Page 1

Electronic Air Cleaner

Model NumberModel Number

Model Number

Model NumberModel Number

SST

S

R

E

G

D

O

-R

E

IT

H

W

SST1000SST1000

SST1000

SST1000SST1000

SST1400SST1400

SST1400

SST1400SST1400

SST1600SST1600

SST1600

SST1600SST1600

SST2000SST2000

SST2000

SST2000SST2000

G

TIN

A

ER

P

O

T

H

LIG

N

O

F

F

O

OWNER’S MANUALOWNER’S MANUAL

OWNER’S MANUAL

OWNER’S MANUALOWNER’S MANUAL

••

InstallationInstallation

•

Installation

••

InstallationInstallation

••

OperationOperation

•

Operation

••

OperationOperation

••

Basic SST Service GuideBasic SST Service Guide

•

Basic SST Service Guide

••

Basic SST Service GuideBasic SST Service Guide

••

Technical Repair GuideTechnical Repair Guide

•

Technical Repair Guide

••

Technical Repair GuideTechnical Repair Guide

••

Repair PartsRepair Parts

•

Repair Parts

••

Repair PartsRepair Parts

Please read and familiarize yourself with the contents of this manual beforePlease read and familiarize yourself with the contents of this manual before

Please read and familiarize yourself with the contents of this manual before

Please read and familiarize yourself with the contents of this manual beforePlease read and familiarize yourself with the contents of this manual before

installing, operating or performing maintenance on the unit.installing, operating or performing maintenance on the unit.

installing, operating or performing maintenance on the unit.

installing, operating or performing maintenance on the unit.installing, operating or performing maintenance on the unit.

White-Rodgers is a division

of Emerson Electric Co.

www.white-rodgers.com

Printed in U.S.A.

PART NO. 37-6373CPART NO. 37-6373C

PART NO. 37-6373C

PART NO. 37-6373CPART NO. 37-6373C

Replaces 37-6373B

0238

Page 2

RULES FOR SAFERULES FOR SAFE

RULES FOR SAFE

RULES FOR SAFERULES FOR SAFE

INSTALLATION AND OPERATIONINSTALLATION AND OPERATION

INSTALLATION AND OPERATION

INSTALLATION AND OPERATIONINSTALLATION AND OPERATION

Please read instructions before installing and using the Electronic Air Cleaner. This will help you obtain the full benefit from

the Electronic Air Cleaner you have selected.

WARNINGWARNING

WARNING

!

WARNINGWARNING

▲

ELECTROCUTION HAZARDELECTROCUTION HAZARD

ELECTROCUTION HAZARD

ELECTROCUTION HAZARDELECTROCUTION HAZARD

Shut off power at fuse panel beforeShut off power at fuse panel before

Shut off power at fuse panel before

Shut off power at fuse panel beforeShut off power at fuse panel before

servicing. Failure to do so could resultservicing. Failure to do so could result

servicing. Failure to do so could result

servicing. Failure to do so could resultservicing. Failure to do so could result

in serious personal injury or death.in serious personal injury or death.

in serious personal injury or death.

in serious personal injury or death.in serious personal injury or death.

WARNINGWARNING

!

WARNING

WARNINGWARNING

▲

Do not attempt installation of this unit unless you areDo not attempt installation of this unit unless you are

Do not attempt installation of this unit unless you are

Do not attempt installation of this unit unless you areDo not attempt installation of this unit unless you are

familiar with the necessary tools, equipment, utilityfamiliar with the necessary tools, equipment, utility

familiar with the necessary tools, equipment, utility

familiar with the necessary tools, equipment, utilityfamiliar with the necessary tools, equipment, utility

connections and potential hazards.connections and potential hazards.

connections and potential hazards.

connections and potential hazards.connections and potential hazards.

Installation should be performed only by a qualifiedInstallation should be performed only by a qualified

Installation should be performed only by a qualified

Installation should be performed only by a qualifiedInstallation should be performed only by a qualified

service provider.service provider.

service provider.

service provider.service provider.

Failure to do so could result in reduced performanceFailure to do so could result in reduced performance

Failure to do so could result in reduced performance

Failure to do so could result in reduced performanceFailure to do so could result in reduced performance

of the unit, serious personal injury or death.of the unit, serious personal injury or death.

of the unit, serious personal injury or death.

of the unit, serious personal injury or death.of the unit, serious personal injury or death.

1. Read the Owners Manual and the Rules for Safe

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of filter or

unsatisfactory service.

2. Follow a regular service and maintenance schedule

for efficient operation.

3. Unit must run for one full hour after installation. This

will allow the collecting cells to reach peak efficiency.

4. If Air Flow Monitor is required, order F859-0381 kit.

WARNINGWARNING

!

WARNING

WARNINGWARNING

▲

Installation of this unit must comply with localInstallation of this unit must comply with local

Installation of this unit must comply with local

Installation of this unit must comply with localInstallation of this unit must comply with local

electric codes or other applicable codes.electric codes or other applicable codes.

electric codes or other applicable codes.

electric codes or other applicable codes.electric codes or other applicable codes.

Review and understand local codes prior toReview and understand local codes prior to

Review and understand local codes prior to

Review and understand local codes prior toReview and understand local codes prior to

installation.installation.

installation.

installation.installation.

Do not use this apparatus in an explosiveDo not use this apparatus in an explosive

Do not use this apparatus in an explosive

Do not use this apparatus in an explosiveDo not use this apparatus in an explosive

atmosphere.atmosphere.

atmosphere.

atmosphere.atmosphere.

Failure to do so could result in serious personalFailure to do so could result in serious personal

Failure to do so could result in serious personal

Failure to do so could result in serious personalFailure to do so could result in serious personal

injury or death.injury or death.

injury or death.

injury or death.injury or death.

CAUTIONCAUTION

!

CAUTION

CAUTIONCAUTION

▲

CABINET AND CELLS MAY CONTAINCABINET AND CELLS MAY CONTAIN

CABINET AND CELLS MAY CONTAIN

CABINET AND CELLS MAY CONTAINCABINET AND CELLS MAY CONTAIN

SHARP EDGES.SHARP EDGES.

SHARP EDGES.

SHARP EDGES.SHARP EDGES.

Use care when servicing unit or handl-Use care when servicing unit or handl-

Use care when servicing unit or handl-

Use care when servicing unit or handl-Use care when servicing unit or handling cells. Failure to do so could resulting cells. Failure to do so could result

ing cells. Failure to do so could result

ing cells. Failure to do so could resulting cells. Failure to do so could result

in minor personal injury.in minor personal injury.

in minor personal injury.

in minor personal injury.in minor personal injury.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

Rules for Safe Installation and Operation ............2

How the Air Cleaner Works..................................3

Construction of the Air Cleaner ............................ 3

Preinstallation.......................................................4

Installation ............................................................6

Wiring Instructions ...............................................7

Operation ............................................................. 8

Maintenance and Washing...................................8

Specifications .......................................................9

Basic SST Service Guide...................................10

Technical Repair Guide......................................11

Air Cleaner Retrofit (Upgrade) Kit Installation....13

Repair Parts .......................................................14

Wash Reminder ................................................. 16

DID YOU GET THE RIGHT SIZEDID YOU GET THE RIGHT SIZE

DID YOU GET THE RIGHT SIZE

DID YOU GET THE RIGHT SIZEDID YOU GET THE RIGHT SIZE

AIR CLEANERAIR CLEANER

AIR CLEANER

AIR CLEANERAIR CLEANER

Model SST1000 Model SST1000

Model SST1000 is designed for heating or cooling blow-

Model SST1000 Model SST1000

ers delivering 600 to 1200 cubic feet of air per minute

(cfm.)

Model SST1400 Model SST1400

Model SST1400 is designed for heating or cooling blow-

Model SST1400 Model SST1400

ers delivering 1000 to 1600 cfm.

Model SST1600 Model SST1600

Model SST1600 is designed for heating or cooling blow-

Model SST1600 Model SST1600

ers delivering 1000 to 2000 cfm.

Model SST2000 Model SST2000

Model SST2000 is designed for heating or cooling blow-

Model SST2000 Model SST2000

ers delivering 1600 to 2200 cfm.

See specifications on page 9.

BASIC TOOLS REQUIREDBASIC TOOLS REQUIRED

BASIC TOOLS REQUIRED

BASIC TOOLS REQUIREDBASIC TOOLS REQUIRED

Tin Snip

Screwdriver

Rule or Tape Measure

Drill

2

Page 3

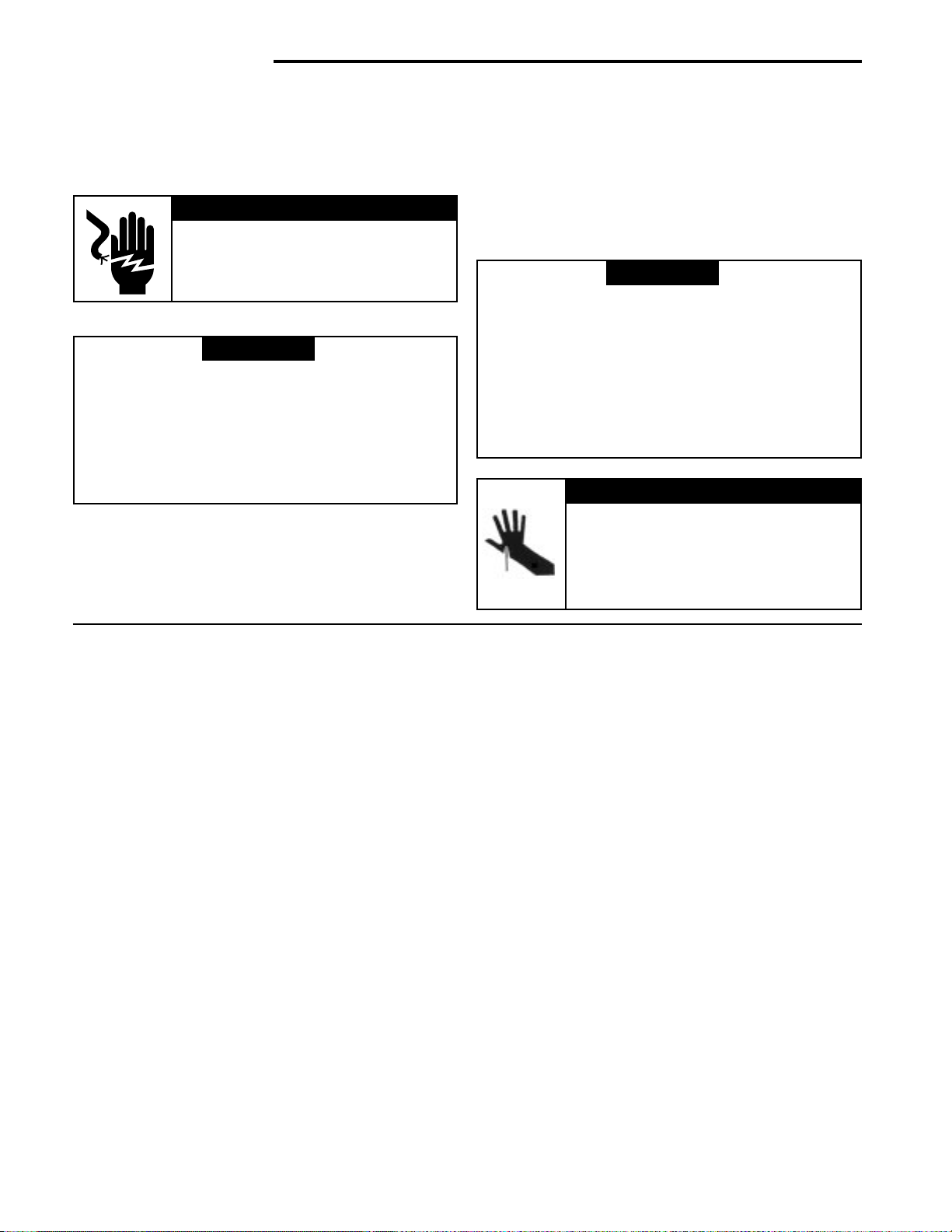

ABC

Dirty Air In Clean Air Out

Cabinet

Pre-Filters

Handle

Contact

Button

Contact

Button

Collecting Cells

Power Pack

HOW THE AIR CLEANER WORKSHOW THE AIR CLEANER WORKS

HOW THE AIR CLEANER WORKS

HOW THE AIR CLEANER WORKSHOW THE AIR CLEANER WORKS

Dirt particles flowing through the ducts (Figure 1) first enters

the pre-filters (A) where large particles (hair, lint, etc.) are

trapped. Smaller particles (smoke, dust, pollen, etc.) pass

through these pre-filters and enter the ionizing section (B).

Here each tiny particle receives a positive electrical charge.

These charged particles then enter the collecting section

(C). This section consists of a series of aluminum plates

which are alternately charged negative and positive.

The positive charge of the particles cause them to be

repelled by the positive plates and attracted to the negative

plates where they are collected . . . just as a magnet

attracts iron filings.

Clean-filtered air re-enters the supply duct system.

White Dust (Lint)White Dust (Lint)

White Dust (Lint)

White Dust (Lint)White Dust (Lint)

An Electronic Air Cleaner is designed to collect two major

types of contaminants: ➀ Irritants (Pollens, Spores, Molds,

Bacteria, etc.) and ➁ Black Soiling Contaminants (Dirt and

Smoke particles).

The residue on the collecting plates of an electronic air

cleaner is black, indicating it is removing dirt from the air

stream. After installing an air cleaner you may notice white

dust (typically, long linty particles or fibers – from carpets,

cotton materials or drapery fabrics). This material is not

collected by the air cleaner because it does not contain the

irritants or soiling contaminants listed above or settles out of

the air before reaching the air cleaner. The presence of

white dust does not indicate an air cleaner requires service.

Figure 1Figure 1

Figure 1

Figure 1Figure 1

Carbon (Charcoal) FiltersCarbon (Charcoal) Filters

Carbon (Charcoal) Filters

Carbon (Charcoal) FiltersCarbon (Charcoal) Filters

Odors are gas molecules, not particles. They cannot be

removed by an Electronic Air Cleaner or by any other

filtration media designed to remove airborne particles.

However, some gases can be absorbed by an activated

carbon filter or diluted with fresh outdoor air. When odors

are present, the addition of charcoal filters will neutralize

odors, such as cooking odors, pet odors, cigar and cigarette odors, ozone, etc. Optional charcoal filters are

available for your Air Cleaner. Refer to the parts list for the

charcoal filter part number for your Air Cleaner. Charcoal

filters require replacement. They cannot be washed. While

there is no rule of thumb for how often they should be

changed, you can use your best judgement based on the

odors you perceive in your environment.

CONSTRUCTION OF THE AIR CLEANERCONSTRUCTION OF THE AIR CLEANER

CONSTRUCTION OF THE AIR CLEANER

CONSTRUCTION OF THE AIR CLEANERCONSTRUCTION OF THE AIR CLEANER

Not only is your air cleaner easy to install, it is also easy to

operate and maintain. Its basic components, and their

functions, are as follows: (See Figure 2)

Cabinet Cabinet

Cabinet - mounts to existing duct work and houses the

Cabinet Cabinet

collecting cells and pre-filters.

Collecting Cells Collecting Cells

Collecting Cells - are made in two sections and perform

Collecting Cells Collecting Cells

the actual collecting of dust, dirt, and other impurities from the air. They contain the ionizing and

collection sections described above.

Each cell must be installed with the ionizing wires

on the air entering side. Each cell must be oriented

with the handles and contact button (Figure 2)

toward the operator.

Pre-filters Pre-filters

Pre-filters - are in two sections which are interchangeable.

Pre-filters Pre-filters

Power Pack- Power Pack-

Power Pack- contains operating and power on lights as well

Power Pack- Power Pack-

They serve as a pre-filter to trap large particles

such as hair and lint before they can enter the cell

sections.

as the solid state components that convert the 120

volt power supply to the high-voltage, direct current

required for the collecting cell.

Figure 2Figure 2

Figure 2

Figure 2Figure 2

3

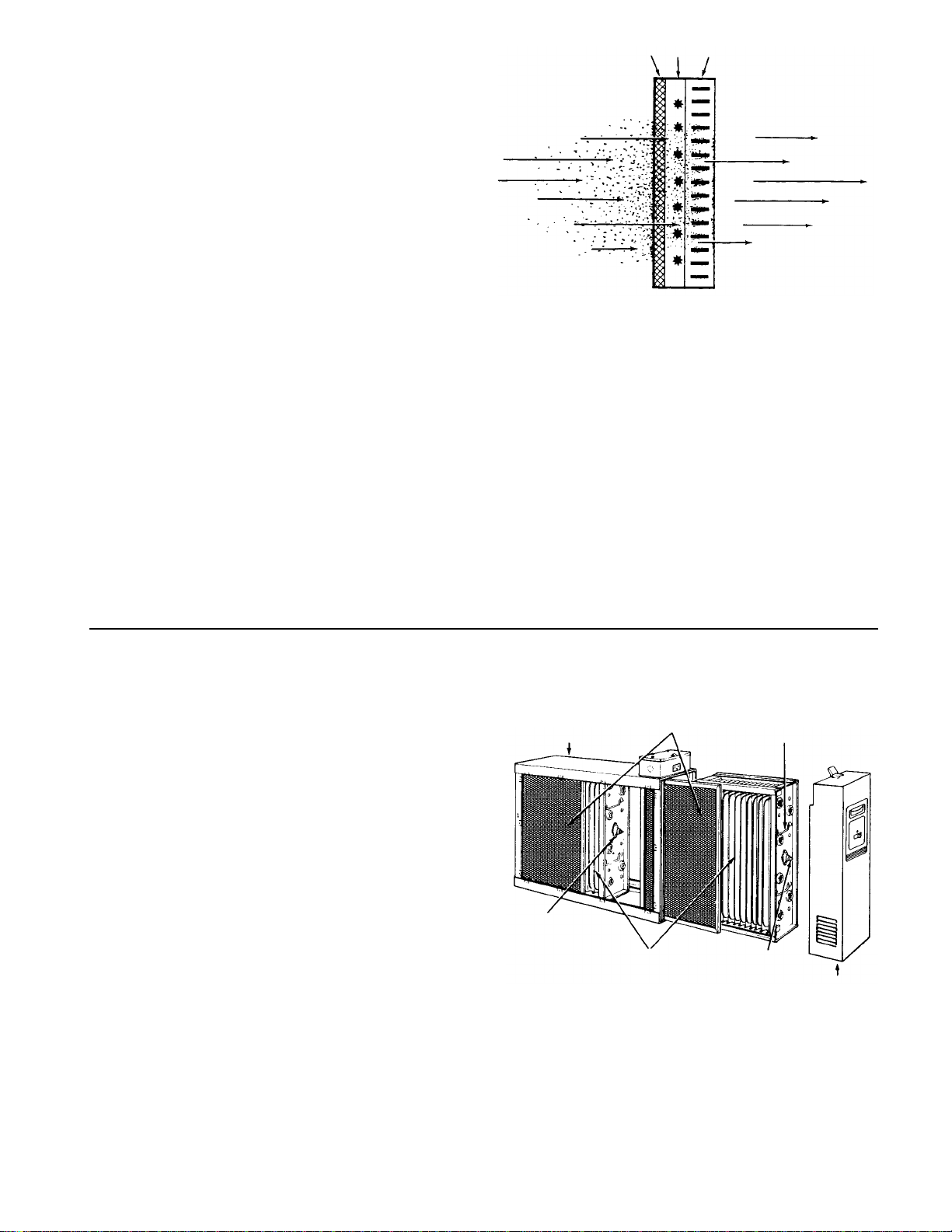

Page 4

SST1000 24 3/4 21 5/16 18 5/8 13 9/16 16 7/16 19 1/16

SST1400 29 11/16 26 1/4 23 5/8 13 9/16 16 7/16 19 1/16

SST1600 25 1/2 21 5/16 18 5/8 17 3/4 20 5/8 23 3/8

SST2000 29 11/16 26 1/4 23 5/8 17 3/4 20 5/8 23 3/8

MODEL NO. A B C D E F

PREINSTALLATIONPREINSTALLATION

PREINSTALLATION

PREINSTALLATIONPREINSTALLATION

Not to Exceed 20

Air Flow

Furnace

Opening

Electronic

Air Cleaner

Opening

Furnace

Transition Section

(if Needed)

Electronic

Air Cleaner

Figure 3

LOCATING THE AIR FILTERLOCATING THE AIR FILTER

LOCATING THE AIR FILTER

LOCATING THE AIR FILTERLOCATING THE AIR FILTER

Your air filter must be mounted in the return air duct of a

central forced-air system, on the air entering side of your

furnace. (See Figure 3 for example.)

Select a location that meets the following:

1. The face of the cell will be at a right angle to the air

stream.

2. Allow the following clearances to permit removal of

cells and pre-filters: (See Figures 4 and 5)

Model SST1000 - 14 inches

Model SST1400 - 15 inches

Model SST1600 - 14 inches

Model SST2000 - 15 inches

For complete dimension data refer to Figure 5.

3. The air filter is not to be placed in the discharge of

either the heating or cooling unit.

IMPORTANT: IMPORTANT:

4.

IMPORTANT: If atomizing spray type humidifier is

IMPORTANT: IMPORTANT:

used, it must be installed downstream from the air

filter.

If your furnace duct system has a pre-installed boot,

discard front cover of boot and slide the air cleaner

component inside the boot. For installation of Air Cleaner

Retrofit (ACR) kits, see page 13.

If furnace opening cannot be enlarged to required size, a

transition sheet metal section must be used. Transition

must be planned for each job. Reduction should not be

more than 4 inches per linear foot, approximately 20

angular degrees (Figure 3).

DIRECTION OF AIR FLOW THROUGH THEDIRECTION OF AIR FLOW THROUGH THE

DIRECTION OF AIR FLOW THROUGH THE

DIRECTION OF AIR FLOW THROUGH THEDIRECTION OF AIR FLOW THROUGH THE

AIR CLEANERAIR CLEANER

AIR CLEANER

AIR CLEANERAIR CLEANER

Your air cleaner is shipped from the factory with air flow

from left-to-right. If this air flow is suitable for the installation, no further changes need to be made (Figure 4). For

right-to-left air flow, remove both pre-filter and cell sec-

Air Flow

(Interchangeable)

Collecting Cell

Cabinet

Contact

Button

Pre-Filters

(Interchangeable)

Outlet Box

(Interchangeable)

Collecting Cell

Handle

Contact

Button

Removal Clearance

Power Pack

See text for Cell

Figure 4

Knockouts for

6 7/8"

E

3/4" Conduit

(three sides)

C

D

B

A

Figure 5

tions. Turn cells upside down (with the same end facing

the cabinet opening). This will locate the ionizing wires at

the right, and both contact buttons and cell handles will be

facing the power door. Air flow direction must agree with

arrow embossed on end of collecting cells.

After installing the cell sections, install pre-filters in cabinet tracks on the right. This will again place the pre-filters

on the air entering side (on the same side as ionizing

wires).

4

F

Page 5

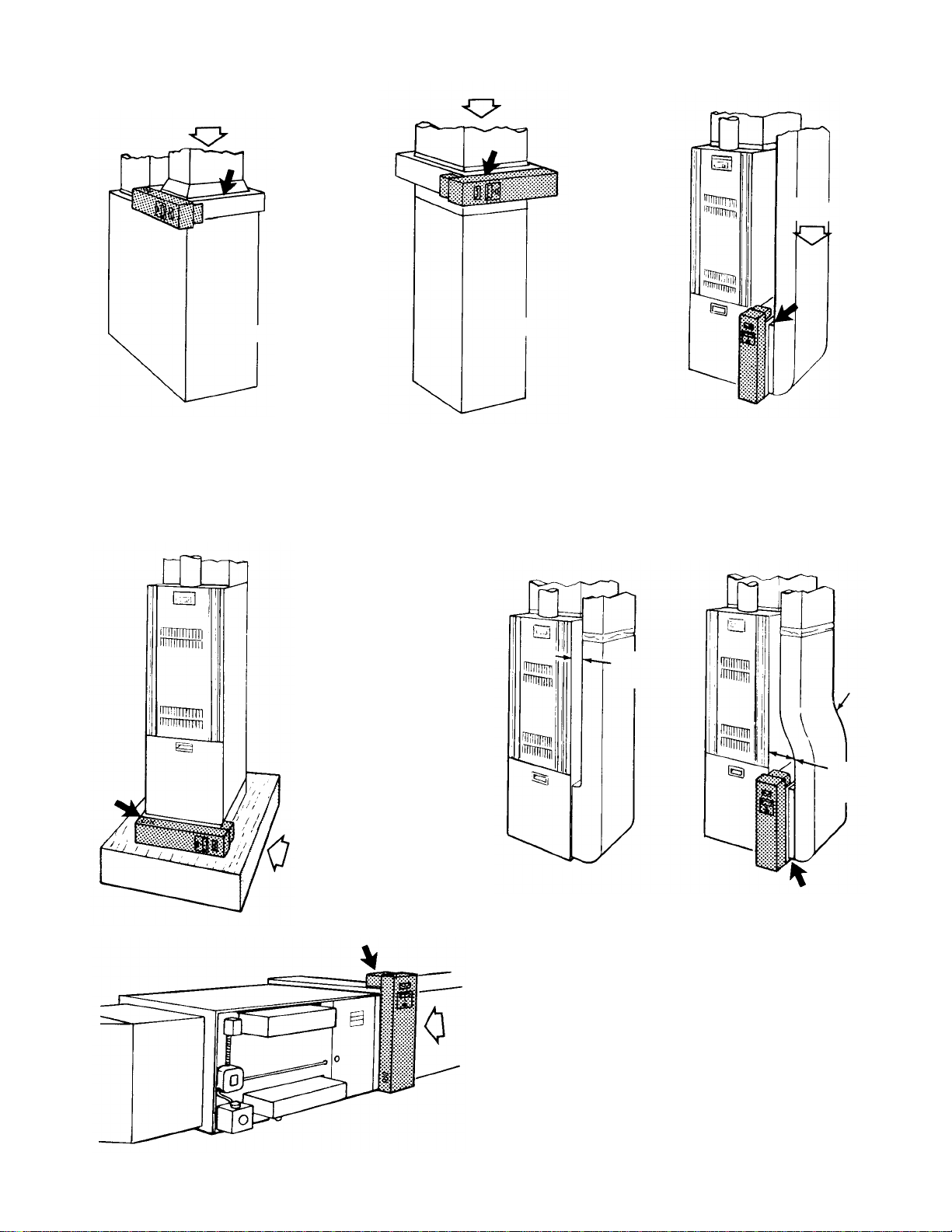

TYPICAL MOUNTING POSITIONSTYPICAL MOUNTING POSITIONS

Air Flow

Figure 8

TYPICAL MOUNTING POSITIONS

TYPICAL MOUNTING POSITIONSTYPICAL MOUNTING POSITIONS

Air Flow

Air Flow

Rear View

Figure 6

BASEMENT FURNACEBASEMENT FURNACE

BASEMENT FURNACE

BASEMENT FURNACEBASEMENT FURNACE

(LOWBOY) (Figure 6)(LOWBOY) (Figure 6)

(LOWBOY) (Figure 6)

(LOWBOY) (Figure 6)(LOWBOY) (Figure 6)

Cleaner is mounted hori-

zontally in return plenum,

just above furnace.

Figure 7

COUNTERFLOWCOUNTERFLOW

COUNTERFLOW

COUNTERFLOWCOUNTERFLOW

FURNACE (Figure 7)FURNACE (Figure 7)

FURNACE (Figure 7)

FURNACE (Figure 7)FURNACE (Figure 7)

Cleaner is mounted horizon-

tally in return duct or plenum,

just above furnace.

HIGHBOY FURNACEHIGHBOY FURNACE

HIGHBOY FURNACE

HIGHBOY FURNACEHIGHBOY FURNACE

(Figure 9)(Figure 9)

(Figure 9)

(Figure 9)(Figure 9)

Installation beneath furnace.

Cleaner mounts horizontally,

where return air enters from

below. Raise furnace and install beneath base.

Rear View

HIGHBOY FURNACEHIGHBOY FURNACE

HIGHBOY FURNACE

HIGHBOY FURNACEHIGHBOY FURNACE

(Figure 8)(Figure 8)

(Figure 8)

(Figure 8)(Figure 8)

Side installation. Cleaner

is mounted vertically,

where return air enters

side inlet of furnace.

Less than

7 Inches

Offset

At Least

9 Inches

Figure 9

Air Flow

Figure 11

OFFSET INSTALLATIONOFFSET INSTALLATION

OFFSET INSTALLATION

OFFSET INSTALLATIONOFFSET INSTALLATION

(Figure 10)(Figure 10)

(Figure 10)

(Figure 10)(Figure 10)

Typical use of duct offset to match air filter opening.

If duct connection to furnace allows less than nine

inches for mounting the air cleaner, shorten the

lateral trunk, or attach an offset fitting to the elbow.

Air Flow

HORIZONTAL FURNACEHORIZONTAL FURNACE

HORIZONTAL FURNACE

HORIZONTAL FURNACEHORIZONTAL FURNACE

(Figure 11)(Figure 11)

(Figure 11)

(Figure 11)(Figure 11)

Cleaner is mounted vertically

in the return duct near furnace.

5

Figure 10

Page 6

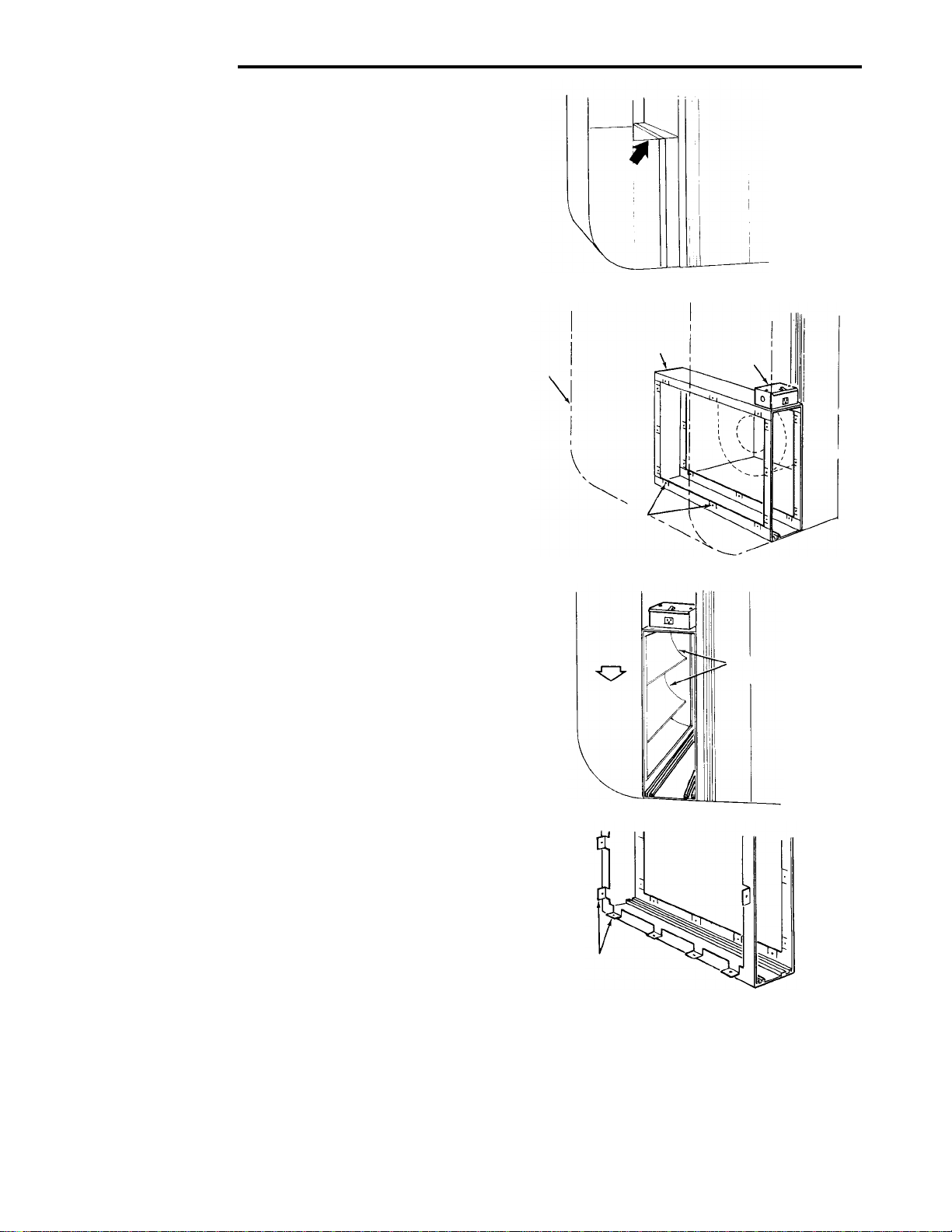

Air Flow

Turning

Vanes

Figure 14

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

REMOVE OLD FILTER AND DISCARDREMOVE OLD FILTER AND DISCARD

REMOVE OLD FILTER AND DISCARD

REMOVE OLD FILTER AND DISCARDREMOVE OLD FILTER AND DISCARD

(Figure 12)(Figure 12)

(Figure 12)

(Figure 12)(Figure 12)

NOTE: This filter may be mounted in the furnace compartment.

CLEAN BLOWER COMPARTMENTCLEAN BLOWER COMPARTMENT

CLEAN BLOWER COMPARTMENT

CLEAN BLOWER COMPARTMENTCLEAN BLOWER COMPARTMENT

It is suggested that the furnace blower compartment,

blower and blower housing be cleaned to ensure clean air

circulation.

Figure 12

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

The following is a typical installation of the air cleaner on

a “Highboy” furnace (Figure 8).

1. Place the air filter cleaner on the floor. Stand it upright

with the power door facing you (Figure 4). If a

horizontal installation is being planned, lay the cleaner

on its side, this will help you to visualize the relative

location of all parts.

Allow ample space for wiring and servicing the power

supply box (Figure 13).

2. Release the latch, remove the power pack (by grasping handle and pulling power pack away from cabinet)

and set it aside. Remove the collecting cells and prefilters. Set pre-filters and cells aside in a safe location

until the cabinet is installed.

3. Set the cabinet next to the furnace. If necessary,

enlarge the opening in the furnace (if possible) to

match the opening in the cabinet.

If the furnace opening cannot be enlarged, a transition fitting should be used. (Figure 3).

The cabinet can be attached directly (Figure 13), or

a starting collar can first be fitted to the furnace inlet.

A butt or slip joint can be used.

Securely attach the cabinet to furnace inlet, using at

least two of the mounting holes on each side of the

cabinet.

4. Using butt joint, attach duct work (normally an elbow)

to the upstream side of air cleaner cabinet. (Note the

use of the sheet metal turning vanes inside the elbow

to improve air distribution over the face of the cells.)

(Figure 14)

NOTE: NOTE:

NOTE: An optional method of attaching duct work to the

NOTE: NOTE:

cabinet is to modify the cabinet (Figure 15) by bending the

tabs outward at a 90° angle and attaching duct work to

tabs.

Transition FittingsTransition Fittings

Transition Fittings

Transition FittingsTransition Fittings

If the air duct does not fit the cabinet opening, a transition

fitting should be used. Gradual transitions are preferred

for greatest efficiency. Not more than four inches per

linear foot (approximately 20° angle) should be allowed

(Figure 3).

Power

Frame

Duct

Mounting

Holes

Optional method

(Bend tabs outward at 90˚ angle)

5. Connect the vertical duct section to the elbow. Wedge

a wood block between floor and elbow for support

(Figure 16).

6. Seal all joints in the return air system downstream

from the air cleaner with duct tape to prevent dust

from entering the air stream. Tape is usually applied

on the outside of ducts, but may also be applied on the

inside, or both.

Supply

Box

Figure 13

Figure 15

6

Page 7

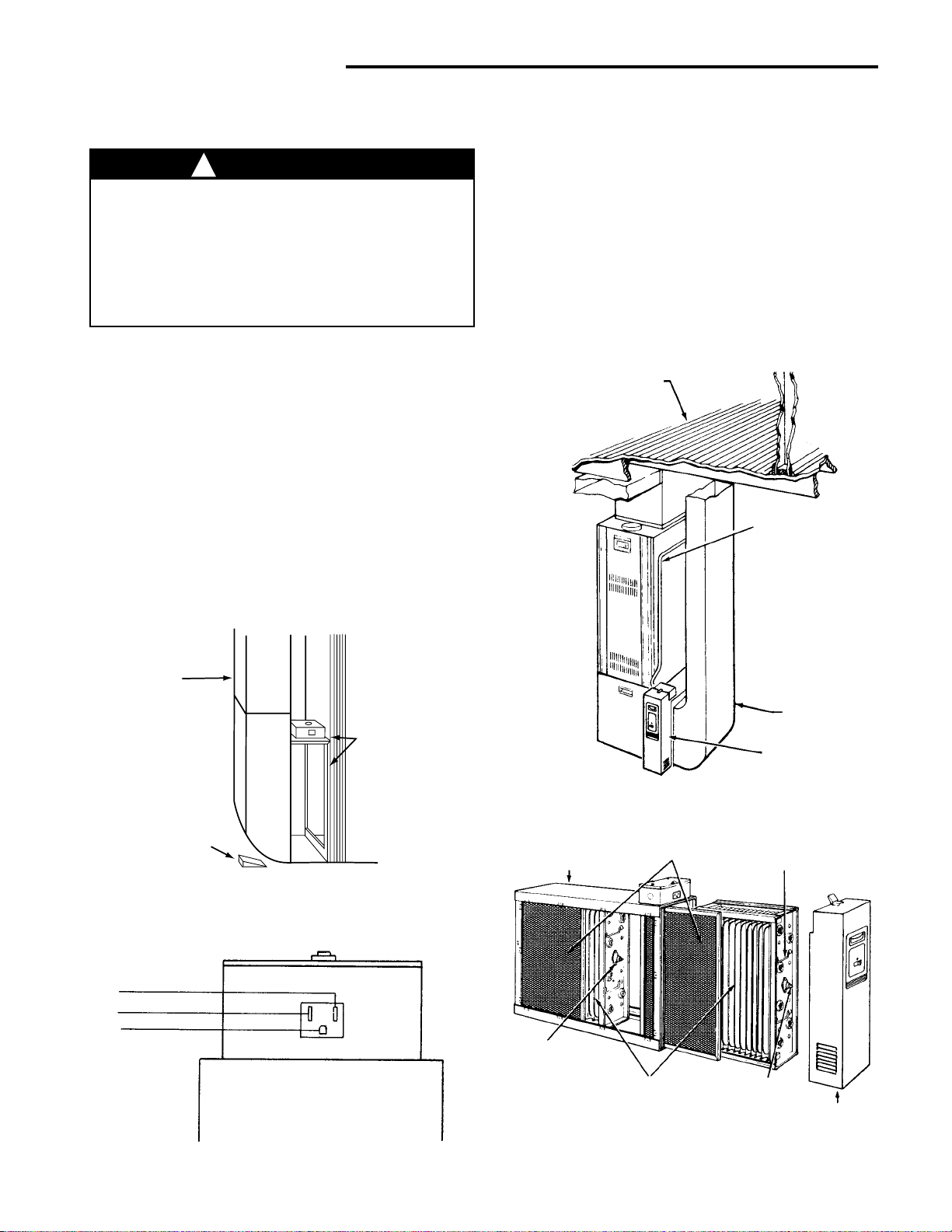

Cabinet

Pre-Filters

Handle

Contact

Button

Contact

Button

Collecting Cells

Power Pack

WIRING INSTRUCTIONSWIRING INSTRUCTIONS

WIRING INSTRUCTIONS

WIRING INSTRUCTIONSWIRING INSTRUCTIONS

7. With the cabinet installed, the air cleaner can now be

wired to electrical input source.

!

WARNING

Installation of this unit must comply with localInstallation of this unit must comply with local

Installation of this unit must comply with local

Installation of this unit must comply with localInstallation of this unit must comply with local

electric codes or other applicable codes.electric codes or other applicable codes.

electric codes or other applicable codes.

electric codes or other applicable codes.electric codes or other applicable codes.

Review and understand local codes prior to in-Review and understand local codes prior to in-

Review and understand local codes prior to in-

Review and understand local codes prior to in-Review and understand local codes prior to installation.stallation.

stallation.

stallation.stallation.

Failure to do so could result in serious personalFailure to do so could result in serious personal

Failure to do so could result in serious personal

Failure to do so could result in serious personalFailure to do so could result in serious personal

injury or death.injury or death.

injury or death.

injury or death.injury or death.

8. This air cleaner unit has no air flow monitor installed,

it does require electrical wiring through the furnace

controls. Connect wiring to the furnace control terminals. (EAC-H) for power, (EAC-N) for neutral, and

connect metal frame of EAC to ground. If air flow

monitor is required for operation, order F859-0381 Air

Flow kit. Install kit and connect a 120 VAC 60 Hz input

circuit. A 20 amp circuit is more than adequate.

9. Remove junction box cover and install the required

bushing into the 3/4 in. Knock out. With the supply

voltage turned off, route three (3) wires into junction

box for connections. (See Fig. 17.)

Insure all wires are clamped, wire connectors properly installed and grommets used to prevent wire

abrasion.

10. With the cabinet Installed, reinstall pre-filter(s) and

collecting cell(s) (Figure 19).

NOTE: The contact button and handles on the cell

must be facing you and ionizing wires must be on the

air intake side.

11. Install the power pack as follows:

Engage the lip on lower inside edge of power pack in

the flange on cabinet and carefully close the power

pack, making sure that the electrical connector prongs

on the power pack enter the slots in the socket on

cabinet. When the power pack is fully in place, engage the latch and snap it closed.

Floor

Conduit

Vertical

Section

Wood Block

Hot

Neutral

Grounding

Conductor

Figure 16

Front View

Figure 17

Tape All

Joints

Duct

Electronic

Air Cleaner

Figure 18

Figure 19

7

Page 8

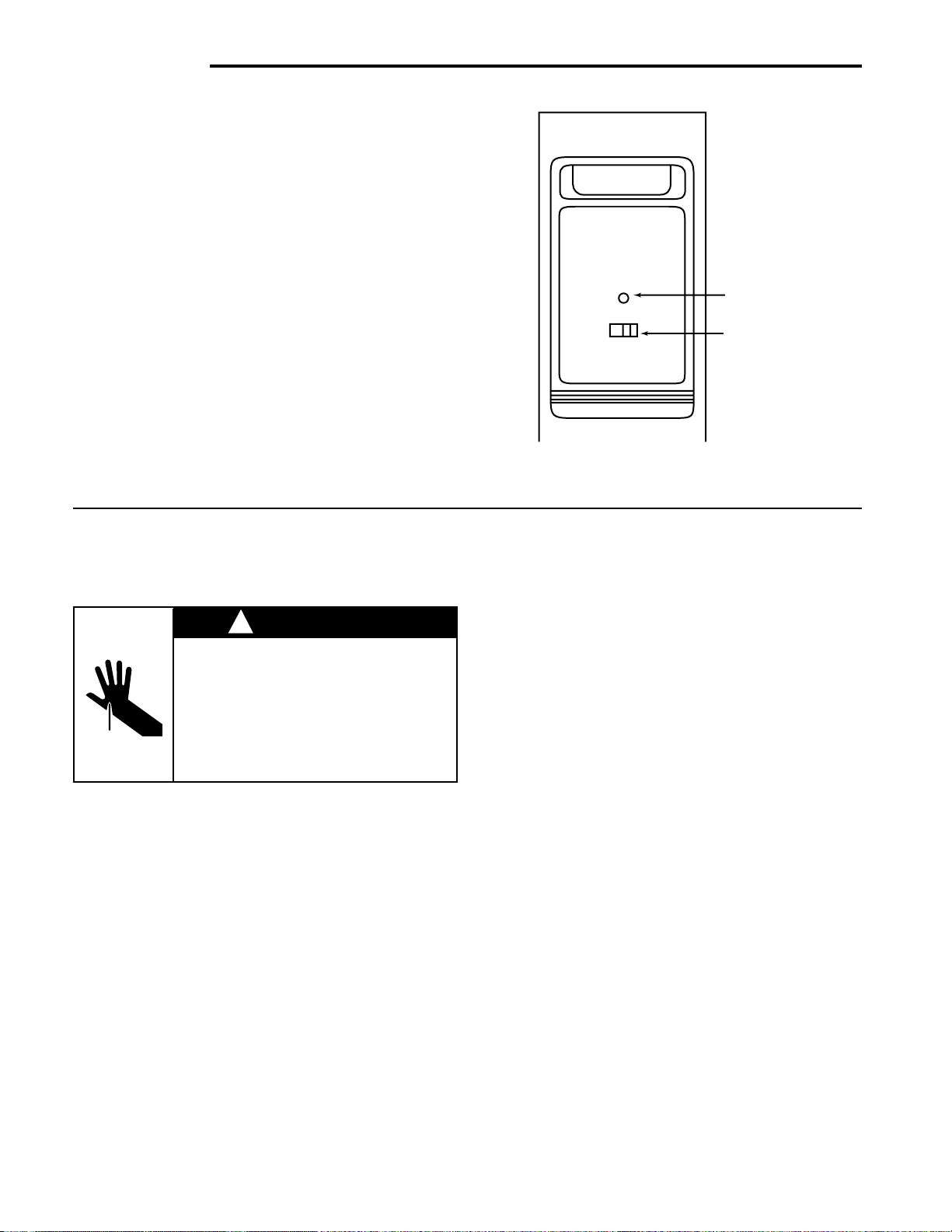

OPERATIONOPERATION

OPERATION

OPERATIONOPERATION

1. With the 120 VAC power turned on at the circuit

breaker for the furnace, push the air cleaner ON-OFF

switch to the “ON” position (Figure 20).

2. With the furnace blower running, the air cleaner will

be operating. An arcing or “snapping” sound may be

heard. This will occur occasionally, however the unit

is operating properly.

3. With the furnace blower running, the Operating Light

should be ON. If the Operating Light is not ON this

signifies that the cells need washing, or that trouble

exists in the unit.

If, after washing the cells, the Operating Light stays off,

the cell could be wet, improperly placed in the cabinet or

may need servicing.

NOTE: NOTE:

NOTE: An occasional flicker of the light accompanied by

NOTE: NOTE:

harmless sparking or snapping noise may occur. This is

caused by trapping large particles of dirt. If arcing is

continuous, the cells should be washed or checked for

service problems see Basic SST Service Guide.

Operating

Light

On-Off

Switch

Figure 20

MAINTENANCE AND WASHINGMAINTENANCE AND WASHING

MAINTENANCE AND WASHING

MAINTENANCE AND WASHINGMAINTENANCE AND WASHING

!

CAUTION

CABINET AND CELLS MAY CON-CABINET AND CELLS MAY CON-

CABINET AND CELLS MAY CON-

CABINET AND CELLS MAY CON-CABINET AND CELLS MAY CONTAIN SHARP EDGES.TAIN SHARP EDGES.

TAIN SHARP EDGES.

TAIN SHARP EDGES.TAIN SHARP EDGES.

Use care when servicing unit orUse care when servicing unit or

Use care when servicing unit or

Use care when servicing unit orUse care when servicing unit or

handling cells.handling cells.

handling cells.

handling cells.handling cells.

Failure to do so could result inFailure to do so could result in

Failure to do so could result in

Failure to do so could result inFailure to do so could result in

minor personal injury.minor personal injury.

minor personal injury.

minor personal injury.minor personal injury.

For maximum efficiency your air cleaner cell(s) and prefilter(s) should be inspected once a month and cleaned

when necessary. Cleaning will usually be required every

one to three months, depending upon the particular

household circumstances. When cleaning is required the

following procedure should be used:

CLEANING THE CELLSCLEANING THE CELLS

CLEANING THE CELLS

CLEANING THE CELLSCLEANING THE CELLS

1. Turn the air moving system “OFF.”

2. Push the ON-OFF switch on the power pack to the

“OFF” position (Figure 20). Wait 15 seconds and both

the power pack and the collecting cell(s) will be

automatically discharged.

3. Release the latch on top of power pack and pull the

power pack straight away from cabinet at the top.

Then lift pack out of ledge at bottom edge of cabinet.

Set power pack aside.

4. Remove the cell(s) and pre-filter(s) from cabinet.

Using a solution of warm water and low sudsing

detergent, soak cell(s) and pre-filter(s) for 20 to 30

minutes.

NOTE: NOTE:

NOTE: Ionizing wires may become coated causing

NOTE: NOTE:

loss of cleaning ability by the collecting cell. Using a

damp cloth, wipe each ionizing wire, exercising care

not to damage them.

5. Remove the cell(s) and pre-filter(s) from solution and

rinse thoroughly with clean water.

6 Allow cell(s) and pre-filter(s) to drip dry for a

mum of 2 hours. mum of 2 hours.

mum of 2 hours. Cell(s) and pre-filter(s) may be

mum of 2 hours. mum of 2 hours.

tipped at a slight angle to expedite the drip-dry

process.

7. Reinstall the cell(s) and pre-filter(s) in the cabinet.

8. Replace the power pack. Turn furnace fan on. After

30 minutes push ON-OFF switch on the power pack

to the “ON” position.

A moderate amount of arcing or “snapping” may

occur at this time, which will indicate that the cell(s)

are still damp. If the noise is objectionable, push the

ON-OFF switch to the “OFF” position and allow

additional time for cell(s) and pre-filter(s) to dry. In

some cases the Operating Light will remain OFF

during this initial activation of the air cleaner, and this

would indicate that the cell(s) are not completely dry.

The Operating Light should remain ON while the

furnace fan is running once the drying is complete.

mini-mini-

mini-

mini-mini-

8

Page 9

REPLACING AN IONIZING WIREREPLACING AN IONIZING WIRE

REPLACING AN IONIZING WIRE

REPLACING AN IONIZING WIREREPLACING AN IONIZING WIRE

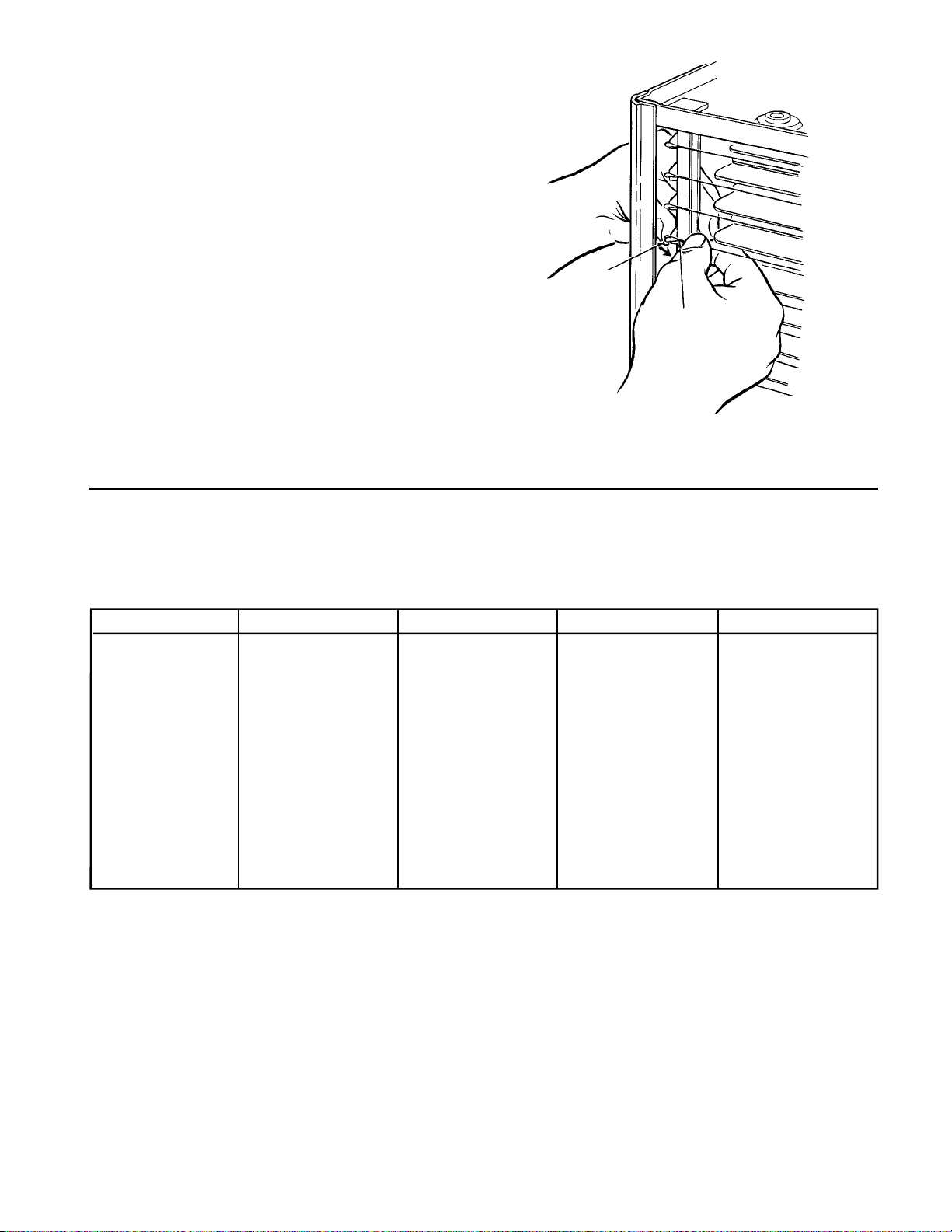

If an ionizing wire should break, it can be replaced as

follows:

1. Remove all pieces of broken wire. Make sure supports at each end are in good condition and not bent

out of shape.

2. Hook the new wire onto the support at one end.

3. Hold your finger against the support at the other end

(Figure 21) and hold the ionizing wire between thumb

and forefinger as shown or use needle nose pliers.

Press inward on spring support. Hook end of wire

over small tab at end of support and release. Make

sure wire is securely anchored at each end.

Support

Ionizing

Wire

Figure 21

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS SST1000 SST1400 SST1600 SST2000

Rated Capacity 600 - 1200 cfm 1000 - 1600 cfm 1000 - 2000 cfm 1600 - 2200 cfm

Max. Pressure Drop .08 in. W.G. .08 in. W.G. .12 in. W.G. .09 in. W.G.

Cell Weight (2) 7 lbs. each (2) 9 lbs. each (2) 9 lbs. each (2) 9 lbs. each

Power Pack Weight 9 lbs. 9 lbs. 10 lbs. 10 lbs.

Unit Weight 35 lbs. 42 lbs. 38 lbs. 45 lbs.

Power Consumption 40 Watts (Max) 40 Watts (Max) 40 Watts (Max) 40 Watts (Max)

Electrical Input 120 VAC 60 hz. 120 VAC 60 hz. 120 VAC 60 hz. 120 VAC 60 hz.

Electrical Output 1.0 Ma 1.2 Ma 1.5 Ma 1.7 Ma

@ 6450 VDC (nom)

Max. Ozone Output .05 ppm .05 ppm .05 ppm .05 ppm

Temperature Rating 40 F to 125 F 40 F to 125 F 40 F to 125 F 40 F to 125 F

9

Page 10

BASIC SST SERVICE GUIDEBASIC SST SERVICE GUIDE

BASIC SST SERVICE GUIDE

BASIC SST SERVICE GUIDEBASIC SST SERVICE GUIDE

This guide will cover most homeowner complaints. If, after checking the items listed, the unit still fails to operate

properly, contact the nearest Authorized Service Center.

SERVICE INDICATIONSERVICE INDICATION

SERVICE INDICATION

SERVICE INDICATIONSERVICE INDICATION

ON/OFF switch “ON”

Blower ON

Operating Light ON

ON/OFF switch “ON”

Blower ON A. Check fuse or circuit breaker.

Operating Light OFF B. Ensure power pack is properly installed and latched.

ON/OFF Switch “ON”

Blower OFF A. Remove power pack and clear contamination inside black bushing around

Operating Light ON the small sensor element.

Excessive arcing during

normal operation - A. Allow cell(s) to dry after cleaning before applying power.

Operating Light may blink

Unit functioning NormallyUnit functioning Normally

Unit functioning Normally

Unit functioning NormallyUnit functioning Normally

1.1.

Power is not being supplied to air cleaner.Power is not being supplied to air cleaner.

1.

Power is not being supplied to air cleaner.

1.1.

Power is not being supplied to air cleaner.Power is not being supplied to air cleaner.

2.2.

Collecting cell shorted - Turn power Off - Remove power pack - RemoveCollecting cell shorted - Turn power Off - Remove power pack - Remove

2.

Collecting cell shorted - Turn power Off - Remove power pack - Remove

2.2.

Collecting cell shorted - Turn power Off - Remove power pack - RemoveCollecting cell shorted - Turn power Off - Remove power pack - Remove

collecting cells - Replace power pack - Restore power (ensure blower is collecting cells - Replace power pack - Restore power (ensure blower is

collecting cells - Replace power pack - Restore power (ensure blower is

collecting cells - Replace power pack - Restore power (ensure blower is collecting cells - Replace power pack - Restore power (ensure blower is

operating).operating).

operating).

operating).operating).

A. If Operating Light comes ON check cells for bent plates, loose ionizing

wire(s) or cracked insulator(s).

B. If Operating Light remains OFF, malfunction is in the power pack. (See

power supply Checkout Procedure).

1.1.

Air flow sensor contaminated/misalignedAir flow sensor contaminated/misaligned

1.

Air flow sensor contaminated/misaligned

1.1.

Air flow sensor contaminated/misalignedAir flow sensor contaminated/misaligned

B. Ensure small sensor element is centered in bushing.

2.2.

Air sensor left in bypassed condition after servicing.**Air sensor left in bypassed condition after servicing.**

2.

Air sensor left in bypassed condition after servicing.**

2.2.

Air sensor left in bypassed condition after servicing.**Air sensor left in bypassed condition after servicing.**

3.3.

Faulty air flow sensor panel.Faulty air flow sensor panel.

3.

Faulty air flow sensor panel.

3.3.

Faulty air flow sensor panel.Faulty air flow sensor panel.

1.1.

Wet collecting cell.Wet collecting cell.

1.

Wet collecting cell.

1.1.

Wet collecting cell.Wet collecting cell.

2.2.

Damaged collecting cell(s).Damaged collecting cell(s).

2.

Damaged collecting cell(s).

2.2.

Damaged collecting cell(s).Damaged collecting cell(s).

A. Remove cell(s) and inspect for bent plates, loose ionizing wire(s), cracked

insulator(s), etc.

3.3.

Collecting cells dirty.Collecting cells dirty.

3.

Collecting cells dirty.

3.3.

Collecting cells dirty.Collecting cells dirty.

A. Clean cells as instructed in this manual.

4.4.

Faulty power supply (see power supply checkout procedure)Faulty power supply (see power supply checkout procedure)

4.

Faulty power supply (see power supply checkout procedure)

4.4.

Faulty power supply (see power supply checkout procedure)Faulty power supply (see power supply checkout procedure)

SERVICE CHECKSSERVICE CHECKS

SERVICE CHECKS

SERVICE CHECKSSERVICE CHECKS

**NO**NO

TE:TE:

**NO

TE: Your air cleaner is equipped with an air flow sensor (switch) which turns the unit ON and OFF in

**NO**NO

TE:TE:

response to the system blower. It may have been “wired out” during a service check and inadvertently left in this

condition

10

Page 11

TECHNICAL REPAIR GUIDETECHNICAL REPAIR GUIDE

The solid-state power supply is not

designed for individual component part

replacement and must be replaced as

a complete "snap-in" unit.

Input voltage: 120 VAC 60 Hz.

Output to light: 1.5 to 2.5 VDC

H.V. Output: 6450 VDC (nom)

Collecting Cell

Specifications

Power Supply

Specifications

1000 cfm - 1.0 Ma @ 6450VDC

1400 cfm - 1.2 Ma @ 6450 VDC

1600 cfm - 1.5 Ma @ 6450 VDC

2000 cfm - 1.7 Ma @ 6450 VDC

TECHNICAL REPAIR GUIDE

TECHNICAL REPAIR GUIDETECHNICAL REPAIR GUIDE

!

WARNING

Do not attempt repair of this unit unless you areDo not attempt repair of this unit unless you are

Do not attempt repair of this unit unless you are

Do not attempt repair of this unit unless you areDo not attempt repair of this unit unless you are

familiar with the necessary tools, equipment,familiar with the necessary tools, equipment,

familiar with the necessary tools, equipment,

familiar with the necessary tools, equipment,familiar with the necessary tools, equipment,

utility connections and potential hazards.utility connections and potential hazards.

utility connections and potential hazards.

utility connections and potential hazards.utility connections and potential hazards.

Repair should be performed only by a qualifiedRepair should be performed only by a qualified

Repair should be performed only by a qualified

Repair should be performed only by a qualifiedRepair should be performed only by a qualified

service provider.service provider.

service provider.

service provider.service provider.

Failure to do so could result in reduced perfor-Failure to do so could result in reduced perfor-

Failure to do so could result in reduced perfor-

Failure to do so could result in reduced perfor-Failure to do so could result in reduced performance of the unit, serious personal injury ormance of the unit, serious personal injury or

mance of the unit, serious personal injury or

mance of the unit, serious personal injury ormance of the unit, serious personal injury or

death.death.

death.

death.death.

This guide contains service checks to assist service

personnel in locating and correcting any malfunction that

might occur to render the air cleaner ineffective or inoperative. The air cleaner has been designed with replaceable components, such as the high-voltage power supply

and air flow switch. This allows the serviceman to replace

a faulty component rather than attempt repairs of such

components in the field.

All voltage measurements indicated can be made with a

high voltage D.C. probe and a general purpose volt ohm

meter. For example: Simpson 260 or equivalent.

For test purposes, the air flow switch may be “wired out”

of the system. This will eliminate the need for air flow

across the sensing thermistor to energize the power

supply (see Fig 23).

NOTE: All tests to be performed with the Ozone Reduction Jumper intact.

NOTE: When servicing the power pack components, all

wiring must be routed to factory specifications.

120 V AC

Connector

L1

Wht

Blk

L2

Blu

Gnd

ON/OFF

Switch

Wht

Blk

Operating

Light

Red

Wht

Blu

Wht/Brn/Air Flow

Blk

Power

Supply

Power Pack

Assembly

Wht/Brn

Cover Assembly

(If Required)

Airflow Switch

Blk

Wht

Cell Contact

& Insulator

Figure 22

11

Page 12

POWER SUPPLYPOWER SUPPLY

POWER SUPPLY

POWER SUPPLYPOWER SUPPLY

CHECKOUT PROCEDURECHECKOUT PROCEDURE

CHECKOUT PROCEDURE

CHECKOUT PROCEDURECHECKOUT PROCEDURE

1. Turn power switch to the “OFF” position and remove

the power pack from cabinet.

2. If air flow switch is installed, locate air flow switch and

remove power pack cover. If air flow switch is not

installed, go to step 4.

3. Disconnect the three-pin plastic connector and jumper

the two female pins (white wire to white-brown wire)

as shown in Fig. 23.

Plastic Connector

Male Pin

Jumper Lead

Female Pins

Method of jumping lead wires of

connector plug from air flow switch.

Figure 23

4. Place power pack on a well insulated workbench.

Connect meter negative (-) lead to the sheet metal

chassis and the high voltage probe to high voltage

contact on back cover of power pack. Connect AC

power to power pack using an extension cord and turn

power switch to the “ON” position.

tools away from high voltage contact.tools away from high voltage contact.

tools away from high voltage contact.

tools away from high voltage contact.tools away from high voltage contact.

5. If Operating Light comes ON and output voltage is

between 6100 and 6800 VDC, power supply is good.

6. If voltage is good but Operating Light does not come

on, replace Operating Light.

CELL TESTCELL TEST

CELL TEST

CELL TESTCELL TEST

1. Place collecting cell on a well insulated workbench

with the cell contact button pointing upward.

2. Select a power pack (with air flow switch bypassed

and ozone reduction jumper intact) that reads between 6100 and 6800 VDC at the cell contact with no

cell attached.

3. Place power pack on top of collecting cell ensuring

that there is proper contact between the cell contact

on the power pack contact.

Keep hands andKeep hands and

Keep hands and

Keep hands andKeep hands and

4. Using a standard extension cord, apply 120 VAC to

power pack. Turn power switch to “ON” position.

5. Connect meter negative (-) lead to metal frame of

collecting cell. Use high voltage probe to measure

voltage at collecting cell ionizer or cell plates. Voltage

should be 6100 to 6800 VDC.

NOTE:NOTE:

NOTE: A new “out-of-box” cell may cause the voltage

NOTE:NOTE:

to be lower than normal for a short period of time. To

obtain a more accurate measurement, “age” the cell

by applying high voltage to the cell for 15 to 30

minutes.

6 If voltage is below 6100 VDC, check cell for foreign

objects, bowed/bent/loose plates, broken ionizing

wires or cracked insulators. Wash cells if required. If

Operating Light remains OFF, replace collecting cell.

AIR FLOW MONITOR TESTAIR FLOW MONITOR TEST

AIR FLOW MONITOR TEST

AIR FLOW MONITOR TESTAIR FLOW MONITOR TEST

1. Connect a multimeter set to read 120 VAC to power

supply terminals marked “LINE.”

2. Connect 120 VAC to power pack plug, turn power

switch “ON.”

3. Blow on thermistor at air flow monitor. 120 VAC

should appear at multimeter. Stop blowing and voltage should disappear in 10 - 15 seconds.

4. If voltage did not appear (Step 3), disconnect power

to power pack. Locate air flow switch and remove

power pack cover. Disconnect the three-pin plastic

connector. Jumper the two female pins (white wire to

white-brown wire) as shown in Fig. 23. Reconnect

power to power pack. Turn power switch “ON.”

A. If 120 VAC appears at multimeter, replace air

flow monitor.

B. If 120 VAC does not appear on multimeter,

problem is other than air flow monitor. Recheck

all primary wiring.

NOTE: The air flow monitor is designed to operate in the

temperature range of 65° to 120° F. Operation outside

this range is not recommended.

12

Page 13

OZONE REDUCTIONOZONE REDUCTION

OZONE REDUCTION

OZONE REDUCTIONOZONE REDUCTION

All electronic air cleaners typically produce a small

amount of ozone that is within established limits.

Some customers may notice an odor especially at

high altitudes or low air flow rates.

This power supply has a “hairpin” shaped jumper

wire labeled W1 (see Fig 24) that can be cut and

separated in case of such complaints. This will

cause the power supply to limit the maximum

operating power to a lower level.

Ozone Reduction JumperOzone Reduction Jumper

Ozone Reduction Jumper

Ozone Reduction JumperOzone Reduction Jumper

ELECTRONIC AIR CLEANER RETROFIT (ACR) KITSELECTRONIC AIR CLEANER RETROFIT (ACR) KITS

ELECTRONIC AIR CLEANER RETROFIT (ACR) KITS

ELECTRONIC AIR CLEANER RETROFIT (ACR) KITSELECTRONIC AIR CLEANER RETROFIT (ACR) KITS

W1

WHT/BRN BLK

E3 E2

LINE

Cut and separate

Ozone Reduction

Jumper

Figure 24

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

1. Remove the two pre-filters from the package and insert

into cabinet tracks opposite the furnace. These will be

used to catch the larger particles that are in the air

stream before entering the collecting cell.

2. Insert the two collecting cells into the cabinet behind

the pre-filters. Be sure ionizing wires are directly

behind the pre-filters so the particles can be charged

as soon as the air leaves the pre-filters.

3. Remove cover plate on the power supply junction box

and remove the knockout needed to bring the wire to

the female receptacle.

4. Position receptacle with ground in the down position as

shown in Fig 17 (page 7) and pull wires through the

receptacle locator on the junction box. Snap the

receptacle into the hole until secure.

5. Connect ground wire from receptacle and ground wire

in kit to cabinet with rivet and washer as follows:

a) Place washer on rivet

b) Place terminal from ground wire on rivet

c) Place terminal from receptacle ground wire on

rivet

d) Insert rivet in hole in junction box and secure.

WIRINGWIRING

WIRING

WIRINGWIRING

5. For wiring installation (see page 7) and follow all wiring

instructions 7, 8 and 9.

6. Install the power pack (see page 7) instruction 11.

7. For operation (see page 8 – Operation).

Cabinet

Contact

Button

Pre-Filters

Collecting Cells

Handle

Contact

Button

13

Page 14

REPAIR PARTSREPAIR PARTS

REPAIR PARTS

REPAIR PARTSREPAIR PARTS

1

2

5

4

3

5

6

2

3

7

10

11

12

13

14

9

8

18

5

14

Page 15

REPAIR PARTSREPAIR PARTS

REPAIR PARTS

REPAIR PARTSREPAIR PARTS

PARTS LIST FOR ELECTRONIC AIR CLEANERS

When ordering repair parts, always give the following information as

shown in this list.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER

4. The NAME OF ITEM - Electronic Air Cleaner.

Always order by “PART NUMBER” . . . Not by “ITEM NUMBER”Always order by “PART NUMBER” . . . Not by “ITEM NUMBER”

Always order by “PART NUMBER” . . . Not by “ITEM NUMBER”

Always order by “PART NUMBER” . . . Not by “ITEM NUMBER”Always order by “PART NUMBER” . . . Not by “ITEM NUMBER”

ITEM

NO.

1 Cabinet N/A N/A N/A N/A

2 Pre-Filter • F825-0431 • F825-0432 • F825-0337 • F825-0338

3 Collecting Cell • F811-0398 • F811-0397 • F811-0321 • F811-0319

4 Junction Box Cover F838-0072 F838-0072 F838-0072 F838-0072

5 * Screw #6 x 3/8 ------ ------ ------ -----6 Connector, Female F818-0053 F818-0053 F818-0053 F818-0053

7 Power Pack Assembly F858-1021 F858-1022 F858-1023 F858-1024

8 Cell Handle F832-0039 F832-0039 F832-0039 F832-0039

9 Ionizing Wire F843-0484 F843-0484 F843-0500 F843-0500

10 Light F844-0130 F844-0130 F844-0130 F844-0130

11 Switch F876-0202 F876-0202 F876-0202 F876-0202

12 Power Pack, Cabinet Only N/A N/A N/A N/A

13 Connector, Male F827-0026 F827-0026 F827-0026 F827-0026

14 Power Supply F858-1002 F858-1002 F858-1002 F858-1002

15 Cover, Power Pack F820-0098 F820-0098 F820-0220 F820-0220

16 † Manual 37-6373 37-6373 37-6373 37-6373

17 † Charcoal Filter (with mounting clips) F825-0466 • F825-0467 • F825-0468 • F825-0469

18 Air Flow Switch (monitor kit) F859-0381 F859-0381 F859-0381 F859-0381

DESCRIPTION

SST1000 SST1400 SST1600 SST2000

PART NUMBER

* Standard Hardware Item

• Two (2) Required

† Not Shown

15

Page 16

WASH REMINDER SCHEDULEWASH REMINDER SCHEDULE

WASH REMINDER SCHEDULE

WASH REMINDER SCHEDULEWASH REMINDER SCHEDULE

A regular washing schedule is necessary to ensure

proper efficiency. A thorough washing once every month

will be adequate for most installations. More or Less

frequent washing may be necessary on some installations where there is new carpeting, plaster dust or excessive cigarette smoke, etc. (See page 8 for maintenance

and instructions on how to clean a cell.)

Year JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

20___

20___

20___

20___

20___

20___

20___

20___

20___

20___

20___

20___

NOTICE TO CONSUMERS

White-Rodgers

Electronic Air Cleaner

Dear Consumer;

White-Rodgers would like to thank you for purchasing a White-Rodgers Electronic Air

Cleaner or product containing a White-Rodgers Electronic Air Cleaner. Although WhiteRodgers does not extend a warranty directly to consumers, White-Rodgers does extend a

warranty to Wholesalers and Original Equipment Manufacturers who use White-Rodgers

Products. To obtain more information about how your Wholesaler or Original Equipment

Manufacturer’s warranty may benefit you, please contact your Wholesaler or Original

Equipment Manufacturer.

Sincerely,

White-Rodgers

The Emerson logo is

trademark and a service mark

of Emerson Electric Co.

Page 17

Prière de lire attentivement le manuel avant d’installer l’appareil, de le mettrePrière de lire attentivement le manuel avant d’installer l’appareil, de le mettre

Prière de lire attentivement le manuel avant d’installer l’appareil, de le mettrePrière de lire attentivement le manuel avant d’installer l’appareil, de le mettre

Prière de lire attentivement le manuel avant d’installer l’appareil, de le mettre

en marche ou d’en faire l’entretien.en marche ou d’en faire l’entretien.

en marche ou d’en faire l’entretien.en marche ou d’en faire l’entretien.

en marche ou d’en faire l’entretien.

Filtre à air électronique

ModèleModèle

Modèle

ModèleModèle

SST

S

R

E

G

D

O

-R

E

IT

H

W

SST1000SST1000

SST1000

SST1000SST1000

SST1400SST1400

SST1400

SST1400SST1400

SST1600SST1600

SST1600

SST1600SST1600

SST2000SST2000

SST2000

SST2000SST2000

TING

RA

E

P

O

T

LIGH

N

O

FF

O

GUIDE DE LGUIDE DE L

GUIDE DE L

GUIDE DE LGUIDE DE L

••

InstallationInstallation

•

Installation

••

InstallationInstallation

••

ExploitationExploitation

•

Exploitation

••

ExploitationExploitation

••

Guide de révision de base SSTGuide de révision de base SST

•

Guide de révision de base SST

••

Guide de révision de base SSTGuide de révision de base SST

••

Guide technique de réparationGuide technique de réparation

•

Guide technique de réparation

••

Guide technique de réparationGuide technique de réparation

••

Pièces de rechangePièces de rechange

•

Pièces de rechange

••

Pièces de rechangePièces de rechange

White-Rodgers est une division

d’Emerson Electric Co.

www.white-rodgers.com

’UTILISA’UTILISA

’UTILISA

’UTILISA’UTILISA

Imprimé aux USA

TEURTEUR

TEUR

TEURTEUR

PIÈCE NPIÈCE N

PIÈCE N

PIÈCE NPIÈCE N

oo

o

oo

37-6373C 37-6373C

37-6373C

37-6373C 37-6373C

Remplace 37-6373B

0238

Page 18

DIRECTIVES D’INSTALLATION ET

D’EXPLOITATION SÉCURITAIRES

Veuillez lire les directives avant d’installer et d’utiliser le filtre à air

électronique, ce qui vous permettra de profiter pleinement des

avantages de cet appareil.

!

MISE EN GARDEMISE EN GARDE

MISE EN GARDE

MISE EN GARDEMISE EN GARDE

▲

RISQUE D’ÉLECTROCUTIONRISQUE D’ÉLECTROCUTION

RISQUE D’ÉLECTROCUTION

RISQUE D’ÉLECTROCUTIONRISQUE D’ÉLECTROCUTION

Avant de réviser l’appareil, couper le courantAvant de réviser l’appareil, couper le courant

Avant de réviser l’appareil, couper le courant

Avant de réviser l’appareil, couper le courantAvant de réviser l’appareil, couper le courant

au panneau de distribution. Si ces instructionsau panneau de distribution. Si ces instructions

au panneau de distribution. Si ces instructions

au panneau de distribution. Si ces instructionsau panneau de distribution. Si ces instructions

n’étaient pas respectées, des blessuresn’étaient pas respectées, des blessures

n’étaient pas respectées, des blessures

n’étaient pas respectées, des blessuresn’étaient pas respectées, des blessures

graves, voire même un décès, pourraientgraves, voire même un décès, pourraient

graves, voire même un décès, pourraient

graves, voire même un décès, pourraientgraves, voire même un décès, pourraient

survenir.survenir.

survenir.

survenir.survenir.

MISE EN GARDEMISE EN GARDE

MISE EN GARDE

MISE EN GARDEMISE EN GARDE

!

▲

Ne pas tenter d’installer l’appareil avant de s’être complète-Ne pas tenter d’installer l’appareil avant de s’être complète-

Ne pas tenter d’installer l’appareil avant de s’être complète-

Ne pas tenter d’installer l’appareil avant de s’être complète-Ne pas tenter d’installer l’appareil avant de s’être complètement familiarisé avec les outils et les équipements requis,ment familiarisé avec les outils et les équipements requis,

ment familiarisé avec les outils et les équipements requis,

ment familiarisé avec les outils et les équipements requis,ment familiarisé avec les outils et les équipements requis,

avec les exigences en matière de raccordements aux servicesavec les exigences en matière de raccordements aux services

avec les exigences en matière de raccordements aux services

avec les exigences en matière de raccordements aux servicesavec les exigences en matière de raccordements aux services

publics ainsi qu’avec les dangers qui sont présents.publics ainsi qu’avec les dangers qui sont présents.

publics ainsi qu’avec les dangers qui sont présents.

publics ainsi qu’avec les dangers qui sont présents.publics ainsi qu’avec les dangers qui sont présents.

Pour installer l’appareil, il est recommandé de faire appel à unPour installer l’appareil, il est recommandé de faire appel à un

Pour installer l’appareil, il est recommandé de faire appel à un

Pour installer l’appareil, il est recommandé de faire appel à unPour installer l’appareil, il est recommandé de faire appel à un

fournisseur de services agréé.fournisseur de services agréé.

fournisseur de services agréé.

fournisseur de services agréé.fournisseur de services agréé.

Si ces instructions n’étaient pas suivies, les performances deSi ces instructions n’étaient pas suivies, les performances de

Si ces instructions n’étaient pas suivies, les performances de

Si ces instructions n’étaient pas suivies, les performances deSi ces instructions n’étaient pas suivies, les performances de

l’appareil pourraient être réduites et des blessures graves,l’appareil pourraient être réduites et des blessures graves,

l’appareil pourraient être réduites et des blessures graves,

l’appareil pourraient être réduites et des blessures graves,l’appareil pourraient être réduites et des blessures graves,

voire même un décès, pourraient survenir.voire même un décès, pourraient survenir.

voire même un décès, pourraient survenir.

voire même un décès, pourraient survenir.voire même un décès, pourraient survenir.

1. Lire attentivement le guide de l’utilisateur ainsi que les directives

d’exploitation sécuritaire. Si ces directives n’étaient pas suivies,

l’appareil risquerait de fonctionner incorrectement ou pas du tout.

2. Effectuer régulièrement les révisions et l’entretien afin d’assurer

un fonctionnement efficace de l’appareil.

3. Il est essentiel de faire fonctionner l’appareil pendant une heure

complète immédiatement après son installation. Cela permettra

d’assurer le rendement optimal des cellules.

4. Si un détecteur de débit d’air est requis, commander l’ensemble

F859-0381.

!

MISE EN GARDEMISE EN GARDE

MISE EN GARDE

MISE EN GARDEMISE EN GARDE

▲

L’installation de l’appareil doit respecter les codes électriqueL’installation de l’appareil doit respecter les codes électrique

L’installation de l’appareil doit respecter les codes électrique

L’installation de l’appareil doit respecter les codes électriqueL’installation de l’appareil doit respecter les codes électrique

et autres codes en vigueur.et autres codes en vigueur.

et autres codes en vigueur.

et autres codes en vigueur.et autres codes en vigueur.

Avant de procéder à l’installation, prendre soin d’étudier et deAvant de procéder à l’installation, prendre soin d’étudier et de

Avant de procéder à l’installation, prendre soin d’étudier et de

Avant de procéder à l’installation, prendre soin d’étudier et deAvant de procéder à l’installation, prendre soin d’étudier et de

bien comprendre les codes en vigueur.bien comprendre les codes en vigueur.

bien comprendre les codes en vigueur.

bien comprendre les codes en vigueur.bien comprendre les codes en vigueur.

Ne pas utiliser cet appareil en présence de gaz explosifs.Ne pas utiliser cet appareil en présence de gaz explosifs.

Ne pas utiliser cet appareil en présence de gaz explosifs.

Ne pas utiliser cet appareil en présence de gaz explosifs.Ne pas utiliser cet appareil en présence de gaz explosifs.

Si ces instructions n’étaient pas suivies, des blessuresSi ces instructions n’étaient pas suivies, des blessures

Si ces instructions n’étaient pas suivies, des blessures

Si ces instructions n’étaient pas suivies, des blessuresSi ces instructions n’étaient pas suivies, des blessures

graves, voire même un décès, pourraient survenir.graves, voire même un décès, pourraient survenir.

graves, voire même un décès, pourraient survenir.

graves, voire même un décès, pourraient survenir.graves, voire même un décès, pourraient survenir.

ATTENTIONATTENTION

ATTENTION

ATTENTIONATTENTION

!

▲

LE BOÎTIER ET LES CELLULES PEUVENTLE BOÎTIER ET LES CELLULES PEUVENT

LE BOÎTIER ET LES CELLULES PEUVENT

LE BOÎTIER ET LES CELLULES PEUVENTLE BOÎTIER ET LES CELLULES PEUVENT

AVOIR DES BORDS COUPANTS.AVOIR DES BORDS COUPANTS.

AVOIR DES BORDS COUPANTS.

AVOIR DES BORDS COUPANTS.AVOIR DES BORDS COUPANTS.

Manipuler soigneusement les cellules lors deManipuler soigneusement les cellules lors de

Manipuler soigneusement les cellules lors de

Manipuler soigneusement les cellules lors deManipuler soigneusement les cellules lors de

la révision ou de l’installation. Si ces instruc-la révision ou de l’installation. Si ces instruc-

la révision ou de l’installation. Si ces instruc-

la révision ou de l’installation. Si ces instruc-la révision ou de l’installation. Si ces instructions n’étaient pas suivies, des blessurestions n’étaient pas suivies, des blessures

tions n’étaient pas suivies, des blessures

tions n’étaient pas suivies, des blessurestions n’étaient pas suivies, des blessures

légères pourraient survenir.légères pourraient survenir.

légères pourraient survenir.

légères pourraient survenir.légères pourraient survenir.

TABLE DES MATIÈRESTABLE DES MATIÈRES

TABLE DES MATIÈRES

TABLE DES MATIÈRESTABLE DES MATIÈRES

Directives d’installation et d’exploitation sécuritaires ............ 2

Fonctionnement du filtre à air.................................................. 3

Construction du filtre à air ....................................................... 3

Installation préliminaire ............................................................ 4

Installation ................................................................................ 6

Câblage .................................................................................... 7

Exploitation ............................................................................... 8

Entretien et lavage ................................................................... 8

Fiche technique ........................................................................ 9

Guide de révision de base SST ............................................ 10

Guide technique de réparation .............................................. 11

Installation de l’ensemble de mise à niveau du filtre à air ... 13

Pièces de rechange ............................................................... 14

Rappel de lavage ................................................................... 16

AVEZ-VOUS LE BON FILTRE À AIRAVEZ-VOUS LE BON FILTRE À AIR

AVEZ-VOUS LE BON FILTRE À AIR

AVEZ-VOUS LE BON FILTRE À AIRAVEZ-VOUS LE BON FILTRE À AIR

modèle SST1000modèle SST1000

Le

modèle SST1000 est conçu pour les ventilateurs de chauffage ou

modèle SST1000modèle SST1000

de climatisation dont le débit d’air se situe entre 600 et 1 200 pieds

cubes à la minute (pi3/min).

Le modèle SST1400 Le modèle SST1400

Le modèle SST1400 est conçu pour les ventilateurs de chauffage ou

Le modèle SST1400 Le modèle SST1400

de climatisation dont le débit d’air se situe entre 1 000 et 1 600 pieds

cubes à la minute (pi3/min).

Le modèle SST1600 Le modèle SST1600

Le modèle SST1600 est conçu pour les ventilateurs de chauffage ou

Le modèle SST1600 Le modèle SST1600

de climatisation dont le débit d’air se situe entre 1 000 et 2 000 pieds

cubes à la minute (pi3/min).

Le modèle SST2000 Le modèle SST2000

Le modèle SST2000 est conçu pour les ventilateurs de chauffage ou

Le modèle SST2000 Le modèle SST2000

de climatisation dont le débit d’air se situe entre 1 600 et 2 200 pieds

cubes à la minute (pi3/min).

Consulter la fiche technique, qui se trouve à la page 9.

OUTILS DE BASE REQUISOUTILS DE BASE REQUIS

OUTILS DE BASE REQUIS

OUTILS DE BASE REQUISOUTILS DE BASE REQUIS

Cisailles de ferblantier

Tournevis

Règle ou ruban à mesurer

Perceuse

??

?

??

2

Page 19

ABC

Entrée d’air poussiéreux Sortie d’air propre

FONCTIONNEMENT DUFONCTIONNEMENT DU

FONCTIONNEMENT DU

FONCTIONNEMENT DUFONCTIONNEMENT DU

FILFIL

TRE À TRE À

FIL

TRE À

FILFIL

TRE À TRE À

L’air poussiéreux qui circule dans les conduits (figure 1) traverse

d’abord les préfiltres (A), qui captent les grosses particules (cheveux,

poils, etc.). Les particules de plus petite taille (fumée, poussière,

pollen, etc.) traversent les préfiltres et pénètrent dans l’étage

d’ionisation (B). À ce stade, chaque minuscule particule reçoit une

charge électrique positive. Ces particulies ionisées pénètrent alors

dans l’étage collecteur (C). Celui-ci est constitué d’une série de

plaques d’aluminium dotées en alternance d’une charge positive ou

négative.

Les particules, dotées d’une charge positive, sont alors repoussée par

les plaques positives et attirées par les plaques négatives, où elles

s’accumulent, comme la limaille de fer sur un aimant.

L’air filtré regagne enfin le réseau d’alimentation.

La poussière blanche (les peluches)La poussière blanche (les peluches)

La poussière blanche (les peluches)

La poussière blanche (les peluches)La poussière blanche (les peluches)

Le filtre à air électronique est conçu pour capter principalement deux

sortes de contaminants : ➀ les rritants (pollen, spores, moisissures,

bactéries, etc.) ; et ➁ les conaminants salissants (particules de saleté

et de fumée).

Les résidus qui s’accumulent sur les plaques d’un filtre à air électronique

sont noirs ; toute cette saleté est retirée de l’air ambiant. Après

l’installation du filtre à air, il est possible que vous remarquiez une

poussière blanche (en règle générale, de longues particules de

peluches ou de fibres, provenant de moquettes, de tissus de coton et

de rideaux). Ces substances ne sont pas captées par le filtre à air, soit

parce qu’elles ne contiennent pas les irritants et les contaminants

mentionnés plus haut, soit parce qu’elles se sont déposées avant

d’avoir pu atteindre le filtre. La présence de poussière blanche ne

signifie pas qu’il est temps de faire réviser le filtre à air.

AIRAIR

AIR

AIRAIR

Figure 1Figure 1

Figure 1

Figure 1Figure 1

Les filtres à charbon actifLes filtres à charbon actif

Les filtres à charbon actif

Les filtres à charbon actifLes filtres à charbon actif

Les odeurs sont causées par des molécules de gaz et non par des

particules. Ainsi, il est impossible de les éliminer à l’aide d’un filtre à

air électronique ou de tout autre milieu filtrant conçu pour capter les

particules en suspension dans l’air. Or, il est possible d’adsorber

certains gaz à l’aide d’un filtre à charbon actif ou de les diluer par un

apport d’air frais en provenance de l’extérieur. Si des odeurs sont

présentes, comme les odeurs de cuisson, d’animaux de compagnie,

de cigare ou de cigarette, etc., l’ajout d’un filtre à charbon actif les

neutralisera. On peut se procurer des filtres à charbon facultatifs pour

usage avec le filtre à air électronique ; pour en connaître le numéro de

pièce, se reporter à la liste de pièces correspondant au filtre à air

installé. Les filtres à charbon doivent être remplacés régulièrement ;

ils ne peuvent être lavés. Il n’existe aucune règle générale quant à la

fréquence de leur changement ; nous recommandons seulement de

faire appel à votre jugement en fonction des odeurs perçues dans le

foyer.

CONSTRCONSTR

CONSTR

CONSTRCONSTR

Le filtre à air est non seulement facile à installer, mais aussi simple à

utiliser et à entretenir. Voici une brève description de ses principales

composantes et de leurs fonctions (voir la figure 2) :

Le boîtierLe boîtier

Le boîtier

Le boîtierLe boîtier

Les cellules collectricesLes cellules collectrices

Les cellules collectrices

Les cellules collectricesLes cellules collectrices

Les préfiltresLes préfiltres

Les préfiltres

Les préfiltresLes préfiltres

Le module d’alimentationLe module d’alimentation

Le module d’alimentation

Le module d’alimentationLe module d’alimentation

UCTION DU FILUCTION DU FIL

UCTION DU FIL

UCTION DU FILUCTION DU FIL

::

: Il est installé dans les conduites existantes et il renferme

::

les cellules et les préfiltres.

: :

: Composées de deux sections, elles sont

responsables de l’élimination de la poussière, de la saleté et

des autres impuretés. Elles comportent le dispositif

d’ionisation et le collecteur, décrits plus haut.

Chaque cellule doit être installée avec les fils ionisants

orientés vers l’entrée d’air. Les orienter avec les poignées et

le bouton de contact (figure 2) vers l’utilisateur.

::

: Composés de deux sections interchangeables, ils

::

servent à capter les grosses particules, comme les cheveux

et les poils, pour les empêcher de pénétrer dans les cellules.

tension ainsi que de composantes à circuits intégrés qui

convertissent le courant d’alimentation de 120 volts C.A. en

courant continu à haute tension, requis par le collecteur.

: :

::

: Il est doté de voyants de marche et de

::

TRE À TRE À

TRE À

TRE À TRE À

AIRAIR

AIR

AIRAIR

Boîtier

Bouton de

contact

Préfiltres

Cellules

collectrices

Figure 2Figure 2

Figure 2

Figure 2Figure 2

Poignée

Bouton de

contact

Module

d’alimentation

3

Page 20

SST1000 24 3/4 21 5/16 18 5/8 13 9/16 16 7/16 19 1/16

SST1400 29 11/16 26 1/4 23 5/8 13 9/16 16 7/16 19 1/16

SST1600 25 1/2 21 5/16 18 5/8 17 3/4 20 5/8 23 3/8

SST2000 29 11/16 26 1/4 23 5/8 17 3/4 20 5/8 23 3/8

MODÈLE A B C D E F

INSTALLATION PRÉLIMINAIRE

SST1000 629 mm 541 mm 473 mm 344 mm 418 mm 484 mm

SST1400 754 mm 667 mm 600 mm 344 mm 418 mm 484 mm

SST1600 648 mm 541 mm 473 mm 451 mm 524 mm 594 mm

SST2000 754 mm 667 mm 600 mm 451 mm 524 mm 594 mm

MODÈLE A B C D E F

Ne pas

dépasser 20°

Écoulement

de l’air

Écoulement de l’air

Ouverture du

générateur

Cellule collectrice

(interchangeable)

Boîtier

Boîte de

raccordement

Cellule collectrice

(interchangeable)

Poignée

d’alimentation

Module

Ouverture du filtre

à air électronique

Générateur

Section de

transition

(au besoin)

Filtre à air

électronique

Figure 3

CHOIX DE L’EMPLACEMENTCHOIX DE L’EMPLACEMENT

CHOIX DE L’EMPLACEMENT

CHOIX DE L’EMPLACEMENTCHOIX DE L’EMPLACEMENT

DU FILTRE À AIRDU FILTRE À AIR

DU FILTRE À AIR

DU FILTRE À AIRDU FILTRE À AIR

Le filtre à air doit être installé dans la conduite de retour d’air d’un

système central à air pulsé, en amont du générateur d’air chaud. (Voir

l’exemple à la figure 3.)

Choisir un emplacement qui répond aux critères suivants

1. Orienter la face de la cellule perpendiculaire à la direction du

courant d’air.

2. Assurer les dégagements suivants afin de faciliter le démontage

des cellules et des préfiltres (voir les figures 4 et 5) :

Modèle SST1000 : 36 cm (14 po)

Modèle SST1400 : 38 cm (15 po)

Modèle SST1600 : 36 cm (14 po)

Modèle SST2000 : 38 cm (15 po)

Les dimensions exactes sont données à la figure

3. Ne pas installer le filtre à air dans la sortie d’air de l’appareil de

chauffage ou de climatisation.

IMPORTANTIMPORTANT

4.

IMPORTANT

IMPORTANTIMPORTANT

l’installer en aval du filtre à air.

Si le réseau de conduits du générateur d’air chaud comporte déjà un

boîtier intégré, en jeter le couvercle et glisser le filtre à air en place à

l’intérieur. Pour l’installation d’un ensemble de mise à niveau du filtre

à air, se reporter à la page 13.

Si l’ouverture de l’appareil de chauffage ne peut pas être agrandie

suffisamment, on doit alors installer une section de transition en tôle.

La transition doit être adaptée à chaque installation. Le facteur de

réduction ne doit pas dépasser 28 cm au mètre (ou 4 po au pied

linéaire), soit une pente d’environ 20 degrés (figure 3).

: :

: Si un humidificateur à pulvérisation est utilisé,

: :

Bouton de

contact

Préfiltres

(interchangeables)

E

175 mm

(6 7/8 po)

D

Bouton de

Figure 4

C

B

A

contact

Voir le texte concernant le

dégagement requis pour

enlever les cellules

Ouvertures pour

conduit de

19 mm (3/4 po)

(sur trois côtés)

F

SENS DE PASSAGE DE L’AIRSENS DE PASSAGE DE L’AIR

SENS DE PASSAGE DE L’AIR

SENS DE PASSAGE DE L’AIRSENS DE PASSAGE DE L’AIR

DANS LE FILTREDANS LE FILTRE

DANS LE FILTRE

DANS LE FILTREDANS LE FILTRE

Sur livraison, le filtre à air est agencé pour que l’air circule de gauche

à droite. Si cela convient à l’installation, aucune modification n’est

requise (figure 4). Pour permettre que l’air circule de droite à gauche,

retirer les préfiltres et les cellules. Les retourner en gardant la même

extrémité orientée vers le boîtier. Cela placera les fils ionisants à

droite ; de plus, les deux boutons de contact ainsi que les poignées

seront maintenant orientés vers le capot du module d’alimentation.

L’air doit traverser le filtre dans le sens indiqué par les flèches qui sont

estampées sur l’extrémité des cellules

Une fois les cellules installées, glisser les préfiltres dans les rainures

sur le côté droit du boîtier. Ceux-ci se trouveront alors du côté de

l’appareil où l’air entre (soit du même côté que les fils ionisants).

Figure 5

4

Page 21

POSITIONS DE MONTAGE TYPIQUES

Écoulement

Écoulement

de l’air

de l’air

Écoulement

de l’air

Vue de l’arrière

Figure 6

GÉNÉRATEUR DE SOUS-SOLGÉNÉRATEUR DE SOUS-SOL

GÉNÉRATEUR DE SOUS-SOL

GÉNÉRATEUR DE SOUS-SOLGÉNÉRATEUR DE SOUS-SOL

(À CAISSONS JUXTAPOSÉS)(À CAISSONS JUXTAPOSÉS)

(À CAISSONS JUXTAPOSÉS)

(À CAISSONS JUXTAPOSÉS)(À CAISSONS JUXTAPOSÉS)

((

Figure Figure

Figure

Figure Figure

6)6)

6)

6)6)

dans la prise d’air latérale du générateur.

GÉNÉRATEUR À CAISSONSGÉNÉRATEUR À CAISSONS

GÉNÉRATEUR À CAISSONS

GÉNÉRATEUR À CAISSONSGÉNÉRATEUR À CAISSONS

SUPERPOSÉS SUPERPOSÉS

SUPERPOSÉS

SUPERPOSÉS SUPERPOSÉS

Installation sous le générateur d’air.

Installer le filtre horizontalement, là

où le retour d’air pénètre par endessous. Soulever le générateur

(

((

Installer le filtre horizontalement dans le

plénum de retour d’air, juste au-dessus

du générateur.

Vue de l’arrière

Figure 7

GÉNÉRATEUR À CIRCULATIONGÉNÉRATEUR À CIRCULATION

GÉNÉRATEUR À CIRCULATION

GÉNÉRATEUR À CIRCULATIONGÉNÉRATEUR À CIRCULATION

À CONTRE-COURANT À CONTRE-COURANT

À CONTRE-COURANT

À CONTRE-COURANT À CONTRE-COURANT

7)7)

7)

7)7)

Installer le filtre horizontalement dans le

plénum ou la conduite de retour d’air,

(Figure 9)(Figure 9)

(Figure 9)

(Figure 9)(Figure 9)

(Figure(Figure

(Figure

(Figure(Figure

juste au-dessus du générateur.

GÉNÉRATEUR À CAISSONSGÉNÉRATEUR À CAISSONS