.13 3.38 7.18 16.31 13.38 —

318H GMC 6.00 4.00 — 6.00 4.38 4.00 7.31 21.31 17.43 —

321 GMC 6.00 6.50 — 9.00 4.00 5.38 8.63 21.31 20.50 —

324H GMC 7.31 7.50 — 10.00 5.56 5.38 8.43 27.00 21.56 —

327 GMC 7.31 7.63 — 11.50 5.56 7.00 9.00 27.00 20.94 —

230H GMC 8.75 9.38 9.38 14.00 6.50 7.00 7.88 32.38 22.63 24.43

330H GMC 8.75 9.38 9.38 14.00 6.50 7.00 10.88 32.38 25.25 26.94

336H GMC 10.00 9.38 9.38 14.00 7.88 8.00 12.88 38.25 26.75 34.75

342 GMC 10.00 12.00 12.00 18.00 7.43 10.00 11.88 44.13 27.63 34.50

248 GMC 13.63 15.00 13.25 20.00 10.13 12.00 10.88 52.38 29.63 36.88

348 GMC 13.63 15.00 13.25 20.00 10.13 12.00 13.63 52.38 32.13 39.50

260 GMC 16.25 18.00 15.00 24.00 12.25 14.00 16.25 61.50 40.00 42.50

360 GMC 16.25 18.00 15.00 24.00 12.25 14.00 20.00 61.50 43.75 46.25

460 GMC 16.25 18.00 15.00 24.00 12.25 14.00 23.50 61.50 47.13 49.63

560 GMC 20.25 17.00 17.00 30.00 16.25 17.00 27.00 61.50 — 57.20

* Maximum bore uses rectangular key, contact Wichita Engineering.

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

Max. Bore Max. Bore

Rect. Key

Rect. Key

D E

Max. Bore

Rect. Key

G J L L

1

142 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Page 8

With axial

locking device

The axial locking device is

an optional feature offered

by Wichita. This device

prevents dam age to the

mill motor bear ings during

motor start-up by axially

locking the armature

to magnetic center.

Standard Vent Clutches

Grinding Mill Clutches

(See Notes 1 & 2)

(See Note 3)

Notes:

1. Air Hose Kits, page 141.

2. Quick Release Valves, page 144.

3. Roto-couplings, page 144.

Model

Size

ATD– N R S S1 S2

211 GMC 2.25 13.63 N/A — 5.38 1/2" NPT 2 1.62 — 1/2" NPT 5/8”-18

214H GMC 2.25 17.50 3.25 — 3.13 1/2" NPT 2 2.13 — 1/2" NPT 5/8”-18

314H GMC 2.25 17.50 4.75 — 3.13 1/2" NPT 2 2.13 — 1/2" NPT 5/8”-18

318H GMC 2.43 22.00 5.88 — 3.50 1/2" NPT 3 3.06 — 1/2" NPT 1”-14

321 GMC 2.38 25.00 6.25 — 6.25 1/2" NPT 3 4.75 — 1/2" NPT 1”-14

324H GMC 2.75 28.00 6.25 — 5.50 1/2" NPT 3 4.50 — 1/2" NPT 1”-14

327 GMC 2.38 31.00 6.50 — 4.63 1/2" NPT 3 3.75 — 1/2" NPT 1”-14

230H GMC 2.75 34.00 5.63 5.75 5.75 1/2" NPT 4 4.25 5.00 1/2" NPT 1”-14

330H GMC 2.88 34.00 8.13 7.43 5.75 1/2" NPT 4 4.25 5.00 1/2" NPT 1”-14

336H GMC 2.88 41.00 9.13 12.13 4.00 1/2" NPT 4 2.50 10.00 1/2" NPT 1”-14

342 GMC 3.50 49.25 9.63 12.69 5.69 1/2" NPT 4 3.50 10.00 1/2" NPT 1-1/2”-12

248 GMC 3.75 56.00 7.38 13.25 6.13 1/2" NPT 4 2.75 10.00 1/2" NPT 1-1/2”-12

348 GMC 3.50 56.00 9.88 13.38 6.13 1/2" NPT 4 2.75 10.00 1/2" NPT 1-1/2”-12

260 GMC 2.00 66.75 9.00 14.00 11.50 1/2" NPT 6 7.50 10.00 1/2" NPT 1-1/2”-12

360 GMC 2.00 66.75 13.00 14.00 11.50 1/2" NPT 6 7.50 10.00 1/2" NPT 1-1/2”-12

460 GMC 2.00 66.75 16.50 14.00 11.50 1/2" NPT 6 7.50 10.00 1/2" NPT 1-1/2”-12

560 GMC 4.0 74.25 20.13 14.60 — 1/2" NPT 6 — 10.00 1/2" NPT 1-1/2”-12

U V

tap size

spuds

X Y

tap size Supply

Z Air

E

P-1100-WC 1/12

Wichita Clutch 800-964-3262 143

Page 9

Standard Vent Clutches

1/2" NPT (for Optional Mufer 4-263-605-002-0)

Grinding Mill Clutches

Quick Release Valve

8-263-610-011-1 7/8" – 14 Thread

8-263-610-021-1 1/2" NPT

The Wichita Springless Quick Release Valve

discharges twice as fast as any other valve

tested in our laboratory and is four to five times

faster than some common makes of valves.

This valve will close and seal with less than 20

lbs. pressure. Most others require 25 to 30 lbs.

to definitely seal. In actual tests, the Wichita

Valve made many hundreds of thousands of

engagements and dis en gage ments before the

slightest leak occurred, or any parts needed

re place ment. Other valves which were tested

required major re place ment in fewer than 20,000

cycles.

Quality Material

Body and Cap: High strength aluminum alloy

Stem: Molded nylon

Check Valve: Nylon ball

"O" Ring: Neoprene

Standard thread arrangement of 1/2" size.

1/2" pipe thread on the tube connection

and choice of 1/2" pipe thread, or stan dard

7/8-14NF thread for flared fitting thread on

inlet connection. (Fits standard No. 10

high-pressure hose fitting.)

Roto-Couplings

• Long life, no maintenance

• Felt seal eliminates bearing con tam i na tion

• Fast, easy installation

The Wichita Roto-coupling is a device to

connect, or couple, a non-rotating air, gas, or

fluid line to a rotating shaft.

Dimensions: inches

Wichita Part No. AA B C D E F G H Max. RPM

8-240-701-003-1 5/8-18NF 1/4" NPT .40 1.046 2.250 1.500 2.13 3.297 3,500

8-240-705-001-1 1"-14 NF 1/2" NPT .75 1.250 3.188 2.500 3.00 4.438 3,500

8-240-708-001-1 1"-14 NF 3/4" NPT .75 1.313 4.688 2.875 3.69 5.440 3,500

8-240-710-002-1 1-1/2"-12 NF 1" NPT 1.13 1.937 4.875 3.250 3.44 6.812 2,500

8-240-712-001-1 2"-12 NF 1-1/2" NPT 1.13 2.813 5.250 4.250 5.38 8.062 2,500

8-240-714-001-3 2" NPT 2" NPT 1.50 3.000 7.062 4.625 7.00 10.062 1,000

8-240-716-000-3 2-1/2" NPT 2-1/2" NPT 1.88 3.250 9.375 7.000 7.75 12.625 750

144 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Loading...

Loading...