Page 1

ZONING SYSTEM DESIGN

Zoning any forced air system is easy once you know a few of the basic rules. The main consideration is to maintain a constant amount of

air ow (CFM) through the HVAC Unit. This needs to occur when only

one zone is open and if the zones are of varying size when the smallest zone is open. The other consideration is not to oversize a duct

system too much in order to maintain adequate velocity and airow

when all zones are open and may be calling for conditioning on those

design temperature days.

The design of the duct system for today’s zoning is an important

factor to a comfortable and efcient zoning system. The number of

zones, along with their size, often determine the best type of design.

There are scenarios for zoning. The rst, which is typically on new

installations where the duct work can be designed for zoning would

be to oversize the ducts for each zone in order to get more air to the

zone when it may be the only one calling. The scenario for all others

would be to use a by-pass damper to relieve the excess air pressure

in the duct system when a minority number of zones are calling.

The reason for each zone duct being the same size is that any zone

could be the only zone calling and therefore that zone must handle

the CFM of the HVAC Unit. When the duct is sized for 2/3 of the total

CFM the smaller size does restrict the airow and forces the air at

a higher pressure and velocity, however it does not increase the air

typically over that static pressure rating of the blower motor, usually

0.5”W.C. This also keeps the air velocity from being noticeably noisy.

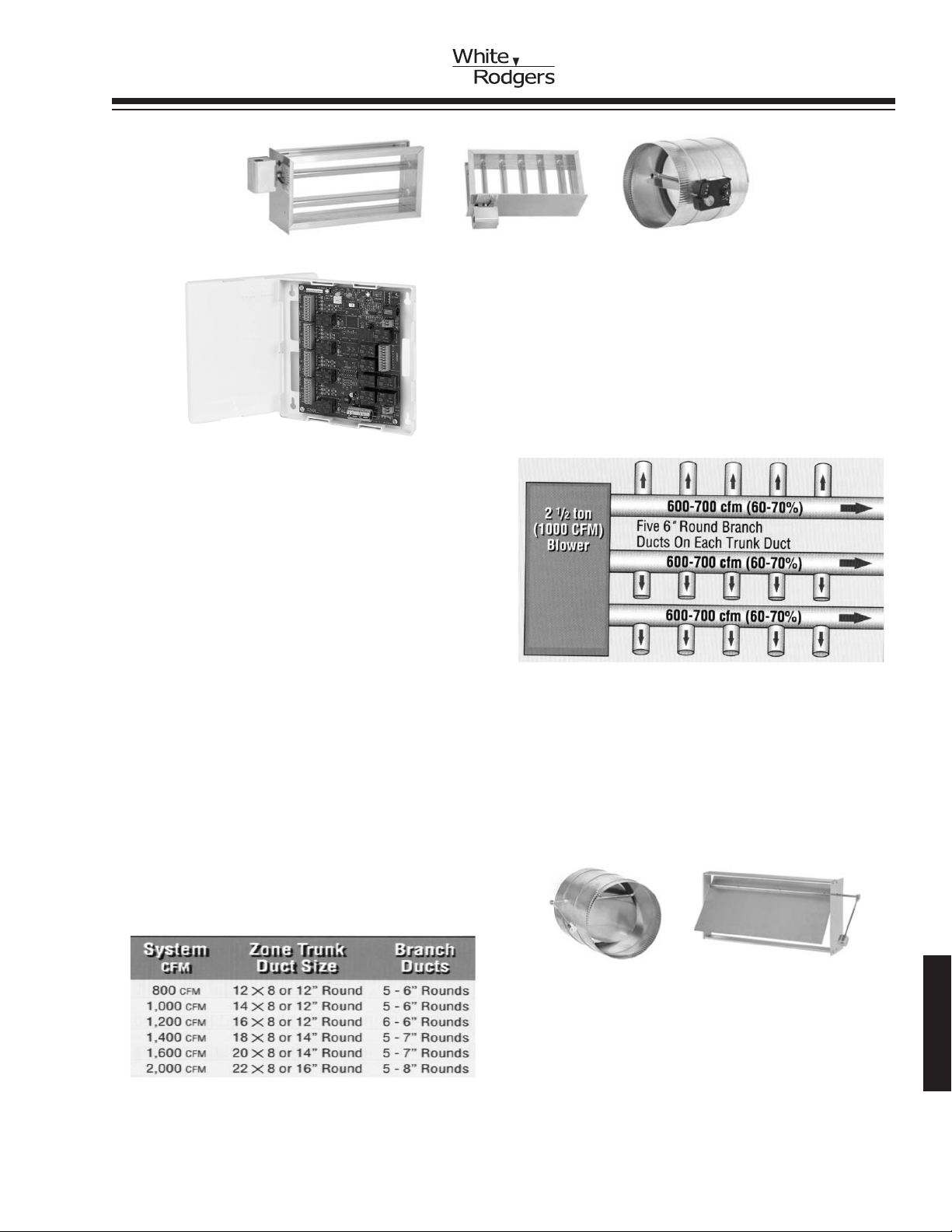

Below is a quick guide to determine the minimum equivalent size of a

zone duct for each size HVAC Unit.

ZONING

DESIGN

In retrot and systems with 4 zones or more, over sizing the ducts is

not practical. In these instances a by-pass damper is used to relieve

the excess air back into the return air duct or dump the air into a

central area of the building, such as a hallway, where often there is

a common return. In this instance try to locate the by-pass air as far

away from the return air intake as possible.

In new installations where ducts are being added it is recommended

to size each zone duct the same and to size the duct for approximately 2/3 of the total HVAC System CFM. This is practical on systems

with 2 or 3 zones and when all zones are approximately equal in size.

This is NOT practical in an installation where 80% of conditioned area

is one zone and 20% is the other zone.

The key to a good zoning system is to deliver the conditioned air to

the calling zone as fast and quietly as possible in order to satisfy the

demand. Whatever air cannot be directed into the zone must then by

by-passed. This develops the formula for calculating the size of the

by-pass damper.

Total CFM - Smallest Zone CFM = By-Pass CFM

Once the amount of by-pass air is known it is just common sense to

size a duct adequately to handle the amount of air. White-Rodgers

has both round and rectangular/square by-pass damper sizes.

Systems over 5 Tons typically are commercial and would use a by-

pass damper to relieve the excess air pressure when the majority of

zones shut down.

www.white-rodgers.com

TECHNICAL HELP

237

Page 2

ZONE 1 CLOSED

DUMPER DAMPER

DUMP ZONE

ZONE 3 CLOSED

ZONE 2 OPEN

ZONING

DESIGN

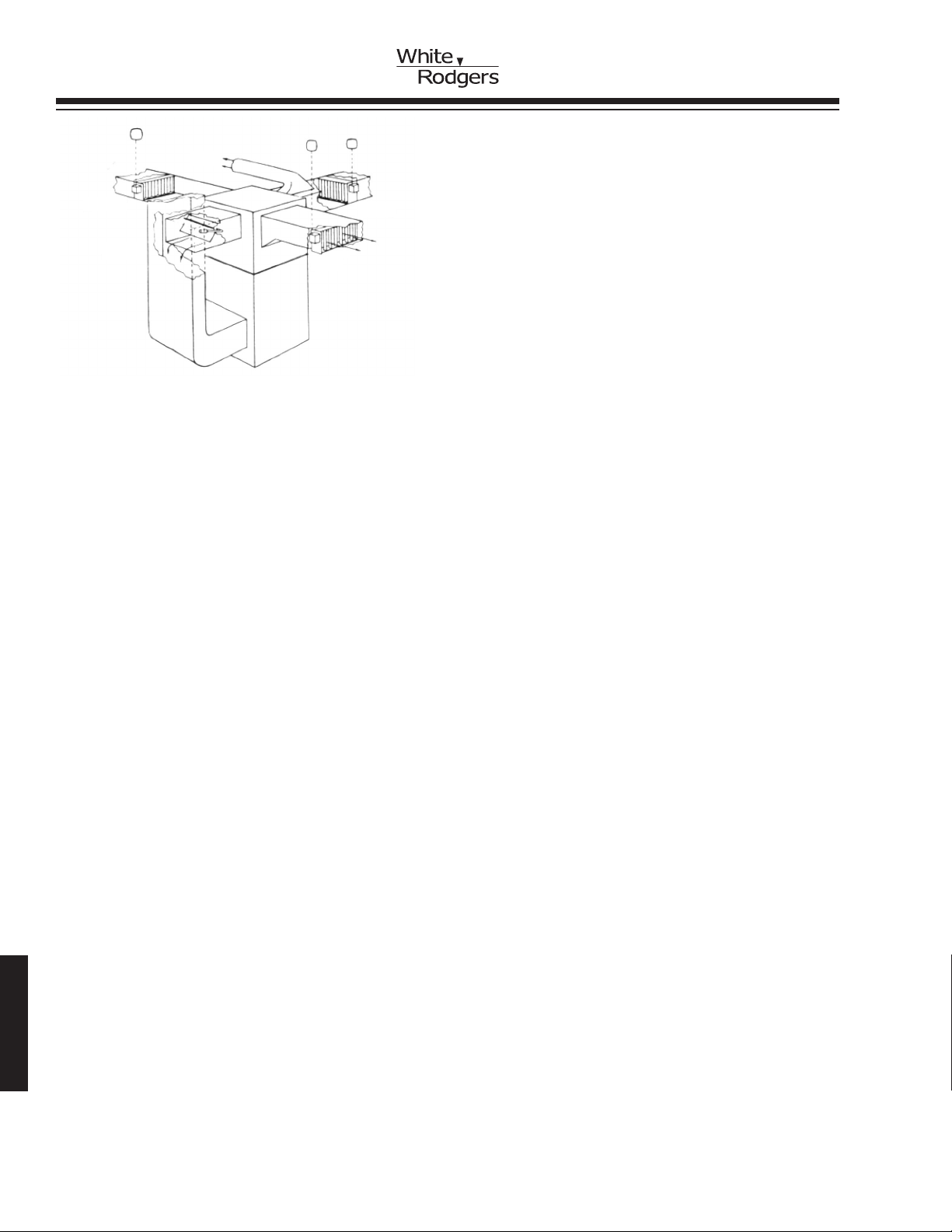

The diagram above shows a typical three zone damper system with

a barometric by-pass, Model CSPRD, between the supply air and return air duct. A round take-off is also shown as an uncontrolled dump

zone delivering air continuously to a non-critical temperature area,

such as a basement or hallway as another method of relieving excess

air. Either a by-pass or a dump zone is used but rarely ever is there a

need for both.

MINIMUM POSITION DAMPER

Another form of by-pass is using minimum position dampers, such as

the CZD and CRDS dampers. Setting the larger zone dampers to a

minimum position can also be a method of relieving excess air pressure. This should be used when only small amounts of air need to be

by-passed as the minimum position air in some cases can cause a

zone to overshoot its comfort zone. Caution must be exercised when

using minimum position dampers for by-pass.

ZONING HEAT PUMPS

Heat Pumps are a very popular form of heating and cooling in the

milder climates of the country. These efcient units use the compressor for both heating and cooling and have a reversing valve that

reverse the ow of refrigerant in order to switch between heating and

cooling modes.

Heat pumps, while very efcient, are also most efcient in milder

climates where often there is more of a cooling demand than a heating demand, such as the southern United States. A heat pump is also

rated based upon its cooling capacity and not the heating capacity

and rely typically on electric resistance heating to supplement the

heat pump in colder weather, often less than 35°F to 40°F. When this

back-up form of heat is used to supplement the heat pump compressor, the cost to heat the home rises dramatically. It is this reason that

zoning should be installed with every heat pump.

Heat pumps with their limited capacity for heating cannot afford to be

run on the colder climates heating the entire home or building. However if the heat pump is zoned, most likely less than the total building

requires heat at any one time. The zone calling typically requires less

than the total BTU capacity of the heat pump, more evenly matching

the heat pumps capacity to the load of the calling zone. By doing so

this lessens the need for the supplemental heat to come on, therefore

providing substantial energy savings.

For example, a typical home may have a 3 Ton (36,000 BTU) heat

pump. The total heating load for the home at heating design temperature maybe 60,000 BTUs or even more. Obviously with only 36,000

BTUs the heat pump can never keep up at design temperatures.

However during milder temperature days, those above 45°F, the heat

pump will often be more than adequate.

Heat pumps most efcient outdoor temperature, typically 45°F to 50°F

and the amount of BTUs produced by the heat pump decreases as

the temperature moves further below this temperature. This is when

the supplemental electric resistance heat is often needed. As the

heat pump compressor heats the air, the electric resistance heaters,

located downstream of the heat pump coil, can come on to supplement the heat pump air. However if the system is zoned and heating

is required for typically only one room or zone, the capacity of the

heat maybe equal to or greater than the heating load of that zone

and even as the output of the heat pump diminishes as the outdoor

temperature falls, the capacity of the heat pump, (BTU output) is

adequate for the zone(s) calling therefore not requiring the use of the

supplemental heating.

The combined use of zoning and heat pumps allows more equally

matched capacity to match the load of those zones calling allowing

the most efcient form of heating to be used. Even during the colder

times when the supplemental electric heat is needed, it is important to

remember that a smaller amount of heating is always required for one

room or zone vs. the whole house. Zoning allows the heating to be

directed only to those areas needing it.

FOSSIL FUEL FURNACES AND ADD-ON HEAT PUMPS

When a heat pump is added on to a fossil fuel (gas or oil) furnace, the

sequence of operation is somewhat different than using electric resistance heating as supplemental heating. The heat pump coil is often

on the supply side of the furnace and both the heat pump and furnace

cannot be run together as the high temperature from the furnace will

cause the heat pump compressor safeties to engage.

All heat pump manufacturers use a fossil fuel kit in order to make

the most effective use of the heat pump and furnace. Simply this

fossil fuel kit uses an outdoor thermostat to switch between the heat

pump and furnace based upon the outdoor temperature or balance

point. The balance point is calculated to determine the most effective

temperature to operate the heat pump vs. the furnace. See the heat

pump manufacturer’s information to calculate the balance point.

When using a White-Rodgers System with an add-on heat pump it is

recommended to use the manufacturer’s fossil fuel kit in order maintain the manufacturer’s warranty. The zone control panel equipment

terminal block will be wired to the thermostat connections on the fossil

fuel kit.

When using any heat pump it is important to remember that with a

limited amount of heating capacity, ZONING is imperative in order to

make maximum use of the heat pump and where the individual zone

load is more closely matched to the capacity of the heat pump.

TECHNICAL HELP

238

www.white-rodgers.com

Page 3

ZONING

DESIGN

ZONING COMMERCIAL SYSTEMS

Zoning for commercial and light commercial ofce buildings makes

even more sense as every person has their own idea of their own

comfort level. The number 1 and 2 complaints in any ofce is its either

TOO HOT or its TOO COLD. Being able to provide each ofce with its

own thermostat to control the temperature is a simple and cost effective way to solve this problem.

Here is a small professional ofce with 4 zones. One zone would be

the waiting room, reception area, another be the receptionist’s ofce,

another be the boss’s/doctor’s ofce, or conference room and the

other smaller rooms be ofces or examining rooms all on the same

zone.

In commercial buildings the need for zoning is increased by the build-

ing exposure when ofces facing south and north are controlled by

the same thermostats. Those south facing ofces on a bright sunny

day may be needing cooling while ofces on the northern side with no

solar gain still need heating. In the morning the entire building may

need heating for a morning warm up and soon after only the perimeter ofces need heating while the interior core needs cooling. Conference rooms that go for hours unused can be shut off and then when

there is a meeting and the ofces are not being used, the conference

room can be controlled comfortably by having its own thermostat.

Zoning also helps the landlord in tenant improvement costs by

eliminating the need to ad separate air conditioning units in order to

satisfy multiple tenants on one HVAC system. While one tenant in a

professional suite maybe an attorney and have more normal working

hours, the doctor and dentist with after hours patients on evenings

and Saturdays can still get conditioning by having there own temperature control.

Commercially, zoning is a very economical alternative to the more

sophisticated VAV and computer controlled HVAC systems. Zone

Control in commercial buildings can range from installing a single

motorized damper and thermostat to control an over-conditioned or

seldom used room or ofce; such as a conference/training room to

zoning every room on the HVAC System.

There is really little difference in zoning a residential 5 Ton Split HVAC

System and a commercial 5, 7-1/2, 10, 15 or 20 Ton Package Rooftop

HVAC Unit. The system components of the dampers, thermostats and

control panel can be the same in many instances. The only difference is the commercial rooftop maybe 2 stage heating and/or cooling

and there may be more zones and the duct sizes may be larger,

however the basic operation remains the same.

The Number 1 and 2 complaints in ofce buildings are people are

either Too HOT…..or Too COLD. Zoning is the less expensive alterna-

tive to the more commercially used VAV Systems and provides just as

good temperature control as those expensive system for a fraction of

the cost.

The design of a commercial zoning is also the same as a residential

system where a by-pass is most typically used. Small commercial

systems that may be just two zones might be able to get away without

a by-pass provided they are only two zones and the ducts for each

zone are large enough to handle 60% to 70% of the total airow.

Commercial zoning systems of three zones or more will need a

by-pass. The by-pass for commercial is often easier as many times

the false ceiling space is used as a common return. Here again it is

always important for the by-pass damper to be located as far away

from the blower as possible. Barometric by-pass dampers can be

used up to 7.5 Tons (3,000CFM). Over 10 Tons (4,000 CFM) should

use a motorized by-pass and a static pressure control.

White-Rodgers Systems can automatically direct the ow of the conditioned air to those zones needing it and automatically switch over

and provide the opposite mode to the other zones eliminating the

need for on site techs to constant balance and adjust outlets based

upon the ever changing conditions.

Light Commercial and Commercial systems are basically just bigger

residential systems with more capacity. Duct design for these will

almost always include a by-pass system, especially those over two

to three zones. The commercial systems are easier to retrot as the

false ceiling space if often used as a common return and a great

place to by-pass the air. Wiring is a snap as well as damper installation all taking place in the false ceiling.

www.white-rodgers.com

ZONING versus MULTIPLE UNITS

For years many HVAC Installers and Home Builders have used

multiple HVAC units in order to accomplish zoning. Installing a unit for

the upstairs and another for the downstairs is typically most common.

While effective to achieve zoning, using multiple units is often an unnecessary and substantially higher added cost.

There are good reasons for using multiple units. They would be that

the load of the home is so big that multiple units are needed. Homes

continue to grow in size and on average homes over 3,000 square

feet will typically require more than 5 Tons of cooling. In these larger

homes, multiple units are necessary. Typically trying to use one

central unit also creates long duct runs that may not properly get the

airow to all areas. Using multiple smaller units can be more effective

however in these instances a zoning system should still be looked at

as each smaller unit could still be subdivided into small zones.

The case for multiple units is also used in existing homes where

add-on air conditioning may be installed and duct work cannot be run

throughout the house. Example a older home without ductwork, that

may utilize steam or hot water heating and air conditioning is being

added. In order to add central air conditioning for both levels ductwork

cannot be run from the basement to the second oor or from the attic

down to the rst oor.

239

TECHNICAL HELP

Page 4

ZONING

DESIGN

However when two units are installed side by side in the same area

and both units add up to less than 6 Tons, this is the case for using

one unit and zoning.

Anytime a contractor can install one unit versus two, or more, the

homeowner wins. Maintenance costs are cut with every unit saved.

Remember the maintenance of air lters, electronic air cleaners,

humidiers, electrical requirements and the life expectancy of these

HVAC units as well, are unnecessary added costs that can be saved

by using one unit and zoning.

Another reason for using one larger unit with zoning is to economical-

ly obtain zoning and the highest efciency HVAC equipment. Often

when multiple HVAC units are installed these units are typically on the

lower scale of efciency. For heating this is an 80% efcient furnace.

For cooling this is a 10 SEER air conditioning unit.

ZONING EFFICIENCY AND DOWNSIZING

The standard way of not living in your whole house all of the time and

mostly occupying one zone of the home at a time proves the need

for zoning. Zoning makes the use of the heating and cooling more

effective by only conditioning those zones being occupied or that may

need it. Therefore typically the majority of the time, even on a two

zone system only one zone is typically calling.

When this occurs the furnace and air conditioner is oversized in BTU

capacity when supplying only a single zone. Due to this many HVAC

Installers will downsize the heating and/or cooling units based upon

the use of zoning. On a two zone system this many not be recommended, however when using 3 or more zones it is practical to

downsize to the next lower capacity unit.

An HVAC Unit should be sized to heat and cool the home at design

temperatures (the hottest days in summer and the coldest days in

winter). Realistically how often do design conditions occur. Of course

this depends upon where you live. In the milder climates downsizing

is much more of a possibility than in the severe heating climates of

Northern states or the southern cooling climates.

HVAC installers have been quite successful in going to the next

smaller size unit when using zoning. In many cases heating and cooling units are often oversized, especially on older homes. Doing a heat

loss and heat gain calculation is very important in determining the

size of the heating and cooling unit. Once the loads are determined

for the overall structure, the affect that zoning will have on the overall

load can be determined. Seldom used zones such as basements

or extra bedroom loads can be looked at as not always needing

conditioning at the same time as more often used zones. In instances

where 3 or more zones are used may be advantageous to downsize

to the next smaller size of heating and cooling unit.

NOTE: There are times during extended periods at design temperatures where it will take longer for the zones to satisfy as the

heating or cooling. It is important to note that some zones would

have to be adjusted in order to direct more BTUs to the more

important zones.

Down sizing while also increasing efciency is often the best way

to go. When considering the alternative of using 2 separate lower

efciency units in order to zone vs. one high efciency unit with zone

damper system, the cost difference is negligible if not sometimes

less. Take for example the following scenario and price out the costs

TECHNICAL HELP

comparison of the following example.

A 100,000BTU Home with 2 Zones.

Two Units @ 80% Efciency vs. One Zoned 90% Efciency

2Units 1 Unit

x 50,000 BTU Each (100,000 Total) x 90,000 BTU (Downsized)

x .8 (80% Efciency) x .9 (90% Efciency)

= 80,000BTU vs. = 81,000BTU

When you look at the two options you can still get more output, with

higher efciency and still provide zoning. Combine this with the potential utility rebates for the higher efciency and that often offsets the

added cost of the zoning system. Even going to one 80,000BTU, 90%

efciency unit will only decrease the total output by 10% . In milder

climates this can be an approach to lower HVAC installed costs when

quoting against the competition with 2 lower efciency units.

Applying higher efciency and zoning to cooling can also increase the

effectiveness of the cooling. Here again if utility rebates are offered

for the higher efciency this can further offset the added cost of zoning and possibly add other comfort options.

Typically the more zones you have the wider the diversity in the use

of the zones. This factor can help in downsizing the unit. Take for

example an exercise room that may only be used a hour or two a day.

The family recreation room that is only used for a few hours in the

evening and not when all are sleeping in the bedrooms or eating in

the kitchen dining room zones.

Zoning and high efciency equipment can increase the overall energy

performance of your home and keep rising energy costs down to

manageable level.

240

www.white-rodgers.com

Loading...

Loading...