Page 1

Industrial Clutch Products

MODEL CBA

Air or Hydraulically

Actuated Combination

Clutch-Brakes

I N D U S T R I A L C L U T C H P R O D U C T S 62

Page 2

MODEL CBA

Air or Hydraulically Actuated Combination Clutch-Brakes

Performance Characteristics

The Model CBA combination clutch-brake is an oil immersed

unit utilizing a self-contained cooling oil-pumping system and

capable of being actuated with either air or hydraulic

pressure.

These units are capable of running at higher speeds and

greater cyclic frequencies without exhibiting the wear

magnitudes common to clutches and brakes operating dry

under the same conditions.

Reliability and longevity are the most important features

these units have to offer and find usage in those

applications requiring the ultimate in clutch and brake

performance.

Over fifteen years of field experience shows intervals

between maintenance and machine up-time to increase from

five to ten times when oil immersed units are used as direct

replacements for those operating dry.

Industrial Clutch Products has designed the Model CBA unit

to be compatible and complementary to their dry unit

products. All of the desirable features found in our standard

line of dry products were carefully evaluated for

incorporation into the Model CBA combination clutch-brake.

The user may expect the lowest possible driven inertia;

fastest speed of response; and the same high quality

ruggedness contained throughout our product line.

The Model CBA unit was designed and developed as part of

our commitment to provide wide ranging and usefully

products for the heavy industrial marketplace. As a result,

the user has another level of performance from which to

choose.

Advantages

Combination clutch-brake eliminates the

possibility of clutch-brake fight

Increase in lining life

Increase in reliabillity

Impervious to adverse operating

environments

Low driven inertia

Fast speed of response

High cyclic rates

High operating speeds

Usages

Original Equipment

Machinery which requires unusually high performance

levels, operating speeds, or cyclic rates as well as precise

stopping accuracy.

Conversions

Machinery which is being upgraded to increase production

rates, reliability, or capacity.

63 I N D U S T R I A L C L U T C H P R O D U C T S

Page 3

Model CBA Combination

Clutch-Brake Description

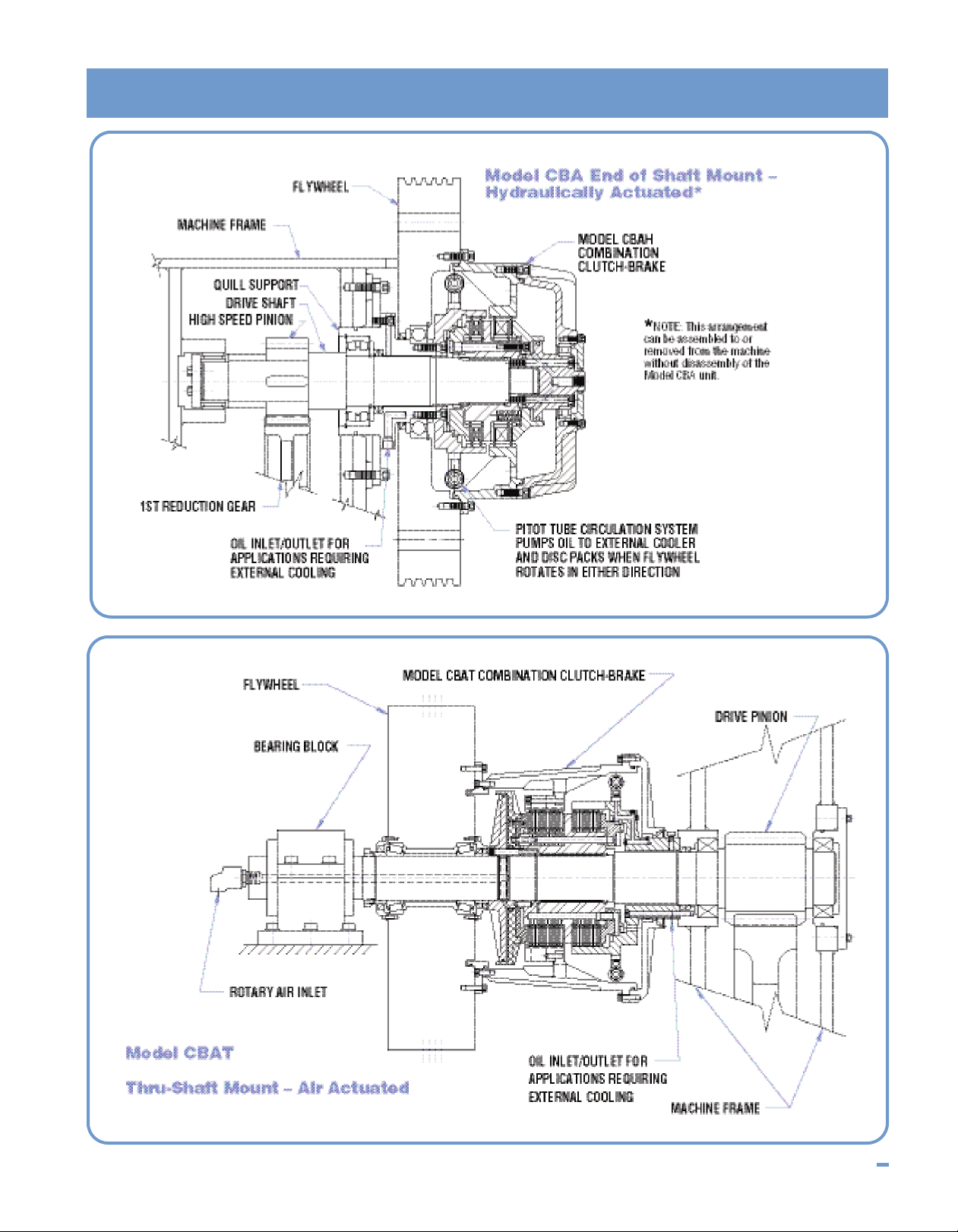

Model CBA

The Model CBA combination clutch-brake is arranged so

that it may be mounted in and end of shaft or thru shaft

configuration. The clutch driving members attach to the

flywheel or input power source. The stationary brake

members are attached to the machine frame by the use of a

quill member which also provides a path for moving the

cooling oil into and out of the unit if the application requires

external cooling. Refer to Figure 1 and Figure 2 for a typical

arrangement of an outboard (CBA) and thru-shaft (CBAT)

mount respectively.

The unit may be provided with either pneumatic or hydraulic

actuation chambers as well as a variety of brake springs to

accommodate the clutch and brake torque requirements.

Due to the many types of machinery configurations, it is

often more convenient to house the clutch-brake unit within

a user provided mounting cavity.

Model CBA

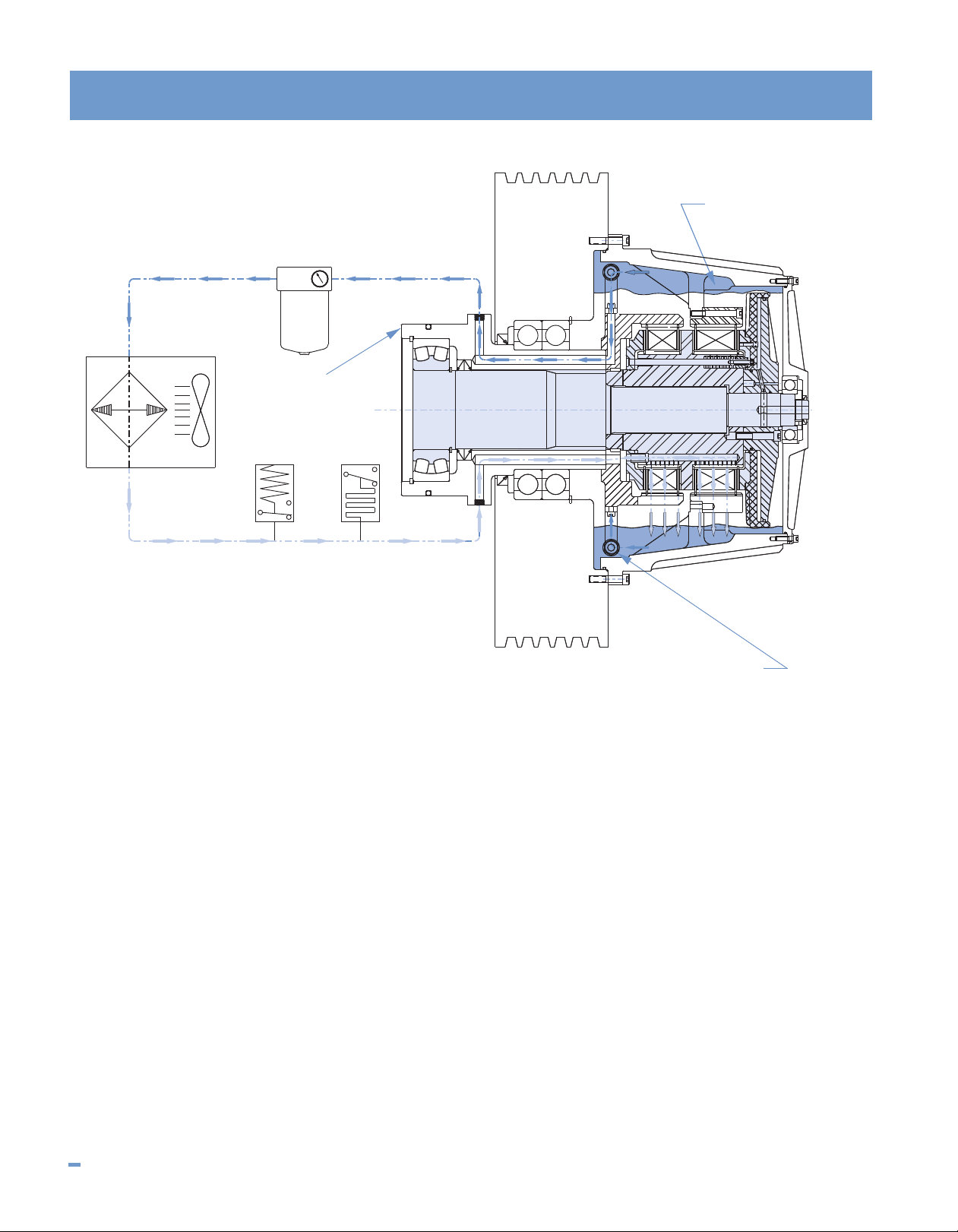

The Model CBA contains its own circulating oil-pumping

system which pumps oil through the disc packs from either

direction of rotation anytime the input member rotates. Refer

to Figure 3. If external cooling is required due to the speed

and cyclic rate, the internal pump output is directed from the

outer housing cavity through the quill/brake support member

and external cooler where the engagement heat is removed.

Cooled oil then returns through the quill/brake support

member into the disk pack where engagement heat is

transferred to the oil. This heated oil is then pumped back to

the cooler for heat removal.

If external cooling is not required, the circulating pump

simply moves the oil internally from the outer housing cavity

through the disk packs and back to the housing cavity where

the engagement heat is transferred through the rotating

housing into the surrounding atmosphere.

The ability of the CBA combination clutch-brake to

continuously and effectively transfer large quantities of

energy in this manner is the key factor to its longevity and

reliabililty. In addition, the torque transmitting members,

being lubricated by this same oil, are well suited to carry the

heavy duty industrial type loads these models encounter.

Model CBAT-32580 Combination Clutch-Brake

installed on a PTC 600-ton 144 x 60 transfer press.

Photo courtesy of Press Technology Corp.

I N D U S T R I A L C L U T C H P R O D U C T S 64

Page 4

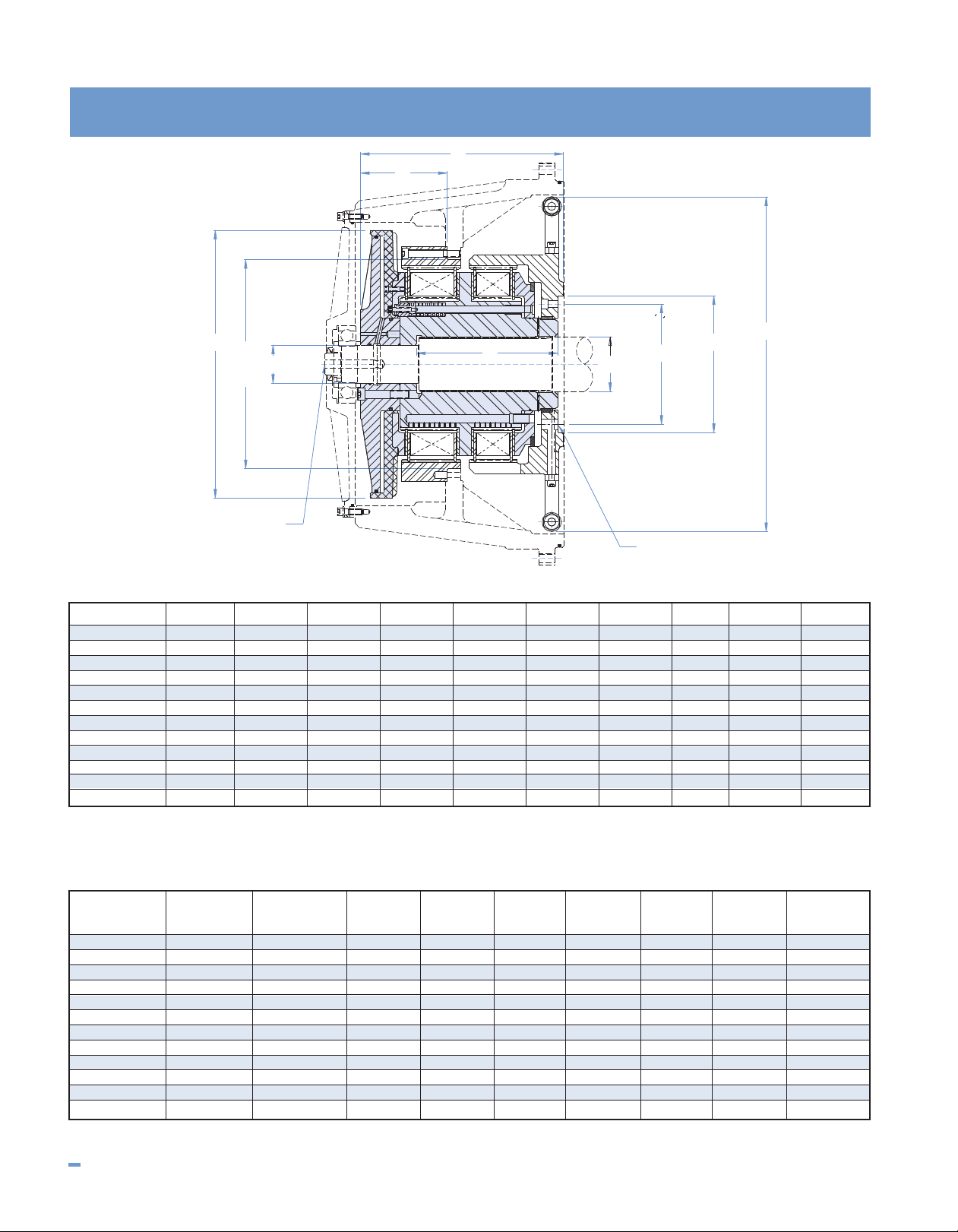

Model CBA

D

A

G

I

H

B

F

J

E

C

DIA.

P

ILOT

O

IL OUTLET TO QUILL

FOR EXTERNAL COOLER OPTION

ACTUATION

INLET

SEE

NOTE 1

SEE

NOTE 2

SEE

N

OTE 1

S

EE

NOTE 1

DIMENSIONAL DATA All dimensions in inches

CBA Model ABCDEFGHI J

CBA-3008 16.88 5.906 5.250 3.625 2.000 11.50 13.75 3.83 9.58 5.68

CBA-4512 16.88 5.906 5.250 3.625 2.000 11.50 13.75 5.21 10.96 7.00

CBA-6015 16.88 5.906 5.250 3.625 2.000 11.50 13.75 6.58 12.33 8.31

CBA-10025 21.63 8.661 7.625 5.000 3.000 15.250 18.25 5.51 12.90 7.65

CBA-14035 21.63 8.661 7.625 5.000 3.000 15.250 18.25 6.20 14.31 9.06

CBA-18045 21.63 8.661 7.625 5.000 3.000 15.250 18.25 6.90 15.72 10.47

CBA-24060 30.63 13.750 12.250 7.000 3.500 19.125 24.50 5.45 14.82 9.37

CBA-32580 30.63 13.750 12.250 7.000 3.500 19.125 24.50 6.06 16.69 11.24

CBA-400100 30.63 13.750 12.250 7.000 3.500 19.125 24.50 7.94 18.56 12.86

CBA-550150 34.13 13.500 12.000 9.250 5.625 34.750 30.50 8.87 22.88 16.01

CBA-650175 34.13 13.500 12.000 9.250 5.625 34.750 30.50 8.87 25.48 18.61

CBA-800200 34.13 13.500 12.000 9.250 5.625 34.750 30.50 8.87 28.08 21.21

NOTES: 1.) Industrial Clutch Prod. will supply shaft end detail and quill support drilling

NOTES: 2.) End of shaft only. For thru-shaft designs, consult engineering.

and machining details. Dimensions may be modified to suit customer requirements.

3.) Use certified drawing dimensions only for final layouts.

4.) DXF and IGES files available upon request.

5.) Dimensions subject to change without notice.

OPERATIONAL DATA

CBA Clutch Torque Brake Torque Volume Outer Inner Stationary Outer Inner Speed

Model (lb.-in.) (lb.-in.) (In.3) (lbs.) (lbs.) (lbs.) (lb.-ft.2) (lb.-ft.2) (RPM)

CBA-3008 30,000 8,000 24 30 103 43 6.5 9.5 1,200

CBA-4512 45,000 12,000 29 41 118 46 8.3 10.6 1,200

CBA-6015 60,000 15,000 33 48 132 52 9.5 11.6 1,200

CBA-10025 100,000 25,000 100 56 253 137 21 44 1,000

CBA-14035 140,000 35,000 100 70 288 151 26 49 1,000

CBA-18045 180,000 45,000 100 101 322 166 39 54 1,000

CBA-24060 240,000 60,000 175 101 635 248 55 204 800

CBA-32580 325,000 80,000 175 148 699 272 83 219 800

CBA-400100 400,000 100,000 175 212 763 296 123 235 800

CBA-550150 550,000 150,000 415 494 978 445 648 495 800

CBA-650175 650,000 175,000 444 549 1093 500 688 537 800

CBA-800200 800,000 200,000 473 604 1208 555 728 697 800

NOTES: 1.) Operating pressure: 80 PSIG air.

2.) Torque capacities can be modified. Higher torques may be obtained using hydraulic actuation. Consult engineering.

Static Dynamic Actuation Weight Weight Weight WR

2

WR

2

Maximum

65 I N D U S T R I A L C L U T C H P R O D U C T S

Page 5

Model CBA

Figure 1

Figure 2

I N D U S T R I A L C L U T C H P R O D U C T S 66

Page 6

Model CBA

MODEL CBA COMBINATION CLUTCH-BRAKE

COOLER

TEMP.

SWITCH

PRES.

SWITCH

OIL ANNULUS

HEATED OIL

FROM CLUTCH-BRAKE

F

ILTER

COOLED OIL

TO CLUTCH-BRAKE

B

RAKE/QUILL

SUPPORT MEMBER

PITOT TUBE CIRCULATION SYSTEM PUMPS OIL

TO EXTERNAL COOLER AND DISC PACKS WHEN

FLYWHEEL ROTATES IN EITHER DIRECTION

Figure 3

EXTERNAL COOLING DESCRIPTION

For those applications requiring external cooling, the pitot

tubes scoop the oil from the rotating column of oil within the

Model CBA’s housing. This oil contains the engagement

heat. The oil is then pumped through passages drilled in the

quill support member to an external cooler where the

engagement heat is removed.

Cooled oil returns through a different set of passages drilled

in the quill support member and is introduced through a

series of orifices directly into the center of the clutch and

brake disc packs. This oil provides the cooling for the disc

packs and removes the heat of engagement. It then returns

to the rotating column of oil where it is again removed by the

pitot tube pumping system and delivered to the cooler to

repeat the cycle.

The pitot tube pumping system is bi-directional and will

pump oil from either direction of rotation. Being a centrifugal

type pumping system, its output is related to the speed of

rotation. This closely matches the cooling oil requirements of

the disc packs since engagement energy is also related to

the speed of rotation in the same manner.

This system is completely self-contained and requires no

additional energy source other than housing rotation. If the

housing rotates, oil is delivered in the correct quantity to the

disc packs.

Low pressure switches,(indicating low oil level), as well as

hi-temperature switches, and a filter are normally included

as shown to complete the cooling lube system.

67 I N D U S T R I A L C L U T C H P R O D U C T S

Loading...

Loading...