Page 1

INSTALLATION

DESCRIPTION

WHITE-RODGERS 90 SERIES

1F95-391

MULTI-STAGE/HEAT PUMP INSTALLATION/CONFIGURATION

This White-Rodgers Digital Thermostat uses

microcomputer technology to provide precise

time, humidity, and temperature control. This

thermostat offers the flexibility to design

SPECIFICATIONS

1F95-391: 7 Day programming; residen-

tial applications.

ELECTRICAL DATA

Electrical Rating:

20 to 30 VAC, 50/60 Hz with common

0.05 to 1.5 Amps per terminal

2.5 Amps maximum total load (all

terminals combined).

Hardwired only.

C terminal is required.

PRECAUTIONS

WARNING

!

Do not short out terminals on gas valve

or primary control to test. Short or

incorrect wiring will damage thermostat

and could cause personal injury and/or

property damage.

Do not use on circuits exceeding

specified voltage. Higher voltage will

damage thermostat and could cause

shock or fire hazard.

Thermostat installation and all components of the system shall conform to

Class II circuits per the NEC code.

heating and cooling programs that fit

building needs. This thermostat is adaptable

to most 24 volt residential forced air multi-

Standard Systems:

Multi-stage gas, oil, electric.

Single-stage or two-stage compressor

heat pump.

THERMAL DATA

Setpoint Temperature Range:

45° to 99°F (7° to 37°C)

CAUTION

!

To prevent electrical shock and/or

equipment damage, disconnect electric

power to system at main fuse or circuit

breaker box until installation is

complete.

NOTE

Read all instructions thoroughly before

beginning installation.

This thermostat is intended for use with a

low voltage system. Do not use on a line

voltage system.

stage or heat pump systems with electric or

fossil fuel auxiliary.

Operating Ambient Temperature:

32° to 110°F (0° to 43°C)

Operating Humidity Range:

90% non-condensing max.

Shipping Temperature Range:

-4° to 149°F (-20° to 65°C)

Do not exceed ratings shown in the Specifications section, above. If in doubt about the

electrical ratings of your heating/cooling

system, have it inspected by a qualified

heating and air conditioning contractor or

licensed electrician.

All wiring must conform to local and

national electrical codes and ordinances.

This control is a precision instrument, and

should be handled carefully. Rough handling

or distorting components could cause the

control to malfunction.

White-Rodgers is a division

of Emerson Electric Co.

www.white-rodgers.com

Part No. 37-6527B

Replaces 37-6527A

0443

Page 2

INSTALLATION

ATTENTION!

This product does not contain mercury.

However, this product may replace a unit

which contains mercury.

Do not open mercury cells. If a cell becomes

damaged, do not touch any spilled mercury.

Wearing non-absorbent gloves, take up the

spilled mercury with sand or other absorbent

material and place into a container which can

be sealed. If a cell becomes damaged, the

unit should be discarded.

Mercury must not be discarded in household

trash. When the unit this product is replacing

is to be discarded, place in a suitable

container and return to White-Rodgers at

2895 Harrison Street, Batesville, AR 72501

for proper disposal.

REMOVE OLD THERMOSTAT

Shut off electricity at main fuse or circuit

breaker box until installation is complete

AND the new thermostat is configured

properly.

Remove the front cover of the old thermostat. With wires still attached, remove wall

plate from the wall.

Identify each wire attached to the thermostat using one of the labels enclosed with the

new thermostat.

Disconnect the wires from the old thermostat

one at a time. DO NOT let the wires fall

back into the wall.

Install the new thermostat using the following procedures.

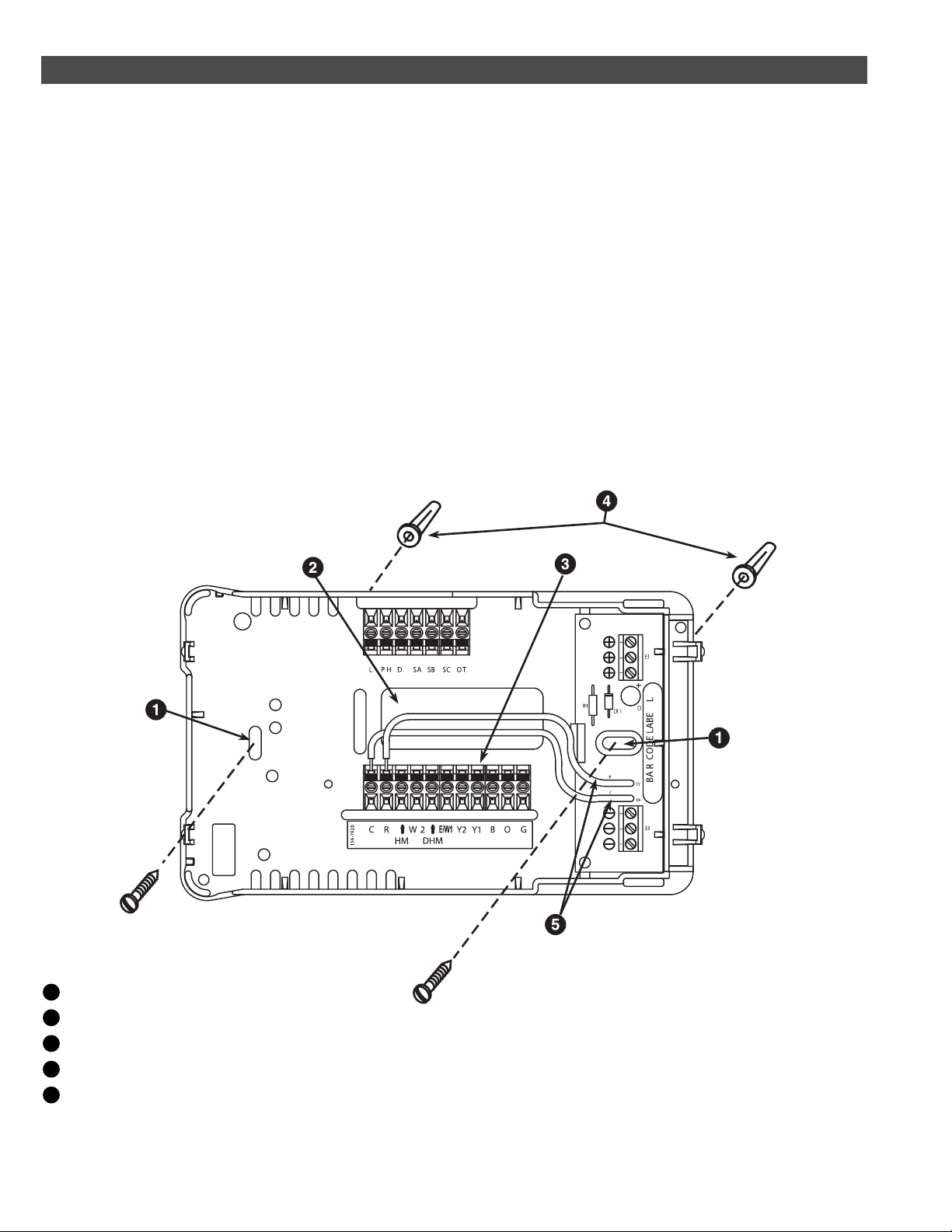

ATTACH BASE TO WALL

Remove packing material from the thermostat. Place fingers of one hand on the center

top and bottom portion of the thermostat.

Grasp the base in the other hand on top and

bottom center and gently pull straight out.

Forcing or prying on the thermostat will

cause damage to the unit.

Place the base over the hole in the wall

where the wires come out and mark mounting hole locations using the base as a

template. Drill

3

⁄16” pilot holes, and install

screw anchors in the wall.

Run wires through hole in base and attach

base to wall (see fig. 1).

Insert the wires into the terminals on the base

using the appropriate wiring diagram and

tighten the terminal screws.

CONFIGURING AND PROGRAMMING

The thermostat must be configured to operate

properly with the system. See the CONFIGURATION section of this manual.

This thermostat can be programmed for

automatic temperature control. Refer to

Operating Instructions for programming.

Mounting screws

1

Pull wires through this opening

2

Insert wires into terminal holes, then tighten screws

3

Screw anchors

4

Jumper connections for remote sensor power

5

(Do not remove)

Figure 1. Thermostat base and terminals

2

Page 3

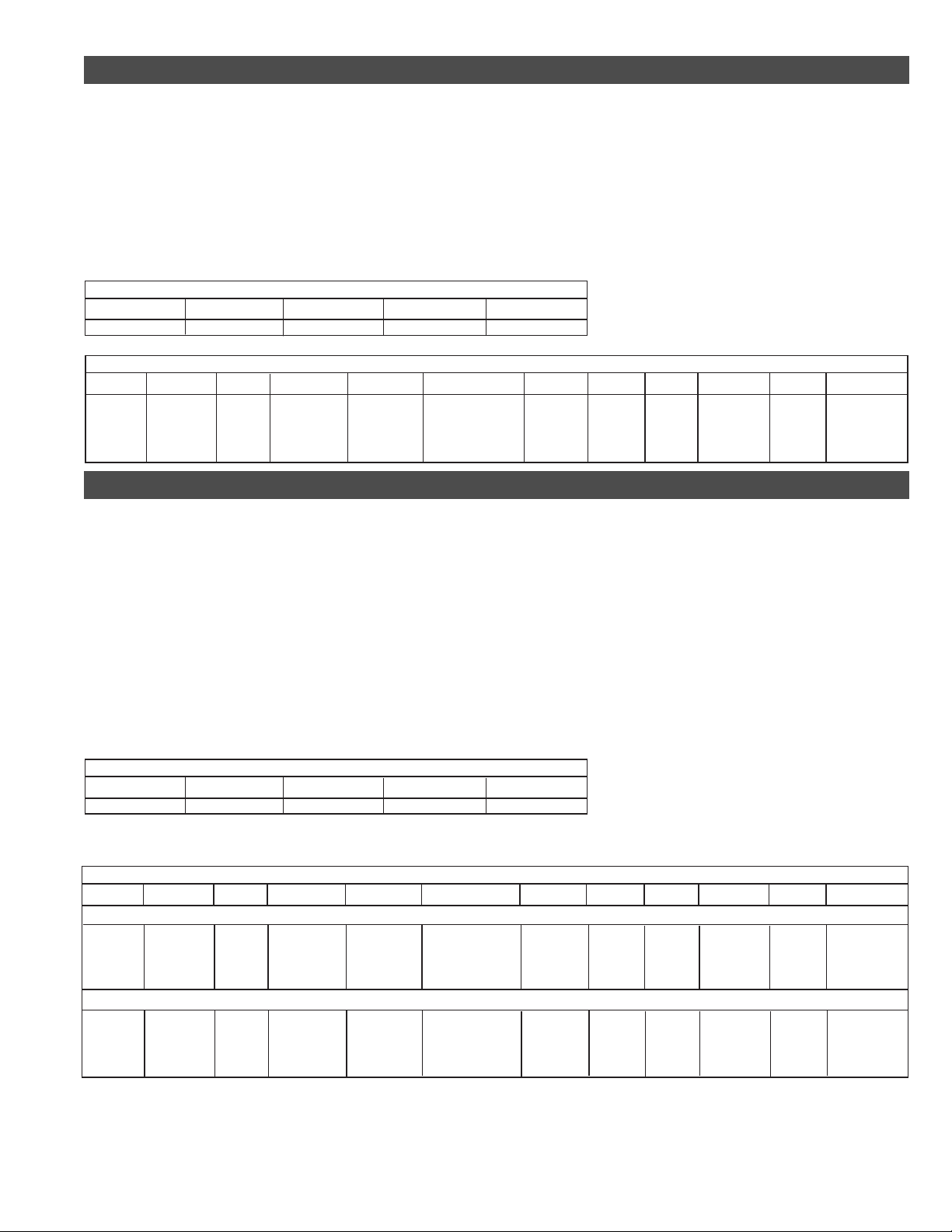

MULTI-STA GE TERMINAL OUTPUTS

Refer to equipment manufacturers’ instructions for specific system wiring information.

You can configure the thermostat for use

with either multi-stage electric heat systems

or multi-stage gas systems. When configured

for electric heat, the G terminal (blower/fan)

will be energized on a call for heat, using the

installer table (pgs. 5 & 6).

THERMOSTAT TERMINALS (Upper)

L SA SB SC OT

Malfunction Light Remote Sense A Remote Sense B Remote Sense C Outdoor Sensor

SYSTEM C R HM W2 DHM E/W1 Y2 Y1 B O G

Multi-Stage

24 Volt

(Common)

24 Volt

(Hot)

Energizes on a

call for heat if

Humidity setpoint is

above room

humidity.

This thermostat is designed to operate a

single-transformer system. If you have a twotransformer system, cut and tape off one

transformer. If transformer safety circuits are

in only one of the systems, remove the

transformer of the system with NO safety

circuits. If required, replace remaining

transformer with a 75VA Class II transformer.

After disconnecting one transformer, the two

commons must be jumpered together.

THERMOSTAT TERMINALS (Lower)

Heat mode

2nd stage

E2/P switch in the P position,

Energizes on a call for

Dehumidification.

E2/P switch in E2 position,

De-energizes on a

call for Dehumidification.

Heat mode

1st stage

Cool mode

2nd stage

Use the terminal output information below to

help you wire the thermostat properly for

your multi-stage system. After wiring, see

CONFIGURATION section for proper

thermostat configuration.

Cool mode

1st stage

Energized in Heat

and Off Mode

Energized in

Cool Mode

Blower/Fan

Energized on

call for Cool

(and Heat if

configured

to Electric Heat).

HEAT PUMP TERMINAL OUTPUTS

Refer to equipment manufacturers’ instructions for specific system wiring information.

You can configure the thermostat for use

with the following heat pump system types:

HEAT PUMP TYPE 1. Single-stage

compressor system; gas or electric backup.

HEAT PUMP TYPE 2. Multi-stage or twocompressor system; gas or electric backup.

This thermostat is designed to operate a

single-transformer system. If you have a twotransformer system, cut and tape off one

transformer. If transformer safety circuits are

in only one of the systems, remove the

transformer of the system with NO safety

circuits. If required, replace remaining

transformer with a 75VA Class II transformer.

After disconnecting one transformer, the two

Use the terminal output information below to

help you wire the thermostat properly for

your heat pump system type. After wiring,

see CONFIGURATION section for proper

thermostat configuration.

commons must be jumpered together.

THERMOSTAT TERMINALS (Upper)

L SA SB SC OT

Malfunction Light Remote Sense A Remote Sense B Remote Sense C Outdoor Sensor

THERMOSTAT TERMINALS (Lower)

SYSTEM C R HM W2 DHM E/W1 Y2 Y1 B O G

Single-stage compressor system; gas or electric backup

Heat Pump 1

Multi-stage or two compressor system; gas or electric backup

Heat Pump 2

24 Volt

(Common)

24 Volt

(Common)

24 Volt

(Hot)

24 Volt

(Hot)

Energizes on a

call for heat if

Humidity setpoint is

above room

humidity.

Energizes on a

call for heat if

Humidity setpoint is

above room

humidity.

Heat mode

3rd stage,

Emergency Mode

2nd stage

Emergency Mode

2nd stage

E2/P switch in P position,

Energizes on a call for

Dehumidification.

E2/P switch in E2 position,

De-energizes on a

call for Dehumidification.

E2/P switch in P position,

Energizes on a call for

Dehumidification.

E2/P switch in E2 position,

De-energizes on a

call for Dehumidification.

Heat mode

2nd stage,

Emergency Mode

1st stage

Heat mode

3rd stage,

Emergency Mode

1st stage

No Output

Heat and

Cool mode

2nd stage

(compressor 2)

Heat and

Cool mode

1st stage

(compressor 1)

Heat and

Cool mode

1st stage

(compressor 1)

Energized in Heat,

Off, Emergency

Mode

Energized in Heat,

Off, Emergency

Mode

Energized in

Cool Mode

Energized in

Cool Mode

Blower/Fan

Energized on

call for Heat and Cool

Blower/Fan

Energized on

call for Heat and Cool

3

Page 4

CONFIGURATION

SWITCHES

RESET SWITCH

See the Troubleshooting section at the end

of this document for more information about

the function of this switch.

E2/P SWITCH (DHM) TERMINAL

S18

FUNCTION

The E2/P switch is located on the back of

the thermostat body (see fig. 2). This switch

controls how the DHM terminal will be

energized.

1. In the P position (up) the DHM terminal will

be energized on a call for dehumidification.

2. In the E2 position (down) the DHM terminal

will always be energized except on a call for

dehumidification. The switch must be in the E2

position on some electronically controlled

variable speed blower systems.

DEHUMIDIFICATION WIRING WITHOUT AN ELECTRONICALLY CONTROLLED VARIABLE SPEED BLOWER SYSTEM

FOR SINGLE STAGE COMPRESSOR SYSTEM ONLY

If you have a single stage compressor system see the diagram below. A relay (customer provided) should be installed as shown in Fig. 5 to

switch the fan speed to the next lower speed on a call for dehumidification from the thermostat. The reduction in air flow allows the coil to remove

more humidity from the air. The relay should be rated for blower motor load. Since this configuration reduces the air flow in cooling, the antifreeze-up control (White-Rodgers CAFC) or equivalent is recommended. The CAFC prevents the air conditioning coil from freezing due to low

air flow, dirty filters, low refrigerant pressure, etc. The CAFC snaps onto the suction line close to the evaporator coil as possible and breaks the

compressor circuit when the suction line drops below 38°F and re-make the circuit at 46°F.

Reset switch

1

E2/P switch

2

Figure 2. Switch locations on back of thermostat body

P

E2

S19

1

2

NOTE: If you have a two stage compressor, the thermostat software will lengthen cycle times for the first stage of cool. The longer cycles will

improve dehumidification while cooling, allowing the DHM terminal not to be used on a two stage compressor system.

Selecting P - DHM Energizes on call for

Dehumidification

Selecting E2 - DHM Deenergizes on call for

Dehumidification

CRG

Y1

E2

DHM

P

N.C.

Customer supplied relay

rated for blower motor load

N.O.

24VAC

TRANSFORMER

Cool Fan Speed

Furnace

Control

Module

MED. HIGH

Heat Fan Speed

HIGH

3-4 speed

Blower

LOW

Motor

COMMON

HOT

120 VAC

NEUTRAL

Figure 3. Typical Wiring for Dehumidifier System

HM

Relay

90-290Q

or equivalent

Humidifier

System

Figure 4. Typical Wiring for 120V Humidifier System

HOT

NEUTRAL

120 VAC

Typical Wiring for 120V Humidifier System

24 VAC

R

I

TRANSFORMER

HOT

NEUTRAL

120 VAC

HM

Humidifier

System

Typical Wiring for 24V Humidifier System

Figure 5. Typical Wiring for 24V Humidifier System

24 VAC

R

I

TRANSFORMER

HOT

NEUTRAL

4

120 VAC

Page 5

INSTALLER CONFIGURATION

BEFORE TURNING POWER ON, please

read the following instructions. Before

operating the system, you must configure

the thermostat to operate properly with

your equipment.

The thermostat, as it comes from the factory,

is configured to operate a standard multi-

stage electric forced hot air system with a

single stage air conditioning compressor

and fan. In this configuration, the thermostat

will turn on the fan immediately on a call for

heat. If you are unsure whether your system

requires the thermostat to control the fan,

contact your furnace/air conditioning system

manufacturer or a qualified heating/air

conditioning service person.

Your new thermostat has an Installer table,

which allows you to customize the thermostat

to meet your requirements.

(The thermostat also has a User menu,

Keypad Lockout menu and a Service

menu; these menus are explained further

in the Operating Instructions.)

The menu settings can be changed at any time

to meet system or personal requirements.

ENTERING THE CONFIGURA TION

MENUS

After properly wiring the thermostat, turn on

power to the system. Momentarily press

RUN

PROGRAM

to make certain the

thermostat is in the run program mode, then

press TIME

FWD

and TIME

BACK

at the

same time to enter the User Configuration

menu. When the display changes to the first

item in the configuration menu, release the

TIME

buttons. Then press and hold SET

DAY

SET

for approximately 3 seconds to

and

enter the Installer table. The display will

change to show the first item on the Installer

table (multi-stage/heat pump selection). Use

the following text, along with the Installer

table, to guide you through the selections.

Once in the table, you set each item to the

proper selection using

press TIME

FWD

to change the display to

the next item or TIME

or , then

BACK

to return to the

previous item.

To exit the table at any time, press PRO-

RUN

GRAM

.

MULTI-STAGE/HEAT PUMP MODE.

(Installer table step 1.) Use this item to select

the system type (multi-stage or heat pump).

IF YOU HAVE A HEAT PUMP SYSTEM,

you must select HEAT PUMP here. This

sets up proper default values for most heat

pump systems. This selection also makes

available some additional menu items that

apply only to heat pump systems.

HEAT PUMP COMPRESSOR

CONFIGURATION.

(Installer table step 2; this item is displayed

only when heat pump was selected in step 1.)

Use this item to select the number of heat

pump compressors.

ELECTRIC HEAT FAN

CONFIGURATION.

(Installer table step 3.) This item determines

whether fan control will be through the

thermostat or through the heating system. If

you have an electric heat or other system that

REQUIRES the thermostat to control the fan,

set this item ON. This allows the thermostat

to energize the fan immediately on a call for

heat. If you are unsure if the system requires

the thermostat to control the fan, contact the

equipment manufacturer or a qualified

heating and air conditioning service person.

If your system controls fan operation (as

with most fossil fuel systems), set this item

to OFF. Note that with heat pump systems,

the fan always cycles with the compressor.

SET CYCLE HEAT, COOL, AUX

(ANTICIPATION).

(Installer table steps 4 through 6; step 6 is for

heat pump only). These items allow the cycle

times in heating, cooling and auxiliary (heat

pump systems only) to be increased or

decreased. The factory set values can be

adjusted higher for longer cycles or lower for

shorter cycles.

NOTE: Some manufacturers still instruct you

to set the anticipator to the current draw of

the equipment. That instruction applies only

to mercury bulb or mechanical thermostats; it

does not apply to this digital thermostat. As

configured at the factory, this thermostat will

maintain an accurate temperature. No further

adjustment is necessary, although you can

use these items to customize the performance

of the thermostat to your requirements.

The adjustment range for HEATING is from

1 to 40 (9 to 40 for heat pump). The factory

preset is 5 (13 for heat pump). The adjustment range for COOLING is from 9 to 40.

The factory preset is 12 (13 for heat pump).

The cooling will not go below 9 because

compressors require a longer cycle. The

adjustment range for AUXILIARY (heat

pump only) is from 1 to 40. The factory

preset is 6.

The chart on page 7 shows how this

adjustment range affects thermostat performance.

PROGRAMMABLE COOL FAN-OFF

AND FAN-ON DELAY.

(Installer table steps 7 and 8.) These items

allow a selection of 0 to 127 seconds of fanoff delay after the thermostat has satisfied the

call for cool, or a fan-on delay of 1 to 30

seconds on a call for cool (or heat pump

compressor activation).

The fan-off delay allows the fan to continue

running after the compressor has shut off.

This distributes the cool air that would

otherwise stay trapped in the air conditioning

coils through the ducts. Ideally the timing

would be set so the fan shuts off just as the

cool air is exhausted. If this timing is set too

long the fan may begin blowing warm air

before it shuts off. Shortening the fan-off

delay will prevent this.

A short delay to allow the A-coil to cool

off (or warm up in heat pump) before the

fan turns on may be preferred. This also

allows the compressor and the fan to come

on at slightly different times, which allows

full power to the compressor on start up.

Recommended setting for fan-on delay is

10 seconds or less.

PROGRAMMABLE HEAT FANOFF DELAY.

(Installer table step 9.) This item allows a

selection of 0 to 127 seconds of fan-off delay

after the thermostat has satisfied the call for

heat if ELECT HEAT FAN (Step 3) is

selected ON.

The fan-off delay allows the fan to continue

running after the burner, heating element,

etc. has shut off. This distributes the heat that

would otherwise stay trapped in the ducts.

Ideally the timing would be set so the fan

shuts off just as the warm air is exhausted. If

this timing is set too long the fan may begin

blowing cool air before it shuts off. Shortening the fan-off delay will prevent this.

PUMP (FOSSIL FUEL KIT ALTERNATIVE STEPS 10 - 13).

(Installer table step 10; heat pump only) This

item controls heat pump compressor

operation with a fossil fuel auxiliary. This

item may eliminate the need for a separate

fossil fuel kit, although we recommend that

you consult the heat pump system manufacturer before using this feature instead of a

kit. This item will allow the thermostat to

turn the heat pump compressor off if the

auxiliary is on for more than one minute,

to prevent compressor head pressure from

getting too high. To use this feature instead

of a kit, select PUMP OFF.

5

Page 6

INSTALLER TABLE

y

NOTE: You must be in the User Configuration Menu to enter the Installer Table. Firmly

press TIME

FWD

and TIME

BACK

at same time and release to enter the Configuration Menu.

Step Press Button(s) Displayed (Factory Default) Press UP or DOWN to select: COMMENTS

1 MLTI STG HEAT PUMP

2 HEAT PUMP

3 ELEC HEAT FAN

4 1 to 40 for multi-stage

5 9 to 40

6 SET CYCL AUX

7 COOL FAN DELA OFF

8

9 HEAT FAN DELA OFF

10 PUMP

11 COMP OFF DELA

12

13

Firmly Press

SET TIME and

SET DAY (hold

for approx. 3 seconds)

TIME FWD

(Heat Pump ONLY)

TIME FWD

TIME FWD

TIME FWD

TIME FWD

(Heat Pump ONLY)

TIME FWD

TIME FWD

TIME FWD

TIME FWD

(Heat Pump ONLY)

TIME FWD

(Heat Pump ONLY)

TIME FWD

(Heat Pump ONLY)

TIME FWD

(Heat Pump ONLY)

(1)

(ON)

SET CYCL (05)

for MLTI_STG, (13) for

HEAT PUMP 1, (24)

for HEAT PUMP 2

SET CYCL (24)

for MLTI_STG, (13) for

HEAT PUMP 1, (24)

for HEAT PUMP 2

(08)

(00)

(01)

(00)

(ON)

(60)

(Balance point temperature)

bPT (35°F)

(Balance point)

bP (05)

2

OFF

9 to 40 for heat pump

1 to 40

0 to 127 seconds

1 to 30 seconds

0 to 127 seconds

OFF

(0) to (99)

5°F to 50°F

(01) to (09)

Selects type of system. Selecting HEAT PUMP

makes additional items for heat pump systems

available.

1. One compressor on Y1.

2. Two compressor on Y1, Y2.

Fan cycles with call for heat if ON. Fan always

cycles with pump stages.

Selects HEAT anticipation adjustment.

Selects COOL anticipation adjustment

Selects AUXILIARY stage anticipation adjustment.

(Heat Pump ONLY

)

Selects time delay for COOL fan OFF

Selects time delay for fan ON. Applies only to

compressor stages for heat pump or COOL.

Selects time delay for fan ON only when

ELECT HEAT FAN (Step 3) is ON

Fossil Fuel Kit Alternative option. Turns compressor

OFF if Auxiliary is ON for longer than one minute.

(Heat Pump 1 & 2)

Available if Pump (Step 10) is OFF. Selects the

delay between de-energizing fossil fuel stage and

restarting Heat Pump stage.

Available if Pump (Step 10) is OFF and OUTDOOR

Sensor ON. Selects outdoor balance point

temperature for Heat Pump.

Available if Pump (Step 10) is OFF and OUTDOOR

Sensor OFF. The higher the number the sooner the

auxilary stage energizes. The lower the number the

longer period of time before auxiliary is energized

14 (Programmable Blower

15

16

TIME FWD

(Heat Pump ONLY)

TIME FWD

TIME FWD

Balance Point) bbP

(OFF)

COMP LOCK

(OFF)

HEAT-OFF COOL-AUTO

or HEAT-EMER-OFF-

COOL-AUTO

(for heat pumps)

10 to 99%

ON

HEAT-OFF-COOL or

HEAT-EMER-OFF-

COOL (for heat pumps)

Available if configured for HEAT PUMP. Adjustable

from 99-10. Lowers the Blower speed if the Heat

Pump duty cycle is above the selected value in

percentage.

Selects compressor short-cycle protection.*

Allows selection of HEAT and COOL or HEAT,

COOL and AUTO with SYSTEM button. (EMER

appears in sequence after HEAT if HEAT PUMP

is selected).

See

Page

5

5

5

5

.

.

5

5

5

5 FAN DELA ON

5

.

5

7

7

7

.

7

7

7

7

Program RUN

Returns to Normal Operation.

* Note: COMP LOCK OFF permanently defeats compressor lockout. You must turn this selection ON if you do not have a system that already provides

compressor short-c

cle protection. Please see “Lockout Bypass Option” to temporarily override compressor lockout.

6

Page 7

COMPRESSOR OFF DELAY

Installer table, step 11 is available if the

fossil fuel kit alternative option (PUMP OFF)

is selected.

This item allows a selection of 0 to 99

seconds, which is the time that the compressor will continue to run after the point that

the auxiliary heat is energized. Running the

compressor after the Auxiliary has started

prevents cool air from creating drafts prior to

the heat exchanger reaching normal temperatures. The factory default value of 60

seconds is typical for most systems. Consult

with your equipment’s manufacturer before

increasing this time.

BALANCE POINT TEMPERATURE

Installer table step 12, bPT, is available only

if the fossil fuel kit option is selected and the

outdoor temperature sensor is used (see the

user menu in the owner manual).

This item allows a selection of 5 to 50° F,

which is the outdoor temperature below

which the thermostat will not energize heat

pump compressor stages. It will use

Auxiliary heat stages (only) until the outdoor

temperature raises 3° above the selected

temperature and then allow compressor

stages to operate. The factory default value

of 35° F is typical for most systems.

BALANCE POINT

Installer table step 13, bP, is available only if

the fossil fuel kit option is selected and the

outdoor temperature sensor is not used. The

Balance Point influences when second stage

comes on. The factory default creates

approximately 1° F between stages. Increasing the setting decreases the separation

between stages. Decreasing the value

increases stage separation. This adjustment

allows a small change in the operation of

your heat pump system versus your auxiliary

system relative to the thermostat adjustment.

Pump

Stage

Fossil

Auxiliary

Stage

Higher number

Lower number

Decreasing

Indoor

temperature

PROGRAMMABLE BLOWER

BALANCE POINT

Installer table step 14, bbP, is available only

when configured for Heat Pump systems, and

wired as shown in Fig. 3.

If the system is running a high percentage of

the time due to cold weather conditions, the

output vent air temperature may be cooler

than normal thus creating a drafty room

condition. This feature will reduce the draft

by lowering the blower speed with the DHM

terminal. The lower speed will make the air

temperature slightly warmer and more

comfortable.

Example: If you want the blower to go to a

lower speed when the system is running

greater than 50% of the time,then reduce the

Blower Balance Point to 50%.

To turn this feature OFF, press

to 99

then press once more to display OFF.

COMPRESSOR LOCKOUT.

(Installer table step 15). This thermostat is

capable of helping to protect the system

against premature compressor failure by

“locking out” the compressor for at least five

minutes after each cycle. When the thermostat is in compressor lockout, the word

COOL will flash on the display. With heat

pump systems, the word HEAT will flash if

the lockout occurs during a heat cycle.

During this period, the compressor will not

be energized.

Stage separation

1˚F at setting 05

Lockout Bypass Option

FOR QUALIFIED SERVICE TECHNICIANS’ USE ONL Y .

HOMEOWNERS SHOULD NOT USE

THIS FEATURE DUE TO POSSIBILITY OF EQUIPMENT OR PROPERTY DAMAGE, OR PERSONAL

INJURY .

COMPRESSOR SHORT TERM CYCLE

PROTECTION

If this thermostat has been configured to

provide short-cycle protection, during the

5-minute lockout period the thermostat

will lock out the compressor to allow

head pressure to stabilize. To override

this feature for one cycle while testing

thermostat operation, press SET

and SET

DAY

buttons at the same time.

TIME

If the system has short-cycle protection, this

item should not need to be enabled. However, if your system does not have short-

cycle protection, turn COMP LOCK ON.

This will protect the compressor from shortcycling and potential premature compressor

failure.

Note that COMP LOCK OFF permanently

disables compressor lockout. If you need to

temporarily disable compressor lockout,

please see Lockout Bypass Option.

DISABLING AUTOMATIC

CHANGEOVER MODE.

(Installer table step 16). This thermostat, as

configured at the factory, provides automatic

changeover, which allows the thermostat to

switch between heating and cooling to

maintain temperature. In this configuration,

when you press the SYSTEM button, the

thermostat will go through HEAT-OFFCOOL-AUTO modes (HEAT-EMER-OFFCOOL-AUTO for heat pumps). Select

HEAT(-EMER)-OFF-COOL to disable the

automatic changeover feature.

(Continued)

HEATING COOLING

Anticipation Value Cycle Length Differential Temperature Cycle Length Differential Temperature

Shorter 0.4–0.6°F (0.2–0.3°C) N/A1–8 N/A

Longer Shorter9–20 0.6–1.0°F (0.3–0.6°C) 0.6–1.0°F (0.3–0.6°C)

Hydronic Longer21–40 1.0–1.6°F (0.6–0.9°C) 1.0–1.6°F (0.6–0.9°C)

These numbers are approximate and represent operation with a typical system. Actual temperature differentials and

run times may vary widely based on your building and equipment, as well as outdoor temperature conditions.

7

Page 8

SERVICE REMINDER

The Service Button Menu allows you to view or program as many as 4 reminders that indicate when service is required.

1. Humidifiers = A programmable run time in hours to indicate on the LCD when the humidifier will need to be serviced.

2. Air Filters = A programmable run time in hours to indicate on the LCD when the filter will need to be serviced or replaced.

3. UV Lights = A programmable run time in days to indicate on the LCD when the Ultra-Violet Bulb will need to be replaced.

4. Service Timer = A programmable run time in days to indicate on the LCD when to call your service contractor.

To enter the Service Button Menu when no service reminders are on the display, press and release the SERVICE button. Press

TIME

setting an item to ON, you can then use or to select the time interval. Press

FWD

to step through the menu items. To turn a menu item OFF or ON when selected, press or . If you are

RUN

to exit the menu and return to

normal operation.

When a service reminder appears on the display, press the SERVICE button to remove it and reset the timer to begin the count

down to the next service interval.

Service Button Menu

Step Press Button(s) Displayed Press or to select: COMMENTS

(Factory Default)

1

2

3

4 SET FLTR TIME

5

6

7

8

SERVICE

TIME

(If PAD TIME is ON)

TIME

TIME

(If FLTR TIME is ON)

TIME

TIME

(If UV TIME is ON)

TIME

TIME

(If SERV TIME is ON)

PRGM

FWD

FWD

FWD

FWD

FWD

FWD

FWD

RUN

P AD TIME

(OFF) Hrs

or

REM PAD TIME

No. of Hrs

SET PAD TIME

(100) Hrs

FL TR TIME

(OFF) /Hrs

or

REM FLTR TIME

No. of Hrs

(200) Hrs

UV TIME

(OFF) Days

or

REM UV TIME

No. of Days

SET UV TIME

(375) Days

SERV TIME

(OFF) Days

or

REM SERV TIME

No. of Days

SET SERV TIME

(175) Days

(ON)

or

(OFF)

25 to 1975

(ON)

or

(OFF)

25 to 1975

(ON)

or

(OFF)

25 to 1975

(ON)

or

(OFF)

25 to 1975

Set Humidifier Maintenance Reminder.

Selects time intervals in increments of 25 hours. The RUN

time accumulates when the HM terminal is energized.

Set Air Filter Maintenance Reminder.

Selects time intervals in increments of 25 hours.

The RUN time accumulates when the fan is operating.

Selects UV Light Maintenance Reminder.

Selects time intervals in increments of 25 days. The RUN

time is the calendar time from when it is entered or reset.

Selects Routine Maintenance Service Call Reminder.

Selects time intervals in increments of 25 days. The RUN

time is the calendar time from when it is entered or reset.

Returns to Normal Operation.

8

Page 9

CHECK THERMOSTAT OPERA TION

FAN OPERATION

If your system does not have a G terminal

Connection, skip to HEAT/HUMIDITY

section below.

1. Turn power on to the system.

2. Press PROGRAM

3. Press

The fan should begin to operate.

4. Press

displayed. The fan should stop operating,

unless a call for heat or cool is active.

FAN

FAN

RUN

.

until FAN ON is displayed.

until FAN AUTO is

HEAT/HUMIDITY

1. Press the

shown at the top of the display.

SYSTEM

button until HEAT is

2.Press the HUMIDITY % button, then

the temperature to the

maximum humidity setpoint and hold

for 5 seconds until ON is displayed.

3.Press the PROGRAM

RUN

.

4.Press the HOLD button.

5.Press the temperature to

raise the temperature setting 4°F

above room temperature. The 1st stage

(LED Green) and then 2nd stage

(LED Yellow) will be energized,

and also the HM terminal should

energize for humidification. The

lowercase letter h will appear to the

6.Press the HUMIDITY % button and

7. Press the PROGRAM

HEAT PUMP EMERGENCY

HEAT MODE

1.Press the

2.Press the temperature

3. LED indicatior will glow red indicat-

4. Lower the termperature a few degrees

NOTE: If the red LED flashes and

check system appears this signals that

there is a malfunction in the Heating/

Cooling system not the thermostat. For

suggestions contact your Heating/

Cooling manufacturer.

right of HOLD, indicating that the

thermostat is calling for Humidification.

If configured for Heat Pump 1, 2, or 3

the third stage of HEAT will be indi-

cated by a Flashing Yellow light.

set your desired humidifier set point

in % RH with the and .

RUN

to

accept the change.

SYSTEM

button to select the

EMER mode.

to

raise the setpoint temperature 2°F

above the room temperature to call

for heat.

ing the thermostat is calling for heat.

below room temperature and the red

LED and the heat should turn off.

COOL/DEHUMIDIFY

1.Press the

SYSTEM

button until COOL is

shown at the top of the display.

2.Press the HUMIDITY % button, then

the temperature to the minimum

humidity setpoint and hold for 5

seconds until ON displayed.

3. Press the PROGRAM

RUN

button.

4. Press the HOLD button.

5. Press the temperature to lower

the temperature setting 1°F

below room temperature and the 1

st

stage of the COOLING system

should begin to operate and the LED

indicator will glow green for first

stage. The lowercase letter d will

appear to the right of HOLD, indicating that the thermostat is calling for

Dehumidification.

6.Press the temperature to lower

your setpoint 4°F below room

temperature, the DHM terminal will

energize causing the FAN to go to

high speed.

7.Press the HUMIDITY % button and

set your desired dehumidification

setpoint in % RH using the and

.

8.Press PROGRAM

RUN

to accept

the change.

TROUBLESHOOTING

RESET BUTTON

If the thermostat does not respond when keys

are pressed, or the thermostat is not operating

properly, you may use the reset button

located on the back of the thermostat body

(see fig. 2). Thermostat programming and

configuration will not be affected by

pressing the reset button. However, the clock

will need to be reset.

RESETTING THERMOST A T

CONFIGURATION AND

PROGRAMMING

The thermostat can be reset back to default

programs and configuration. Removing

power from the thermostat will not reset it,

because the default settings are maintained in

permanent memory. Before resetting the

thermostat, you may want to make note of

the previously selected configuration and

programming. You must reconfigure and

reprogram the thermostat after resetting it

using this method.

TROUBLESHOOTING

Symptom Possible Cause Corrective Action

Thermostat Does Not Follow Program 1. AM or PM set incorrectly in program. Check current clock and program settings including

2. AM or PM set incorrectly on clock. AM or PM designations for each time period. If a

3. Voltage spike or static discharge. voltage spike or a static discharge occurs use

Blank Display and/or Keypad Not Responding 1. Voltage spike or static discharge. Replace batteries and check heat/cool system

2. Battery change required. for proper operation. If a voltage spike occurs

To reset the thermostat, press and release

RUN

PROGRAM

TIME

time. This will reset the thermostat to

factory default programs and configuration.

The display will momentarily go blank,

then all segments on the display will

momentarily be shown. The thermostat will

then go into the HOLD mode and will

maintain factory preset temperatures.

the reset operation listed above.

use the Reset Operation listed above.

BACK

, then press the

and buttons at the same

FAN

,

9

Page 10

TROUBLESHOOTING

Symptom Possible Cause Corrective Action

No Heat/No Cool/No Fan 1. Blown fuse or tripped circuit breaker. Replace fuse or reset breaker.

(Common Problems) 2. Furnace power switch to OFF. Turn switch to ON.

3. Furnace blower compartment door or Replace door panel in proper position to engage

panel loose or not properly installed. safety interlock or door switch.

No Heat 1. Pilot light not lit. Re-light pilot.

2. System button not pressed to display Heat. Set SYSTEM button until HEAT is displayed and

raise temperature above room temperature.

3. Loose connection to thermostat or system. Verify thermostat and system wires are securely

attached.

4. Furnace Lock-Out Condition. Heat may also Many furnaces have safety devices that shut

be intermittent. down when a lock-out condition occurs. If the

heat works intermittently contact the furnace

manufacturer or local service person for

assistance.

5. Heating system requires service or Diagonistic: Set SYSTEM button until HEAT is

displayed and raise setpoint above room

temperature. Within a few seconds the thermostat

should make a soft click sound. This sound

usually indicates the thermostat is operating

properly. If the thermostat does not click, try the

reset operation listed on the previous page. If the

thermostat does not click after being reset contact

your heating and cooling service person or place

of purchase for replacement. If the thermostat

clicks, contact the furnace manufacturer or a service

person to verify the heating is operation correctly.

No Cool 1. System button not pressed to display Cool. Set SYSTEM button until COOL is displayed and

raise temperature below room temperature.

2. Loose connection to thermostat or system. Verify thermostat and system wires are securely

attached.

3. Cooling system requires service or Same procedure as diagnostic for No Heat

thermostat requires replacement. condition except press the SYSTEM button until

COOL is displayed and lower the setpoint below

room temperature. There may be up to a five minute

delay before the thermostat clicks in Cooling.

Heat, Cool or Fan Runs Constantly. 1. Possible short in wiring. Check each wire connection to verify they are not

2. Possible short in thermostat. shorted or touching together. No bare wire should

3. Possible short in Heat/Cool/Fan system. out from under terminal screws. Try resetting the

4. Fan button pressed to display FAN ON. thermostat as described on the previous page. If

the condition persists the manufacturer of your

system or service person can instruct you on how

to test the Heat/Cool system for correct operation. If

the system operates correctly, replace the thermostat.

Furnace Cycles Too Fast or Too Slow 1.The location of the thermostat and/or the size Digital thermostats normally provide precise

(narrow or wide temperature swing) of the Heating System equipment may be temperature control and may cycle faster than

influencing the cycle rate. some older mechanical models. A faster cycle

rate means the unit turns on on off more frequently

but runs for a shorter time so there is no increase

in energy use. If you would like to increase the

cycle time, refer to page 6 under Installer Table for

settings. If an acceptable cycle rate is not acheived

by the adjustment in the Installer Table then you

may want to contact a local heating and air

conditioning service person for further suggestions.

Cooling Cycles Too Fast or Too Slow 1. The location of the thermostat and/or the size The cycle rate for cooling is fixed and can not be

(narrow or wide temperature swing) of the Cooling System can influence the adjusted. Contact a local service person for

rate. suggestions.

10

Page 11

TROUBLESHOOTING

Symptom Possible Cause Corrective Action

Thermostat Setting and Thermostat 1. Thermostat thermometer setting requires The thermometer can be adjusted +/- 5 degrees.

Thermometer Disagree adjustment. See Temperature Display Adjustment in the

Operating Manual under Configuration.

Thermostat Display Shows CHCK PAD, 1. Thermostat service indicators. These indicators can be reset or modified in the

CHNG FLTR, CALL SERV UV, CALL SERV service button menu (see pg. 8).

FAQs

Why does the system run with the

setpoint and room temperature the

same?

Why is the temperature change

display so slow?

How do I temporarily Override the

program and Hold Til Timing?

Aux. = Auxiliary Heat or the second stage of heat in the Heat mode. This is energized

In cooling, as the room temperature falls you will eventually reach the setpoint

temperature. The system will continue to run until it reaches the low side of the

temperature setting. As an example: If set to 78 degrees with the room temperature

falling the thermostat will continue to call for cool as the temperature decreases in the

following manner. 78.9, 78.8, 78.7, 78.6, 78.5, 78.4, 78.3, 78.2, at approximately 78.2

the thermostat will quit calling for cool. This is why it is not unusual for the room

temperature and set temperature to read the same but the system continues to run.

The amount of time it takes for the system to shut off is dependent on system sizing,

thermostat location, etc. Note: The thermostat display only displays whole numbers.

Internally the thermostat calculates decimals.

In heating as the room temperature increases the system will continue to run until the

thermostat reaches the high side of the temperature setpoint.

Digitals are engineered to a specific response rate. Compared to a thermometer it will

seem slow. When left to acclimate and control temperature it will provide precise

temperature control on a properly sized system.

Any time your program is running and you would like to override it for a specific

amount of time, press

display will indicate HOLD, and the number of hours remaining in the hold period will

be indicated with the word HRS. To adjust the length of time for the override, press

TIME FWD or TIME BACK. The time you select will become the new number of hours

for the Hold Til timing. Once your time is selected, let the thermostat rever t back to

normal operation on its own to accept the change.

or until the temperature you want is displayed. The

What is the thermostat Click Test?

Many furnaces have safety devices that shut the system down when a lock-out

condition occurs in the furnace. If the thermostat is turned off or the call for heat is

cancelled (by lowering and then raising the set temperature) the furnace may start

operating again. A diagnostic to see if the thermostat is operating when the room

temperature is below the thermostat setting (in heat) is to lower the setting below the

room temp. Within about 3 seconds the thermostat should make a soft click sound.

This sound is the thermostat turning off the call for heat and usually indicates the

thermostat is operating properly. If the thermostat does not click you would be

suspicious of the thermostat and try resetting it by following it’s reset operation. If the

thermostat does not click after being reset contact your heating and cooling service

person or place of purchase for a replacement. If the thermostat clicks and the heat

works intermittently contact the furnace manufacturer or local service person. They

will want to observe the condition when it is not working.

You can raise and lower the temperature a few degrees above and below the room

temperature and each time expect to hear the thermostat click on and off within a few

seconds. If it clicks, it is operating properly.

11

Page 12

The Emerson logo is a

trademark and a service mark

of Emerson Electric Co.

Loading...

Loading...