Page 1

CAUTION

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

These room thermostats have been designed for controlling cooling equipment operating on line voltage with

heavy electrical loads. They are suitable for operation of

unit coolers, room coolers, etc., or any similar refrigeration application requiring a heavy duty room thermostat.

Models are available with various ranges for meeting the

needs of almost any application.

THESE CONTROLS MUST BE INSTALLED BY A

QUALIFIED INSTALLER.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

This control has been accurately calibrated at the factory.

Any attempt to calibrate this control will void the WhiteRodgers warranty.

The proper location of a heavy duty room thermostat is

very important to assure good performance. The following

general rules will help in determining the proper location:

1. Make sure that it is in a place where air circulates

around it freely. This is important.

2. Never install it on or near an outside wall.

3. Keep it away from windows or doors.

4. Don’t locate it too close to a strong light or any other

false source of heat such as direct sunlight, steam

lines, etc.

5. Mount it on a post or a partitioning wall, but make sure

that there are no pipes or duct work in that wall or

directly behind it.

6. If the electrical conduit leads into a cooler or a warmer

room, plug up the space around the wires in the conduit

with rock wool.

TYPE 151

ROOM THERMOSTAT

Cooling Service, External Dial

INSTALLATION INSTRUCTIONS

DESCRIPTION

W

H

I

T

E

-

R

S

O

R

D

E

G

90

70

80

50

60

40

PRECAUTIONS

To prevent electrical shock and/or equipment

damage, disconnect electric power to system, at

main fuse or circuit breaker box, until installation

is complete.

WARNING

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and

could cause shock or fire hazard.

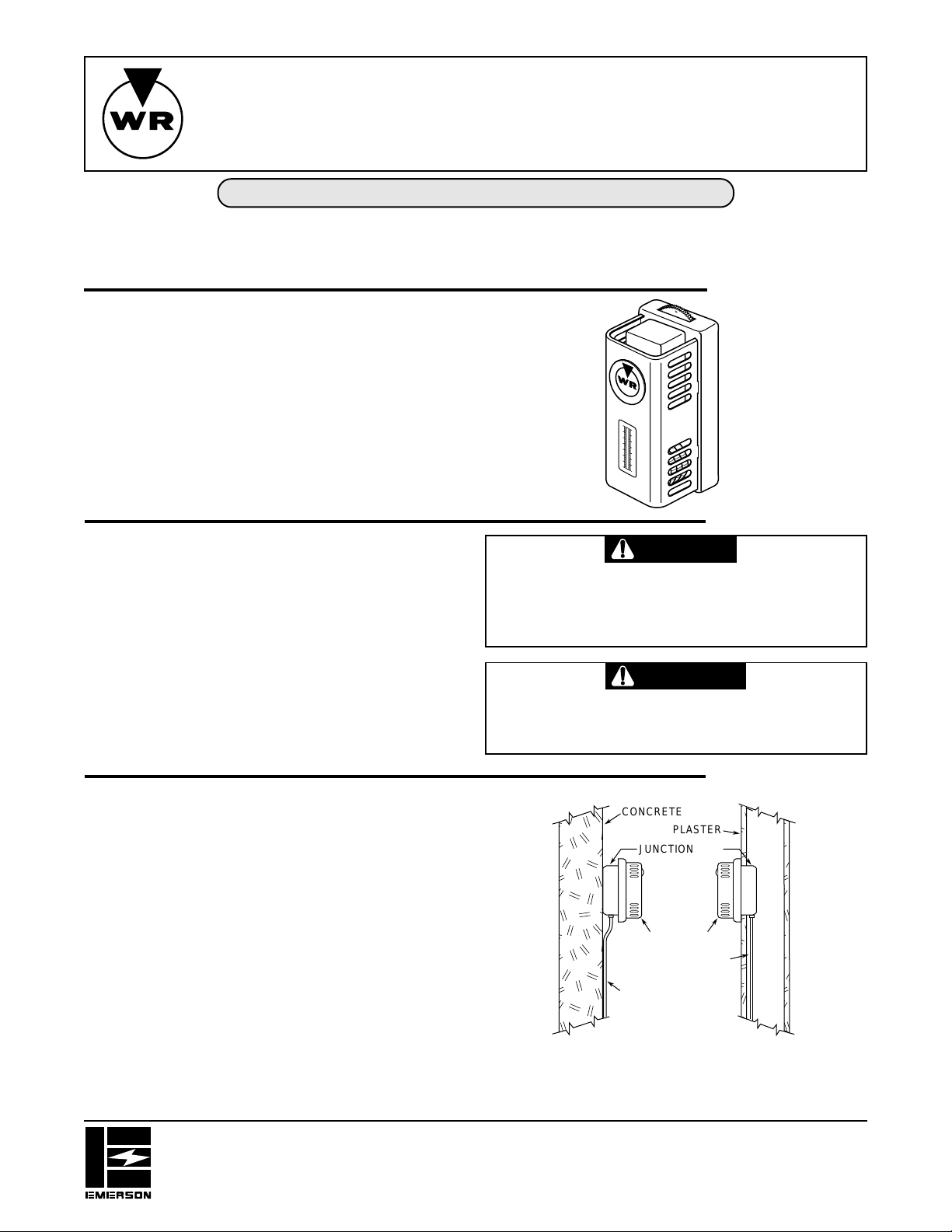

INSTALLATION

CONCRETE

PLASTER

JUNCTION BOX

THERMOSTAT

CONDUIT

INSIDE WALL

CONDUIT

ALONG WALL

WALL INSTALLATION

The mounting plate for this thermostat has two

5

holes 3

/16”apart for attaching the control on a

standard switch box.

Figure 1

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

PART NO. 37-1118B

Replaces 37-1118

9548

Page 2

INSTALLATION CONT.

70

60

80

INDICATING

LINE

IMPORTANT

When control is located where ambient temperature is

below freezing, choose a control location far enough

away from doors and windows so that moisture will not

condense on control.

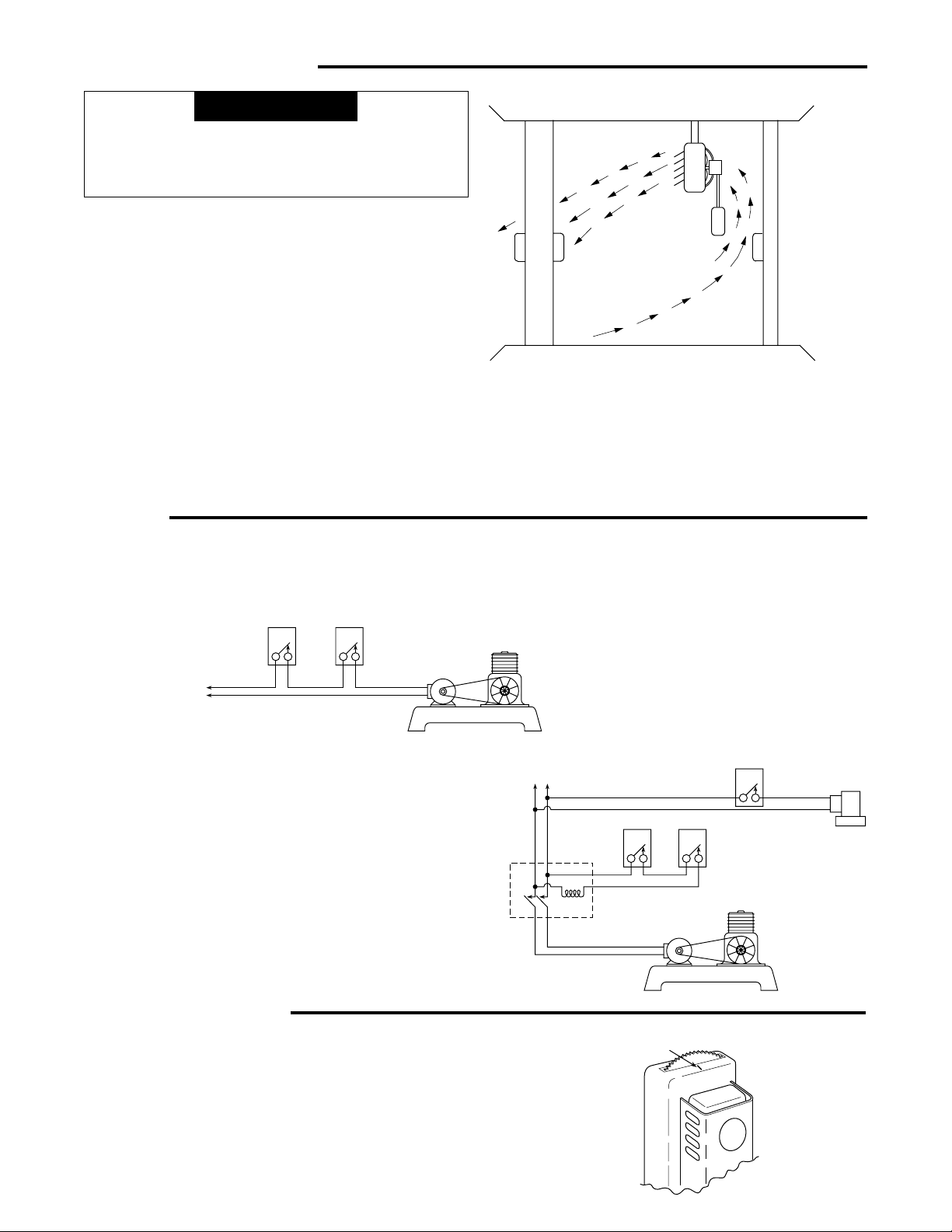

If the thermostat is used with unit coolers, the following

suggestions may help. (See Fig. 2).

1. Position “A” is good if it is sufficiently close to the unit

cooler so that the return air to the cooler flows over the

thermostat.

2. Position “B” is good if it is not necessary to make

frequent adjustments of the dial setting.

3. Position “C” is all right if it is sufficiently far from the

cooler that air flowing over the thermostat is not much

above the average room temperature.

4. In general, position “D” is not advisable because the

post may prevent air from circulating over the thermostat.

CEILING

POST

UNIT

B

D

C

RETURN AIR

FLOOR

Figure 2

PARTITION

WALL OR POST

DIRECTLY

BEHIND UNIT

A

WIRING

All wiring should be done in accordance with local and national electrical codes and ordinances.

If the manufacturer of the cooling equipment has supplied a wiring diagram, follow the manufacturer’s recommendations. The following diagrams show the general use of these controls.

TEMPERATURE

CONTROL

TO LINE SWITCH

AND POWER SUPPLY

HOT

GND

Circuit showing temperature control to open and

close refrigerant valve. Suction pressure control

starts and stops compressor through motor starter.

HIGH SIDE

PRESSURE CONTROL

(IF USED)

MOTOR

STARTER

Circuit showing temperature control controlling compressor directly.

TO LINE SWITCH

AND POWER SUPPLY

HIGH SIDE

PRESSURE

CONTROL

SUCTION

PRESSURE

CONTROL

TEMPERATURE

CONTROL

SOLENOID

REFRIGERANT

VALVE

SETTING THE DIAL

To set the dial, simply move it so that the indicating line on

the case points to the temperature at which the contacts

are to open as the temperature drops.

2

Page 3

WHITE-RODGERS

Utilisateur: conservez ces instructions pour vous y référer au besoin!

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

Ces thermostat d’ambiance ont été conçus spécialement pour

commander des installations de refroidissement fonctionnant

avec des charges électriques élevées à la tension du réseau. Ils

conviennent à l’utilisation de refroidisseurs d’air, de blocs

refroidisseurs de pièces, etc., ou de tout appareil semblable

exigeant un thermostat d’ambiance robuste.

Plusieurs modèles sont disponibles avec des plages variées

permettant d’adapter la commande à presque toutes les

applications possibles.

LA COMMANDE DOIT ÊTRE INSTALLÉE PAR UN TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

Cette commande est un instrument de précision qui doit être

manipulé avec soin. Elle peut se détraquer si elle est manipulée

de façon négligente ou si des composantes sont déformées.

La commande a été calibrée avec précision lors de la fabrication.

Toute tentative de calibrer l’appareil annulera la garantie de

White-Rodgers.

TYPE 151

THERMOSTAT D’AMBIANCE

Pour refroidissement, à cadran extérieur

INSTALLATION INSTRUCTIONS

DESCRIPTION

W

H

I

T

E

-

R

S

O

R

D

E

G

90

70

80

50

60

40

PRÉCAUTIONS

ATTENTION

Afin de prévenir les chocs électriques et les dommages

matériels pendant l’installation, coupez l’alimentation

électrique au panneau de distribution principal.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui dépassent la tension nominale. Une tension trop élevée peut

endommager la commande et poser des risques de

chocs électriques et d’incendie.

Le choix d’un bon emplacement pour un thermostat d’ambiance

robuste est essentiel à son bon rendement. Les règles générales

suivantes aideront à déterminer un bon emplacement :

1. S’assurer que l’air circule librement autour du thermostat .

Ceci est important.

2. Ne jamais installer le thermostat sur un mur extérieur ou à

proximité d’un tel mur.

3. Installer le thermostat à l’écart des portes et fenêtres.

4. Ne jamais installer le thermostat près d’une source ponctuelle

de chaleur, comme les rayons du soleil, des tuyaux de

vapeur, etc.

5. Installer le thermostat sur un poteau ou une cloison intérieure

en s’assurant d’abord qu’il ne se trouve pas directement

devant des tuyaux ou des conduits.

6. Si le conduit électrique traverse un mur vers une pièce plus

chaude ou plus fraîche, placer de la laine minérale autour

des fils dans le conduit.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux États-Unis

INSTALLATION

CONCRETE

BÉTON

RACCORDEMENT

CONDUIT LE

CONDUIT

LONG DU MUR

ALONG WALL

INSTALLATION MURALE

WALL INSTALLATION

La plaque de montage du thermostat est dotée de

The mounting plate for this thermostat has two

5

deux trous séparés par 3-5/16”, qui servent à fixer la

/16”apart for attaching the control on a

holes 3

standard switch box.

commande sur une boîte de raccordement ordinaire.

PLÂTRE

PLASTER

BOÎTE DE

JUNCTION BOX

THERMOSTAT

CONDUIT

CONDUIT

DANS LE MUR

INSIDE WALL

Figure 1

NO DE PIÈCE 37-1118B

Remplace 37-1118

9548

Page 4

INSTALLATION

IMPORTANT

Lorsque le régulateur est installé dans un endroit où la

température ambiante est inférieure au point de

congélation, choisir un emplacement qui est assez loin

des portes et fenêtres pour que l’humidité ne condense

pas sur la commande.

Lorsque le thermostat est utilisé avec des refroidisseurs, les

conseils suivants peuvent s’avérer utiles (voir la fig. 2) :

1. L’emplacement A est convenable s’il est assez près du

refroidisseur pour que l’air de retour circule autour du

thermostat.

2. L’emplacement B est convenable si le point de consigne ne

doit pas être réglé souvent.

3. L’emplacement C est convenable s’il est assez éloigné du

refroidisseur pour que l’air qui circule autour du thermostat

ne soit pas beaucoup plus chaud que la température moyenne

de l’air dans la pièce.

4. En général, l’emplacement D n’est pas recommandé parce

que le poteau peut empêcher l’air de circuler autour du

thermostat.

CÂBLAGE

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux

qui régissent les installations électriques.

PLAFOND

POTEAU CLOISON

REFROIDISSEUR

D

C

AIR DE RETOUR

PLANCHER

B

OU POTEAU SITUÉ

DIRECTEMENT

DERRIÈRE LE

REFROIDISSEUR

A

Fig. 2

Si le fabricant de l’équipement de réfrigération recommande un schéma de câblage, alors veuillez vous y référer. Les schémas

suivants correspondent à un usage typique du régulateur.

Temperature

RÉGULATEUR

control

SOUS

VERS

TENSION

To line switch

L’INTERRUPTEUR

and power supply

ET L’ALIMENTATION

HOT

GND

MALT

Circuit du régulateur employé pour ouvrir et fermer

High side

MANOSTAT DU

pressure control

CÔTÉ ÉLEVÉ

(if used)

(SI EMPLOYÉ)

Circuit du régulateur contrôlant

directement un compresseur.

VERS L’INTERRUPTEUR

To line switch

ET L’ALIMENTATION

and power supply

Temperature

RÉGULATEUR

control

la vanne du réfrigérant. Le manostat d’aspiration

met le compresseur en marche et hors marche par

l’intermédiaire du démarreur du moteur.

DÉMARREUR

DU MOTEUR

Motor

starter

MANOSTAT

High side

DU CÔTÉ

pressure

ÉLEVÉ

control

ÉLECTROVANNE

DU RÉFRIGÉRANT

Suction

MANOSTAT

pressure

control

D’ASPIRATION

Solenoid

refrigerant

valve

MODE D’EMPLOI

Pour régler le thermostat, simplement déplacer le cadran pour

que la ligne indicatrice du boîtier soit alignée sur la température

à laquelle le circuit doit être ouvert suite à une baisse de la

température.

LIGNE

INDICATING

INDICATRICE

LINE

80

70

60

2

Loading...

Loading...