Page 1

CZ-4 & CZ-4K Zoning Panel

Installation & Operating Instructions

Product Data

• Single Stage gas and electric systems

• Multi Stage (2H/2C) gas and electric systems

• Heat Pump (3H/2C)

• 4 zones (use CAZ-2 for additional zones up to 32 total)

• 5-Year Warranty

Specifications

• Construction: ABS Plastic

• Dimensions: 7 ⅝” x 7 ¼” x 1 ⅜”

• Voltage: 24 Volts AC, 50/60 Hz

• Operating Temperature: 0°- 120°

• Shipping/Storage Temperature: -20°- 140°

• Humidity Range: 5% - 95% Non-Condensing

Kit Contents (CZ-4K)

• CZ-4

• CLAS (leaving air sensor)

• 24V Transformer

Recommended Dampers

• CRDS – round damper (24V)

• CZDS – rectangular, side mount motor (24V)

• CZDB – rectangular, bottom mount motor (24V)

• CSPRD – static pressure relief dampers

24V dampers are power close, spring open and are

convertible to power open, spring close

Recommended Thermostats

• 1F78-151 (5+2 programming)

• 1F78-144 (non-programmable)

• 1F85-0471 (5+1+1,5+2,0 programming)

• 1F80-0471 (5+1+1,5+2,0 programming)

• 1F97-1277 (7, 5+1+1,0 programming)

• 1F95-1277 (7, 5+1+1,0 programming)

• 1F85RF-275 (5+1+1,5+2,0 programming) (wireless)

Terminal

Destination

W2/E….…… 2nd Stage Heat (Emergency heat for Heat Pumps)

G…………… Fan Relay

Y…………… Compressor

R…………… Power for Heating/Cooling

W/OB……… Heat Relay/Changeover Valve for Heat Pump

C…………… Common Wire

Description

To prevent electrical shock and/or

equipment damage, disconnect electric

power to system at main fuse or circuit

breaker box until installation is complete

SAVE THESE INSTRUCTIONS FOR

Failure to read and follow all instructions

carefully before installing or operating

this control could cause personal injury

and/or property damage.

FUTURE USE!

1 of 6

© 2004 White-Rodgers by Permission

Form 37-6864A

Page 2

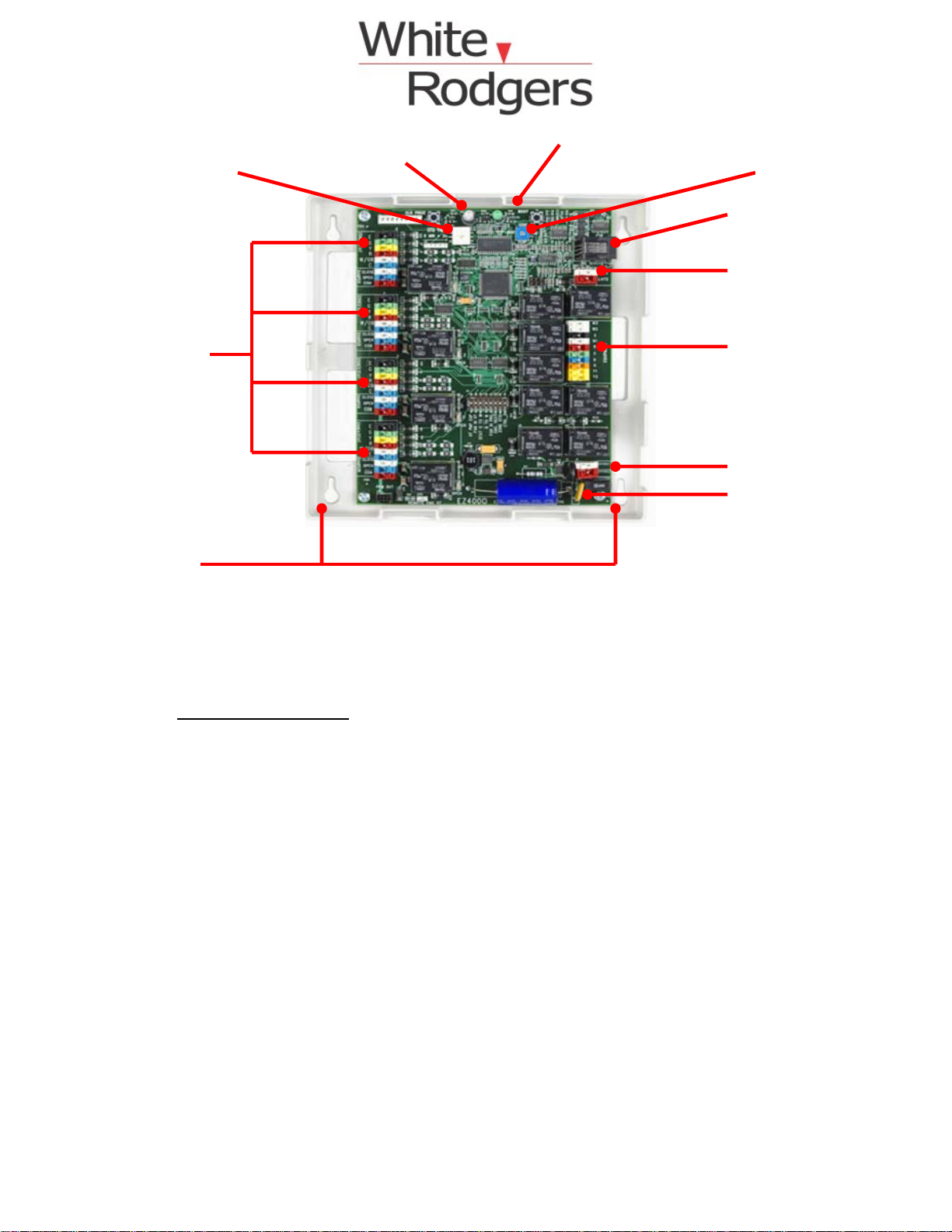

Adj

ustable Stage Timer

System Mode Indicator

Zone Terminal

Blocks for Zone

Thermostats & Zone

Dampers

Mounting Keyholes

Two at Top also.

Table of Contents

Installation 2

Operation 2-3

Set-Up for

Various HVAC Equipment 3

Leaving Air Sensor Air Sensor 3-4

Timers 4

ZoneAdder™

Checkout 4

Wiring 4-5

Troubleshooting 5

Wiring Diagram 6

INSTALLATION

The CZ-4 is a four (4) zone control panel that controls up to four

zones of heating and cooling. The CZ-4 panel is the central control

panel that all zone dampers, zone thermostats, HVAC Equipment,

power transformer, Leaving Air Sensor and ZoneAdder™ panels are

wired.

When installing the CZ-4 panel it is important to pick a central location

where it is most convenient to bring all the wires. Most often this is at

the furnace or air handler. It is often the most convenient location

and closest to power, the HVAC unit controls and the zone dampers

when typically located at or near the plenum.

The CZ-4 panel is made of sturdy ABS plastic and can be mounted to

any flat surface. It is recommended that the panel be mounted to a

wall or return plenum and NOT on the furnace or plenum where it will

be in contact with the hot temperatures. The panel can be located in

an attic space or in an enclosed cabinet of a rooftop unit, in order for

the panel to be in direct exposure to the elements.

The cover easily removes from the case by pulling firmly and

separating the cover from the case exposing the circuit board. There

are 4 key-hole mounting points in each corner of the case. The case

has openings in the rear of the case as well as the side for all wiring.

Wiring can come from the back as well as the side in order to make a

neat installation.

OPERATION

The CZ-4 can control various types of HVAC Equipment all from the

same panel. The CZ-4 features allow the use of single stage

thermostats to control up to three stage heating and two stage cooling

and simple heat pump thermostats to control heat pumps. The CZ-4

has various features that make installation and checkout very simple

for all of the board’s functionality.

The CZ-4’s basic function is zone control. On a call for heating or

cooling, the panel will accept the first call from any zone. Upon

2 of 6

© 2004 White-Rodgers by Permission

Power Indicator LED

Adjustable

Heating

Limit

Additional Zones

(CAZ-2 panel) RJ-11

Connection

CLAS and COAS

Terminal Blocks

HVAC

Equipment

Connections

24V Transformer

Terminal Blocks

Automatic Resetting

Fuse

Form 37-6864A

Page 3

accepting this call the CZ-4 will open the damper(s) to the zone(s)

calling, close the damper(s) to those zones not calling, activate the

needed HVAC controls for heating or cooling, whichever is being

called and not accept any calls for the opposite mode.

Any calls for the opposite mode will be locked out until the initial

mode is either satisfied or a period of time has elapsed that is

sufficient for the first mode to satisfy, a maximum of 20 minutes, when

both calls occur simultaneously. An exclusive sequence determines

the time the unit has been running or needs to continue to run in

order to adequately provide conditioning for each mode. If a

particular mode has already been calling for 20 minutes or longer and

an opposite call comes in the CZ-4 will immediately drop the mode,

enter the purge mode in order to dissipate the conditioned air into the

zones calling before switching over to provide the new conditioning

call to its zones.

When using the CZ-4 to control multi-stage heating and/or cooling,

the extra stages are controlled based upon time after the first stage

call from the thermostat. When any zone calls the panel’s built-in

timer begins and after the set period of time elapses the CZ-4 will

also activate the W2 for Heating or Y2 for Cooling. In heating, after

the second stage is activated the same timer will control the third

stage of heating. The Stage Timer is adjustable from 5 to 23 minutes

after the first stage call. Once the extra stages are on, these stages

will continue to run until the first stage is satisfied or the Leaving Air

Sensor limit setting is reached. (See Leaving Air section for further

information.)

Once all zone thermostats are satisfied for heating and cooling, the

CZ-4 will accept Fan calls allowing Continuous Air Circulation(CAC)

in those zones where the thermostat’s Fan Switch is set to ON.

These zone dampers will be Open while the dampers to the zones

where the Fan Switch is set to AUTO will be CLOSED.

When all zone thermostats are satisfied for both Heating and Cooling,

and all Fan switches are set to AUTO position, the HVAC unit will be

off and all zone dampers will return to a normally open position.

Once a zone calls for heating, cooling or fan, the dampers to the

calling zones remain open and the dampers to the zones not calling

will close.

SET-UP FOR VARIOUS HVAC EQUIPMENT

The CZ-4 is factory set for conventional fossil fuel (oil or gas) single

and up to three stage heating and two stage cooling. The panel only

needs to be configured when using with an conventional electric

furnace or hydro-air system in order to bring the fan on with a call for

heat, or when using with a heat pump equipment and thermostats.

Most all of the panel configuration is done by setting the DIP switches

in the lower center of the panel. Below is show their setting and

functions.

ON

OFF

1 2 3 4 5 6 7 8

1. HP EQP – Heat Pump Equipment – This switch changes

the output of the HVAC Equipment terminals from

conventional Heating and Cooling to a traditional Heat

Pump Output. When OFF, a heat call activates the W1

output and the second stage activates W2. When ON a

Heat call activates the Y1 output to bring on the

compressor for first stage and Y2 for the second stage, of

both heating and cooling. W3 is activated on a third stage

call in either mode.

2. FAN HEAT – Activates the G output to turn the Fan on with

a call for Heat. This is used for Heat Pumps, Electric Heat

furnaces and Hydro-Air Systems. In the OFF position the

CZ-4 will not activate the Fan in heating unless there is a

fan call from one of the zone thermostats.

3. O TO W – Switch Is placed to ON when using Heat Pump

thermostats that use an O terminal to activate the reversing

© 2004 White-Rodgers by Permission

valve in COOLING. The O on the thermostat is wired to W

on the zone terminal in order to determine if the call is for

heating or cooling. All zone thermostats must operate and

be wired the same way.

4. B TO W – Switch is used when using Heat Pump

thermostats that use a B terminal to activate the reversing

valve in HEATING. The B terminal on the thermostat is

wired to W on the zone terminal in order to determine if the

call is for heating or cooling. All zone thermostats must

operate and be wired the same way. NOTE: Some OEMs

use the B terminal as a transformer Common and not

as the heating reversing valve. These thermostats will

use the O terminal for the reversing valve and should

be wired accordingly using DIP Switch #3. The B

terminal will then be wired to the C terminal on the

thermostat terminal block.

5. FAN PRG – This switch keeps the fan running during the

purge time in order to dissipate the conditioned air into the

last zone(s) calling. Placing this switch to ON, prevents the

fan from turning off from the fan control in the HVAC Unit

during the purge mode and coming back on moments later

if another call is waiting. In OFF the fan will be control by

HVAC Fan controls. This is desirable in residential to

prevent cold drafts after heating by having the switch OFF.

6. EMG HEAT – EMERGENCY HEAT – This switch can be

used to place all zones into the Emergency Heat mode.

This switch would be used when single stage thermostats

are used. NOTE: There is no indication on t he panel to

show this switch is ON.

7. ZONE STG – STAGE CONTROL – This switch is used to

control how the second stage of heating and cooling is

determined. In the OFF position, the second stage is

controlled by the timer. In the ON position the second

stage is brought based on the number of zones calling.

Greater than 50% of the zones calling will bring on the

second stage, for both heating and cooling.

8. CTRL 3 – Future Use

One of the many features of the DIP switches is if at anytime the

equipment is changed from single stage to heat pump or vice versa

the thermostats do not need to be changed with the equipment

change. Changing the DIP switch settings is all that is needed.

LEAVING AIR SENSOR (CLAS)

The Leaving Air Sensor, Model CLAS, is a remote sensor that is

located in the supply air duct to sense the leaving air temperature of

the HVAC Unit. The CLAS is a high limit protection for the heating

and a low limit protection for the cooling. When zoning, the airflow

through the HVAC Unit is critical. The CLAS protects the equipment

in low air flow situations as well as when by-pass air is being directed

back into the return air duct.

The heating limit is adjustable from 100°F to 170°F. The cooling limit

is fixed at 40°F. When the CLAS senses heating above its set point,

or cooling below its set point, the CZ-4 will drop both stages of

heating or cooling. The CLAS must sense a 10°F fall for heating or

rise for cooling before re-activating the first stages of heating or

cooling. If two stage heating or cooling is being used the second

stage timer will start again once the first stage is re-activated.

The CLAS requires 2 wires from the sensor to the LAT1 and LAT2

terminals on the CZ-4 panel. The CLAS probe can also be adjusted

for length by loosening the end nut and sliding the probe thru the

mounting plate in order for the probe to pass through any duct

insulation

3 of 6

Form 37-6864A

Page 4

CLAS Terminals

CLAS Terminals

On CZ-4

On CZ-4

LAT1

LAT1

LAT1

LAT1

LAT2

LAT2

LAT2

LAT2

End Nut

End Nut

End Nut

End Nut

NOTE: If the CLAS is not used, the NO SENS OR jumper located

near the LAT terminals must placed across the two pins. When

the sensor is used the jumper must be removed from the pins.

CLAS Leaving Air Sensor

CLAS Leaving Air Sensor

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Adj ustable Length by loosening end

Adj ustable Length by loosening end

Adj ustable Length by loosening end

Adj ustable Length by loosening end

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

STAGE TIMER

The CZ-4 has a built-in stage timer that eliminates the need and

added cost of using two stage thermostats. On a call for either

heating or cooling the timer begins. A minimum of 5 minutes,

adjustable to a maximum of 23 minutes, can be set in order to

activate the W2, W3 and Y2 outputs after the first stage call.

The Stage Timer is marked 0 through 9 and each increment is

indented as the dial is rotated. A minimum 5 minutes is set when the

dial is set to 0. To calculate the stage timing the dial setting is

multiplied by 2 and added to the base of 5 minutes. Example: Dial

setting is 3 x 2 = 6 + 5 = 11 Minutes for the Stage Timer.

STG Time

5 MIN + 2X

When any zone calls the timer starts and activates the second stage

W2 or Y2 after the set time elapses. The timer also controls W3 after

the same time elapses after the W2 call.

PURGE TIME

The CZ-4 has a built-in Purge Time after each call is satisfied and

provides a minimum off time before another call is initiated. The

Purge Time is set at 2.5 minutes after all calls for a particular mode

are satisfied or when the Changeover Timer requires a changeover

due to opposing calls.

After all calls are satisfied or the changeover timer activates, the

Purge Timer begins and the heating or cooling, whichever was on, is

deactivated. Typically the fan may be running during this time and

the damper(s) to the last zone(s) calling will remain open to purge the

conditioned air only into those zones that were calling for the

conditioning. DIP Switch 5 can be set ON to keep the Fan running

during the Purge mode in order to prevent the fan cycling off and

back on between modes. In the instance where the Fan staying may

create a draft, and the frequency of opposite calls is minimal this

switch can be kept to OFF.

The CLR PRGE button on the top left of the panel can be pushed to

override the Purge mode and speed installation and checkout. This

button is only active when the System LED is AMBER.

CLR

MINIMUM ON TIMER

The CZ-4 also has a minimum on time whenever the compressor

operates in order to prevent frequent short cycling. Once there is a

call for cooling or the compressor on a heat pump, the CZ-4 will hold

that call for a period of 2 minutes.

CHANGEOVER TIMER

© 2004 White-Rodgers by Permission

4 of 6

Whenever a call is made for either heating or cooling, the changeover

timer is activated in order to track the amount of time heating or

cooling is on. When an opposite call is made after a first call is

existing the changeover timer calculates the amount of time the unit

has already been supplying the first mode in order to determine how

long it will hold off the opposite call. If an opposite call is made

shortly after the first call, the opposite call may be held off for as

much as 20 minutes. If the first call or subsequent calls for the first

call mode has had that mode operating for up to 20 minutes already

and an opposite call comes in after 20 minutes, the changeover timer

will immediately recognize the opposite call, shutting off the current

mode, enter the purge mode and automatically switch to the opposite

mode.

The longer a call has been running up to 20 minutes, the shorter the

wait time will be for an opposite call. If a call is over 20 minutes and

an opposite call is made the changeover will be immediate following

the purge time. This intelligent changeover timing makes the CZ-4

unique to any other zoning system.

ZONEADDER™ CONTROL (CAZ-2)

The CZ-4 Zone Panel can be added onto with the Model CAZ-2. The

CAZ-2 is available as a 2 zone adder panel and expands any CZ-4

panel to an almost unlimited number of zones. The CZA panel is

connected by a 6 conductor RJ11 telephone cable. This makes

wiring between the CZ-4 and CAZ-2 literally a snap.

CHECKOUT

The CZ-4 has unique features that simplify the checkout of the

system and has LED readouts that constantly indicate the system

operation. Once 24 Volt Power is applied to the panel the Green

Power LED will illuminate. This will stay illuminated constantly when

power is applied.

The System LED will provide several different indications based upon

color and if it is flashing.

Heat ON – RED

Heat Limit – RED Flashing

Cool ON - GREEN

Cool Limit - GREEN Flashing

FAN ON/PURGE - AMBER

TIME DELAY – AMBER Flashing

Each zone has its own small Green indicator LED next to each zone

relay. This light is lit when the specific zoning is calling for the mode

shown on the System LED.

WIRING

The CZ-4 is very simple to wire and requires only a minimum number

of connections. The CZ-4 terminal blocks are screw-less and all

wires can easily be pushed into their respective terminal by depressing the button for each point and releasing once the wire is

seated. To remove the wire, just press its button again and remove

the wire.

Form 37-6864A

Page 5

SI N GLE STA G E TH ERM O STA T

SI N GLE STA G E TH ERM O STA T

SI N GLE STA G E TH ERM O STA T

SI N GLE STA G E TH ERM O STA T

C W R Y G

C W R Y G

C W R Y G

C W R Y G

ZONE PANEL

ZONE PANEL

CONNECTIONS

CONNECTIONS

CONNECTIONS

CONNECTIONS

E

E

E

E

G

G

G

G

R

R

R

R

W/O/B

W/O/B

W/O/B

W/O/B

Y

Y

Y

Y

C

C

C

C

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

COM

COM

COM

COM

THERMOSTAT

THERMOSTAT

THERMOSTAT

THERMOSTAT

DAMPER

DAMPER

DAMPER

DAMPER

MOTOR

MOTOR

MOTOR

MOTOR

WIRING DIAGRAM 2 –

Three Stage Heating Equipment and up to Two Stage Cooling

HEATING COO LING EQUIPMENT

W3

W2

E

W1

R

G

B

EQ U I P M EN T

O

Y1

Y2

Single Stage , Two Stage and

Third Stage Heat Relay

Second Stage Heat Relay

First Stage Heat Relay

24V. Transformer

Fan Relay

First Stage Cooling Relay

Second Stage Cooling Relay

WIRING DIAGRAM 3 – Heat Pump Thermostats

HEAT PUMP THERMOSTAT

HEAT PUMP THERMOSTAT

HEAT PUMP THERMOSTAT

HEAT PUMP THERMOSTAT

C

R Y G E

C

R Y G E

C

R Y G E

C

R Y G E

O/B

O/B

O/B

O/B

ZONE PANEL

ZONE PANEL

CONNECTIONS

CONNECTIONS

CONNECTIONS

CONNECTIONS

E

E

E

E

G

G

G

G

R

R

R

R

W/O/B

W/O/B

W/O/B

W/O/B

Y

Y

Y

Y

C

C

C

C

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

COM

COM

COM

COM

THERMOSTAT

THERMOSTAT

THERMOSTAT

THERMOSTAT

DAMPER

DAMPER

DAMPER

DAMPER

MOTOR

MOTOR

MOTOR

MOTOR

WIRING DIAGRAM 4 –

AIR TO AIR HEAT PUMP CONNECTIONS

AIR TO AIR HEAT PUMP CONNECTIONS

W3

W3

W2

W2

E

E

W1

W1

R

R

G

G

EQ U I P M EN T

EQ U I P M EN T

B

B

O

O

Y1

Y1

Y2

Y2

Typical Heat Pump Equipment WIRING DIAGRAM 1 – Single Stage Thermostat

HEAT PUMP CONTROLS

HEAT PUMP CONTROLS

Emergency Heat Relay

Emergency Heat Relay

24V. Transformer

24V. Transformer

Fan Relay

Fan Relay

Reversing Valve

Reversing Valve

Compressor Relay

Compressor Relay

Second Stage Heat Relay

Second Stage Heat Relay

TROUBLESHOOTING

The CZ-4 is a very simple control to troubleshoot, especially with the

LED indicators. The only other device needed is a simple Volt/Ohm

meter. Almost all problems can be traded to an external component

or wiring to the CZ-4. While the CZ-4 has been designed to operate

under extreme voltage conditions and is fuse protected, like any

computer the micro-processor can hang up and not operate properly.

For these instances a BOOT button has been installed that re-boots

the micro-processor just like your computer. Pressing this button for

a few seconds and then release it will allow the micro-processor to reboot and in most all cases eliminate the problem. If not the following

procedure can help isolate the problem.

BOOT

Zone(s) Not Calling

Each zone has a Green LED next to the zone relay when it is calling

and that calling is being recognized by the CZ-4. If a zone is

supposed to be calling and the Zone LED is not on, check for 24VAC

across the thermostat terminal C and the Y, if a Cool call, W if a Heat

Call, or G if a Fan call. If there is no voltage here at the panel the

panel is not getting the signal from the thermostat. The problem is

mis-wiring, a broken wire or a problem in the thermostat. To check

the zone on the panel, place jumper from R to Y, R to W or R to G to

see that the panel is operating properly.

Zone(s) Will Not Shut Off

If a zone will not stop calling, the Zone LED should still be on.

Depending on the call disconnect the Y, W or G wire from the

terminal strip. The zone will drop out. Check the thermostat wiring

for a mis-wiring or short that keeps the zone calling.

Damper Motor Checkout

Each zone has Green indicator light located to the right of the zone

damper’s relay. When all zones are satisfied all zone lights are lit

Green indicating all zone dampers will be Open. To check this there

will be 24VAC across the COM and Open terminal. When any zone

calls, the damper(s) to the satisfied zone(s) will power close and the

indicator light will go out. When the damper is to be closed there will

be 24VAC across COM and CLOSE.

5 of 6

© 2004 White-Rodgers by Permission

Form 37-6864A

Page 6

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

C W R Y G

C W R Y G

C W R Y G

C W R Y G

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

C W R Y G

C W R Y G

C W R Y G

C W R Y G

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

C W R Y G

C W R Y G

C W R Y G

C W R Y G

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

SI N G LE ST A G E TH ERM O ST A T

C W R Y G

C W R Y G

C W R Y G

C W R Y G

CZ-4 WIRING DIAGRAM

5

5

5

E

E

E

E

G

G

G

G

R

R

R

R

W/O/B

W/O/B

W/O/B

W/O/B

Y

Y

Y

Y

C

C

C

C

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

COM

COM

COM

COM

E

E

E

E

G

G

G

G

R

R

R

R

W/O/B

W/O/B

W/O/B

W/O/B

Y

Y

Y

Y

C

C

C

C

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

COM

COM

COM

COM

E

E

E

E

G

G

G

G

R

R

R

R

W/O/B

W/O/B

W/O/B

W/O/B

Y

Y

Y

Y

C

C

C

C

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

COM

COM

COM

COM

E

E

E

E

G

G

G

G

R

R

R

R

W/O/B

W/O/B

W/O/B

W/O/B

Y

Y

Y

Y

C

C

C

C

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

COM

COM

COM

COM

THERMOSTAT

THERMOSTAT

THERMOSTAT

THERMOSTAT

DAMPER

DAMPER

DAMPER

DAMPER

MOTOR

MOTOR

MOTOR

MOTOR

THERMOSTAT

THERMOSTAT

THERMOSTAT

THERMOSTAT

DAMPER

DAMPER

DAMPER

DAMPER

MOTOR

MOTOR

MOTOR

MOTOR

THERMOSTAT

THERMOSTAT

THERMOSTAT

THERMOSTAT

DAMPER

DAMPER

DAMPER

DAMPER

MOTOR

MOTOR

MOTOR

MOTOR

THERMOSTAT

THERMOSTAT

THERMOSTAT

THERMOSTAT

DAMPER

DAMPER

DAMPER

DAMPER

MOTOR

MOTOR

MOTOR

MOTOR

5

6

6

6

6

4

4

4

4

3

3

3

3

7

7

7

7

2

8

2

8

2

8

2

8

1

1

1

1

9

9

9

9

0

0

0

0

8

8

8

8

8

8

7

7

7

7

7

7

6

6

6

6

6

6

5

5

5

5

5

5

4

4

4

4

4

4

3

3

3

3

3

3

2

2

2

2

2

2

1

1

1

1

1

1

ON

ON

ON

ON

ON

ON

100F

100F

100F

100F

CTRL 3

CTRL 3

CTRL 3

CTRL 3

ZONE STG

ZONE STG

ZONE STG

ZONE STG

EMG HEAT

EMG HEAT

EMG HEAT

EMG HEAT

FAN PRG

FAN PRG

FAN PRG

FAN PRG

B TO W

B TO W

B TO W

B TO W

O TO W

O TO W

O TO W

O TO W

FAN HT

FAN HT

FAN HT

FAN HT

HP EQP

HP EQP

HP EQP

HP EQP

135F

135F

135F

135F

170F

170F

170F

170F

NO SENSORNO SENSOR

NO SENSORNO SENSOR

EQ U I P M EN T

EQ U I P M EN T

W3

W3

W2

W2

W1

W1

Y1

Y1

Y2

Y2

CLAS Terminals

CLAS Terminals

CLAS Terminals

CLAS Terminals

On CZ-4

On CZ-4

On CZ-4

On CZ-4

E

E

R

R

G

G

B

B

O

O

LAT1

LAT1

LAT1

LAT1

LAT1

LAT1

LAT1

LAT1

LAT2

LAT2

LAT2

LAT2

LAT2

LAT2

LAT2

LAT2

HEATING COOLING EQ UIPMENT

HEATING COOLING EQ UIPMENT

24VAC

24VAC

24VAC

24VAC

CLAS Leaving Air Sensor

CLAS Leaving Air Sensor

CLAS Leaving Air Sensor

CLAS Leaving Air Sensor

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Mounted in Supply Air Plenum

Adjustable Length by loosening end

Adjustable Length by loosening end

Adjustable Length by loosening end

Adjustable Length by loosening end

Adjustable Length by loosening end

Adjustable Length by loosening end

Adjustable Length by loosening end

End Nut

End Nut

End Nut

End Nut

End Nut

End Nut

End Nut

End Nut

Adjustable Length by loosening end

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

nut, adjusting length and re-tightening

Third Stage Heat Relay

Third Stage Heat Relay

Second Stage Heat Relay

Second Stage Heat Relay

First Stage Heat Relay

First Stage Heat Relay

24V. Transformer

24V. Transformer

First Stage Cooling Relay

First Stage Cooling Relay

Second Stage Cooling Relay

Second Stage Cooling Relay

Fan Relay

Fan Relay

C

C

R

R

St. Louis, Missouri Markham, Ontario

www.white-rodgers.com

6 of 6

© 2004 White-Rodgers by Permission

Form 37-6864A

Loading...

Loading...