Page 1

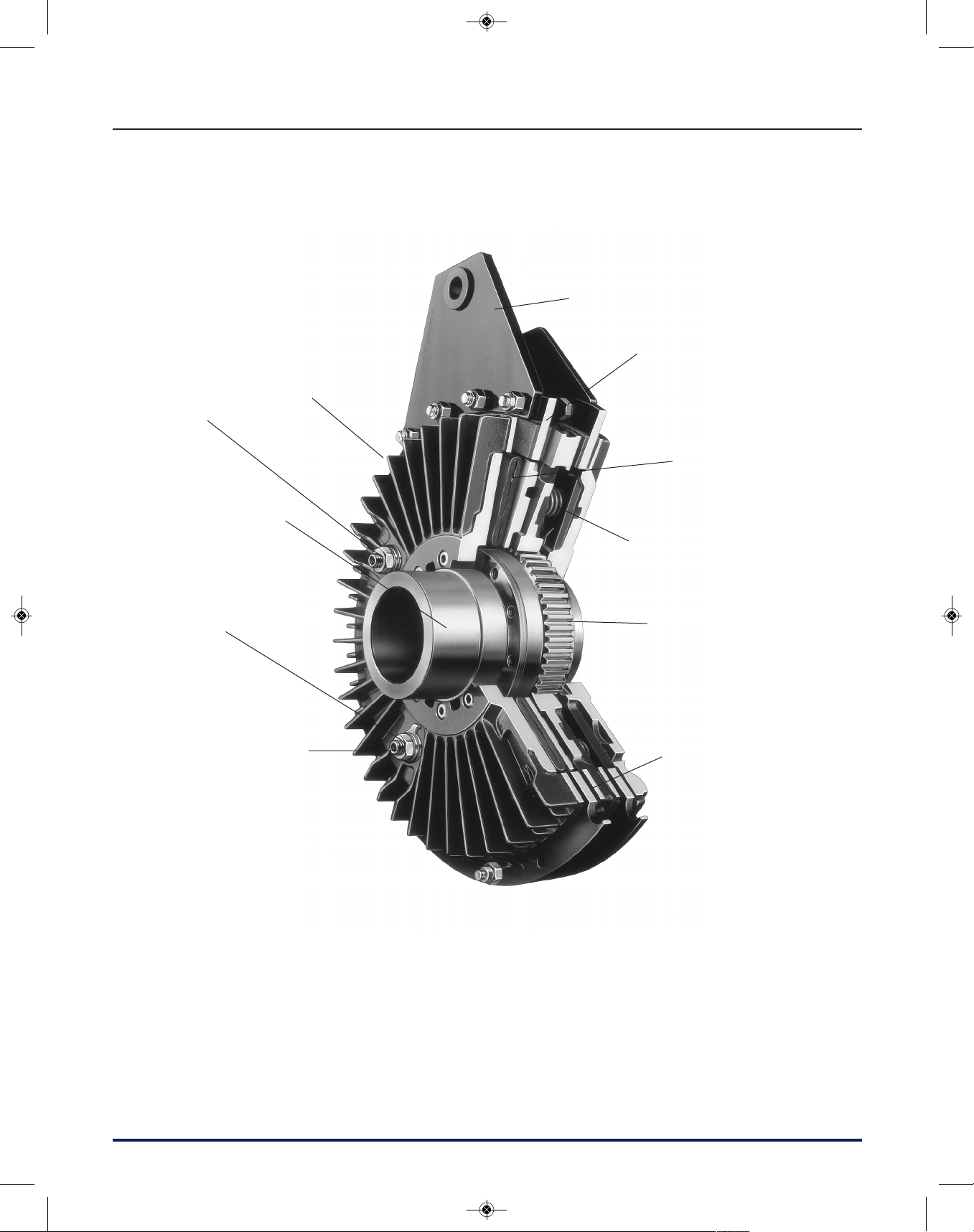

Combination Clutch/Brake

10 Wichita Clutch 800-964-3262

P-1100-WC • 1/11

• For metalforming equipment

• Fast, smooth cycling

• Cool running with higher torque

• Compact disc design

• Simple Installation

The Wichita Combination Clutch-Brake

provides fast, smooth cycling for stamp ing

presses and metalforming equip ment.

The simple Wichita air tube concept

combines an air actuated clutch and a

spring-set brake in a com pact disc design.

Multiple mounting options

for compatability with other

competitive designs

Friction drive plates supplied

in split form for ease of

installation

Long life air tube.

No O-rings

Asbestos free

friction material

Precision die

springs

Low stress internal

spline eliminates

pins

Extra fins for maximum

heat

dissipation

Optional shrink-disc

hub for ease of installation

and removal. No

keyways required.

All air connections are

external. Optional quick

release valves available

for faster cycling

Design Advantages

• No shaft seals for faster, lower cost

installation

• Optional shrink disc mounting for

simplified, easier installation

• Cool running for faster cycle rates,

higher torques

• Models 380-910 have a single air-tube

design that provides long life and high

reliability

This cut-a-way shows

Model 380-910 design

New larger inlets for

CCB size 675-910 for

a more rapid clutch

and brake response

External locking nut

on air inlet to increase

air tube life

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 10

Page 2

A

Combination Clutch/Brake

P-1100-WC 1/12

Wichita Clutch 800-964-3262 11

Operation

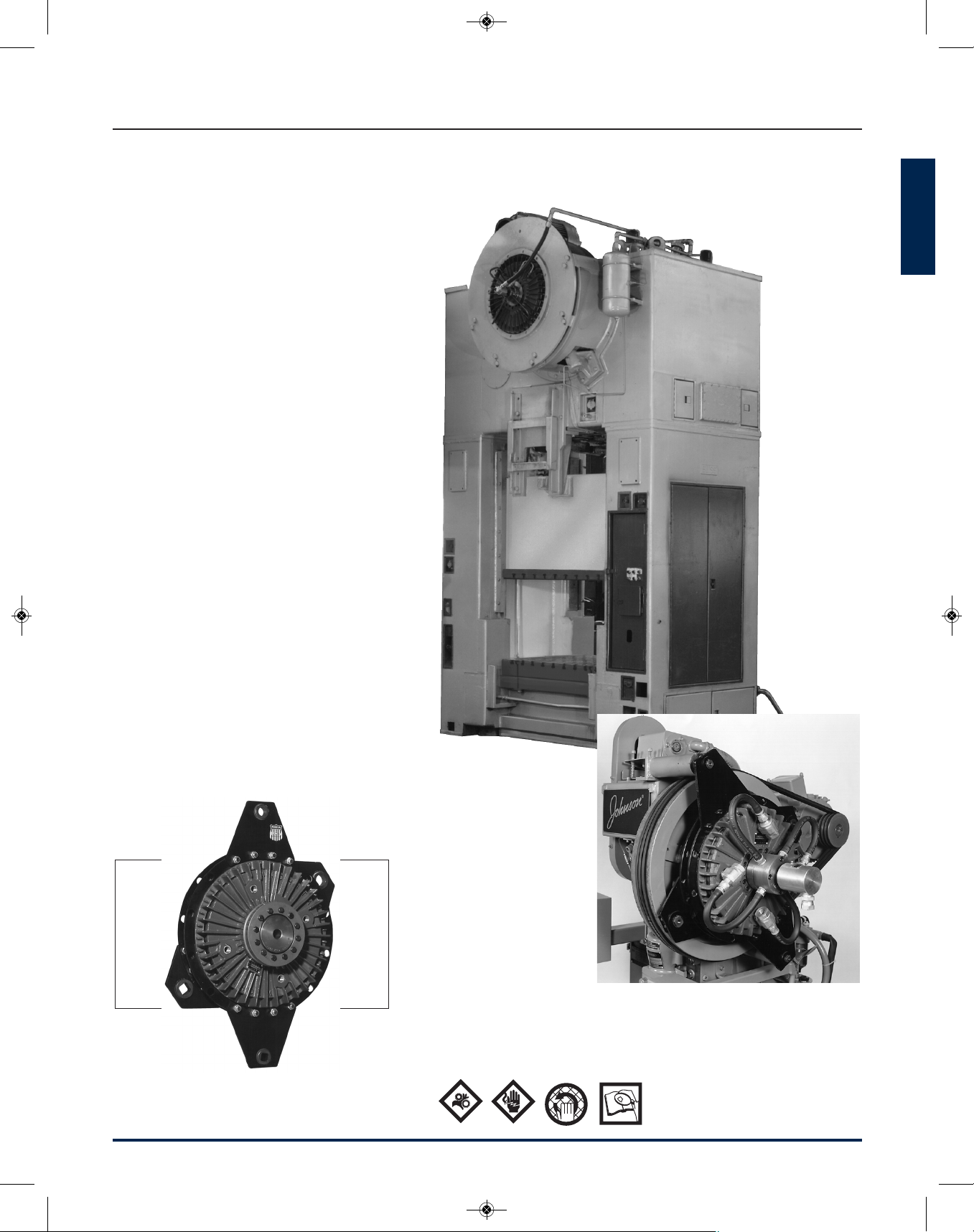

The Wichita Combination Clutch/Brake

provides fast, smooth cycling for stamping

presses and metalforming equipment.

The simple air-tube concept combines an air

actuated clutch and spring-set brake in a

compact, pancake assembly that prevents

overlap. The extra fins and cooling slots allow

for excellent heat dissipation. A low stress

spline eliminates driving pins between the

shaft and centerplate, while the precision die

springs provide con sis tent long-life braking

action.

The high performance air-tube design in sizes

380 and above, with optional quick air-release

valves, provides faster cycling than piston

and cylinder models. There are no o-rings or

piston seals to wear-out and leak, and no

lubrication or adjustment is necessary. Worn

friction plates can be relined at Wichita’s

factory on an ex change basis.

Installation of the CCB is also easy. The

simple air system has external connections

and requires no shaft seals. Metric mount ing

and SAE fasteners are standard. Available in

eight sizes with an optional hub for shrink

disc mounting. Clutch capacities through

340,000 lb.in. and brake torque through

250,000 lb.in.

Wichita Combination Clutch/Brakes are

manufactured and assembled in the United

States and backed by a global sales, service

and distributor organization.

Wichita CCB is ideal for

retrofit applications.

The simple external air

system with quick release

valves provides smooth,

fast cycling.

Optional

Optional shrink disc hub provides ease of

mounting with no keyways.

Typical Applications

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 11

Page 3

Combination Clutch/Brake

12 Wichita Clutch 800-964-3262

P-1100-WC 1/12

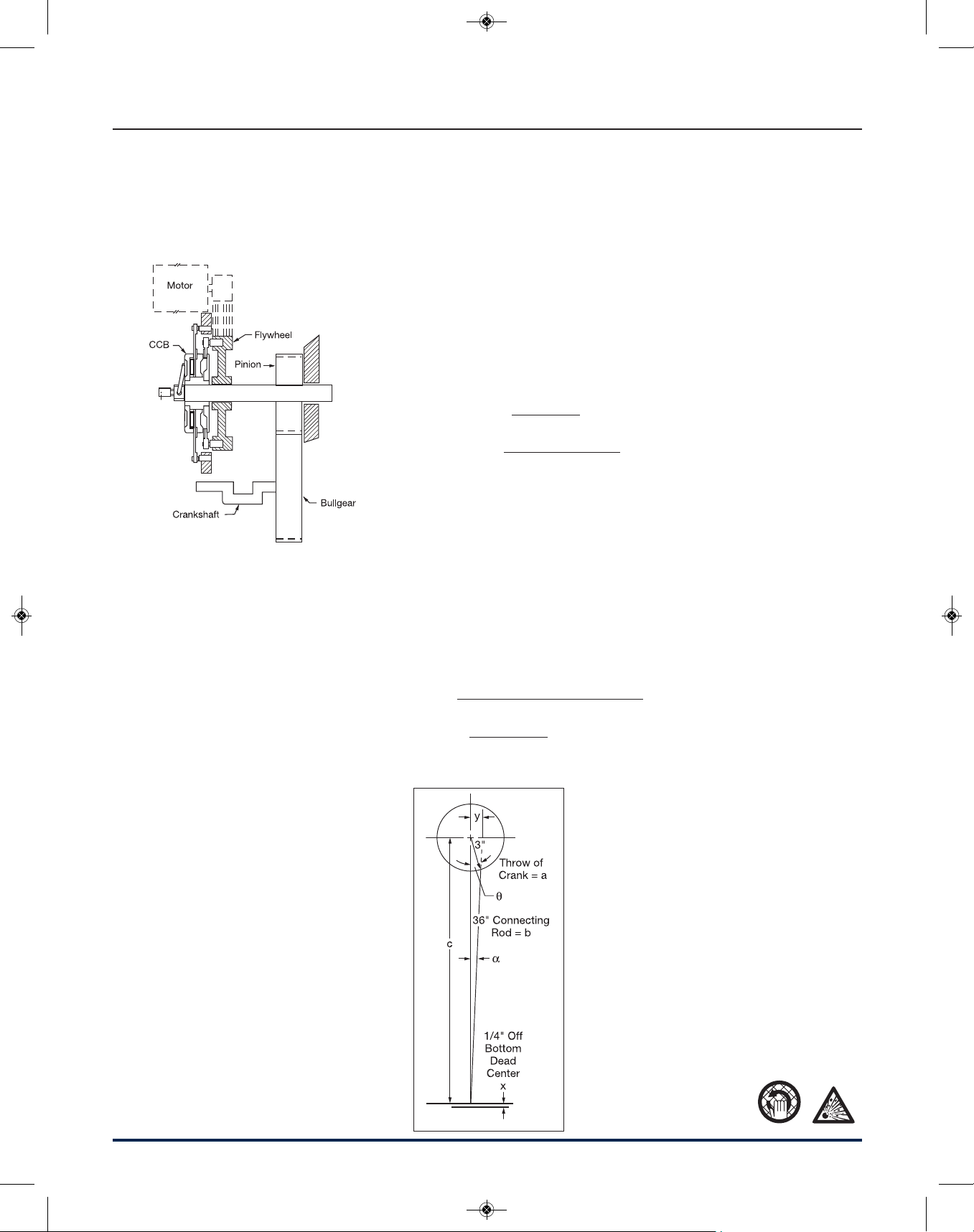

Clutch/Brake Selection

A typical Combination Clutch/Brake application

w

ould be on a geared punch press. To properly

select a CCB the fol low ing application

information is needed.

1. To determine the proper Application Duty

Factor for a Geared Punch Press, consult

page 16. Under Duty “B” or Normal, the

Duty Factor is 1-1/2.

2. To determine the application clutch torque,

t

he following information is needed:

a. Torque @ Crank

= (Rated Tonnage) (2000 lb./ton) (Torque

A

rm)

b. Torque Arm = y = (c) (tan a)

c = a + b - x

=

3 + 36 - .25

= 38.75 in.

b

2

+ c2- a

2

Cos α =

2bc

(36)

2

+ (38.75)2- (3)

2

=

(2) (36) (38.75)

= .99948

= 1.8478°

c. Torque Arm = y = (c) (tan α)

= (38.75) (tan 1.8478)

= (38.75) (.03226)

= 1.25 in.

Torque @ Crank

=(Rate Tonnage) (2000 lb./ton)(Torque Arm)

= (200) (2000) (1.25)

= 500,000 lb.in.

Required Torque @ Clutch

(Torque @ Crank) x (Crank shaft RPM)

= lb.in.

Clutch Shaft RPM

(500,000) (30)

=

lb.in.

204

= 73,529 lb.in.

Application Data

Press Type . . . . . . . . . . . . Geared Punch Press

Rated Tonnage . . . . . . . . . . . . . . . . . . 200 tons

Crankshaft Speed . . . . . . . . . . . . . . . . 30 RPM

Degrees of Crank to Start . . . . . . . . . . . . . . 90°

Distance Above Bottom – x . . . . . . . . . . .25 in.

1/2 of Press Stroke (throw) = a . . . . . . . . . 3 in.

WR

2

of Parts on Backshaft . . . . . . . . . 78 lb.ft.

2

Required Clutch Torque. . . . . . . . . 73,529 lb.in.

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 in.

Clutch/Brake Shaft. . . . . . . . . . . . . . . 204 RPM

Degrees of Crank to Stop . . . . . . . . . . . . . . 120

Connecting rod length = b . . . . . . . . . . . . 36 in.

WR

2

of Parts on Crankshaft . . . . . 39,091 lb.ft.

2

Cycles/Minute . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air Pressure Available. . . . . . . . . . . . . . 100 PSI

Shaft Size . . . . . . . . . . . . . . . . . . . . . . . . 4.5 in.

Selection

Press clutch and brake selection is

based on:

1. Application Duty Factor

2. Application clutch torque

3. Application brake torque necessary

to stop

4. Maximum Energy Input

5. Heat generated during cycling

6. Bore size

1/4" distance

above bottom

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 12

Page 4

A

Combination Clutch/Brake

P-1100-WC 1/12

Wichita Clutch 800-964-3262 13

( )

4. Calculate energy input required for the

combination clutch/brake.

a. Kinetic Energy =

(WR

2

)(CCB RPM)

2

5,873

KE =

(1041)(204)

2

= 7,376 lbs.ft.

5,873

b. Maximum energy input to the CCB 600

is 14,229 ft.lbs. Therefore, CCB 600 has

sufficient energy input capacity.

5. To determine the Heat Horsepower

Capacity of the CCB at backshaft speed,

you need the following in for ma tion:

a. Heat HP capacity of CCB 600 @

200 RPM. (Look up capacity under the 200

RPM heading on page 16.)

Heat HP = 3.7 Heat HP @ 200 RPM.

b. To determine the Cycles Per Minute

Ca pac i ty, you need the following

in for ma tion:

(Heat HP @ CCB speed) (1.9 x 10

8

)

(WR

2

) (RPM)

2

or

3.7 (1.9 x 108)

(1041) (204)

2

= 16 CPM

Final Selection:

CCB 600 with 1/2 spring compliment. Also available

with shrink disc shaft mounting.

(See pages 18–19 for various mounting

arrangments).

Note:

This application example is for preliminary

sizing only. Contact a Wichita Sales Engineer

or the factory for final selection.

Application selection torque = the required

torque of 73,529 lb. in. x 1.5

= 110,294 lb.in. (Application Duty Factor for

“

Geared Punch Press”, page 16.

Preliminary selection of CCB based on clutch

torque is the CCB 600 with 50% spring

c

ompliment. The clutch torque for this model

is 124,350 lb.in. @ 80 PSI.

d. Maximum bore for CCB 600 is 5.0 in. bore

a

cceptable.

3. To determine application brake torque necessary

to stop the equipment the following information

is needed:

a.

The inertia of rotating parts referred to the

backshaft. It is given in the application data

that the inertia (WR

2

) of parts on the

crankshaft is 39,091 lb. ft.

2

at 30 RPM. To

calculate WR

2

referred to the backshaft:

30 RPM of Crankshaft

2

x 39,091 lb.ft.

2

204 RPM of Backshaft

= 845 lb.ft.2@ 204 RPM

Total WR2referred to backshaft is:

845 lb.ft.

2

+ 78 lb.ft.2= 923 lb.ft.

2

(WR2of parts on backshaft from application

data)

Total WR

2

to start and stop is:

923 lb.ft.

2

+ 118 lb.ft.2= 1041 lb.ft.

2

(WR2of CCB-600 from page 15)

b. The brake stop time required is 120°. (Based

on rotation at 30 RPM).

Angle to Stop 60

Stop Time =

360 crankshaft RPM

120 60

= = .5 sec.

360 30

c. Required deceleration torque =

(WR

2

) (CCB RPM) (1041) (204)

or

(25.6) (Stop Time sec.) (25.6)(.5)

= 16,590 lb.in.

d. Application brake torque =

(18,466) (1.5) or 27,700 lb.in.

The CCB 600 has a rated brake

torque capacity of 35,850 lb.in.

with 50% spring compliment.

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 13

Page 5

Combination Clutch/Brake

14 Wichita Clutch 800-964-3262

P-1100-WC 1/12

Specifications

Size 380 thru 910

Maximum operatiing pressure is 100 PSI, (7BAR)

* Operating the unit above the Balance speed to Maximum, it is recommended to have the unit balanced. It is suggested to operate the unit in a continuous running,

non-cyclic mode. Operating the unit in a cyclic, single-stroking mode, may result in some dusting of the friction material.

** For dry operation only. It is essential to keep the friction material free of lubricants.

( )

Clutch Maximum

Dynamic Brake Swept Maximum Speed

Slip Torque Dynamic Friction Energy Balance

Spring Capacity Slip Torque Area Input Speed*

CCB Compliment @ 80 PSI** Capacity in.2 lb.ft. RPM

Model % lb.in. (Nm) lb.in. (Nm) (cm2) (Joules) (RPM)

100% 23,000 (2,600) 18,000 (2,030)

380

75% 27,500 (3,100) 13,500 (1,525) 60 4,640 1,550

50% 32,000 (3,600) 9,000 (1,015) (387) (6,290) (895)

25% 36,500 (4,120) 4,500 (505)

100% 43,400 (4,900) 34,500 (3,890)

470

75% 52,000 (5,870) 25,900 (2,920) 120 9,280 1,250

50% 60,650 (6,845) 17,250 (1,945) (774) (12,581) (725)

25% 69,275 (7,800) 8,625 (975)

100% 68,100 (7,685) 54,000 (6,095)

550

75% 81,600 (9,210) 40,500 (4,570) 184 14,229 1,060

50% 95,100 (10,735) 27,000 (3,050) (1,187) (19,291) (620)

25% 108,600 (12,260) 13,500 (1,525)

100% 88,500 (9,900) 71,700 (8,090)

600

75% 106,425 (12,000) 53,775 (6,070) 184 14,229 970

50% 124,350 (14,035) 35,850 (4,045) (1,187) (19,291) (570)

25% 142,275 (16,060) 17,925 (2,220)

100% 132,000 (14,900) 105,400 (11,910)

675

75% 158,350 (17,875) 79,050 (8,930) 308 23,818 860

50% 184,700 (20,845) 52,700 (5,955) (1,987) (32,291) (500)

25% 211,050 (23,820) 26,350 (2,975)

100% 173,210 (19,570) 156,220 (17,652)

760

75% 214,550 (24,240) 117,165 (13,236) 360 27,839 765

50% 255,900 (28,915) 78,110 (8,826) (2,323) (37,743) (450)

25% 291,115 (32,890) 39,055 (4,415)

100% 254,500 (28,750) 199,000 (22,480)

830

75% 309,700 (34,990) 149,300 (16,870) 404 31,241 700

50% 337,300 (38,110) 124,400 (14,055) (2,606) (42,356) (410)

25% 392,500 (44,345) 74,600 (8,430)

100% 346,800 (39,150) 258,400 (29,160)

910

75% 411,400 (46,430) 193,800 (21,870) 462 35,726 640

50% 476,000 (52,725) 129,200 (14,580) (2,981) (48,437) (375)

25% 540,600 (66,000) 64,600 (7,290)

Model Size Assembly (100% SPR. COMPL) Drawing Numbers Part Family

380 7-915-100-209-0000 7-915-100-931-1&2 546

470 7-918-100-205-0000 7-918-100-931-1&2 547

550 7-922-100-209-0000 7-922-100-931-1&2 549

600 7-923-100-209-0000 7-923-100-931-1&2 551

675 7-927-100-209-0000 7-927-100-931-1&2 552

760 7-930-100-209-0000 7-930-100-931-1&2 553

830 7-933-100-209-0000 7-933-100-931-1&2 555

910 7-935-100-209-0000 7-935-100-931-1&2 554

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 14

Page 6

A

Combination Clutch/Brake

P-1100-WC 1/12

Wichita Clutch 800-964-3262 15

Specifications

Size 380 thru 910

Dimensions: inches (mm)

Maximum Bores ‘R’

Twin Rect. Internal External Total

Square Key Keys Shrink Disc Parts Parts Weight

CCB in. in. in. Inertia Inertia (RR Style)

Model (mm) (mm) (mm) lb.ft.

2

(kgm

2

) lb.ft.

2

(kgm

2

) lb. (kg)

380

2-7/8 3-3/16 3-1/8

12.4 (.52) 4 (0.17) 99 (45)

(73) (81) (80)

470

3-3/8 3-3/4 4-1/8

33.3 (1.4) 16 (0.67) 190 (86)

(86) (95) (105)

550

4-1/2 4-3/4 5-1/2

70.2 (3.0) 23 (0.97) 290 (132)

(114) (121) (140)

600

5 5 6-3/32

118 (5.0) 72 (3.0) 380 (172)

(127) (127) (155)

675

5 5-1/2 6-3/32

209 (8.8) 80 (3.4) 530 (240)

(127) (140) (155)

760

6-3/10 6-7/8 7-7/8

370 (15.6) 154 (6.5) 760 (345)

(160) (175) (200)

830

6-7/8 7-1/2 8-15/32

455 (19.2) 226 (9.5) 635 (288)

(175) (191) (215)

910

7-1/8 8-3/8 9-1/4

820 (34.5) 280 (11.8) 1,190 (540)

(181) (213) (235)

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 15

Page 7

Combination Clutch/Brake

16 Wichita Clutch 800-964-3262

P-1100-WC 1/12

* Beyond maximum speed limit

Application Duty Factors

Heat Horsepower Capacity

Speed – RPM

CCB 100 200 300 400 500 600 700 800 900

170 .12 .16 .20 .23 .25 .27 .28 .30 .31

190 .16 .21 .25 .28 .30 .32 .34 .35 .36

230 .28 .35 .42 .45 .48 .51 .54 .58 .61

310 .51 .63 .74 .84 .93 .98 1 1.07 1.12

380 1 1.3 1.6 1.8 1.9 222.4 2.7

470 1.7 2.1 2.4 2.8 3.1 3.4 3.6 3.9 4.2

550 2.5 3.0 3.5 3.9 4.3 4.7 5.1 5.6 6

600 3 3.7 4.3 4.9 5.5 5.9 6.2 6.6 7

675 3.7 4.4 5 5.8 6.5 7.1 7.6 8.1

*

760 5 6.1 7.1 7.7 8.3 8.9 9.5

**

830 6.5 7.9 9.3 10.2 11.1 11.9 12.7

**

910 8 9.8 11.5 12.8 14 15.2

***

Duty B Duty C Duty D

Normal – Factor Heavy – Factor Extra Heavy – Factor

Field of Application 1-1/2 3-1/4 5-1/2

Metal Production Press Brake Shear Forming Press

& Forming Non-Geared Punch Press Back Geared Punch Press Forging Press

Flywheel Drive* Double Back Shaft Drive* Header Press

Geared Punch Press Deep Draw Press Knuckle Press

Single Back Shaft Drive*

Single Reduction Drive* Transfer Press

Single Gear Drive* Toggle Press

* Alternate common industry name for above machine type

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 16

Page 8

A

Combination Clutch/Brake

P-1100-WC 1/12

Wichita Clutch 800-964-3262 17

Component Parts

Size 380 thru 910

1. Hub

2. Bolt

3. Back Plate

4. Center Plate

5. Drive Plate

6. Air-Tube Holding Plate

7. Pressure Plate

8. Air-Tube

9. Air-Tube Holding Plate Bolts

10. Shim

11. Brake Springs

12. End Cap

13. Short Mounting Bracket

14. Long Mounting Bracket

29. Hex Head Capscrew (HHCS)

30. Flex Lock Nuts

31. Socket Head Capscrew (SHCS)

33. Air Spud

34. Air Manifold

35. Socket Head Capscrew (SHCS)

Not Shown:

• Bolt & Nut between Pressure

Plate and Center Plate

• Clip, Bolt & Nut on Ring Mount

15. Drive Pin (Round Clutch)

16. Drive Pin (Square Clutch)

17. Drive Pin (Square Brake)

18. Drive Pin (Round Brake)

19. Drive Bushing (Round Clutch)

20. Drive Bushing (Square Clutch)

21. Drive Bushing (Square Brake)

22. Drive Bushing (Round Brake)

23. Snap Ring

24. Snap Ring

25. Snap Ring

26. Snap Ring

27. Retainer Plate (Brake Drive Pin)

28. Retainer Plate (Clutch Drive Pin)

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 17

Page 9

Combination Clutch/Brake

18 Wichita Clutch 800-964-3262

P-1100-WC 1/12

RP (Ring to Pin)

RR (Ring to Ring)*

PP (Pin to Pin)*

* Dimensions same as RP design

All ring drives to have pins located

in pin size counterbores 0.13" deep.

PEP

(Pin to Extended Pin)

RR

(Ring to Ring)

PP

(Pin to Pin)

Component Parts

Size 380 thru 910

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 18

Page 10

A

Combination Clutch/Brake

P-1100-WC 1/12

Wichita Clutch 800-964-3262 19

Dimensions: inches (mm)

* Maximum bores with square key. Larger bores available with shallow keys.

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

Dimensions: inches (mm)

Component Parts

Size 380 thru 910

C, C1, C2dimensions are ± .007 (.18)

E E1 E2

Model A Max. +.000/ +.001/ +.001/ G G

1

No. Bore* B B1 B2 C C1 C2 D -.002 -.000 -.000 RR PP

380

2.875 17.13 22.05 26.77 16.063 19.488 25.000 14.94 0.709 1.181 0.866 3.24 4.32

(73) (435) (560) (680) (408) (495) (635) (380) (18) (30) (22) (82.2) (109.7)

470

3.375 21.06 27.36 33.66 19.685 24.016 31.102 18.50 0.984 1.575 1.181 4.02 4.88

(86) (535) (695) (855) (500) (610) (790) (470) (25) (40) (30) (102.1) (124.0)

550

4.500 24.41 30.71 37.40 22.992 27.362 34.843 21.65 0.984 1.575 1.181 5.06 6.42

(114) (620) (780) (950) (584) (695) (885) (550) (25) (40) (30) (128.4) (163.1)

600

5.000 26.77 34.25 42.32 25.197 30.315 38.976 23.62 1.181 1.772 1.575 4.83 6.22

(127) (680) (870) (1,075) (640) (770) (990) (600) (30) (45) (40) (122.6) (158.0)

675

5.000 30.51 39.37 48.56 28.543 34.646 44.685 26.57 1.378 2.165 1.772 5.39 6.98

(127) (775) (1,000) (1,235) (725) (880) (1,135) (675) (35) (55) (45) (136.9) (177.3)

760

6.300 34.06 42.91 52.56 31.890 38.189 48.622 29.92 1.575 2.165 1.772 5.96 7.50

(160) (865) (1,090) (1,335) (810) (970) (1,235) (760) (40) (55) (45) (151.4) (190.5)

830

6.875 37.50 49.31 63.09 — 43.307 57.087 32.68 1.772 2.954 2.560 7.19 8.75

(175) (953) (1,252) (1,602) — (1,100) (1,450) (830) (45) (75) (65) (182.6) (222.3)

910

7.125 40.35 52.76 65.75 37.992 46.457 60.039 35.82 1.772 2.953 2.559 7.43 9.61

(181) (1,025) (1,340) (1,670) (965) (1,180) (1,525) (910) (45) (75) (65) (188.7) (244.1)

Lengths

Model K

Thread

No. Qty. Size L N

1

N2 O P R S S1 S2 T1 T2 J U1 U

2

380 4 1/2" NPT

4.41 1.00 1.00 0.47 2.05 0.96 0.75 2.36 1.77 0.79 0.63

3/8–16 NC #10–24 NC #10–24 NC

(112) (25) (25) (12) (52.0) (45.5) (19) (60) (45) (20) (16)

470 4 1/2" NPT

5.50 1.378 1.00 0.41 2.60 1.12 0.87 3.15 2.36 1.06 0.79

1/2–13 NC 1/4–20 NC #10–24 NC

(140) (35) (25) (10.5) (66.5) (28.5) (22) (80) (60) (27) (20)

550 4 1/2" NPT

6.30 1.378 0.984 0.51 3.17 1.34 1.18 3.15 2.36 1.06 0.79

1/2–13 NC 1/4–20 NC #10–24 NC

(160) (35) (25) (13.0) (80.5) (34) (30) (80) (60) (27) (20)

600 4 1/2" NPT

7.28 1.378 1.378 0.49 3.19 1.32 1.06 3.54 3.15 1.16 1.06

5/8–11 NC 5/16–18 NC 1/4–20 NC

(185) (35) (35) (12.5) (81.0) (33.5) (27) (90) (80) (29.5) (27)

675 4 1" NPT

8.00 1.772 1.378 0.49 3.88 1.42 1.25 4.33 3.54 1.52 1.16

3/4–10 NC 5/16–18 NC 1/4–20 NC

(203) (45) (35) (12.5) (98.5) (36) (32) (110) (90) (38.5) (29.5)

760 4 1" NPT

9.06 1.772 1.378 0.49 4.23 1.59 1.50 4.33 3.54 1.52 1.16

7/8–9 NC 5/16–18 NC 1/4–20 NC

(230) (45) (35) (12.5) (107.5) (40.5) (38) (110) (90) (38.5) (29.5)

830 4 1" NPT

8.00 1.75 1.75 0.50 4.32 1.94 1.75 5.91 5.12 1.71 1.71

1–8 NC 5/16–18 NC 5/16–18 NC

(203) (45) (45) (12.7) (109.7) (49.3) (44.5) (150.1) (130) (43.5) (43.5)

910 3 1" NPT

10.24 2.362 1.772 0.89 4.90 2.10 1.75 5.91 5.12 2.07 1.71

1–8 NC 3/8–16 NC 5/16–18 NC

(260) (60) (45) (22.5) (124.5) (53.5) (44.5) (150) (130) (52.5) (43.5)

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 19

Page 11

Combination Clutch/Brake

20 Wichita Clutch 800-964-3262

P-1100-WC 1/12

End Cap Air Manifold

Clearance & Wear Chart

Model Kit No. A B C D E F

.875 H.C.

1/2" NPT

380 8-546-021-000-1 4.188 3.12 N/A 13/32 Drill 1"-14 NF

3 at 120°

4 at 90°

1.250 H.C.

1/2" NPT

470 8-547-021-000-1 4.188 3.12 N/A 13/32 Drill 1"-14 NF

3 at 120°

4 at 90°

4.937 /

3.000 H.C. 2.000 H.C.

1/2" NPT

550 8-549-021-000-1 3.12 13/32 Drill 13/32 Drill 1-1/2"-12 NF

4.935

3 at 120° 3 at 120°

4 at 90°

2.875 H.C.

1/2" NPT

600 8-552-021-000-1 4.938 3.12 13/32 Drill N/A 1-1/2"-12 NF

3 at 120°

4 at 90°

2.875 H.C.

1/2" NPF

675 8-552-021-000-1 4.938 3.12 13/32 Drill N/A 1-1/2"-12 NF

3 at 120°

4 at 90°

3.500 H.C.

1/2" NPT

760 8-553-021-000-1 7.000 3.12 N/A 13/32 Drill 1-1/2"-12 NF

3 at 120°

4 at 90°

4.000 H.C.

1" NPT

830 4-555-021-000-3 9.50 4.06 N/A 9/16 Drill 1-1/2"-12 NF

4 at 90˚

4 at 90˚

7.255 /

5.000 H.C. 3.250 H.C.

1/2" NPT

910 8-554-021-000-1

3.12 17/32 Drill 17/32 Drill 2"-12 NF

7.250

3 at 120° 3 at 120°

6 at 60°

Minimum Maximum Roto Clearance W+ Wear Tank Vol. Pipe Size Coupling*

Model in. (mm) in. (mm) K+ in. (mm) in.3 liters in. (mm) Part No.

380 1/32 (0.8) 0.1 (2.5) 86 0.12 (3) 100 1.6 3/4 (19) 8-240-708-001-1

470 1/32 (0.8) 0.1 (2.5) 134 0.16 (4) 155 2.5 3/4 (19) 8-240-708-001-1

550 3/64 (1.2) 0.11 (2.8) 196 0.20 (5) 250 4.1 1 (32) 8-240-710-002-1

600 3/64 (1.2) 0.11 (2.8) 215 0.20 (5) 275 4.5 1 (32) 8-240-710-002-1

675 1/16 (1.6) 0.12 (3.2) 280 0.25 (6) 390 6.4 1 (32) 8-240-710-002-1

760 1/16 (1.6) 0.12 (3.2) 360 0.25 (6) 500 8.2 1 (32) 8-240-710-002-1

830 3/32 (2.4) 0.16 (4) 489 0.25 (6) 800 13.1 1-1/2 (38) 8-240-710-002-1

910 3/32 (2.4) 0.16 (4) 530 0.28 (7) 1000 16.4 1-1/2 (38) 8-240-712-001-1

*See page 35 for dimensions

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 20

Page 12

A

Combination Clutch/Brake

P-1100-WC 1/12

Wichita Clutch 800-964-3262 21

Hose Kit for Air Manifold or

Cross Drilled Shaft Mounting

Model Part Number

380 8-938-812-402-5 ELB

8-938-820-401-5 QRV

470 8-947-812-402-5 ELB

8-947-820-401-5 QRV

550 8-955-812-402-5 ELB

8-955-820-401-5 QRV

600 8-960-812-402-5 ELB

8-960-820-401-5 QRV

675 8-967-812-402-5 ELB

8-967-820-401-5 QRV

760 8-976-812-402-5 ELB

8-976-820-401-5 QRV

830 8-983-813-401-5 ELB

8-983-831-401-5 QRV

Hose Kit for Shrink Disc

Mid-Shaft Mounting

Model Part Number

380 8-938-812-401-5 ELB

8-938-822-401-5 QRV

470 8-947-812-401-5 ELB

8-947-822-401-5 QRV

550 8-955-812-401-5 ELB

8-955-822-401-5 QRV

600 8-960-812-401-5 ELB

8-960-822-401-5 QRV

675 8-967-812-401-5 ELB

8-967-822-401-5 QRV

760 8-976-812-401-5 ELB

8-976-822-401-5 QRV

830 8-983-813-402-5 ELB

8-983-831-402-5 QRV

Hose Kit for Shrink Disc

Mid-Shaft Mounting

Model Part Number

910 8-991-812-503-5 ELB

8-991-822-503-5 QRV

Hose Kit for Air Manifold or

Cross Drilled Shaft Mounting

Model Part Number

910 8-991-812-502-5 ELB

8-991-820-501-5 QRV

* Optional Quick Release Valves

can replace elbows on most units.

Air Hose Kits

Sizes 380 thru 910

Wichita Air Hose Kits contain all the necessary parts

(fittings, hoses and extensions) to completely plumb

the brake air system. The Hose Kit part number is

de ter mined by model number, type of shaft mounting

and whether or not a quick release valve is needed.

Muffler Part Number: 4-263-605-002-0

WE9289 P1100WC PCB Catalog v4_NEW_P-1100-WC.qxd 1/31/12 10:51 AM Page 21

Loading...

Loading...