Page 1

Stove Builder International Inc.

1700, Léon-Harmel

Québec(Québec)

G1N 4R9

Installation and Operating

Instructions for Wood and

Combined Wood-electric Furnaces

THIS MANUAL CONCERNS THE FOLLOWING FURNACES

WOOD COMBINED ELECTRIC

PSG-2000 15 KW, 18 KW, 20 KW

PSG-3000 15 KW, 18 KW, 20 KW, 25 KW

PSG-4000 18 KW, 20 KW, 25 KW, 30 KW

PSG-4500 18 KW, 20 KW, 25 KW, 30 KW

PSG-5000 40 KW, 50 KW, 60 KW

All the instructions must be read carefully

before installing and operating furnace.

CONGRATULATIONS!

You have just purchased one of the best wood or combined

wood-electric furnace on the market.

We are convinced that your furnace will provide you

with many years of comfort, safely.

Keep these instructions!

Page 2

Table of contents

INTRODUCTION ..................................................................................................................... 4

1. CHIMNEY AND DRAFT...................................................................................................... 4

2. SAFETY RULES................................................................................................................. 4

.............................................................................................................................................4 GENERAL REQUIREMENTS

................................................................................................................................................5 ODOUR FROM THE PAINT

......................................................................................................................................................................5 ASH DISPOSAL

.........................................................................................................................5 CREOSOTE BUILD-UP AND REMOVAL

.............................................................................................................................................................6 SMOKE DETECTOR

.......................................................................................................................................................................6 ASH DRAWER

...........................................................................................................................................................................6 ASH GRATE

3. APPLIANCE INSTALLATION............................................................................................. 6

..................................................................................................................................................................6 UNIT LOCATION

.........................................................................................................7 CLEARANCES TO COMBUSTIBLE MATERIALS

...................................................................................................................................7 PIPE CONNECTOR AND DAMPER

.................................................................................................................................................................................8 DAMPER

...............................................................................................................................................................8 COMBUSTION AIR

............................................................................................................................................9 ELECTRICAL CONNECTION

.......................................................................................................................................................10 ELECTRIC ELEMENT

....................................................................................................................................................................11 THERMOSTAT

...................................................................................................................................................................11 FAN CONTROL

4. OPERATING INSTRUCTIONS.......................................................................................... 12

.......................................................................................................................................................................12 Control system

..............................................................................................................................................................................13 HEATING

..................................................................................................................13 EARLY SIGNS OF OVERFIRED FURNACE

..............................................................................................................................................13 WOOD AS HEATING FUEL

................................................................................................................................................................14 CHIMNEY FIRES

5. MAINTENANCE ................................................................................................................ 15

.....................................................................................................................15 MAINTENANCE OF THE EXCHANGERS

...............................................................................................................15 MAINTENANCE OF THE BLOWER MOTOR

................................................................................................................................................................................16 FILTERS

....................................................................................................................................16 DOOR GASKET MAINTENANCE

6. REPLACEMENT PARTS................................................................................................... 16

................................................................................................................................................................................16 GASKET

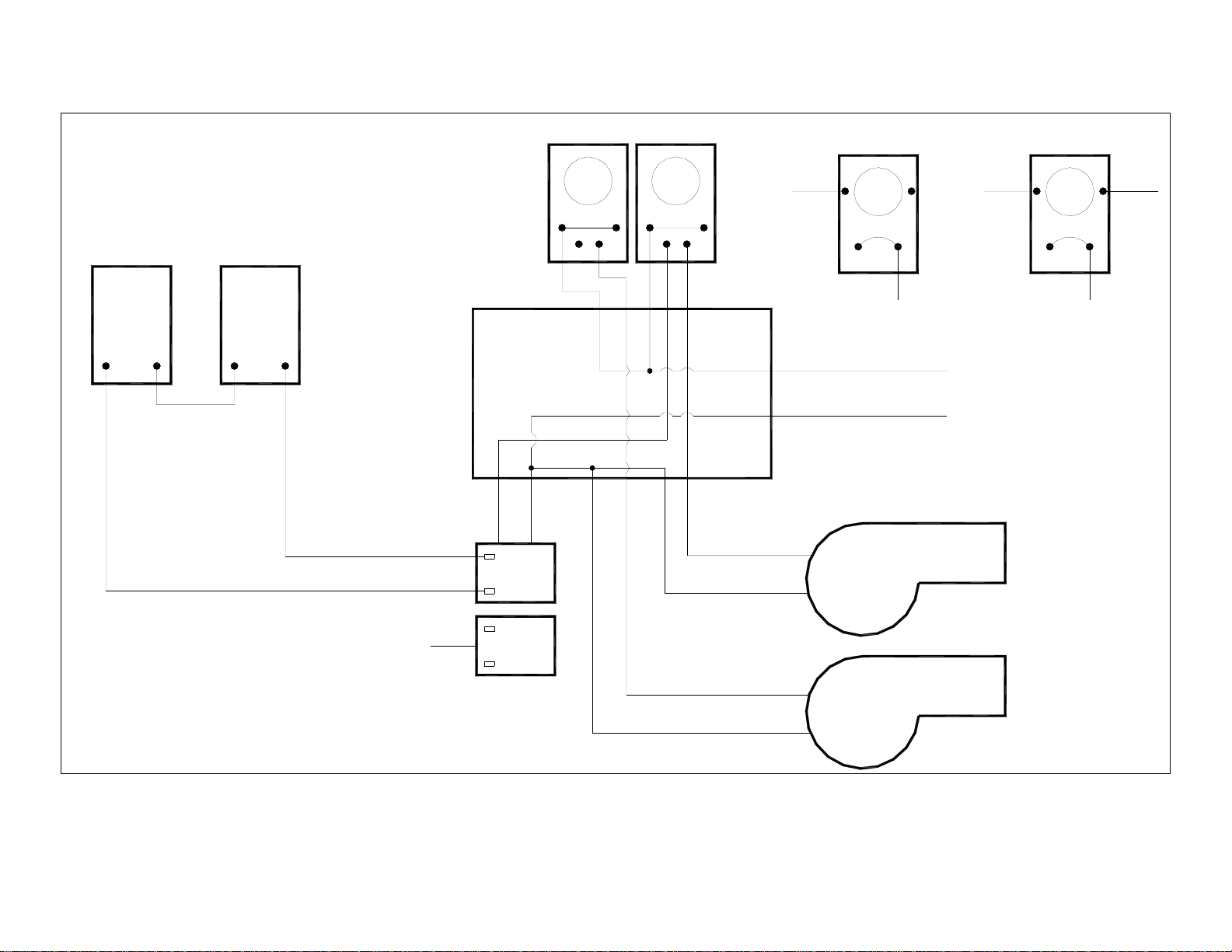

7. ELECTRIC DIAGRAMS FOR UNITS BUILT FROM 2005 ................................................ 17

................................................................................................................................................17 WOOD-ONLY FURNACES

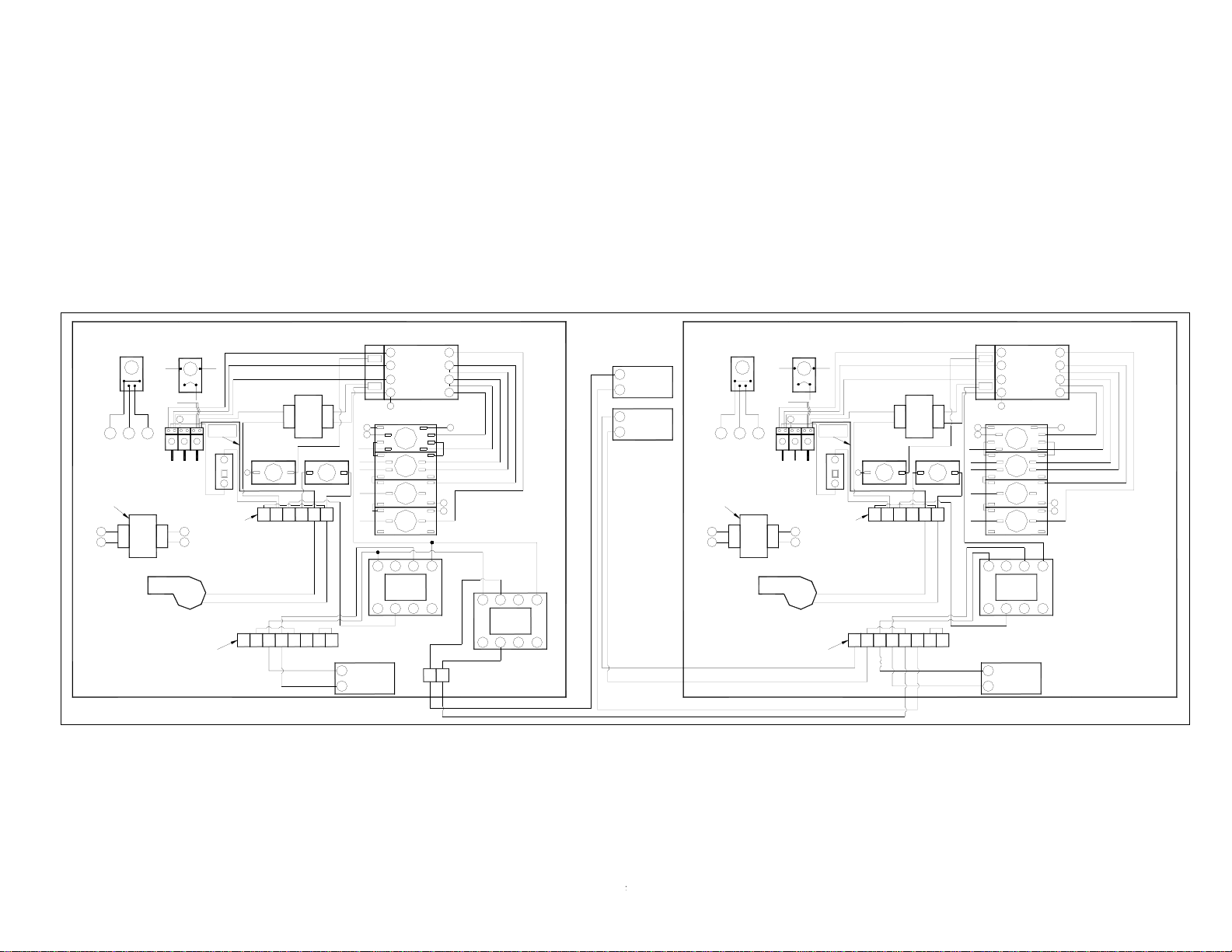

.......................................................................................................................................18 WOOD/ELECTRIC FURNACES

................................................................................................................................19 PSG5000 WOOD-ONLY FURNACES

.......................................................................................................................20 PSG5000 WOOD/ELECTRIC FURNACES

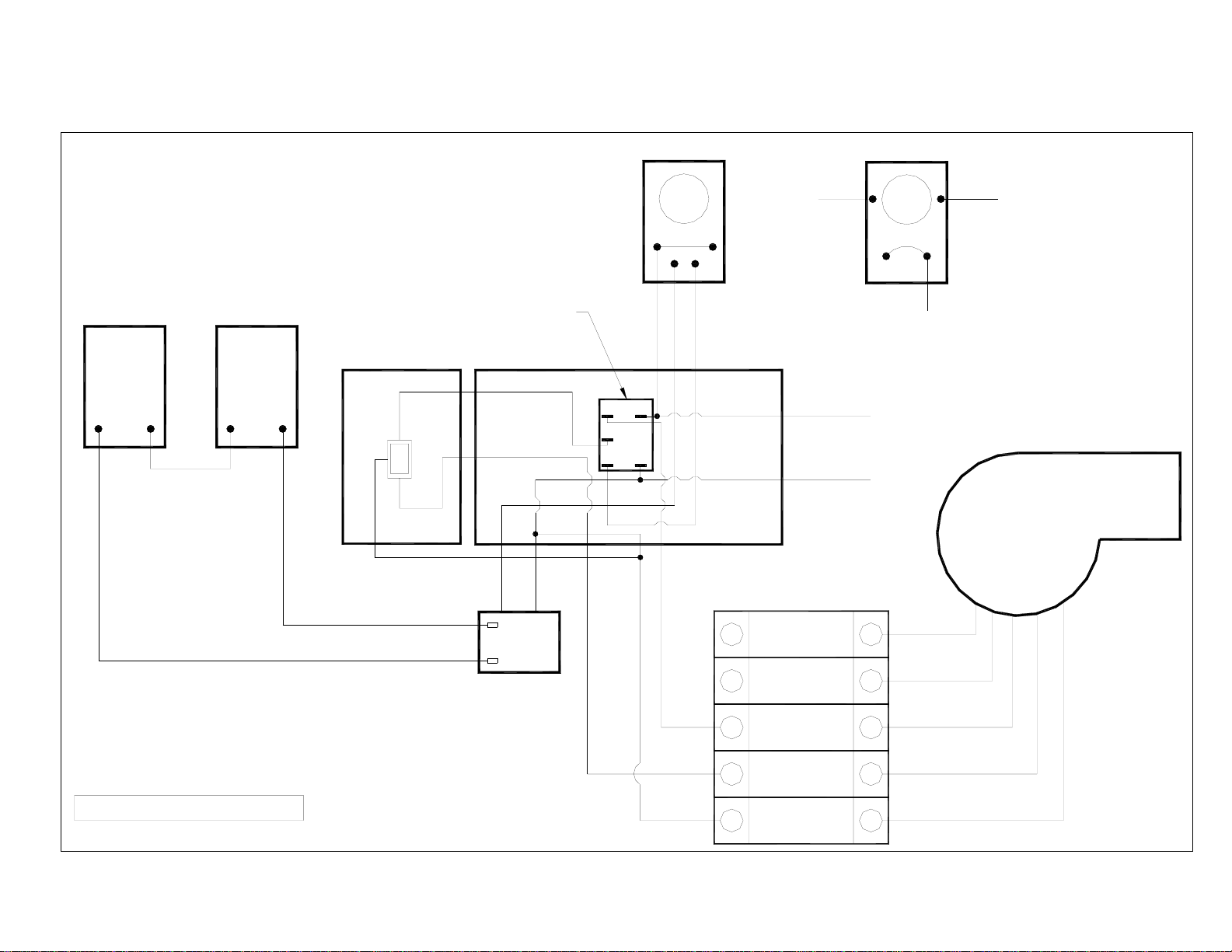

8. ELECTRIC DIAGRAMS FOR UNITS BUILT BEFORE 2005............................................ 21

..................................................................................................................21 WOOD ONLY FURNACES PSG 4000 & 4500

...............................................................................................................................22 WOOD ONLY FURNACES PSG 5 000

........................................................................................................23 WOOD/ELECTRIC FURNACES PSG 4000 & 4500

.........................................................................................24 WOOD/ELECTRIC FURNACES PSG 5000 40KW @ 60KW

............................................................................................................25 WOOD ONLY FURNACES PSG 2000-3000-4000

...................................................................................................26 WOOD/ELECTRIC FURNACES PSG 2000-3000-4000

9. TECHNICAL SPECIFICATIONS ....................................................................................... 27

2

Page 3

10. SELECTION CRITERIA (COMBINED WOOD/ELECTRIC FURNACE).......................... 28

11. TROUBLESHOOTING..................................................................................................... 29

12. DUCTS AND REGISTER MEASUREMENTS ................................................................. 30

LIMITED LIFETIME WARRANTY................................................................................. 31

3

Page 4

INTRODUCTION

To get maximum performance from your PSG furnace, keep in mind the following:

• Comply with local codes (if in doubt, contact your local heating specialist).

• Refer to the furnace’s certification label and your instruction manual for minimum installation clearances.

• Make sure that your furnace has been installed in accordance with the required standards specified on the

furnace’s identification label.

1. CHIMNEY AND DRAFT

This furnace must be connected to a chimney approved for wood-burning appliances; the chimney connector for a

PSG 2000 must have 6" diameter; 7” for PSG3000 and PSG4000, for all other models, use an 8" diameter chimney

connector.

Use the supplied barometric draft control. Never use a manual chimney damper.

The barometric control must be adjusted so that the maximum draft measured at the furnace outlet does not exceed

-0.06 in. w.c. Please note that a draft exceeding -0.06 in. w.c. could produce an uncontrollable fire. On the other

hand, the minimum draft required is -0.04 in. w.c. in the evacuation pipe on the wood side, no matter what type of

furnace (PSG Wood, PSG Wood/Electric and PSG Wood/Oil).

• Never light your furnace using chemicals or other liquid fuels. Never installed automatic feeder on that unit.

• Never store wood near the furnace. Respect the required minimum clearances between combustibles and

your furnace.

• Keep your furnace, chimney and smoke pipe connector clean and in good working order at all times. We

recommend that you establish clear procedures for wood storage, system maintenance and operation of

your furnace. Check creosote accumulation daily until you can determine by experience how often to clean.

Weekly cleanings may be necessary in mild weather, while a monthly cleaning may be all that is required

during the colder months of the year.

• Keep loading and ash drawer doors shut during operation and make sure their gaskets are in good

condition. To replace defective gaskets, see your dealer.

• A plentiful supply of air and a vigorous fire will reduce creosote accumulation.

All controls adjustments must be performed by a qualified technician. The controls settings and the blower speed must

conform to the recommendations of the National Warm Air Heating and Air Conditioning Association and respect the

recommended static pressure ranges in the warm air bonnet of the furnace (see General Technical data static

pressure).

2. SAFETY RULES

GENERAL REQUIREMENTS

Make sure the chimney outlet and the pipes are clean and in good condition.

Do not use chemical products or liquids to light the fire.

Do not burn wood coated with paint, glue or chemical products.

Do not burn wastes or flammable liquids such as gasoline, naphtha or motor oil.

Do not install an automatic feeder on this furnace.

Do not store wood in the vicinity of the furnace. Respect the required clearances between combustible materials

and the source of heat.

4

Page 5

W A R N I N G

-THE ASH DRAWER GET VERY HOT.

-DO NOT MANIPULATE WITH BARE HANDS.

ODOUR FROM THE PAINT

It is normal that a smoke odor emanate from the unit when you first light it. It is recommended to burn it at high rate

and ventilate the building until the odour resorbs.

ASH DISPOSAL

Ashes must be placed in a metal container with a tight fitting lid. The container should be placed outside, well away

from combustible materials. If the ashes are meant to be buried in soil, you should wait until all cinders have

thoroughly cooled.

CREOSOTE BUILD-UP AND REMOVAL

When wood is burned slowly, it produces tar and other organic vapours which, when combined with moisture, form

creosote. The creosote vapours condensate in a relatively cool chimney flue. As a result, creosote residue

accumulates in the flue lining.

N.B.: To minimize the frequency of the chimney cleaning, buy your firewood at least one year before using it. Store it

in a dry place in order to obtain the minimum moisture rate and optimize the efficiency. Do not store wood or

combustible materials within the installation minimum clearances or the space required to reload the appliance and

remove the ashes.

When ignited, creosote produces an extremely hot fire inside the chimney.

To avoid this situation, it is important to do the turnover of wood. Inspect the chimney system at regular intervals to

determine a cleaning cycle. A weekly cleaning might be required during mild temperature periods but a monthly

cleaning should be sufficient during cold periods. If a significant layer of creosote has accumulated, it should be

removed immediately to eliminate the risk of a chimney fire. Remember that a small hot fire is preferable to a

large smouldering one to prevent creosote build-up within the system. An emergency plan is necessary in case of a

chimney fire. It’s recommended to clean up the heat exchangers at the end of season in order to prevent corrosion

build-up.

5

Page 6

SMOKE DETECTOR

r

We highly recommend the use of a smoke detector. It must be installed at least 15 feet (4,57 m) from the appliance

in order to prevent undue triggering of the detector when reloading.

ASH DRAWER

Your appliance is equipped with an ash drawer to collect ashes produced by the combustion of wood. This drawer

must not be left open during combustion as this will cause over firing and serious damage to the furnace.

The drawer must be cleaned regularly.

It is important that the door and the ash drawer be kept closed while the appliance is in use.

Maintain all gaskets in good condition: in case of deterioration, contact your dealer fo

replacement.

ASH GRATE

You must replace the ash grate if it is damaged and a replacement may be obtained from your dealer.

3. APPLIANCE INSTALLATION

UNIT LOCATION

The furnace must be installed where outside air supply is sufficient for proper combustion. In airtight houses, it

might be necessary to install an outside air inlet (see details in: «3- INSTALLATION» D- COMBUSTION AIR).

The furnace must be positioned so that the connector is as short as possible in order to minimize the use of 90

elbows.

The owner must ensure a proper installation to allow a safe operation of the appliance.

o

6

Page 7

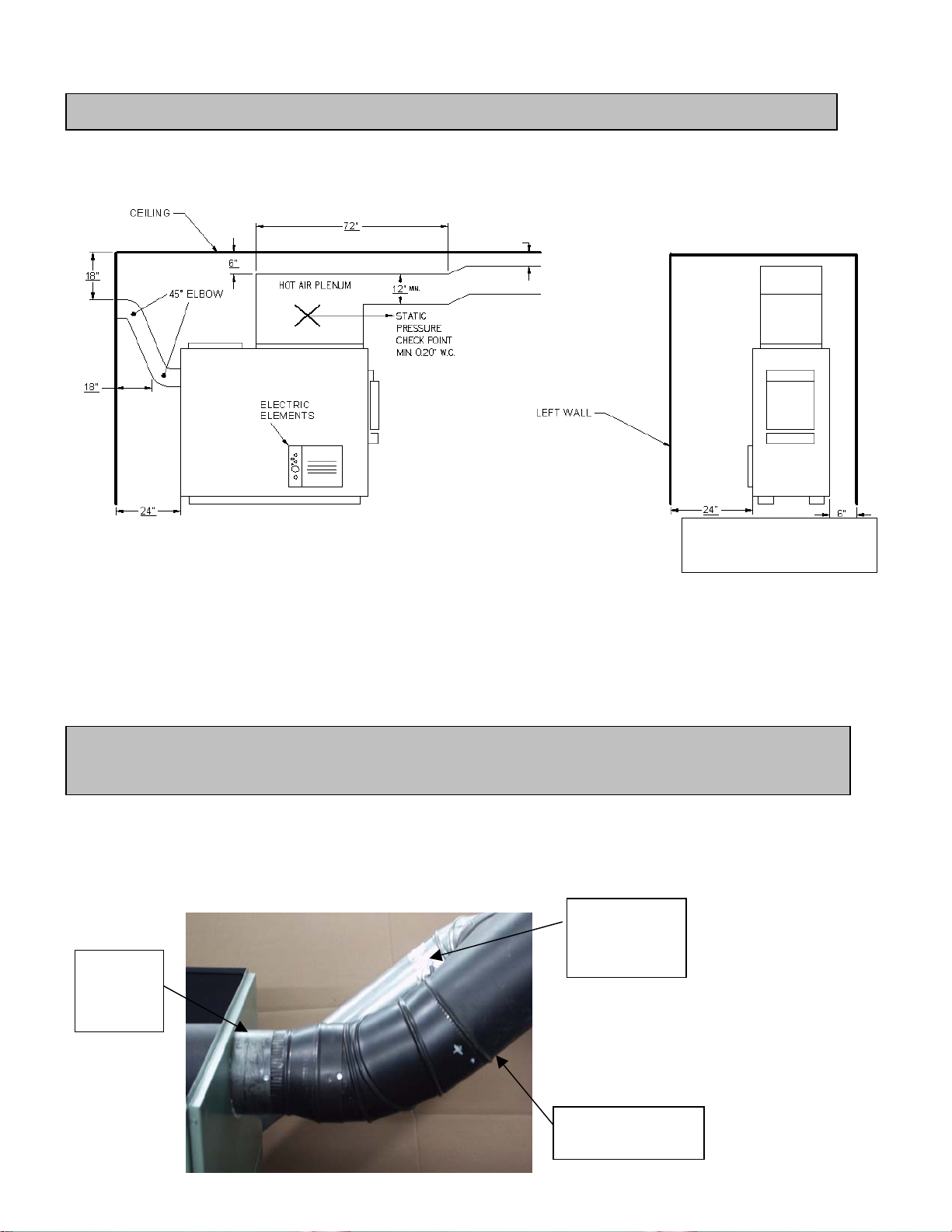

CLEARANCES TO COMBUSTIBLE MATERIALS

N.B. This appliance must be installed in accordance with the instructions on the unit’s certification.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS FOR P SG FURNACES

2”

24” both sides for

PSG5000

N.B. THE AIR RETURN CONDUITS SHOULD BE AT LEAST EQUAL TO THE COLD AIR

PLENUM DIMENSIONS.

PIPE CONNECTOR AND DAMPER

Before proceeding to connection, remove all accessories such as:

scraper, shovel and poker in the evacuation pipe of the furnace.

A 6” diameter chimney listed for use with wood burning heating appliances is recommended for the PSG2000, 7” for

PSG3000-4000 and 8” for the others models. Install the barometric control provided with the furnace. Never install a

manual damper.

WOOD

FLUE

PIPE

7

OIL FLUE

PIPE

(OPTION)

MAIN

COLLECTOR

Page 8

For a proper installation, follow the advices below:

1. All the joints of the evacuation pipe must be secured, using three screws.

Make sure that each screw goes through the inner walls of both connectors (male and female). See

pictures below showing a male-female coupling.

PROPER INSTALLATION UNPROPER INSTALLATION

2. A minimum rise of 1/4 inch per horizontal foot must be respected.

CAUSE RESTRICTION

DAMPER

The barometric control must be adjusted so that the maximum draft measured at the furnace outlet is limited to -0.06

in. w.c. Please note that a draft higher than -0.06 in. H2O could result in an uncontrollable fire. On the other hand,

the minimum draft to be respected is -0.04 in. w.c. in the evacuation pipe on the solid fuel side, no matter what

type of furnace.

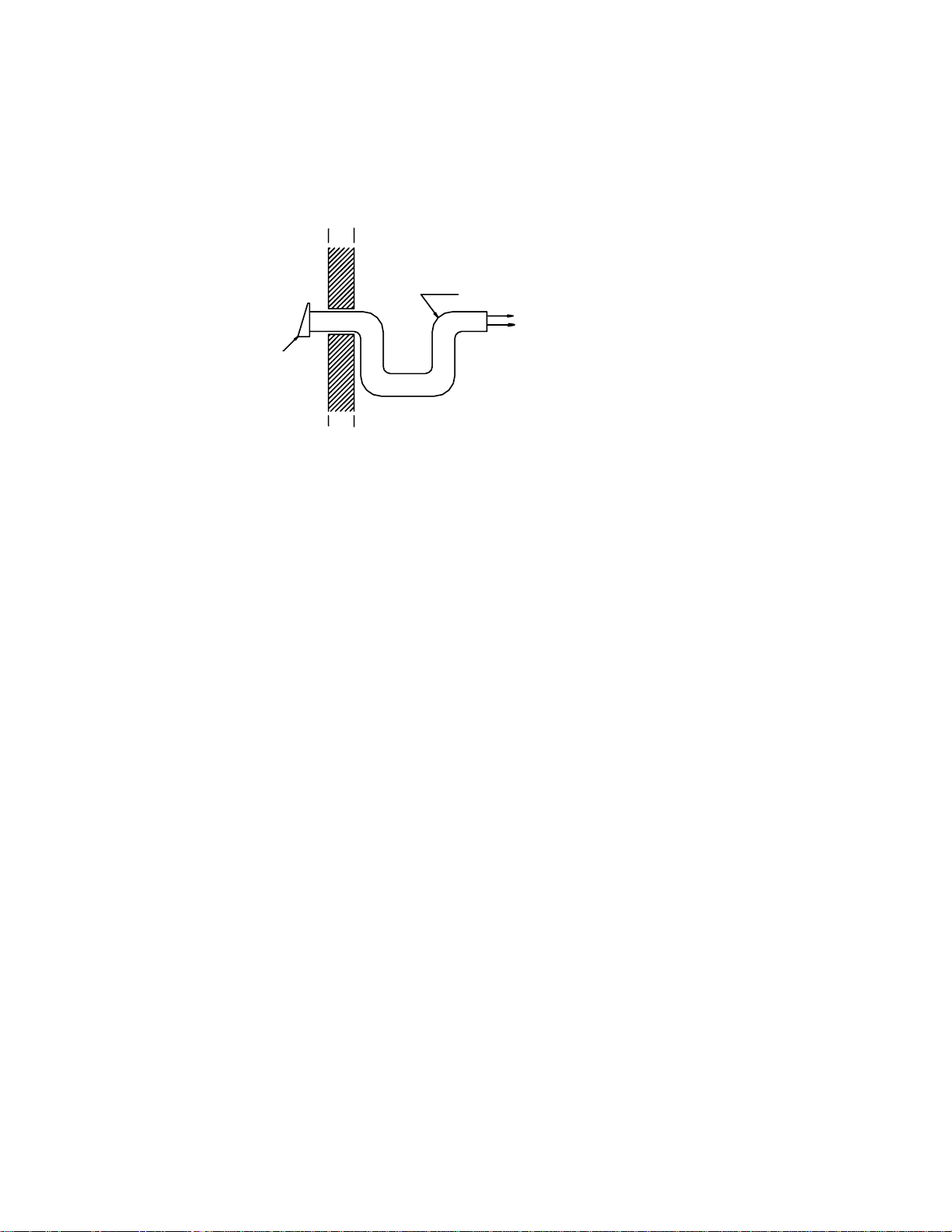

COMBUSTION AIR

In the event that the furnace and the chimney are completely cold, it might be necessary before lighting, to provide

fresh air by opening a door or a window for a few minutes.

Take note that a house constructed or renovated in order to be airtight is liable to lack fresh air which is necessary

for a proper combustion and a proper operation of heating units.

In such a case, when starting up the fire, do not operate appliances which evacuate air outside the house such as:

- Range hood

- Air exchanger

- Cloths dryer

- Bathroom fan

- Ventilated central vacuum system

8

Page 9

y

w

NOTE:

It is recommended to install an outside air inlet of minimum 4” diameter in the room where the heating appliance is

installed (see drawing below). To do so, it is preferable to choose a wall which is not exposed to extreme winds,

according to the conditions surrounding your house.

Insulated conduit full lenght

Free air

entr

Exterior

N

.B. The owner of the furnace is responsible for the room salubrity in case of negative pressure or temporary

negative pressure.

LECTRICAL CONNECTION

E

The following instructions do not supersede the local cod

e.

OOD ONLY

W

Installed limit control on support roper location of the appliance (two holes are predrilled on the edge of

provided on p

the furnace), and connected to the electrical box along with the transformer. Install the servo-motor on the front facade

above the door, on the right side (use pre-drilled holes). The chain that links the air inlet latch to the motor must have a

play of 1/8 in. When there is no call for heat, the air inlet latch must be completely shut and the chain must be affixed

to the servo-motor at “8 o’clock”.

The switch located on the fan limit control activates high speed operation, in either automatic or manual (continuous

operation) modes.

e switch located on the electric unit controls low speed operation, in either ON (continuous operation) or OFF

Th

modes.

ARNING: USE FEEDING WIRES SUITABLE FOR 75OC

W

all

*

Fresh air

intake

W

OOD/ELECTRIC

The limit control is a manual reset thermostatic captor and is located directly inside the electric element (see

WIRING DIAGRAMS). The electric elements must be installed as shown on the diagram. Install the combined limit

control on the support provided, at the determined location. The connections must conform to the diagram.

Install the servo-motor on the front façade above the door, on the right side (use pre-drilled holes). The chain that

links the air inlet latch to the motor must have a play of 1/8 in. When there is no call for heat, the air inlet latch must be

completely shut and the chain must be affixed to the servo-motor at “8 o’clock”.

*

9

Page 10

The switch located on the fan limit control activates the blower at high speed, in either automatic or manual

(continuous operation) modes.

The switch located on the electric unit controls low speed operation, in either ON (continuous operation) or OFF

modes (PSG 3000 or PSG 4000 models only).

WARNING: USE FEEDING WIRES SUITA

* (With all reserves on the minimum combustion air to be increased depending on the type and quality of the

combustible).

BLE FOR 75 C

O

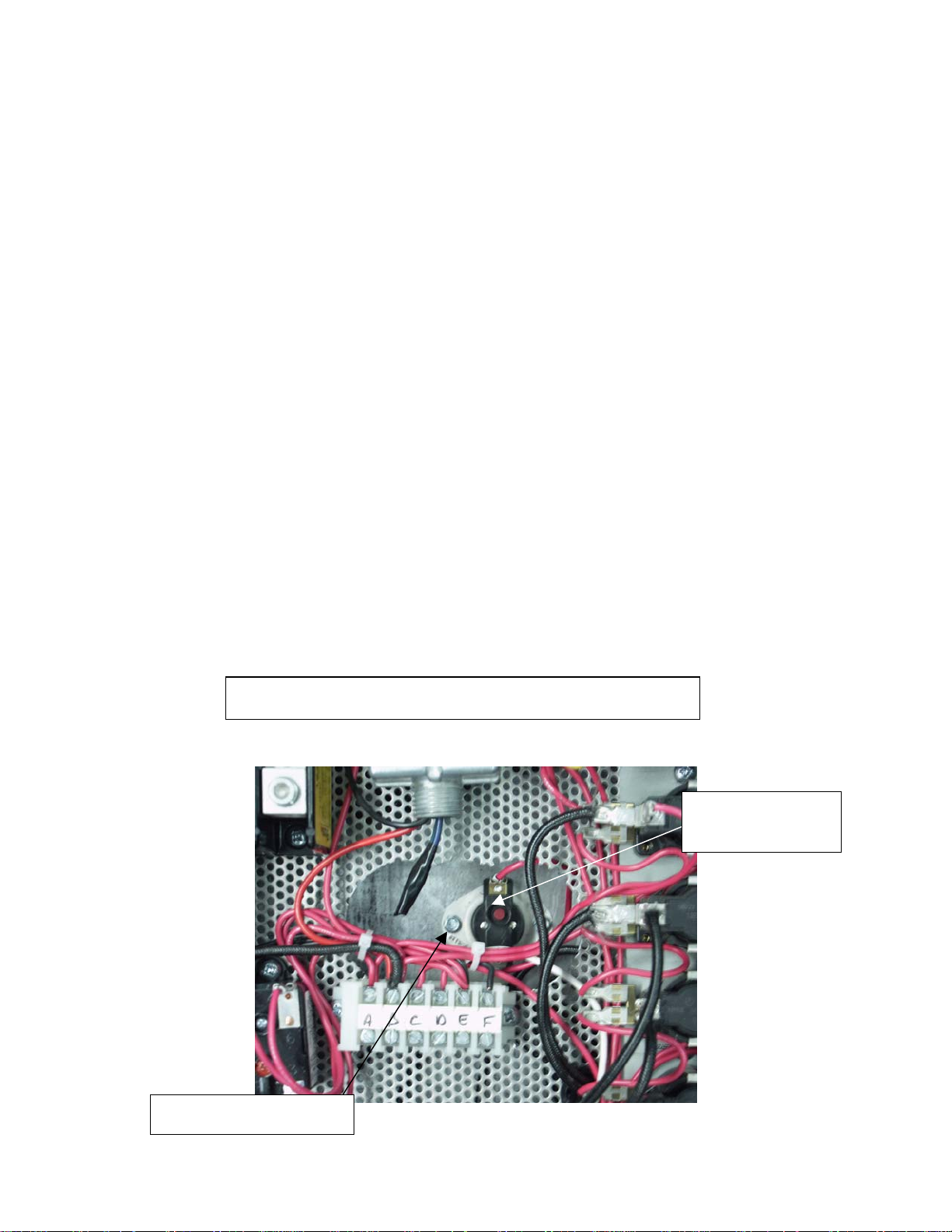

LECTRIC ELEMENT

E

The WOOD / ELECTRIC combin

heating, the other one controls the wood heating. With this system, the electric heating has priority over the wood

heating. When the thermostat activates the electric heating, the air inlet closes down (if opened), the blower starts and

the electric elements are successively activated per block of 5 kW. The system might be equipped with an exterior

thermostat which will allow the last block of elements (5 kW) to start up only when the outside temperature is cold

enough. This will reduce the power of the systems by 5 kW during mild temperature for more comfort.

When the call for electric heating is completed, the wood system will take over if the starting point of the wood

system is superior to the electric system.

So, in normal bi-energy use, you must set the wood system thermostat 2

thermostat.

Take note that this furnace is equipped with a four speed motor. Aside from low speed, three choices are available:

medium-low, medium-high or high.

If the temperature of the element exceeds the limit allowed, the thermodisk will disengage the element. For

reactivation, press the red button “manual reset” of the thermodisk L-170 and find out why the temperature limit has

been exceeded (static pressure too high, fan breakage, dirty filter, etc.)

INSIDE VIEW OF THE ELECTRIC ELEMENT

ed model is installed with two thermostats: one thermostat controls the electric

o

to 3o higher than the electric system

Red button

manual rese

t

Thermodisk L-170

10

Page 11

OUTSIDE VIEW OF THE ELECTRIC ELEMENT

THERMOSTAT

The thermostat must be installed on an inside wall in a location where it is not likely to be affected by the draft

coming from an air outlet. It must be installed at a minimum of 55 inches above the floor.

N.B. The combined wood / electric model must be installed with two thermostats at same level.

FAN CONTROL

The fan control setting varies depending on the type of heating installation. The setting “out of service” is preset at

o

F in factory. This setting should provide a proper operation for most installations. The temperature “in service” is

110

pre-set at 150

It is preferable for a prolonged operation of the blower that the setting “out of service” be low enough. But a setting

“out of service” too low will cause a cold air circulation. To modify the setting, turn the button at the desired position on

the temperature scale.

The adjustment of all controls must be performed by a qualified technician. The controls setting and the blower

speed must conform to the recommendations of the “Warm Air Heating and Air Conditioning National Association”. To

obtain a continuous air circulation during summer, push the manual switch of the limit control from the “automatic”

position to the “manual or summer” position.

The switch located below the limit control or on the electric unit, controls the low speed either at the “on” position or

the “off” position. For a better efficiency we recommend to leave the high speed on automatic(wood side fan limit

control).

o

F.

11

Page 12

4. OPERATING INSTRUCTIONS

Control system

On the wood furnaces only, the thermostat controls the air inlet damper. When the thermostat calls for heat, the

damper opens and the fire burns up. When the furnace gets hot enough, the combined limit control activates the

blower motor at the speed selected for wood heating.

The chain that links the air inlet damper to the motor must have a play of 1/8 inch. When there is no call for heat,

the air inlet damper must be completely closed and the chain must be affixed to the servo-motor at “8 o’clock”.

* (With all reserve on the minimum air to be increased depending on the type and quality of the combustible).

LIGHTING:

1. Open the door

Note: In the case that there is a bed of coals in the bottom of the furnace, go to step b) Pre-heating.

2. Place one or two dry kindlings at the front of the furnace.

3. Place newspaper strips on top of the kindlings.

4. Cover the newspaper with more kindlings and small pieces of dry wood.

5. Add newspaper strips, then light the fire a low as possible and leave the door 1/2" (13 mm) opened. If you fail

lighting the fire, you might experience a back draft through the air inlets.

PREHEATING

*

1. Once the kindling is well ignited or the coals revived, put 2 or 3 fire logs in such a way that the flames can interlace

between the logs then close the door. It is important to respect these loading sequences so that the wood will burn

from the front to the back of the furnace.

2. Wait 15 to 20 minutes, then proceed with loading the furnace.

12

Page 13

HEATING

1. When loading the furnace, lower the kindled pieces of wood and place them at the center of the combustion

chamber before adding new logs.

2. Do not overload. Air must circulate freely in the upper part of the furnace in order to obtain an efficient operation of

the appliance. Please note that a small hot fire will produce much less residues than a large smouldering one.

IMPORTANT: DURING THE HEATING PROCESS, REMOVE THE ASHES AND WOOD THAT COULD

OBSTRUCT THE 1/4" (6.4 mm) HOLE LOCATED BELOW THE DOOR INSIDE THE FURNACE.

PROCEDURE TO OPEN THE LOADING DOOR

TO MINIMIZE THE RISK OF A BACK DRAUGHT OPEN THE DOOR 1”

AND WAIT ABOUT 10 SECONDS BEFORE OPENING COMPLETELY.

THE PURPOSE IS TO STABILIZE THE PRESSURE INSIDE THE FURNACE.

EARLY SIGNS OF OVERFIRED FURNACE

1. Roaring fire.

2. Chimney connector is glowing red.

3. Extreme heat coming from the furnace. If this occurs,

completely, and wait until the glow has completely subsided.

DO NOT OPEN THE DOOR

, shut-off the air inlet opening

ALWAYS KEEP THE DOOR AND THE ASH DRAWER CLOSED

(except for lighting and maintenance).

WOOD AS HEATING FUEL

We recommend that you burn dry wood only.

There are two important factors to be considered when choosing a type of wood: the moisture content and the wood

density. Hardwood, such as maple, oak and beech will provide better results because of the high density and minimal

tar produced during combustion. It is highly recommended to use wood that has been dried at least six months.

not use coal as heating fuel in this appliance.

Do

13

Page 14

Whenever a high rate of smoke is noticed in the room, you must:

1. Open doors and windows.

2. Make sure the furnace door is closed as well as the damper (if necessary, lower the thermostat starting point or

undo the chain of the damper and close manually the barometric draft control).

3. When the furnace has cooled down, inspect the chimney to detect obstructions and consult a specialist to

determine the cause.

CARBON MONOXYDE IS A LETHAL GAS (ODOURLESS AND COLOURLESS), WHICH YOU MUST

BEWARE OF.

CHIMNEY FIRES

This might occur when the fire gets extremely hot. Burning cardboard, branches or pieces of wood can ignite the

creosote residue accumulated in the evacuation flue system. The usual signs are:

1. Rumbling

2. The flue gets extremely hot

3. Flames are coming out of the chimney

In case of a chimney fire, first call your local fire department and sprinkle the roof around

the chimney with water.

Make sure that the furnace door is closed as well as the damper (if necessary, lower the thermostat starting point or

release the chain from the damper and CLOSE the barometric draft control manually).

If the fire gets uncontrollable due to an improper use or because the draft is too strong, follow the same procedure

as in a chimney fire except that you will have to OPEN manually the barometric draft control.

LOCAL FIRE DEPARTMENT.

Phone number: ___________________________________

14

Page 15

5. MAINTENANCE

MAINTENANCE OF THE EXCHANGERS

The evacuation pipe and the exchangers should be inspected regularly during the burning season. Using the

scraper, clean the three exchanger pipes.

INSTRUCTIONS

o

Wait until fire is completely out before cleaning.

1

o

Remove the smoke pipe connector from the furnace.

2

o

Inspect the furnace’s heat exchangers (rectangular tubes) through the smoke outlet for creosote accumulation.

3

o

Using the supplied scraper, clean the heat exchangers and the combustion chamber and remove creosote residues.

4

o

Reassemble the smoke pipe connector.

5

CHIMNEY MAINTENANCE

One of the most efficient methods is to sweep the chimney, using a hard brush. Brush up and down. Soot and

creosote residue will come off the inside surface and fall at the bottom of the chimney where it can be removed easily.

The chimney must be checked regularly and if creosote has accumulated, it must be removed. Cleaning on a

monthly basis should be sufficient during the coldest months.

Smoke flue inspection

- The smoke flue should be inspected regularly during the heating season.

- If possible, the smoke flue should be dismantled and cleaned.

- The flue should be inspected to detect any defect.

- If no defect is noticed, put the flue back in place; otherwise, it must be replaced.

- Use only wood as a combustible.

- Seasoned hard wood logs 18” to 22” long are recommended as a combustible.

Regular maintenance is required for safe and efficient operation of a controlled-combustion heating system. Chimney,

gaskets and smoke pipes must remain in good working condition. Change the air filter regularly, with the same type

and same size.

MAINTENANCE OF THE BLOWER MOTOR

The two bearings of the motor must be lubricated once a year using non detergent SAE 20 oil.

DO NOT OVERLUBRICATE

15

Page 16

FILTERS

The furnace must not be operated without the filters. In order to operate a slow combustion heating system

efficiently and safely, you have to ensure a regular maintenance. This means that the chimney, the joints and the flue

must be in good condition. The air filters must be replaced regularly. Use the same size and same type as the original

filters.

DOOR GASKET MAINTENANCE

It is important to maintain the door gasket in good condition. After a while, the gasket might sag; a door adjustment

may be then required.

6. REPLACEMENT PARTS

Your PSG furnace is designed to burn clean and required little maintenance. It’s recommended conduct a visual

inspection at least once a month to uncover that any damage on the unit. Repairs must be done as soon as possible

with the original parts. You can find a complete list of replacement parts on our website at

GASKET

We recommend to replace gasket that seal the door once a year, in order to maintain a good control of the combustion

for maximum efficiency and security. To replace your door gasket, remove the old gasket and glue. Clean the surface

thoroughly, apply glue sold for that particular use, and put the new gasket onto the door. Wait for at least 2 hours

before lighting your furnace.

www.psg-distribution.com.

16

Page 17

7. ELECTRIC DIAGRAMS FOR UNITS BUILT FROM 2005

WOOD-ONLY FURNACES

FAN LIMIT HONEYWELL L6064(MOTOR (G-10) 4 SPEED AND (G-12) 2 SPEED)

HONEYWELL

L6064

FAN

LINE

LIMIT

LOAD

HIGH LINELOW

ON 150°F

OFF 110°F

LIMIT 250°F

THERMOSTAT SERVO-MOTOR

24 V.A.C.24 V.A.C.

BLUE

RED

BLACK TRANSFO

JUNCTION BOX

BLUE

ON

1

2

SWITCH

3

OFF

BLACK

L1

BLACK

120 V.A.C.

WHITE

L2

BLOWER

4 SPEED

MOTOR

BLACK

WHITE

THERMINAL

BOARD

120 V.A.C.

TRANSFORMER

24 V.A.C.

MOVE THIS WIRE

TO CHANGE

MOTOR SPEED

WHITE

RED

BLACK

HIGH

MED HIGH

MED LOW

LOW

REVISION JUNE 17TH 2005

COMMUN

Page 18

WOOD/ELECTRIC FURNACES

FAN LIMIT HONEYWELL L6064(MOTOR (G-10) 4 SPEED AND (G-12) 2 SPEED)

ELEMENTS

HONEYWELL

L6064

FAN

LINE

B

POWER

BLOCK

RELAY

LOW LINEHIGH

E

1

LIMIT

LOAD

A C

BLACK

BLACK

ON 150°F

OFF 110°F

LIMIT 250°F

TRANSFO

120V

24V

20VA

POWER

BLOCK

E

240V

L1

BREAKER

1

6

BLOWER

4 SPEED

MOTOR

15 KW @ 30KW

S4S3

S2 S5

S6S1

CONNECTORS INDENTIFICATION OF THE SEQUENCER

N L2

20 A

COMMAND

BLOCK

COMMAND

BLOCK

POWER

BLOCK

TERMINAL

HIGH

MED HIGH

MED LOW

LOW

COMMON

REVISION JUNE 16TH 2005

25 KW OR 30 KW ONLY

BLACK

BLACK/RED

L -170 RESET

RELAY

6

MOVE THIS WIRE

TO CHANGE MOTOR SPEED

31 2 45

TRANSFO

240V

24V

40VA

DACB

FAN

1

2

3

FE

768

COIL

24V

COMMAND

4

BLOCK

7

A

SEQUENCER

S3

S1

S1

S2

S3S1

S2

S1

S3

S1

S1

S3

S1

RELAY

POWER

BLOCK

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

12 78

RELAY

3456

COMMAND

BLOCK

CONTACTOR

40 A IND/50A RES

PER POLE

600 V.A.C. MAX.

S4

S5

S5

S4

S4

S4

S5 S6

POWER

B

S6

S6

S6

S6

S6S1

S6

S6

BLOCK

25 KW OR 30 KW ONLY

30 KW ONLY

7

8

BLOCK

COMMAND

1

WOOD

THERMOSTAT

2

3

ELECTRIC

THERMOSTAT

4

5

SERVO

MOTOR

6

Page 19

PSG5000 WOOD-ONLY FURNACES

FAN LIMIT HONEYWELL L6064(MOTOR (G-12) 2 SPEED)

HONEYWELL

L6064

FAN

LIMIT

ON 150°F

OFF 110°F

LIMIT 250°F

HONEYWELL

L6064

FAN LIMIT

THERMOSTAT SERVO-MOTOR

24 V.A.C.24 V.A.C.

JUNCTION BOX

FAN

1

2

3

FAN

1

2

3

WHITE

BLACK

120 V.A.C.

TRANSFORMER

24 V.A.C.

LINE

BLACK

LOW HIGH

RED

LOAD

LINE

BLACK

LINE LOAD

LINELOW HIGH

RED

RED - HIGH SPEED

BLACK - LOW SPEED

WHITE - COMMON

WHITE

L1 - BLACK

120 V.A.C. OR 240 V.A.C.

L2 - WHITE

BLOWER

2 SPEED

MOTOR

REVISION

JUNE 21ST 2005

RED - HIGH SPEED

BLACK - LOW SPEED

WHITE - COMMON

2 SPEED

MOTOR

Page 20

HONEYWELL

L6064

FAN LIMIT

LINE

ON 150°F

ELEMENTS

OFF 110°F

LIMIT 250°F

LOAD

HIGHLOW

LINE

E

240V

ABC

BLOCK

RELAY

24V

BLACK

1

20VA

BLOWER

TRANSFO

120V

BLACK

POWER

E

20 KW @ 30KW

S2

S1

CONNECTORS INDENTIFICATION OF THE SEQUENCER

S4S3

S5

S6

POWER

BLOCK

NL1 L2

COMMAND

1

BLOCK

COMMAND

6

BLOCK

COMMAND

BLOCK

25KW OR 30 KW ONLY

20 A

BREAKER

POWER

BLOCK

RED - HIGH SPEED

WHITE - COMMON

BLACK - LOW SPEED

RELAY

6

L-170 RESET

A B

32 41

PSG5000 WOOD/ELECTRIC FURNACES

FAN LIMIT HONEYWELL L6064(MOTOR (G-12) 2 SPEED)

HONEYWELL

CONTACTOR

COIL

24V

40 A IND/50A RES

PER POLE

600 V.A.C. MAX.

RELAY

7

POWER

A

BLOCK

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

ELECTRIC

THERMOSTAT

COMMAND

4

BLOCK

SEQUENCER

S3

S1

S1

S2

S3

S1

S1

S2

S1

S3

S1

S1

S3

S1

S5 S6

18

RELAY

#1

3245

S4

S5

S5

S4

S4

S4

S6

S6

S6

S6

S6

S6

S6

7

6

910

POWER

B

BLOCK

7

8

BLOCK

COMMAND

25KW OR 30 KW ONLY

187

2

RELAY

#2

3 456

30 KW ONLY

TRANSFO

240V

24V

40VA

FAN

1

2

3

C

DFE

65

87

3

4 4

1

WOOD

THERMOSTAT

2

SERVO

MOTOR

L6064

POWER

BLOCK

RELAY

20 KW @ 30KW

E

1

HIGHLOW LINE

BLACK

BLACK

ON 150°F

OFF 110°F

LIMITFAN

LIMIT 250°F

ELEMENTS

POWER

E

LOADLINE

BLOCK

240V

L2NL1

ACB

TRANSFO

120V

24V

20VA

BLOWER

COMMAND

1

BLOCK

COMMAND

6

BLOCK

COMMAND

BLOCK

25KW OR 30 KW ONLY

20 A

BREAKER

L -170 RESET

RELAY

6

POWER

BLOCK

RED - HIGH SPEED

WHITE - COMMON

BLACK - LOW SPEED

12 345678

TRANSFO

240V

24V

40VA

B

A FCDE

POWER

BLOCK

5 KW ELEM.

FAN

5 KW ELEM.

1

2

5 KW ELEM.

3

5 KW ELEM.

5 KW ELEM.

RELAY

COIL

24V

7

S1

A

S1

S1

S1

S1

S1

S1

S1

21

3 4

3

CONTACTOR

40 A IND/50A RES

PER POLE

600 V.A.C. MAX.

COMMAND

4

BLOCK

SEQUENCER

S3

S2

S3

S2

S3

S3

RELAY

ELECTRIC

THERMOSTAT

S6

S4

S5

S6

S5

S6

S6

S4

S6

S4

S6

S6

S4

S6

S5

87

56

POWER

B

BLOCK

25KW OR 30 KW ONLY

30 KW ONLY

7

8

BLOCK

COMMAND

20

Page 21

8. ELECTRIC DIAGRAMS FOR UNITS BUILT BEFORE 2005

WOOD ONLY FURNACES PSG 4000 & 4500

BELT-DRIVE G12 MOTOR

WHITE RODGERS

ON 150°F

OFF 110°F

FL

LIMIT 250°F

HONEYWELL

L4064

FL

WHITERED

THERMOSTAT

24 V.A.C.

15 MARS 1990

SERVO-MOTOR

24 V.A.C.

RED

BLACK

WHITE

JUNCTION BOX

ON

NOIR

L1

120 V.A.C.

SWITCH

OFF

BLANC

NOIR

120 V.A.C.

TRANSFORMER

24 V.A.C.

RED - HIGH SPEED

WHITE - COMMON

BLACK - LOW SPEED

2 SPEED

MOTOR

L2

BLOWER

21

Page 22

WOOD ONLY FURNACES PSG 5000

BELT-DRIVE G12 MOTOR

THERMOSTAT

24 V.A.C.

SERVO-MOTOR

24 V.A.C.

JUNCTION BOX

WHITE

BLACK

120 V.A.C.

TRANSFORMER

24 V.A.C.

WHITE RODGERS

FL

RED

BLACK

HONEYWELL

ON 150°F

OFF 110°F

L

BLACK

F

LIMIT 250°F

RED

WHITE

L4064

F

L

NOIR

L1

HONEYWELL

L4064

F

NOIR

L

BLANCROUGEROUGE

120 V.A.C. OR 240 V.A.C.

L2

BLOWER

MOTOR

BLACK

WHITE

1 SPEED

MOTOR

120/240

MARCH 15TH 1990

IMPORTANT: A BREAKER IS MANDATORY FOR 240 VOLT

VERIFY CONNECTIONS OF THE MOTOR 3/4 H.P.

IF CONNECTED ONTO THE RIGHT CIRCUIT(120/240)

FOR 240 VOLT ONLY

240 V.A.C.

TRANSFORMER

24 V.A.C.

22

MOTOR

BLACK

1 SPEED

120/240

MOTOR

WHITE

Page 23

WOOD/ELECTRIC FURNACES PSG 4000 & 4500

BELT-DRIVE G12 MOTOR

POWER

BLOCK

RELAY

LOW SPEED

SWITCH

BLACK

BLUE

BLACK

E

BLACK

1

WHITE RODGERS

L

RED

WHITE

BLACK

BLACK

WHITE

TRANSFO

120V

24V

20VA

F

ON 150°F

OFF 110°F

LIMIT 250°F

RED

DCBA

BLOWER

RED

ELEMENTS

E

240V

1

2 SPEED

MOTOR

HONEYWELL

L4064

POWER

BLOCK

L2NL1

COMMAND

BLOCK

COMMAND

6

BLOCK

LF

WHITE

BLACK

110 VOLT

MOTOR 3/4 H.P.

FOR 240 V

20 A

BREAKER

POWER

BLOCK

HIGH SPEED - RED

COMMON - WHITE

LOW SPEED - BLACK

RELAY

6

TRANSFO

240V

24V

40VA

CONTACTOR

COIL

24V

RELAY

7

POWER

BLOCK

A

5 KW ELEM.

F- 110L- 160

FEDCBA

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

40 A IND/50A RES

PER PÔLE

600 V.A.C. MAX.

COMMAND

4

BLOCK

SEQUENCER

POWER

B

BLOCK

7

8

BLOCK

COMMAND

1

25 KW ONLY

WOOD

THERMOSTAT

2

3

ELECTRIC

THERMOSTAT

7812

RELAY

4

5

SERVO

MOTOR

3456

6

15 KW @ 30KW

COMMAND

BLOCK

8712 3456

23

Page 24

WOOD/ELECTRIC FURNACES PSG 5000 40KW @ 60KW

BELT-DRIVE G12 MOTOR

WHITE RODGERS

F

L

BLACK

RED

BLACK

WHITE

C AB

IMPORTANT:

IT IS MANDATORY TO CHANGE THE

TRANSFORMER 120-24 FOR A 240-24

IF YOU USED 3/4 H.P. MOTOR ON 240 V

TRANSFO

BLACK

POWER

BLOCK

RELAY

120V

E

24V

BLACK

1

20VA

20 KW @ 30KW

ON 150°F

OFF 110°F

LIMIT 250°F

BLOWER

RED

HONEYWELL

L4064

F L

ELEMENTS

POWER

E

BLOCK

240V

NL1

COMMAND

1

BLOCK

COMMAND

6

BLOCK

COMMAND

BLOCK

F

ON 150°F

OFF 110°F

LIMIT 250°F

AC

BLOWER

RED

ELEMENTS

E

240V

HONEYWELL

L4064

F

WHITE

POWER

BLOCK

L2NL1

COMMAND

1

BLOCK

COMMAND

6

BLOCK

COMMAND

BLOCK

L

BLACK FROM

TRANSFO

110 VOLT LINE

3/4 H.P. MOTOR

240 V

BREAKER

WHITE

BLACK

20 A

POWER

BLOCK

TRANSFO

240V

24V

40VA

L -160

RELAY

6

BA

32

14

CONTACTOR

COIL

24V

40 A IND/50A RES

PER POLE

600 V.A.C. MAX.

COMMAND

4

BLOCK

SEQUENCER

RELAY

7

POWER

A

BLOCK

5 KW ELEM.

F -110

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

EDC

F

5 KW ELEM.

2

1

POWER

B

BLOCK

7

8

BLOCK

COMMAND

78

RELAY

65

43

8765

3

ELECTRIC

THERMOSTAT

4

WHITE RODGERS

L

BLACK

RED

BLACK

WHITE

B

IMPORTANT:

IT IS MANDATORY TO CHANGE THE

TRANSFORMER 120-24 FOR A 240-24

IF YOU USED 3/4 H.P. MOTOR ON 240 V

TRANSFO

120V

BLACK

POWER

E

BLOCK

RELAY

24V

BLACK

1

20VA

20 KW @ 30KW

RELAY

CONTACTOR

COIL

24V

40 A IND/50A RES

PER PÔLE

600 V.A.C. MAX.

BLOC

4

COMMANDE

SEQUENCER

7

A

2

POWER

B

BLOCK

7

8

BLOCK

COMMAND

781

1

WOOD

THERMOSTAT

2

SERVO

MOTOR

RELAY

3

654

78

RELAY

651243

109

BLACK FROM

TRANSFO

WHITE

110 VOLT LINE

3/4 H.P. MOTOR

240 V

L2

20 A

RELAY

6

BREAKER

POWER

BLOCK

WHITE

BLACK

1 42 3 5

L- 160

TRANSFO

240V

24V

40VA

DBCA

POWER

BLOCK

5 KW ELEM.

F- 110

5 KW ELEM.

5 KW ELEM.

5 KW ELEM.

E F

5 KW ELEM.

7 8

6

3

ELECTRIC

THERMOSTAT

4

Page 25

WOOD ONLY FURNACES PSG 2000-3000-4000

DIRECT-DRIVE G10 MOTOR

WHITE RODGERS

FL

ON 150°F

OFF 110°F

LIMIT 250°F

RED

HONEYWELL

L4064

LF

BLACK FROM

TRANSFO

THERMOSTAT

24 V.A.C.

SERVO-MOTOR

24 V.A.C.

RELAY

BLACK

BLACK TRANSFO

RED

JUNCTION BOX

RED

ON

1

3

2

OFF

SWITCH

BLACK

4

2

5

31

L1

120 V.A.C.

L2

BLACK

BLOWER

4 SPEED

MOTOR

TERMINAL

WHITE

BLACK

BOARD

120 V.A.C.

TRANSFORMER

24 V.A.C.

WHITE

BLACK

RED

HIGH

MED HIGH

MED LOW

REVISION MAY 20TH 1994

LOW

COMMUN

25

Page 26

WHITE RODGERS

LF

BLACK

WHITE

RED

BLACK

B

C

POWER

BLOCK

RELAY

BLACK

E

BLACK

1

A

ON 150°F

OFF 110°F

LIMIT 250°F

TRANSFO

120V

24V

20VA

RED

WOOD/ELECTRIC FURNACES PSG 2000-3000-4000

DIRECT-DRIVE G10 MOTOR

HONEYWELL

L4064

F

L1

WHITE

ELEMENTS

POWER

E

BLOCK

240V

1

6

L

BLACK TO

TRANSFOMER

L2N

COMMAND

BLOCK

COMMAND

BLOCK

20 A

BREAKER

POWER

BLOCK

L -170 RESET

RELAY

6

COIL

24V

TRANSFO

240V

24V

40VA

FAN

5

FAN

RELAY

A

CB D

E

F

RELAY

7

A

POWER

BLOCK

ELEM. 5 KW

ELEM. 5 KW

ELEM. 5 KW

ELEM. 5 KW

ELEM. 5 KW

4

SEQUENCER

CONTACTOR

40 A IND/50A RES

PER POLE

600 V.A.C. MAX.

COMMAND

BLOCK

POWER

B

BLOCK

25 KW ONLY

30 KW ONLY

7

8

BLOCK

COMMAND

BLOWER

4 SPEED

MOTOR

15 KW @ 30KW

TERMINAL

BOARD

HIGH

MED HIGH

MED LOW

LOW

COMMUN

COMMAND

BLOCK

FAN RELAY

POWER

BLOCK

D

TO CHANGE MOTOR SPEED

2

5

3

E

POWER

BLOCK

MOVE THIS WIRE

4

1

POWER

BLOCK

1 2 4365

POWER

BLOCK

A

B

2 1

3 456

78

87

RELAY

1

WOOD

THERMOSTAT

2

3

ELECTRIC

THERMOSTAT

4

5

SERVO

MOTOR

6

Page 27

9. TECHNICAL SPECIFICATIONS

A

B

C

D

E

F

G

PIPES

WEIGHT

2000 3000 4000 4500 5000

45 ¼" 47" 50" 52 ½" 54 ½"

23 ½" 25 ½" 29 ½" 33 ½" 54"

45 ½" 47 ¼" 48" 48" 56 ¾"

15 ⅞" 15 ⅞" 19" 19" 19 ¾"

26 ⅜" 28" 28" 30" 31 ½"

22 ½" 24 ½" 28 ½" 32 ½" 51 ⅛"

40 ½" 41 ¼" 42" 42" 49 ½"

7" 8" 8" 8" 8"

445 540 600 660 1200

GENERAL TECHNICAL DATA

MODEL BELT DRIVE DIRECT DRIVE

FAN MOTOR SPEED

H

2000 N/A G-10 1/3 4 950 68 70000 0,2 0,4 11 x 20

3000 N/A G-10 1/3 4 1300 78 110000 0,2 0,6 12 x 24

4000 N/A G-10 1/3 4 1300 128 180000 0,2 0,6 12 x 24

4000 G-12 3/4 2 N/A 1800 93 180000 0,2 0,8 12 x 24

4500 G-12 3/4 2 N/A 1800 121 235000 0,2 0,8 12 x 24

5000 G-12 3/4 2 N/A 3600 125 350000 0,2 1,45 20 x 24

(

*

TECHNICAL DATA – ELECTRIC MODE

MODEL OUTPUT

(C.F.M.)

15 KW 950

1300

1800

18 KW 950

1300

1800

20 KW 950

1300

1800

25 KW 950

1300

1800

30 KW 1300

1800

WOOD 15 120

TEMP. VAR.

O

(

F)

50

36

26

60

44

32

67

49

35

83

61

44

73

53

FAN MOTOR SPEED OUTPUT

BTU/HR AMPERES

TOTAL

51195 75 100 4 120/240 3 – 5 KW

61434 87 100 4 120/240 2 – 5 KW, 2 – 4 KW

68260 95 115 3 120/240 4 – 5 KW

85325 115 140 2 120/240 5 – 5 KW

102390 140 170 1 120/240 6 – 5 KW

BREAKER

REQUIRED

(C.F.M.)

FEEDER

GAUGE

TEMP

VAR.

O

F) (WOOD) ( "WATER)

SINGLE PHASE

BTU/

HR

VOLTAGE

STATIC

PRESSURE

2

ELEMENTS

FILTER

(2)

O

QTY

27

Page 28

10. SELECTION CRITERIA (COMBINED WOOD/ELECTRIC FURNACE)

RESIDENTIAL AREA

House including: basement, first floor and second floor (half)

Floor area * New house Existing house

1100 square feet or less PSG 2000 – 15 PSG 2000 – 18 or 20

1100 to 1450 square feet PSG 3000 – 18 PSG 3000 – 20 or 25

1400 to 2000 square feet PSG 4000 – 20 PSG 4000 – 25 or 30

2000 to 3000 square feet PSG 4500 – 25 PSG 4500 – 30

COMMERCIAL AREA

Building including: Walls 14 to 16 feet high

Garage doors, no basement

Floor area

2500 to 3800 square feet PSG 4500 Wood

4000 to 10000 square feet PSG 5000 – 40 or 60

* Consider main floor only.

28

Page 29

11. TROUBLESHOOTING

PROBLEM

1. Sudden drop in heating

performance follows adequate

heating from first loadings.

2. Insufficient heat from first loadings,

low draft

3. Poor heating in the rooms while

hot air plenum and furnace are hot.

4. Furnace burns too much wood.

5. Fan starts too late.

6. Creosote accumulation, very

average performance.

7. Hot air plenum remains barely

warm while furnace in full operation.

CAUSES

Ash accumulation at lower intake

blocks combustion air intake and

causes deposits in heat exchanger

and flue pipes.

Wrong setting of draft regulator

(opening too large).

Restriction in chimney flue (excessive

length of chimney connector, rightangled elbows).

Inadequate duct installation.

Insufficient static pressure.

Unbalanced system (too many hot air

outlets for too few cold air intakes).

The thermostats controlling the air

combustion damper is located too

close to cold air and demands heat

continuously.

Wrong setting of air intake register.

Poor building insulation.

Ash drawer left open.

Furnace too small for heating needs.

Unbalanced ventilation system,

insufficient heat near thermostat.

Fan starting temperature is too high.

Cold air return is too cold.

Inappropriate location of fan limit

control in hot air plenum.

Damp wood.

Insufficient draft.

Clogged chimney.

Damp wood.

Too much cold air return in relation to

hot air ducts.

Unbalanced ventilation system.

SOLUTIONS

Clear air intake of any ash

accumulation.

Clean heat exchanger and flue pipes.

Set draft regulator (reduce opening).

Reduce distance between furnace

and chimney and eliminate 90

elbows.

Maximum length: 10 feet.

Tight-angle elbows: maximum 3.

Reposition ducts.

Relocate thermostat.

Adjust chain between damper motor

and combustion air damper.

Balance the ventilation system as to

increase the flow air in room where

thermostat is located.

Lower starting temperature (the fan

limit control is normally set at 150

under certain conditions, this limit

should be reduced.

Reduce the cold air intake.

Relocate fan limit control within the

hot air plenum.

Use dry wood.

Adjust draft regulator.

Clean chimney, chimney connector

and furnace heat exchangers.

Use dry wood.

Redistribute ventilation system.

o

o

F);

IMPORTANT NOTE

WE STRONGLY RECOMMEND CONSULTING A HEATING SYSTEM SPECIALIST

FOR THE INSTALLATION OF A CENTRAL HEATING VENTILATION SYSTEM.

N.B.: STOVE BUILDER INTERNATIONAL INC. IS NOT LIABLE FOR ANY FAULTY INSTALLATION WHICH RENDERS THIS

UNIT INOPERATIVE

29

Page 30

12. DUCTS AND REGISTER MEASUREMENTS

(sample calculations)

SIMPLIFIED METHOD

DISTRIBUTION SYSTEM

Ducts size (heat)

4 inch outlet reduce by 1”

5 inch outlet reduce by 2” Always by 8” thick

6 inch outlet reduce by 3”

N.B.: The main duct must be reduced every 2

outlets.

Ducts specifications (heat)

Dimensions Length Elbow Average equivalence

o

4” 10’ 1 x 90

5” 10’ 1 x 90

6” 10’ 1 x 90

DAMPER

For a 4” warm air outlet: 2” x 10” damper

For a 5” warm air outlet: 2” x 12” damper or 4” x 10”

For a 6” warm air outlet: 2” x 14” damper or 4” x 12”

Max 4,000 Btu

o

o

Max 6,000 Btu

Max 7,000 Btu

HOUSE DIMENSIONS

Example: 28 x 40 bungalow: 1,120 sq. ft.

28 x 40 x 8: 8,960 cu. ft. x 1.8 Ch. air/hr: 16,128 Btu

Exposed walls:

40 + 40 + 28 + 28: 136 x 8: 1,088 cu. ft. x 22: 23,936 Btu

Number of windows:

12 of 3 x 4: 144 x 60: 8,640 Btu

Number of doors:

2 x 3 x 7: 42 x 100:

Non-insulated basement: 25%

Insulated basement: 15%

or 54 Btu per sq. ft.

FOR ELECTRIC ELEMENTS 80%:48,672 Btu or 14,28 kW

TO BE ADDED: House 1 1/2 floor = 25%

House 2 floors = 40%

BEDROOM (for example: 12 x 12)

12 x 12 x 8: 1,152 cu. ft. x 1.8 Ch. air/hr: 2,074 Btu

WARM AIR SYSTEM INSTALLATION

4,200 Btu

52,904 Btu

7,906 Btu

60,840 Btu

Exposed walls:

12 + 12 x 8: 192 x 22: 4,224 Btu

Windows:

3 x 4 x 60

7,018 Btu

720 Btu

30

Page 31

1700, rue Léon-Harmel, Québec (Québec) G1N 4R9

tel. : (418) 527-3060 fax : (418) 527-4311

e-mail : tech@sbi-international.com web site : www.psg-distribution.com

LIMITED LIFETIME WARRANTY

The PSG warranty extends only to the original consumer purchaser and is not transferable. This warranty covers brand new

products only, which have not been altered, modified nor repaired since shipment from factory. Proof of purchase (dated bill of

sale), model name and serial number must be supplied when making any warranty claim to your PSG dealer

This warranty applies to normal use only. Damages caused by misuse, abuse, improper installation, lack of maintenance, over firing,

negligence or accident during transportation are not covered by this warranty.

This warranty does not cover any scratch or discoloration caused by over firing, abrasives or chemical cleaners. Any defect or

damage caused by the use of unauthorized parts or others than original parts void this warranty.

An authorized qualified technician must perform the installation in accordance with the Instructions supplied with this product and

all local and national building codes. Any service call related to an improper installation is not covered by this warranty.

Returned products are to be shipped prepaid to PSG for investigation. If a product is found to be defective, PSG will repair or replace

such defect and reasonable transportation fees will be refund. Repair work covered by the warranty, executed at the purchaser

domicile by an authorized qualified technician requires the prior approval of PSG. Labour cost and repair work to the account of PSG

are based on predetermined rate schedule and must not exceed the wholesale price of the replacement part.

PSG at its discretion may decide to repair or replace any part or unit after inspection and investigation of the defect. PSG may, at its

discretion, fully discharge all obligations with respect to this warranty by refunding the wholesale price of any warranted but

defective parts

PSG shall in no event be responsible for any special, indirect, consequential damages of any nature, which are in excess of the

original purchase price of the product.

DESCRIPTION

Combustion chamber (weldings only) Lifetime 5 years

Perforation caused by rust 5 years n/a

Stainless steel baffle 5 years 1 year

Carbon steel baffle 2 years 1 year

Handle assembly 5 years n/a

Ash drawer Lifetime 1 year

Cast iron parts 5 years 1 year

Ceramic glass (thermal breakage only) 1 year n/a

Paint, refractory bricks, gasket, blower, thermal switch (thermodisc) and

rheostat

Plating 1 year n/a

Shall your unit or a components be defective, contact immediately your PSG dealer. Prior to your call make sure you have the

following information necessary to your warranty claim treatment:

• You name, address and telephone number; • Serial number and model name as indicated on the

• Bill of sale, dealer’s name;

Before shipping your unit or defective component to our plant, you must obtain from your PSG dealer an

Authorization Number. Any merchandise shipped to our plant without authorization will be refused

automatically and returned to sender.

nameplate fixed to the back of your unit;

• Nature of the defect and any relevant information.

WARRANTY APPLICATION

PARTS LABOUR

1 year n/a

31

Loading...

Loading...